Basalt fibre composite rib and basalt fibre composite inhaul cable

A basalt fiber and composite bar technology is applied in the field of fiber bars and cables made of fiber bars. , short-term and long-term mechanical properties and excellent chemical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

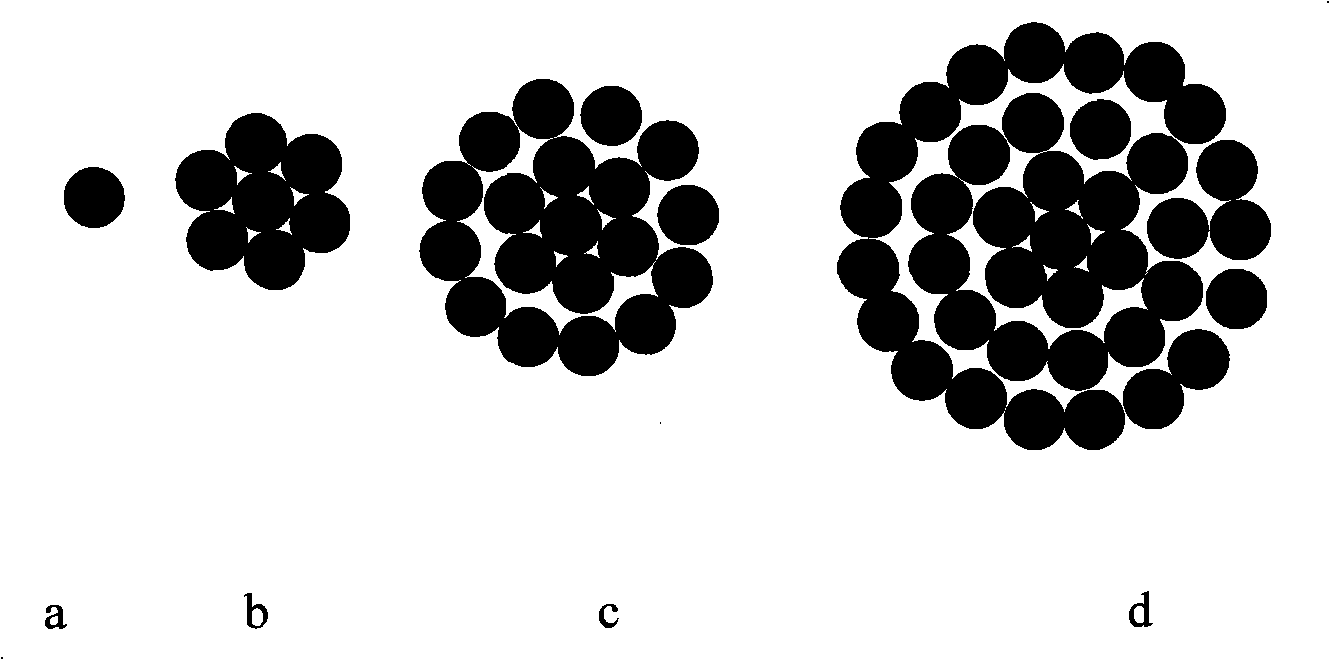

[0029] The design concept of the present invention, the composite mode of the fiber reinforcement (stranded wire) of the cable, the layout of the section of the cable, the forming process of the fiber reinforcement and the production process of the cable are described below.

