Power grid transmission line

A technology for power transmission lines and power grids, applied in the direction of power cables, power cables for overhead applications, circuits, etc., can solve the problems of increasing the weight of composite material mandrels, increasing the sag of overhead cables, and high density of glass fibers to achieve reduction Effect of unit weight, reduction of stiffness, and improvement of toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

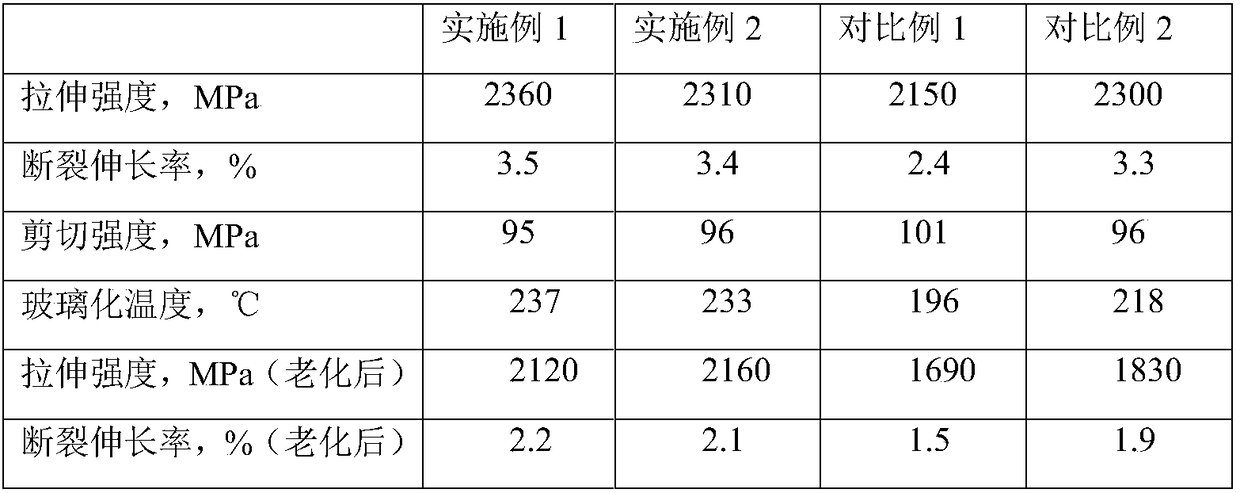

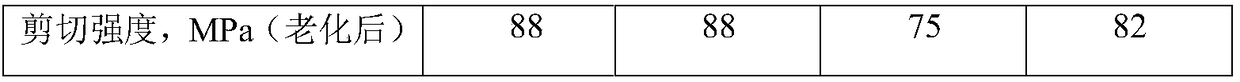

Embodiment 1

[0027] Power grid transmission line, comprising a carbon fiber composite core and at least one layer of conductive outer layer formed by twisting and twisting more than six aluminum wires with a tile-shaped cross section; the carbon fiber composite core is composed of a carbon fiber center layer and a carbon fiber center layer The aramid fibers on the layer and the epoxy resin layer containing modified graphene are composed; the modified graphene is surface-modified by polyurethane.

[0028] The preparation method of the epoxy resin of modified graphene comprises the following steps: 1) graphene is dispersed in deionized water with ultrasonic wave, adjusts the pH value to 11, adds N,N-dimethylformamide and hydrazine hydrate, reacts After 12h, the reaction product obtained is washed to neutrality and dried to obtain a modified graphene precursor, wherein the mass ratio of graphene, amide compound and hydrazine hydrate is 1:300:10; 2) polyurethane is melted, and Add modified gra...

Embodiment 2

[0030] The power grid transmission line is composed of a carbon fiber composite core and at least one layer of conductive outer layer formed by twisting around and twisting more than four aluminum wires with a tile-shaped cross-section; the carbon fiber composite core is composed of a carbon fiber center layer and a carbon fiber center layer The aramid fibers on the layer and the epoxy resin layer containing modified graphene are composed; the modified graphene is surface-modified by polyurethane.

[0031] The preparation method of the epoxy resin comprising modified graphene comprises the following steps: 1) graphene is dispersed in deionized water by ultrasonic waves, the pH value is adjusted to 12, succinimide and hydrazine hydrate are added, after reacting for 24h, The obtained reaction product is washed to neutrality and dried to obtain a modified graphene precursor, wherein the mass ratio of graphene, amide compound and hydrazine hydrate is 1:800:15; 2) melt the polyurethan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com