Polyester fabric with good color fixation and preparation method thereof

A technology of polyester cloth and color properties, which is applied in the field of polyester cloth and its preparation, can solve problems such as friction, washing, staining, hidden dangers of dyeing quality, and different sizes of fastness, so as to improve dimensional stability and coating The effect of good strength and uniformity improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

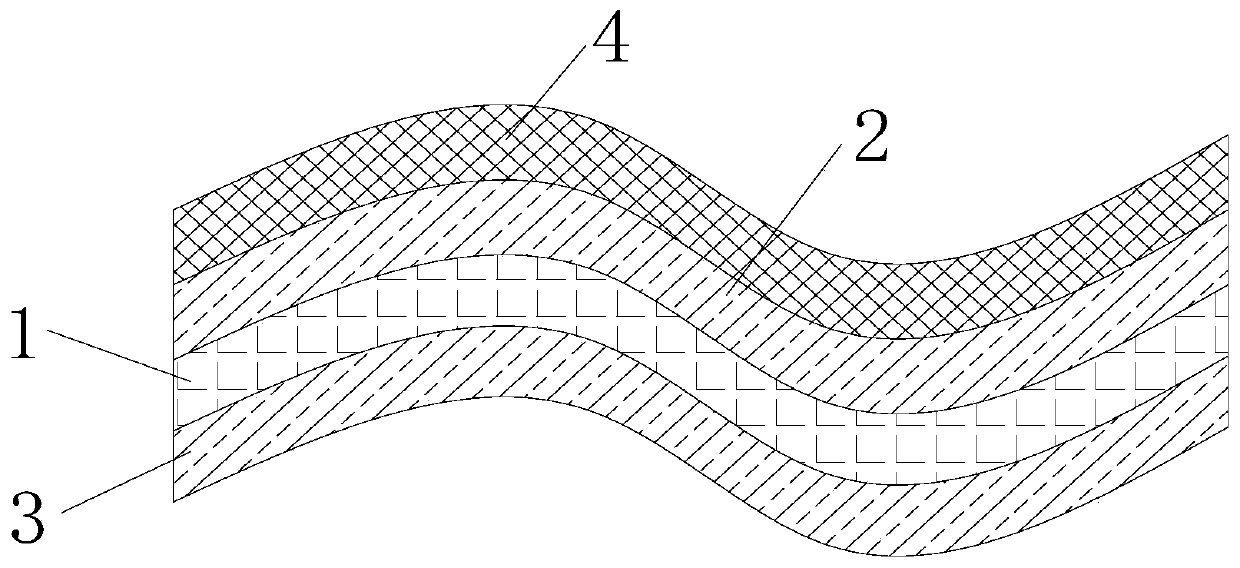

[0032] The embodiment of the present invention discloses polyester cloth with good color fixing property and its preparation method, such as Figure 1-2 As shown, including polyester fabric 1, first PU coating 2, second PU coating 3 and PVC calendering film 4, the two sides of polyester fabric 1 are respectively provided with first PU coating 2 and second PU coating 3, And the side of the first PU coating 2 away from the polyester fabric 1 is provided with a PVC calendered film 4;

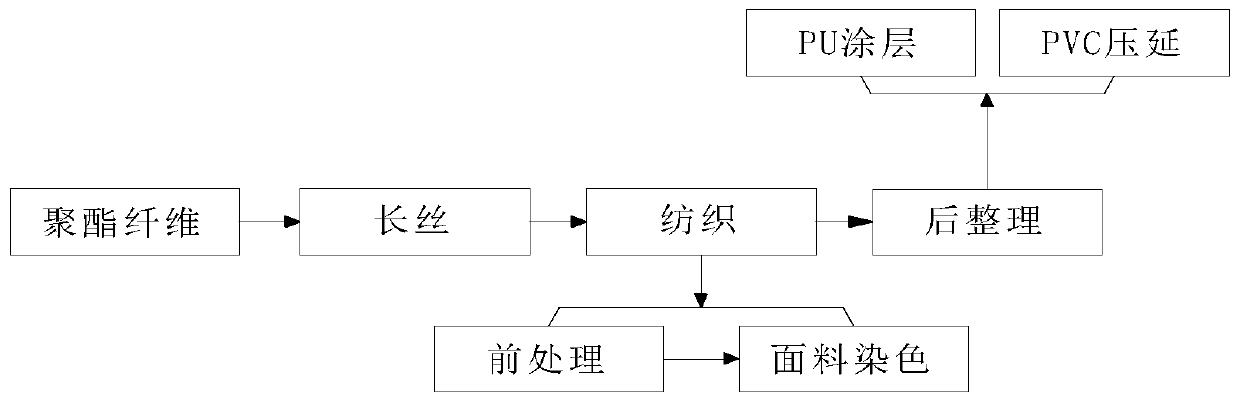

[0033] The preparation steps are: polyester fiber→filament→spinning→finishing;

[0034] Carry out pretreatment and fabric dyeing to polyester fabric 1 during weaving;

[0035] Fabric dyeing adopts high-temperature and high-pressure method. The steam pressure is greater than 1Pa in a closed container, and the temperature is 120-130°C. The process of dyeing polyester with disperse dyes is: dyeing at 60-90°C→dyeing at 130°C for 60min→washing or reduction cleaning;

[0036] When dyeing with high tem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com