Patents

Literature

62results about How to "Light weight unit" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Composite waterproof plate, ad its manufacturing method and use

InactiveCN1640640AImprove waterproof performanceImprove corrosion resistanceWood working apparatusDomestic articlesPolymer scienceAdhesive

The present invention relates to a composite water-proof material. It is made up by using (by weight portion) 20-70 portions of plant fibre, 10-60 portions of flyash and 5-40 portions of adhesive through the processes of mixing them, die-pressing and polymerization. The described adhesive is formed from maleic anhydride, phthalic anhydride, polyalcohol, styrene or mixture of their homologous compounds, also can include trimeric cyanamide, acrylic acid or rosin and dicyclopentadiene. Its raw material composition also can include 10-40 portions of new and old plastics. Said plate material has strong strength and good water-proof property, so that it has extensive application range.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

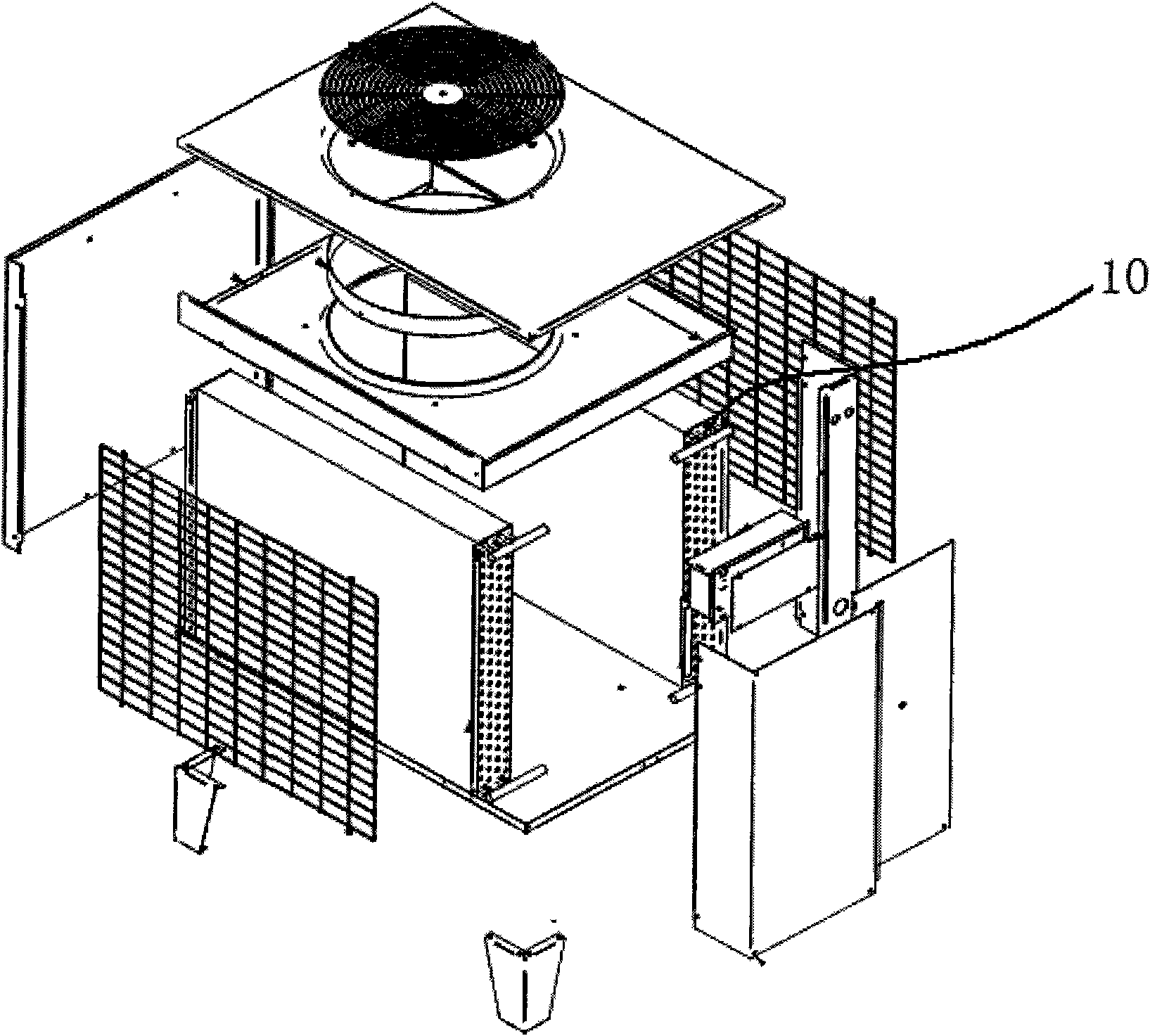

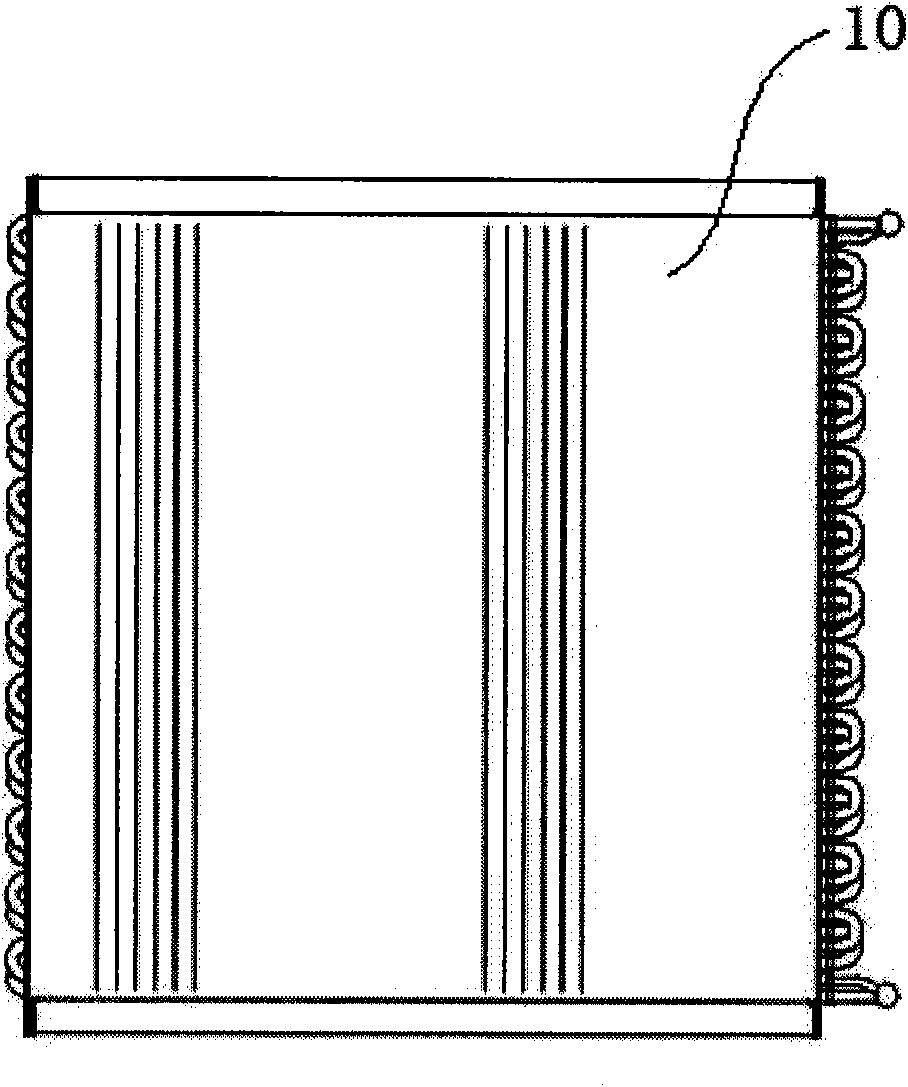

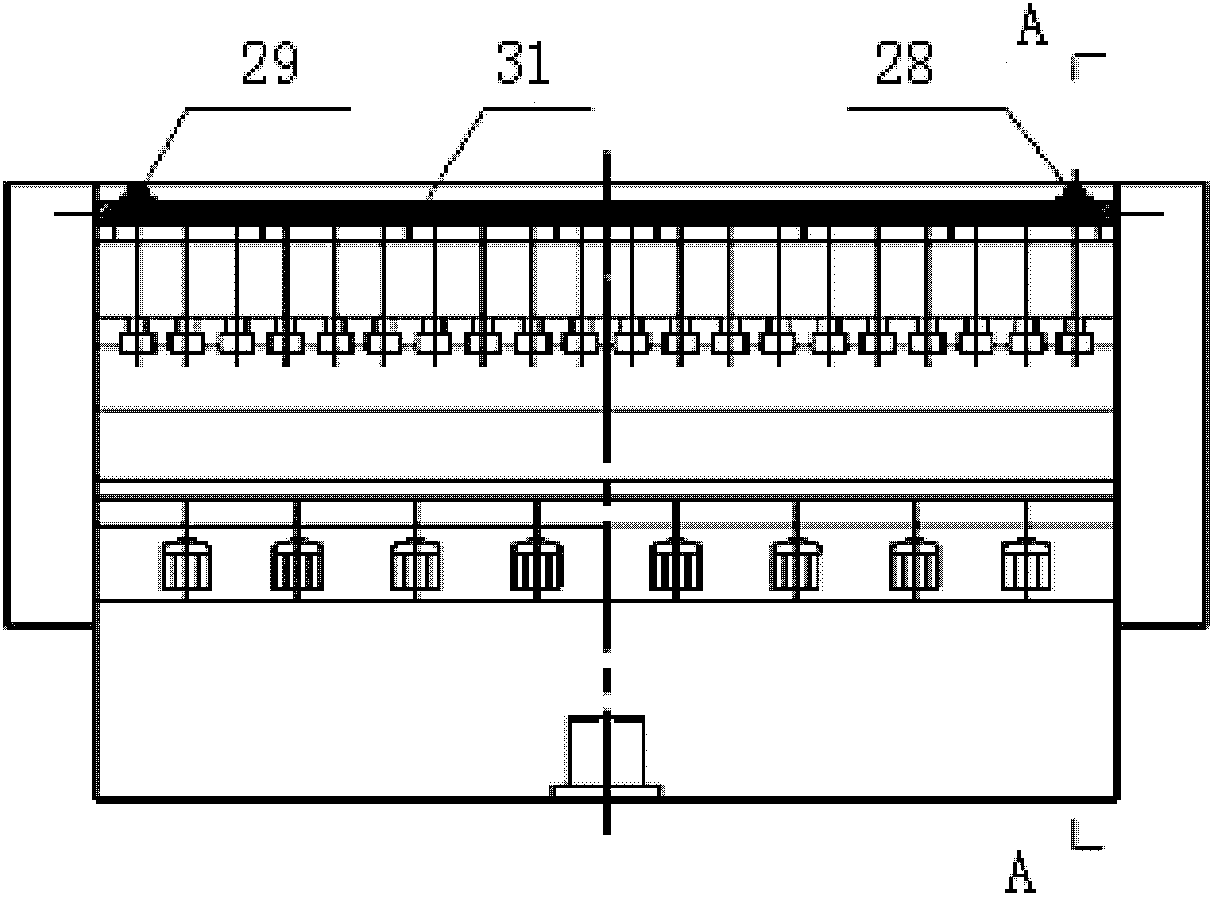

Heat exchanger with micro-channel, parallel-flow and all-aluminum flat pipe welding structure and application

InactiveCN101936670ASmall flow resistanceImprove heat transfer efficiencyEvaporators/condensersStationary conduit assembliesPotential differenceEngineering

The invention discloses a heat exchanger with a micro-channel, parallel-flow and all-aluminum flat pipe welding structure. The heat exchange part of the heat exchanger is formed by arranging flat pipes consisting of aluminum extruded thin-walled sections in parallel. Compared with the prior art, the heat exchanger with the micro-channel, parallel-flow and all-aluminum flat pipe welding structure has the advantages that: 1, the heat exchange efficiency of a refrigerant and the inner walls of the flat pipes is improved by 40 percent, and the flow resistance of the refrigerant in collecting pipes of the heat exchanger is reduced by 40 percent; 2, the heat exchange efficiency of fins on an air side is improved by 40 percent, and the wind resistance of the heat exchanger on the air side is reduced by 40 percent; 3, the heat exchange performance of the whole heat exchanger is improved by 40 percent; 4, compared with the prior art, the heat exchanger consumes 40 percent less refrigerant; and5, compared with the conventional copper-aluminum structure, the all-aluminum structure endows the heat exchanger with longer service life because of no copper-aluminum potential differences. The heat exchanger adopting the flat pipes has the characteristics of capability of bearing the conventional limitation of high-pressure resistance value of the refrigerant, compact product structure, light unit weight, short process flow, high manufacturing reliability and relatively lower cost. The invention also discloses the application of the heat exchanger.

Owner:王磊

Method of producing compound water-proof sheet material of bamboo bits and coal ash

The invention relates to a bamboo cuttings and powder coal composite water-proof plate and a method for manufacturing the same, the composite water-proof plate is made by blending, press molding and polymerizing 20 to 70 potions by weight of bamboo cuttings, 10 to 60 potions by weight of powder coal, 5 to 40 potions by weight of adhesive and TAIC. The compositions of bamboo cuttings and powder coal composite water-proof plate provided by the invention can also comprises 1 to 12 potions by weight of new and old plastic materials. The bamboo cuttings and powder coal composite water-proof plate has high intensity and favorable water-proof performance; most of the raw materials adopted are the scrap products in industry and agriculture, thereby the environment pollution can be degraded. The bamboo cuttings and powder coal composite water-proof plate can be widely used in the floor manufacturing industry, the furniture industry, the decoration and construction material industry as well as the inner decoration material in automobile industry.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI +1

