Patents

Literature

117results about How to "No environmental issues" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

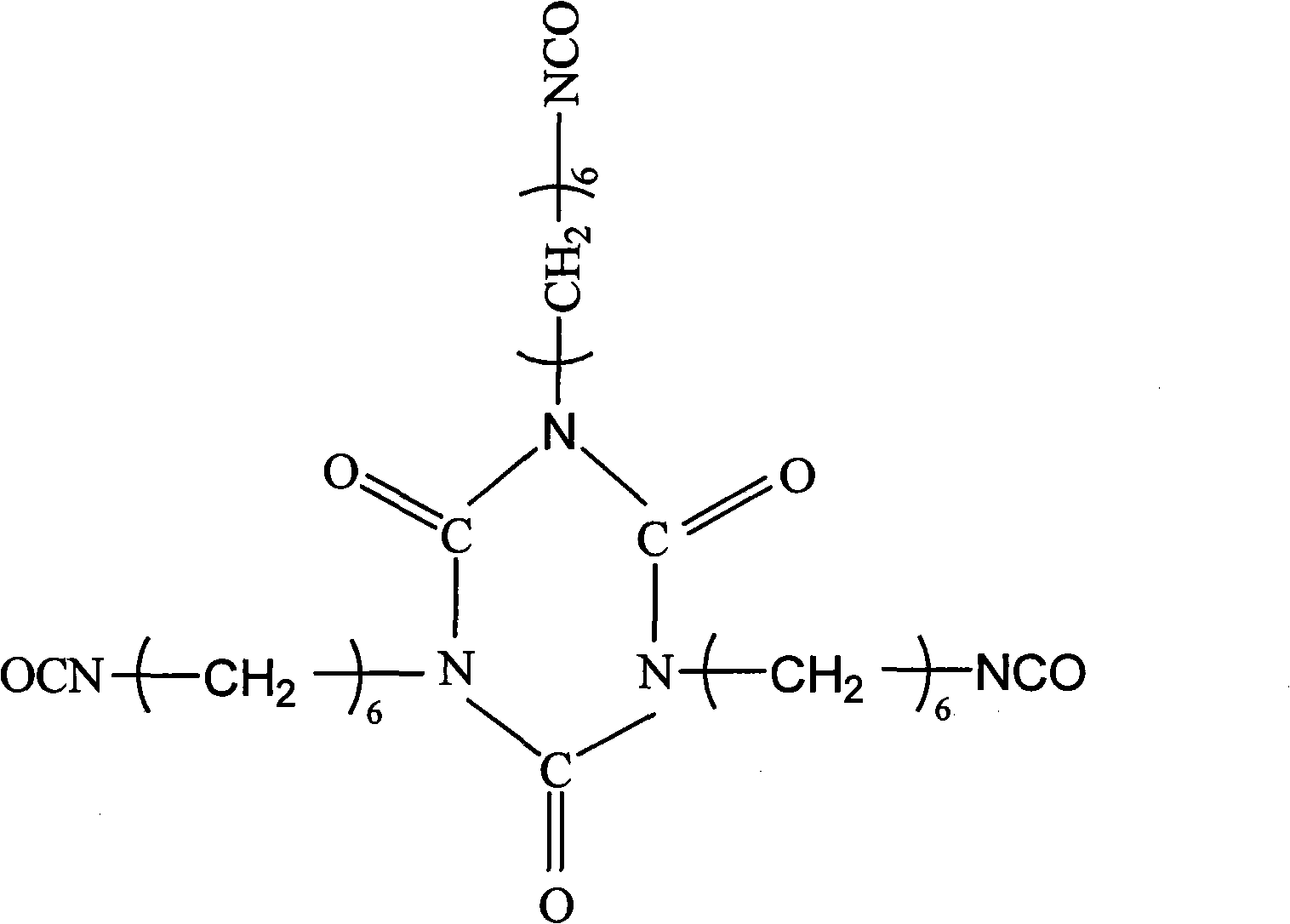

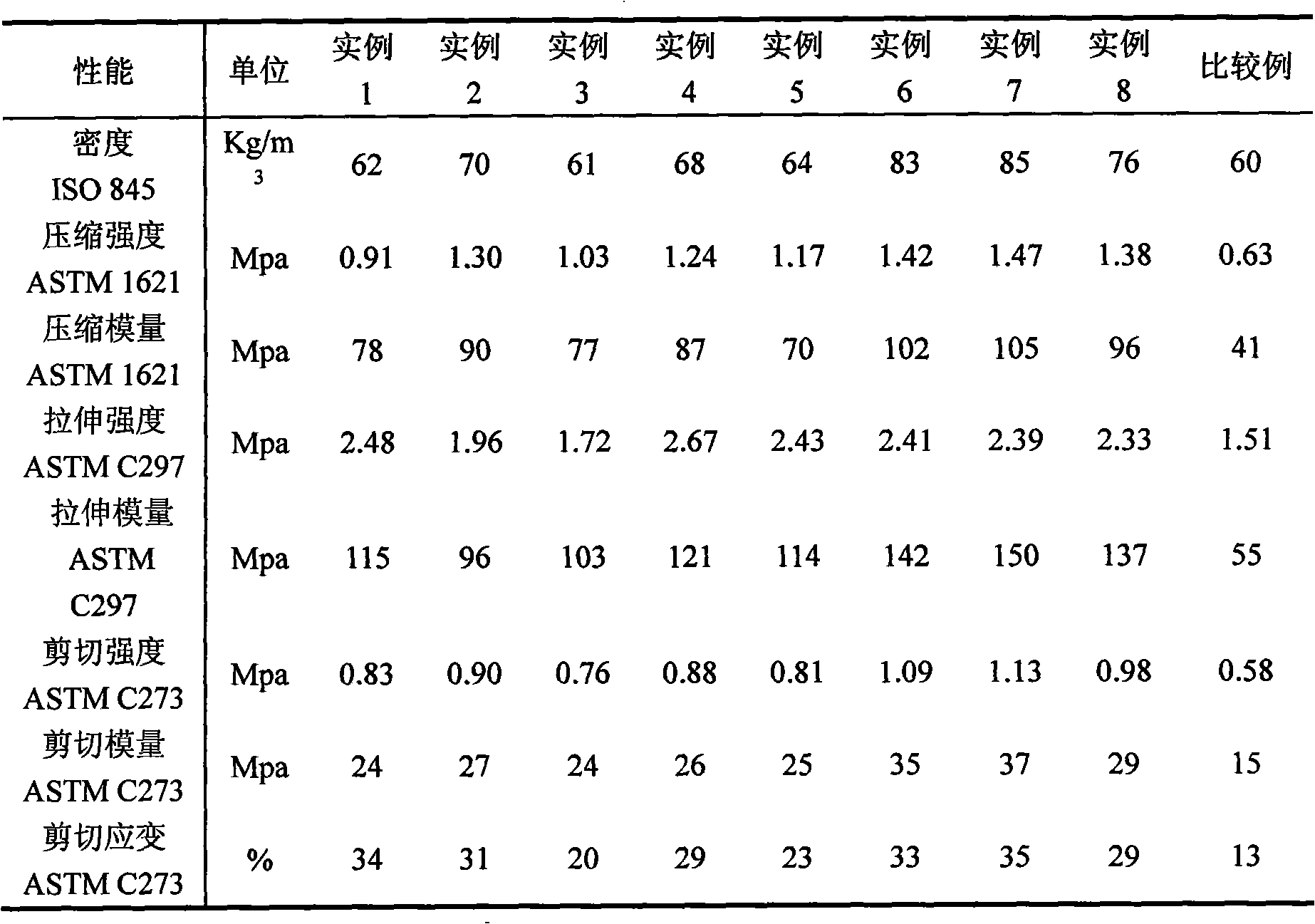

Improved crosslinked polyvinyl chloride structural foam and preparation method thereof

ActiveCN101580573ASimple manufacturing process controlWide operating range of parametersFoaming agentPolyvinyl chloride

The invention relates to improved crosslinked polyvinyl chloride structural foam and a preparation method thereof. The foam is prepared from the following materials in portion by weight: 100 portions of polyvinyl chloride resin, 30 to 120 portions of isocyanate, 0.05 to 10 portions of epoxy components, 1 to 12 portions of foaming agent, 0.5 to 10 portions of triazine compound, and 1 to 30 portions of acid anhydride. The preparation method thereof comprises the following steps: (1) mixing the raw materials evenly to obtain a pasty mixture; (2) pouring the pasty mixture obtained in step (1) into a die, and fully decomposing the foaming agent to obtain a semi-foaming die pressing block; (3) cooling the semi-foaming die pressing block to room temperature; (4) placing the semi-foaming die pressing block obtained in step (3) into hot bath or steam to carry out swelling; and (5) cooling a swelled semi-finished product obtained in step (4) to room temperature, and then adopting hot water spray or curing post treatment in the steam to fully react the isocyanate so as to obtain cured block or plate crosslinked polyvinyl chloride structural foam. The foam has fine and even holes, and has good mechanical property and temperature resistance.

Owner:CHANGZHOU TIANSHENG NEW MATERIALS

A silicone modified aluminum hydroxide solid elastomer and preparation method thereof

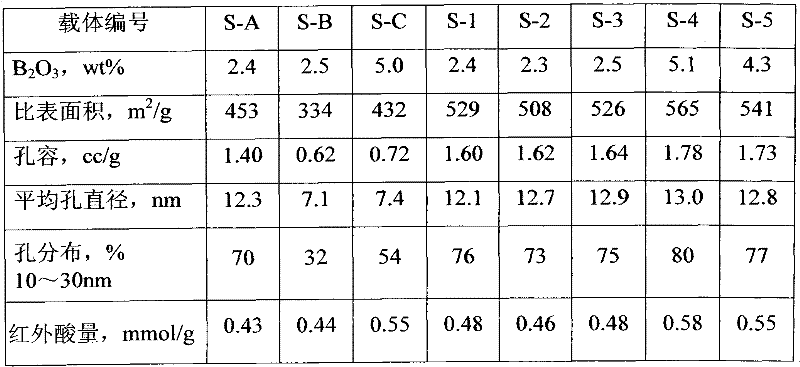

ActiveCN1951554AHigh specific surface areaLarge specific surface areaCatalyst carriersOrganosiliconSalt solution

The invention relates to a method for preparing aluminum hydroxide wafer which is modified by silicon. Wherein, said wafer is baked and converted into silicon-modified gamma-Al203, to obtain following properties, that specific surface area is 400-600m2 / g, the hole capacity is 1.0-2.0cm3 / g, and the silica mass percentage is 2%-20%. In its preparation, after the neutralization between acid aluminum salt solution and alkali compound solution, it adds organic silicon to age, and composite via general steps. The invention has simple method.

