Patents

Literature

35results about How to "Low saturated water absorption" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

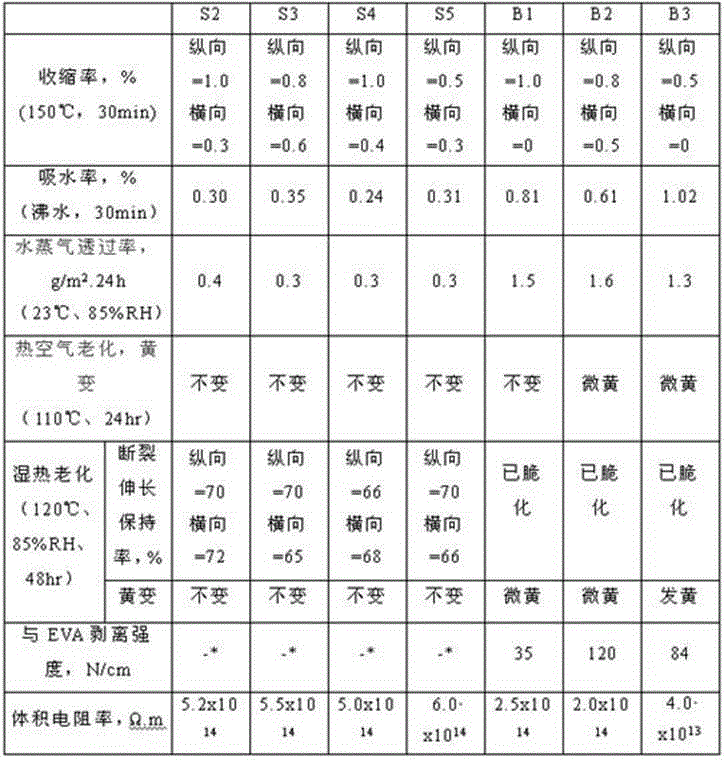

Modified polypropylene resin composition and solar energy rear panel made of the same

ActiveCN103066141AImprove low temperature impact resistanceAging resistantPhotovoltaic energy generationSemiconductor devicesSurface layerWater vapor permeability

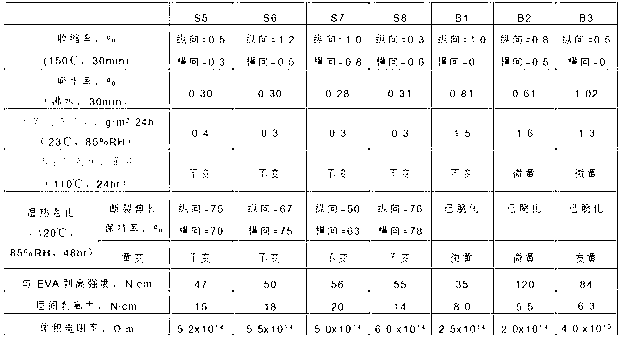

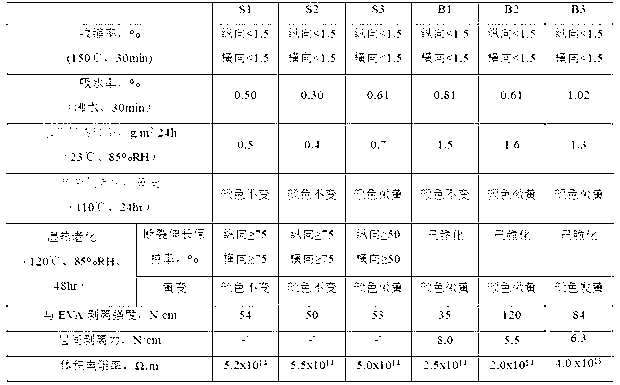

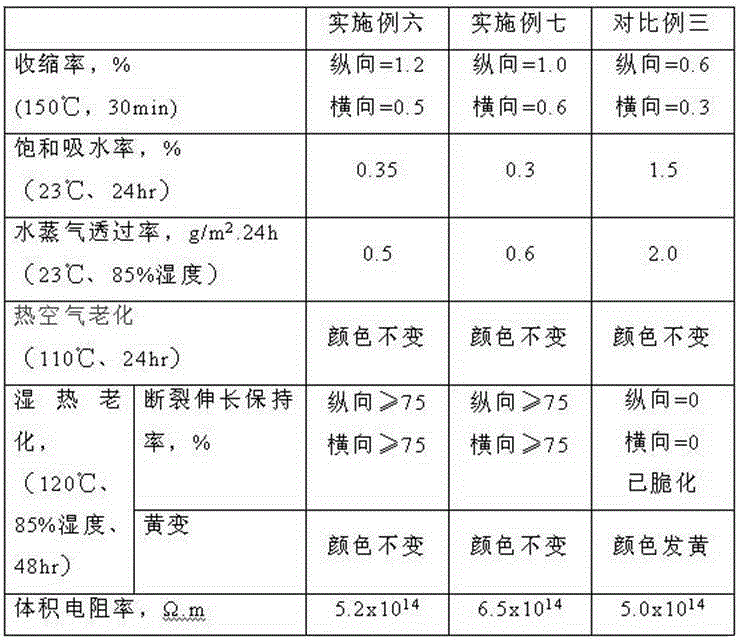

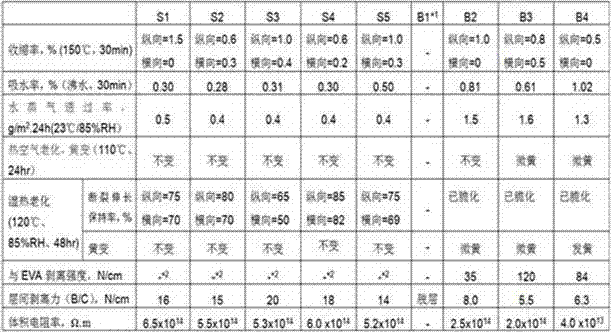

The invention discloses a solar energy rear panel and a preparation method of the solar energy rear panel. The solar energy rear panel comprises an inner surface layer, a core layer and an outer surface layer from inside to outside. By a mass rate, the inner surface layer is 10%-20%, the core layer is 20%-40%, and the outer surface layer is 40%-60%. The inner surface layer and the outer surface layer are made of polyamide resin, fillings and additive, and the core layer is made of the modified polypropylene resin composition. The modified polypropylene resin composition comprises the following components: 100 parts of polypropylene resin, 5-50 parts of graft polyethylene, 0-2.5 parts of additive and 0-100 parts of fillings. Meanwhile, the invention discloses the novel modified polypropylene resin composition used for the solar energy rear panel. Due to the novel modified polypropylene resin composition, a final product obtained has good low temperature resistance and impact resistance, meanwhile anti-aging performance and especially has performance of humidity resistance and resistance to aging. The solar energy rear panel prepared by the novel modified polypropylene resin composition is better than other rear panels in terms of water absorption, water vapor permeability, and interlaminar peeling and has excellent electrical insulating property. A shrinking rate, hot air aging and insulation property required by the solar energy rear panel are met, and the novel modified polypropylene resin composition can be used for solar energy battery components manufacturing .

Owner:SUZHOU DUCHAMPS ADVANCED MATERIALS CO LTD

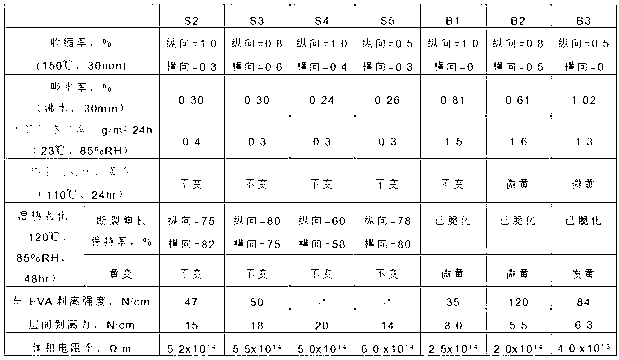

Polyamide backplane for solar energy assembly

ActiveCN103057223AImprove water absorptionExcellent heat and humidity resistanceFinal product manufactureSynthetic resin layered productsSurface layerWater vapor

The invention discloses a polyamide backplane for a solar energy assembly. The polyamide backplane comprises an inner surface layer, a core layer, and an outer surface layer from the inside to the outside, wherein by mass, the ratio of inner surface layer to the core layer to the outer surface layer is 10-20:60-80:10-20. The inner surface layer and the outer surface layer are made from a polyamide resin, fillers and additives; the core layer is made from a modified polyamide resin composition; and the modified polyamide resin composition comprises a polyamide resin, grafted polyethylene, a polypropylene resin, fillers and additives. The novel polyamide backplane of the present invention is prepared by using coextrusion technology, the final product obtained has excellent adhesion and interlayer peeling force, anti-aging, particularly anti-damp and heat aging performance, and also has low saturation water absorption, low water vapor transmission and excellent electrical insulating properties, and is easy in preparation and low in cost, suitable for industrial production.

Owner:SUZHOU DUCHAMPS ADVANCED MATERIALS CO LTD

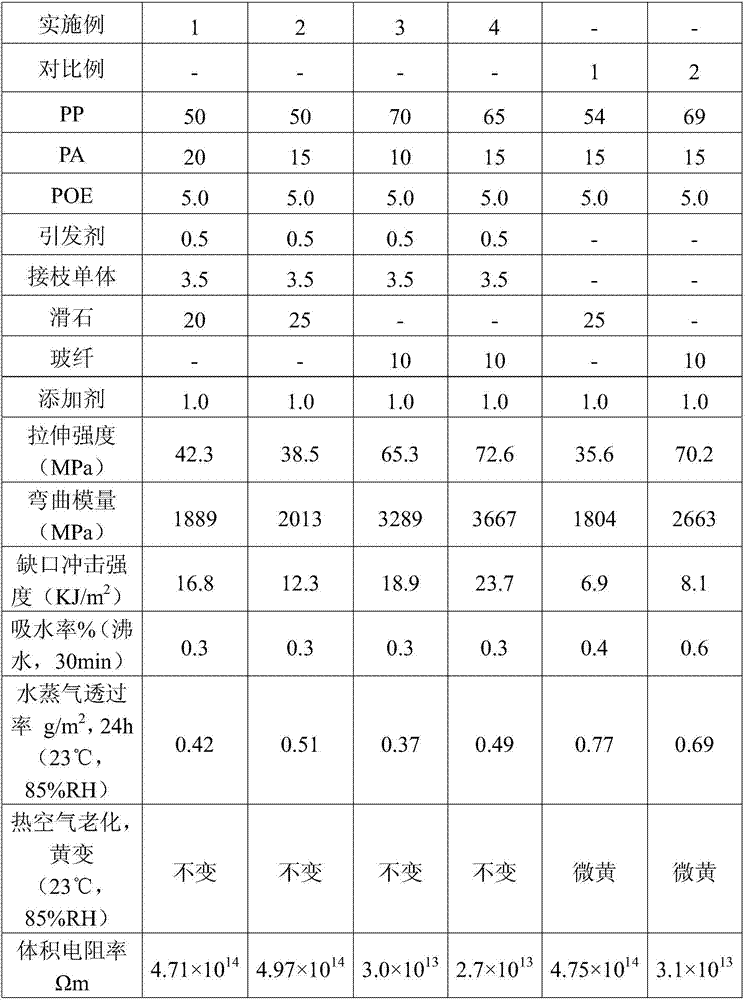

Resin composition for base material of solar backboard

ActiveCN103897266AImprove low temperature resistanceGood moisture and heat aging resistanceSemiconductor devicesWater vapor permeabilityBoPET

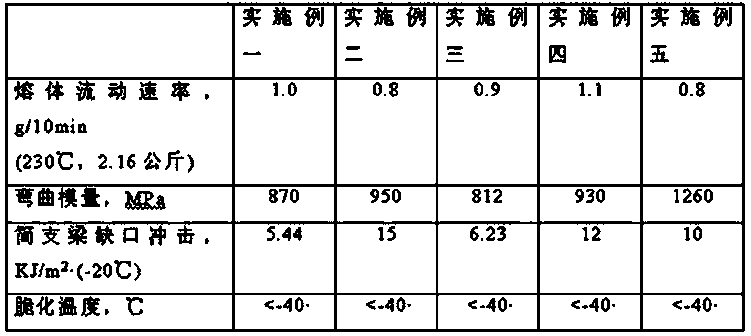

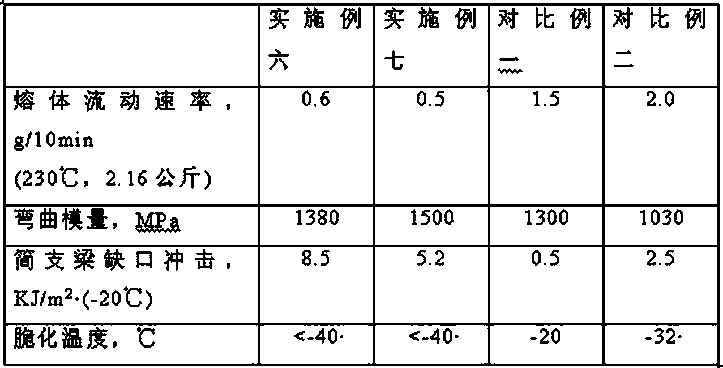

The invention discloses a resin composition for a base material of a solar backboard. The resin composition comprises the following components in parts by weight: 100 parts of component A and 20-100 parts of component B, wherein the component A is homo-polypropylene, segmented co-polypropylene or the mixture of homo-polypropylene and segmented co-polypropylene; the DSC (differential scanning calorimetry) melting point of the component A is 160-165 DEG C, and the melt flow rate is 1-2g / 10 minutes; the component B is homo-polyethylene, co-polyethylene or the mixture of homo-polyethylene and co-polyethylene; the DSC (differential scanning calorimetry) melting point of the component B is 120-135 DEG C, the melt flow rate is 1-2g / 10 minutes, and the density is 0.941-0.959 g / cm<3>. The base material of the solar backboard prepared from the novel resin composition developed by the invention has excellent low-temperature resistance, damp-heat aging resistance and electrical insulating performance and low saturated water absorption rate and water vapor permeability, and can be used for replacing an existing BOPET (biaxially oriented polyester film).