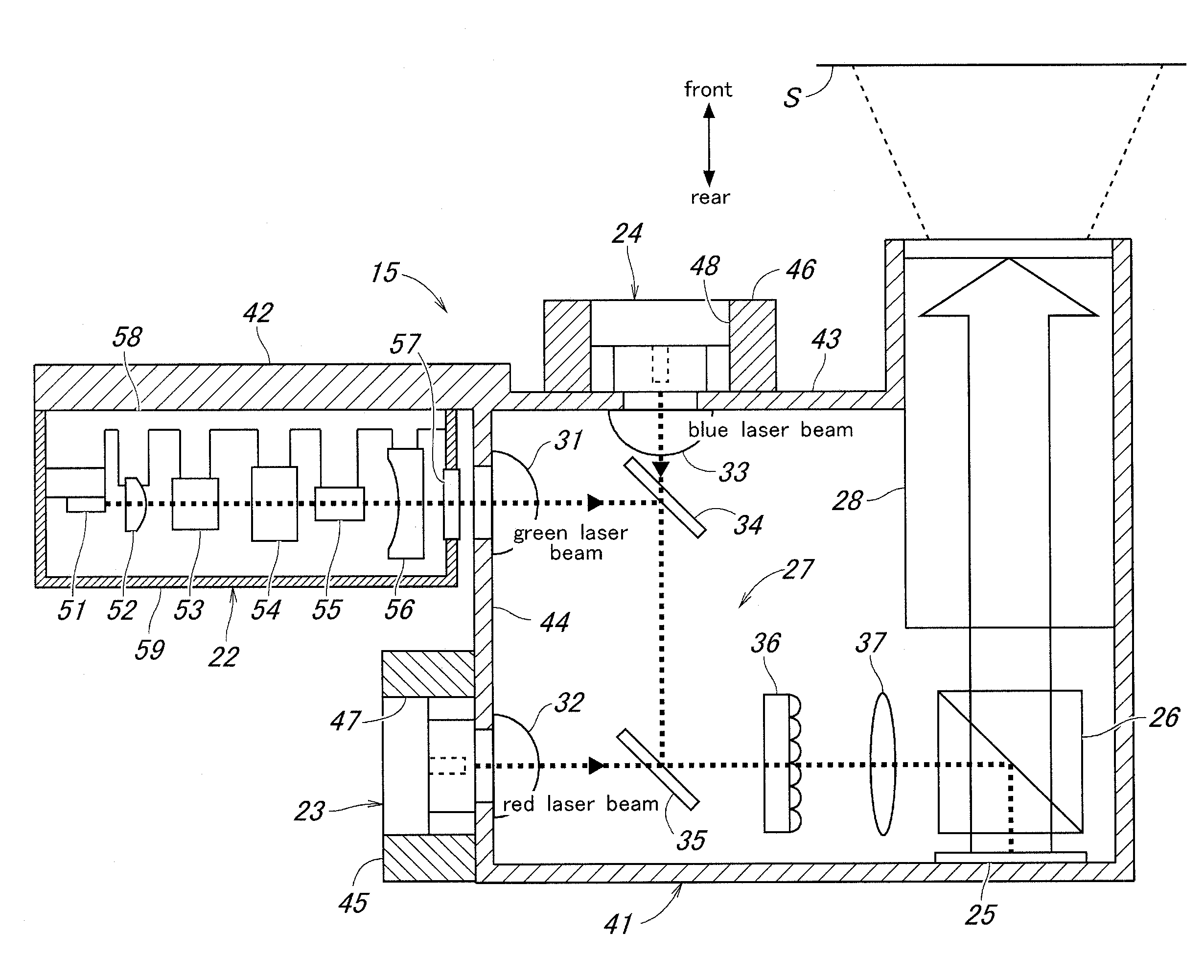

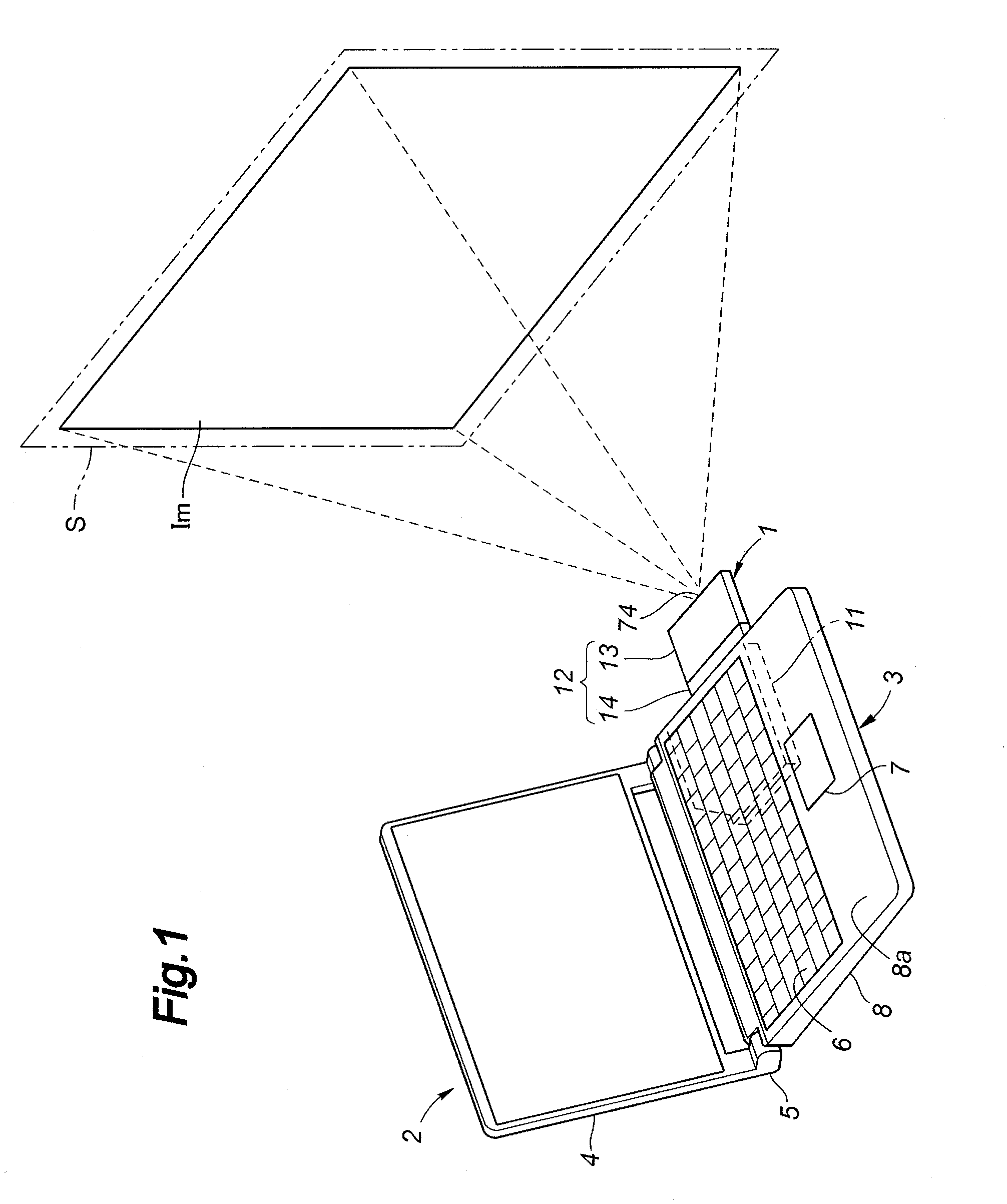

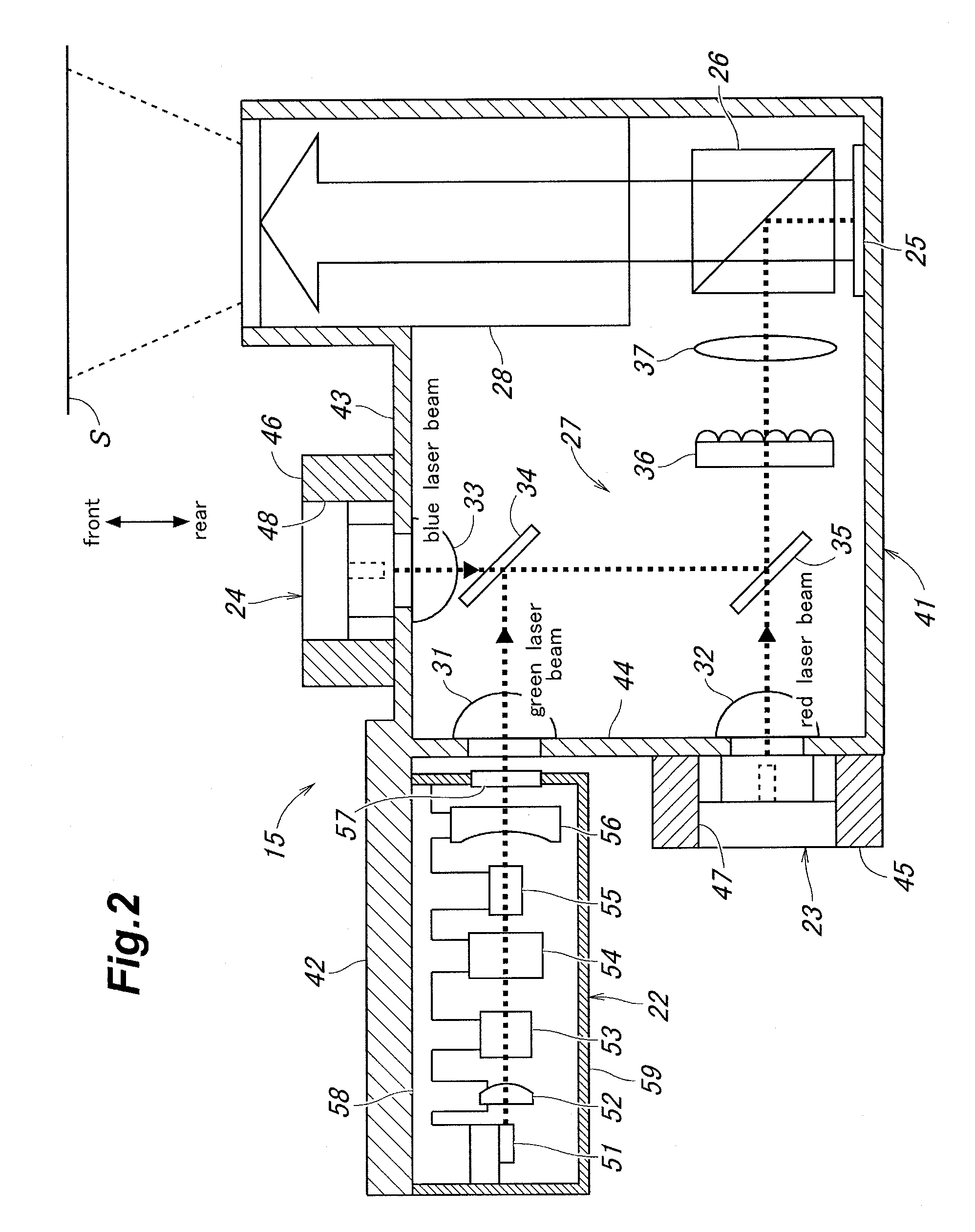

Projector lens system and image display system using same

In a projector lens system including at least three lens elements and telecentric on a side of an optical modulator, two of the lens elements located on outer most ends of the projector lens system facing conjugate points of the projector lens system consist of plastic lenses, and an aperture stop of the projector lens system is located between the two outer most lens elements while at least one of the lens elements other than the two outer most lens elements most adjacent to the aperture stop consists of a glass lens. Thereby, the cost and weight of the projector lens system can be reduced while achieving the required optical properties.

Owner:PANASONIC CORP

Ultra clear float solar battery glass production process and product thereof

ActiveCN103253864AHigh light transmittanceReduce reflectivityGlass severing apparatusPhotovoltaic industryEngineering

The invention belongs to the technical field of special glass production, and provides an ultra clear float solar battery glass production process and a product thereof. The process comprises the following steps: (1) preparing raw materials, (2) feeding and melting, (3) carrying out clarification, (4) carrying out homogenization, (5) carrying out tin stripping molding, (6) annealing, and (7) cutting. With the ultra clear float solar battery glass production process, ultra clear float solar battery glass with a thickness of 2.5 mm can be produced, wherein the glass has characteristics of high transmittance, low reflectivity and light unit weight, and is applicable for photovoltaic industry to be adopted as a photoelectric conversion substrate and a light-heat conversion panel so as to be used for solar battery manufacturing. In addition, with application of the process to produce the ultra clear float solar battery glass, the production cost is low so as to reduce a production cost of the whole photovoltaic industry chain.

Owner:XINYI PHOTOVOLTAIC IND (ANHUI) HLDG CO LTD

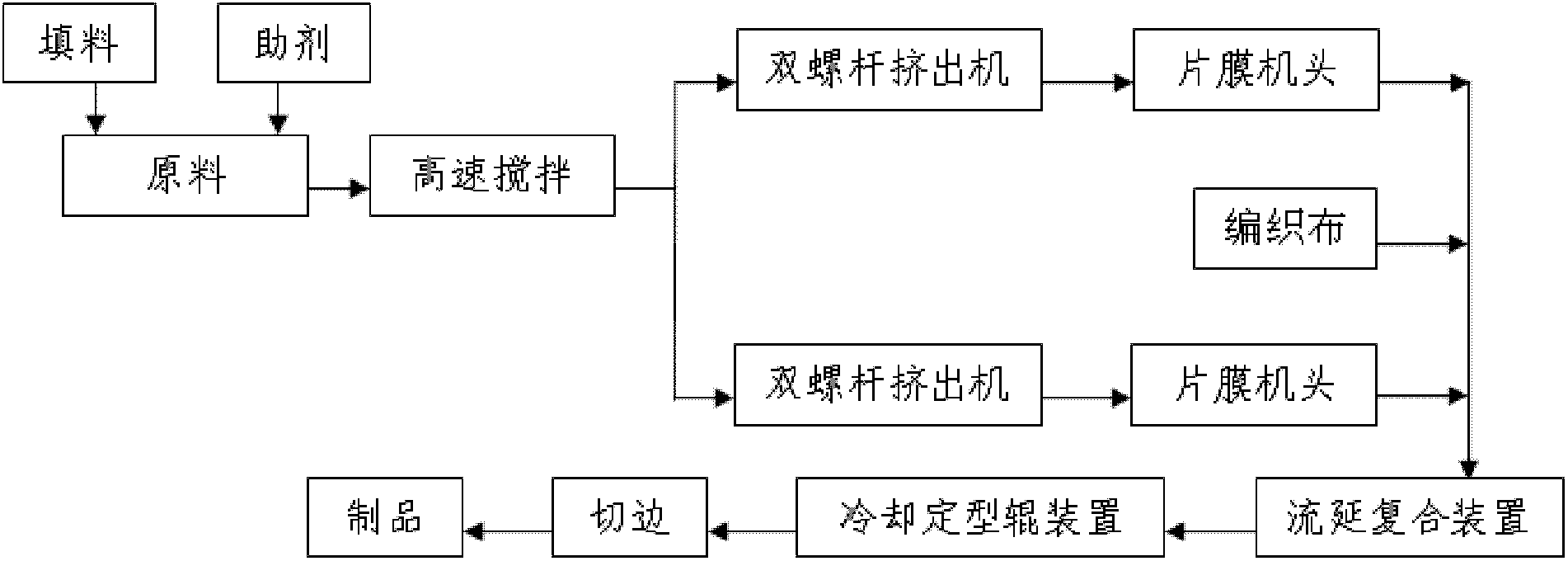

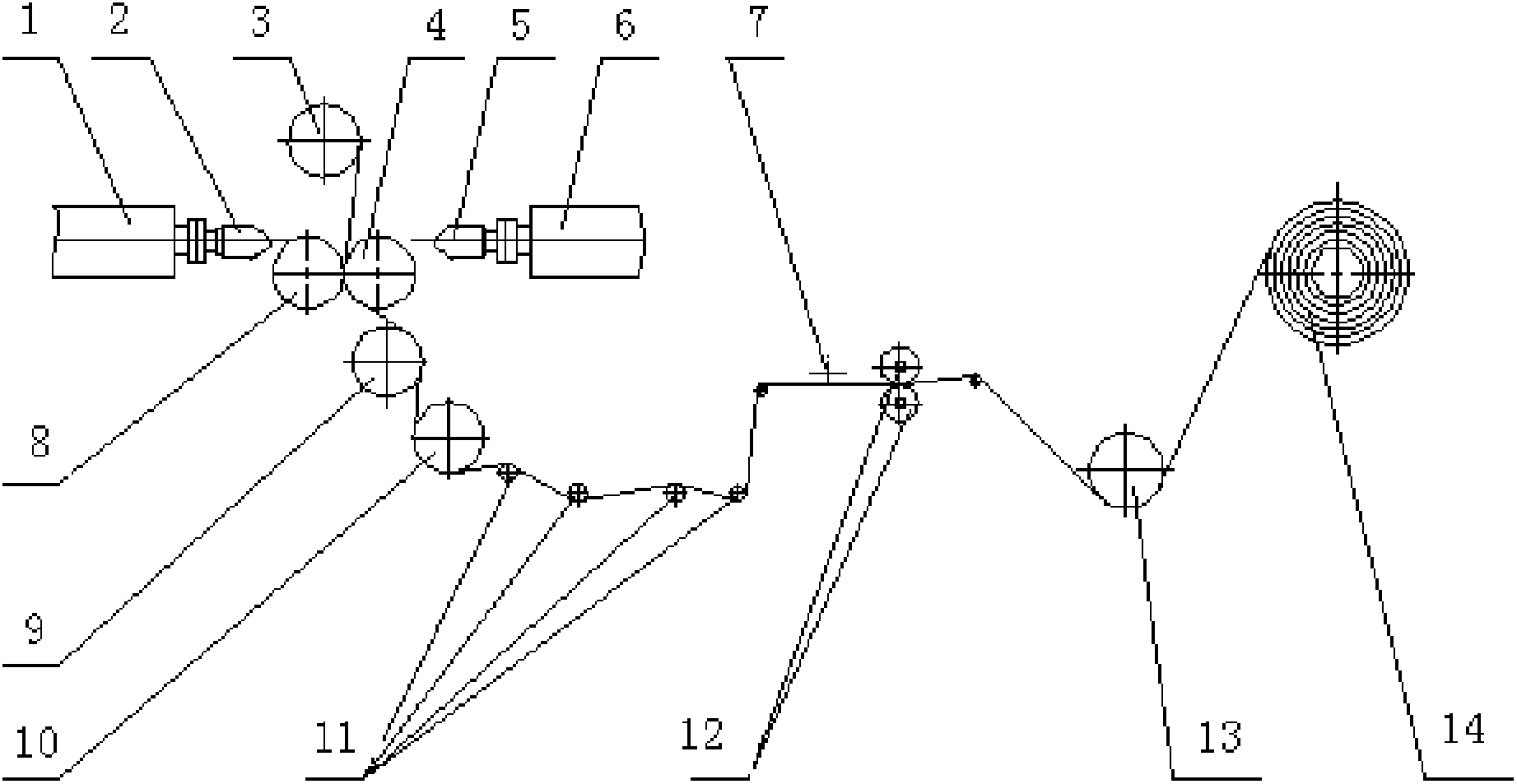

Process and equipment for continuously producing and molding dual-extrusion current coating plastic clip net film products

InactiveCN102490366AEvenly heatedImprove plasticizing effectVolumetric Mass DensitySurface structure

The invention relates to a process and equipment for continuously producing and molding dual-extrusion current coating plastic clip net film products. The process comprises the following steps of: uniformly stirring raw materials formed by mixing resin, packing and functional aids, and feeding the mixed raw materials into a twin-screw extruder; setting temperature of the extruder and the temperature of a sheet die; controlling the temperature of a die lip; staring the extruder to make a melted material flow out through the sheet die and introduced into a current coating composite roll; introducing woven cloth between two thin films and subjecting the woven cloth to composite forming; and cooling to finalize, performing roller guiding, edge shearing, flattening and finally rolling to form the clip net film product under the traction action of a traction roller. According to the process and the equipment, the melted raw materials are extruded by the twin-screw extruder, plasticized and stretched through current coating, the surface structure of the film is changed, and micropores are formed between base material plastic and packing materials, so that the density of the film is reduced. Thus, the clip net film product produced by the dual-extrusion current coating molding process has low specific gravity and light unit weight under the condition of same proportions, the equipment has a simple and reasonable structure, the production cost is a quarter of that of gluing equipment, and continuous production and molding are realized.