Owner:CHINA PETROLEUM & CHEM CORP +1

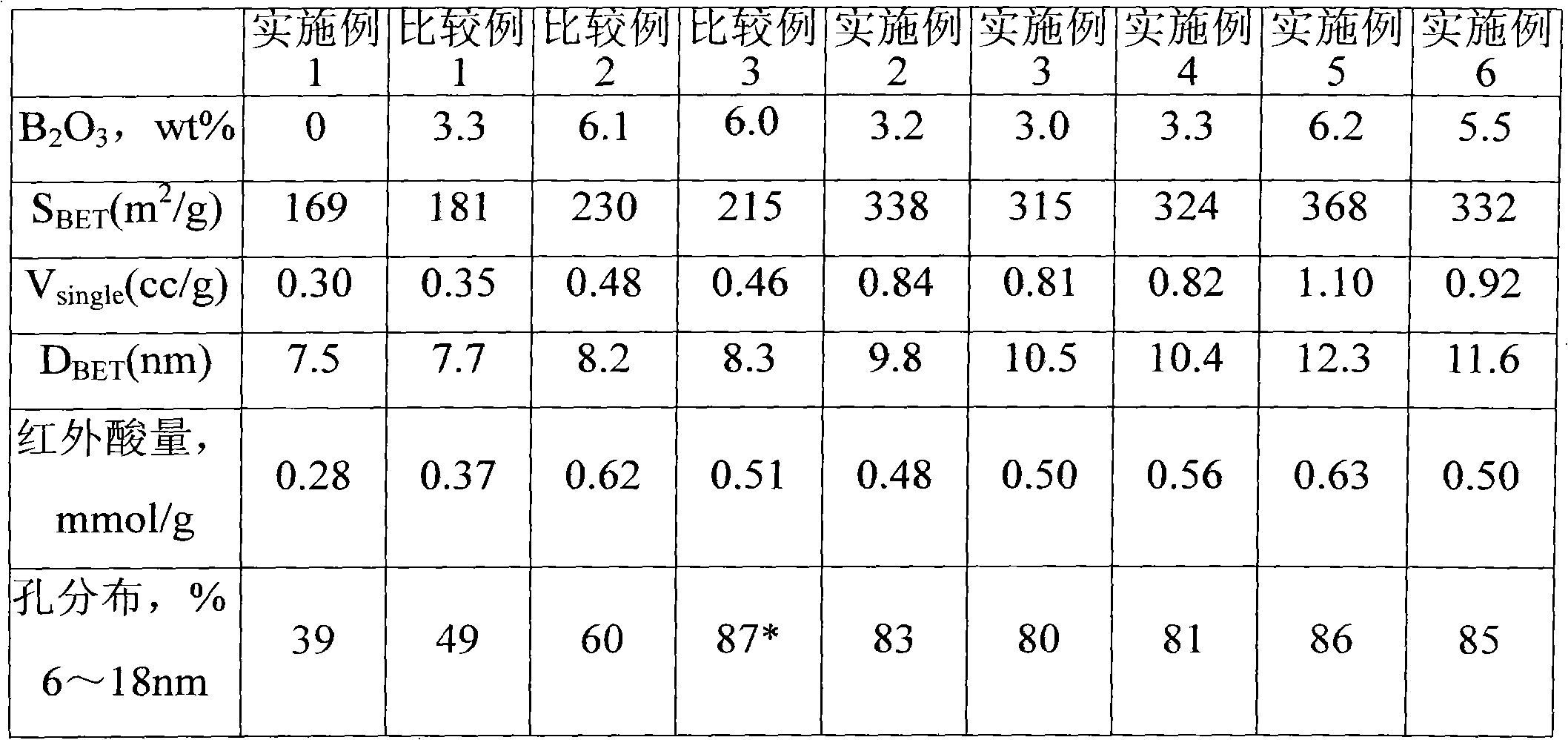

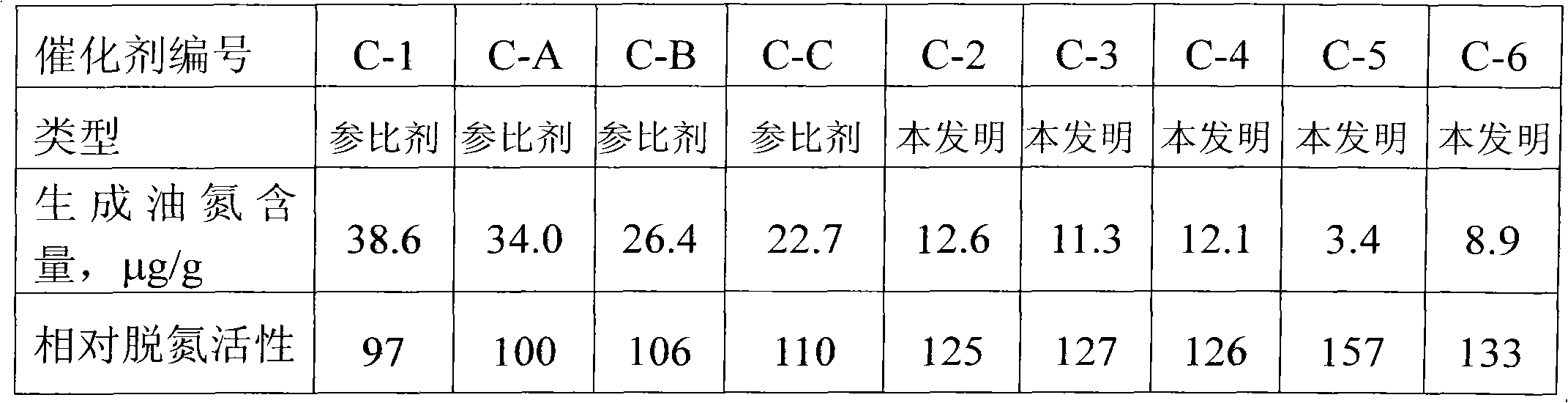

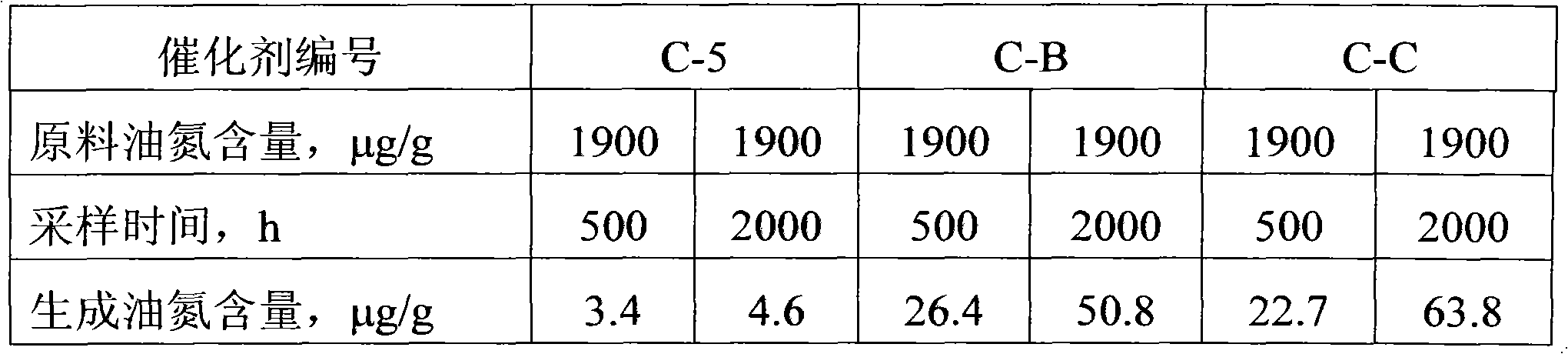

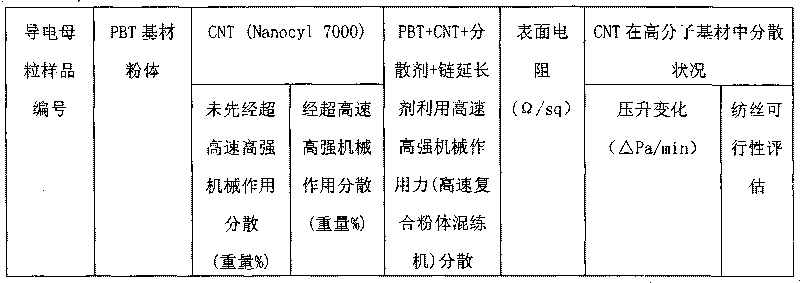

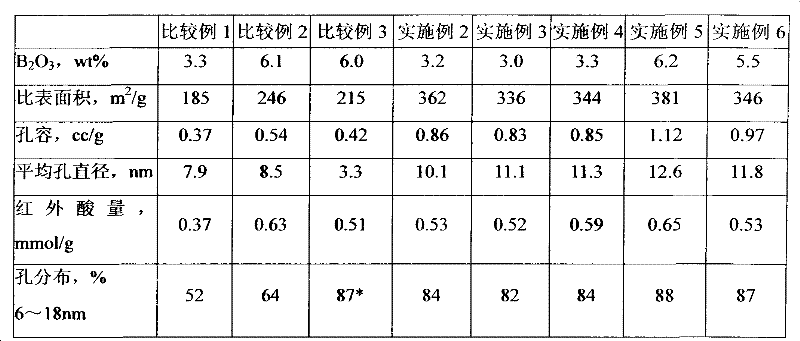

Preparation method of hydrotreatment catalyst

ActiveCN102728374ARegular hole structureEvenly distributed holesMetal/metal-oxides/metal-hydroxide catalystsRefining to eliminate hetero atomsLarge poreAluminium hydroxide gel

The invention discloses a preparation method of a hydrotreatment catalyst, comprising the following steps of: introducing silicon and boron additives in the way that an organic silicon source is added after aluminium hydroxide gel forming and then a boron-containing organic compound solution is added, so as to obtain silicon and boron containing aluminium hydroxide, mixing parts of an active metal component with boron-containing aluminium hydroxide by a kneading method, carrying out three-stage roasting to obtain a catalyst intermediate, loading residual part of the active metal onto the catalyst intermediate by dipping, and drying to obtain the hydrotreatment catalyst. By the adoption of the method provided by the invention, the silicon and boron additives and the active metal component are uniformly distributed on the surface of the catalyst. In addition, the active metal component has different existing forms in the catalyst when introduced in the two modes, loss rate of the catalyst activity is reduced by mutual cooperation, and running period of a device is prolonged. The catalyst has large pore volume, large specific surface area, appropriate pore structure and acidity, and is especially suitable for hydrodenitrogenation process of heavy hydrocarbon.

Owner:CHINA PETROLEUM & CHEM CORP +1

Pigment of multi-gradition discolour at diffierent direction and production process thereof

InactiveCN1597793ALow priceEasy to get materialsInorganic pigment treatmentPigment preparationRefractive indexColor changes

The invention provides a multilayer disclour pigment with different colors according to different viewing angle and its producing method, using synthetic thin glass plate as a substrate, alternatively coating the surface of the thin glass plate with at least three metal oxide layers with refractivity greater than 1.8 and less than 1.8, where the metal oxide layer with refractivity less than 1.8 is always between the other two ones with refractivity greater than 1.8. The invention uses chemical hydrolyzation process to alternatively coat high- and low- refractivity oxide layers on the surface of the thin glass plate. It has low price, wide color change range, and simple manufacture process.

Owner:SHANTOU LONGHUA PEARL LUSTRE PIGMENTS CO LTD

Aureous bead pigment having strong metallic texture and method for producing the same

ActiveCN101134850AStrong golden interference colorImprove vividnessInorganic pigment treatmentInterference colorHydrolysis

The present invention provides one kind of golden pearlescent pigment with strong metal texture. The golden pearlescent pigment includes flaky base with at least three layers of alternately coated ferric oxide layer of optical thickness 10-200 nm and silica layer of optical thickness 10-320 nm. The present invention provides also the pigment preparing process, which is one wet chemical hydrolysis process to deposit ferric oxide layers and silica layers on the flaky base. The golden pearlescent pigment has strong golden interference color and brilliancy and brightness greatly than common pearlescent pigments. It has low cost, simple preparation process and stable product quality.

Owner:SHANTOU LONGHUA PEARL LUSTRE PIGMENTS CO LTD

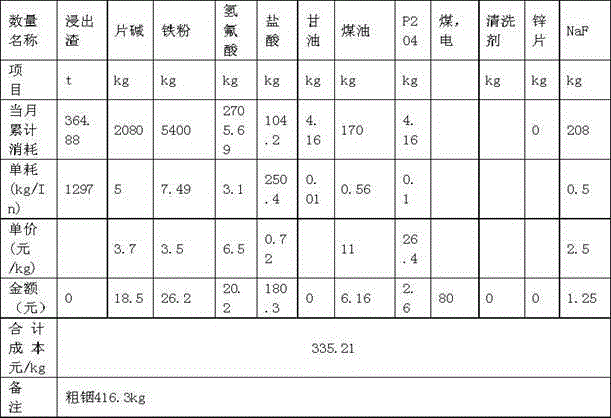

Method for extracting and separating indium and tin from indium-containing leaching residues

InactiveCN104831077AHigh purityHigh concentration of indiumProcess efficiency improvementEnvironmental resistanceIndium

The invention relates to a method for extracting and separating indium and tin from indium-containing leaching residues. The method comprises the following steps: leaching a complex middle-low grade zinc oxide material containing Cu, Pb, Zn and Ag by using a concentrated NH4Cl solution as a leaching agent to make zinc form a zinc ammonia complex solution; allowing all Fe, As, In and Sn elements in ores to enter residues; adding iron powder to the above obtained leached solution to remove bismuth, lead and iron; filtering to obtain a hydrochloric acid system solution containing indium and tin; and simultaneously extracting indium and tin by adopting P2O4, carrying out complexing stripping on tin by adopting fluoride, and stripping indium by adopting hydrochloric acid. The method has the advantages of one-time thorough separation of indium and tin, short flow, low cost, wide raw material source, high recovery rate of various metals, and no environmental protection problem, and allows the zinc recovery rate in the whole flow to reach above 95%.

Owner:郴州雄风环保科技有限公司

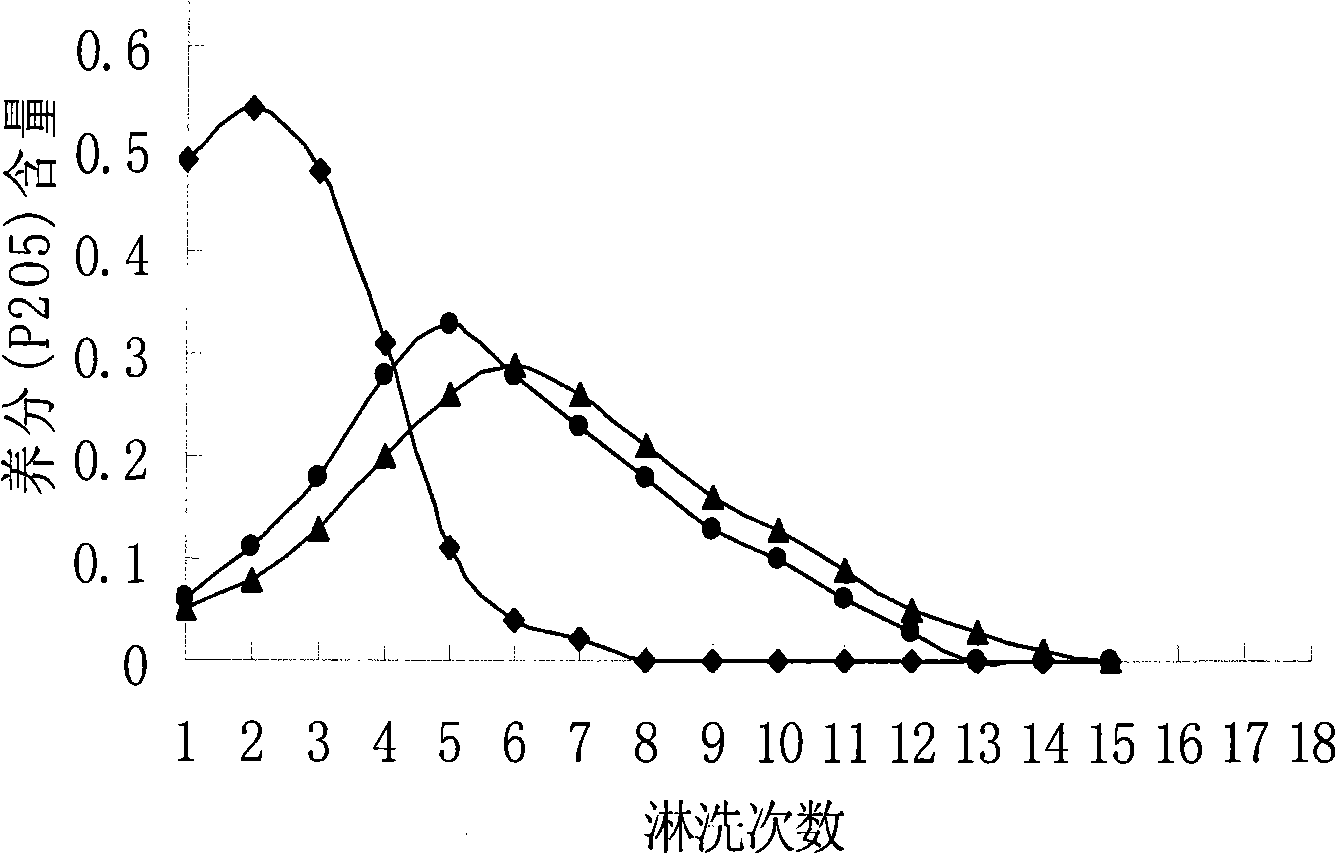

Preparation for coating material containing phosphate fertilizer and coating method thereof

InactiveCN101270011AIncrease viscosityGood sustained release effectFertilizer mixturesPhosphoric acidAqueous solution

The present invention discloses a preparation method of a slow-release phosphorus fertilizer, and a preparation method that is used for a coating material that is used for the slow-release phosphorus fertilizer. The slow-release phosphorus fertilizer is a coated fertilizer that is coated by a coating outside the phosphorus fertilizer; the coating material is made of improved attapulgite. For the improvement of the attapulgite, the attapulgite is improved by dipping the aqueous solution of sodium carbonate or phosphoric acid; then the improved attapulgite is separated, dried and milled for dispersion.

