Composite waterproof plate, ad its manufacturing method and use

A board and wood technology, which is applied in the field of composite waterproof board and its preparation, can solve the problems of non-waterproof and fire prevention, environmental pollution, low board strength, etc., and achieve the effects of reducing consumption, improving impact resistance, and improving waterproof and anti-corrosion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

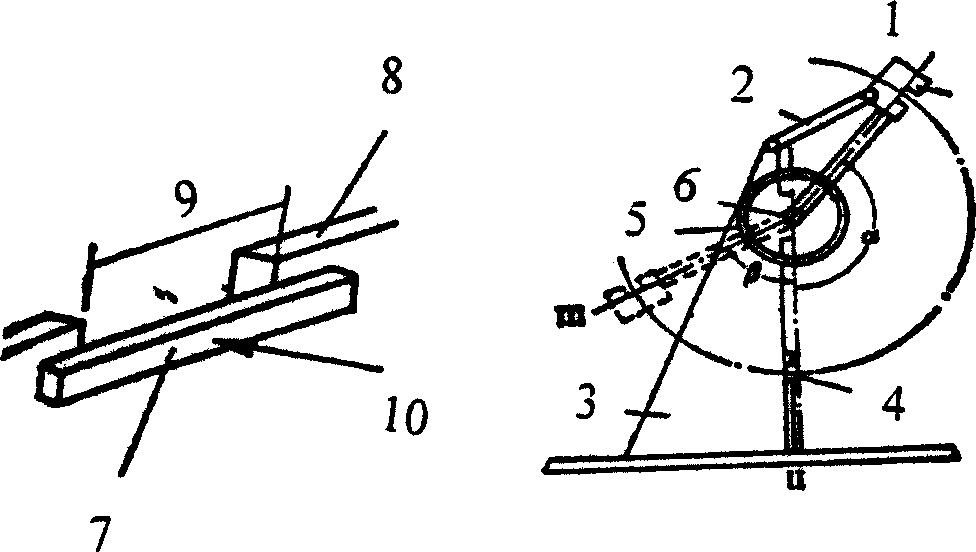

Image

Examples

Embodiment 1

[0049] Embodiment 1, prepare composite waterproof board 1

[0050] At room temperature, the mass ratio of binder—maleic anhydride (technical grade), phthalic anhydride (technical grade), propylene glycol (technical grade), styrene (technical grade) is 10:15: Mix 100g of a 10:30 mixture with 2g of hydrogen peroxide evenly, and then mix with 100g of wheat straw with a length of 5-20 mm to make a pre-molding material; pour 100g of power plant fly ash (300 mesh) into this In the pre-molding pressing material, mix evenly to make the molding pressing material.

[0051] In order to facilitate demoulding, brush a small amount of engine oil in the mold, take 130g of molding compound and fill it into the cavity, press it flat with your hands, cover the mold and press the template for compaction. Heat the upper and lower heating plates of the flat vulcanizing press to 110°C, and pressurize the loaded mold to 5MPa in the vulcanizing press, hold the pressure and keep it warm for 10 minute...

Embodiment 2

[0074] Embodiment 2, prepare composite waterproof board II

[0075] At room temperature, the mass ratio of binder—maleic anhydride (technical grade), phthalic anhydride (technical grade), propylene glycol (technical grade), styrene (technical grade) is 10:15: Mix 100g of 10:30 mixture with 2g of benzamide peroxide evenly, then mix with 100g of wheat straw with a length of 5 to 20 mm to make a pre-molding material; 100g of polyvinyl chloride (PVC) fine powder (Beijing The second organic chemical plant, building material type 5) and 100g of power plant fly ash (300 mesh) are mixed evenly and then poured into this pre-molding material, and mixed evenly to make a molding material.

[0076] In order to facilitate demoulding, brush a small amount of engine oil in the mold, take 140g of molding compound and fill it into the mold cavity, press it flat with your hands, cover the mold and press the template for compaction. Heat the upper and lower heating plates of the flat vulcanizing...

Embodiment 3~29

[0078] Examples 3-29, preparation of composite waterproof boards III-XXIX

[0079] Composite waterproof boards III-XXIX were prepared according to the method of Examples 1 and 2, and tested according to the method of Example 1, listed in Table 3 and Table 4.

[0080] Table 3. Composition of composite waterproof panels

[0081]

Example

plant fibers and

Parts by weight

fly ash and its

Parts by weight

Plastic and its

Parts by weight

Adhesives and their

Parts by weight

3

20

Firepower

power plant

fly ash

25

(PE)

40

A, B, C, D =

10:15:10:30

(wt%)

5

4

20

Firepower

power plant

fly ash

15

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Impact strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com