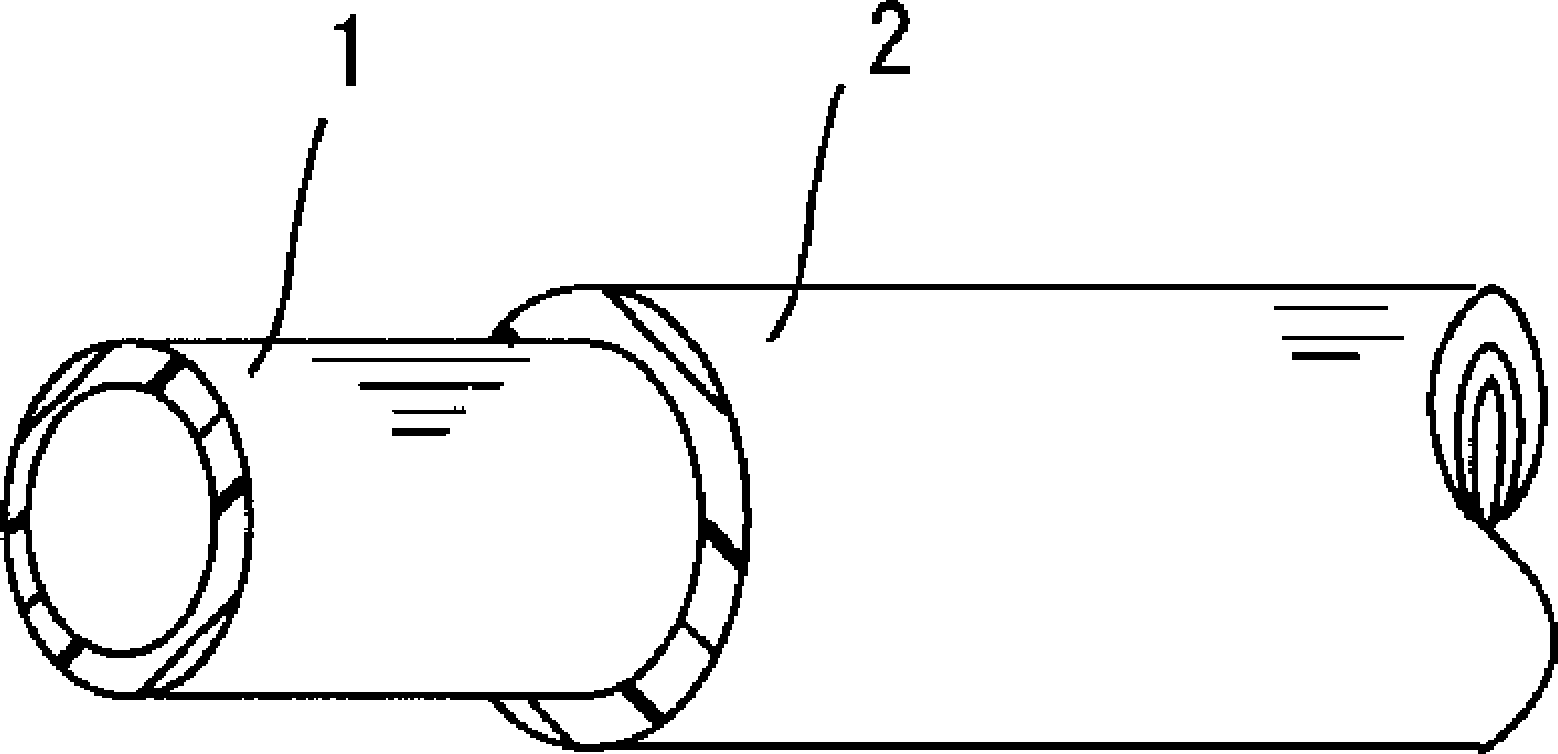

Fuel Hose

A hose and fuel technology, applied in the direction of hoses, applications, pipes, etc., can solve the problems of increasing the thickness of the fluororesin layer, expensive hoses, low permeability, etc., to achieve excellent heat resistance, low material cost, high-rise The effect of cohesion between

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~15、 comparative example 1~9