Owner:LANZHOU UNIVERSITY

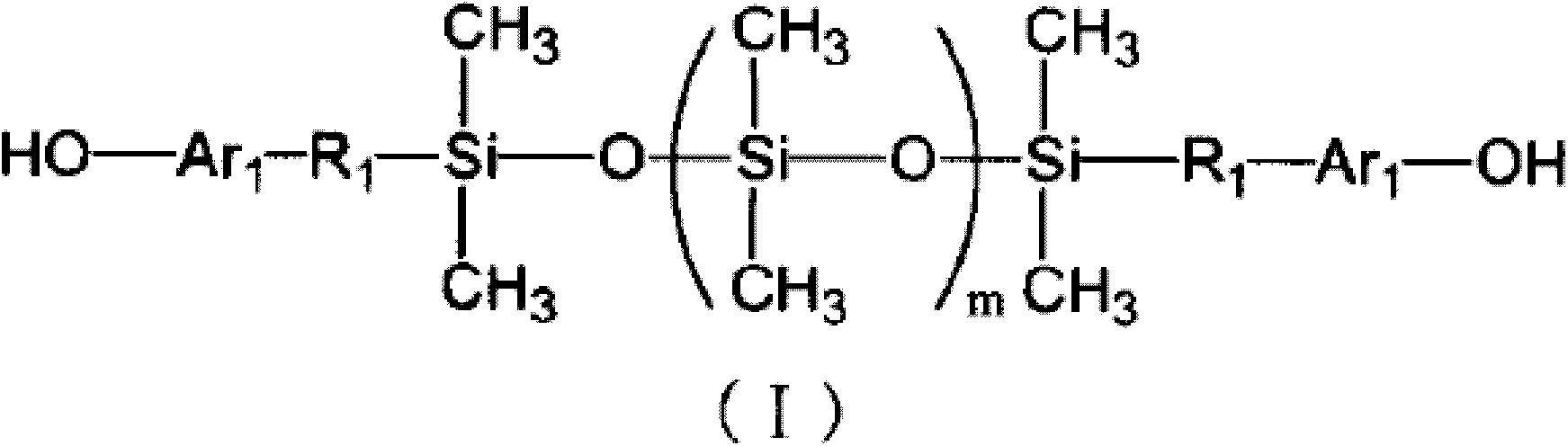

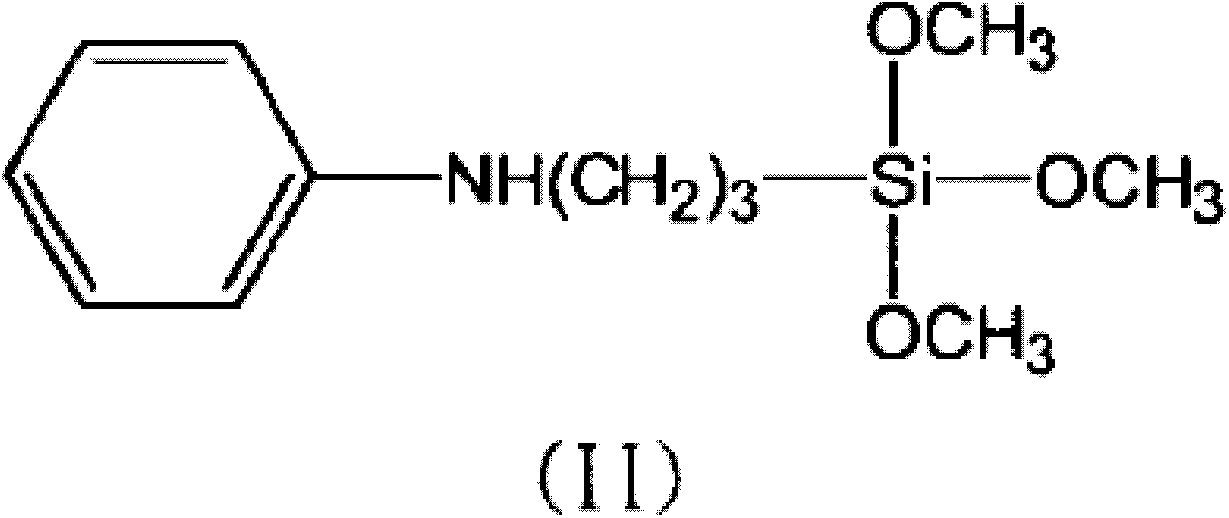

Process for producing compatibilized resin, thermosetting resin composition, prepreg, and laminate

InactiveCN103189418ALow thermal expansionLow heat resistancePrinted circuit aspectsElectrical equipmentHeat resistanceCopper foil

Provided is a process for producing a compatibilized resin which comprises reacting a cyanate compound, a siloxane resin having a hydroxy group at an end, and an epoxy resin to a specific conversion. Also provided is a thermosetting resin composition which comprises: a compatibilized resin (A1) produced by the process or a thermosetting resin (A2) obtained by reacting a cyanate compound with a siloxane resin having a hydroxy group at an end to a specific conversion; and fused silica (B) in which the surface has been treated with a trimethoxysilane compound. Furthermore provided are a prepreg, a laminate, and a wiring board each obtained using the resin composition. The thermosetting resin composition is excellent in terms of all of low thermal expansion, adhesiveness to copper foils, heat resistance, flame retardancy, copper-clad heat resistance (T-300), dielectric properties, and drillability. With the composition, increases in the density of wiring boards and high reliability thereof, which are required at present, are attained. The composition can be widely used for producing electronic appliances, etc.

Owner:RESONAC CORPORATION

Hydrotreating catalyst and preparation method thereof

ActiveCN102039203AHigh activityImprove stabilityCatalyst carriersCatalyst activation/preparationSimple Organic CompoundsAluminium hydroxide

The invention discloses a hydrotreating catalyst and a preparation method thereof. In the method, a boron aid is introduced by adding stable boron-containing organic compound solution after aluminium hydroxide is gelatinated, so that the boron aid is uniformly distributed in the catalyst and the activity phase transformation promoting effect of the boron acid is enhanced; moreover, the obtained catalyst has a high pore volume, a large specific surface area, an appropriate pore structure and appropriate acidity, enhances the activity and stability of the catalyst and is particularly suitable for the hydro-denitrogenation process of heavy hydrocarbons.

Owner:CHINA PETROLEUM & CHEM CORP +1

Optimization method for crystallization of glucose

InactiveCN105821095AImprove qualityNo pollution in the processFermentationAlpha-amylaseHigh pressure

The invention discloses an optimization method for crystallization of glucose. The optimization method comprises the following steps: adjusting the concentration and pH value of starch milk in a material blending tank, adding high-temperature-resistant alpha-amylase and carrying out primary high-pressure injection and secondary enzymatic continuous liquefaction reaction via a liquefaction injector so as to hydrolyze starch milk into liquefied starch liquid; allowing the liquefied starch liquid to enter a vacuum flash evaporation cooling system, adding glucoamylase, allowing the obtained mixture to enter a saccharification tank for saccharification, carrying out microfiltration, ultrafiltration and decoloring on a saccharified material, and then successively carrying out removal of peculiar smell via a deodorization adsorption resin, concentration and crystallization; and adding purified water to dissolve crystal and successively carrying out nanofiltration, recrystallization, centrifugation, drying, screening and packaging. The optimization method enables a glucose crystallization process to be further optimized, does not cause the environmental protection problems like waste water and residues in the whole process and has the characteristics conservation of energy, reduction in consumption and environmental protection.

Owner:HULUNBEIER NORTHEAST FUFENG BIOTECHNOLOGIES CO LTD

Inkjet printing thickener and method for preparing same

ActiveCN102153694ANo infiltrationNo environmental issuesDyeing processVegetal fibresCross-linkPolymer science

The invention provides an inkjet printing thickener and a method for preparing the same. The method for preparing the inkjet printing thickener comprises the following steps: mixing aqueous ammonia with an acrylic monomer until the pH value of the mixture is 6.5-7, adding a cross-linking agent, stirring and mixing to prepare a water phase; mixing an emulsifier with an organic solvent to prepare an oil phase; adding and stirring the water phase to the oil phase, dropwise adding aqueous initiator solution, polymerizing for 1-4 hours at 50-80 DEG C, reducing temperature, discharging, adding a phase transfer agent, and stirring fully and uniformly to obtain the finished product. The inkjet printing thickener provided by the invention has high solid content, moderate viscosity and strong electrolyte resistance and can be used by adopting a padding process during pre-treatment for inkjet printing to ensure that the printed patterns have clear outlines, deep color and no infiltration.

Owner:苏州百氏高化工有限公司

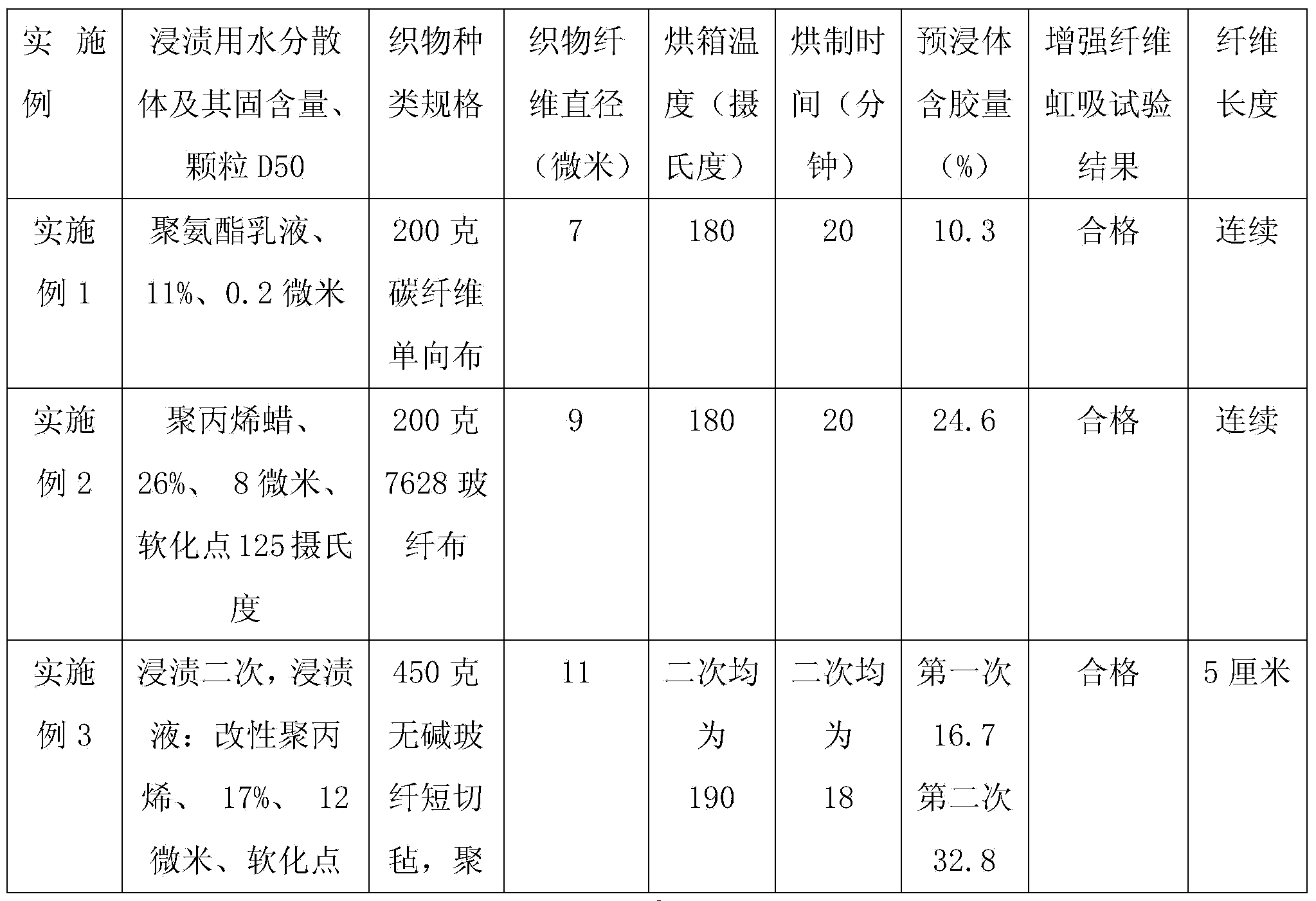

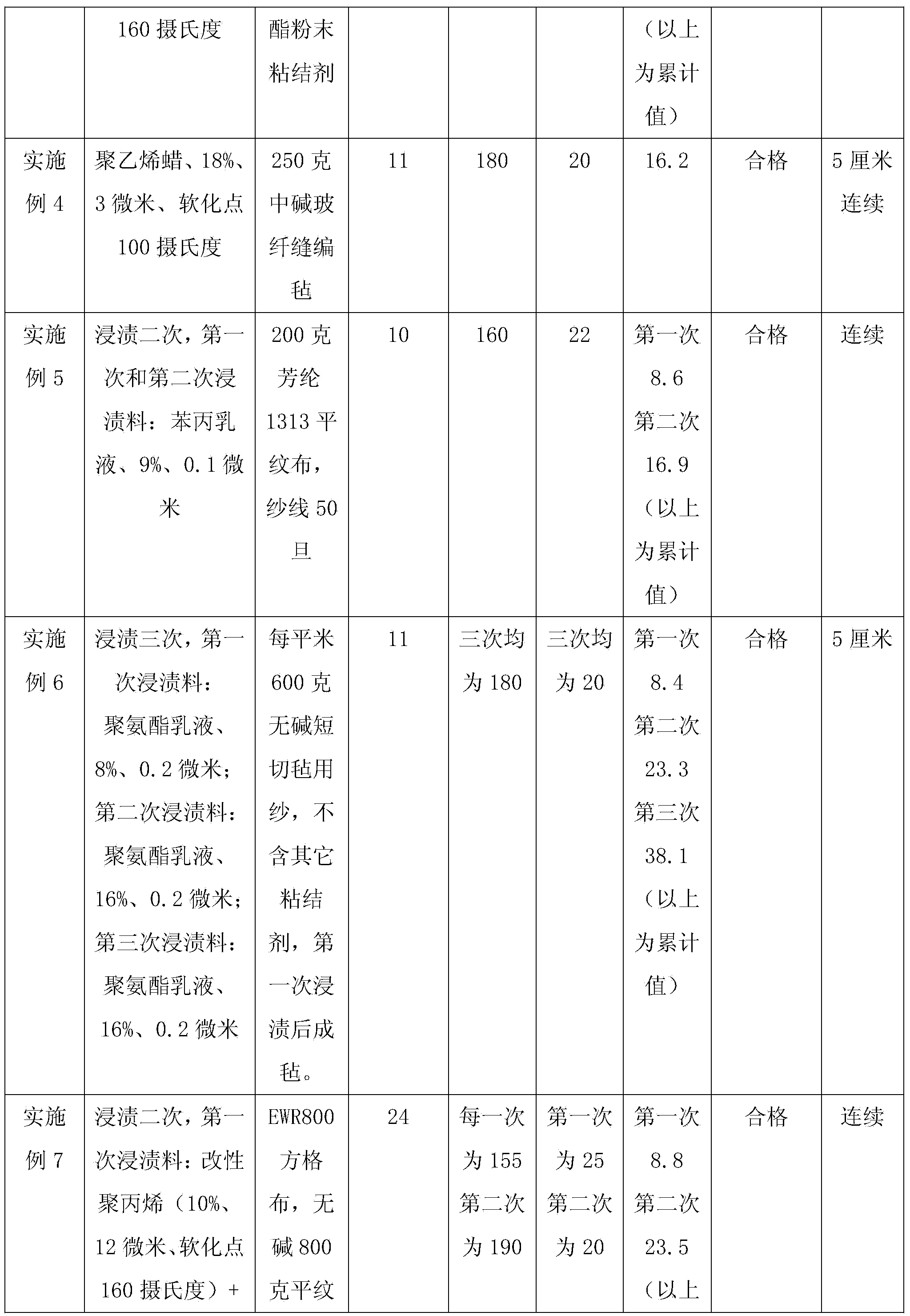

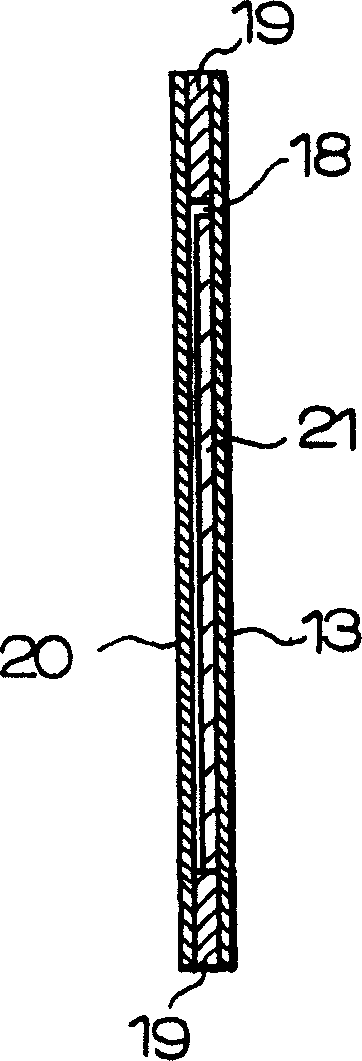

Thermoplastic composite preimpregnation body plate

InactiveCN103613775ASolving Effective Impregnation ProblemsGuaranteed to pass the siphon testSynthetic resin layered productsEnvironmental resistancePolymer science

