Modified polypropylene composition for solar cell back panel and preparation method thereof

A technology of polypropylene composition and solar cell, which is applied in the direction of circuits, photovoltaic power generation, electrical components, etc., and can solve problems such as difficulty in meeting the performance requirements of solar backsheets, poor electrical insulation, poor adhesion, and poor moisture and heat aging resistance , to achieve excellent interlayer peeling force, excellent low temperature impact resistance and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

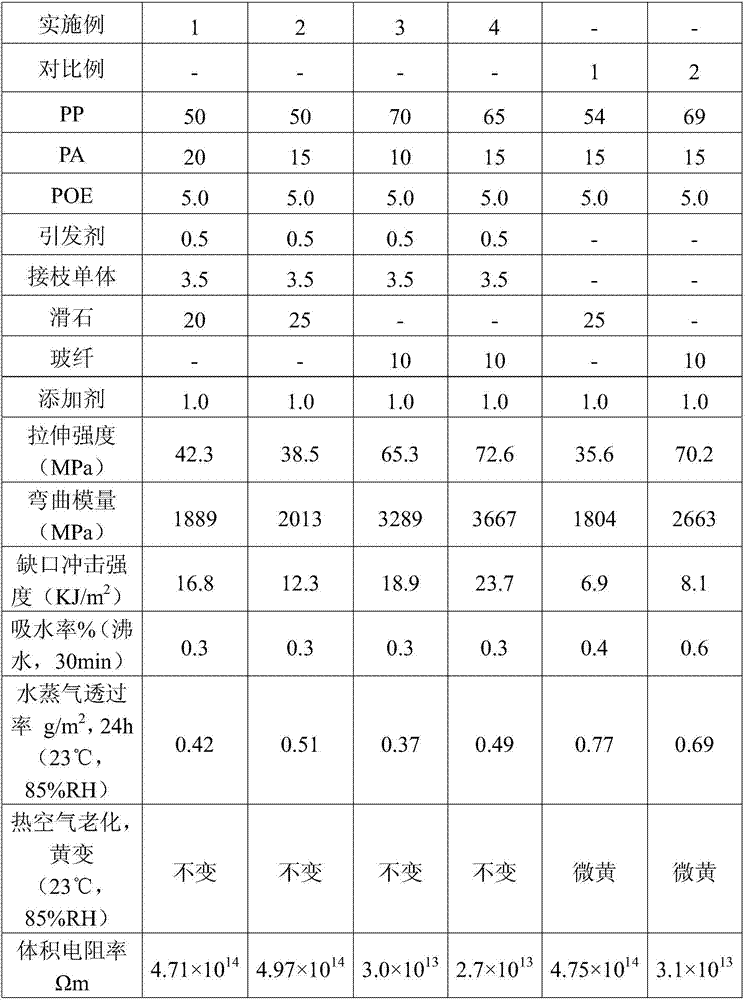

Examples

Embodiment 1

[0053]This example illustrates the preparation method of the modified polypropylene composition of the present invention, and the weight of all substances is 100 parts by weight.

[0054] First, 50 parts of polypropylene (PPH, L5E89, MI=3.0g / 10min, 2.16kg, 230℃), 20 parts of polyamide (PA6, 1013B, MI=15g / 10min, 2.16kg, 230℃), 5 parts Polyolefin elastomer (POE, 8150, MI=0.5g / 10min, 2.16kg, 190°C), 0.5 parts of initiator (double 2,5: TAIC=3:1), 3.5 parts of grafted monomer (maleic anhydride , MAH) and 1 part of additive (0.25 part of antioxidant 1010, 0.25 part of antioxidant 168, 0.25 part of UV-327, 0.25 part and light stabilizer 622) were added to the high-speed mixer and mixed for 3 to 5 minutes;

[0055] Next, add the above mixture into the lower hopper of the extruder, and at the same time, 20 parts of reinforcing filler talc (808A, 2500 mesh) are added to the screw extruder through the screw side feed port and jointly melted and extruded. It is set to increase from 170°C...

Embodiment 2

[0058] First, 50 parts of polypropylene (PPH, L5E89, MI=3.0g / 10min, 2.16kg, 230℃), 15 parts of polyamide (PA6, 1013B, MI=15g / 10min, 2.16kg, 230℃), 5 parts Polyolefin elastomer (POE, 8150, MI=0.5g / 10min, 2.16kg, 190°C), 0.5 parts of initiator (double 2,5: TAIC=3:1), 3.5 parts of grafted monomer (maleic anhydride , MAH) and 1 part of additive (0.25 part of antioxidant 1010, 0.25 part of antioxidant 168, 0.25 part of UV-327, 0.25 part and light stabilizer 622) were added to the high-speed mixer and mixed for 3 to 5 minutes;

[0059] Next, the above mixture was added to the lower hopper of the extruder, and 25 parts of reinforcing filler talc (808A, 2500 mesh) were added to the screw extruder through the screw side feeding port at the same time and melted and extruded together. It is set to increase from 170°C to 260°C;

[0060] Finally, through water cooling, air drying, granulator granulation and other processes, a modified polypropylene composition for solar battery back sheet...

Embodiment 3

[0062] First, 70 parts of polypropylene (PPH, L5E89, MI=3.0g / 10min, 2.16kg, 230℃), 10 parts of polyamide (PA6, 1013B, MI=15g / 10min, 2.16kg, 230℃), 5 parts Polyolefin elastomer (POE, 8150, MI=0.5g / 10min, 2.16kg, 190°C), 0.5 parts of initiator (double 2,5: TAIC=3:1), 3.5 parts of grafted monomer (maleic anhydride , MAH) and 1 part of additive (0.25 part of antioxidant 1010, 0.25 part of antioxidant 168, 0.25 part of UV-327, 0.25 part and light stabilizer 622) were added to the high-speed mixer and mixed for 3 to 5 minutes;

[0063] Next, add the above mixture into the lower hopper of the extruder, and at the same time, add 10 parts of reinforced filler glass fiber (Jianshi, 508A, 3.0mm) into the screw extruder through the screw side feeding port and jointly melt and extrude, twin-screw The temperature of each zone is set to increase from 170°C to 260°C;

[0064] Finally, through water cooling, air drying, granulator granulation and other processes, a modified polypropylene comp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com