Preparation method of orange PA66 with stable color

A kind of PA66, color stabilization technology, applied in the field of orange PA66 preparation, can solve the problems of quality control disturbance, limited application, customer complaints, etc., to solve the effect of poor color stability, reduce sports activity, and reduce density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

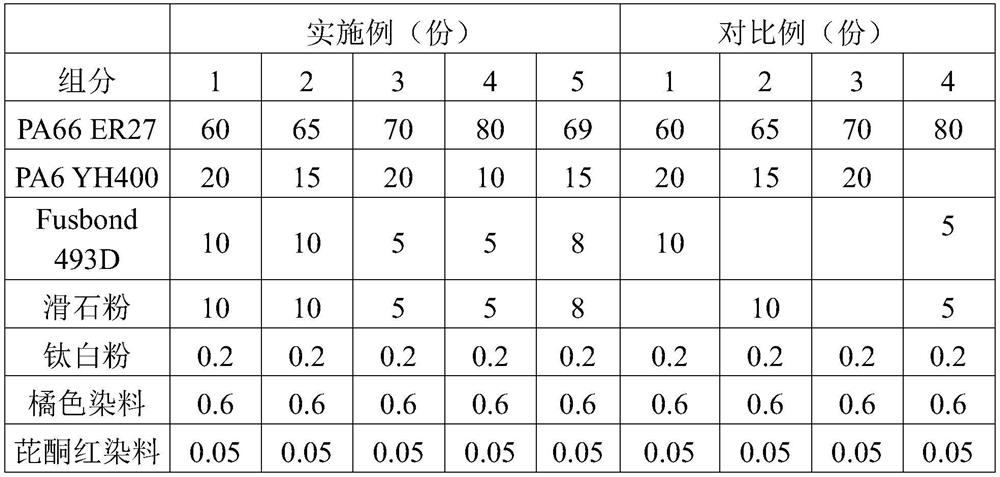

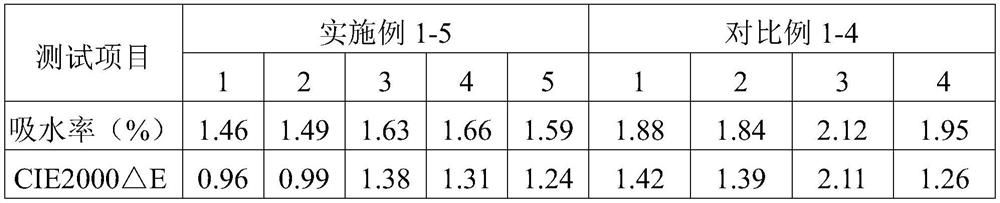

[0019] The present embodiment is the preparation method of the orange color PA66 of stable color, and it is made by the raw material of following weight part:

[0020] Polyamide PA66 ER27, 60-80 parts;

[0021] Polyamide PA6YH400, 10-20 parts

[0022] Talc powder HTP05L, 5-10 parts;

[0023] Maleic anhydride ethylene copolymer Fusband 493D, 5-10 parts;

[0024] Titanium dioxide RTC-30, 0.2 parts;

[0025] Orange dye Macrolex 3G Orange, 0.6 parts

[0026] Perenone red dye Macrolex EG Red, 0.05 parts.

[0027] The preparation method of the orange PA66 with stable color in this example includes: mixing the above components evenly according to the set ratio, and then extruding them by extrusion process, wherein the extrusion temperature is 240-280°C, and the screw extrusion speed is 300~500rpm.

[0028] In this example, when using the color-stable orange PA66 preparation method to prepare the product, the equipment used includes Coperion STS 50 twin-screw extruder, Brabender...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com