The invention discloses a thermoplastic composite preimpregnation body plate, which is prepared by a thermoplastic composite preimpregnation body or is compounded by the thermoplastic composite preimpregnation body and thermoplastic polymer through hot melting. The thermoplastic composite preimpregnation body is prepared by steps of steeping fabric prepared by reinforced fibers in thermoplastic polymer aqueous dispersion, drying and dehydrating, melting the polymer, cooling and shaping, and the length of the reinforced fibers is more than 2cm. According to the preparation method of the thermoplastic composite preimpregnation body, an organic solvent is not used, water is taken as a dispersion medium, the aqueous dispersion of polymer substitutes for the organic solvent, so that the preparation method is environment-friendly; the aqueous dispersion used by the preparation method has low viscosity and is beneficial to steeping of the polymer on fiber bundles, the immersion treatment is convenient, the production efficiency is high, the production cost is low, and the problem of effectively steeping the reinforced fiber fabric by the thermoplastic polymer is solved; compared with the composite board prepared by the prior art, the preimpregnation body plate is sharply improved in tensile strength and deformation performance.

Owner:南京彤天广元高分子材料有限公司

Combination cultivation kit of beadroll bacterium, hemophilus and mycoplasma, and uses thereof

InactiveCN101270382APhysical health hazardNo radioactivityMicrobiological testing/measurementMycoplasma cultureOrganism

The invention relates to a combined culture reagent box of Candida Albicans, hemophilic bacteria and mycoplasma and application thereof. The reagent box comprises a culture medium and a CO2 generator. The culture medium comprises culture medium of Candida Albicans, culture medium of hemophilic bacteria and culture medium of mycoplasma. The pH value of the culture medium is 6.3 plus or minus 0.5. The invention is used to detect Candida Albicans, hemophilic bacteria and mycoplasma, also evaluate the microecology of the urogenital tract of male and female, diagnose the infection of Candida Albicans, hemophilic bacteria and mycoplasma, and evaluate the curative effect of the bacteria. Compared with the prior art, the combined culture reagent box of Candida Albicans, hemophilic bacteria and mycoplasma of the invention has the advantages of the simple operation, the reliable method, the stable characteristics, and easily observing and judging the results, provides a diagnostic tool with more scientific, more convenient, more humanized and more accurate, is favorable for biological or medical practice and commercialized transportation and has the good social and economic efficiency.

Owner:叶鹰

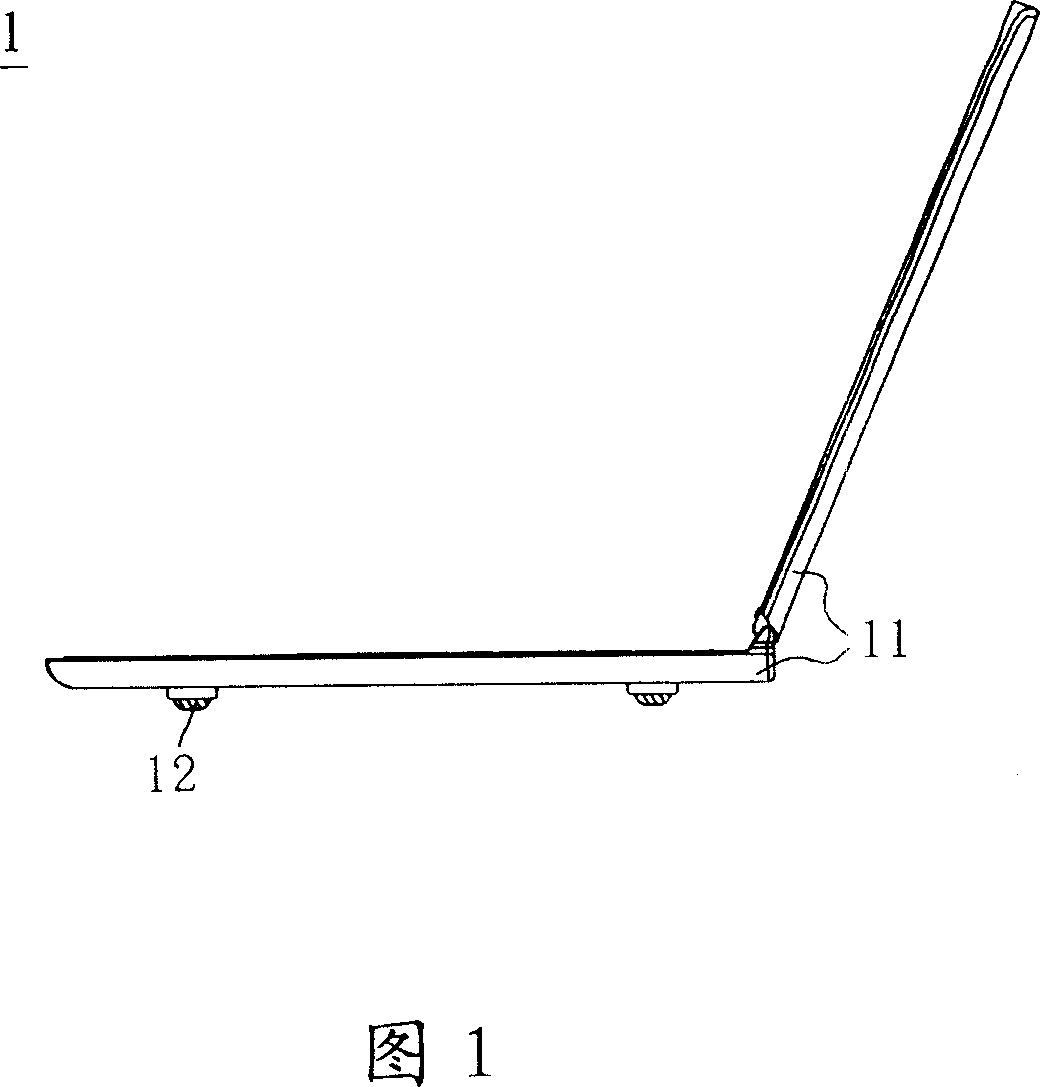

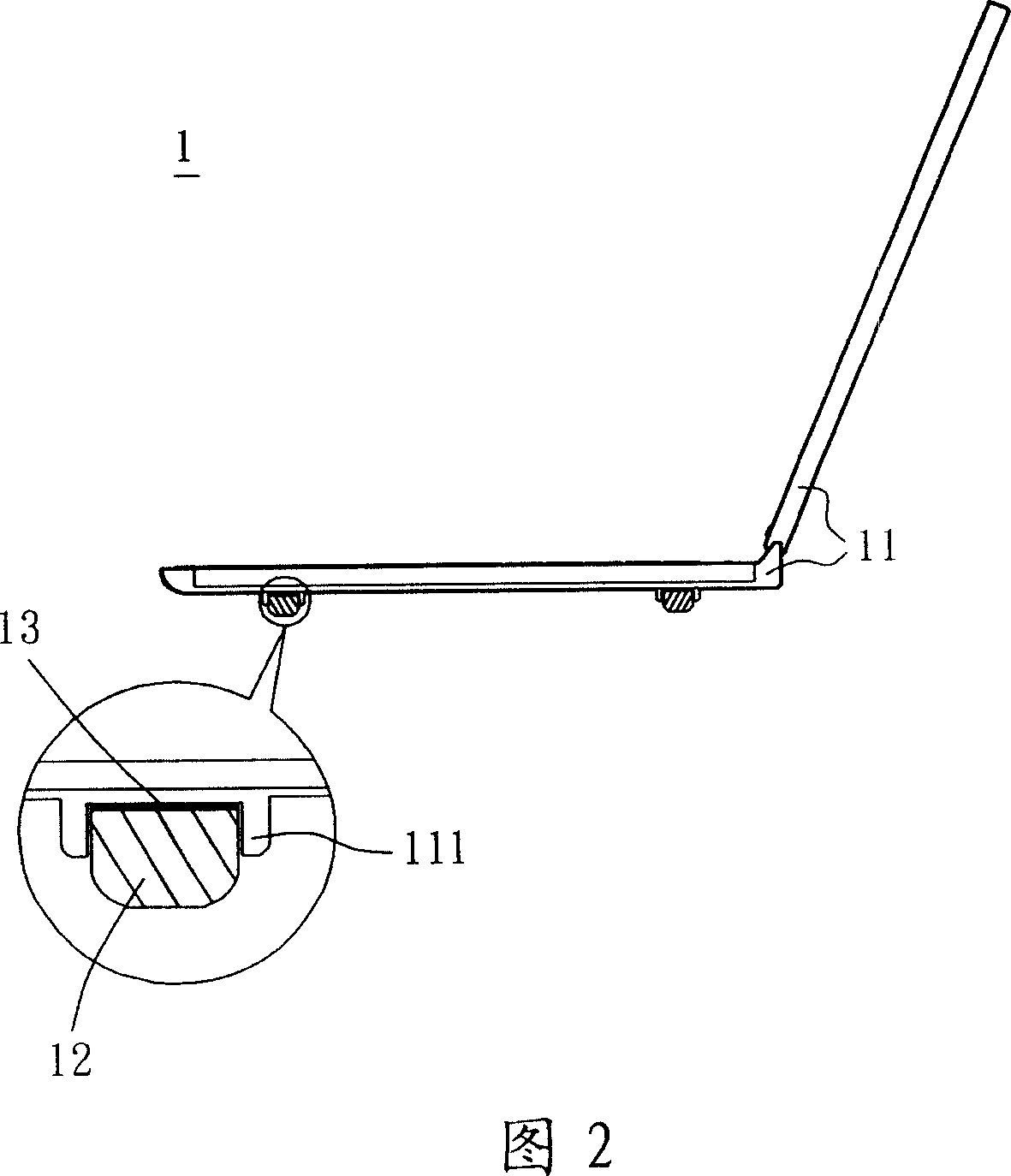

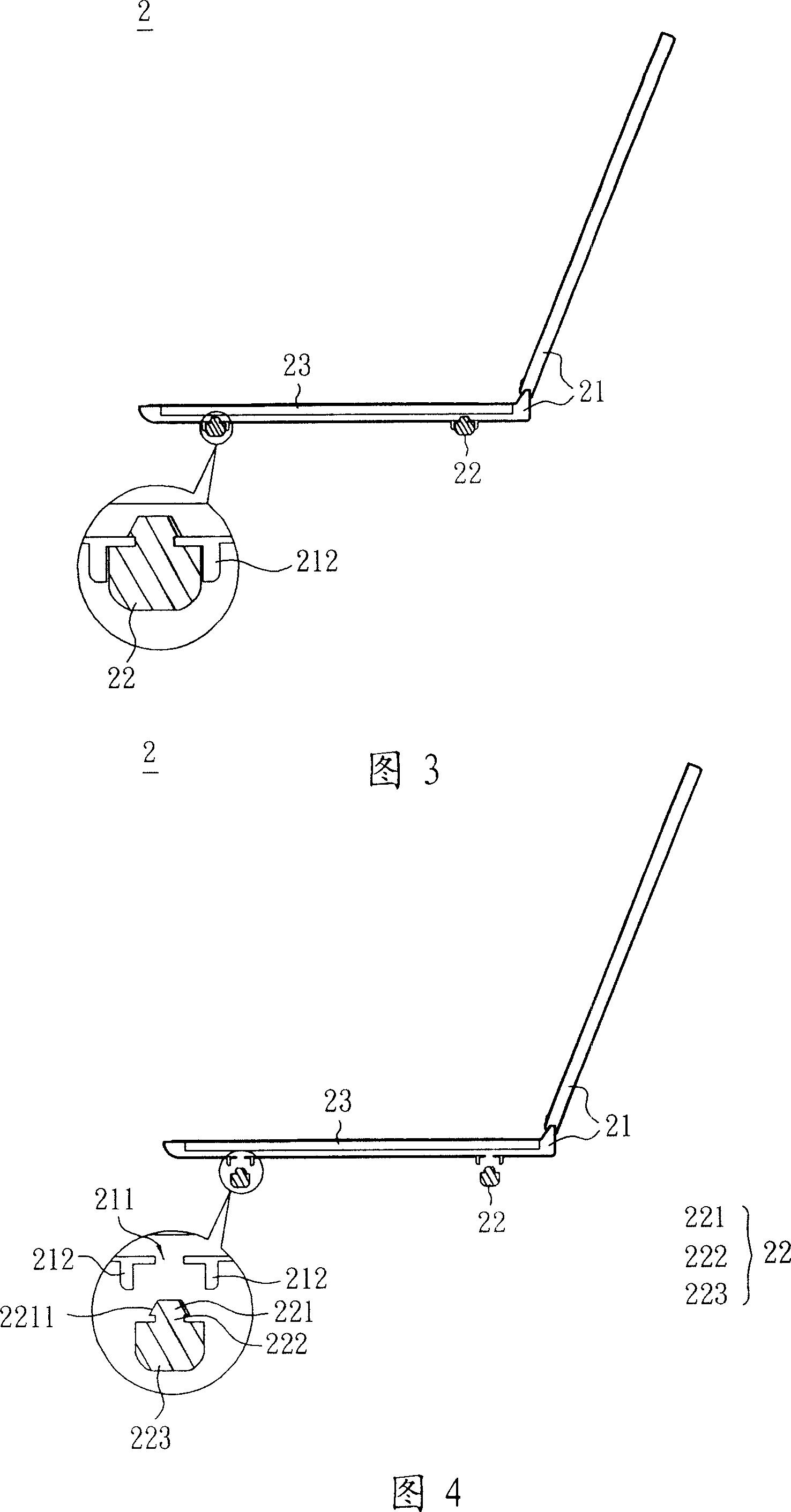

Electronic device

InactiveCN1945490AHigh bonding strengthExtended service lifeDigital data processing detailsSupport structure mountingEngineering

