Combined type unreinforced thermal-insulating sandwich external wall slab and manufacturing method for inner laminate and outer laminate of same

A combined, exterior wall panel technology, applied in the direction of manufacturing tools, building structures, building components, etc., can solve the problems of complex construction, poor fire safety in exterior wall insulation construction, and self-heavy surface thickness of wall panels. Good cracking effect, green environmental protection fire safety, and the effect of reducing maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

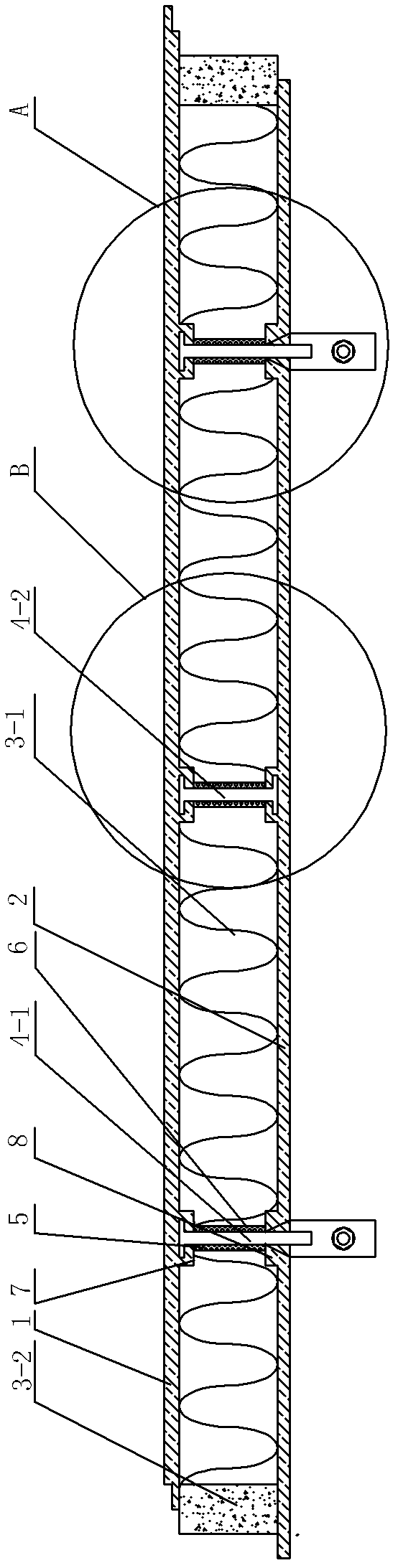

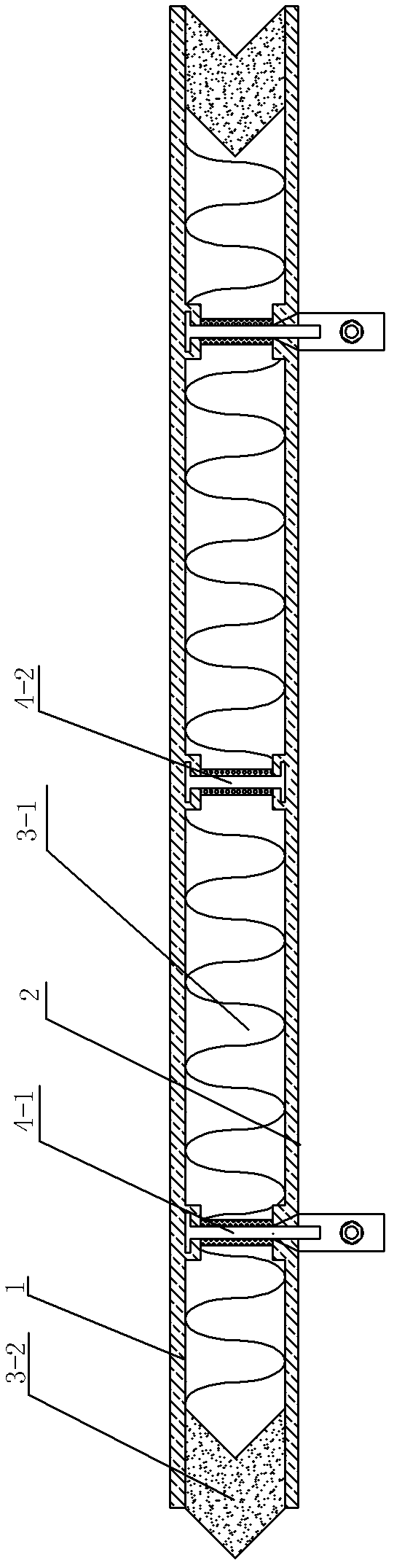

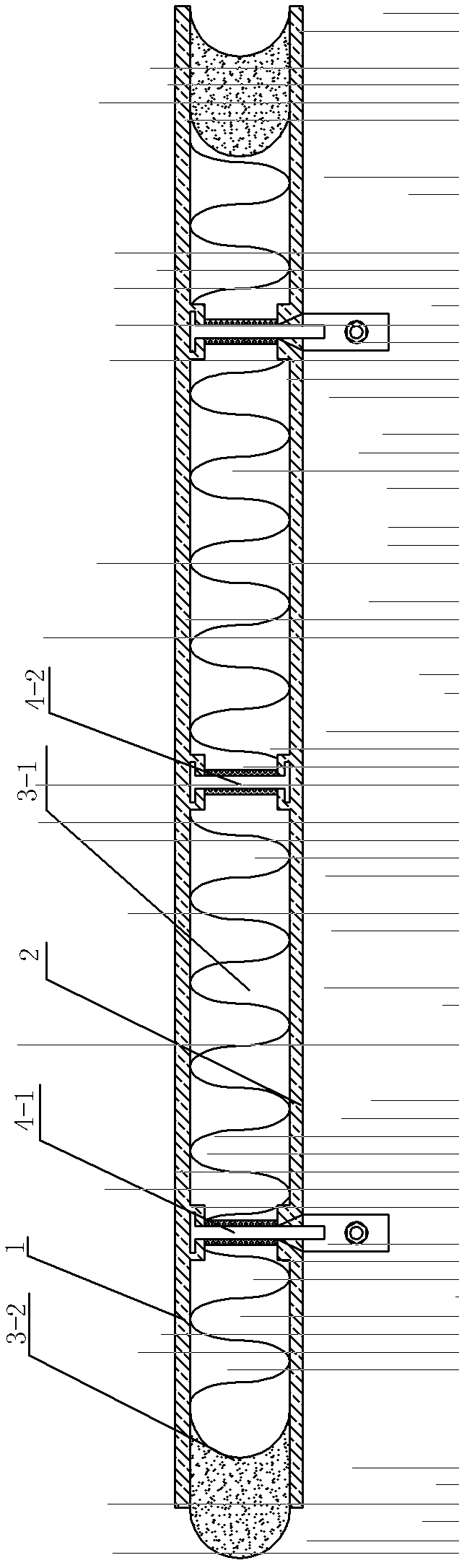

[0019] Specific implementation mode one: combine Figure 1-Figure 7 Describe this embodiment, the wall panel of this embodiment includes outer layer board 1, inner layer board 2, insulation core layer, a plurality of first FRP connectors 4-1, a plurality of second FRP connectors 4-2 and a plurality of A filling layer 5, the insulation core layer includes rock wool layer 3-1 and two extruded boards or waterproof rock wool strips 3-2, rock wool layer 3-1 and two extruded boards or waterproof rock wool strips 3-2 Set between the outer layer board 1 and the inner layer board 2, each end of the rock wool layer 3-1 is provided with an extruded board or waterproof rock wool strip 3-2, and the rock wool layer 3-1 is evenly distributed with multiple Each reserved hole 6 is provided with a first boss 7 on the inner end surface of the outer layer plate 1 corresponding to each reserved hole 6, and a first boss 7 is arranged on the inner end surface of the inner layer plate 2 corresponding...

specific Embodiment approach 2

