Fine-denier Modal fiber blended color yarn and its production method

A modal fiber and yarn spinning technology is applied in the field of spinning engineering in the production of the textile industry, which can solve the problems of low color yield, single color structure of the yarn, and poor color fastness, etc. Endless effects of color combinations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

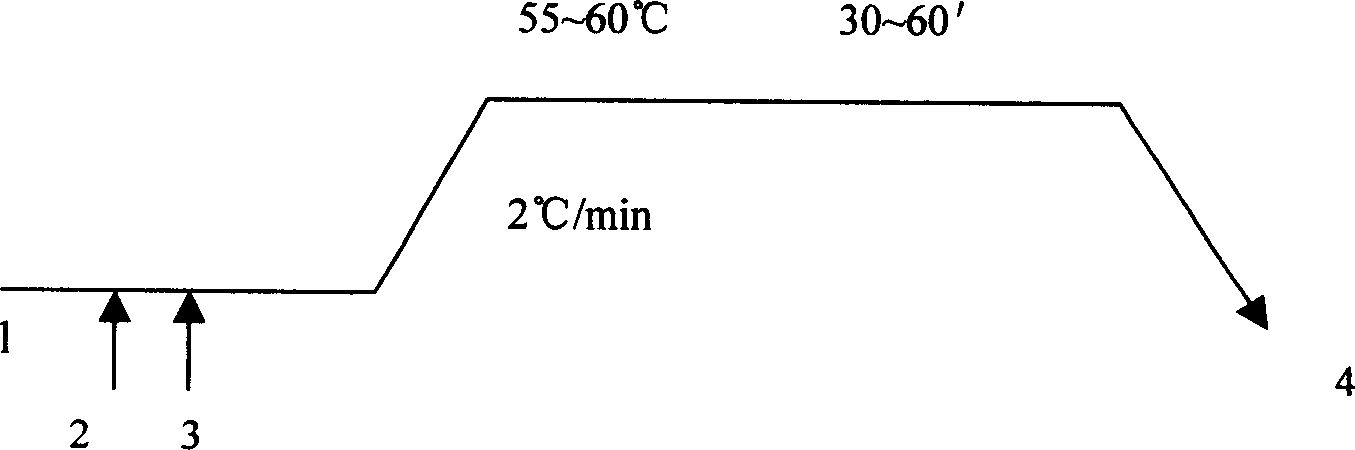

[0055] Select 160 kilograms of fine denier modal loose fibers, put them into a solution with a bath ratio of 1:8 at room temperature, and contain 1% chelating dispersant, 1% biological enzyme scouring agent, heat up to 55 ° C for 30 minutes, let go Foot water, clean with water overflow.