Owner:ASUSTEK COMPUTER INC

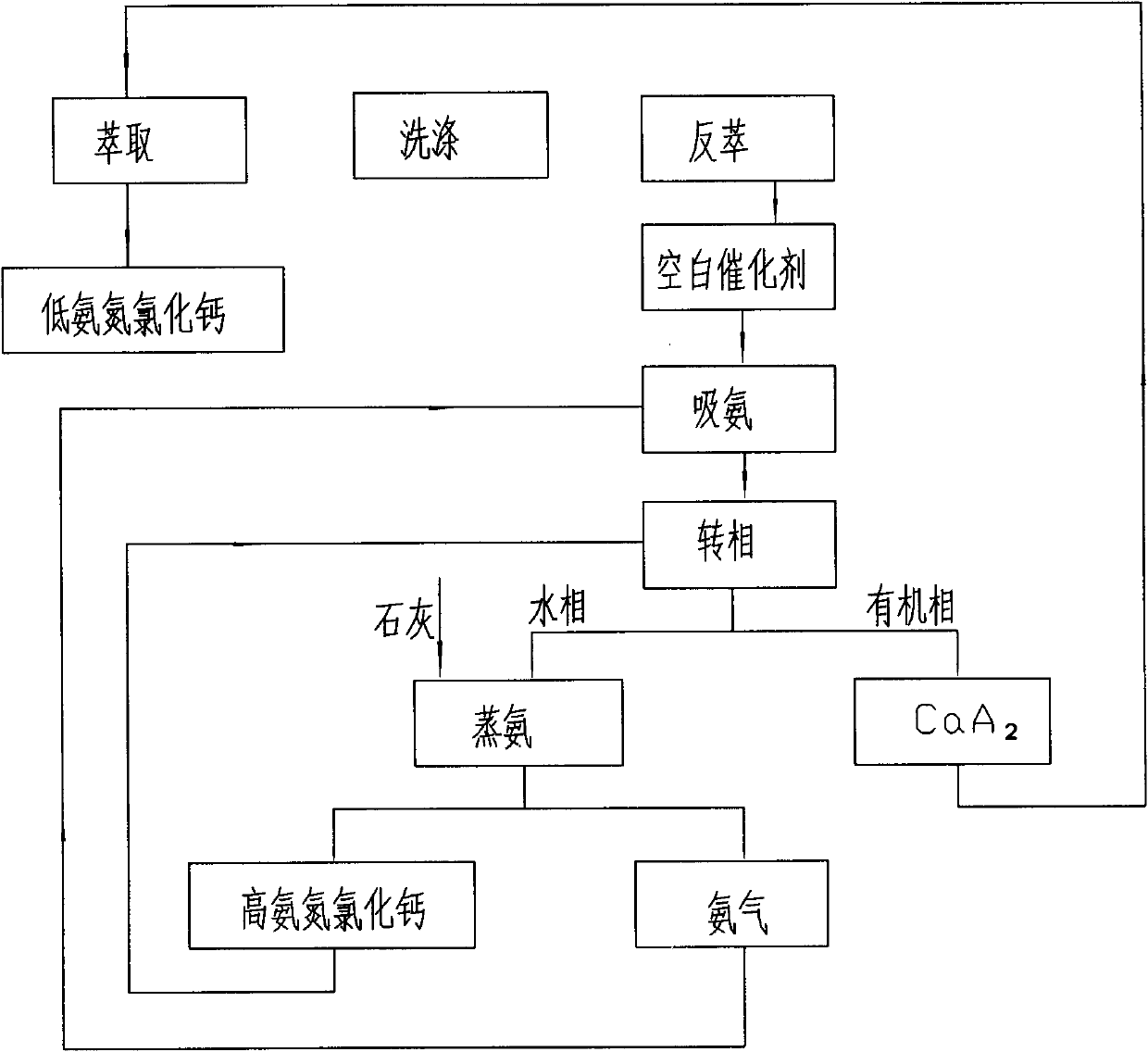

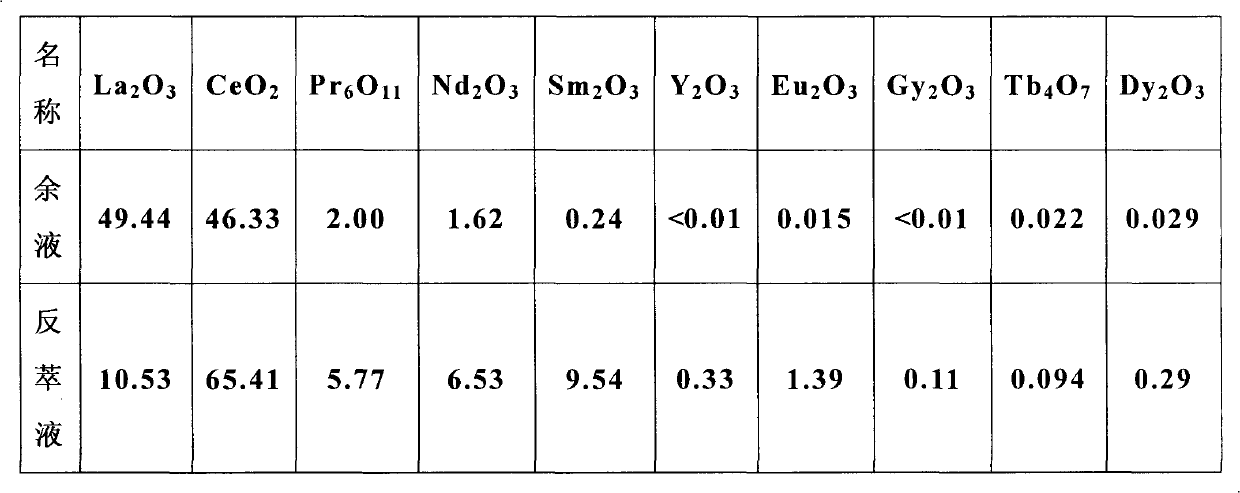

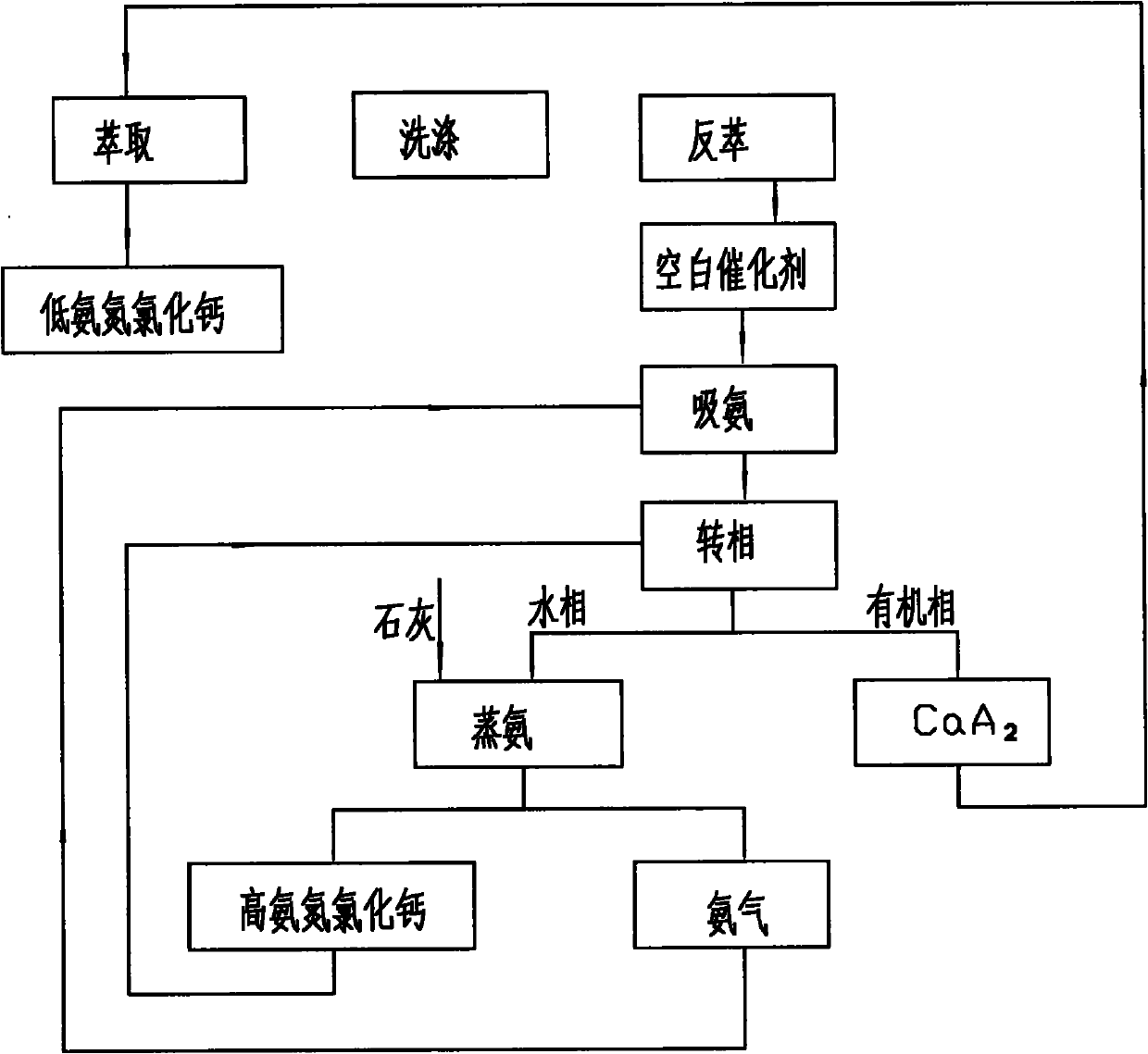

Method for preparing calcium soap by utilizing quick lime and method for processing produced emulsified compound

InactiveCN101948483ALow priceImprove economic efficiencyGroup 5/15 element organic compoundsFiltration separationAmmonium chloride mixtureHigh concentration

The invention relates to a method for preparing calcium soap by utilizing quick lime or lime milk and a method for processing produced emulsified compound, in particular to a technical method for preparing calcium soap in a rare earth extraction section by utilizing quick lime or lime milk. The method comprises the following steps: carrying out ammonia steaming-ammonia absorbing: carrying out dual firing and ammonia steaming on the quick lime or lime milk and ammonium chloride solution according to the molar ratio that n Ca+: n ammonium chloride =1: 1.5-2.2; absorbing the steamed ammonia gas by blank extracting agent to form ammonium soap; filtering or clarifying the reacted solution to obtain high concentration ammonia nitrogen calcium chloride solution; and carrying out phase inversion: mixing and stirring the ammonium soap with the high concentration ammonia nitrogen calcium chloride solution prepared by ammonia steaming-ammonia absorbing for 5-15 min, wherein the ammonium enters the aqueous phase to form ammonium chloride, the calcium enters the organic phase to form the calcium soap. In the invention, as the quick lime is adopted, the economic benefits are high, no three wastes is discharged and nopollution to the environment is generated; and meanwhile, consumption of the extracting agent can be reduced by more than 2 / 3 and the yield of the rare earth is improved.

Owner:王德兴

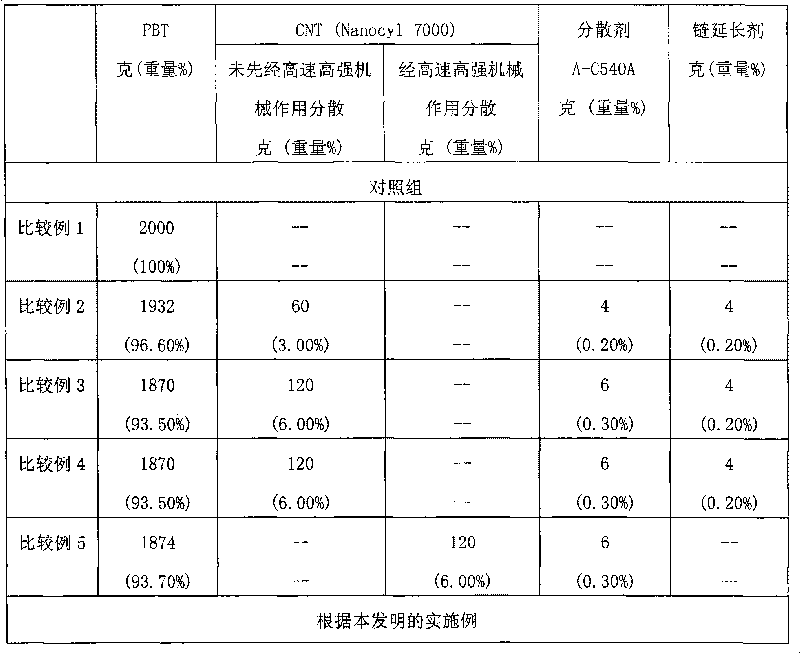

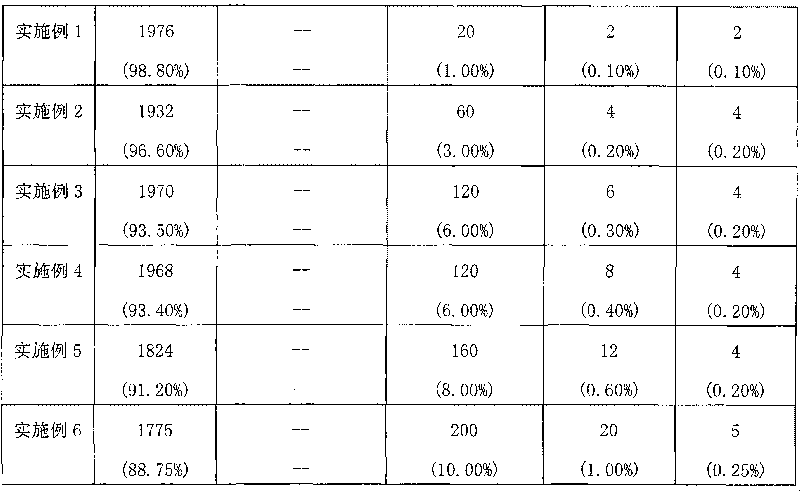

Conductive batch and conductive single fiber

ActiveCN101747597ADisperse quickly and evenlyHigh recovery rateElectroconductive/antistatic filament manufactureMelt spinning methodsSingle fiberPolybutylene terephthalate

The invention relates to a polyester substrate powder containing a poly (butylene terephthalate) high molecular substrate, a uniformly dispersive nanometer carbon tube powder, a dispersion agent and a chain extending agent, a conductive batch with uniform and smooth surface, a method for preparing the conductive batch, a conductive single fiber formed by the conductive batch, a method for preparing the conductive single fiber, and a textile prepared from the conductive single fiber. The invention has the advantage that the nanometer carbon tube fiber material with high conductivity is prepared; and the spinning property of the conductive batch can be improved to avoid the phenomena of blockage and filament breakage in the spinning procedure.