Owner:DALIAN PLASTICS RES INST CO LTD

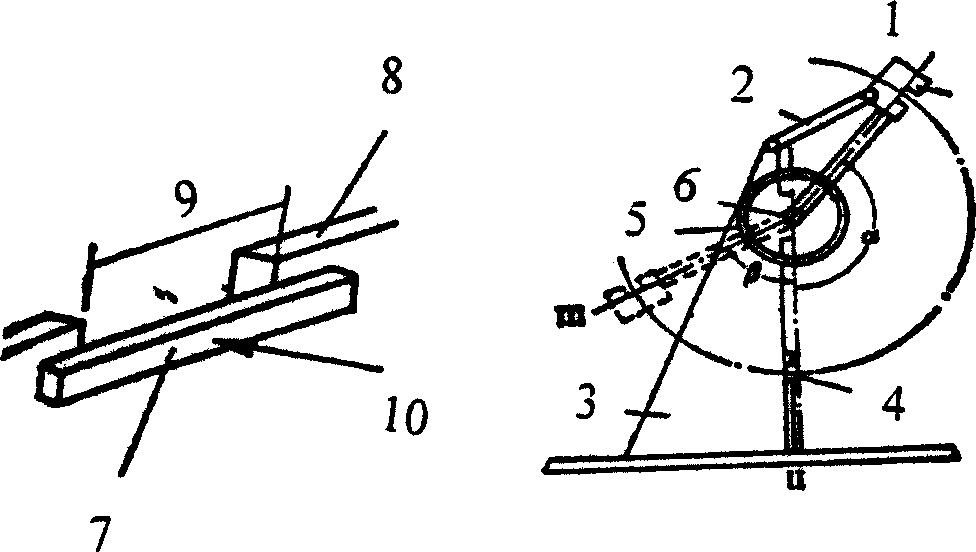

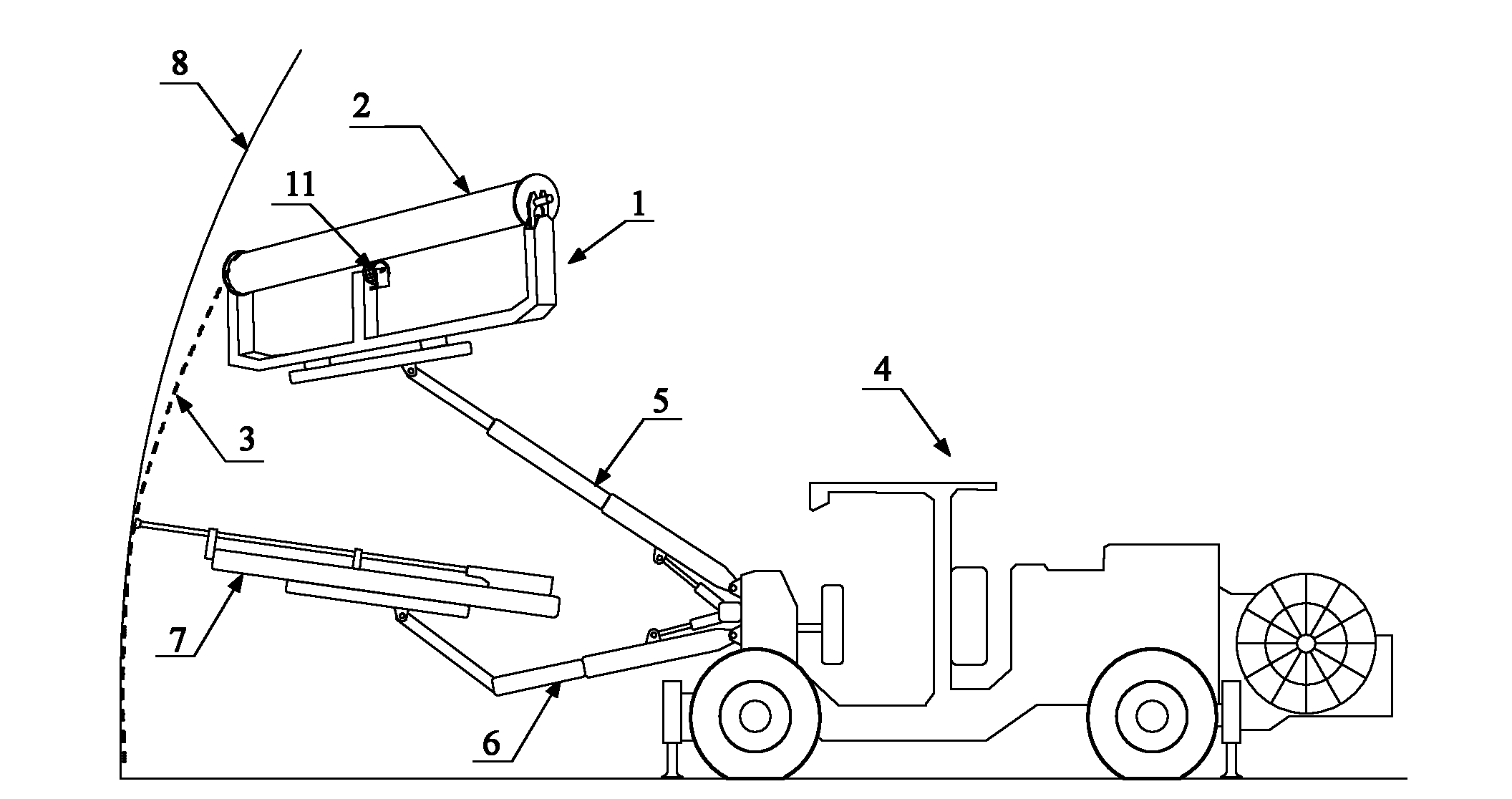

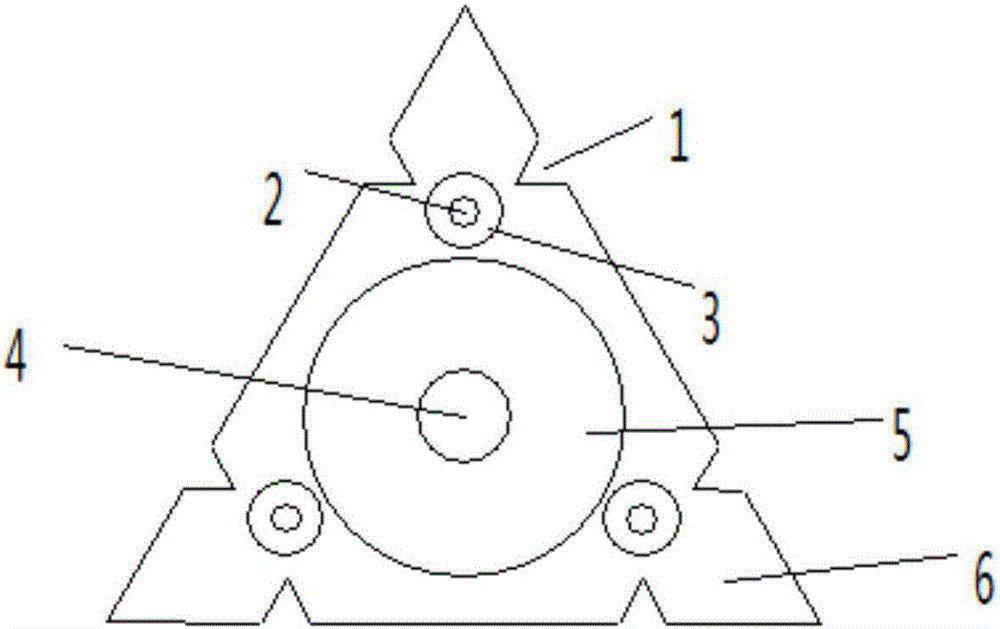

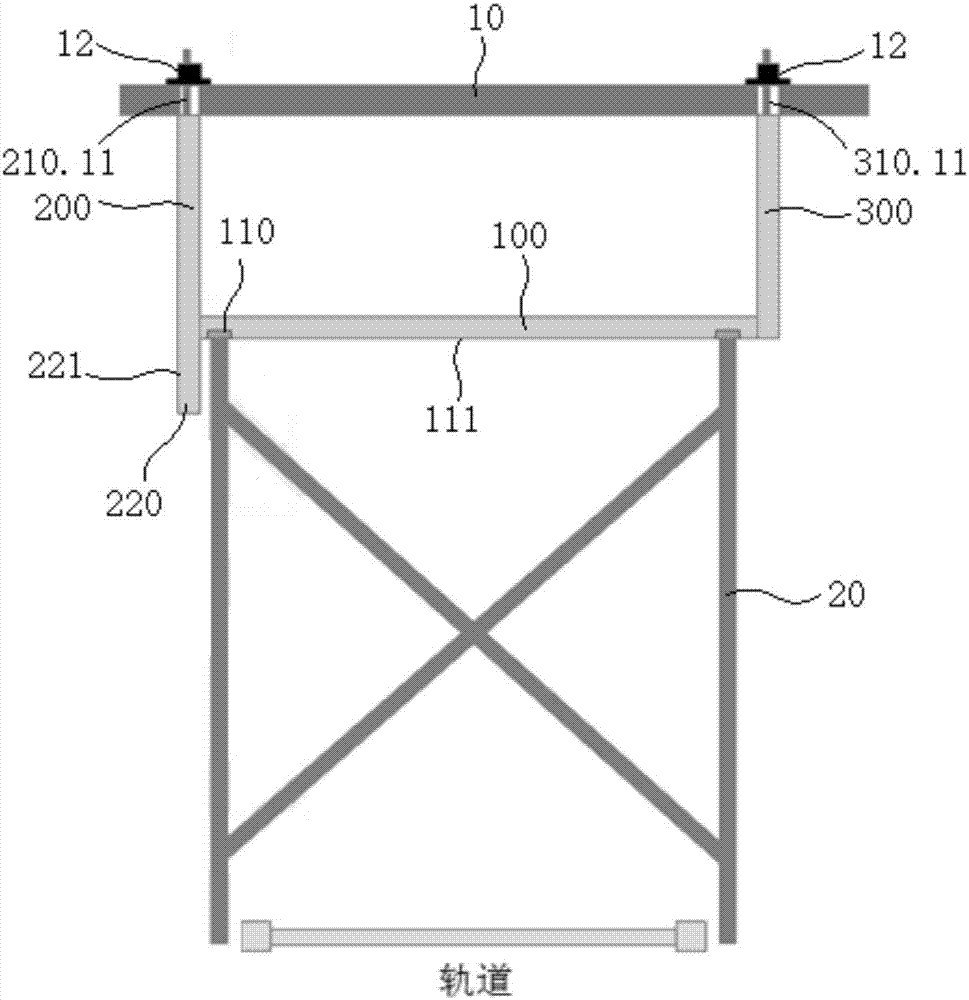

Flexible metal net bracket, paving device and paving method

InactiveCN101915110AMeet the need for strengthQuick installationUnderground chambersTunnel liningControl systemEngineering

The invention discloses a flexible net bracket, a paving device and a paving method, which can promote the construction efficiency. The bracket comprises a bracket main body which is formed by two hanging arms connected on a support beam, wherein each hanging arm is provided with a fixing device for fixing a flexible metal net scroll; the support beam is provided with at least one support base elastically connected to a rotatable friction wheel; the friction wheel is kept tangent with the flexible metal net scroll; the bracket is assembled on a moving drilling arm on a drilling jumbo so as to form the paving device. After the flexible metal net scroll is taken and supported, the drilling arm and the flexible metal net scroll are moved through a control system of the drilling jumbo so as to drive the friction wheel to rotate. The flexible metal net scroll is driven to rotate and pave on a working side. A drilling device is used for drilling holes and assembling a bolt in order to fix the flexible metal net. The invention is suitable for conveniently paving and fixing the flexible metal net in an underground cavity. The assembly process is mechanical, the construction is safe and the efficiency is high.

Owner:四川博华工程材料有限公司 +1

Composite membrane, preparation method thereof and solar cell assembly

InactiveCN104992995AGuaranteed weather resistanceLight weight unitFinal product manufactureSynthetic resin layered productsBlock layerBlocking layer

Owner:ZHANGJIAGANG KANGDE XIN OPTRONICS MATERIAL

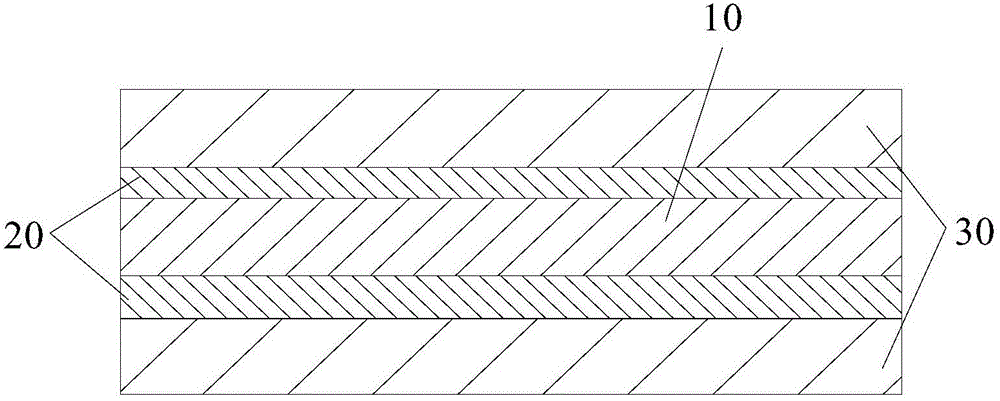

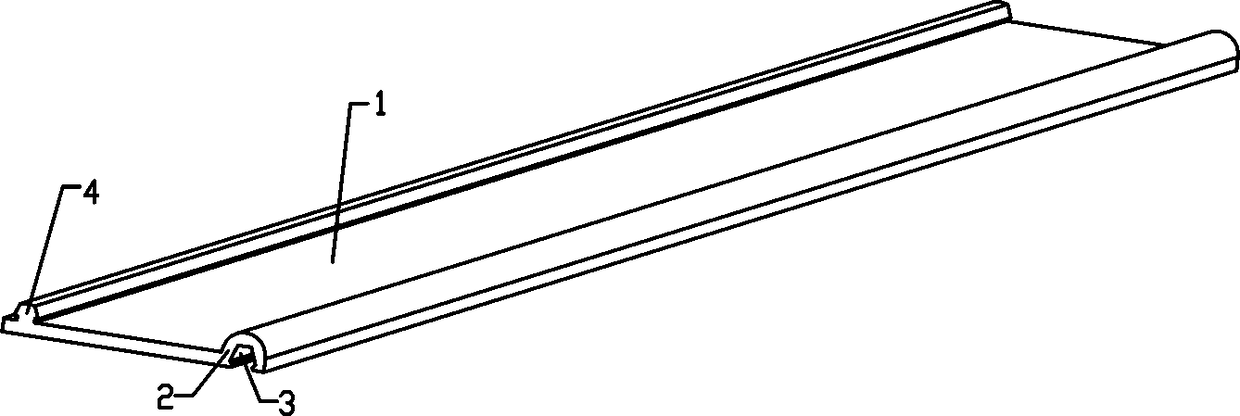

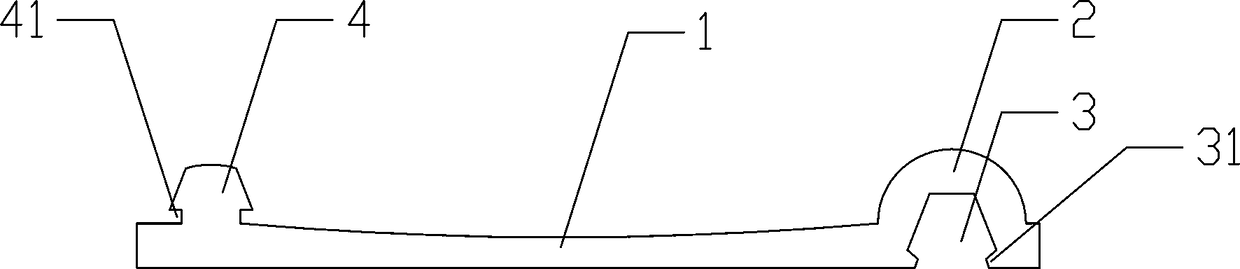

Triangular cross section drop optical cable and manufacturing method thereof

PendingCN106646796AReduce unit weightReduce weightFibre mechanical structuresAccess networkIsoetes triquetra

The invention relates to the technical field of optical cables and relates to a triangular cross section drop optical cable and a manufacturing method thereof. An outer sheath layer with an equilaterally triangular cross section coats three fiber units and a reinforcing assembly formed by a central reinforcing member and a central reinforcing member cushion layer to form the triangular cross section drop cable, wherein the central reinforcing member is placed at the midpoint of the equilateral triangle, the three fiber units are rotationally symmetric outside the central reinforcing member cushion layer and are arranged on three center lines of the triangle respectively, the outer sheath layer is provided with acute-angled separation grooves on both sides of each fiber unit, and the angular bisector of each separation groove points to the fiber. The triangular cross section drop optical cable is increased by 50% in fiber density and prevents repeated construction. The central reinforcing member cushion layer uses a foaming process. The central reinforcing member uses a high-flexible aramid fiber rod so as to decrease 30% unit weight. The optical cable is good in bending performance, reduces construction cost and construction difficulty. A tight sleeve layer uses nylon material to improve the anti-pressure ability of the branched fiber. The optical cable is suitable for urban networks and access networks.

