Low temperature resistant and weather-proof ASA (acrylonitrile styrene acrylate copolymer) material and preparation method thereof

A technology of low temperature resistance and weather resistance, which is applied in the field of low temperature and weather resistance ASA materials and its preparation, can solve the problems of xenon lamp aging, low temperature impact resistance and weather resistance, and achieve low cost, improved low temperature impact resistance and high efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

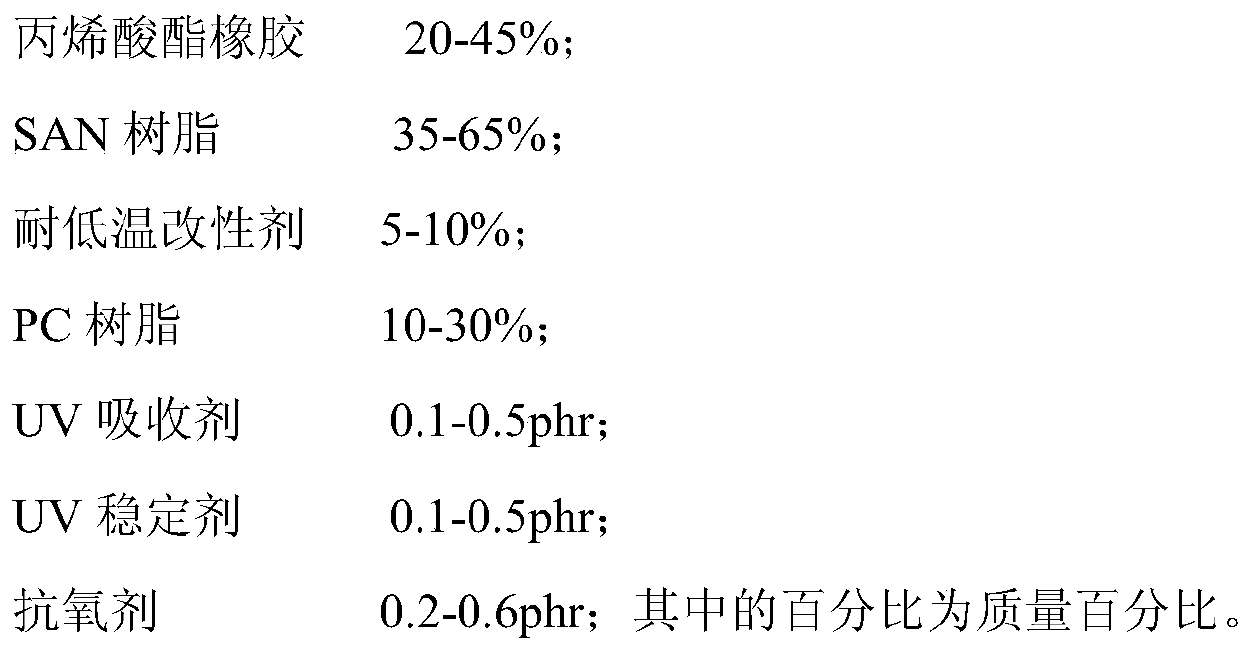

[0023] formula:

[0024]

[0025] The preparation process includes:

[0026] Acrylate rubber, SAN resin and PC resin are mixed in proportion and sent to the twin-screw, low temperature modifier, UV absorber, UV stabilizer and antioxidant are mixed and then added by weight loss weighing scale, and processed at 220°C Granulate. The feeding accuracy is within 0.5%. The twin-screw diameter is 65 mm and the rotation speed is 800 RPM.

