Composite membrane, preparation method thereof and solar cell assembly

A composite film and functional technology, applied in electrical components, chemical instruments and methods, circuits, etc., can solve the problems of inconvenient product transportation, installation and maintenance, non-compliance with the lightweight requirements of photovoltaic products, and hard and flexible glass texture. Achieve the effect of ensuring weather resistance, convenient transportation and installation, and reducing unit weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

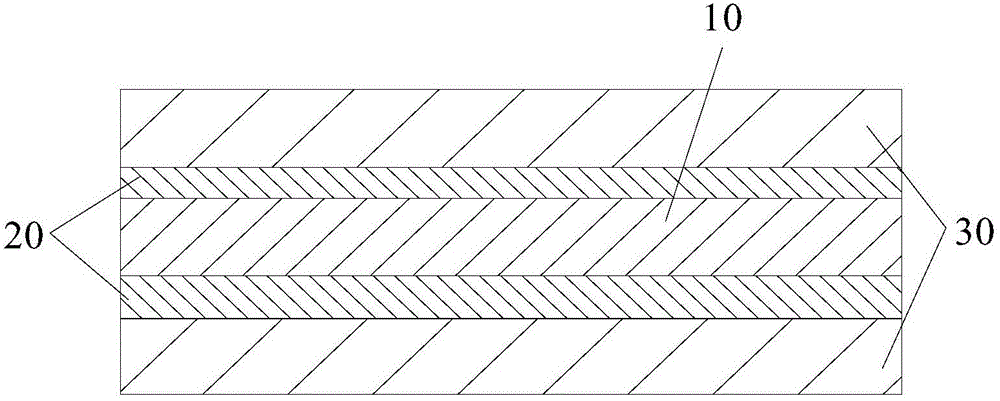

[0034] According to another aspect of the present invention, there is provided a method for preparing the above-mentioned composite film. The preparation method includes the following steps: separately preparing a water vapor barrier layer 10 and a weather-resistant functional monolayer; forming a bond on one surface of the weather-resistant monolayer Single layer, and the weather-resistant functional single layer and the bonding single layer constitute the functional unit layer; the functional unit layer is superimposed on the two opposite surfaces of the water vapor barrier layer 10, and the bonding single layer is attached to the surface of the water vapor barrier layer 10 , The bonding single layers located on both sides of the water vapor barrier layer 10 constitute the bonding layer 20, and the weather resistant functional single layers located on both sides of the water vapor barrier layer 10 constitute the weather resistant functional layer 30.

[0035] Wherein, the step o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com