[0030] 1. Design ideas

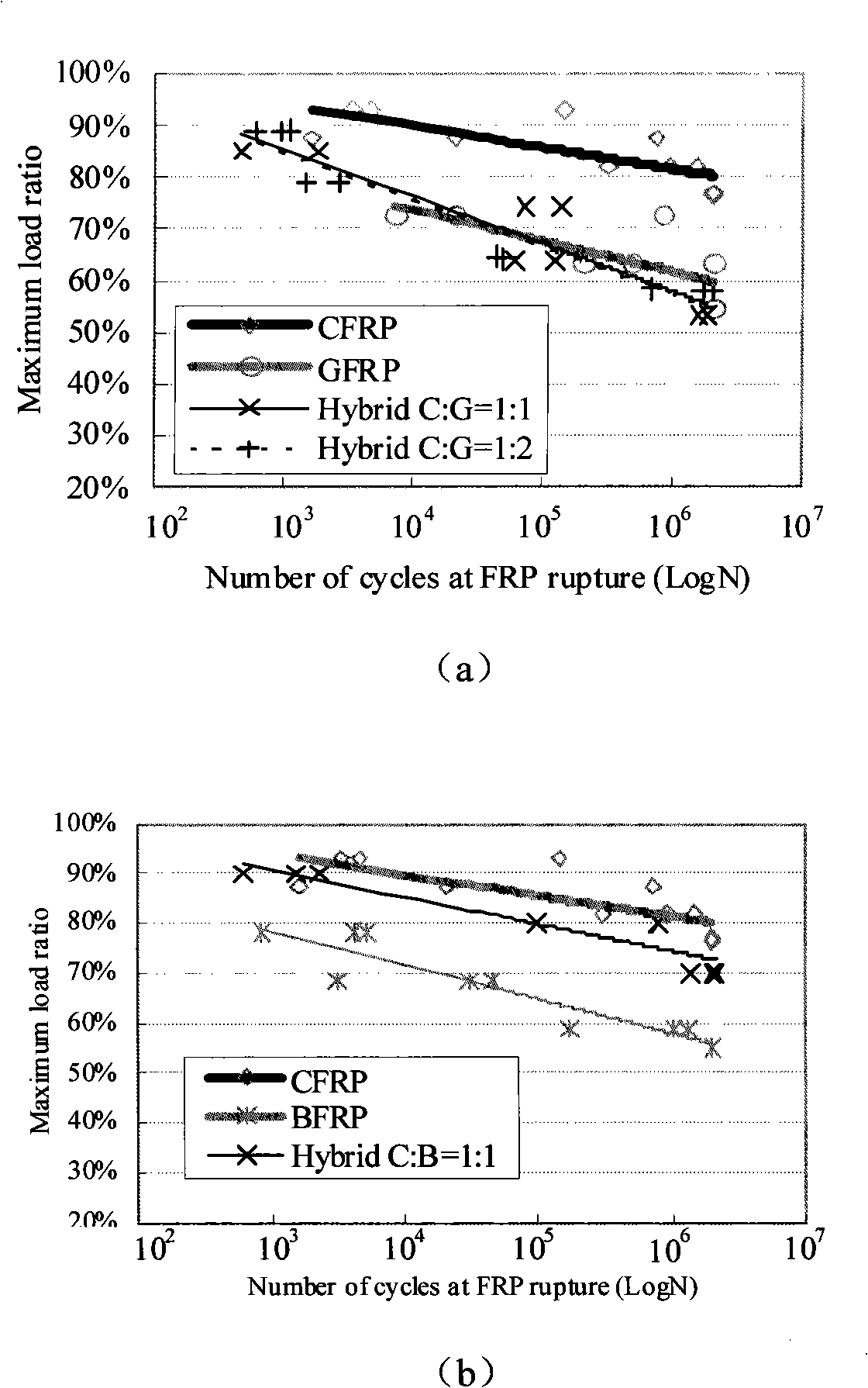

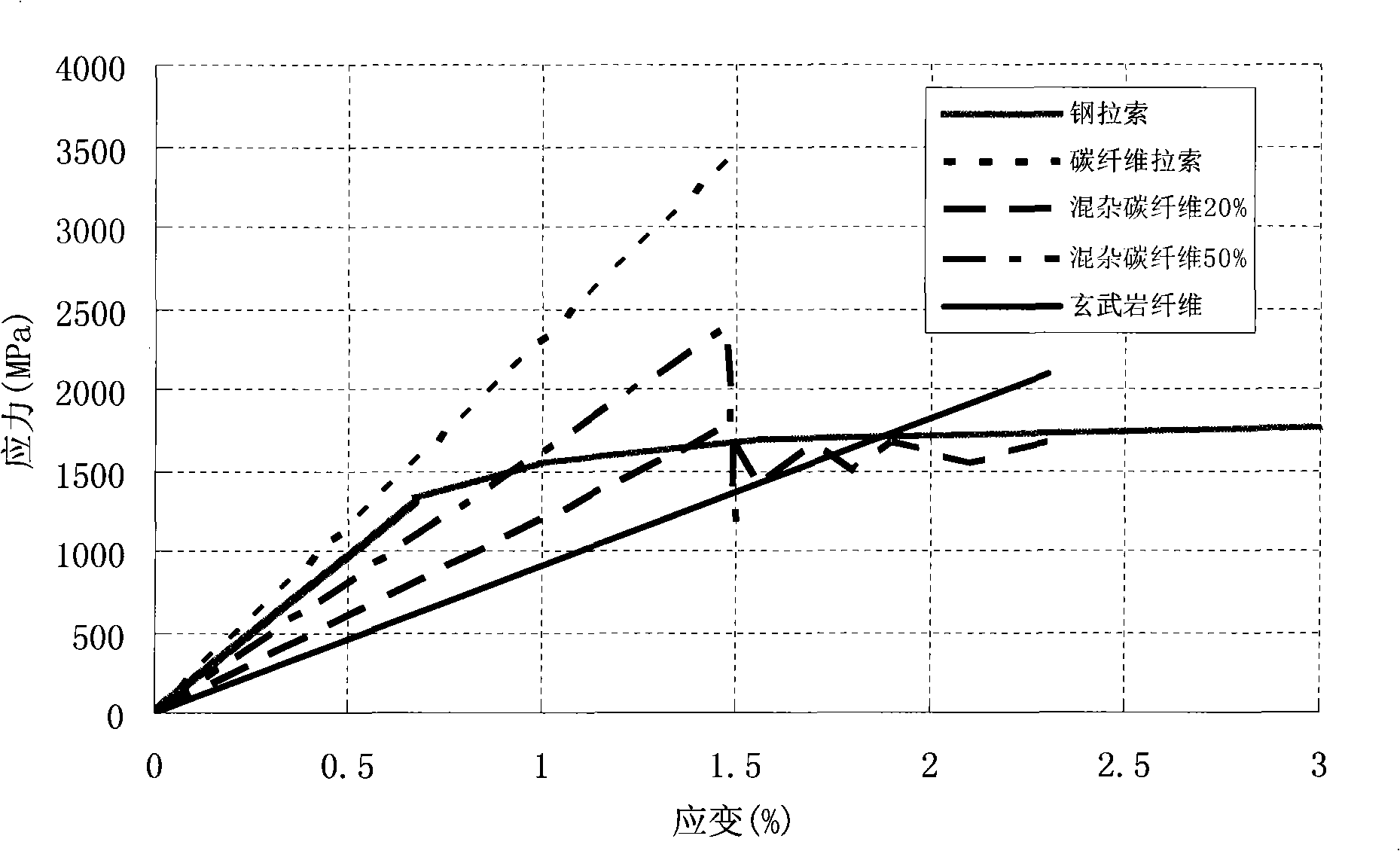

[0031] Aiming at many problems in the commonly used steel cables (steel strand cables or steel bundle cables): susceptible to various acid and alkali electric corrosion; low fatigue resistance; self-heavy, etc. And taking into account the practical problems of the carbon fiber cable currently being studied: expensive, brittle and low shear strength, poor aerodynamic stability, etc. The present invention uses basalt fiber with balanced performance in various aspects and outstanding economic performance as the main material of the cable to solve the limitation that the fiber material is expensive and cannot be used in large quantities. At the same time, part of the carbon fiber cab...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elastic modulus | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com