Owner:TAIWAN TEXTILE RESEARCH INSTITUTE

Method for preparing catalyst by hydrotreatment

ActiveCN102451699ACentralized distributionRegular hole structureMetal/metal-oxides/metal-hydroxide catalystsRefining to eliminate hetero atomsSimple Organic CompoundsAluminium hydroxide

The invention discloses a method for preparing a catalyst by hydrotreatment. The method comprises the following steps: gelatinizing aluminum hydroxide and adding a stable boron-containing organic compound solution, introducing a boron auxiliary agent to obtain the boron-containing aluminum hydroxide, mixing active metal ingredients with boron-containing aluminum hydroxide by a wet-mixing-kneadingmethod, three-segment roasting to obtain a catalyst intermediate, dipping the residual partial active metal and loading on the catalyst intermediate, drying to obtain the hydrotreatment catalyst. According to the invention, the boron auxiliary agent and the active metal ingredients are uniformly distributed on the surface of the catalyst, active metal ingredients introduced by two modes has different forms in the catalyst, mutual cooperation enables reduction of activity loss rate of the catalyst, and the running period of the apparatus can be prolonged. The catalyst has the characteristics of large pore volume and large specific surface area, and possesses proper pore structure and acidity, is especially suitable for hydrodenitrogenation process of heavy hydrocarbon.

Owner:CHINA PETROLEUM & CHEM CORP +1

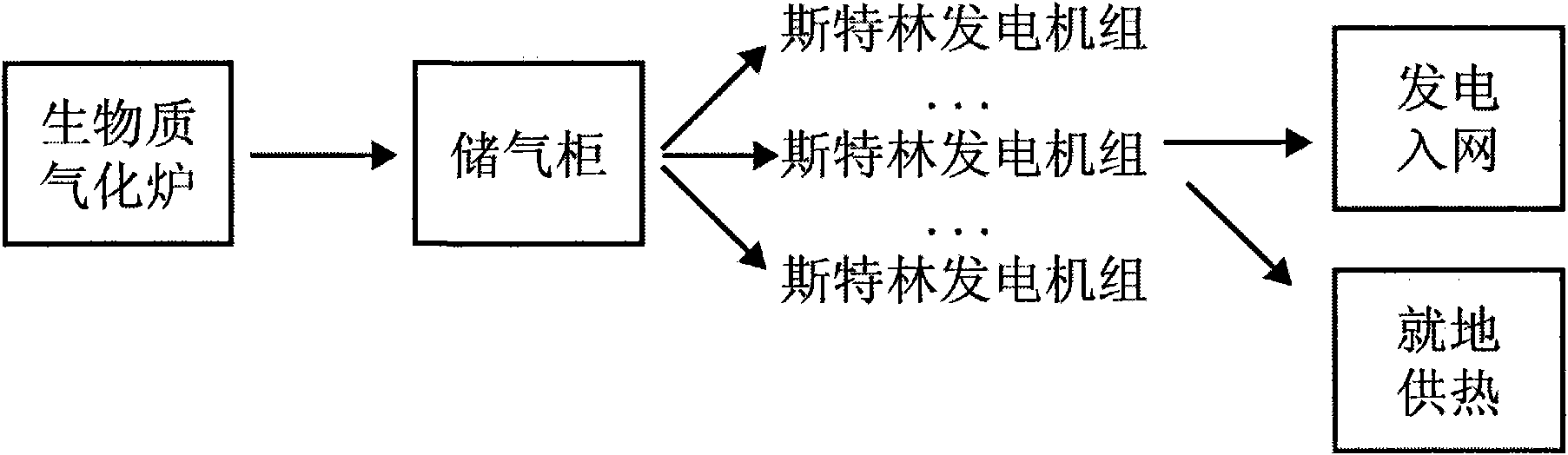

Method and device for generating by using plant straw biological substances and Strling engine

InactiveCN101592098ASolve the use problemDigest and realize comprehensive utilizationBiofuelsSpecial form destructive distillationExternal combustion engineEngineering

The invention discloses a method and a device for generating by using plant straw biological substances and a Strling engine; the method comprise the following steps (1) putting plant straw and / or leaf, chaff, sawdust or bamboo cannabis and other biological substances into a biomass gasifier; (2) carrying out pyrolytic reaction on the biological substances in the gasifier to generate combustible gas; (3) directly feeding the combustible gas into a fuel gas external combustion engine, that is to say a combustion chamber of the Strling engine, and generating high temperature of above 500 DEG C by full combustion of the combustible gas in the combustion chamber; (4) transmitting the temperature of the combustion gas in the combustion chamber of the Strling engine to working substances by a heater to facilitate the working substances flowing into a high temperature heat cavity by condensing from a low temperature cold cavity to be quickly heated so as to expand and do work to push a piston to reciprocate continuously, thus driving a generator to generate. The invention realizes the synthetic utilization of agricultural and forestry wastes, thus not only helping to protect the environment but also providing clean energy. So the invention has good popularization and application prospect.

Owner:李宜

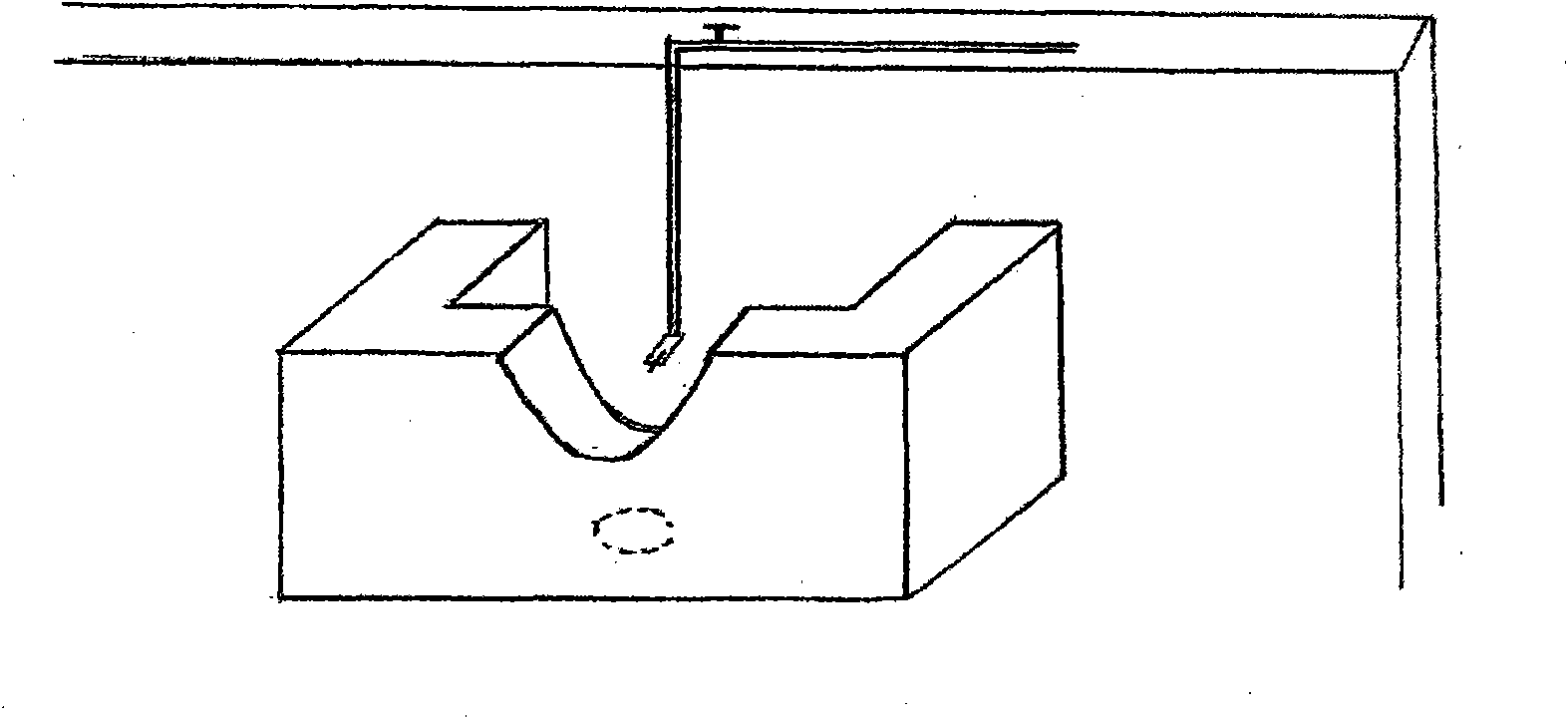

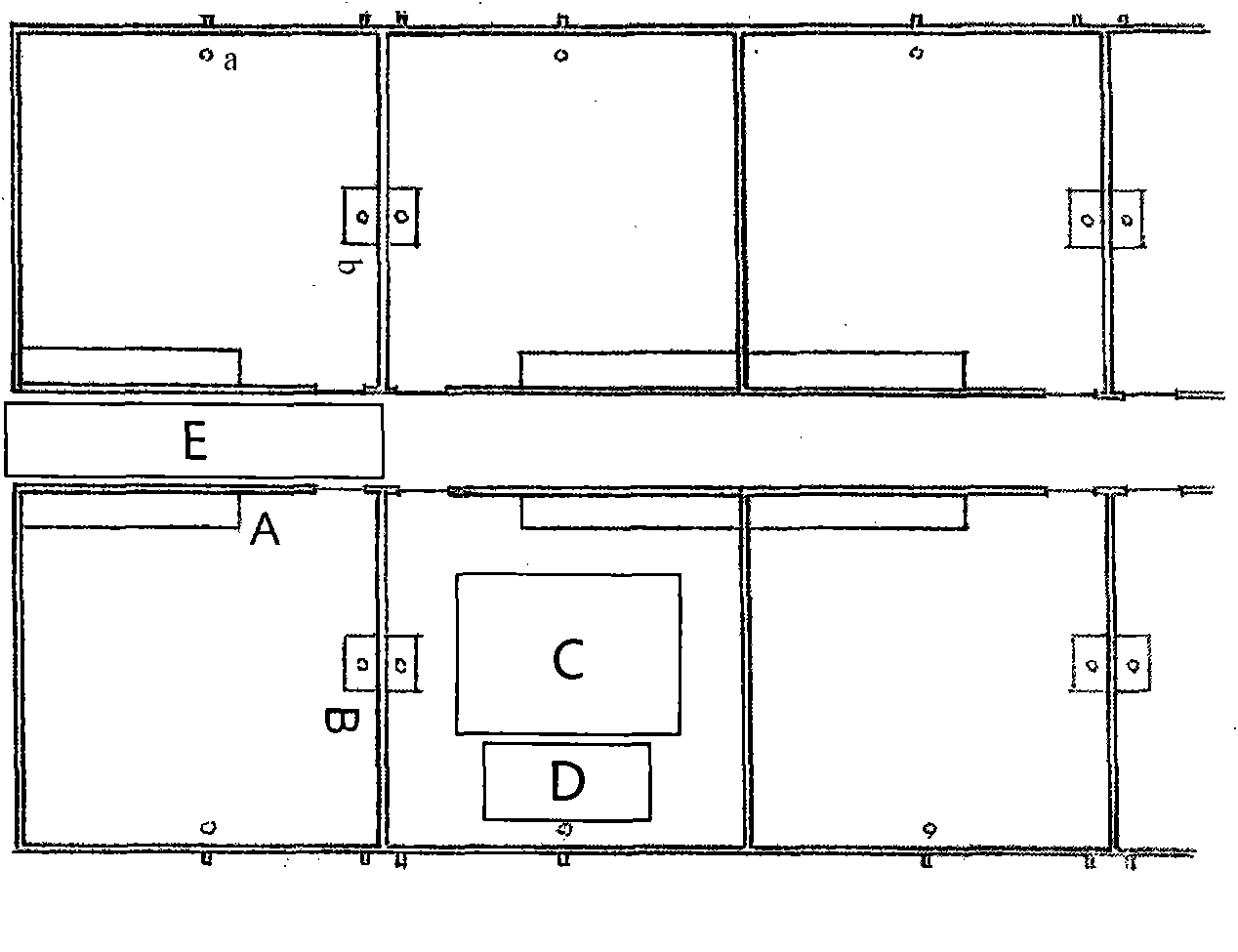

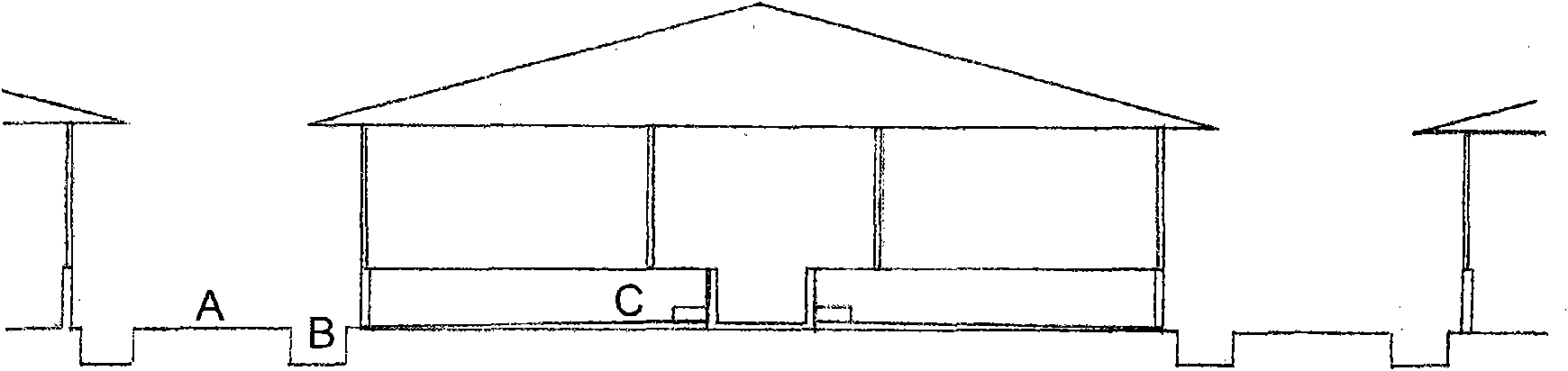

Environmentally-friendly dry odorless pig raising method and pigsty thereof

ActiveCN101911922AOdorlessZero odorAnimal housingMultistage water/sewage treatmentPig farmsHuman waste

The invention provides an environmentally-friendly dry odorless pig raising method and a pigsty thereof. A raising feed trough, a water drinking trough and a drain port are formed in the pigsty; the ground in the pigsty has gradient of 8 to 12 centimeters; and a dirt discharge port for excrement, urine and flushing is not formed in the pigsty. The invention also provides the method for raising pigs by using the pigsty. The method is convenient to clear the excrement in the pigsty by using spread padding, and the pigs drink plant extract blending solution. The environmentally-friendly dry odorless pig raising pigsty and the pig raising method are suitable for reforming a scale and intensive large-sized culturing farm and a traditional pig farm, in particular the reformation of the traditional pig farm; the reformed pig farm meets the environmentally-friendly standard; and the method has the advantages of no odor, zero emission, zero pollution, cost saving, strong disease resistance, high meat yield, delicious meat and high added value. Besides the pig raising income, the method can provide the pig excrement of the primary pollution source for an organic fertilizer plant to produce organic fertilizers so as to generate additional economic benefit.

