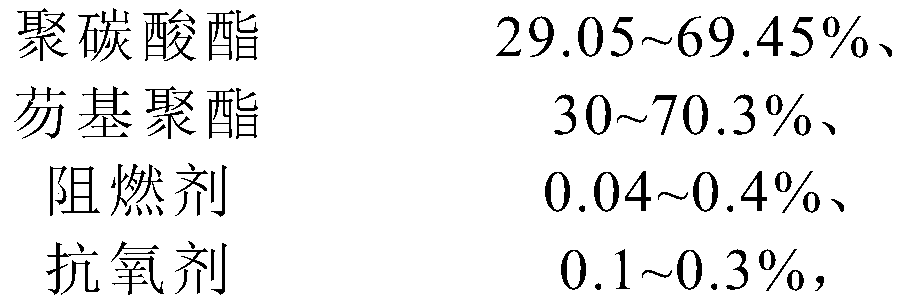

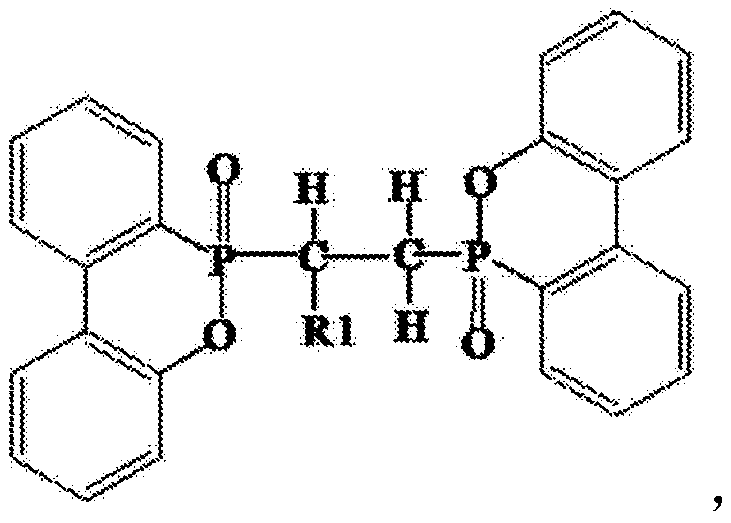

Low-temperature-impact-resistant high-transmittance flame-retardant polycarbonate composite material and preparation method thereof

A flame-retardant polycarbonate and composite material technology, applied in the field of polymer materials, can solve the problems of low birefringence, decreased transparency, high birefringence of polycarbonate, etc., and achieve small birefringence and high glass transition temperature , the effect of high refractive index

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0068] The preparation of modified montmorillonite nanomaterial in the present embodiment is as follows:

[0069] (1) Mix sodium-montmorillonite (Na-MMT) and deionized water according to the ratio of solid-liquid ratio 1g / 100ml, and ultrasonically vibrate at room temperature for 1 hour to destroy the layered structure of sodium-montmorillonite, so that It is uniformly dispersed in deionized water to form a premix, then mix the premix and deionized water at a volume ratio of 1:5, heat to 80°C and maintain this temperature, stir with a stirrer for 40min, and form montmorillonite Suspension: mix triphenylbutylphosphonium bromide (BuTPP-Br) and deionized water according to the ratio of solid to liquid ratio 2g / 100ml, after completely dissolving, a BuTPP-Br solution is formed;

[0070] (2) According to the volume ratio of BuTPP-Br solution and montmorillonite suspension of 1:15, gradually add BuTPP-Br solution to the montmorillonite suspension, and then keep the temperature at 80°C...

Embodiment 2

[0073] The preparation of modified montmorillonite nanomaterial in the present embodiment is as follows:

[0074] (1) Mix sodium-montmorillonite (Na-MMT) and deionized water according to the ratio of solid-to-liquid ratio of 0.8g / 100ml, and ultrasonically vibrate at room temperature for 1.5 hours to destroy the layered structure of sodium-montmorillonite, Make it evenly dispersed in deionized water to form a premix, then mix the premix and deionized water at a ratio of 1:6 by volume, heat to 70°C and maintain this temperature, stir with a stirrer for 50min to form montmorillonite Soil suspension; triphenylbutylphosphonium bromide (BuTPP-Br) and deionized water are mixed according to the ratio of solid-to-liquid ratio 1.6g / 100ml, after completely dissolving, a BuTPP-Br solution is formed;

[0075] (2) According to the ratio of BuTPP-Br solution and montmorillonite suspension volume ratio of 1:17, gradually add BuTPP-Br solution to the montmorillonite suspension, and then keep t...

Embodiment 3

[0078] The preparation of modified montmorillonite nanomaterial in the present embodiment is as follows:

[0079] (1) Mix sodium-montmorillonite (Na-MMT) and deionized water according to the ratio of solid-to-liquid ratio of 1.2g / 100ml, and ultrasonically vibrate at room temperature for 0.5 hours to destroy the layered structure of sodium-montmorillonite, Make it evenly dispersed in deionized water to form a premix, then mix the premix and deionized water at a volume ratio of 1:4, heat to 90°C and maintain this temperature, stir with a stirrer for 30min to form montmorillonite Soil suspension; triphenylbutylphosphonium bromide (BuTPP-Br) and deionized water are mixed according to the ratio of solid-to-liquid ratio of 2.5g / 100ml, after completely dissolving, a BuTPP-Br solution is formed;

[0080] (2) According to the ratio of BuTPP-Br solution and montmorillonite suspension volume ratio of 1:13, gradually add BuTPP-Br solution to the montmorillonite suspension, and then keep t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Notch shock | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com