Owner:SUZHOU DUCHAMPS ADVANCED MATERIALS CO LTD

Polyamide resin and polyamide composition composed thereof

The invention discloses a polyamide resin, which is composed of the following repeated unit components: a component A which is 80-99mol / % of a 10T unit formed by decamethylene diamine and terephthalic acid; and a component B which is 1-20mol / % of a 1010 unit formed by decamethylene diamine and sebacic acid, wherein the sebacic acid is substituted by m-phthalic acid or other aliphatic dicarboxylic acid containing 2-14 carbon atoms. A polyamide composition containing the polyamide resin comprises the following components in percentage by weight: 30-99.9% of polyamide resin, 0-60% of reinforcing filler, 0-50% of flame retardant, and 0.1 to 10% of other auxiliary agents. The polyamide resin and the composition composed thereof disclosed by the invention have the advantages that with the water saturated absorptivity lower than 0.8wt%, and the resin and the composition can be applied to situations in which the requirement on water saturated absorptivity is high, such as being applied to an engine oil pipe; with the melting point higher than 260 DEG C, and strong heat resistance, and the resin and the compositions can be applied to situations in which the reflow soldering temperature exceeds 260 DEG C; with the breaking elongation of 14-45%, and the notch impact strength of 6.9-12.0kJ / m2 (23 DEG C), the resin and the composition have high tenacity and can be applied to situations in which the requirement on water saturated absorptivity is high, such as being applied to an engine oil pipe.

Owner:KINGFA SCI & TECH CO LTD

Solar-powered back plate and manufacturing method thereof

ActiveCN103050563AHigh temperature resistanceImproved environmental stress cracking resistanceFinal product manufacturePhotovoltaic energy generationSurface layerAging resistance

The invention discloses a solar-powered back plate. The solar-powered back plate comprises an inner surface layer, a core layer and an outer surface layer in the mass ratio of (10-20):(20-40):(40-60) from inside to outside, wherein the inner surface layer is made from vinyl resin, a filler and an additive; the outer surface layer is made from polyamide resin, a filler and an additive; and the core layer is made from a modified polyethylene resin composition. The invention further develops a novel polyethylene resin composition, which comprises 100 parts of crosslinked polyethylene resin, 0-50 parts of grafted polyethylene, 0.1-0.5 parts of catalyst, 0-100 parts of filler and 0-2.5 parts of additive. The novel solar-powered back plate developed by the invention is prepared through a coextrusion process; and a prepared final product has the advantages of superior adhesion, high interlaminar peeling strength, aging resistance, particular damp-heat aging resistance, low saturated water absorptivity, low water vapor transmittance and superior electric insulating property, simple preparation process, low cost and suitability for industrial production.

Owner:SUZHOU DUCHAMPS ADVANCED MATERIALS CO LTD

Backplane for solar energy assembly and preparation method thereof

ActiveCN103057228AReduce transmittanceAging resistantSynthetic resin layered productsPhotovoltaic energy generationSurface layerWater vapor

The invention discloses a backplane for a solar energy assembly and a preparation method thereof. The backplane comprises an inner surface layer, a core layer, and an outer surface layer from the inside to the outside, wherein by mass, the ratio of inner surface layer to the core layer to the outer surface layer is 10-20:20-40:40-60. The inner surface layer is made from a polyamide resin or a vinylite, fillers and additives; the outer surface layer is made from a polyamide resin, fillers and additives; and the core layer is made from a modified polyethylene resin composition. The modified polyethylene resin composition comprises the following components: 100 parts of the polyethylene resin, 5 to 50 parts of a grafted polyethylene, 0 to 2.5 parts of additives, and 0 to 100 parts of fillers. The present invention also discloses a novel modified polyethylene resin composition used for the backplane for a solar energy assembly, the final product obtained has a low water absorption and a low water vapor transmission, so the backplane prepared from the obtained product has interlayer peeling strength superior to other backplanes and excellent electrical insulating properties, thereby fulfilling requirements of backplanes for the shrinkage rate, hot air aging resistance and insulation properties, and can be used for manufacturing solar cell modules.

Owner:SUZHOU DUCHAMPS ADVANCED MATERIALS CO LTD

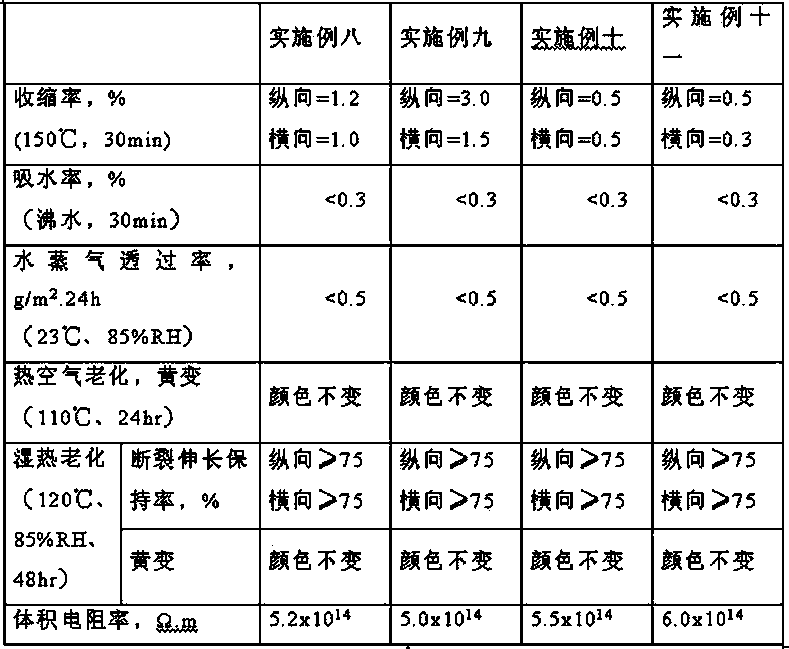

Modified polypropylene composition for solar cell back panel and preparation method thereof

InactiveCN107151384AImprove low temperature impact resistanceAging resistantPhotovoltaic energy generationSemiconductor devicesElastomerPolyolefin

The invention discloses a modified polypropylene composition for a solar cell back panel. The modified polypropylene composition comprises the following components in percentage by weight: 40 to 80 percent of polypropylene, 5 to 30 percent of polyamide, 2 to 15 percent of polyolefin elastomer, 0.1 to 1.0 percent of an initiator, 0.5 to 5.0 percent of a grafting monomer, 0 to 30 percent of reinforcing filler, and 0 to 5 percent of an additive. The composition provided by the invention has excellent low-temperature impact resistance and aging resistance, has low saturated water absorptivity, low water vapor permeability and excellent electrical insulating property, and can be used for manufacturing a solar back panel.