Owner:BEIJING HENGTONG SIBO COMM TECH CO LTD

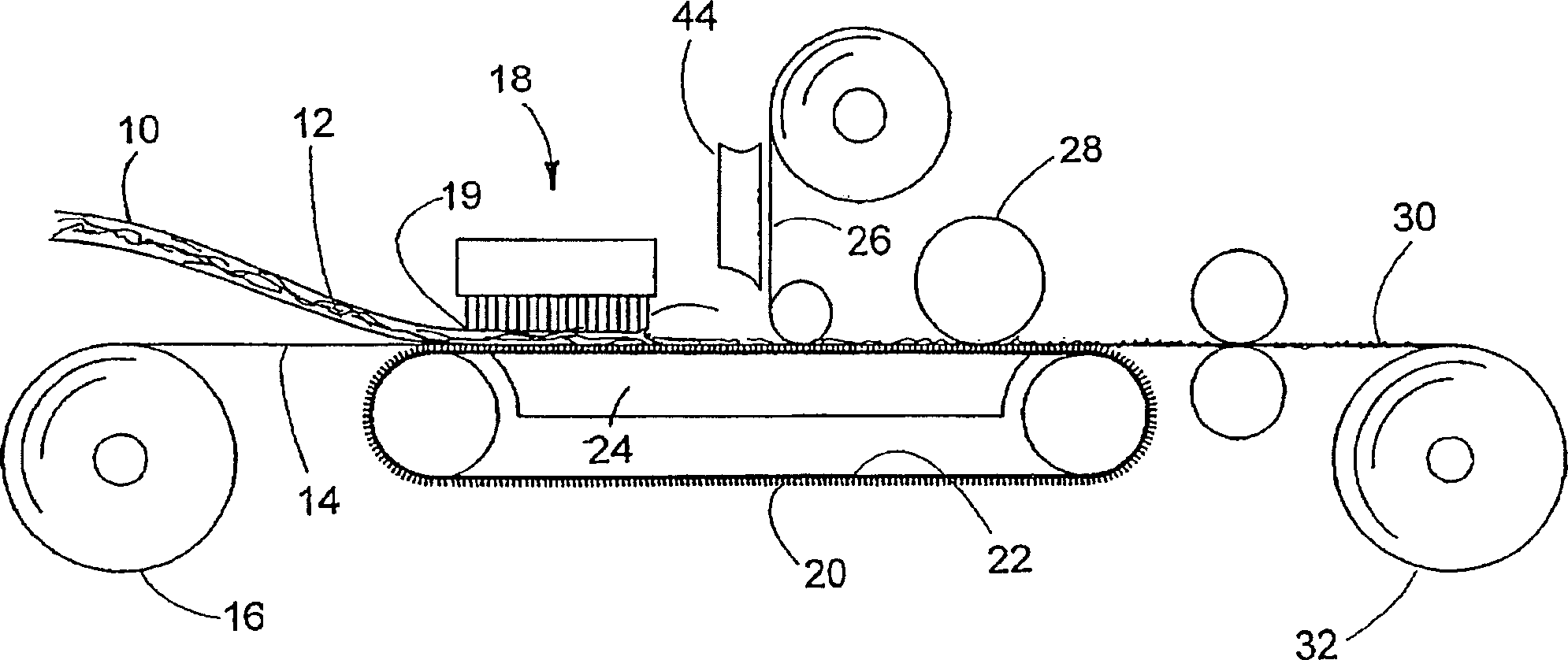

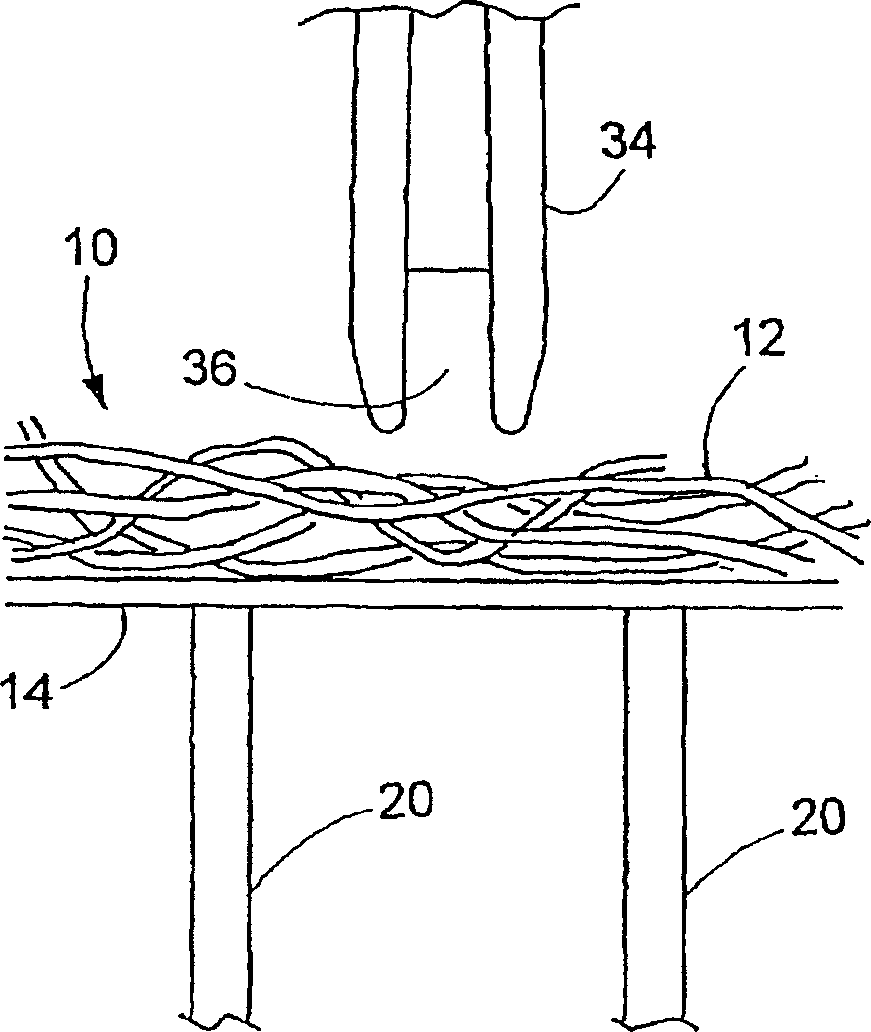

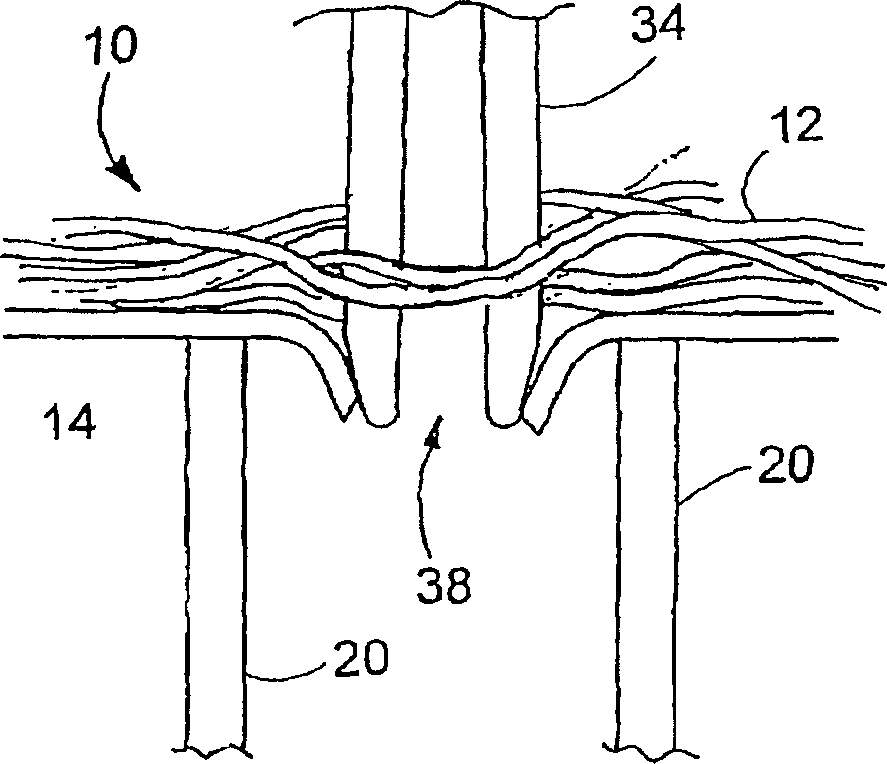

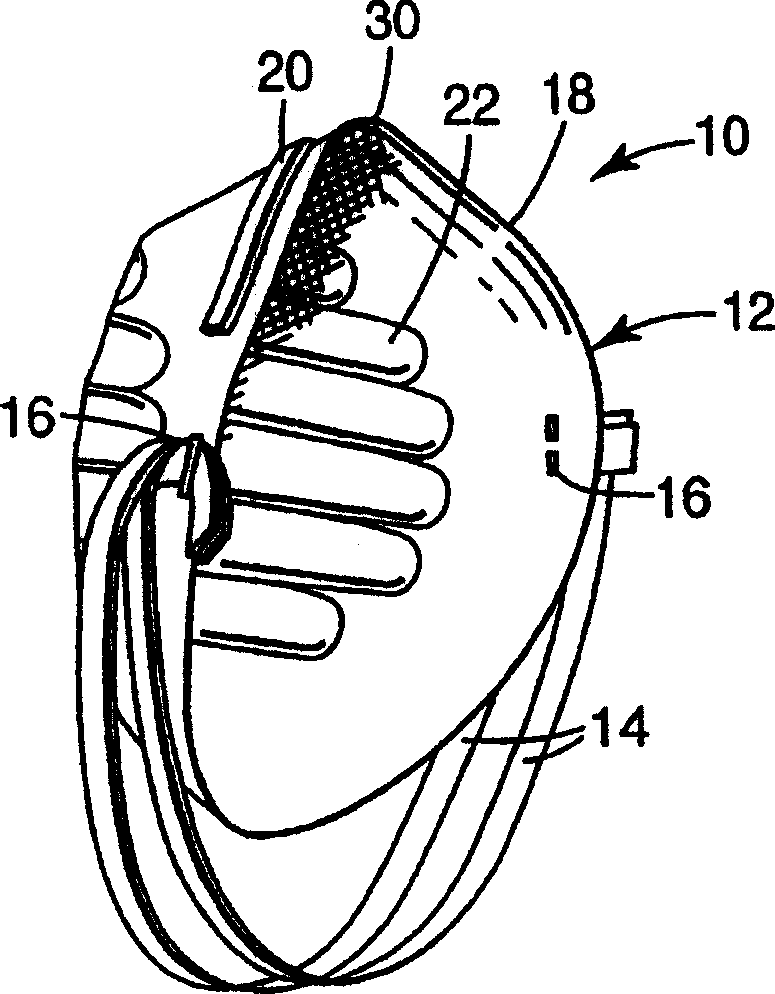

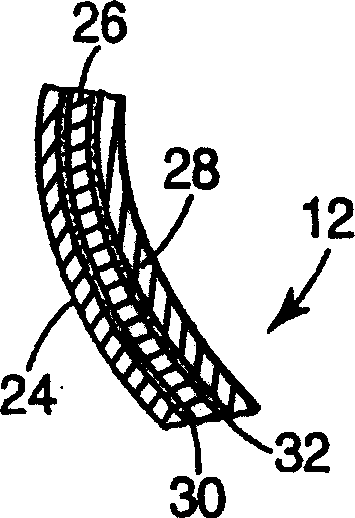

Needling through carrier sheets to form loops

ActiveCN1753630AReduce demandLight weight unitPersonal careLayered product treatmentFiberEngineering

A loop fastener product is formed by needling a batt of fibers (12) through a carrier sheet such as a plastic film, to form loops (40) on the other side of the carrier sheet (14). A binder (46), such as a powder resin or plastic film, is placed over the fiber side of the product and fused to the carrier sheet (14) to bond the fibers (12) in place. In some cases the product is needled in only discrete areas, leaving other areas free of loops (40). The product may be formed into outer covers for disposable diapers. Fibers (12) of one resin are readily combined with films and backings of other resins to produce particularly thin and low weight loop materials.