Embodiment 2

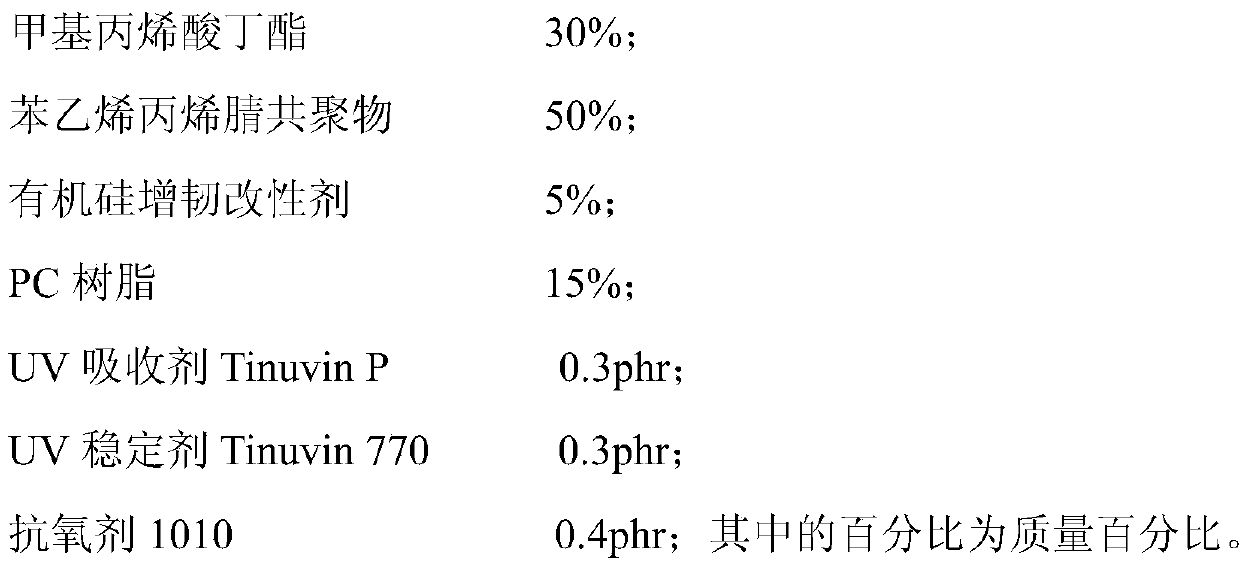

[0028] formula:

[0029]

[0030] The preparation process includes:

[0031] Acrylate rubber, SAN resin and PC resin are mixed in proportion and sent to the twin-screw, low temperature modifier, UV absorber, UV stabilizer and antioxidant are mixed and then added by weight loss weighing scale, processed at 230°C Granulate. The feeding accuracy is within 0.5%. The diameter of the twin-screw is 75 mm, and the rotation speed is 700 RPM.

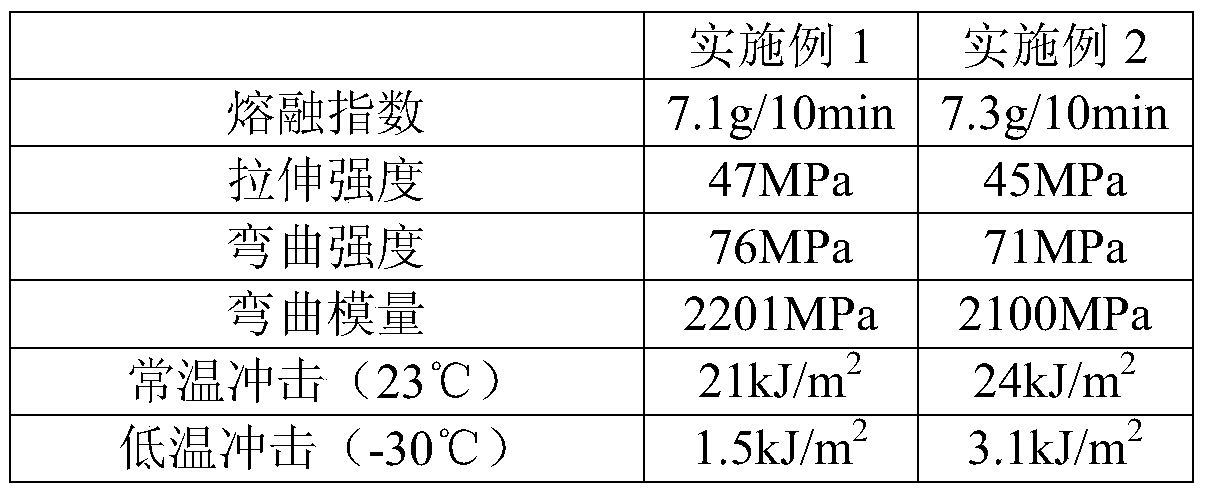

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com