Repair tube for overhead transmission lines

A technology for overhead transmission lines and maintenance pipes, applied in overhead installation, cable installation, electrical components, etc., can solve problems such as uneven electric field of wires in the bushing, cumbersome operation, high insulation level, etc., to increase the reliability of power supply , easy to operate, enhance the effect of insulation level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

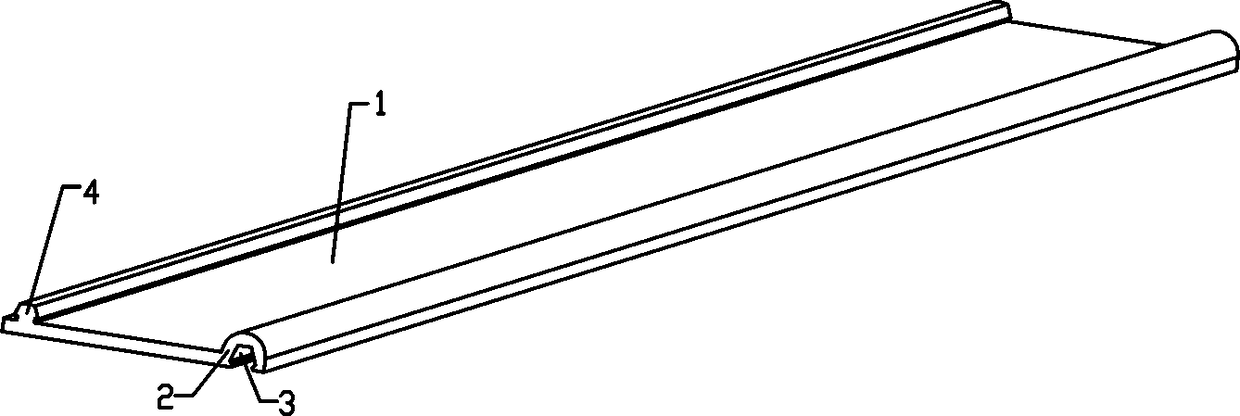

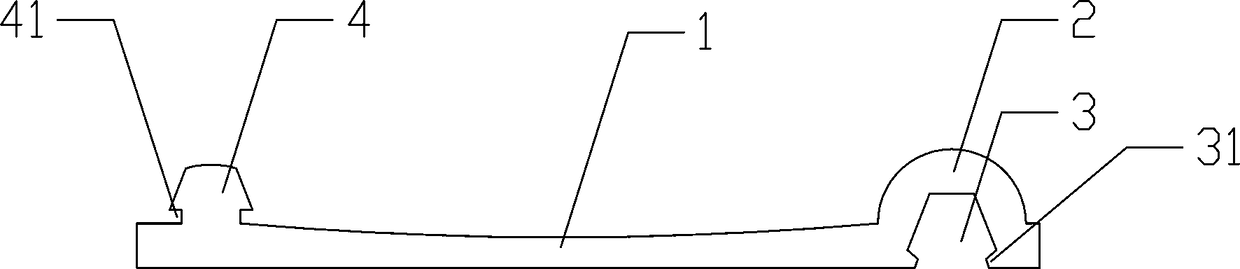

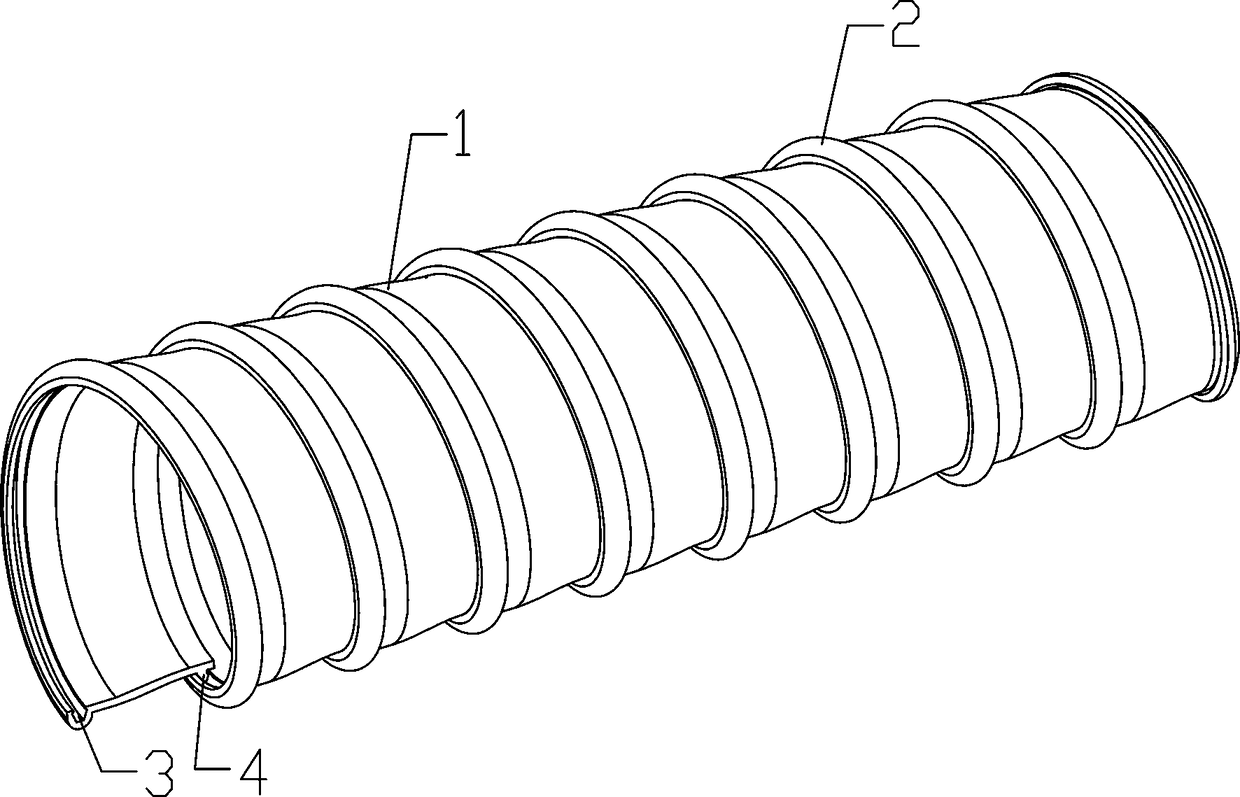

[0027] The invention discloses a maintenance pipe for an overhead power transmission line, which is formed by bonding a strip-shaped insulating part 1 to its outer surface in a winding manner. The outer surface of the insulating part 1 is Reverse ribs 4 and protruding lines 2 extending along the length direction are respectively provided at both ends, the reverse ribs 4 and protruding lines 2 are arranged in parallel, and the inner surface of the strip-shaped insulating part 1 is provided with a The groove 3 adapted to the reverse rib 4, the bottom of the reverse rib 4, that is, the two sides of the connection between the reverse rib 4 and the strip-shaped insulating part 1 are respectively provided with a slot 41, and the bottom of the groove 3 Ribs 31 adapted to the slots 41 are respectively provided on both sides. When the strip-shaped insu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com