Maintenance pipe for overhead wire

A technology for overhead wires and repair pipes, applied in the direction of conductors, insulated conductors, climate change adaptation, etc., can solve the ineffective tree-line contradiction, increase the labor intensity of line operators, and tree-line contradiction wear resistance is not good Advanced problems, to achieve the effect of increasing power supply reliability, long-term anti-aging performance, and diversification of means

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] Embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings.

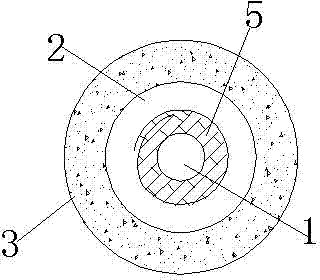

[0041] Embodiment 1 of the present invention, such as figure 2 As shown, a repair tube for overhead wire is wrapped on the outside of overhead wire 1, wherein the repair tube includes an insulating protective tube 2 and a composite protective layer 3, and the insulating protective tube 2 is wound or wrapped around the overhead wire 1 The outer side of the insulating protective tube 2 and the overhead conductor 1 are provided with an adhesive 5; the composite protective layer 3 is wrapped on the outer side of the insulating protective tube 2.

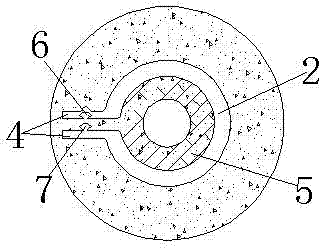

[0042] Further, in order to increase the adsorption force of the insulating protection tube 2 and the overhead wire 1, the second embodiment of the present invention, such as image 3 As shown, the difference from Embodiment 1 is that: the insulating protective tube 2 is provided with movable openings a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com