Owner:HUAZHONG AGRI UNIV

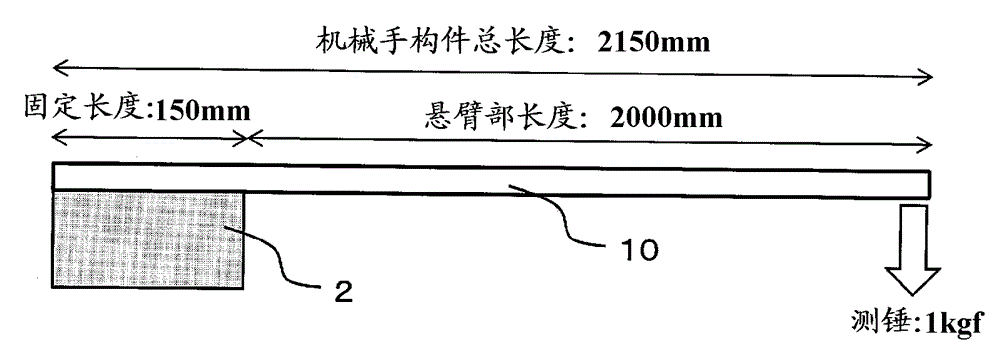

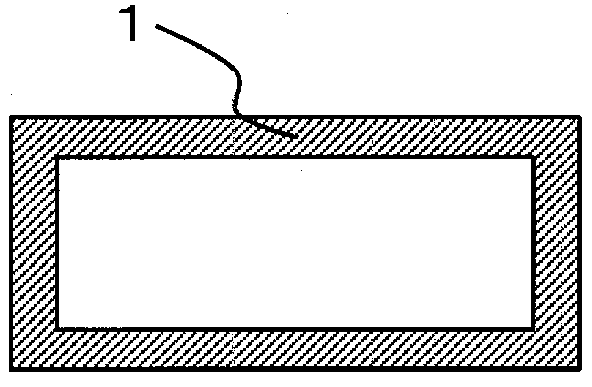

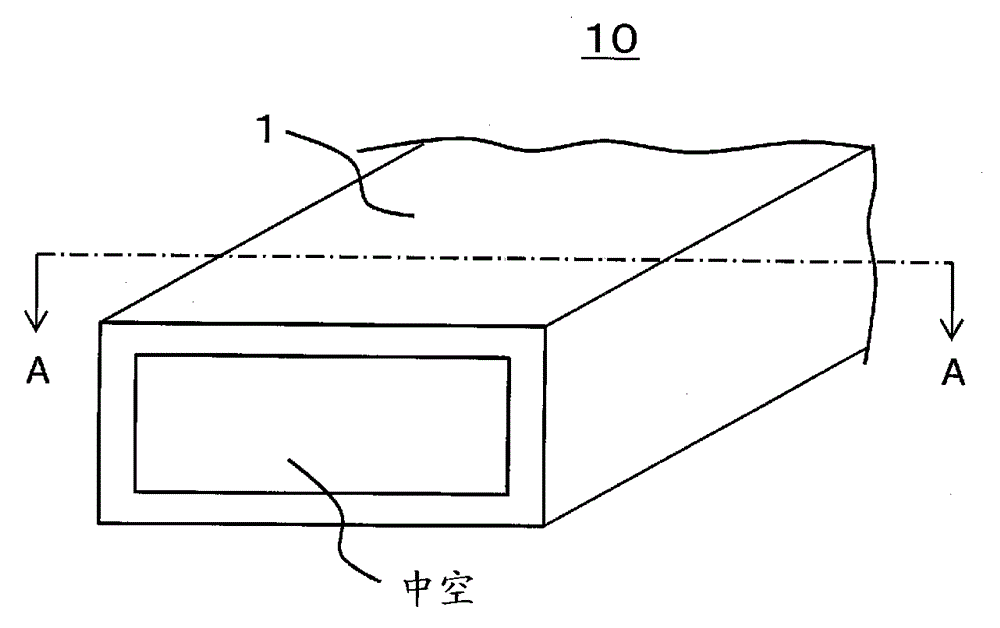

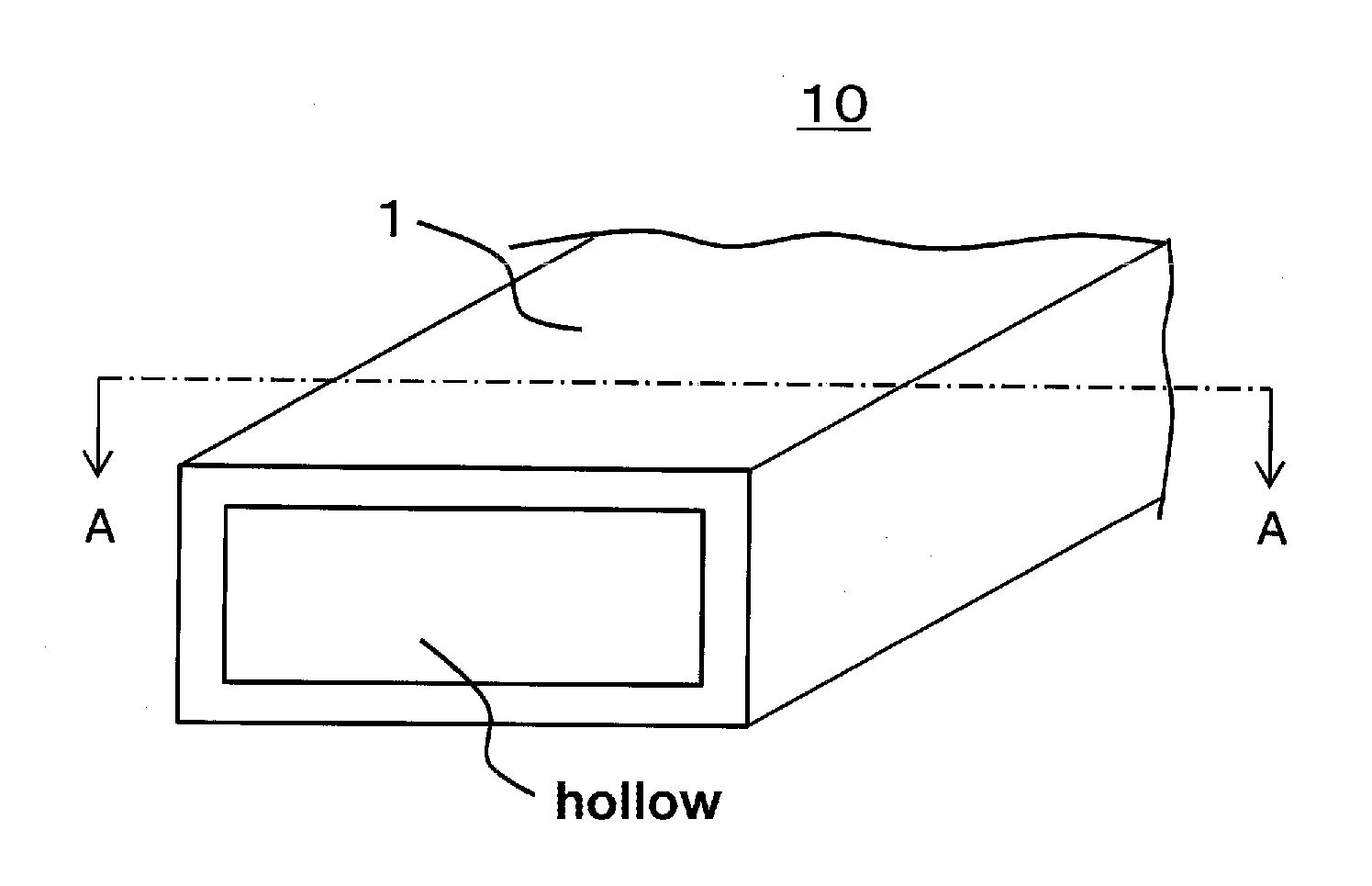

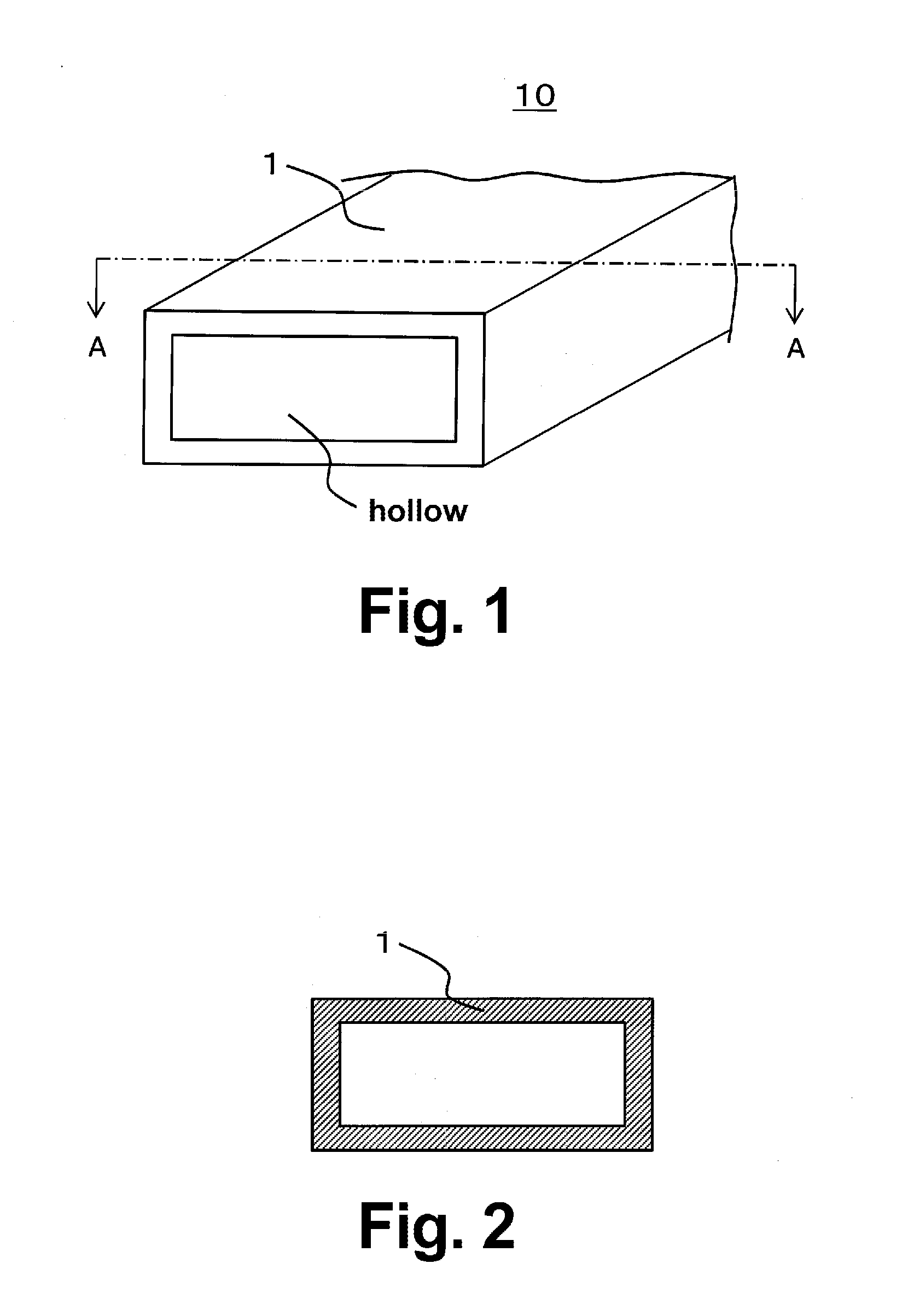

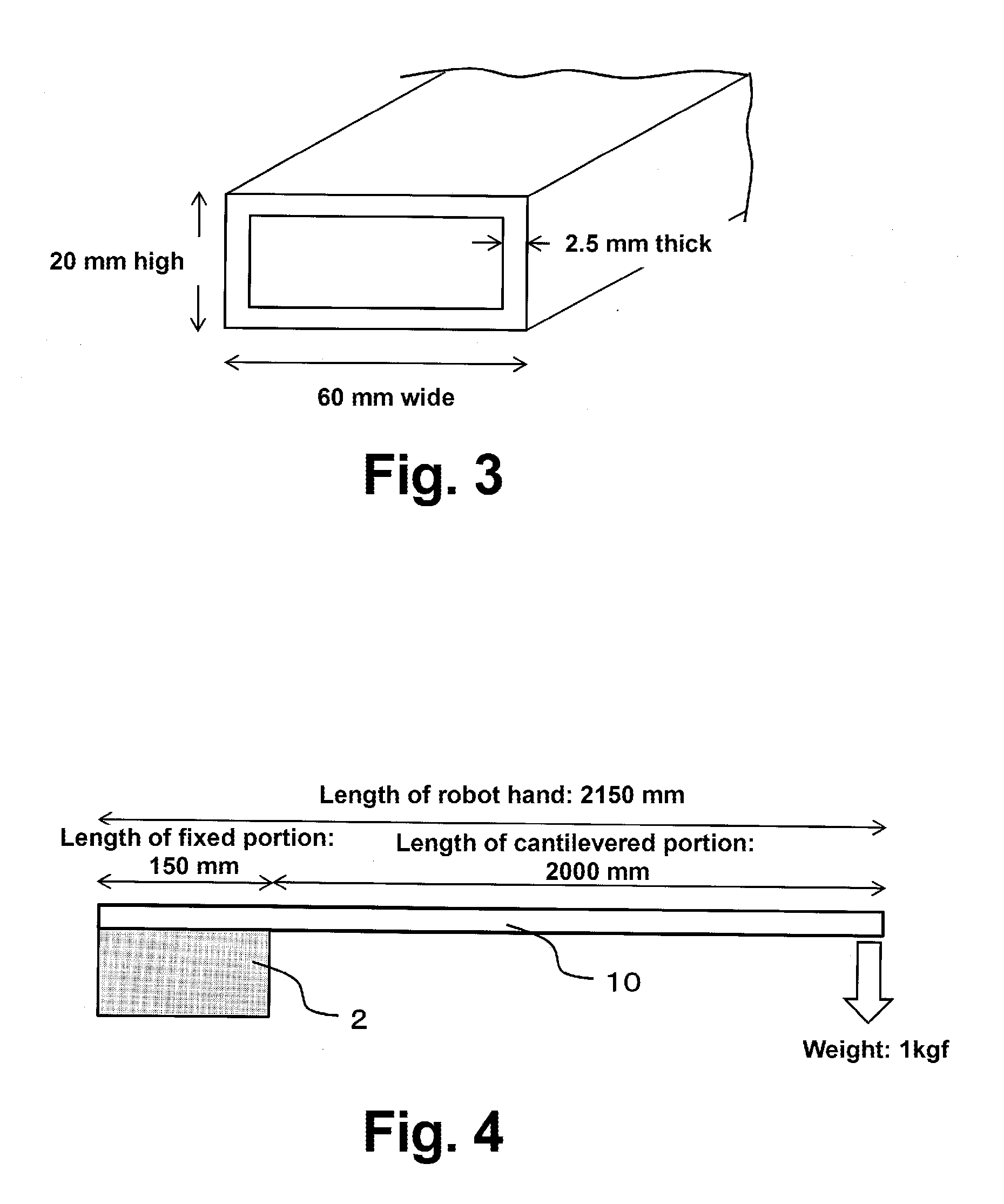

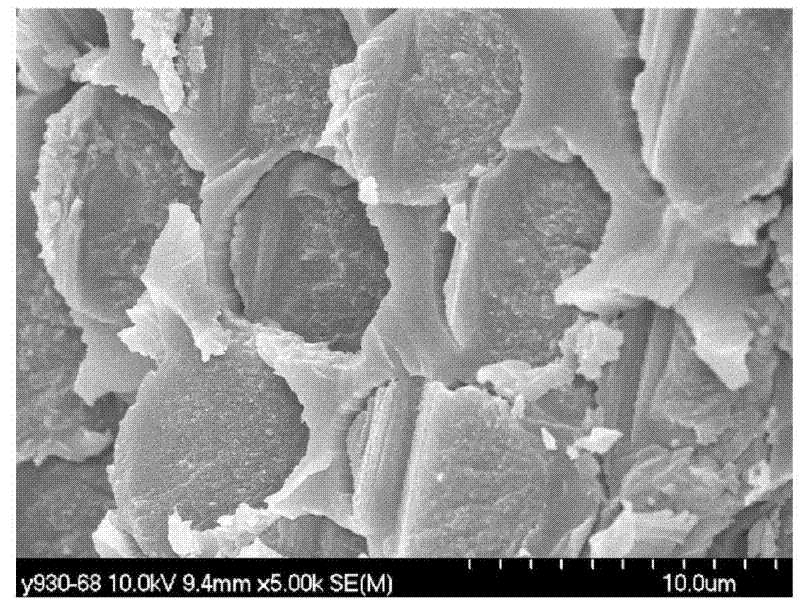

Prepreg, carbon-fiber-reinforced composite material, and robot hand

ActiveCN104974521ALow saturated water absorptionImprove heat resistanceSynthetic resin layered productsThin material handlingFiberRobot hand

Provided are a carbon-fiber-reinforced composite material having a low saturated water absorption and excellent TML, CVCM, and heat resistance, a robot hand, and a prepreg suitable therefor. The prepreg includes a CFRP sheet composed of resin composition (a) containing 100 parts by mass of cyanate ester resin (a1) having in its molecule not less than 2 cyanate groups, 0.01 to 0.5 parts by mass of metal coordination catalyst (a2), and 1 to 20 parts by mass of thermoplastic, toughness enhancer (a3), and carbon fibers (b) containing carbon fibers (b1) having a tensile elastic modulus of not lower than 450 GPa. The prepreg is useful for a supporting section of a robot hand.

