Needling through carrier sheets to form loops

A sheet and carrier technology, applied in the direction of acupuncture machines, synthetic resin layered products, and other household appliances, can solve problems that affect the overall performance of ring materials or the bearing capacity of ring products, dimensional stability and processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

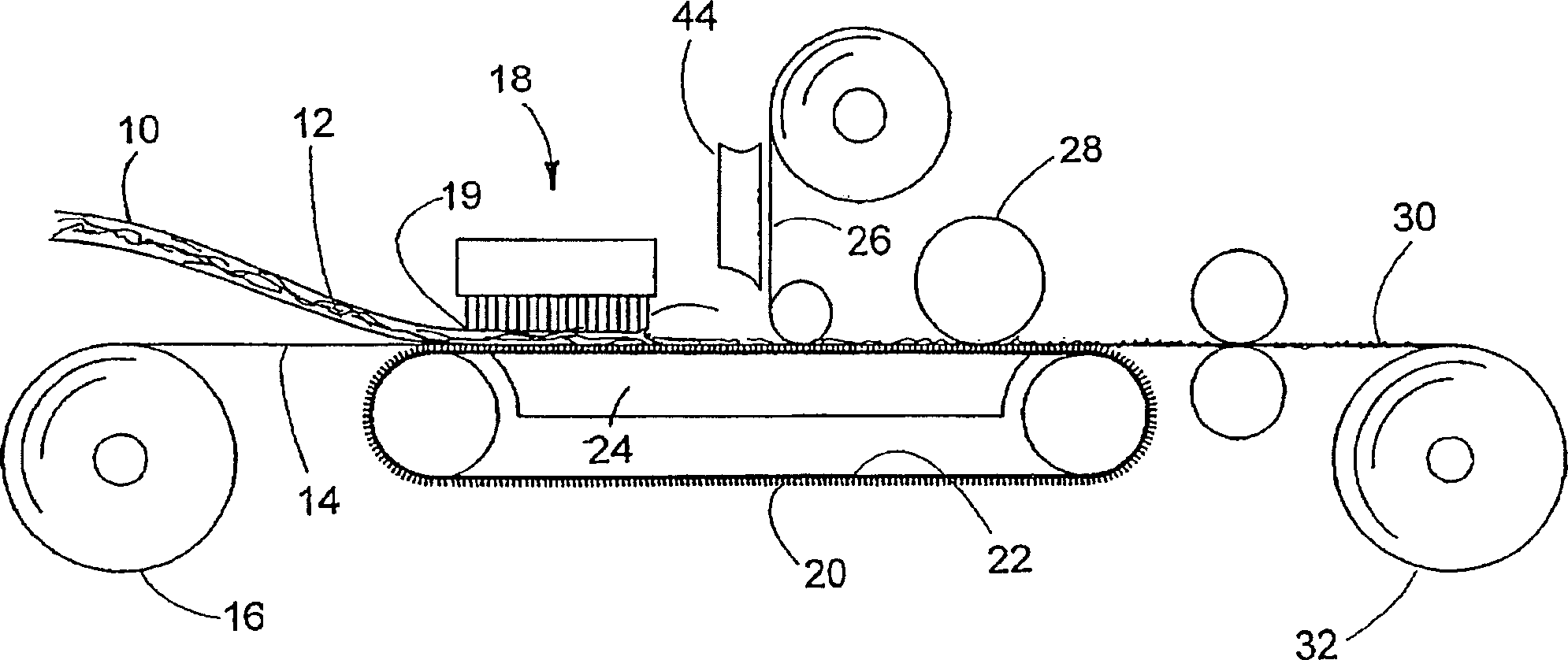

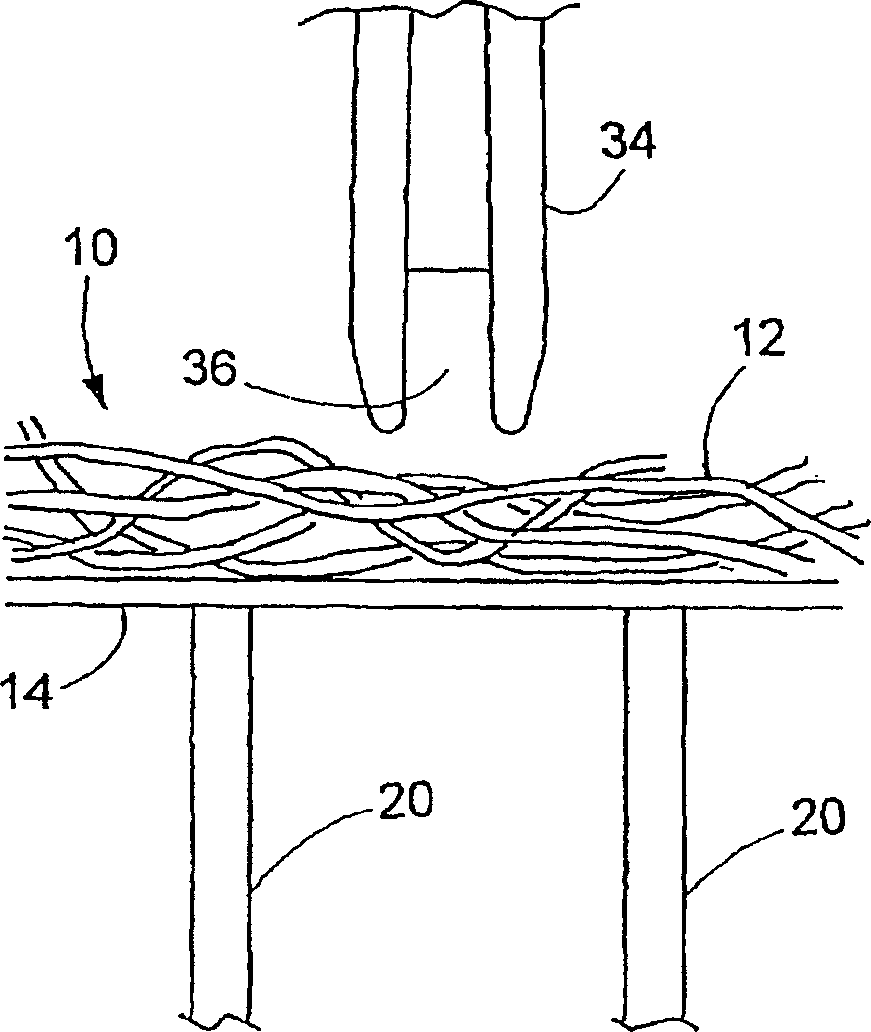

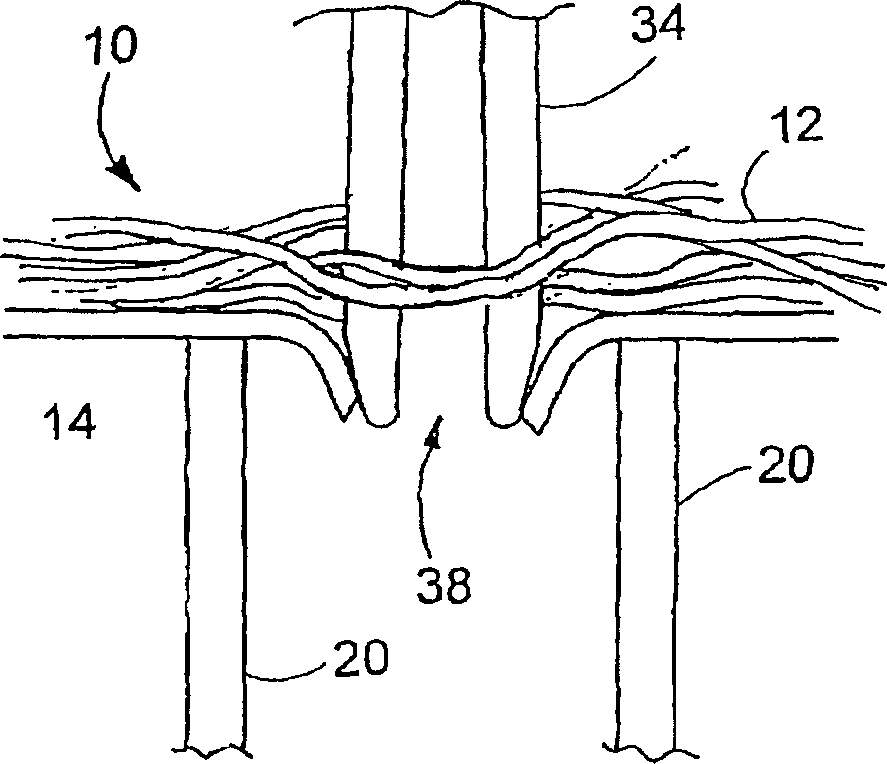

[0091] First, according to figure 1 , as the film sheet 14 is continuously unwound from the spool 16, the carded layer 10 of fibers 12 is placed over it. The fibers 12 and film 14 are then fed to a needling station 18 where the film is pierced from the fiber side. The needles are guided through the template 19 above the fibers and the fibers are pulled through the film forming a loop on the back of the film. During needling, the film is supported on a bed of nails 20 which extends from a drive support belt 22 which is able to move through the needling station with the film, which is supported on a screen or by a standard lower pallet (not shown) support. A stationary reaction plate 24 located below the belt 22 provides reaction pressure during needling. After needling is complete, with the film still on the bed of nails 20 , the backing film 26 is placed on the fiber side of the film 14 and the two film sheets are bonded together under the pressure of heated rollers 28 towa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com