Steel for Fasteners Containing Niobium 12.9 Grade Rail Transit Mobile Equipment and Its Heat Treatment Process

A technology for rail transit and mobile equipment, applied in the field of alloy steel, which can solve problems such as difficult production, high production cost, and high consumption of precious alloys, and achieve excellent fatigue resistance, improved fatigue resistance, and excellent fatigue resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The following examples are used to illustrate the present invention, but the protection scope of the present invention is not limited to the following examples.

[0029] The production process of the present invention is: converter or electric furnace smelting→external refining→continuous casting into billet→low temperature controlled rolling and controlled cold rolling of high-speed wire rod→drawing→annealing→drawing→cold heading→quenching and tempering heat treatment→coating .

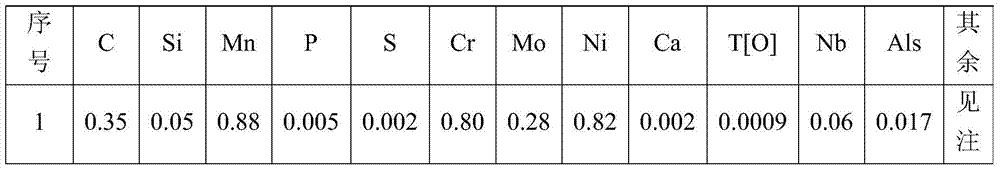

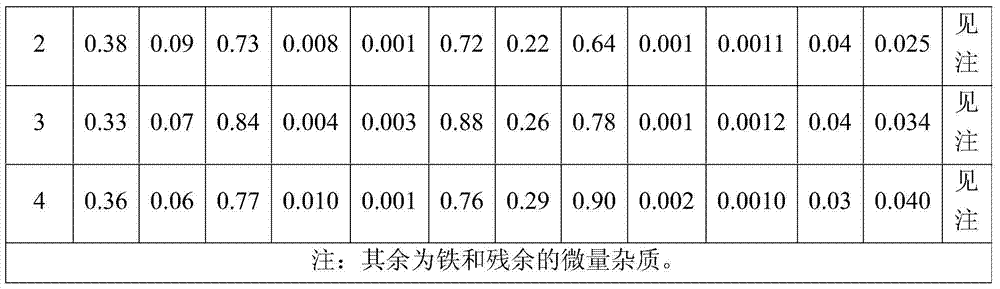

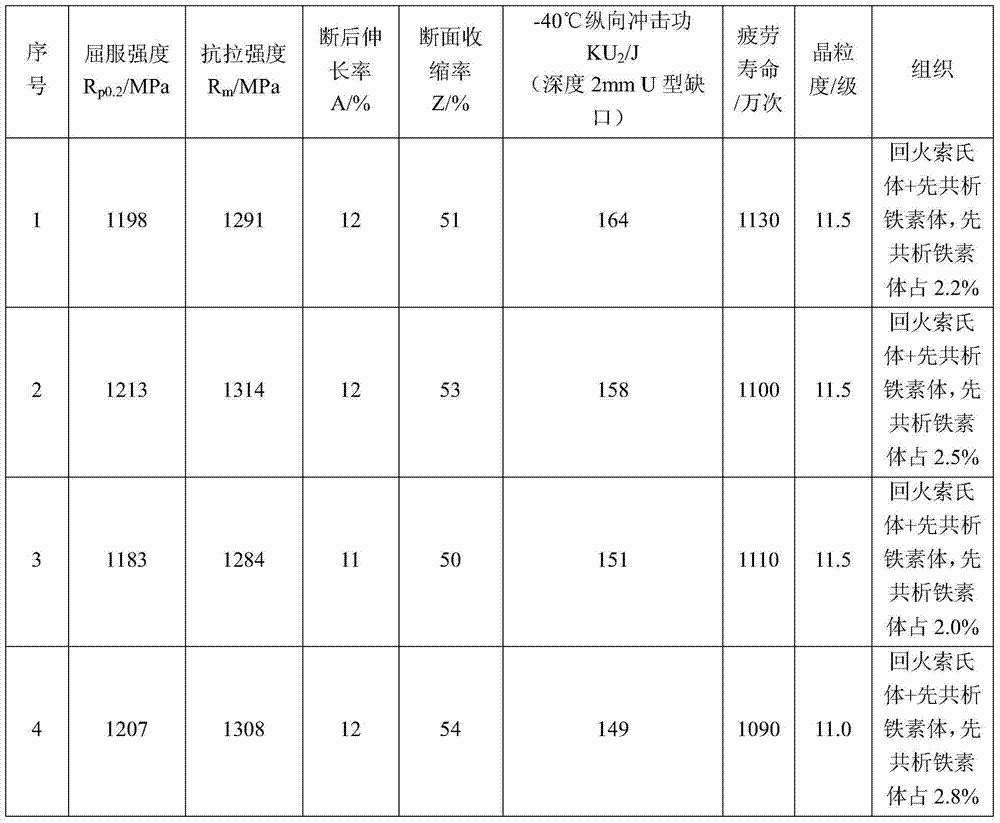

[0030] Embodiments of the smelting chemical composition and performance of the high-strength and high-toughness fasteners for rail transit mobile equipment containing niobium 12.9 of the present invention are as follows:

[0031] See Table 1 for the smelting chemical composition mass percentage (wt%) of 12.9-grade steel for high-strength and high-toughness fasteners used in rail transit mobile equipment with specifications M8-M24. The performance indicators after heat treatment are shown in T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com