Owner:杨兆松

Boron-containing alumina carrier and preparation method thereof

ActiveCN102451771AEffectively regulates acidityImprove anti-cokingCatalyst carriersAdhesiveAluminium hydroxide

The invention discloses a preparation method of a boron-containing alumina carrier. The method comprises the following steps of: gelling the conventional aluminum hydroxide; adding into a stable boron-containing organic compound solution; aging, filtering, washing and drying to obtain dry boron-containing aluminum hydroxide gel; mixing and molding with an adhesive; and heating and performing gradual programmed heating and baking to obtain the boron-containing alumina carrier. Boron-containing alumina is a high-performance carrier component, which can be used for providing a large pore volume and a large specific surface area, has an appropriate pore structure and acidity, and is particularly suitable for a catalyst material needed by a heavy hydrocarbon catalytic processing process.

Owner:CHINA PETROLEUM & CHEM CORP +1

A kind of environment-friendly PVC artificial leather surface treatment agent and preparation method thereof

InactiveCN102260999ASolve serious environmental problemsPlay a role in sterilizationFibre treatmentAdditive ingredientFire retardant

The invention discloses an environment-friendly PVC artificial leather surface treatment agent and a preparation method thereof. The single-component room-temperature-curing water-based acrylic acid grafted water-based urethane oil is used as a raw material, and a phosphide flame-resistant plasticizer is used as a flame retardant. It is made of auxiliary materials such as dispersant and dispersant, which effectively solves the serious environmental protection problems in the production process of solvent-based PVC artificial leather surface treatment agent. Lubricating, sterilizing, anti-mildew, anti-hydrolysis, anti-moisture absorption, anti-separation and other functions.

Owner:JIANGSU GUOXIN SYNTHETIC LEATHER

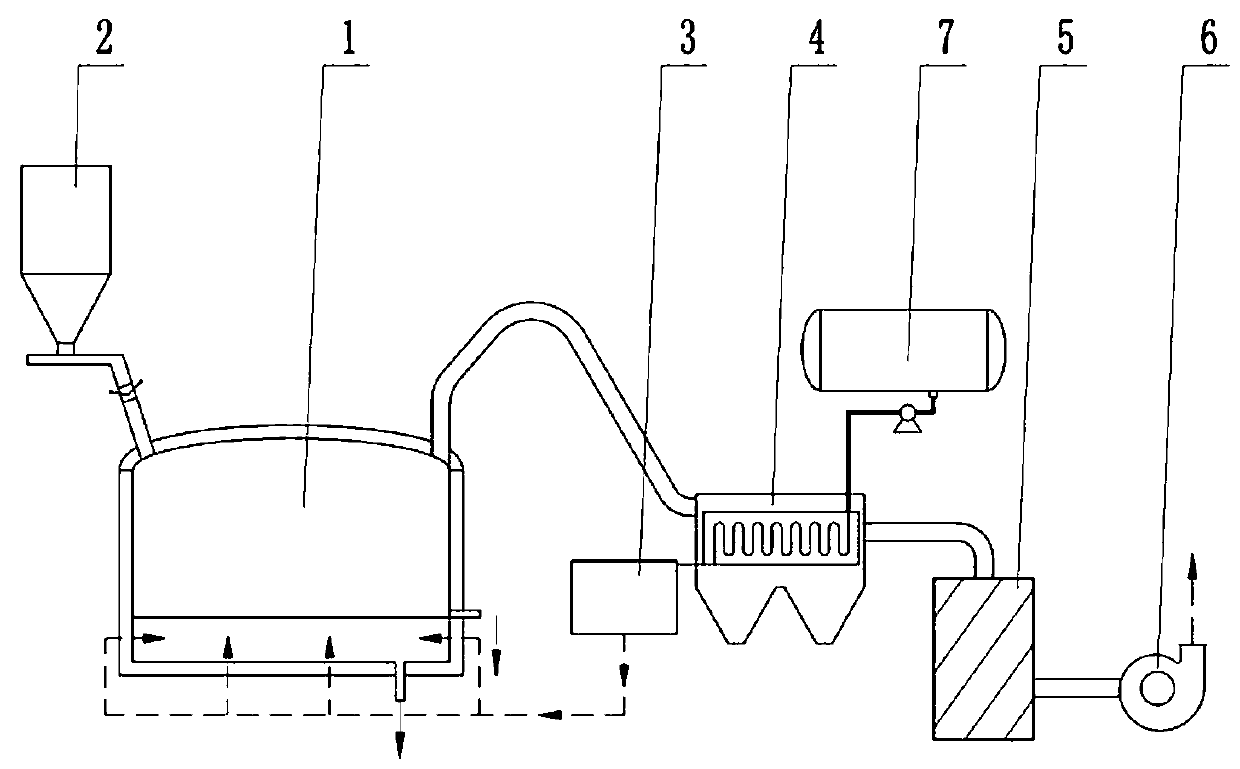

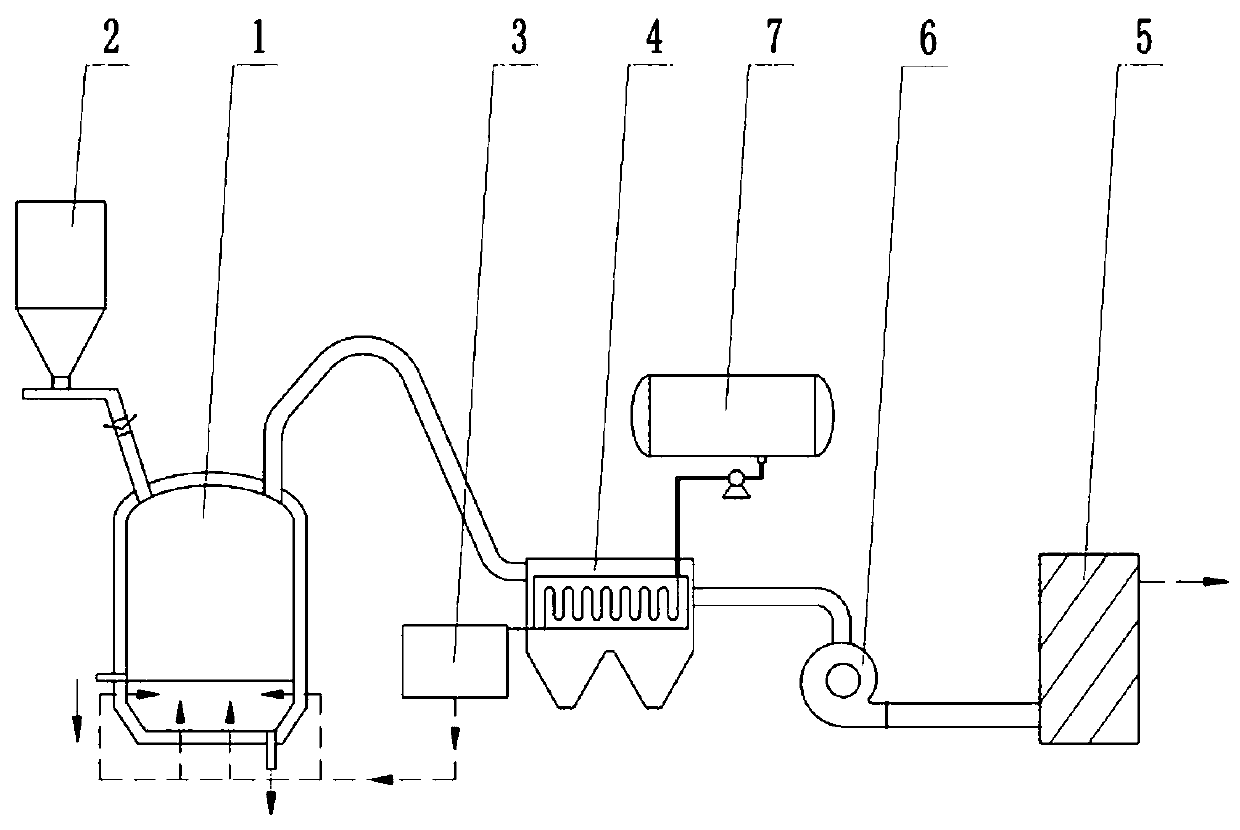

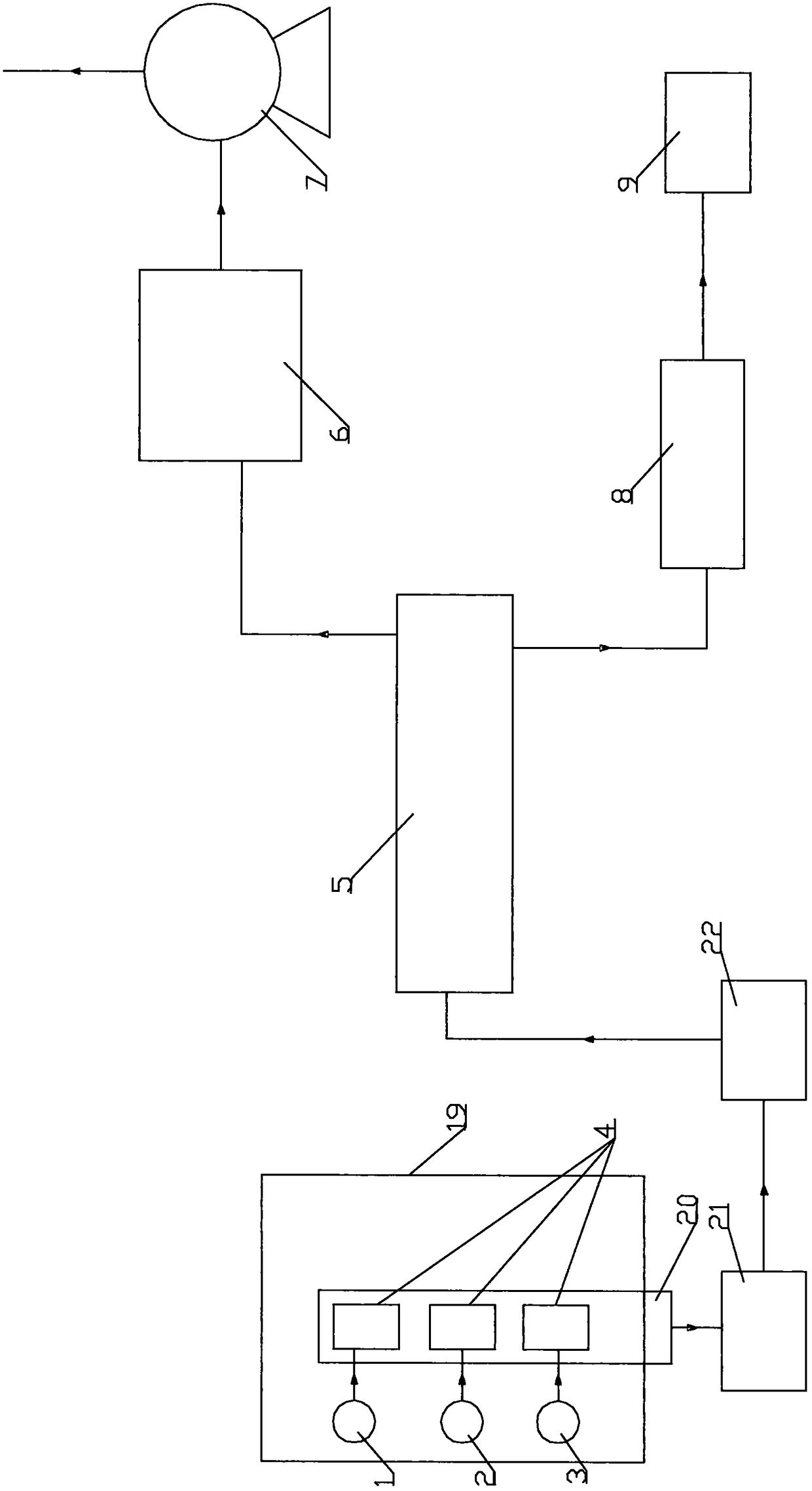

Arsenic alkali slag resource utilization device and method thereof

PendingCN110144467AEasy to handleReduce power consumptionProcess efficiency improvementAutomatic controlSlag

The invention discloses an arsenic alkali slag resource utilization device. The device comprises an electric reduction furnace, a powder air lock meter feeding device, an ammonia spraying device, a heat exchanger, a residual ammonia collating device, a centrifugal fan and an ammonia storage device. An arsenic alkali slag resource utilization method comprises the following steps that preheated arsenic alkali slag powder materials are fed into the electric reduction furnace, the ammonia is directly sprayed into the material in the furnace to be subjected to the reduction reaction, elemental antimony obtained through the reduction reaction is discharged out of a bottom outlet of the reduction furnace, rough antimony is obtained, residue is discharged out of a residue discharging opening of the side of the reduction furnace, alkali slag is obtained, elementary arsenic steam obtained through spraying reduction sublimation enters a cooler to be condensed and solidified along with hot waste airflow pulled out of an induced draft fan, rough arsenic is obtained, waste gas enters the residual ammonia collating device for waste ammonia collecting and circular use, the process flow is simple,automatic control is easy, investment is small, the treatment amount is good, the device is safe and environment friendly, the arsenic alkali slag is treated and separated thoroughly, and the arsenicalkali slag difficultly treated well serves as a raw material for producing arsenic, antimony and alkali.