Owner:JXTJ NIPPON OIL & ENERGY CORP

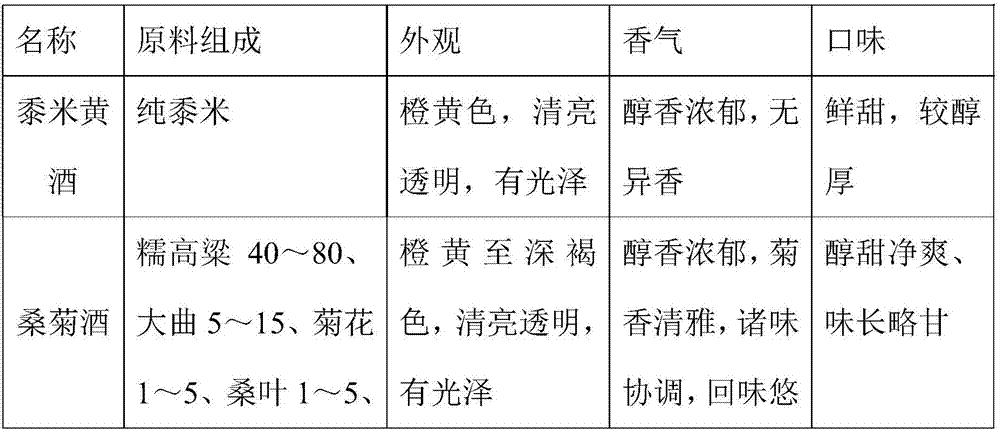

Mulberry leaf chrysanthemum wine and preparation method thereof

PendingCN107400608ALow saturated water absorptionLow gelatinization temperatureAntinoxious agentsAlcoholic beverage preparationLeesBiotechnology

Belonging to the technical field of brewing of drinking health care wine, the invention provides a mulberry leaf chrysanthemum wine and a preparation method thereof. Glutinous sorghum, kudzuvine root, mulberry leaf and chrysanthemum are adopted as the raw materials. The preparation method includes: soaking and steaming glutinous sorghum, then adding kudzuvine root, mulberry leaf and chrysanthemum, carrying out saccharification fermentation, then adding a certain amount of primary pulp Baijiu to conduct alcoholic fermentation so as to obtain vinasse liquid; then subjecting the vinasse liquid to press filtering, and taking the clear liquid to prepare raw wine; sterilizing the raw wine, conducting conventional filtration, then regulating the alcohol content and sugar content, and performing subpackaging, thus obtaining the mulberry leaf chrysanthemum wine.

Owner:晋中市宏艺生物科技有限公司

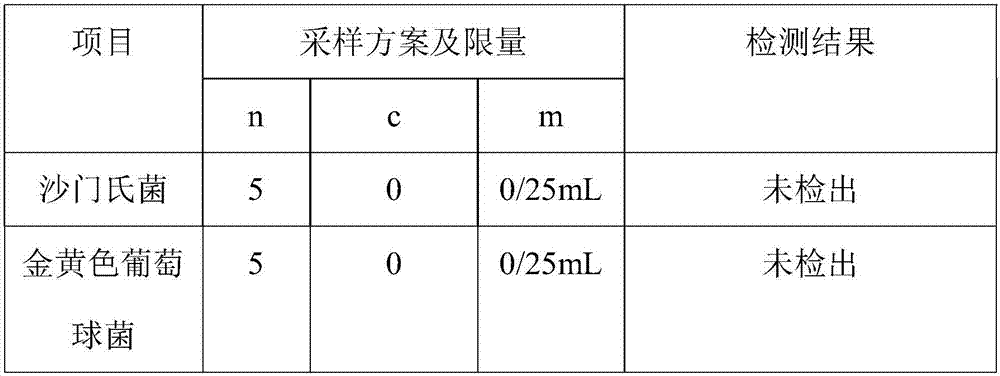

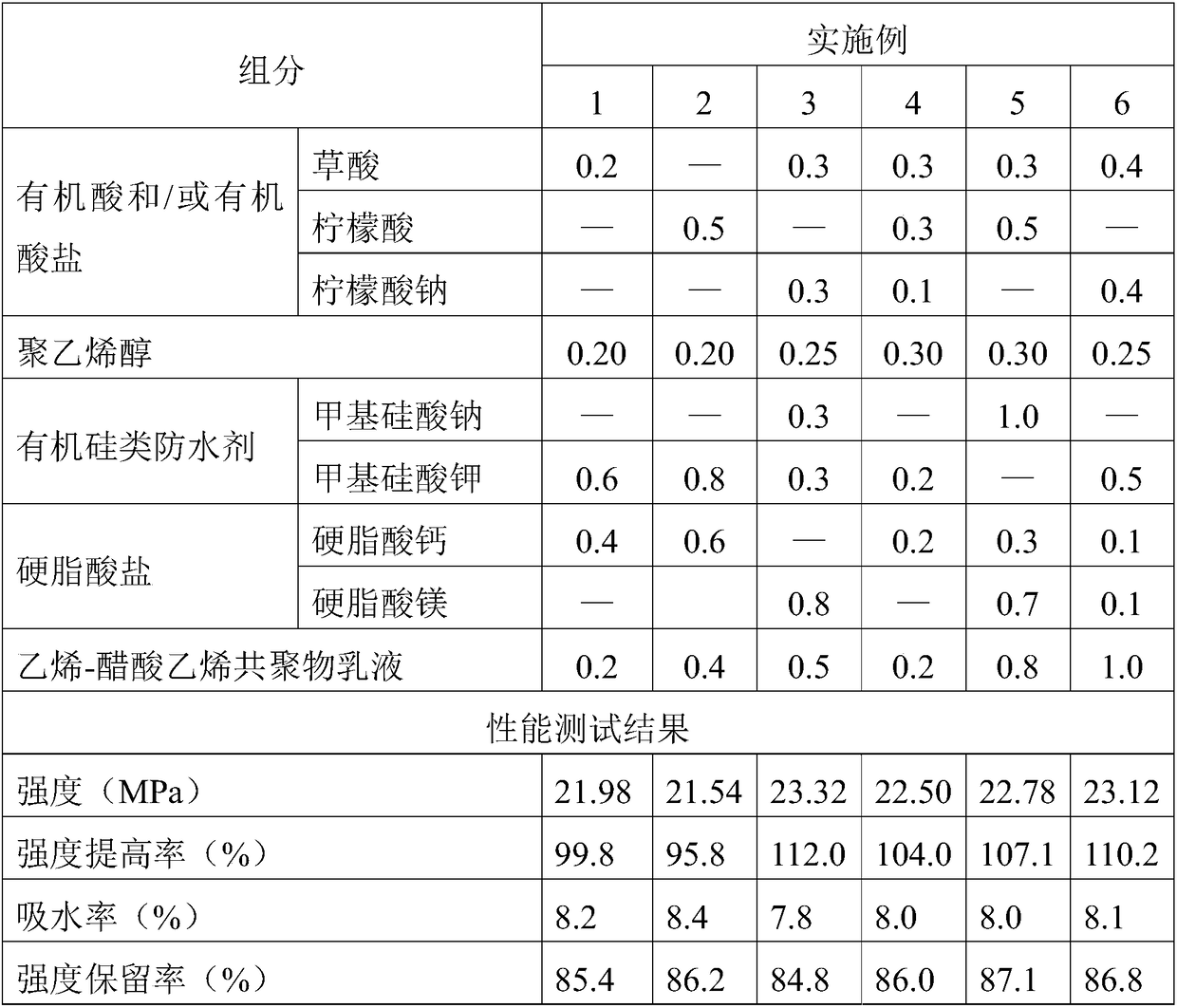

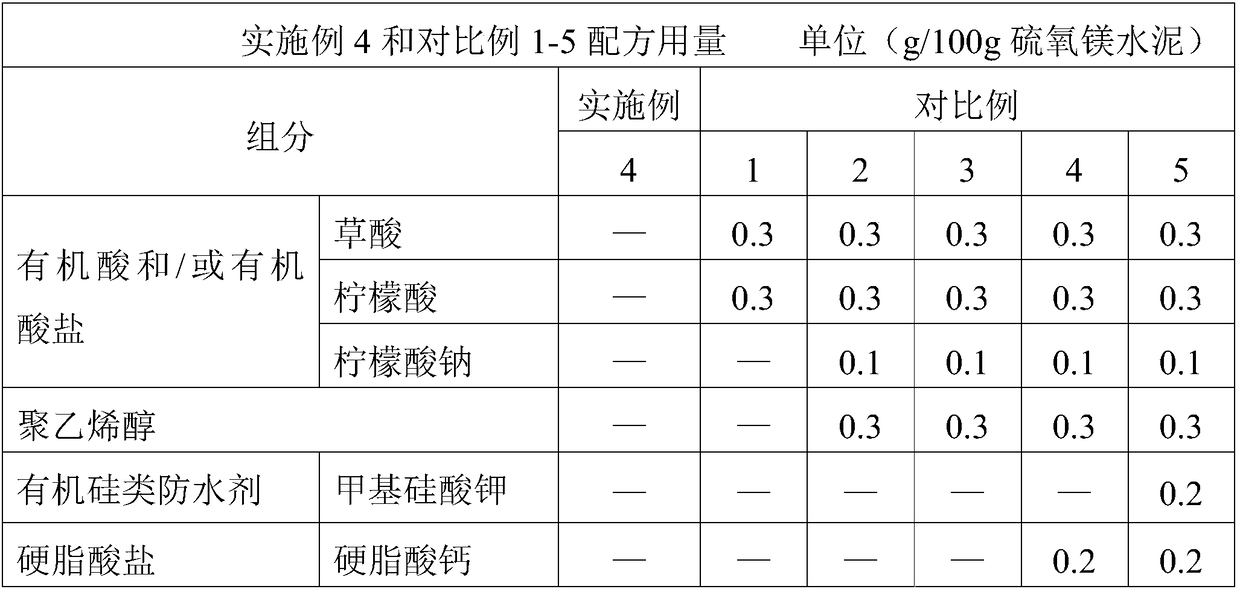

High-strength and low-water-absorption magnesium oxysulfate cement

The invention discloses a high-strength and low-water-absorption magnesium oxysulfate cement, which comprises magnesium oxide powder, a magnesium sulfate solution, dried wood fiber, a medium alkali glass fiber cloth and a composite modifier, wherein the composite modifier comprises, by weight (calculated as the total weight of the magnesium oxysulfate cement), 0.2-0.8% of an organic acid and / or anorganic acid salt, 0.2-0.3% of polyvinyl alcohol, 0.2-1.0% of an organic silicon waterproofing agent, 0.2-1.0% of stearate, and 0.2-1.0% of an ethylene-vinyl acetate copolymer emulsion. According tothe present invention, the composite modifier is added on the basis of the original formula of the magnesium oxysulfate cement, such that the final set strength of the magnesium oxysulfate cement is increased by 90-110%, and the saturated water absorption rate is substantially reduced to 8% from 37%; and with the ethylene-vinyl acetate copolymer emulsion, the structure of the magnesium oxysulfatecement is subjected to weather-resistant film forming property protect, such that the strength retention rate of the modified magnesium oxysulfate cement is substantially improved.

Owner:林成华

Preparation method of recombined wood

InactiveCN109773925AHigh bonding strengthLow saturated water absorptionWood treatment detailsDomestic articlesWood veneerAbsorption rate

The invention belongs to the field of recombined wood and particularly relates to a preparation method of recombined wood. The provided preparation method comprises the following steps of a, soaking wood veneers into methyl-silicate-modified phenolic resin glue and drying the wood veneers to obtain primary sizing veneers; b, soaking the primary sizing veneers into unmodified phenolic resin glue and drying the veneers to obtain secondary sizing veneers; c, carrying out die pressing on the secondary sizing veneers to obtain the recombined wood. According to the method, different kinds of phenolic resin glue are adopted for carrying out two-step glue dipping on the wood veneers, so that the bonding strength of the recombined wood obtained by subsequent die pressing is greatly improved, and the saturated water absorption rate of the recombined wood is reduced. It is indicated by experimental results that the bonding strength of the recombinant wood prepared by the method can reach 2.2-4.0MPa, and the saturated water absorption rate is 15-17.5%.

