Process and equipment for continuously producing and molding dual-extrusion current coating plastic clip net film products

A technology of extrusion casting and molding process, applied in the field of making advertising light box cloth, can solve the problems of inability to achieve continuous production, large investment in calendering equipment, and large labor investment, and achieve simple and reasonable equipment structure, light unit weight, plasticization good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention takes polyvinyl chloride resin, plasticizer, stabilizer, filler and other functional additives as the main raw materials, adopts the casting method to form at one time, and composites the net film product, and the polyvinyl chloride resin can be selected SG-3, SG-4 or SG-5 type resin, the filler is calcium carbonate products with a mesh size of 800 or more; the product formula for producing transparent sandwich film is as follows: 100 parts of polyvinyl chloride resin, 30-60 parts of plasticizer, 4-6 parts of stabilizer, 5-10 parts of other functional additives; the formula for producing high-fill interlayer film products is as follows: 100 parts of polyvinyl chloride resin, 40-70 parts of plasticizer, 4-6 parts of stabilizer, 50-100 parts of filler, 5-10 parts of other functional additives.

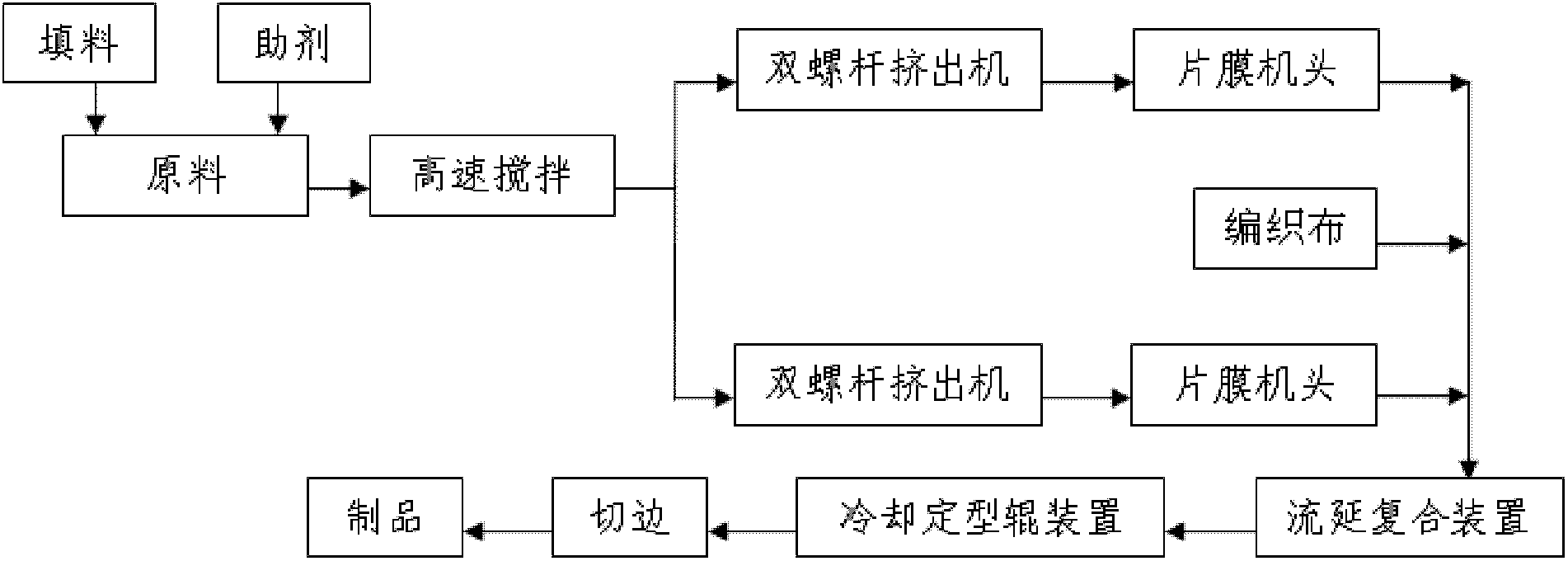

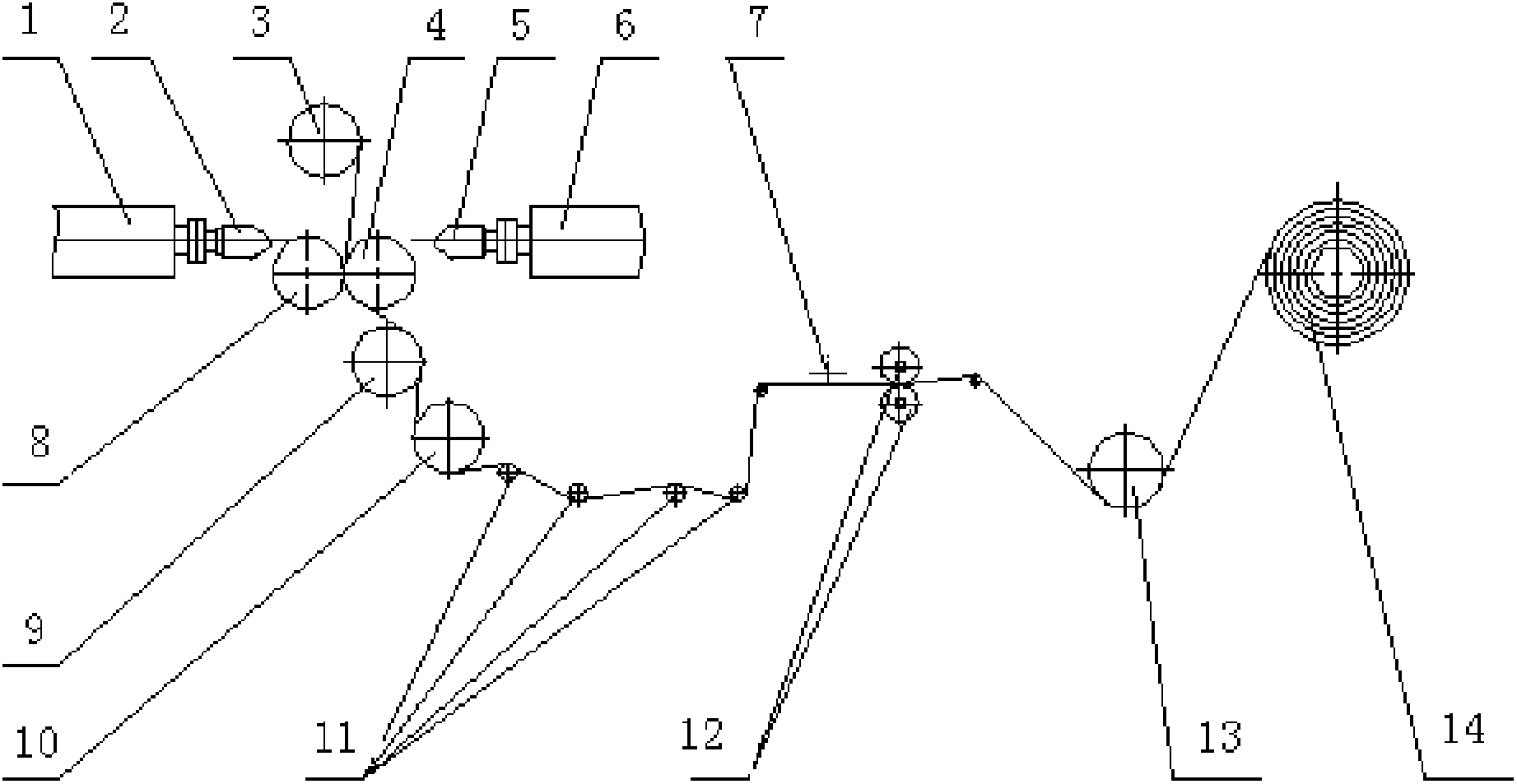

[0030] Its continuous production molding process such as figure 1 with figure 2 As shown, the mixed raw materials formed by polyvinyl chloride resin, fill...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com