Sealed switching connector

A technology for transfer connectors and contacts, which is applied in the direction of connection, parts of connection devices, electrical components, etc., can solve the problem that the sealing performance cannot meet the sealing requirements, improve the pressure resistance, reduce the pressure, Effect of improving high-pressure sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

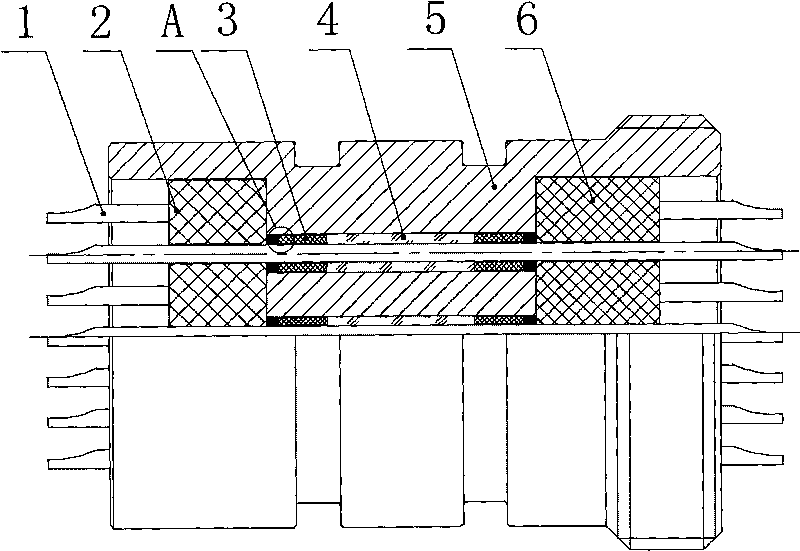

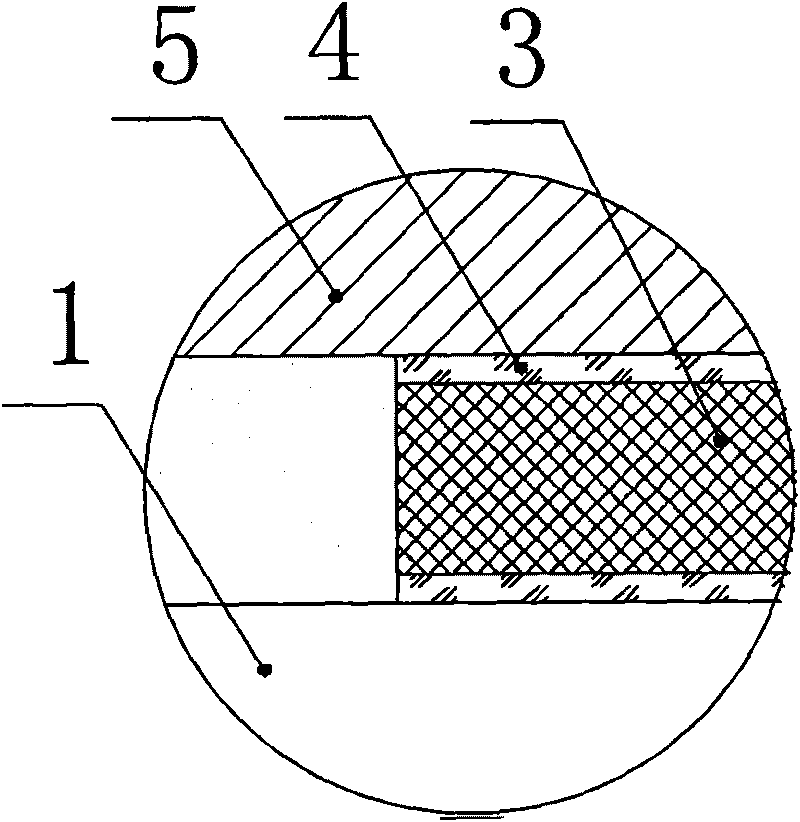

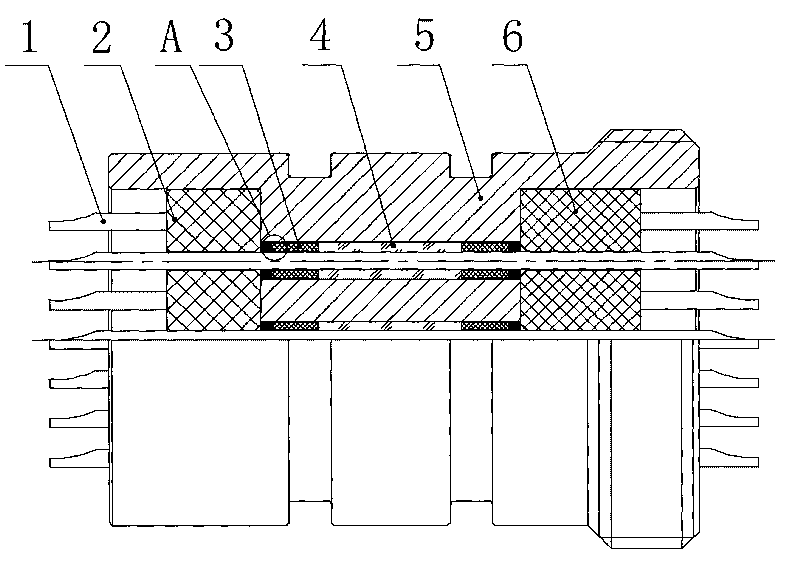

[0013] Such as figure 1 , figure 2 As shown, the transfer connector of the present invention includes a metal shell 5, and a connecting thread is provided on the outer circle of one end of the metal shell 5 to facilitate the installation and positioning of the connector. There are two sealing ring grooves for fitting O-shaped sealing rings radially. In the metal shell 5, there are several pin passages penetrating the bottom surface of the two grooves in the axial direction. Each pin passage is respectively equipped with solder cup-type sealing pins 1 for connecting cables. The welding ends of the two ends of the pin 1 respectively extend axially and protrude from the end face of the metal shell 5; the ports of each sealed pin 1 located at at least one end of the pin channel are respectively sleeved with a ceramic tube 3, in this embodiment , both ends of the sealing pin 1 are sleeved with ceramic tubes 3, between the two ceramic tubes 3 in the pin channel, between the outer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com