Owner:CHAMBROAD CHEM IND RES INST CO LTD

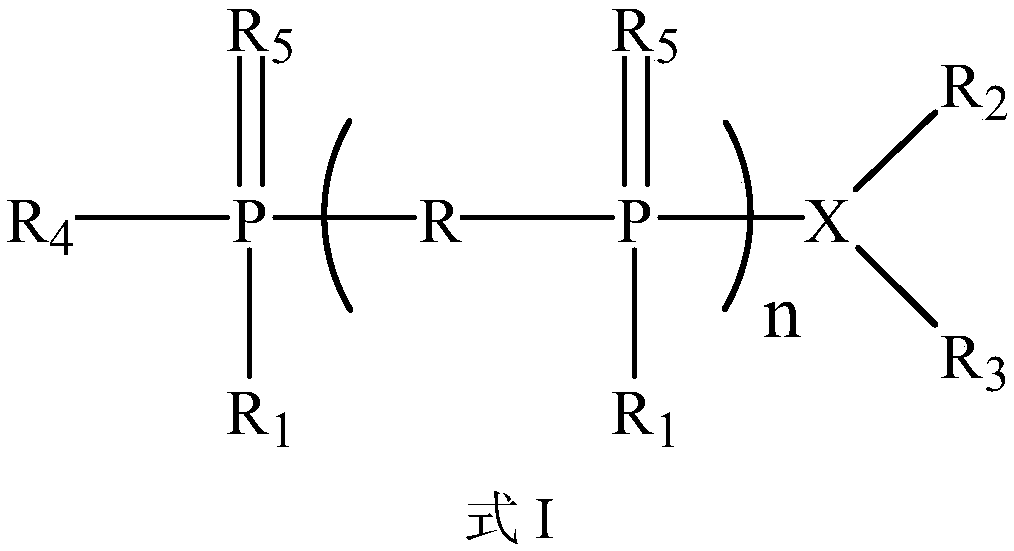

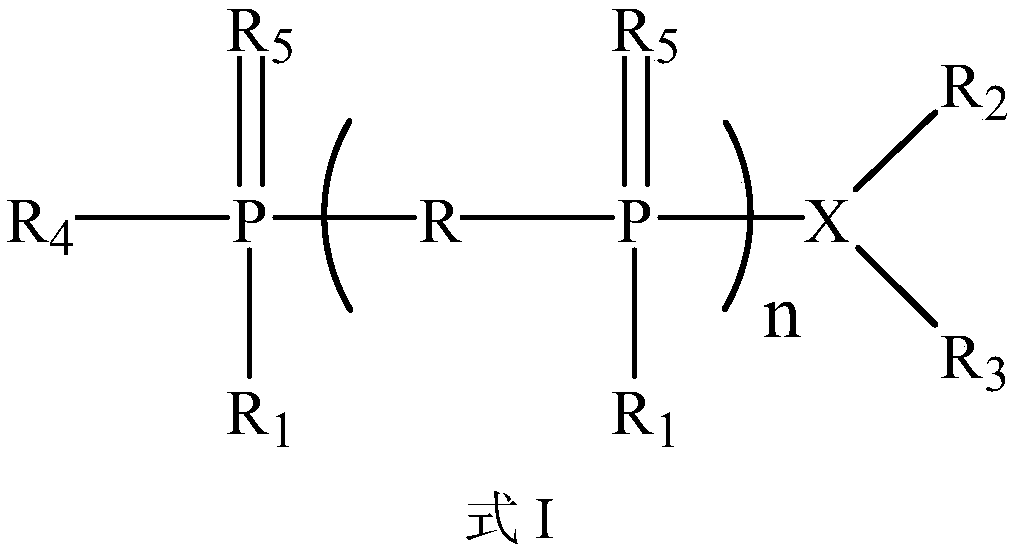

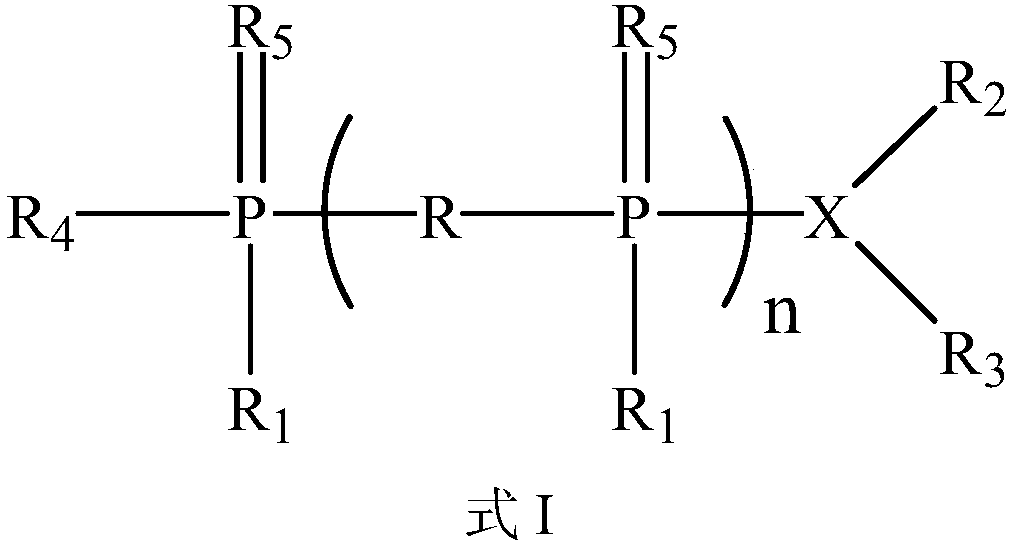

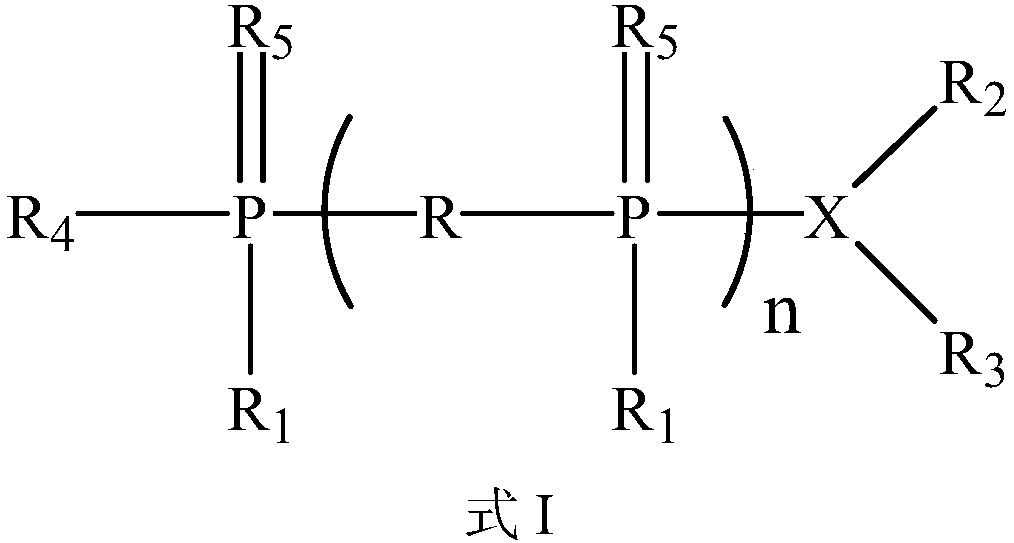

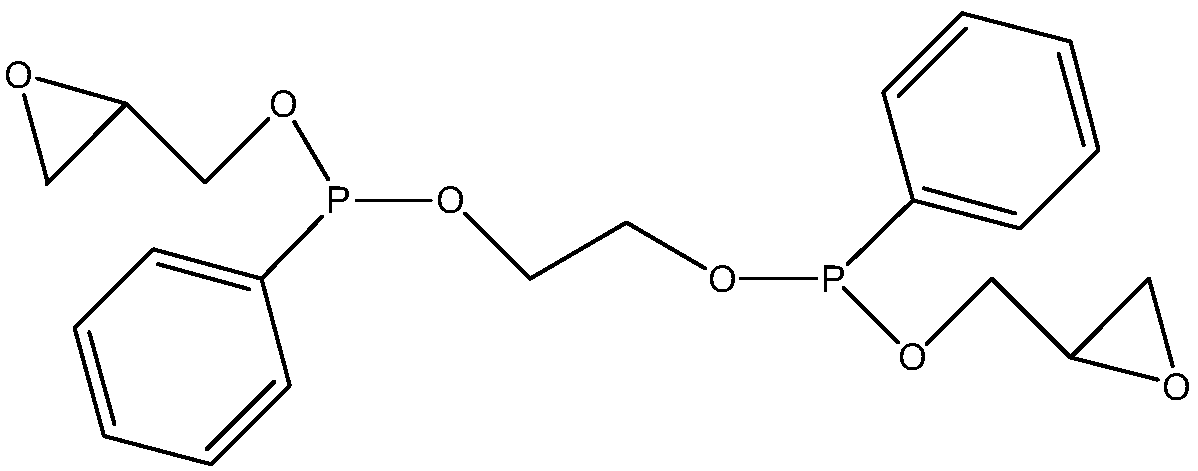

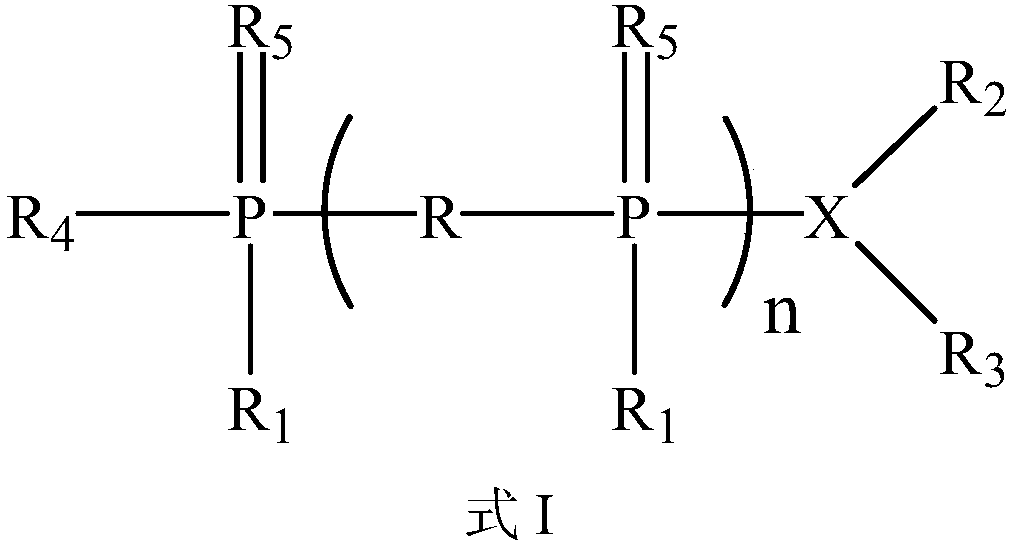

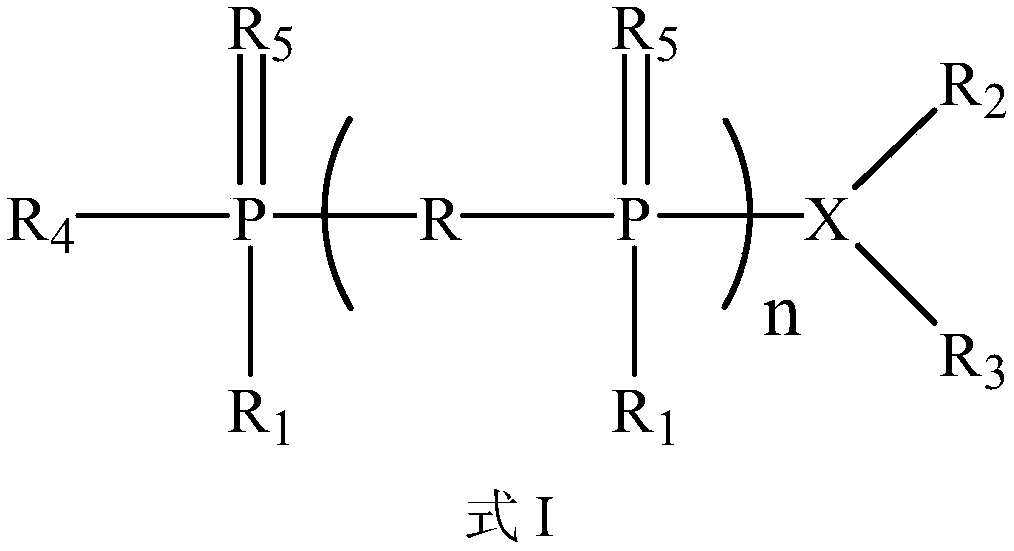

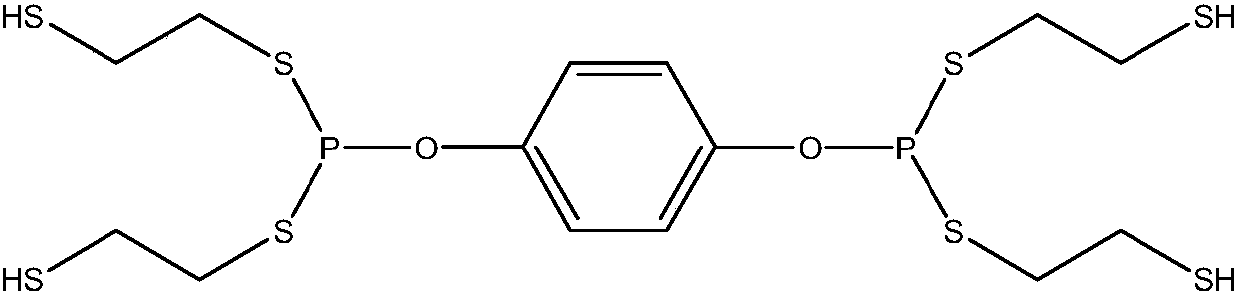

Reactive flame retardant, preparation method and application thereof

InactiveCN109897219AImprove flame retardant performanceImprove combustion effectGroup 5/15 element organic compoundsHeat resistanceCopper

The invention provides a reactive flame retardant, a preparation method and application thereof. The composite materials, copper clad laminates and potting materials prepared from the reactive flame retardants have good flame retardance, good heat resistance, water resistance and mechanical properties. The reactive flame retardant provided by the invention has the advantages of low preparation cost, abundant raw material sources and good performance, and has wide application prospects.

