Methacrylic resin composition

A technology of methacrylate and methacrylic acid, which is applied in the field of methacrylic resin composition, can solve the problems of difficulty in obtaining high-precision optical components, low productivity of molded products, and dimensional changes, and achieves good appearance and saturated water absorption. Low, small size change effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

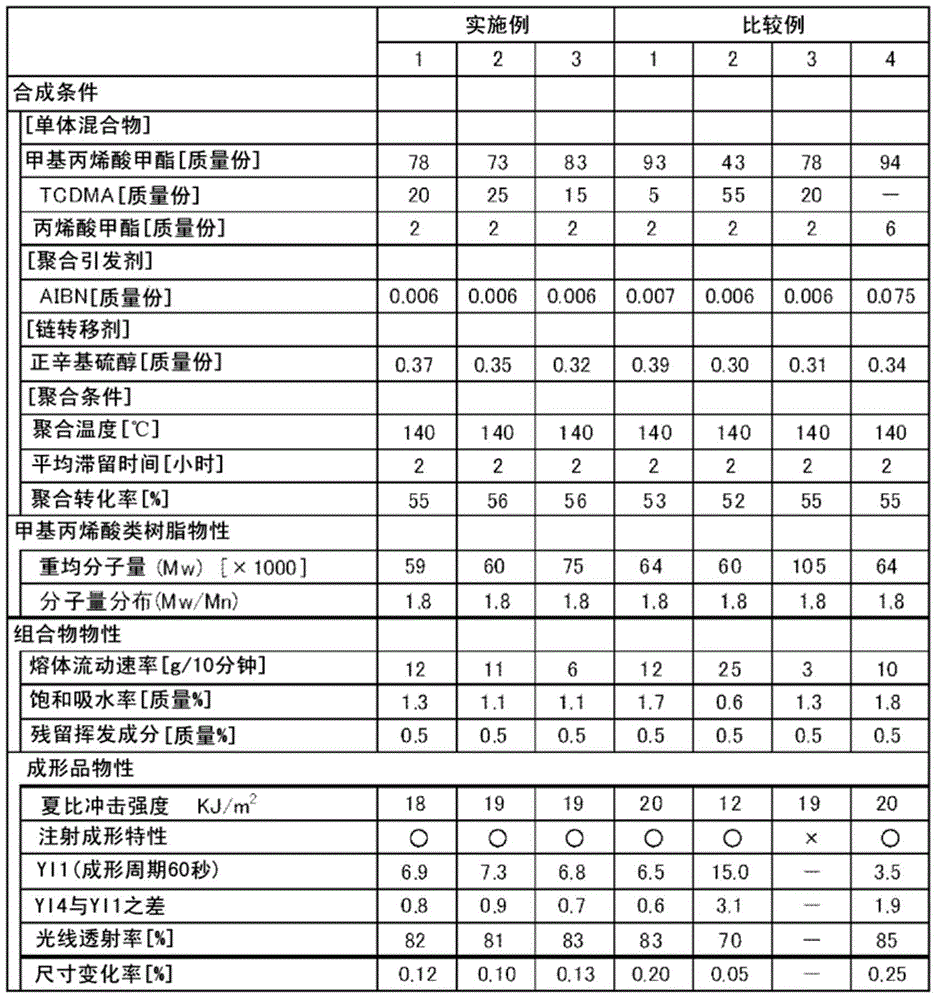

[0125] 78 parts by mass of purified methyl methacrylate, 20 parts by mass of dicyclopentyl methacrylate, and 2 parts by mass of methyl acrylate were added to an autoclave equipped with a stirrer and a collection pipe to prepare a monomer mixture. The yellowness index of the monomer mixture was 0.9. Add 0.006 parts by mass of a polymerization initiator (2,2'-azobis(2-methylpropionitrile (AIBN), dehydrogenation capacity: 1%, 1-hour half-life temperature: 83°C) to the monomer mixture and chain transfer Agent (n-octyl mercaptan) 0.37 parts by mass was dissolved to obtain a raw material liquid. Oxygen in the production apparatus was driven out with nitrogen.

[0126] A certain amount of the raw material liquid was discharged from the autoclave, and supplied to a continuous flow tank reactor controlled at a temperature of 140° C. at a constant flow rate so that the average residence time was 120 minutes, and bulk polymerization was performed. The reaction solution was fractionated ...

Embodiment 2

[0134] In addition to changing the amount of methyl methacrylate to 73 parts by mass, changing the amount of dicyclopentyl methacrylate to 25 parts by mass and changing the amount of n-octyl mercaptan to 0.35 parts by mass, by implementing The same method as Example 1 was used to obtain the granular methacrylic resin composition of the present invention. The polymer physical properties of the obtained granular methacrylic resin composition were measured by the same method as in Example 1. In addition, molded articles (flat plate L and flat plate S) were produced in the same manner as in Example 1, and physical properties were evaluated. These results are shown in Table 1.

Embodiment 3

[0136] In addition to changing the amount of methyl methacrylate to 83 parts by mass, changing the amount of dicyclopentyl methacrylate to 15 parts by mass and changing the amount of n-octyl mercaptan to 0.32 parts by mass, by implementing The same method as Example 1 was used to obtain the granular methacrylic resin composition of the present invention. The polymer physical properties of the obtained granular methacrylic resin composition were measured by the same method as in Example 1. In addition, molded articles (flat plate L and flat plate S) were produced in the same manner as in Example 1, and physical properties were evaluated. These results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com