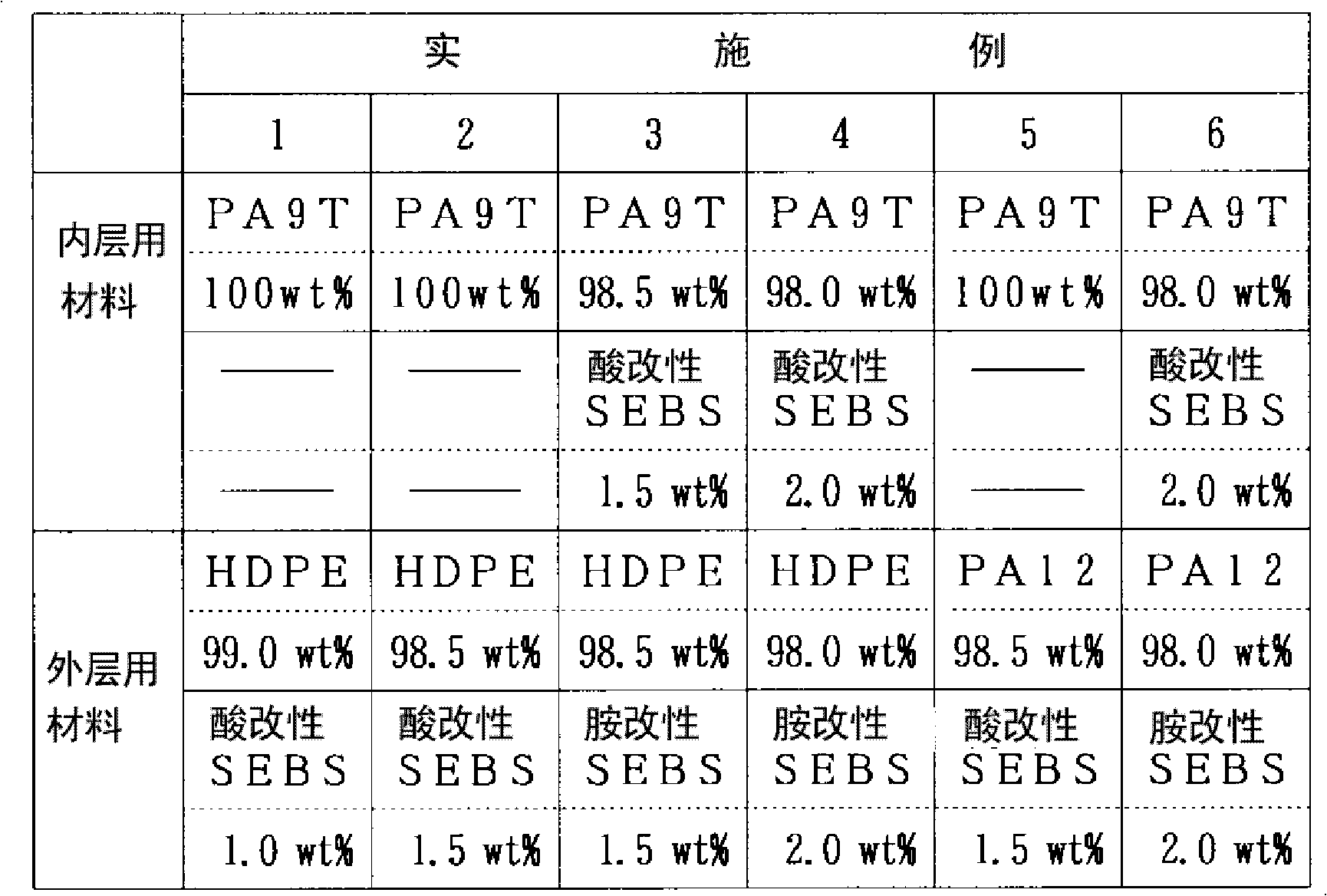

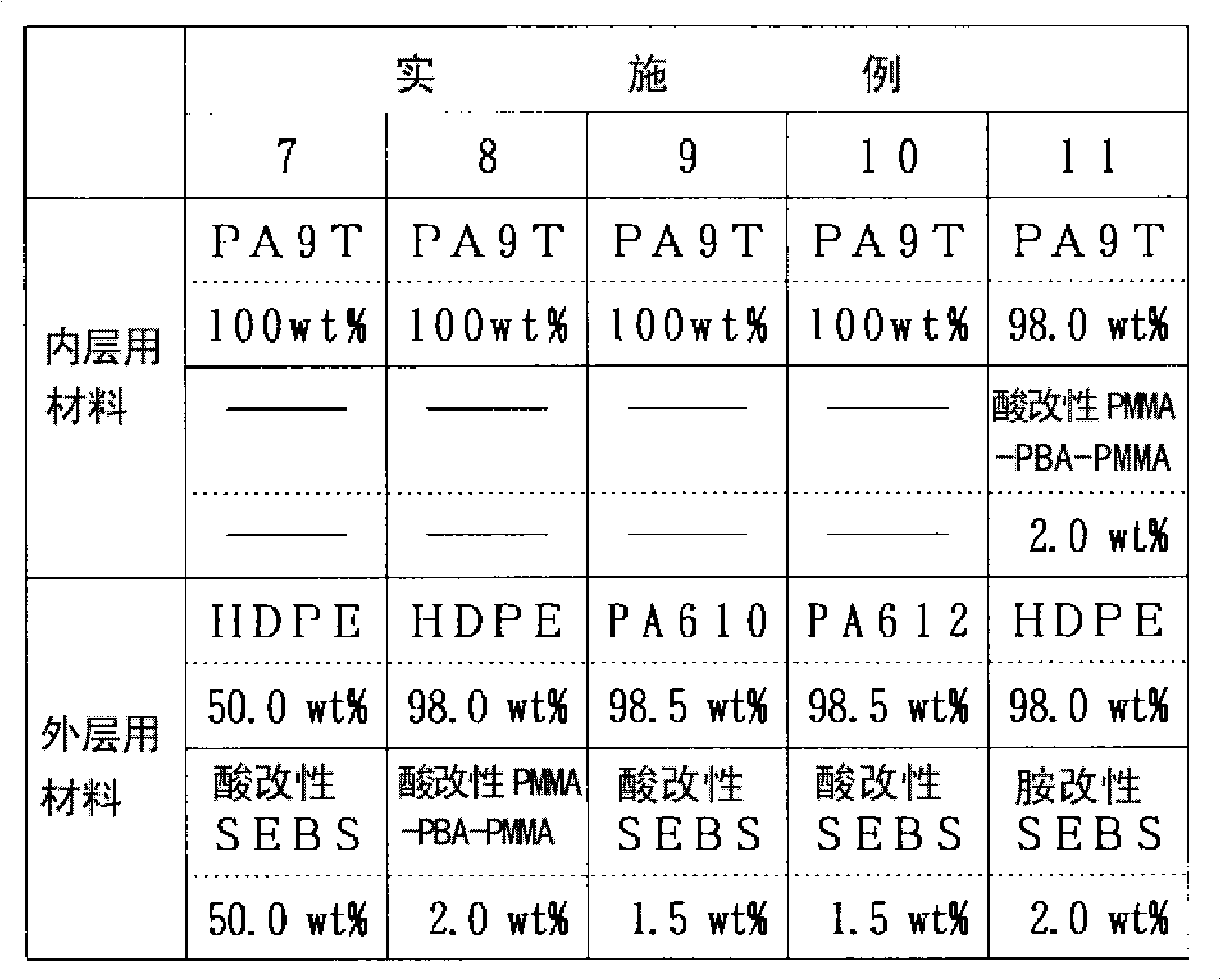

[0076] Prepare the materials for the innermost layer (only Examples 12 to 15), materials for the inner layer, and materials for the outer layer shown in Tables 1 to 5 below, and heat each of the above materials from each extruder filled with them. Melt extrusion (co-extrusion), confluence into one mold, and pass this into a shaping die to produce a smooth hose with an inner diameter of 6 mm. In addition, in Table 1 - Table 5, the layer formation material is not described, and it means that formation of the said layer was not performed. In addition, in the following Tables 1 to 5, the layer forming materials containing modified SEBS and acid-modified PMMA-PBA-PMMA together with polymers such as PA9T, HDPE, and PA12 are shown in the same table. Weight ratio (wt%) Use a twin-screw kneading extruder (TEX30α manufactured by Nippon Steel Works) for uniform kneading (the inner layer material is kneaded at 260-330°C, and the outer layer material is kneaded at 200-250°C ), and the cur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com