Owner:GUANGDONG GUANGSHAN NEW MATERIALS CO LTD

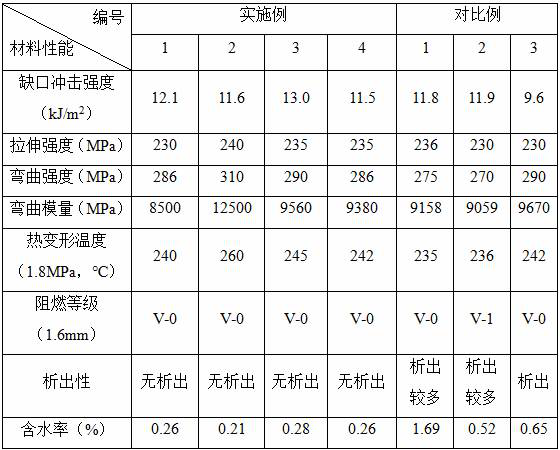

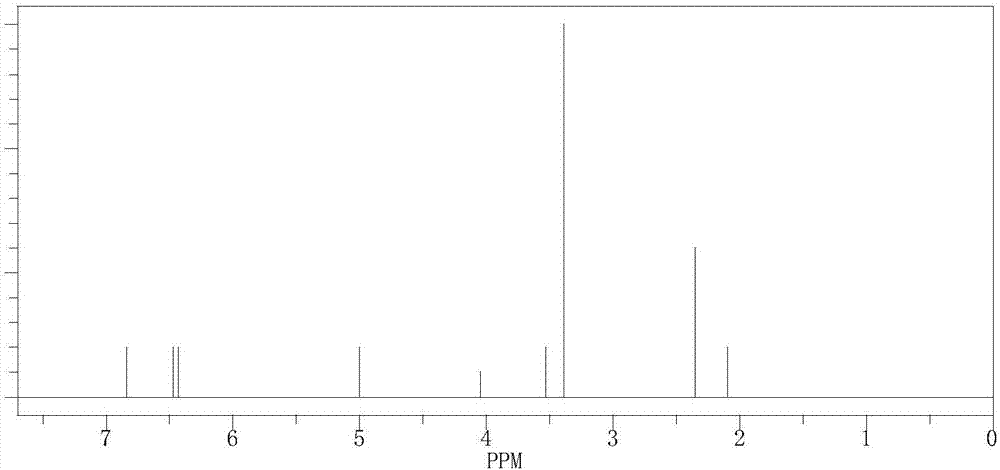

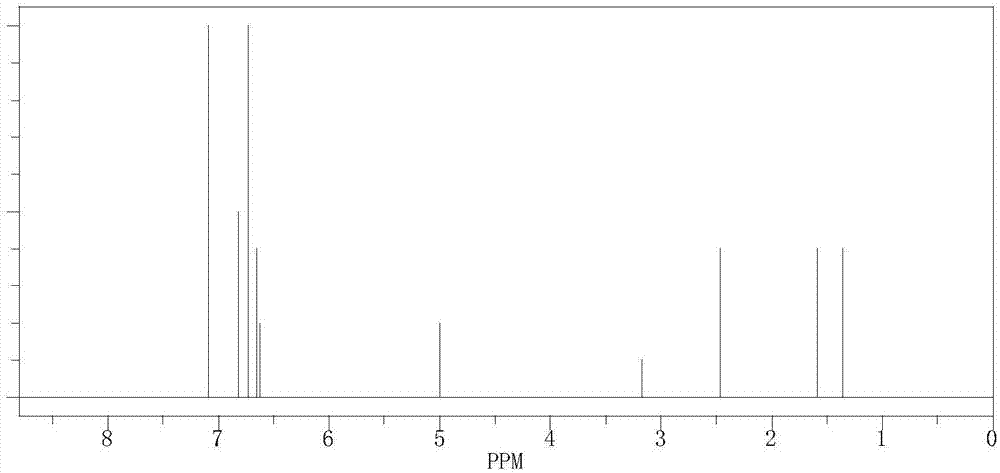

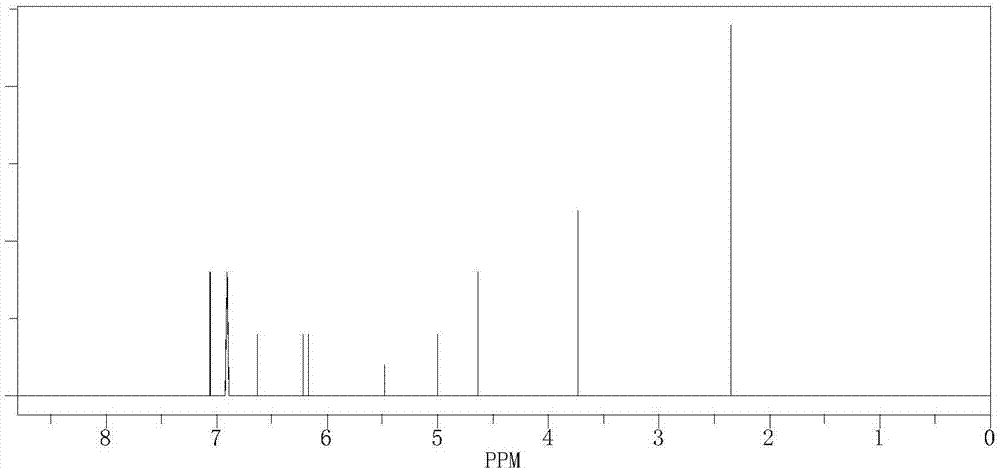

Precipitation-free, low-water-absorption, halogen-free and flame-retardant reinforced nylon 66 as well as preparation method and application thereof

ActiveCN112920598ASmall water absorptionSolve technical problems that are easy to separate outFlame resistancePolymer chemistry

Owner:长沙五犇新材料科技有限公司

Polyamide resin and polyamide composition composed of polyamide resin

The invention discloses a polyamide resin. The polyamide resin is composed of following repeat unit ingredients: 80 to 99mol% of an ingredient A, which is 10T unit composed of decamethylene diamine and terephthalic acid; and 1 to 20mol% of an ingredient B, which is 1010 unit composed of decamethylene diamine and decanedioic acid; wherein decanedioic acid is substituted by isophthalic acid or other aliphatic dicarboxylic acids with 2 to 14 carbon atoms. The invention also discloses a polyamide composition containing the polyamide resin. The polyamide composition comprises, by weight, 30 to 99.9% of the polyamide resin, 0 to 60% of a reinforcing filler, 0 to 50% of a flame retardant, and 0.1 to 10% of other auxiliary agents. Saturated water absorptivity of the polyamide resin and the polyamide composition is less than 0.8wt%, so that the polyamide resin and the polyamide composition can be used for components, such as engine oil tubes, with relatively high requirements on saturated water absorptivity; melting point is higher than 260 DEG C, and heat resistance is high, so that the polyamide resin and the polyamide composition can be used for environments with a reflow soldering temperature more than 260 DEG C, and the like; elongation at break ranges from 14 to 45%; notch impact strength ranges from 6.9 to 12.0kJ / m<2> (23 DEG C); toughness is high, so that the polyamide resin and the polyamide composition can be used for components, such as engine oil tubes, with relatively high requirements on toughness.

Owner:KINGFA SCI & TECH CO LTD

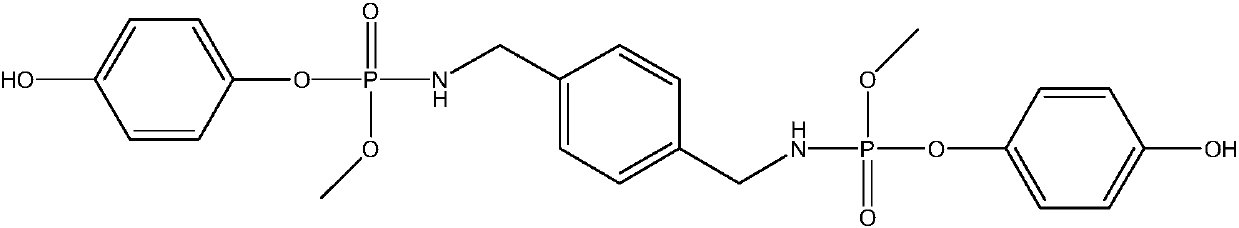

Phosphonitrile compound containing phenolic hydroxyl group, preparation method and application thereof

InactiveCN107325129AImprove mechanical propertiesImprove flame retardant performanceGroup 5/15 element organic compoundsCircuit susbtrate materialsHeat resistanceMechanical property

The invention provides a phosphonitrile compound containing a phenolic hydroxyl group, a preparation method and an application thereof. A copper-clad plate which is prepared from the phosphonitrile compound containing the phenolic hydroxyl group has excellent fire resistance, heat resistance, water resistance, caking property, mechanical property and electrical property. The phosphonitrile compound containing the phenolic hydroxyl group is characterized by low compounding cost, simple preparation method, abundant raw material source and wide application prospect.

Owner:GUANGDONG GUANGSHAN NEW MATERIALS CO LTD

Synergistic silicon modified phenolic resin adhesive and preparation of scrimber of silicon-modified phenolic resin adhesive

ActiveCN111171770ARich sourcesSimple preparation processNon-macromolecular adhesive additivesWood compressionPolymer scienceSilicic acid

The invention relates to a silicon-modified phenolic resin adhesive and scrimber prepared from the adhesive. According to the invention, a phenolic resin is modified with methyl silicic acid; in orderto improve the bonding effect of the silicon-modified phenolic resin, an adhesive controllable introduction agent is added; and by using the adhesive controllable introduction technology, the bondingstrength and the water repellency of scrimber prepared from the silicon-modified phenolic resin are greatly improved, and the saturated water absorption rate of the scrimber is reduced.

Owner:QINGDAO UNIV OF SCI & TECH

Prepreg, carbon-fiber-reinforced composite material, and robot hand

InactiveUS20150274913A1Low in saturated water absorptionLong-term useSynthetic resin layered productsSpecial tyresRobot handFiber-reinforced composite

Provided are a carbon-fiber-reinforced composite material having a low saturated water absorption and excellent TML, CVCM, and heat resistance, a robot hand, and a prepreg suitable therefor. The prepreg includes a CFRP sheet composed of resin composition (a) containing 100 parts by mass of cyanate ester resin (a1) having in its molecule not less than 2 cyanate groups, 0.01 to 0.5 parts by mass of metal coordination catalyst (a2), and 1 to 20 parts by mass of thermoplastic, toughness enhancer (a3), and carbon fibers (b) containing carbon fibers (b1) having a tensile elastic modulus of not lower than 450 GPa. The prepreg is useful for a supporting section of a robot hand.