[0020] Specific implementation mode two: combination figure 2 , image 3 and Figure 4 To illustrate this embodiment, one of the two waterproof rock wool strips in this embodiment is convex, and the remaining one is concave. The shape of each rock wool strip is angular, arc-shaped or polygonal, and the waterproof rock wool strip The performance index is density ≥ 120kg / m 3 , Compressive strength ≥ 60Kpa, thermal conductivity lower than 0.04W / (m·K), water absorption < 2.0%. The design of this structure extends the length of the heat transfer path to avoid the formation of cold bridges. Other implementation manners are the same as the specific implementation manner 1.

specific Embodiment approach 3

[0021] Specific implementation mode three: combination figure 1 To illustrate this embodiment, one end of the outer layer 1 of this embodiment is set in an upper stepped shape, the other end of the outer layer 1 is set in a lower stepped shape, and the extruded board is lapped on the outer layer 1 and the inner layer 2 Above, the density of extruded board is 32-36kg / m 3 , Compressive strength ≥ 250KPa, thermal conductivity < 0.04W / m·K, water absorption < 1.0%.

[0022] The design of this structure extends the length of the heat transfer path to avoid the formation of cold bridges. The rock wool layer 3-1 is arranged in the middle of the outer layer 1, the inner layer 2 and the extruded plastic board or waterproof rock wool strip 3-2, so that it will not get wet to ensure the thermal insulation performance, and the extruded plastic board or waterproof rock wool strip 3-2 has a certain strength, avoiding the problem of extrusion deformation, and the extruded board or waterproo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com