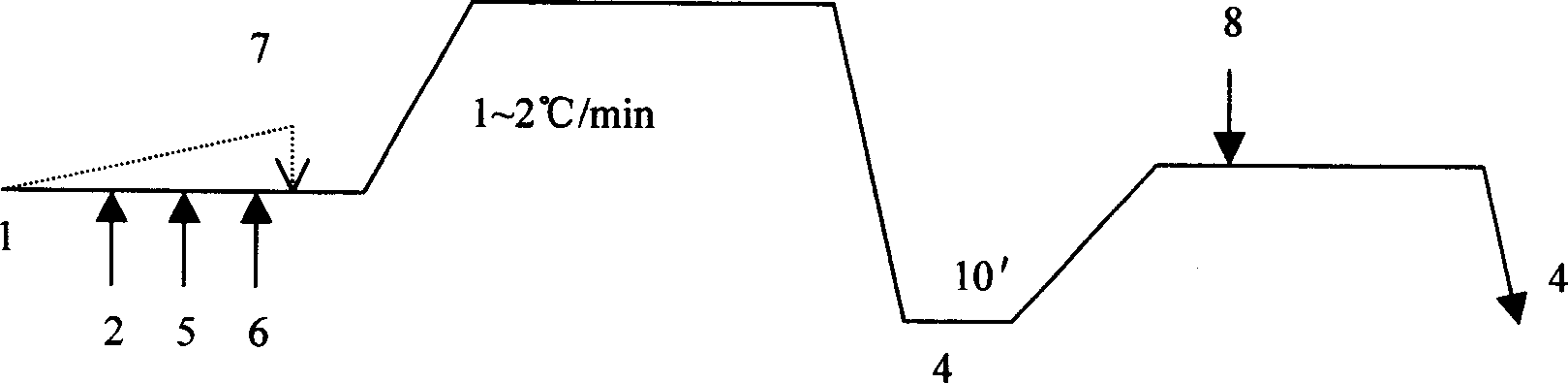

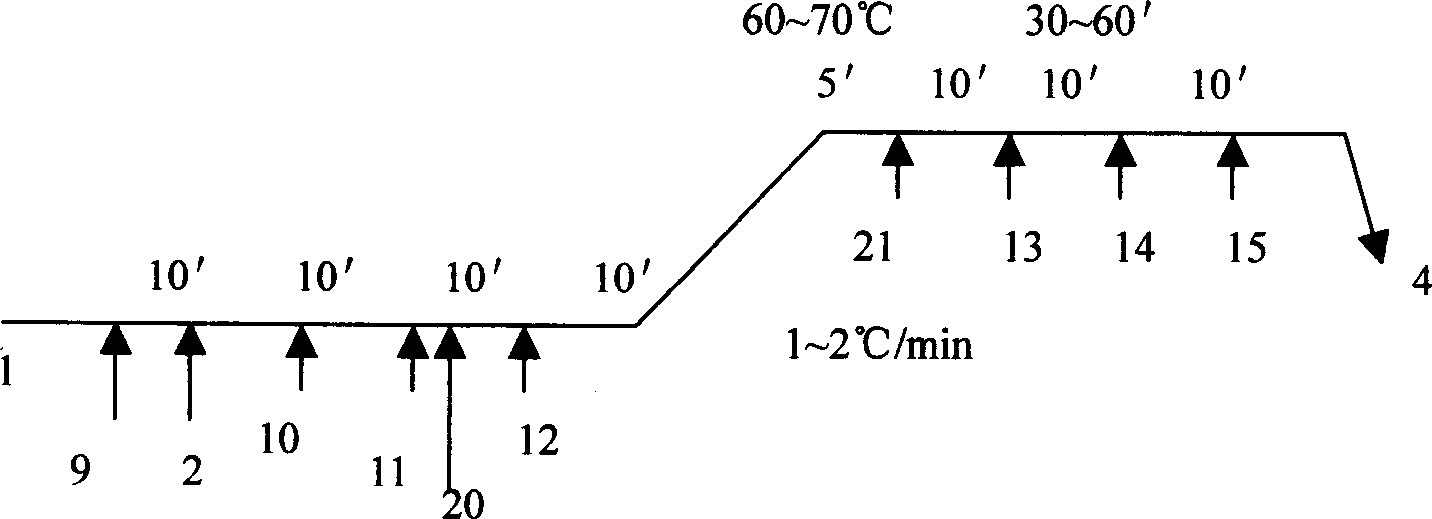

[0056] Using reactive dyes, according to different color requirements and dye ratios, pour the dye and 1 / 5 Yuan Ming powder into the dyeing vat chemical material for 20 minutes, and add 1% fiber protective agent and 2 / 5 Yuan Ming after 10 minutes of normal temperature operation Add the remaining 2 / 5 yuan Mingfen after continuing to operate for 10 minutes, then heat up to the temperature required for dyeing at 1°C / min, select the appropriate alkali addition rate curve according to the characteristics of different dyes, add baking soda and soda ash, a small Add soda first and run for 5 minutes, such as image 3 As shown, the rate of adding alkali should be slow first and then fast, and the alk...

Embodiment 2~3

[0058] The specific steps of spinning are as follows:

[0059] 1. After pre-opening fine denier modal fibers and other chemical fibers or cotton fibers, carry out dyeing treatment, including scouring or bleaching, dyeing, post-treatment and other steps.

[0060] 2. According to the color requirements of the product, match the proportion of fibers of different colors, and weigh various fibers according to the proportion.

[0061] 3. Lay and mix the weighed fibers of different types and colors according to regulations, and lay 1 to 3 layers for each color. If the batch is large, divide it into several small batches for mixing.

[0062] 4. After the raw materials are mixed, they are further mixed in the cleaning process and quantitatively rolled. The dry weight of the lap is 300-550 g / m; the length of the lap is 33-45 meters.

[0063] 5. Card the lap into strips on the carding machine (FA201B). Raw sliver weight is 12-22g / 5m; stripping speed is 45-65m / min.

[0064] 6. Perform...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| twist factor | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com