Owner:VELCRO IP HLDG LLC

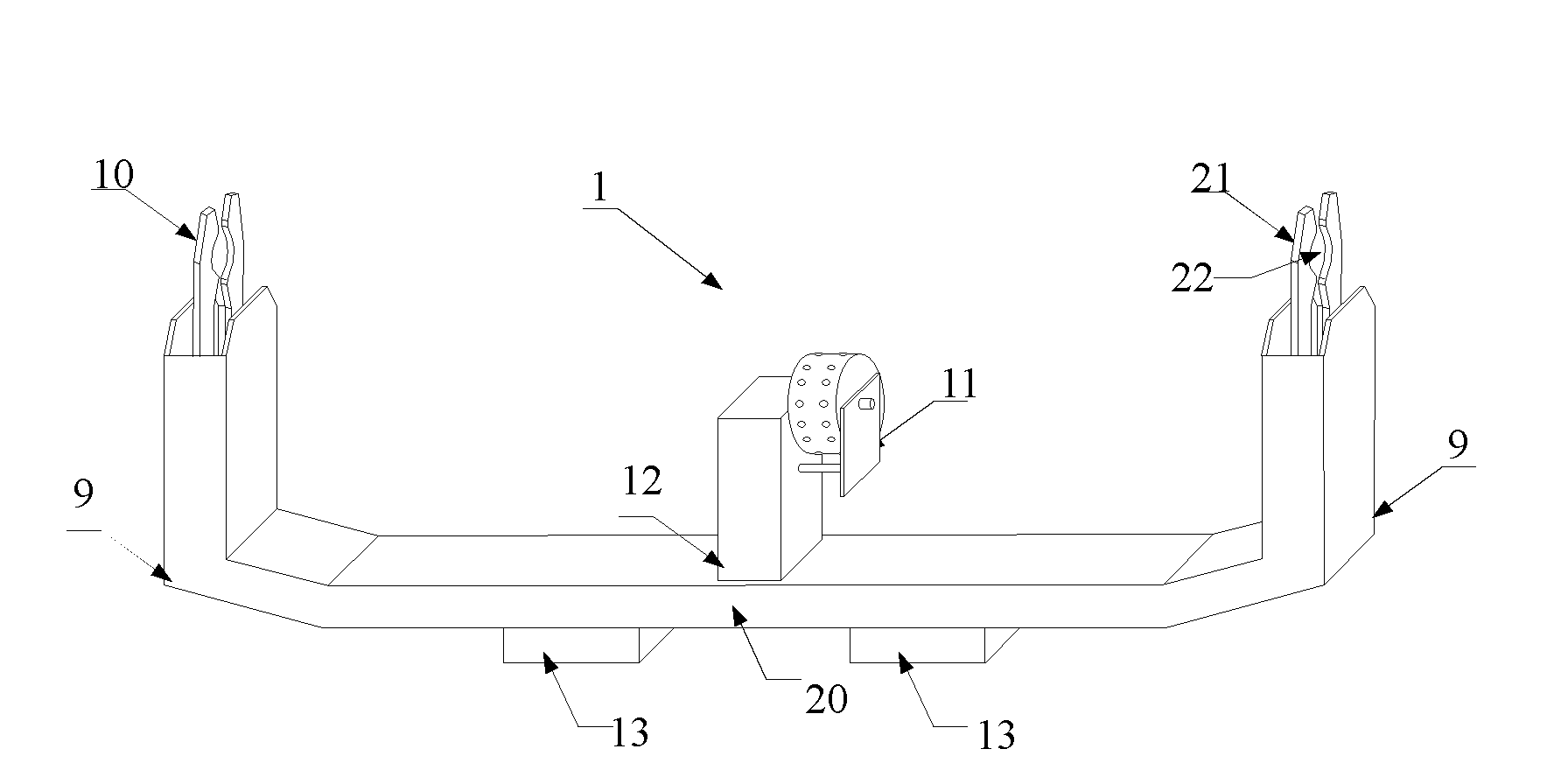

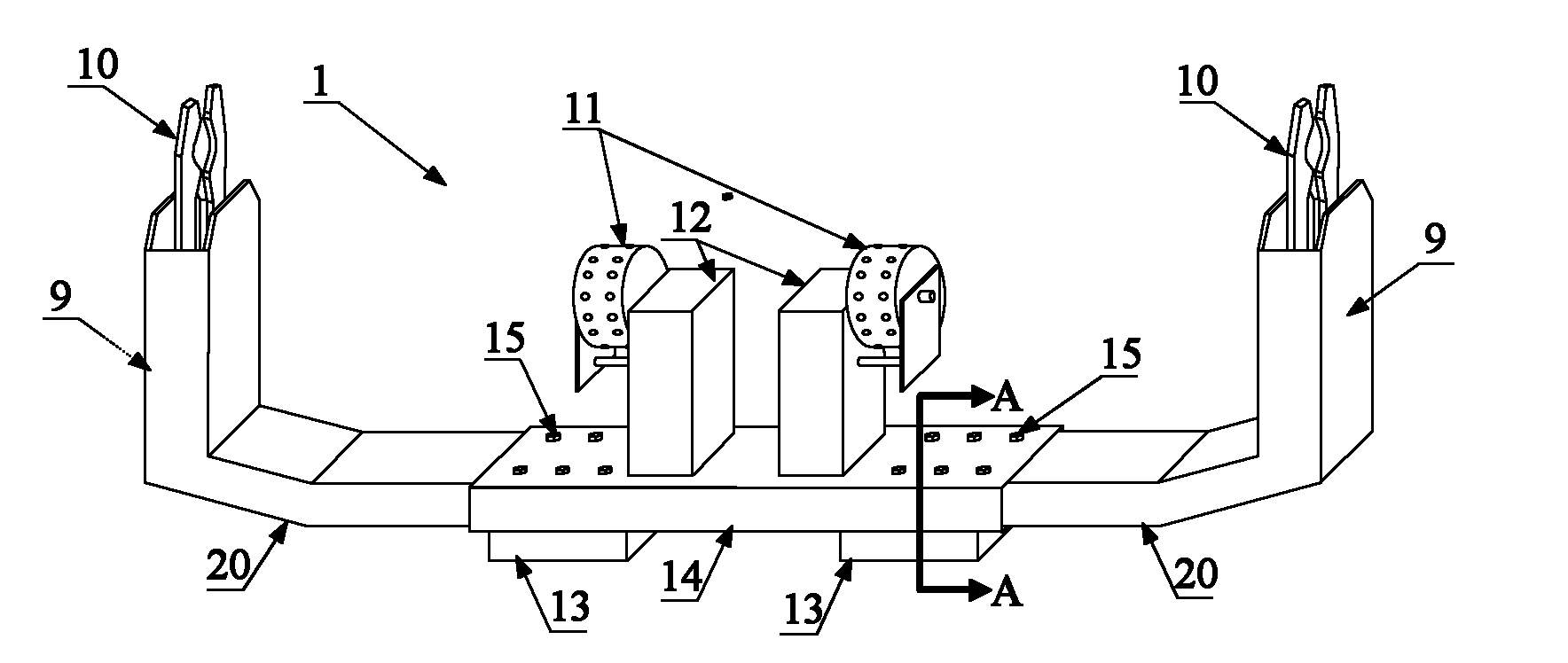

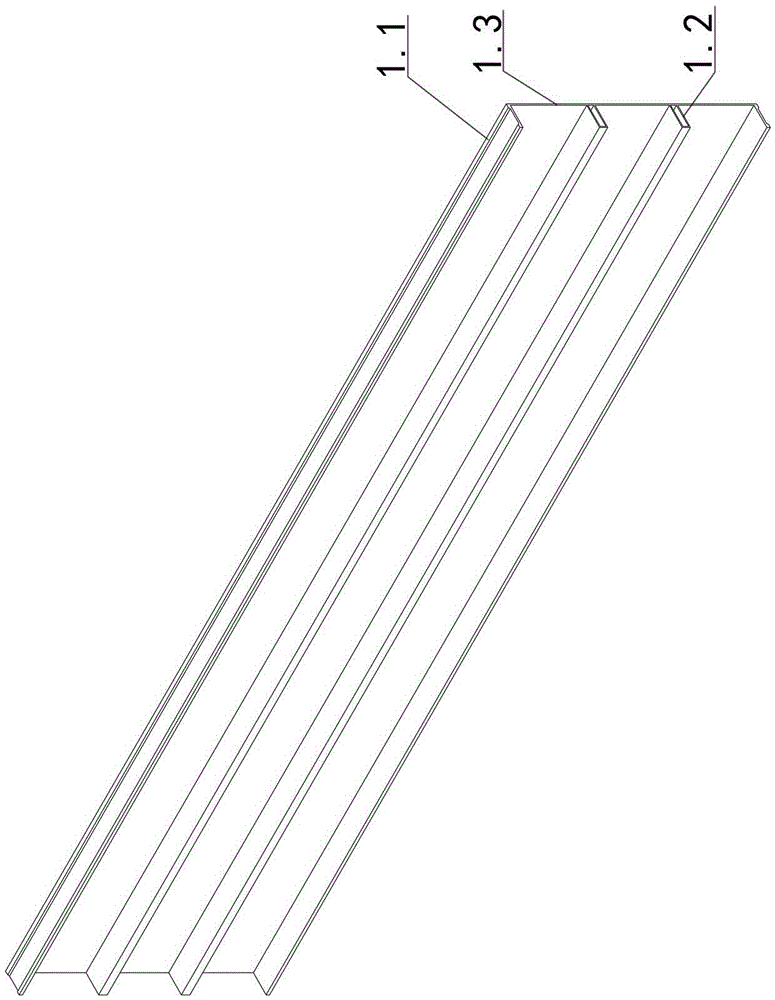

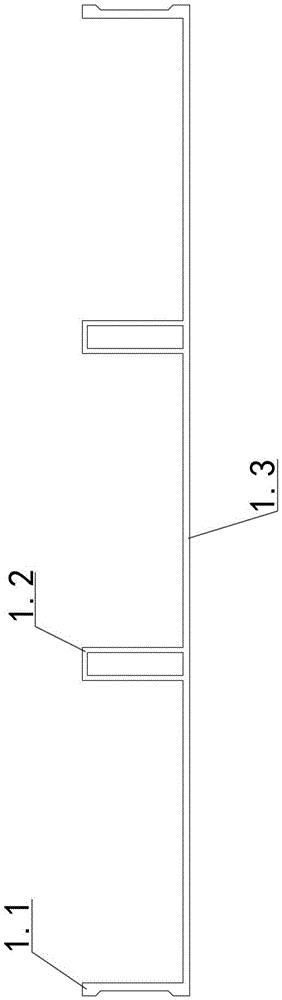

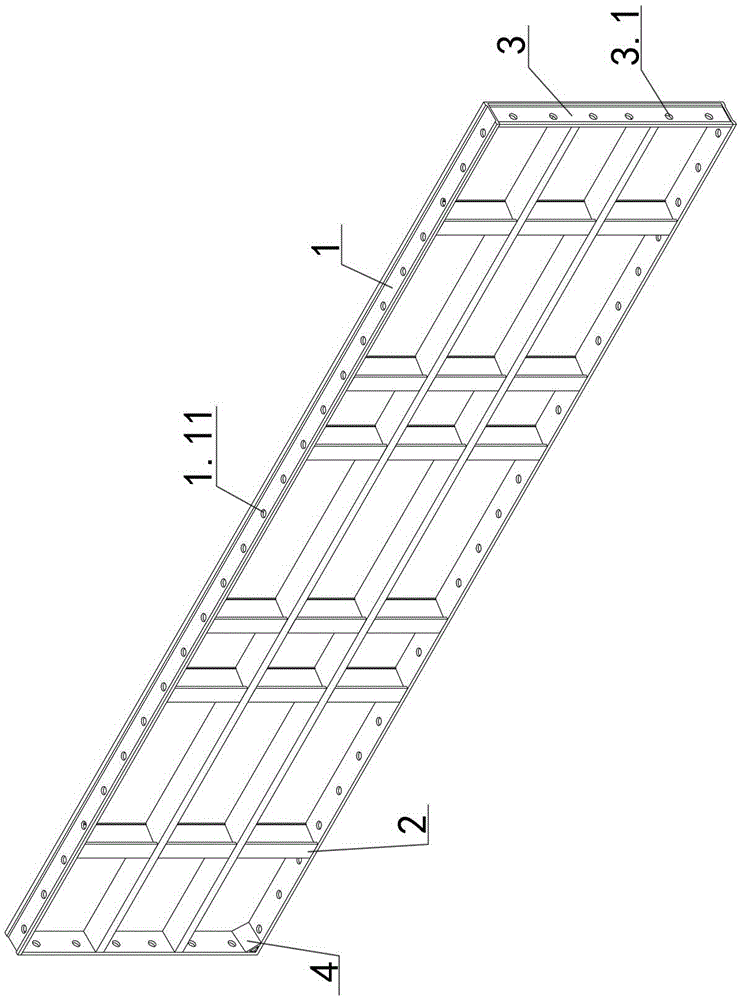

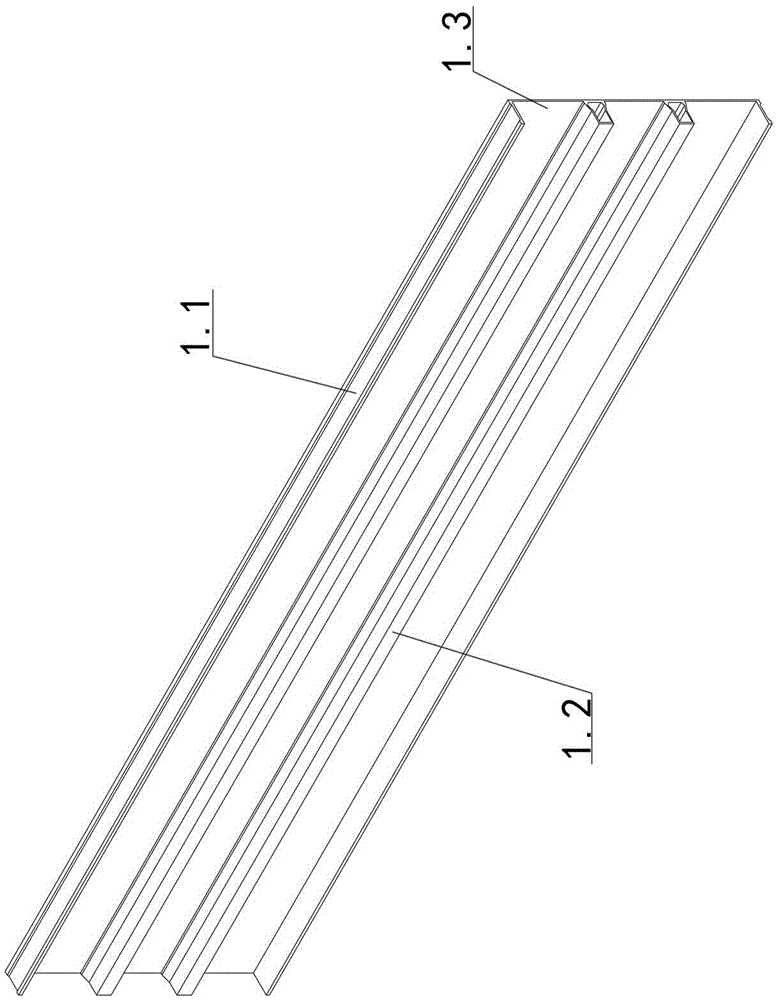

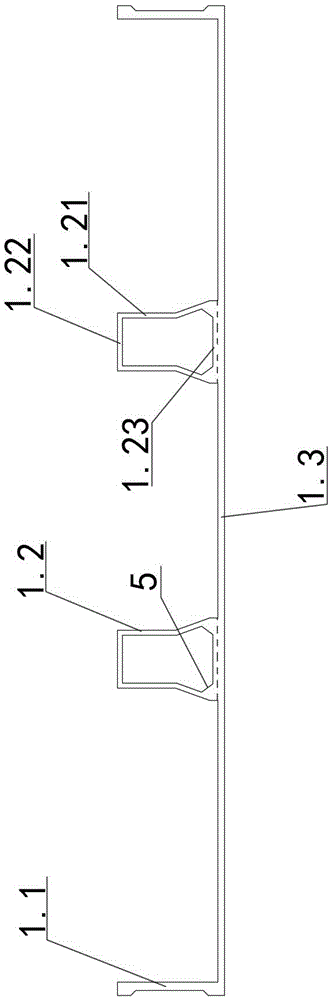

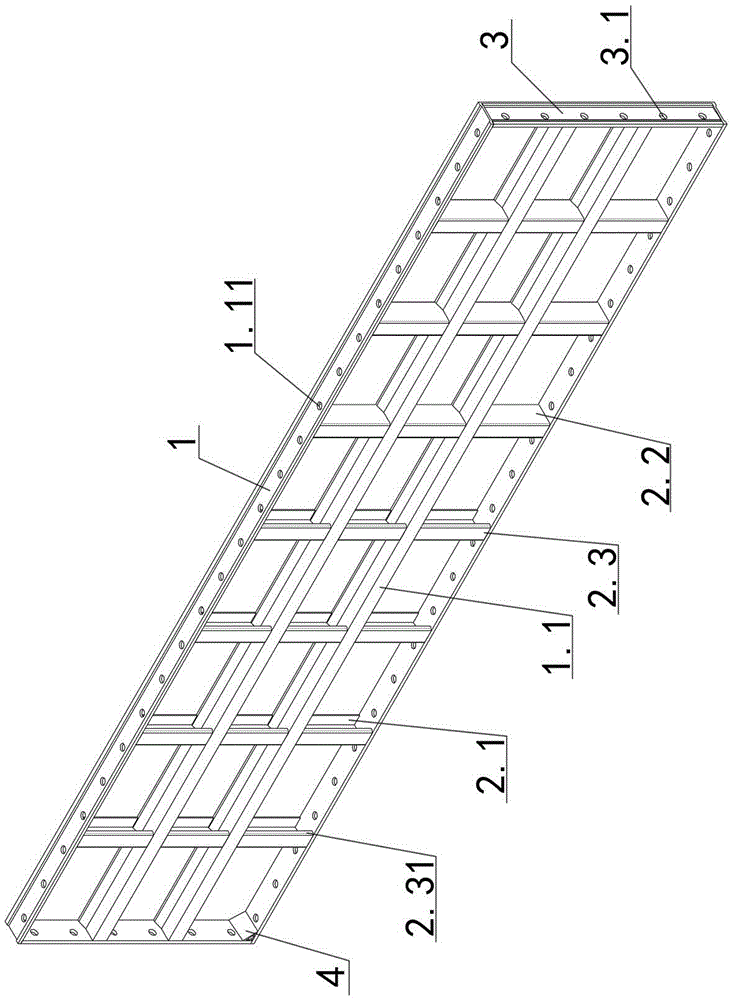

Aluminum alloy formwork rectangular-section profile and unit formwork structure of aluminum alloy formwork

InactiveCN105421762AReasonable section structureSectional structure is clearSheets/panelsForming/stuttering elementsMachiningAluminium alloy

The invention provides an aluminum alloy formwork rectangular-section profile and a unit formwork structure of an aluminum alloy formwork. The aluminum alloy formwork rectangular-section profile is an integrally-formed aluminum alloy special-shaped board and is composed of a groove and a set of longitudinal reinforcing ribs, wherein the groove is formed by a rectangular panel and two opposite longitudinal side frames arranged on the back face of the panel, and the longitudinal reinforcing ribs are evenly distributed at the bottom of the groove. The unit formwork structure of the aluminum alloy formwork comprises the aluminum alloy formwork rectangular-section profile, transverse side frames, transverse reinforcing ribs and corner reinforcing blocks. The aluminum alloy formwork rectangular-section profile and the unit formwork structure are clear in structure, easy to form and low in later formwork machining amount, machining cost is reduced, it can be guaranteed that the formwork is low in weight, safe in use and long in service life, construction efficiency is improved, standardized, systematic and industrial production is easier, formwork disassembly and assembly are rapid, easy and convenient, installation is firm, construction efficiency is high, and construction cost is low.

Owner:CHINA STATE CONSTRUCTION ENGINEERING CORPORATION +1

Float semi-tempered glass production process and product thereof

InactiveCN103253850AHigh light transmittanceReduce reflectivityGlass tempering apparatusPhotovoltaic industryPhotoelectric conversion

The invention belongs to the technical field of special glass production, and provides a float semi-tempered glass production process and a product thereof. The process comprises the following steps: (1) preparing raw materials, (2) feeding and melting, (3) carrying out clarification, (4) carrying out homogenization, (5) carrying out tin stripping molding, (6) annealing, (7) cutting, and (8) carrying out semi-tempering. With the float semi-tempered glass production process, ultra clear float semi-tempered glass with a thickness of 2.5 mm can be produced, wherein the glass has characteristics of high transmittance, low reflectivity, light unit weight and strong strength, and is applicable for photovoltaic industry to be adopted as a photoelectric conversion substrate and a light-heat conversion panel so as to be used for solar battery manufacturing. In addition, with application of the process to produce the ultra clear float semi-tempered glass, the production cost is low so as to reduce a production cost of the whole photovoltaic industry chain.

Owner:XINYI PHOTOVOLTAIC IND (ANHUI) HLDG CO LTD

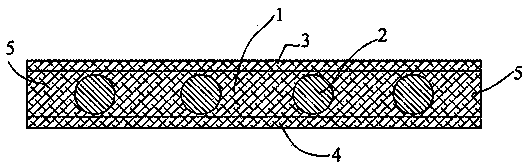

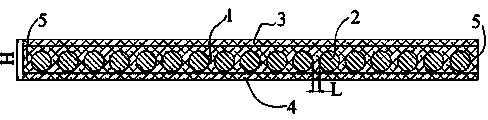

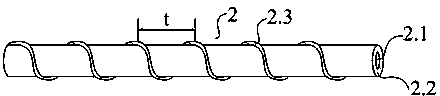

High-temperature-resistant dewaxing molecular sieve double-wall corrugated pipe and preparation method

InactiveCN104629147AIncrease stiffnessImprove flame retardant performanceRigid pipesMolecular sieveMicrosphere

The invention discloses a high-temperature-resistant dewaxing molecular sieve double-wall corrugated pipe and a preparation method. The high-temperature-resistant dewaxing molecular sieve double-wall corrugated pipe is prepared from the following raw materials in parts by weight: 80-86 parts of high-density polyethylene, 2-3 parts of POE plastic, 1-2 parts of octyl isothiazolone, 4-5 parts of flaming retarding master batch, 5-10 parts of master batch, 1-2 parts of tert-butyl aluminum benzoate, 2-4 parts of poly-4-methyl-1-amylene, and 5-10 parts of modified aluminum oxide hollow microspheres. The preparation method of the high-temperature-resistant dewaxing molecular sieve double-wall corrugated pipe comprises the following steps: stirring to disperse the raw materials in the formula for 5-10 minutes at the room temperature at the rotation speed of 100-200rpm, stirring at 90-100 DEG C, automatically cooling after being uniformly stirred, automatically feeding, extruding by using a single-screw extruder, pulling out a product from a forming machine, performing fixed-scale cutting by using a cutting machine, inspecting, and storing in a warehouse. The high-temperature-resistant dewaxing molecular sieve double-wall corrugated pipe has the beneficial effects that the problems that the mounting and use property and the drainage reliability can be affected as the ring stiffness of a polyethylene double-wall corrugated pipe at high temperature is degraded can be solved.

Owner:杭州波达塑料科技股份有限公司

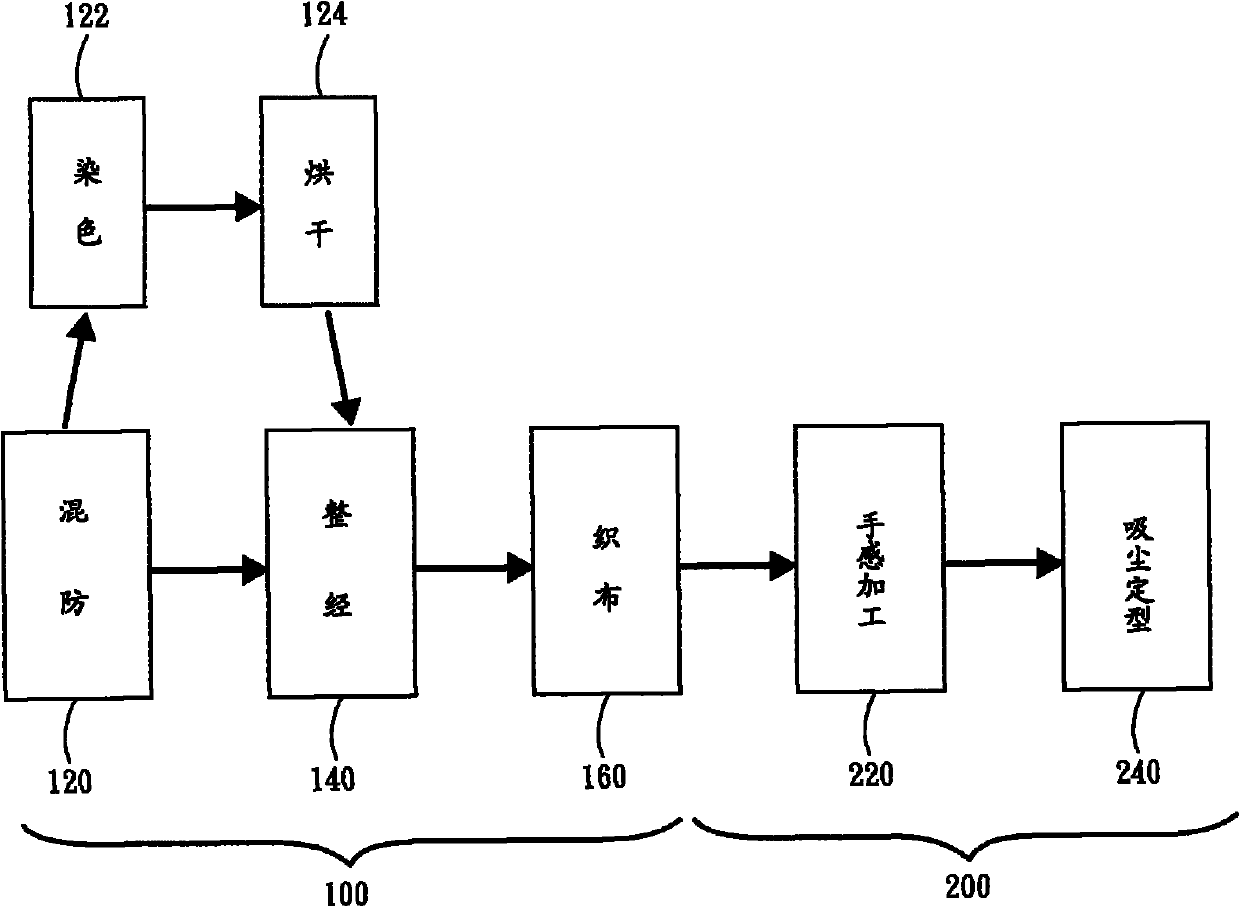

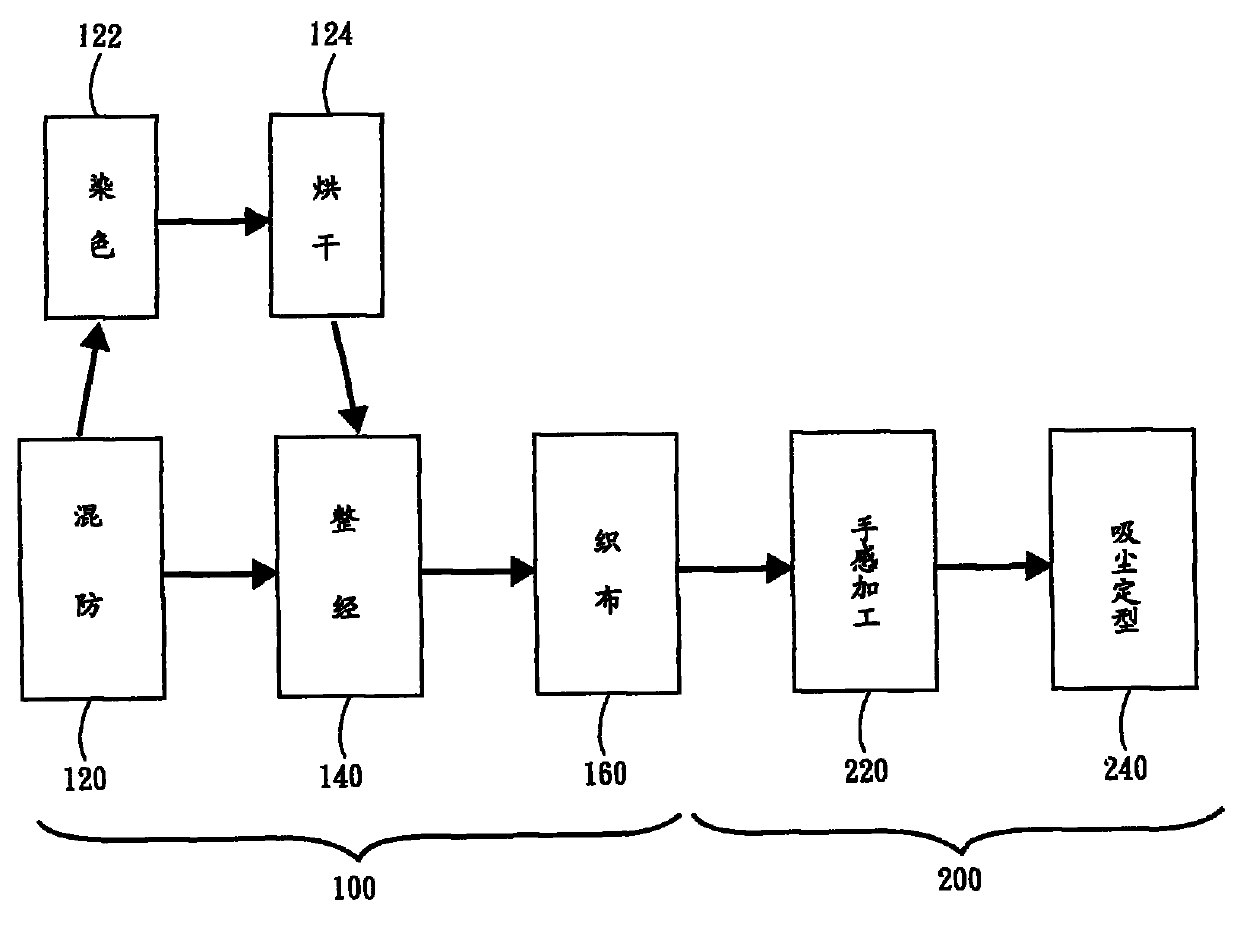

Environment-friendly high-flame-retarding blended conductive fabric and manufacturing process thereof

InactiveCN102199829AImprove flame retardant performanceNo environmental issuesFibre treatmentWoven fabricsYarnMetal fibers

The invention discloses an environment-friendly high-flame-retarding blended conductive fabric and a manufacturing process thereof, which are in accordance with safety standards for fabrics for air transportation. The environment-friendly high-flame-retarding blended conductive fabric comprises wool blended yarns and an environment-friendly flame retardant, wherein the wool blended yarns comprise wool yarns and non-wool yarns which may be artificial fibers or metal fibers; and the environment-friendly flame retardant comprises phosphates and nitrides and account for 5 to 30 percent of the weight of the environment-friendly high-flame-retarding blended conductive fabric. The manufacturing process comprises a weaving process and a finishing process of the wool blended yarns, wherein the finishing process comprises a step of adding the environment-friendly flame retardant which comprises the phosphates and nitrides and account for 5 to 30 percent of the weight of the wool blended yarns.