Owner:JX NIPPON OIL & ENERGY CORP

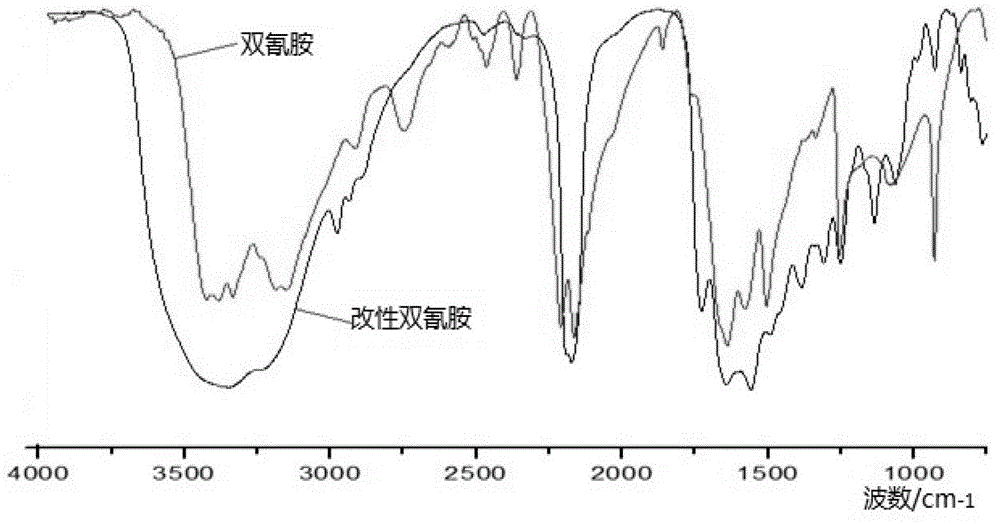

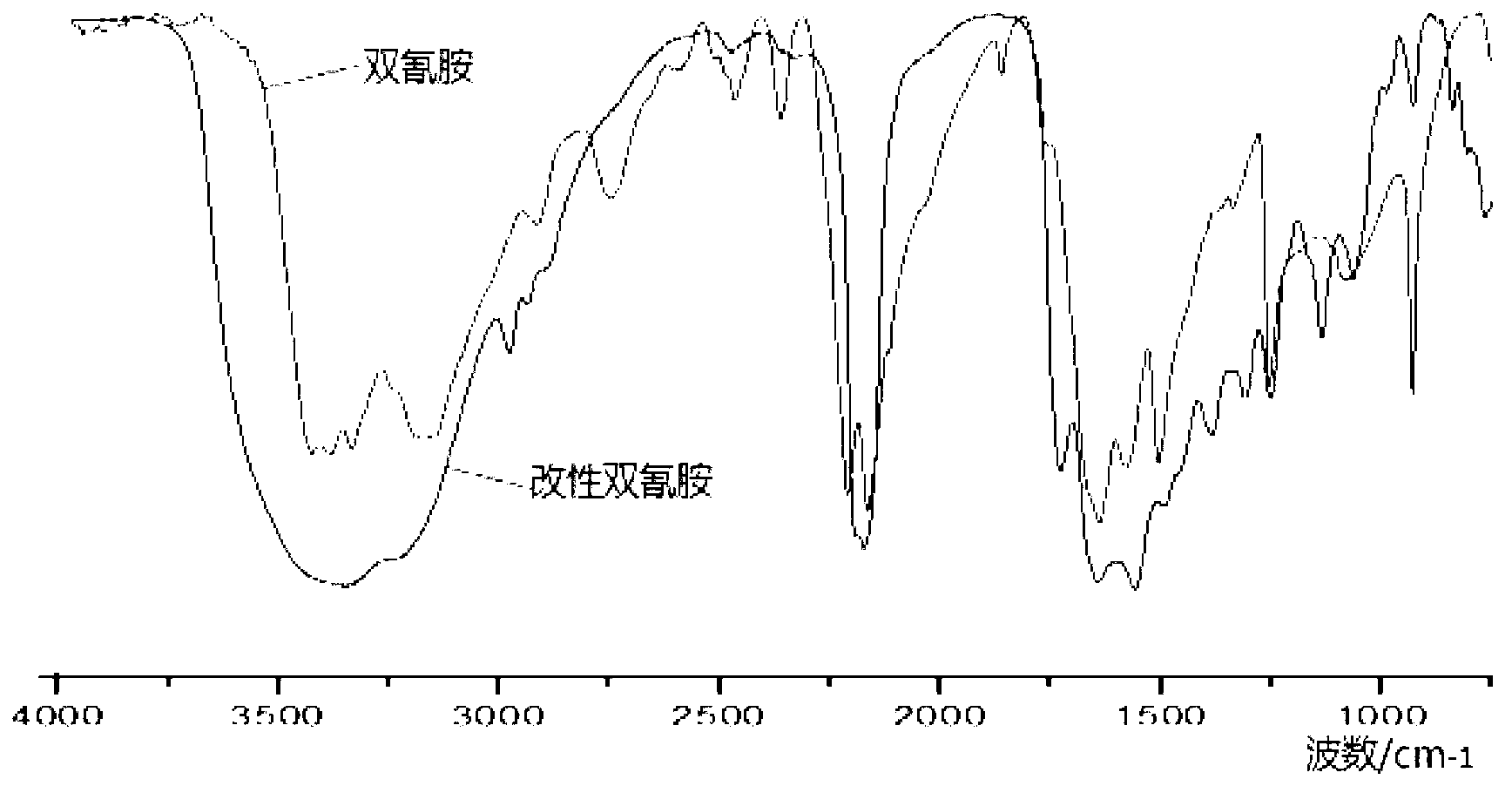

A kind of preparation method of water-based epoxy resin sizing agent for carbon fiber

The invention discloses a preparation method of a water-based epoxy resin sizing agent for carbon fibers, which relates to a preparation method of the sizing agent. The invention solves the problems of high cost of the existing foreign emulsion-type sizing agent and poor performance of the domestically researched emulsion-type sizing agent. Method: 1. Prepare water-based epoxy resin; 2. Prepare water-soluble epoxy resin curing agent; 3. Dilute the water-based epoxy resin with deionized water and then disperse to obtain water-based epoxy resin emulsion; 4. Water-based epoxy resin Mix the emulsion with a water-soluble epoxy resin curing agent to obtain a water-based epoxy resin emulsion system; 5. Mix the water-based epoxy resin emulsion system and additives to obtain a water-based epoxy resin sizing agent for carbon fibers. The water-based epoxy resin sizing agent for carbon fibers of the present invention has good performance, good reinforcing effect on carbon fibers, good bundling, smoothness, and flexibility, and can simultaneously satisfy the overall looseness of filaments between fibers, fiber opening, The performance index of crosslinking degree between single fibers, and the cost is low.

Owner:HARBIN INST OF TECH

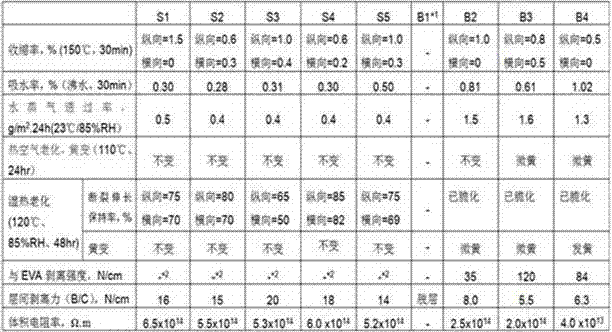

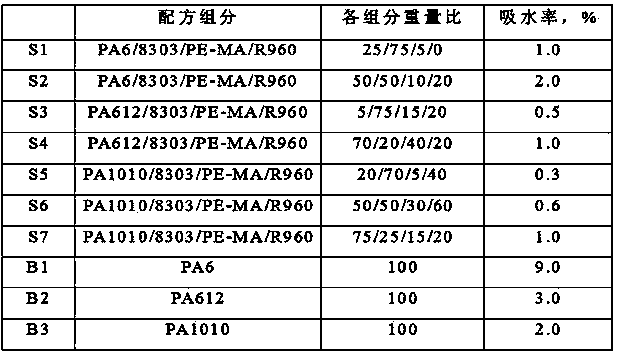

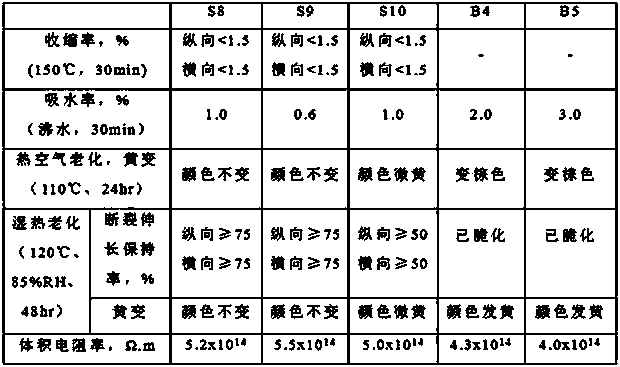

A modified polyamide resin composition and backplane substrate film prepared by the same

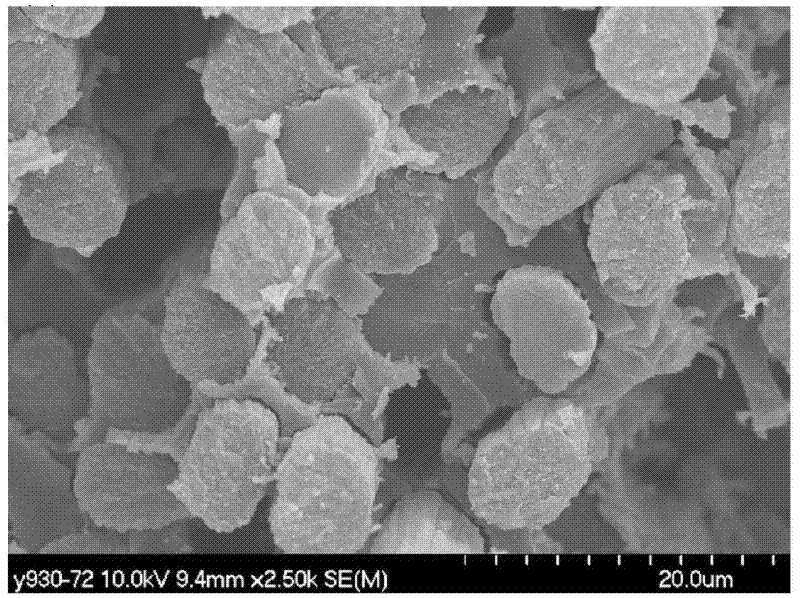

ActiveCN103059558BImprove water absorptionGood moisture and heat aging resistancePhotovoltaic energy generationSemiconductor devicesWater vaporGraft reaction

The present invention discloses a modified polyamide resin composition and backplane substrate film prepared by the same. The modified polyamide resin composition comprises the following components, by mass: 5-75 parts of polyamide resin, 5-75 parts of polypropylene resin, 5-50 parts of grafted polyethylene, and 0-100 parts of a filler. The grafted polyethylene is prepared from the following components via graft reaction: 100 parts of polyethylene resin, 0.5-2.0 parts of a grafting agent, and 0.03-0.2 parts of an initiator. According to the present invention, a new resin composition used for backplane substrates of solar energy assemblies is developed; the final product obtained has anti-aging, particularly anti-damp and heat aging performance, and also has low saturation water absorption, low water vapor transmission and excellent electrical insulating properties, and backplane substrate film prepared therefrom further has high adhesion and mechanical strength, and can be used for manufacturing backplane of solar energy assemblies.

Owner:SUZHOU DUCHAMPS ADVANCED MATERIALS CO LTD

Reactive flame retardant, preparation method and application thereof

InactiveCN109897164AImprove combustion effectImprove heat resistanceGroup 5/15 element organic compoundsMaterial qualityChemistry

The invention provides a reactive flame retardant, a preparation method and application thereof. The reactive flame retardant has excellent flame retardance and no fuming, can be applied in compositematerials, resin compositions, epoxy resin compositions, copper clad laminates and other fields, not only can improve the flame retardance and heat resistance of epoxy resin compositions and copper clad laminates, but also can improve the mechanical properties and water resistance of the materials and comprehensively improve the material quality.

Owner:GUANGDONG GUANGSHAN NEW MATERIALS CO LTD

Latent single-component LCD (liquid crystal display) packaging adhesive

InactiveCN103254863BFix incompatibilitiesImprove latencyMacromolecular adhesive additivesEpoxy resin adhesivesEpoxyLatent image

The invention discloses a latent single-component LCD (liquid crystal display) packaging adhesive which comprises the following raw materials in percentage by mass: 51-70% of epoxy resin E-44, 8-15% of epoxy resin modifier, 10-15% of latent liquid curing agent, 1-5% of silane coupling agent, 0.5-5% of solvent, 0.1-0.5% of defoaming agent, 0.1-0.5% of leveling agent, 0.1-0.5% of wetting dispersant, 10-15% of calcium carbonate and 0.1-2% of titanium white. The preparation method comprises the following steps: uniformly stirring epoxy resin E-44, epoxy resin modifier, curing agent, silane coupling agent and solvent; and adding the remaining raw materials, uniformly stirring, and standing at normal temperature to remove bubble. The LCD packaging adhesive can be cured at 120-150 DEG C to perform LCD binding, and has the characteristics of no yellowing, high binding strength, favorable light transmittance, low curing shrinkage rate, long storage life and the like.

