Glass sintering sealed through-wall electric coupler

An electrical connector and glass sintering technology, which is applied in the direction of connection and connection device components and circuits, can solve problems such as electrical properties such as insulation resistance affecting products, high weight control requirements, and external structural dimensions of products. Achieve the effect of increasing the contact surface, improving the internal sealing performance, and improving the production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] A glass sintered and sealed through-wall electrical connector according to the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments:

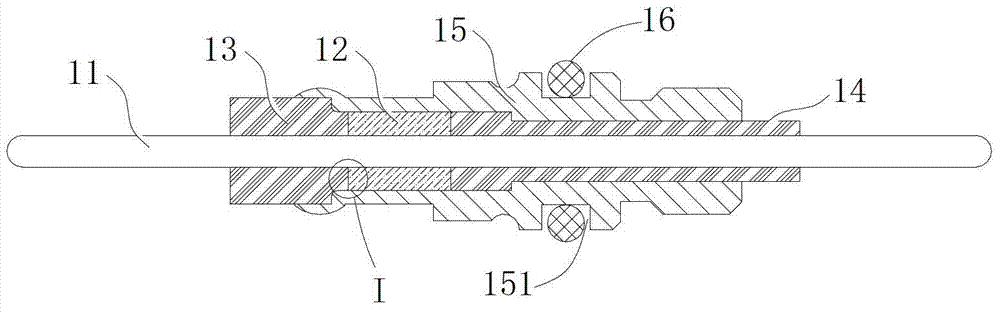

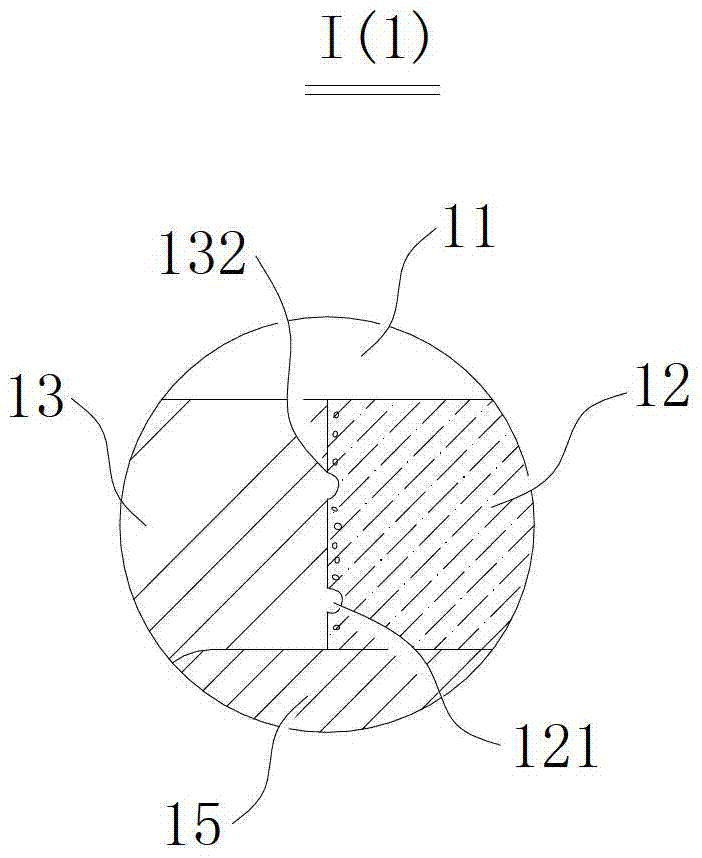

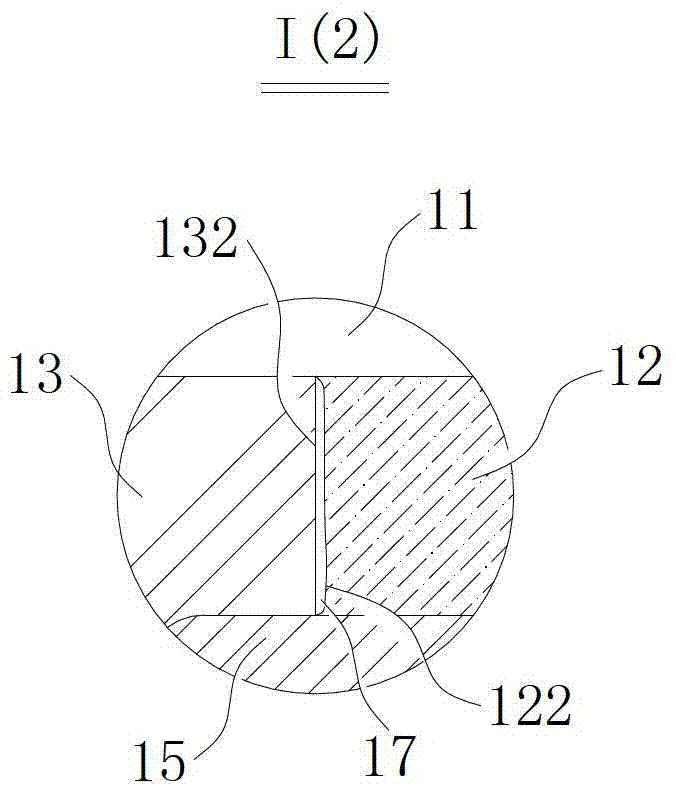

[0024] For glass sintering and sealing through-wall electrical connectors, there are various sealing and pressure-bearing structures in the prior art, figure 1 Shown is a structural cross-sectional view of a glass sintered and sealed through-wall electrical connector in the prior art. As shown in the figure, it includes a conductor pin 11 capable of transmitting current, surrounded by a glass insulator 12, a first ceramic insulator 13 and a second ceramic insulator 14, and is arranged on the periphery of the above insulators (12, 13, 14) There is a metal casing 15 on which a sealing ring 16 is arranged at an annular groove 151 . Internal sealing is realized by glass sintering structure; external sealing is realized by compression deformation of common sealing ring 16, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com