Owner:FUCHI TEXTILE

Combined type unreinforced thermal-insulating sandwich external wall slab and manufacturing method for inner laminate and outer laminate of same

ActiveCN102505800AWith insulationFlame retardantClimate change adaptationCeramic shaping apparatusFiberCrack resistance

The invention relates to a combined type unreinforced thermal-insulating sandwich external wall slab and a manufacturing method for an inner laminate and an outer laminate of the same in order to solve the problems of poor fireproof safety for the thermal insulating construction of an external wall, cracking resistance of a wall slab material, complex construction caused by the employment of a reinforced keel as well as large thickness of a surface layer and high self-weight of a wall slab caused by conventional connecting pieces. In the first scheme, one extruded sheets or waterproof rock wool bars are respectively arranged at two ends of a rock wool layer, the head of each first FRP (Fiber Reinforced Plastic) connecting piece is arranged in a first lug boss, the other end of the same is arranged at the outer part the an inner laminate after penetrating through a corresponding preserved hole and a second lug boss, the head of each second FRP connecting piece is arranged in the first lug boss, and the other end of the same is arranged in the second lug boss after penetrating the corresponding preserved hole. In the second scheme, cement, pulverized fuel ash, silver sand, swelling agent and defoaming agent are uniformly mixed in a mixing machine in sequence; and materials are discharged and molds are cast after adding water reducing agent, water and steel fiber into the mixture. The combined type unreinforced thermal-insulating sandwich external wall slab is applied to building field.

Owner:HARBIN INST OF TECH

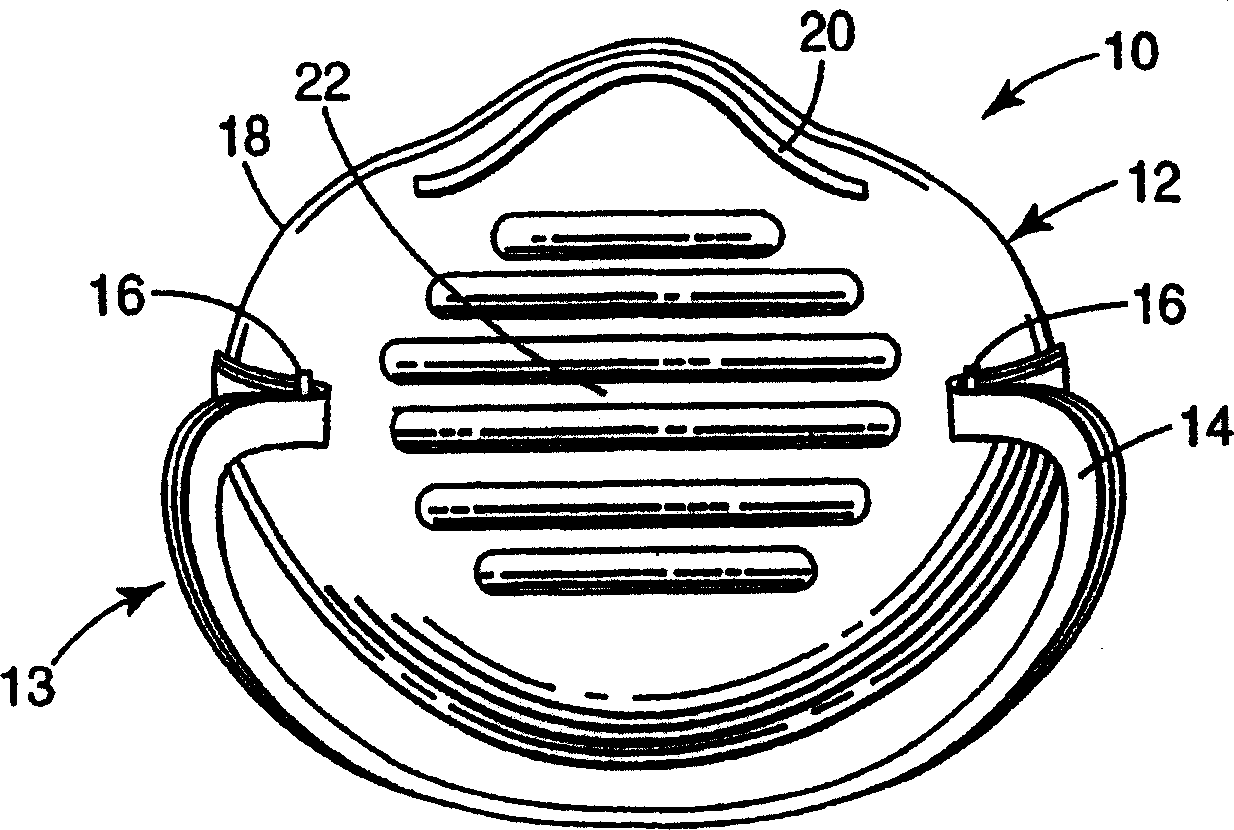

Crush resistant filtering face mask

Owner:3M INNOVATIVE PROPERTIES CO

Aluminum alloy formwork trapezoid cross section profile and unit formwork structure of aluminum alloy formwork

InactiveCN105421761AReasonable section structureSectional structure is clearSheets/panelsForming/stuttering elementsAbnormal shapedMachining

The invention discloses an aluminum alloy formwork trapezoid cross section profile and a unit formwork structure of an aluminum alloy formwork. The aluminum alloy formwork trapezoid cross section profile is an integrally-formed aluminum alloy abnormal-shaped plate and is composed of a groove body and a group of longitudinal reinforcing ribs, wherein the groove is formed by a rectangular panel and two opposite longitudinal side frames on the back face of the panel, and the longitudinal reinforcing ribs are evenly distributed at the bottom of the groove body. The unit formwork structure of the aluminum alloy formwork comprises the aluminum alloy formwork trapezoid cross section profile, transverse side frames, transverse reinforcing ribs and corner reinforcing blocks. The aluminum alloy formwork trapezoid cross section profile and the unit formwork structure of the aluminum alloy formwork, the structure is clear, forming is easy, later-period machining amount of the formwork is small, the machining cost is reduced, it can be ensured that the formwork is low in weight, safe to use and long in service life, the construction efficiency is improved, standardized, systematic and industrial production is easier, formwork assembly and disassembly are fast, easy and convenient, installation is firm and reliable, the construction efficiency is high, and the construction cost is low.

Owner:CHINA STATE CONSTRUCTION ENGINEERING CORPORATION +1

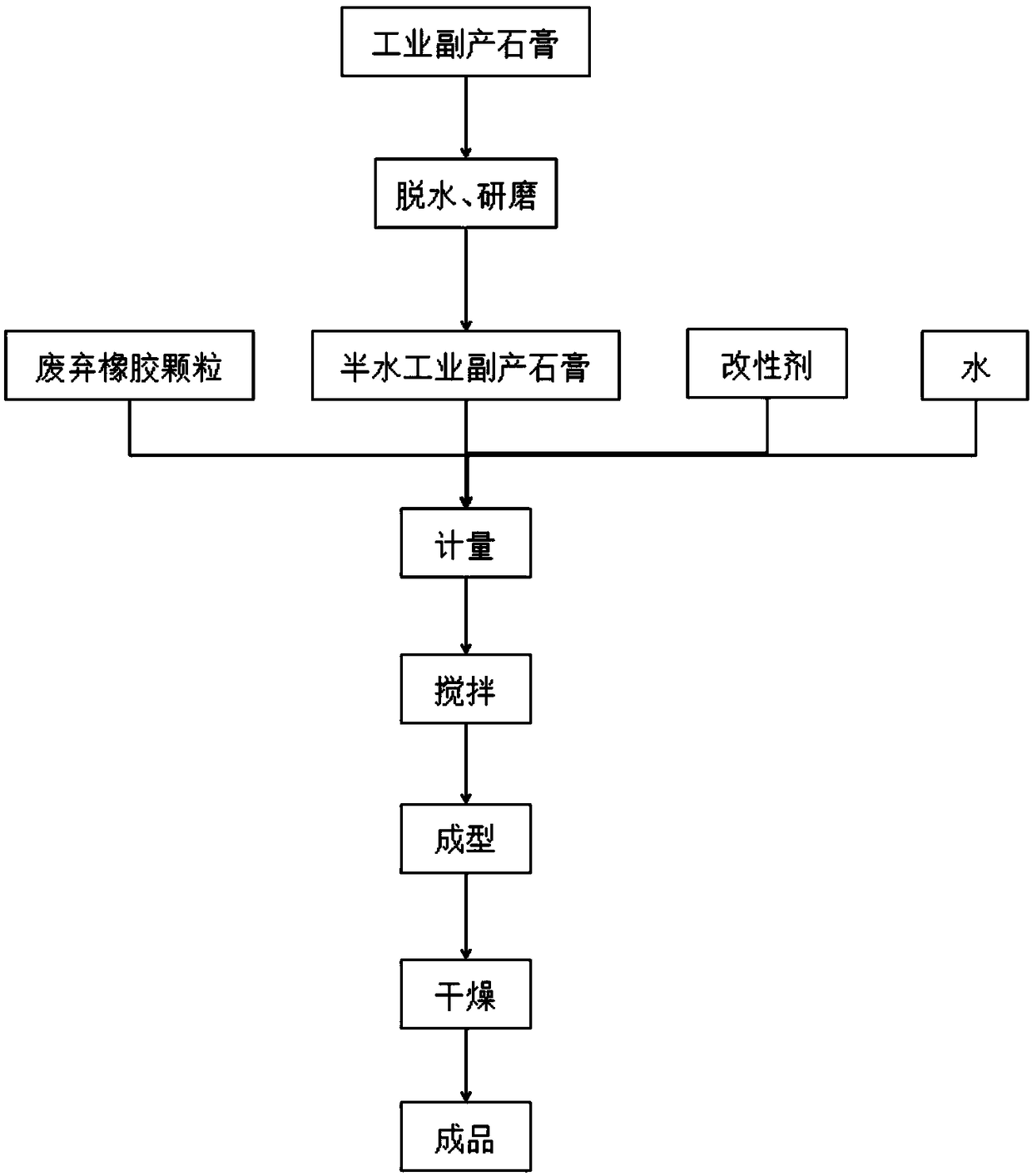

Industrial byproduct gypsum waste rubber particle wall body material and preparation method thereof

InactiveCN109265118AImprove sound insulation performanceImprove impact resistanceGranularityWaste rubber

The invention discloses an industrial byproduct gypsum waste rubber particle wall body material and a preparation method thereof, which belongs to the technical field of construction materials. The industrial byproduct gypsum waste rubber particle wall body material is prepared from the following raw materials by weight percent: 50 to 55 percent of semi-hydrate industrial byproduct gypsum, 3 to 12percent of waste rubber particles, 2 to 5 percent of modifier, and 35 to 40 percent of water. The preparation method comprises the following steps: heating and dehydrating industrial byproduct gypsumto form semi-hydrate industrial byproduct gypsum, grinding the semi-hydrate industrial byproduct gypsum into powder with a granularity of 0.074 to 0.109 mm, uniformly mixing and stirring the semi-hydrate industrial byproduct gypsum powder, waste rubber particles, modifier and water, pouring the mixture into a mold, naturally drying, and removing the mold, thus obtaining the industrial byproduct gypsum waste rubber particle wall body material. The hydration cementing effect of the treated semi-hydrate industrial byproduct gypsum is used for improving the strength of the wall body material, andthe waste rubber particles are used for reducing the unit weight of the wall body material and improving the sound insulation of a wall body.

Owner:KUNMING UNIV OF SCI & TECH

Caragana composite artificial plate and preparation method

The present invention relates to one kind of composite intermediate peashrub board and its making process. The composite intermediate peashrub board is made with intermediate peashrub in 45-90 weight portions, fly ash in 5-35 weight portions, adhesive in 5-20 weight portions, and initiator in the amount of 0.5-3.5 wt% of the adhesive, and through the steps of cutting intermediate peashrub, dedusting, screening, peeling, milling, applying glue, drying, spreading, pre-pressing and hot pressing. The making process is simple and pollution-free, and uses no-formaldehyde adhesive. The produced composite intermediate peashrub board is environment friendly, water-proof, and suitable for in producing furniture, office equipment, floor board, etc.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI +1