Owner:SOUTH CHINA UNIV OF TECH

Latent single-component LCD (liquid crystal display) packaging adhesive

InactiveCN103254863AFix incompatibilitiesImprove latencyMacromolecular adhesive additivesEpoxy resin adhesivesEpoxyLatent image

The invention discloses a latent single-component LCD (liquid crystal display) packaging adhesive which comprises the following raw materials in percentage by mass: 51-70% of epoxy resin E-44, 8-15% of epoxy resin modifier, 10-15% of latent liquid curing agent, 1-5% of silane coupling agent, 0.5-5% of solvent, 0.1-0.5% of defoaming agent, 0.1-0.5% of leveling agent, 0.1-0.5% of wetting dispersant, 10-15% of calcium carbonate and 0.1-2% of titanium white. The preparation method comprises the following steps: uniformly stirring epoxy resin E-44, epoxy resin modifier, curing agent, silane coupling agent and solvent; and adding the remaining raw materials, uniformly stirring, and standing at normal temperature to remove bubble. The LCD packaging adhesive can be cured at 120-150 DEG C to perform LCD binding, and has the characteristics of no yellowing, high binding strength, favorable light transmittance, low curing shrinkage rate, long storage life and the like.

Owner:SOUTH CHINA UNIV OF TECH

Reactive flame retardant, preparation method and application thereof

InactiveCN109897339AImprove combustion effectImprove mechanical propertiesGroup 5/15 element organic compoundsEpoxyHeat resistance

The invention provides a reactive flame retardant, a preparation method and application thereof. The copper clad laminates prepared from the reactive flame retardant have good flame retardance, and good heat resistance, water resistance, mechanical and electrical properties. Being used for epoxy resin curing agents, the reactive flame retardant not only can replace conventional curing agents, butalso lower the curing temperature of epoxy resin and realize low temperature curing. The reactive flame retardant provided by the invention has the advantages of low preparation cost, abundant raw material sources and good performance, and has wide application prospects.

Owner:GUANGDONG GUANGSHAN NEW MATERIALS CO LTD

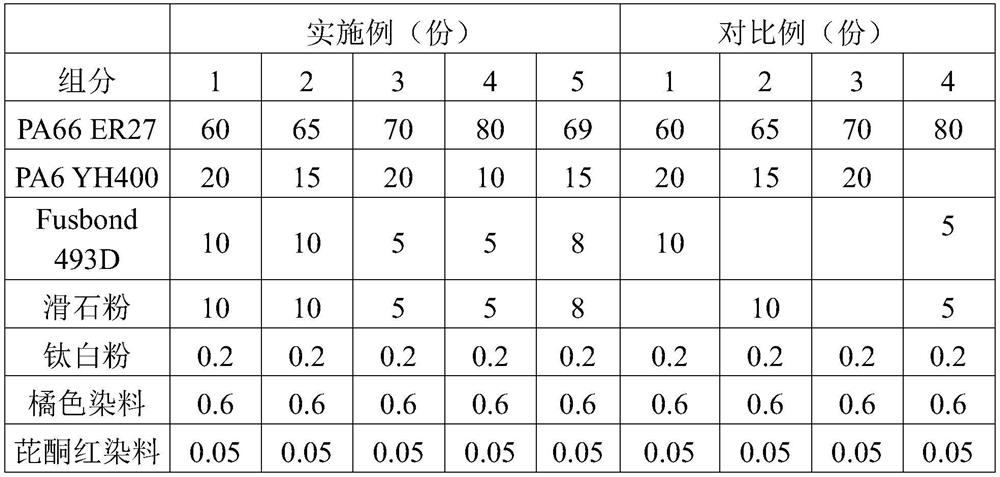

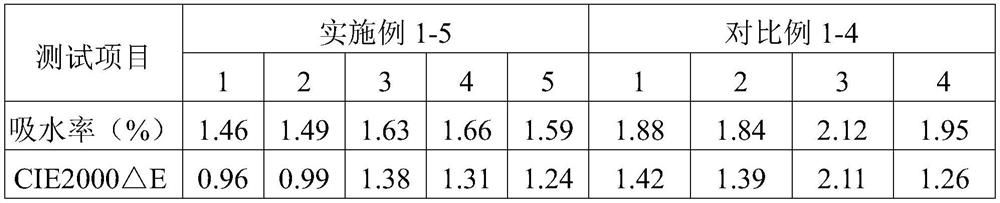

Preparation method of orange PA66 with stable color

PendingCN114181525AImprove saturated water absorptionLow saturated water absorptionMaleic anhydridePolyamide

The invention discloses a preparation method of orange PA66 with stable color. The orange PA66 is prepared from the following raw materials in parts by weight: 60-80 parts of polyamide PA66; 10 to 20 parts of polyamide PA6; 5 to 10 parts of talcum powder; 5 to 10 parts of maleic anhydride ethylene copolymer; 0.2 part of titanium dioxide; 0.6 part of orange dye; and 0.05 part of pyrene red dye. According to the invention, the color stability of orange nylon is greatly improved, and the color fixing property is greatly improved.

Owner:柏力开米复合塑料(昆山)有限公司

Synergistic Silicon Modified Phenolic Resin Adhesive and Preparation of Reconstituted Wood

ActiveCN111171770BRich sourcesSimple preparation processNon-macromolecular adhesive additivesWood compressionPolymer scienceResin adhesive

The invention relates to a silicon-modified phenolic resin adhesive and the preparation of recombined wood by using the adhesive. Silicon-modified phenolic resin is modified with methyl silicic acid. In order to improve the bonding effect of silicon-modified phenolic resin, a controllable adhesive introduction agent is added, and the controllable introduction of adhesive technology is used to greatly improve the silicon-modified phenolic resin. Modified phenolic resin prepared the bond strength and water repellency of recombined wood, and reduced the saturated water absorption of recombined wood.

Owner:QINGDAO UNIV OF SCI & TECH

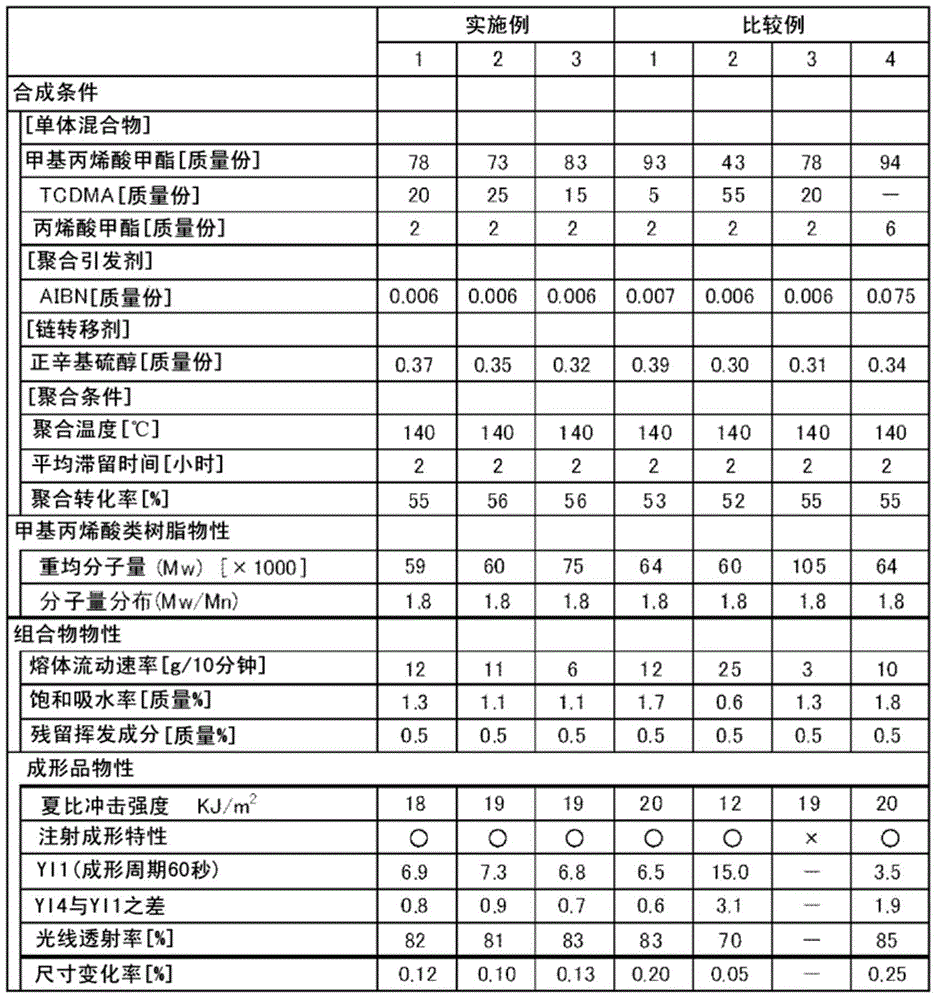

Methacrylic resin composition

Owner:KURARAY CO LTD

A kind of solar backboard and preparation method thereof

ActiveCN103895304BGood adhesionExcellent interlayer peeling forceSynthetic resin layered productsLaminationPolyolefinSurface layer

The invention discloses a solar energy back panel. The solar energy back panel comprises an upper surface layer, a core layer and a lower surface layer from top to bottom, wherein the mass ratio of the upper surface layer to the core layer to the lower surface layer is (10-20):(60-80):(10-20), the upper surface layer is a polyethylene resin composition layer, the lower surface layer is a polypropylene resin composition layer, and the core layer is a polyolefin resin composition layer. The new solar energy back panel is developed, and experiments prove that the solar energy back panel has good adhesion and interlayer stripping properties, ageing resistance, high-temperature and damp-heat aging resistance, low saturated water absorptivity, low low-temperature impact resistance, low water vapor permeability and excellent electrical insulating property, and can completely meet the requirement of the back panel of a solar cell module.

Owner:SUZHOU DUCHAMPS ADVANCED MATERIALS CO LTD

A kind of resin composition for solar backboard base material

ActiveCN103897266BImprove low temperature resistanceGood moisture and heat aging resistanceSemiconductor devicesWater vapor permeabilityBoPET

The invention discloses a resin composition for a base material of a solar backboard. The resin composition comprises the following components in parts by weight: 100 parts of component A and 20-100 parts of component B, wherein the component A is homo-polypropylene, segmented co-polypropylene or the mixture of homo-polypropylene and segmented co-polypropylene; the DSC (differential scanning calorimetry) melting point of the component A is 160-165 DEG C, and the melt flow rate is 1-2g / 10 minutes; the component B is homo-polyethylene, co-polyethylene or the mixture of homo-polyethylene and co-polyethylene; the DSC (differential scanning calorimetry) melting point of the component B is 120-135 DEG C, the melt flow rate is 1-2g / 10 minutes, and the density is 0.941-0.959 g / cm<3>. The base material of the solar backboard prepared from the novel resin composition developed by the invention has excellent low-temperature resistance, damp-heat aging resistance and electrical insulating performance and low saturated water absorption rate and water vapor permeability, and can be used for replacing an existing BOPET (biaxially oriented polyester film).

Owner:SUZHOU DUCHAMPS ADVANCED MATERIALS CO LTD

Resin composition for solar backsheet base material and preparation method

ActiveCN103897265BImprove low temperature impact resistanceAging resistantSemiconductor devicesPolymer sciencePolypropylene

Owner:SUZHOU DUCHAMPS ADVANCED MATERIALS CO LTD

Solar-powered back plate and manufacturing method thereof

ActiveCN103050563BHigh temperature resistanceImproved environmental stress cracking resistanceFinal product manufacturePhotovoltaic energy generationSurface layerAging resistance

The invention discloses a solar-powered back plate. The solar-powered back plate comprises an inner surface layer, a core layer and an outer surface layer in the mass ratio of (10-20):(20-40):(40-60) from inside to outside, wherein the inner surface layer is made from vinyl resin, a filler and an additive; the outer surface layer is made from polyamide resin, a filler and an additive; and the core layer is made from a modified polyethylene resin composition. The invention further develops a novel polyethylene resin composition, which comprises 100 parts of crosslinked polyethylene resin, 0-50 parts of grafted polyethylene, 0.1-0.5 parts of catalyst, 0-100 parts of filler and 0-2.5 parts of additive. The novel solar-powered back plate developed by the invention is prepared through a coextrusion process; and a prepared final product has the advantages of superior adhesion, high interlaminar peeling strength, aging resistance, particular damp-heat aging resistance, low saturated water absorptivity, low water vapor transmittance and superior electric insulating property, simple preparation process, low cost and suitability for industrial production.

Owner:SUZHOU DUCHAMPS ADVANCED MATERIALS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com