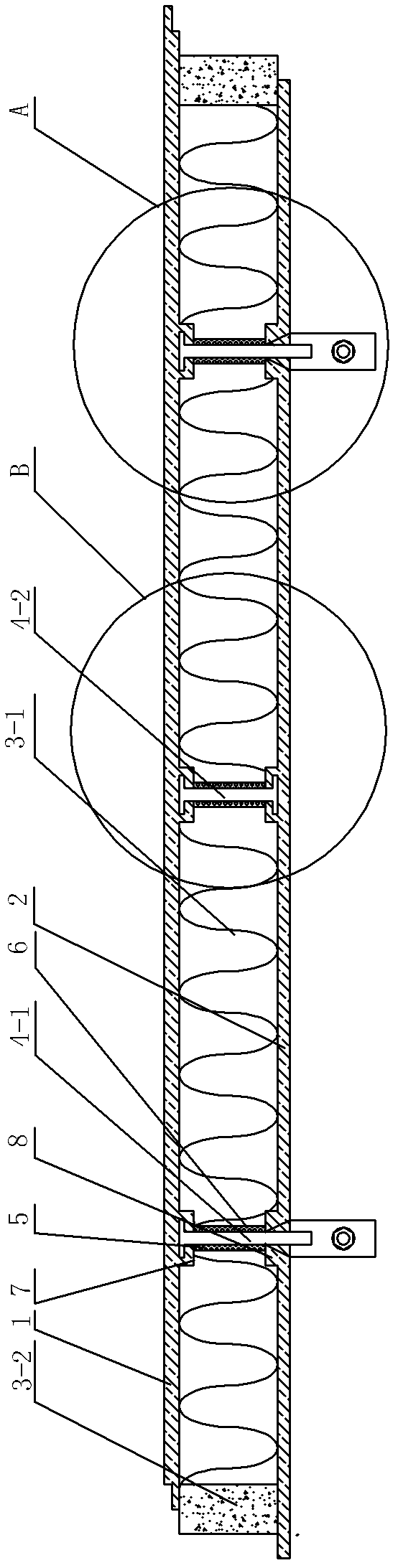

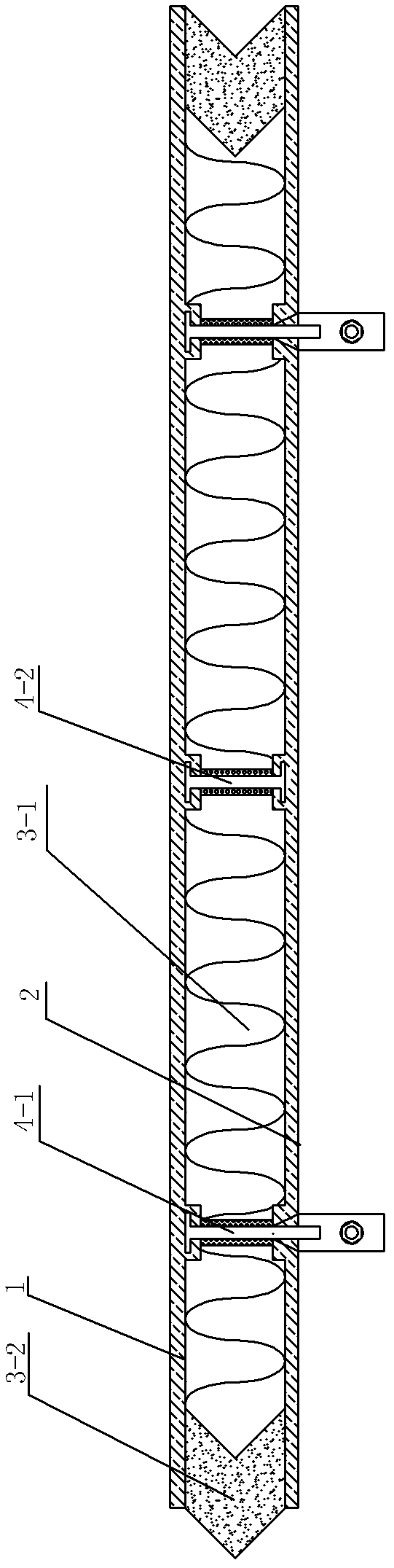

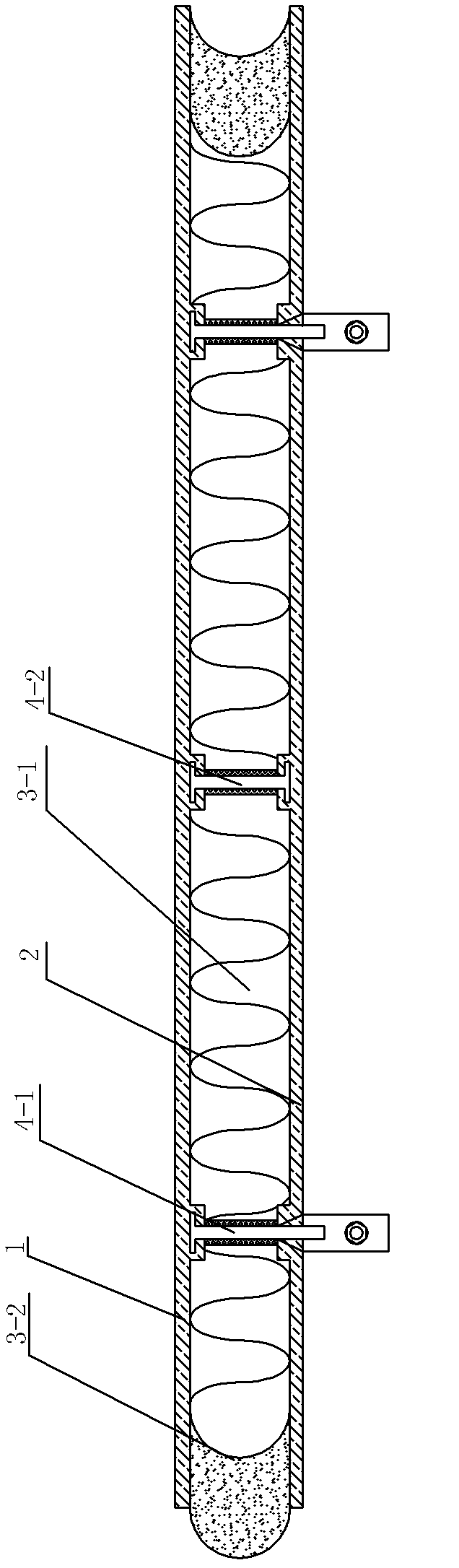

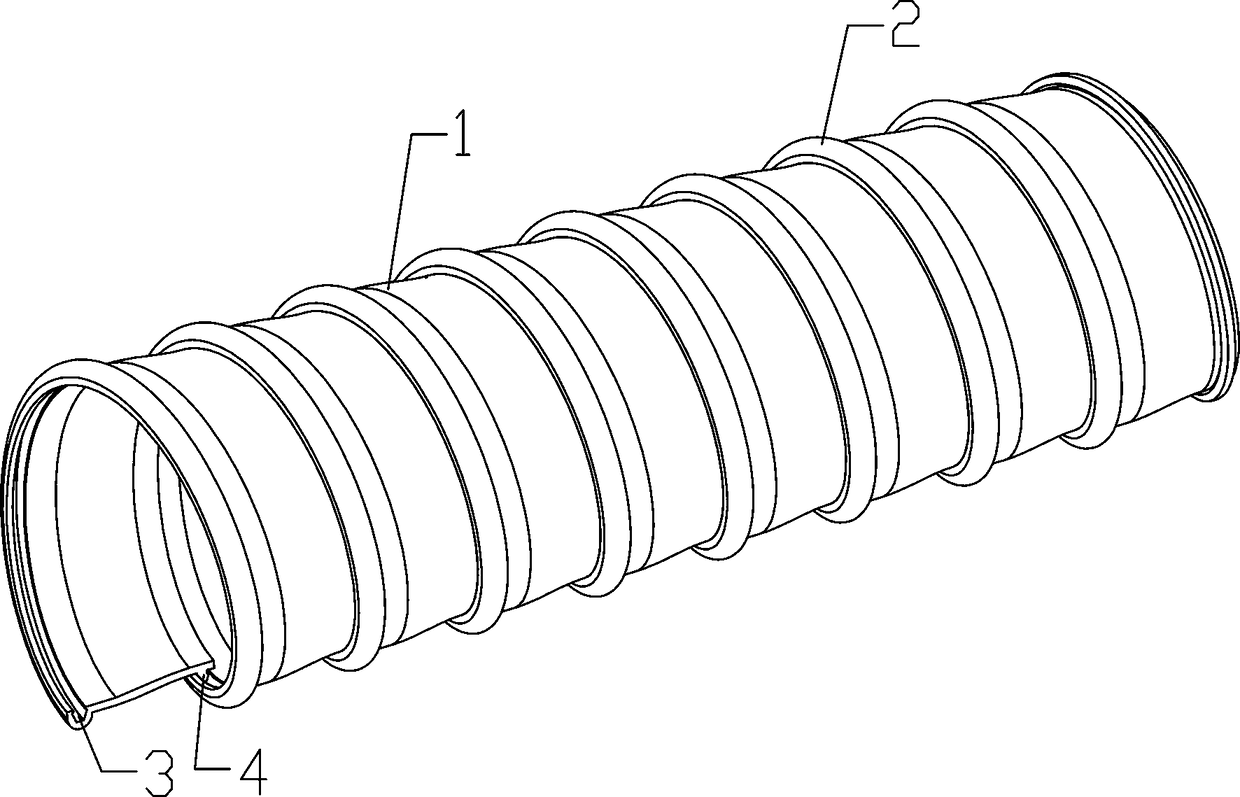

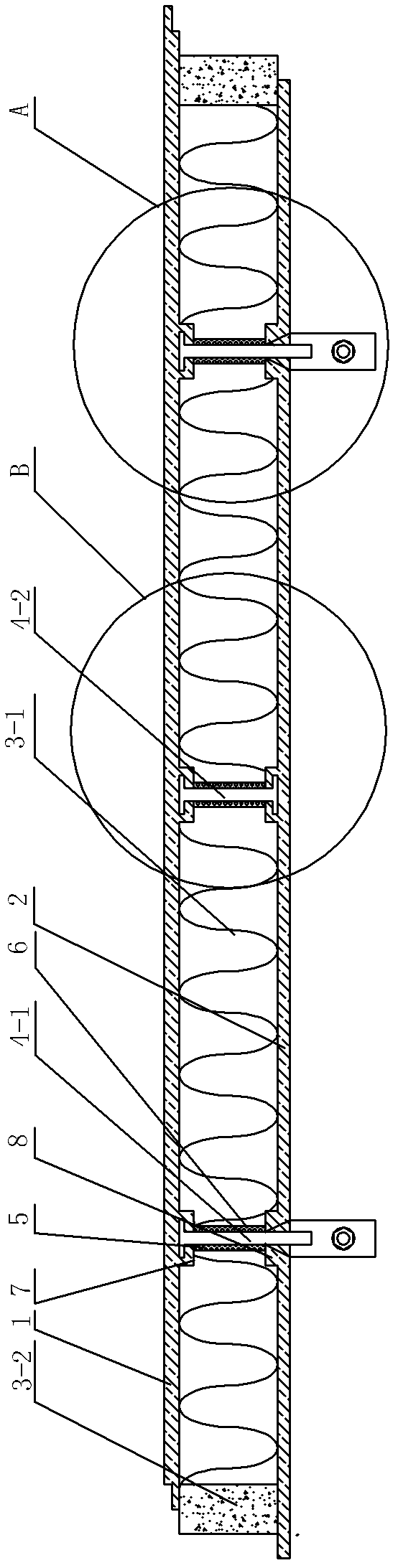

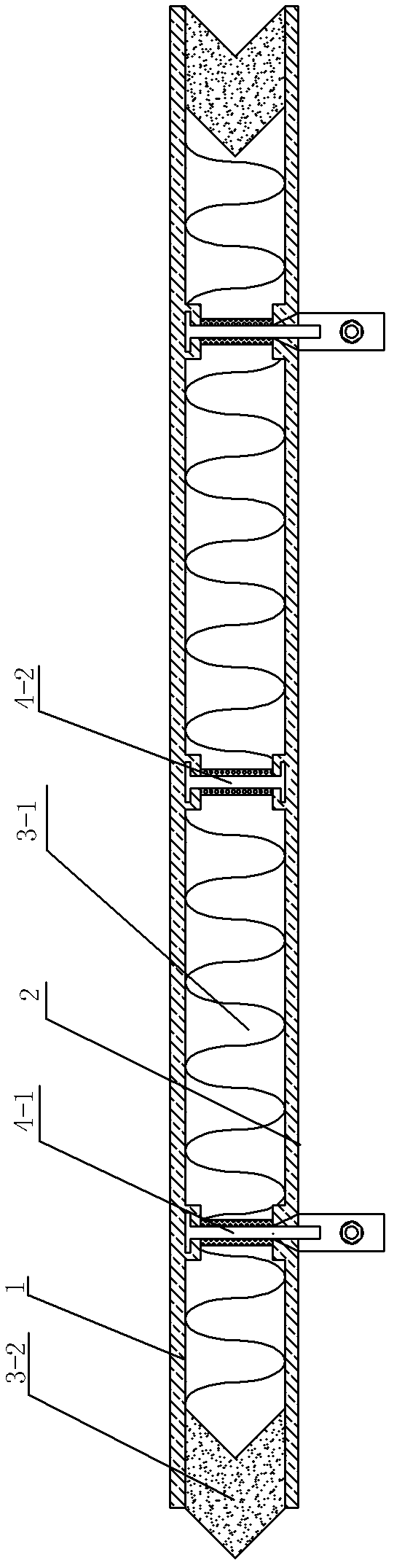

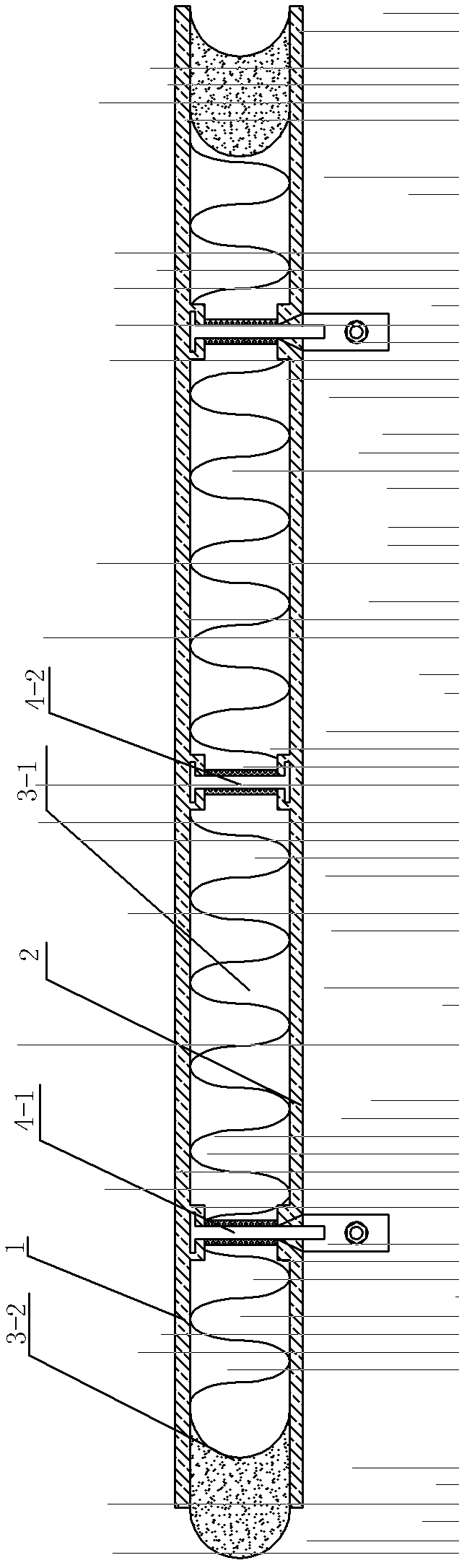

Repair tube for overhead transmission lines

InactiveCN109119962AIncrease creepage distanceImprove the insulation levelOverhead installationTransmission lineTransportation cost

The invention discloses a repair tube for overhead transmission lines. The repair tube for overhead transmission lines is characterized in that the repair tube is formed by attaching the inner surfaceof a strip-shaped insulating portion to the outer surface thereof by winding; two ends of the outer surface of the strip-shaped insulating portion are respectively provided with a reverse rib and a raised strip extending in the longitudinal direction; the reverse rib and the raised strip are arranged in parallel; a groove matching the reverse rib is formed at the location, opposite to the raisedstrip, on the inner surface of the strip-shaped insulating portion; when the strip-shaped insulating portion is wound into a repair tube, the reverse rib is embedded in the groove; the surface of thegroove is also provided with a shielding layer; and an adhesive layer is arranged between the reverse rib and the groove; The repair tube for overhead transmission lines is long-strip-shaped before application, and can become cylindrical through self-spiral, so that the diameter of the repair tube can be adjusted, and the overhead transmission lines with different wire diameters can be repaired only by means of the repair tube, and the repair tube is convenient to carry by a line operation worker, thus reducing the transportation cost. The repair tube for overhead transmission lines can fix and buckle the strip-shaped insulating portion which becomes cylindrical through self-spiral by means of the reverse rib and the groove, thus being easy for operation, and being high safety.

Owner:STATE GRID E COMMERCE CO LTD +1

Combined type unreinforced thermal-insulating sandwich external wall slab and manufacturing method for inner laminate and outer laminate of same

ActiveCN102505800BWith insulationFlame retardantClimate change adaptationCeramic shaping apparatusFiberCrack resistance

Owner:HARBIN INST OF TECH

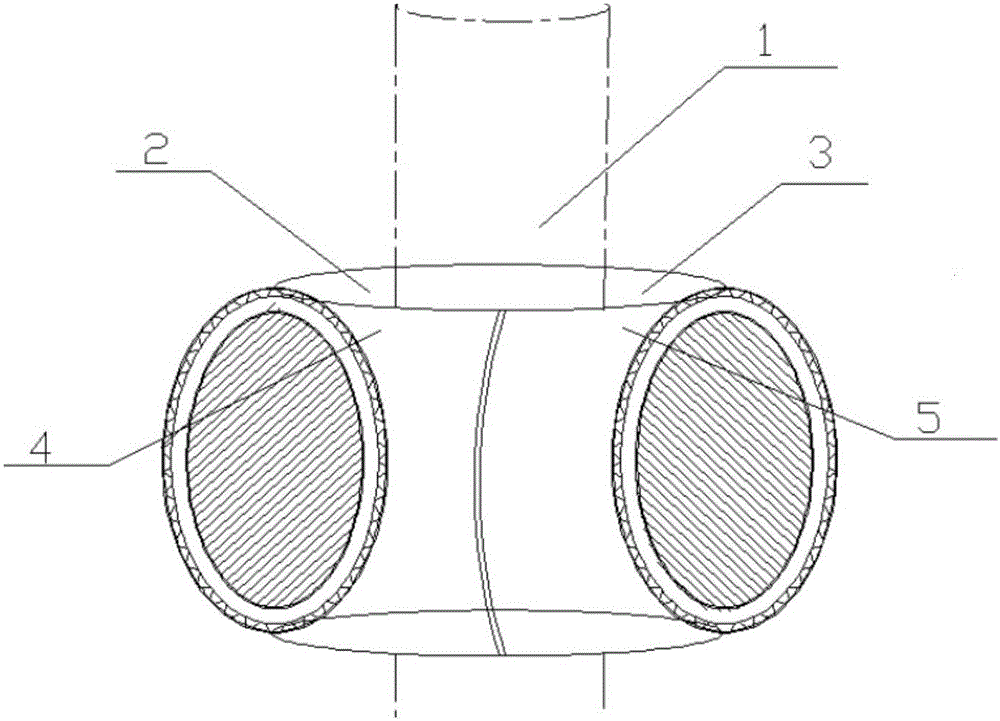

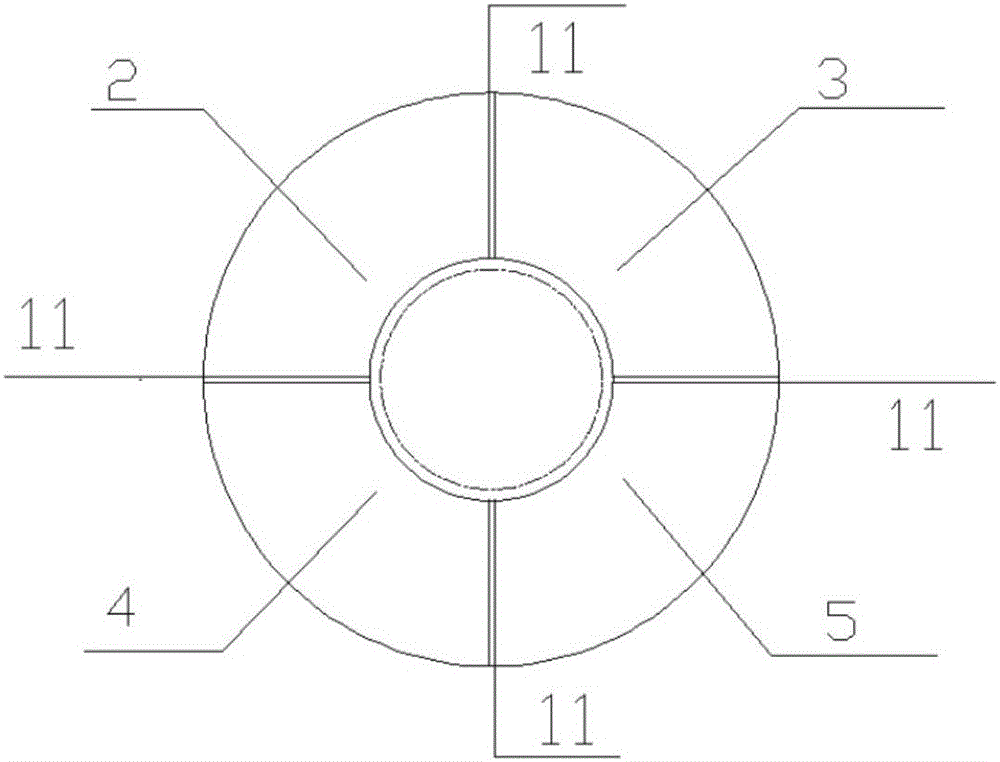

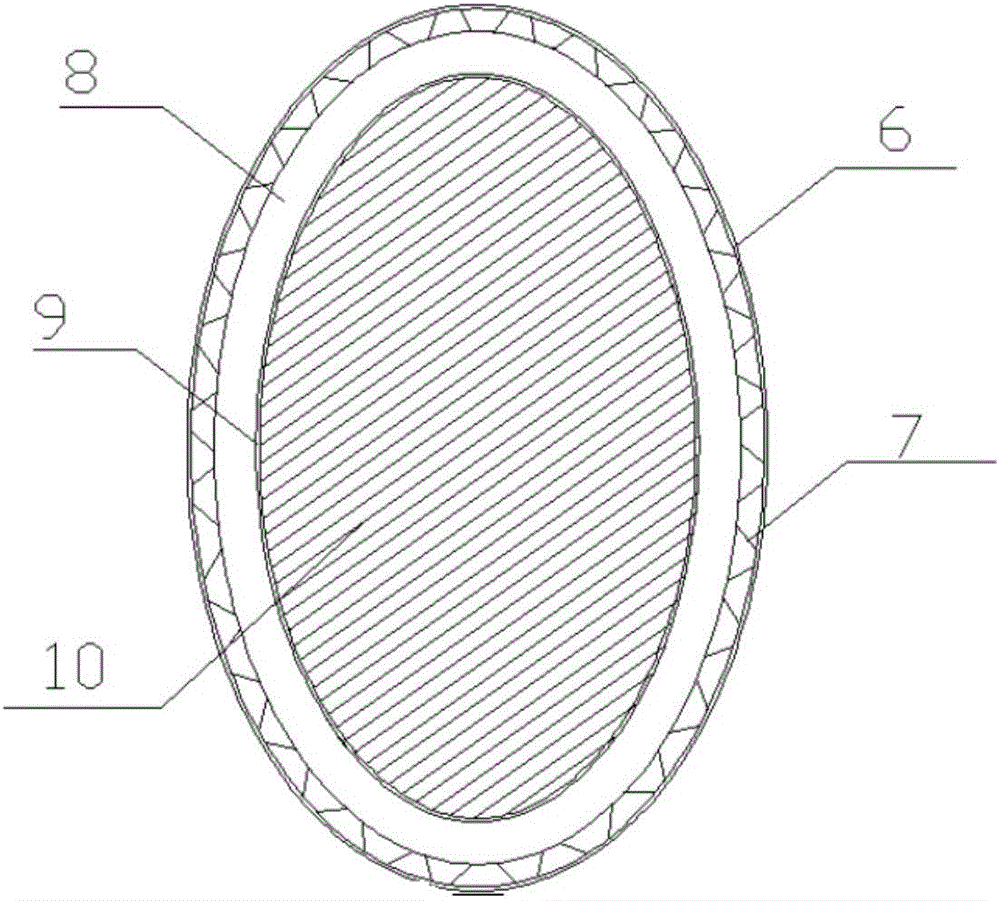

Self-floating collision prevention device based on composite materials

InactiveCN105908678AGood mechanical propertiesStable in natureClimate change adaptationShipping equipmentPolyurethane elastomerInterior space

The invention discloses a self-floating collision prevention device based on composite materials; and the device coasts a stand column of a marine structure, and floats up and down along with a water level. The device is characterized by forming a ring body by multiple connected collision prevention units; the cross sections of the collision prevention units are fan rings, and the longitudinal sections are ellipses; and the collision prevention units are formed by glass fiber resins, corrugated sandwich steel plates, polyurethane elastomers, inner-layer steel plates and polyurethane foam multilayer composite materials from edge to internal in sequence, wherein an internal space formed by the inner-layer steel plates is filled with polyurethane foams. The self-floating collision prevention device is stable in water property, resistant in corrosion, excellent in impact resistance, and green and environment-friendly.

Owner:JIANGSU UNIV OF SCI & TECH

High-hardness high-tenacity soft door seal magnetic stripe

InactiveCN108399993AHigh hardnessHigh hardness and high toughnessMagnetic materialsFerrite powderEngineering

The invention discloses a high-hardness high-tenacity soft door seal magnetic stripe. The high-hardness high-tenacity soft magnetic stripe is characterized by comprising the following materials in parts by weight: 100 parts of ferrite powder, 5-10 parts of chlorinated polyethylene, 1-5 parts of polyethylene, 0.5-1 part of a stabilizing agent, and 0.5-1 part of a lubricating agent. The refrigeratordoor seal magnetic stripe disclosed by the invention is high in hardness and tenacity, good in product stability, safe and reliable to use, environment-friendly and nontoxic; the relatively high hardness is kept in a high temperature environment; after being folded in half, the door seal magnetic stripe cannot be broken; the door seal magnetic stripe is relatively low in unit weight, low in cost,good in tensile property, relatively uniform and steady in elongation and good in dimensional homogeneity; the severe contraction problem can be avoided; and the material technology in the inventionis not limited for manufacturing the refrigerator door seal magnetic stripe, and also can be used for manufacturing other sheet, round roller, square rubber magnetic-plastic products.

Owner:ANHUI HIGASKET PLASTICS CO LTD

Ultra-thin ultra-white float solar cell glass manufacturing process and its products

ActiveCN103253849BHigh light transmittanceReduce reflectivityGlass tempering apparatusPhotovoltaic energy generationPhotovoltaic industryEngineering

The invention belongs to the technical field of special glass production, and provides an ultrathin ultra clear float solar battery glass production process and a product thereof. The process comprises the following steps: (1) preparing raw materials, (2) feeding and melting, (3) carrying out clarification, (4) carrying out homogenization, (5) carrying out tin stripping molding, (6) annealing, and (7) cutting. With the ultrathin ultra clear float solar battery glass production process, ultrathin ultra clear float solar battery glass with a thickness of 2.0-3.0 mm can be produced, wherein the glass has characteristics of high transmittance, low reflectivity and light unit weight, and is applicable for photovoltaic industry to be adopted as a photoelectric conversion substrate and a light-heat conversion panel so as to be used for solar battery manufacturing. In addition, with application of the process to produce the ultrathin ultra clear float solar battery glass, the production cost is low so as to reduce a production cost of the whole photovoltaic industry chain.

Owner:XINYI PHOTOVOLTAIC IND (ANHUI) HLDG CO LTD

Power grid transmission line

InactiveCN108091428AImprove toughnessLight weight unitClimate change adaptationPower cables for overhead applicationEpoxyConductive polymer

A power grid transmission line is composed of a carbon fiber composite core and at least one conductive outer layer formed by winding and stranding more than four conductive metal wires having the tile-shaped cross section, the carbon fiber composite core is composed of a carbon fiber central layer, aramid fibers coating the carbon fiber central layer and an epoxy resin layer containing modified graphene; and the modified graphene is subjected to surface modification by adopting polyurethane. The transmission line is longer in service life, the unit weight of the cable is reduced, and the distance between the towers in the conveying process can be increased; the toughness of the carbon fiber composite core is improved, the rigidity is reduced, and the curl performance of the carbon fiber composite core is improved.

Owner:RONGCHENG POWER SUPPLY CO STATE GRID SHANDONG ELECTRIC POWER CO +1

Environment-friendly decorative picture wallpaper

ActiveCN105908576AImprove performanceFacilitate cross-linkingSpecial paperPaper/cardboardSurface layerCarrageenan

The invention relates to a building decoration material, in particular to environment-friendly decorative picture wallpaper which comprises a decorative picture surface layer, a waterproof layer and an adhesive bottom layer. The decorative picture surface layer is a paper decorative picture and is formed by processing crude paper. The waterproof layer is formed by coating an adhesion waterproof material formed by adding a waterproof agent to carrageenan. The adhesive bottom layer is anti-mildew and antibacterial non-woven paper processed by a dig solution. The obtained environment-friendly decorative picture wallpaper has the advantages of being environmentally friendly, capable of optimizing the environment, simple in construction, low in cost, bright and stable in color, simple in use method, friendly to the environment and the like and has good market application prospects.

Owner:杭州唯曦科技有限公司

Light-type high-strength steel wire rope core conveyor belt

The invention provides a light-type high-strength steel wire rope core conveyor belt and solves the problems that a steel wire rope of a steel wire rope core is great if an existing steel wire rope core conveyor belt needs to achieve certain high strength so that the thickness of the conveyor belt is great and the weight is heavy. The light-type high-strength steel wire rope core conveyor belt comprises core rubber, the steel wire rope core, upper covering rubber, lower covering rubber and edge rubber; and the steel wire rope of the steel wire rope core comprises a rope core and a plurality of threads of steel wires A, and further comprises a thread of a steel wire B which is spirally entwisted at the periphery of the plurality of threads of steel wires A around the length direction of the steel wire rope. According to the conveyor belt, the strength of the single steel wire rope is enhanced and the diameter is reduced; the tight arrangement of the steel wire ropes in the steel wire rope core can be realized; compared with the existing conveyor belt, the conveyor belt with the same belt width and the same strength, the quantity of the steel wire ropes is greatly increased so that the thickness of the conveyor belt is greatly thinned and the unit weight is greatly reduced; and all performance parameters of the conveyor belt are optimized and the material cost and the transportation cost are saved.

Owner:QINGDAO HUAXIA RUBBER IND

Glass manufacturing process for ultra-clear float solar cells

ActiveCN103253864BHigh light transmittanceReduce reflectivityGlass severing apparatusPhotovoltaic industryEngineering

The invention is applicable to the technical field of special glass production, and provides a glass manufacturing process for ultra-clear float solar cells and its products. The process includes the following steps: (1) raw material batching; (2) feeding and melting; (3) Clarification; (4) homogenization; (5) tin annealing; (6) annealing; (7) cutting. The ultra-clear float solar cell glass manufacturing process provided by the present invention can produce ultra-clear float solar cell glass with a thickness of 2.5mm. This kind of glass has high light transmittance, low reflectivity and light unit weight, and is very suitable It is used in the photovoltaic industry as a substrate for photoelectric conversion and a panel of a photothermal conversion system for the manufacture of solar cells; in addition, the production cost of ultra-clear float solar cell glass is low by using the process of the present invention, thereby also reducing the overall cost. The production cost of the photovoltaic industry chain.

Owner:XINYI PHOTOVOLTAIC IND (ANHUI) HLDG CO LTD

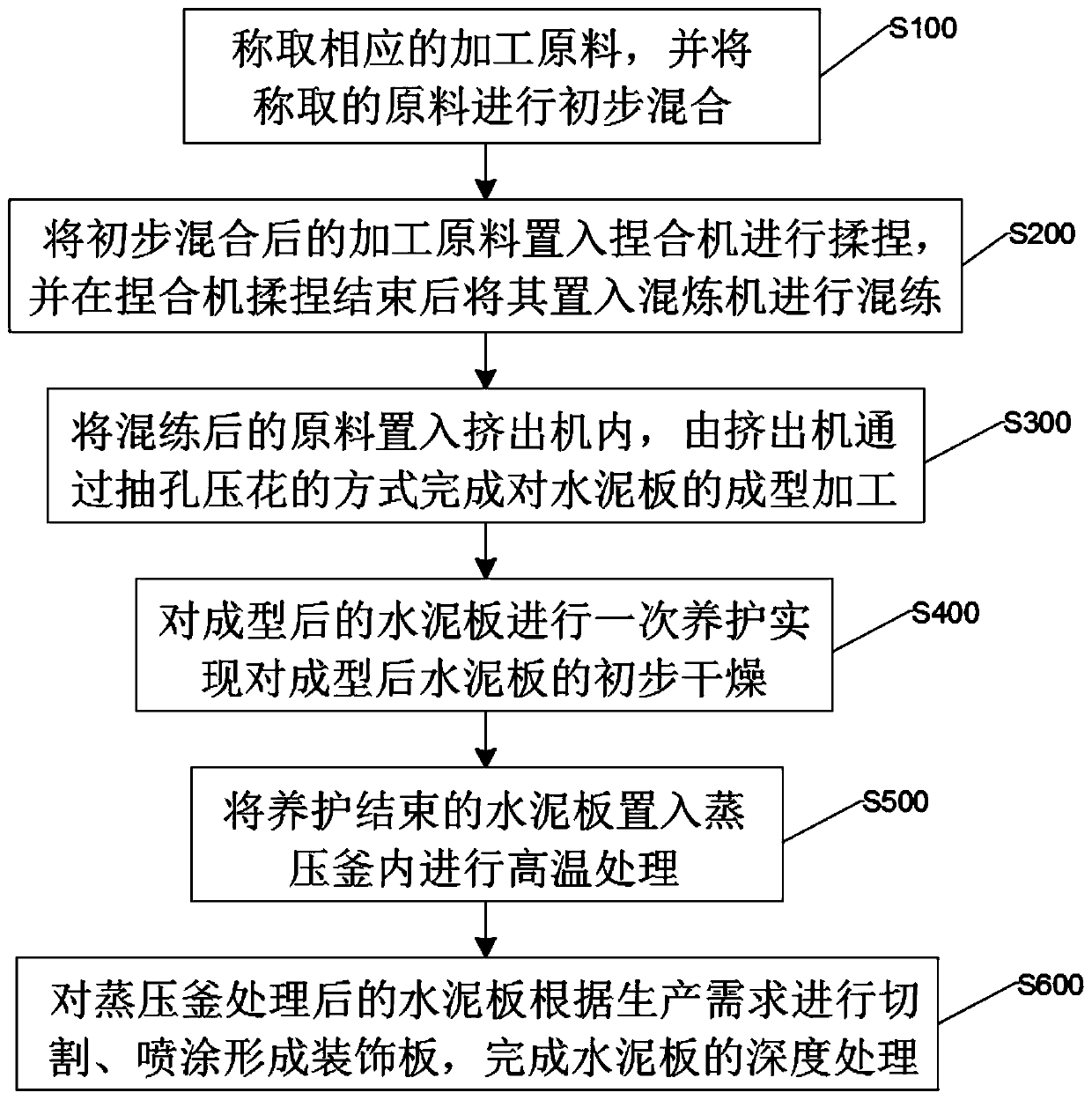

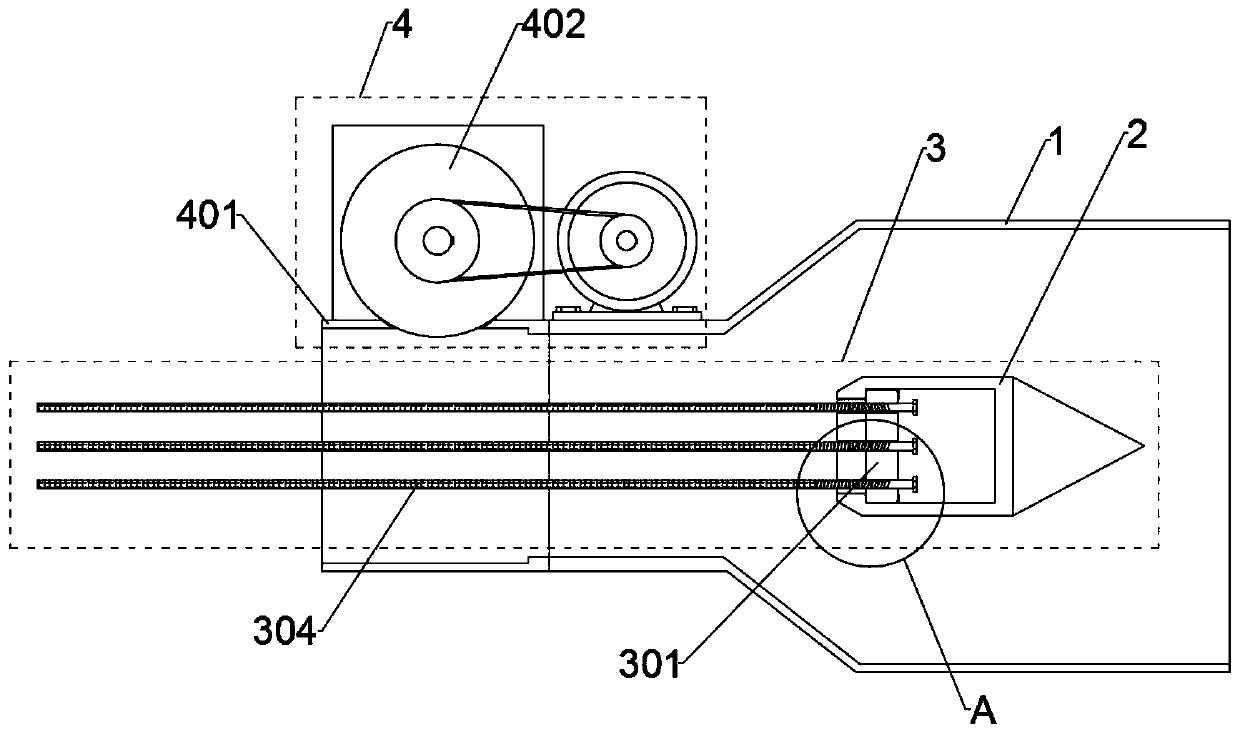

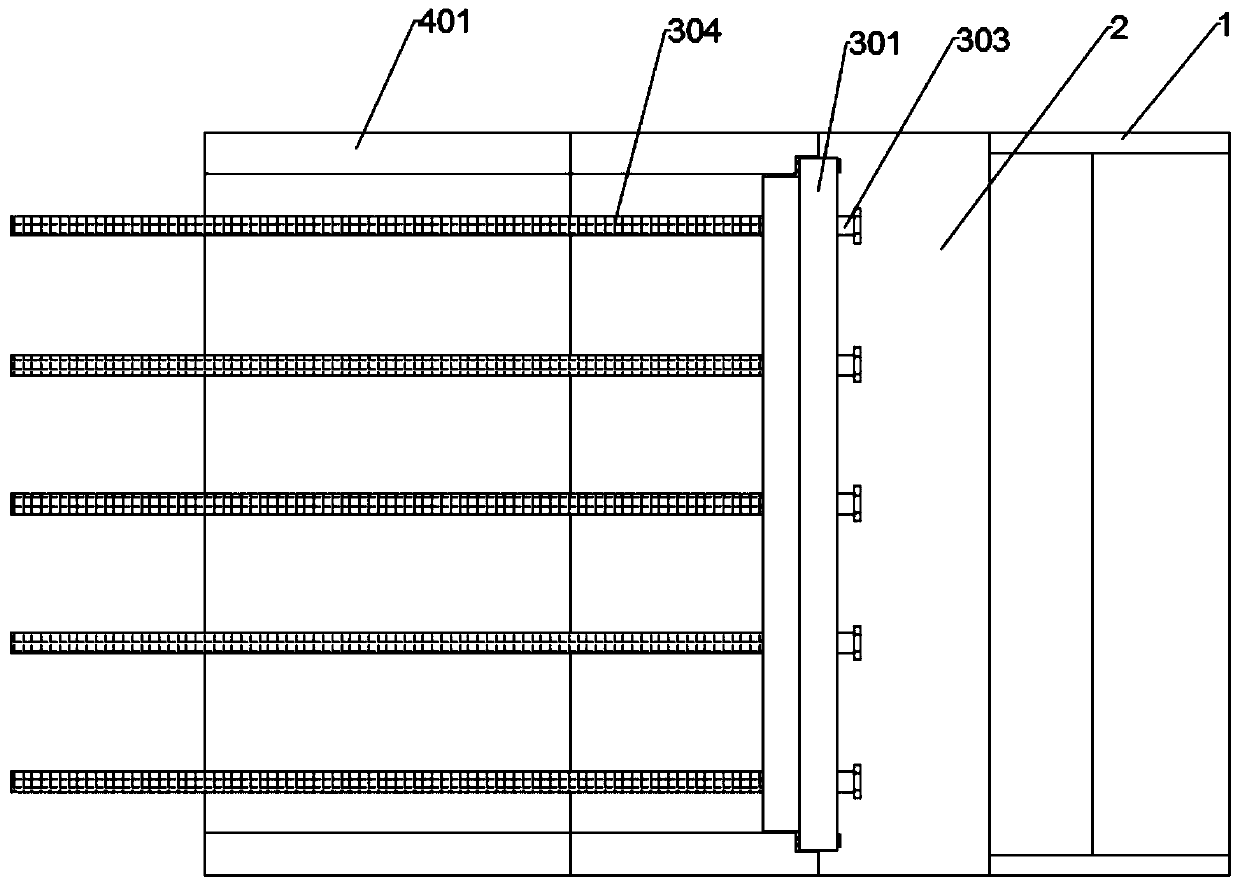

Production and manufacturing method and device for cement board formed by extrusion hole drawing and embossing

InactiveCN110640889AMeeting Diversity RequirementsLight weight unitCeramic shaping plantsKneader reactorCement board

The embodiment of the invention discloses a production and manufacturing method for a cement board formed by extrusion hole drawing and embossing. The production and manufacturing method comprises thefollowing steps: machining raw materials are weighed to be preliminarily mixed, the preliminarily-mixed raw materials are kneaded through a kneading machine, after kneading is completed, the raw materials are placed into a mixing mill to be subjected to mixing milling, the raw materials subjected to mixing milling are placed into an extrusion machine, and forming machining of the cement board iscompleted by the extrusion machine in hole-drawing and embossing modes. The production and manufacturing device for the cement board formed by extrusion hole drawing and embossing comprises a die headplaced on the extrusion machine and used for conducting forming machining on the raw materials, and a fixed sleeve penetrating through the die head; and the end, away from the extrusion machine, of the fixed sleeve is provided with a hole-drawing assembly used for conducting hole drawing on the cement board, and an embossing assembly corresponding to the hole-drawing assembly is further arrangedon the die head. Through the arranged hole-drawing assembly, a drawn hole can be supported by a fixing rod to emboss the surface of the cement board when embossing is conducted through the embossing assembly, collapse of the drawn hole can be avoided in the embossing process, and embossing is more convenient.

Owner:北新绿色住宅有限公司 +1

Prefabricated fabricated ultra-high-performance concrete flue plate structure

PendingCN107100661AAchieve productionImprove product qualityTunnel/mines ventillationArchitectural engineeringFlue

The invention discloses a prefabricated fabricated ultra-high-performance concrete flue plate structure. The structure comprises a bottom plate, a left side plate and a right side plate, and an inversed-U-shaped structure is defined by the bottom plate, the left side plate and the right side plate; and a plurality of vent holes are formed in the bottom plate, a plurality of fastening pieces fixedly connected with a flue top plate are arranged at the upper edges of the left side plate and the right side plate, and the bottom plate, the left side plate and the right side plate are prefabricated and integrally formed through ultra-high-performance concrete. The prefabricated fabricated ultra-high-performance concrete flue plate structure has the beneficial effects that a factory fabrication mode is adopted, production of flue plates of various sizes can be achieved, and the factory fabrication mode is obviously superior to a cast-in-place mode in product quality; and by adoption of an on-site splicing mode, the working procedures such as on-site formwork erecting, pouring, curing and formwork removal are omitted, and construction efficiency is greatly improved.

Owner:SHANGHAI URBAN CONSTR MATERIAL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com