Owner:长沙紫宸科技开发有限公司

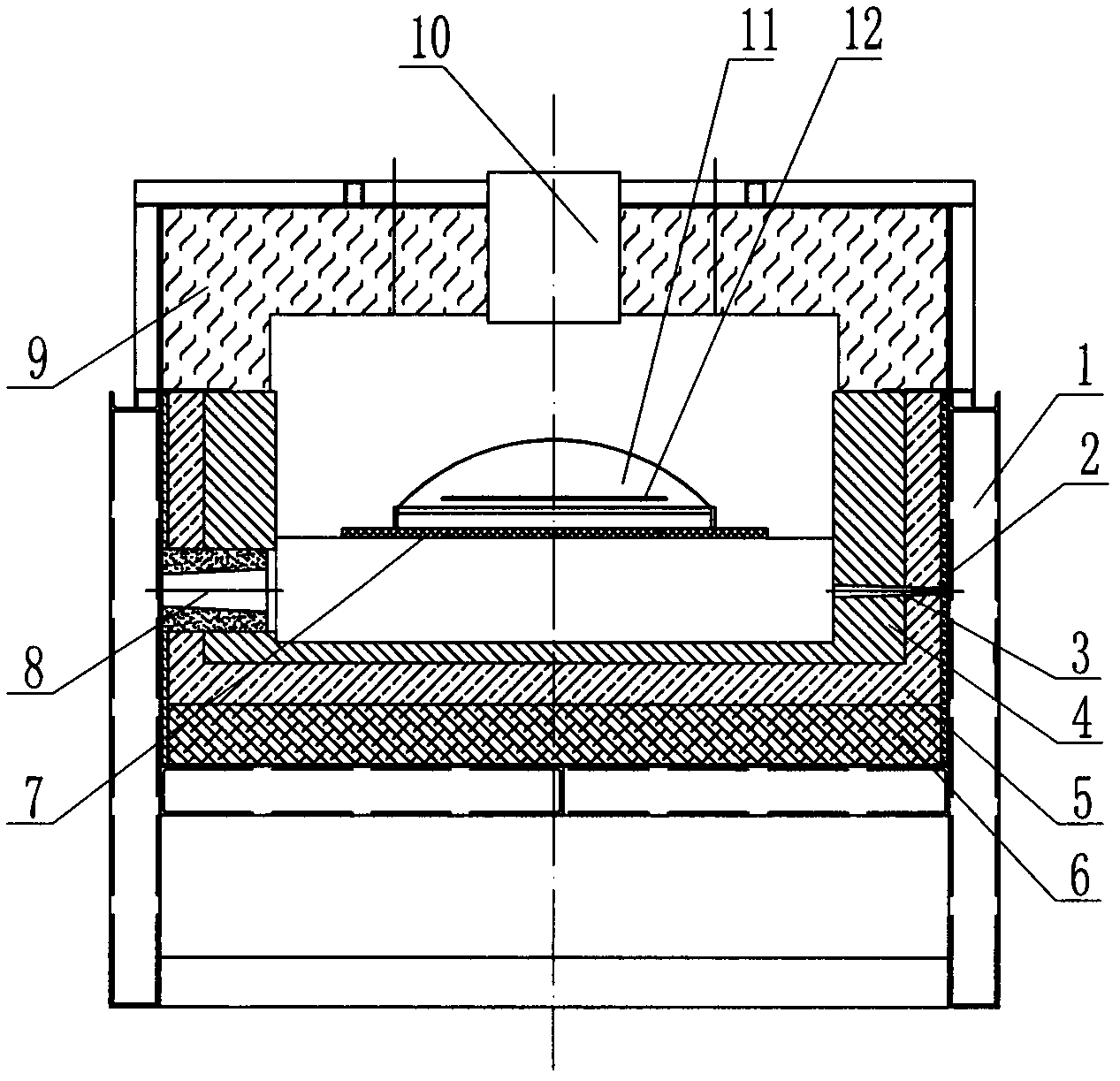

Gas type fine reduction furnace for steel strips

InactiveCN102319904ABurn fullySmall temperature differenceMuffle furnacesRetort furnacesHearthHigh load

The invention discloses a gas type fine reduction furnace for steel strips. The fine reduction furnace comprises a bracket, a shell, an observation hole, an inner furnace wall, an outer furnace wall, a bottom lining, a heat storage plate, a nozzle, a furnace roof, a vent and a muffle pipe. The shell is prepared into a horizontal rectangular box body by using a metal plate; the shell is supported by the bracket; and a hollow hearth with rectangular transverse section, consisting of the bottom lining, the outer furnace wall, the inner furnace wall and the furnace roof, is formed in the cavity of the shell. The bottom of one side of the hearth is provided with the nozzle for introducing gas, the corresponding position of the other side of the hearth is provided with the observation hole, and the vent is formed in the center of the furnace roof. The heat storage plate is horizontally placed and used for supporting the muffle pipe, the steel strip passes through the muffle pipe in the length direction, the bottom of the heat storage plate is positioned above the nozzle, and the muffle pipe is arranged on the heat storage plate to receive radiant heat. The bottom of a bottom plate of the muffle pipe is provided with a rib reinforcing structure, and the structure reduces the stress and the deformation of the muffle pipe at a high temperature and under a high load and prolongs the service life of the muffle pipe. A gas heating structure is adopted in the fine reduction furnace, so that the gas is jet from the nozzle and combusted fully, the heat efficiency is high, the temperature in the hearth is uniform, and the reduction quality consistency of the iron powder is good.

Owner:泰州市志远节能炉业设备制造厂

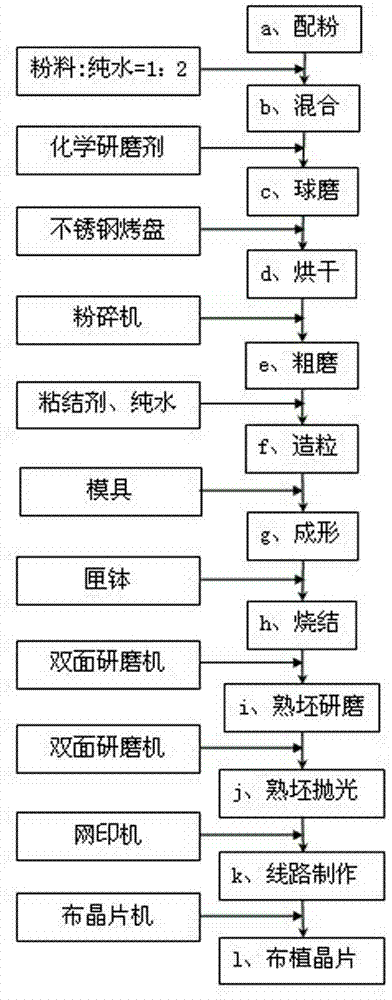

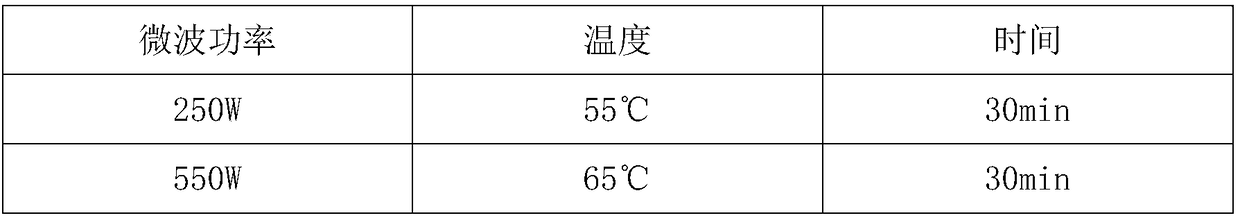

Nanostructure composite LED (Light Emitting Diode) ceramic substrate and manufacturing method thereof

InactiveCN102821550ALow purity requirementLow costPrinted circuit detailsPrinted circuit manufactureInfraredRare-earth element

The invention discloses a nanostructure composite LED (Light Emitting Diode) ceramic substrate and a manufacturing method thereof. The key steps of the manufacturing method are as follows: aluminum oxide with the purity of over 95% is taken as a primary ingredient, zinc oxide and magnesium oxide, which form semiconducting electronic ceramics of a particle boundary layer, are taken as secondary ingredients, and additionally, rare-earth elements and nano inorganic polymers, which can be used for improving the conductivity, electron mobility, intercalation and doping of the composite ceramic particle boundary layer, are taken as microscale ingredients; during manufacturing, pure water is taken as proportioning water; and the nanostructure composite LED ceramic substrate manufactured through a series of procedures and specific processes has the characteristics of nonconducting performance, antistatic performance, electromagnetic interference resistance, 0% of water immersion, longitudinal heat conductivity higher than transverse heat conductivity, two excellent heat dissipating modes, i.e., heat conduction and infrared radiation, and the like, has no any toxic components, and is environmentally-friendly, safe and especially suitable for being used as a high-power LED substrate.

Owner:佛山市煜丰机械有限公司 +1

Preparation method of silica-doped high-performance graphene material

The invention discloses a preparation method of a silica-doped high-performance graphene material. The preparation method comprises the following steps: step one, adding graphene oxide into deionizedwater, then adding a dispersing agent and carrying out ultrasonic dispersion for 20 to 40 minutes to obtain graphene oxide dispersion liquid; step two, adding a sodium hydroxide solution into the graphene oxide dispersion liquid and carrying out microwave reaction for 1 to 3 hours to obtain alkalized graphene oxide dispersion liquid; step three, adding ethyl silicate and tea polyphenol in sequenceinto absolute ethyl alcohol; after uniform stirring, slowly dropwise adding a mixed solution into the alkalized graphene oxide dispersion liquid and carrying out gradient microwave reaction for 3 to5 hours to obtain a reaction mixed solution; step four, adding hydrochloric acid into the reaction mixed solution until neutral is formed; then carrying out ultrasonic reaction for 30 to 60 minutes and filtering to obtain graphene precipitate; step five, putting the graphene precipitate into the absolute ethyl alcohol and carrying out ultrasonic reaction for 20 to 40 minutes, filtering and dryingto obtain the silica-doped graphene material. The preparation method of the silica-doped high-performance graphene material, disclosed by the invention, has the advantages that the blank of the preparation method of silica-doped graphene is filled up; in addition, reaction conditions are mild and environmental protection problems are avoided.

Owner:SHAOXING UNIVERSITY

Coal ash slag comprehensive utilization device and comprehensive utilization method

PendingCN108889771ASolve environmental problemsNo additional landSolid waste disposalCement productionBoiler slagBall mill

The invention belongs to a coal ash slag comprehensive utilization device and comprehensive utilization method. The device comprises a gasification slag raw material storage bay, a boiler slag raw material storage bay, a gas making slag raw material storage bay and the gasification slag raw material storage bay are connected with the front end of a conveying device through corresponding belt scales, the tail end of the conveying device is connected with an inlet of a ball mill, a gas outlet of the top of the ball mill is communicated with air through a first bag type dust collector and a firstinduced draft fan, an outlet of the ball mill is connected with a tee joint through a first pneumatic conveying chute and a first hoister, a second end of the tee joint is connected with a first finished product warehouse sequentially through a second pneumatic conveying chute, a first tee valve and a second hoister, and a third end of the tee joint is connected with a second finished product warehouse sequentially through a third pneumatic conveying chute, a second tee valve and a third hoister. The device has the advantages that overall investment is low, dust-free production can be realized, operation is simple, and a plurality of varieties of products can be produced according to practical requirements.

Owner:HENAN XINLIANXIN FERTILIZER

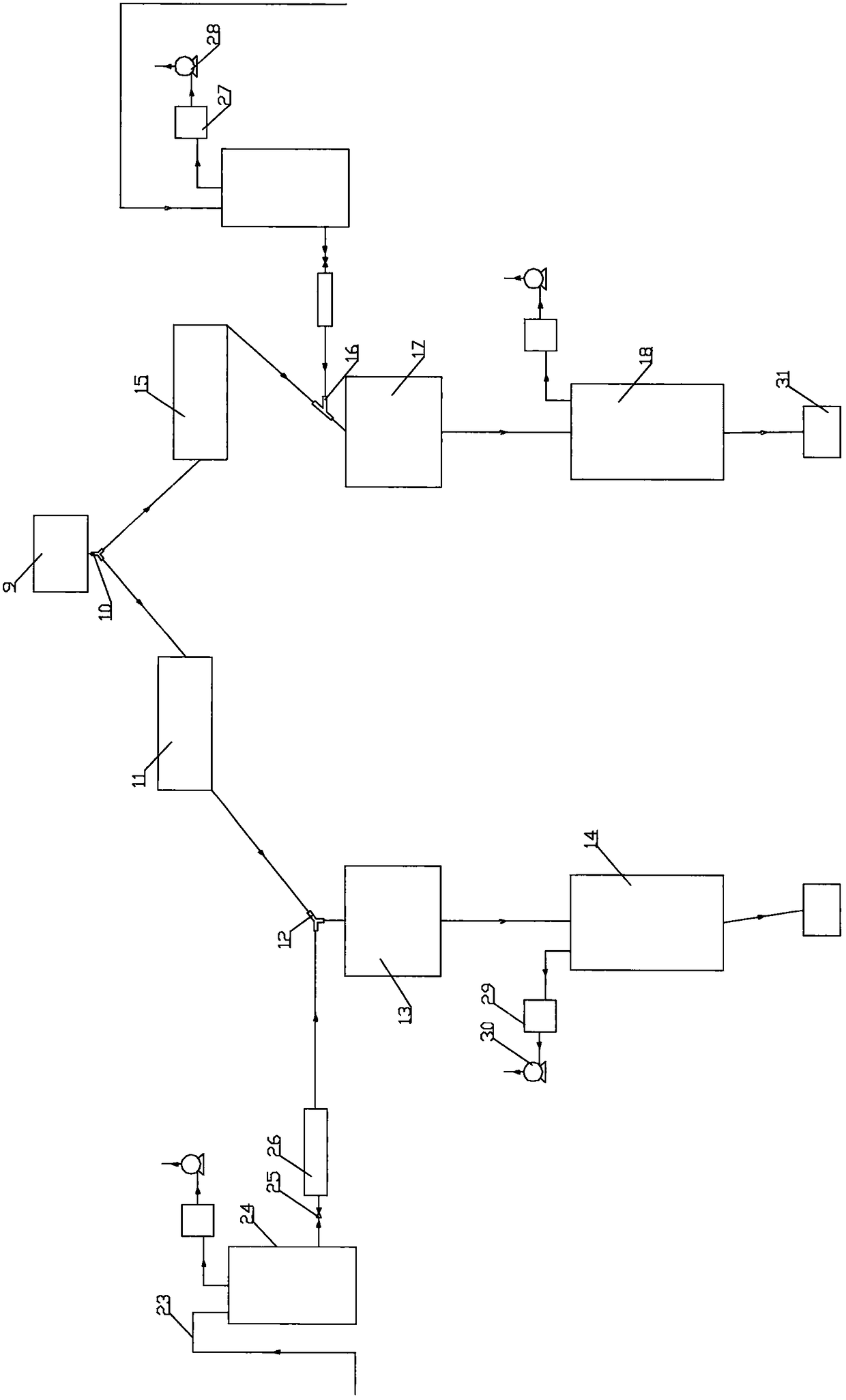

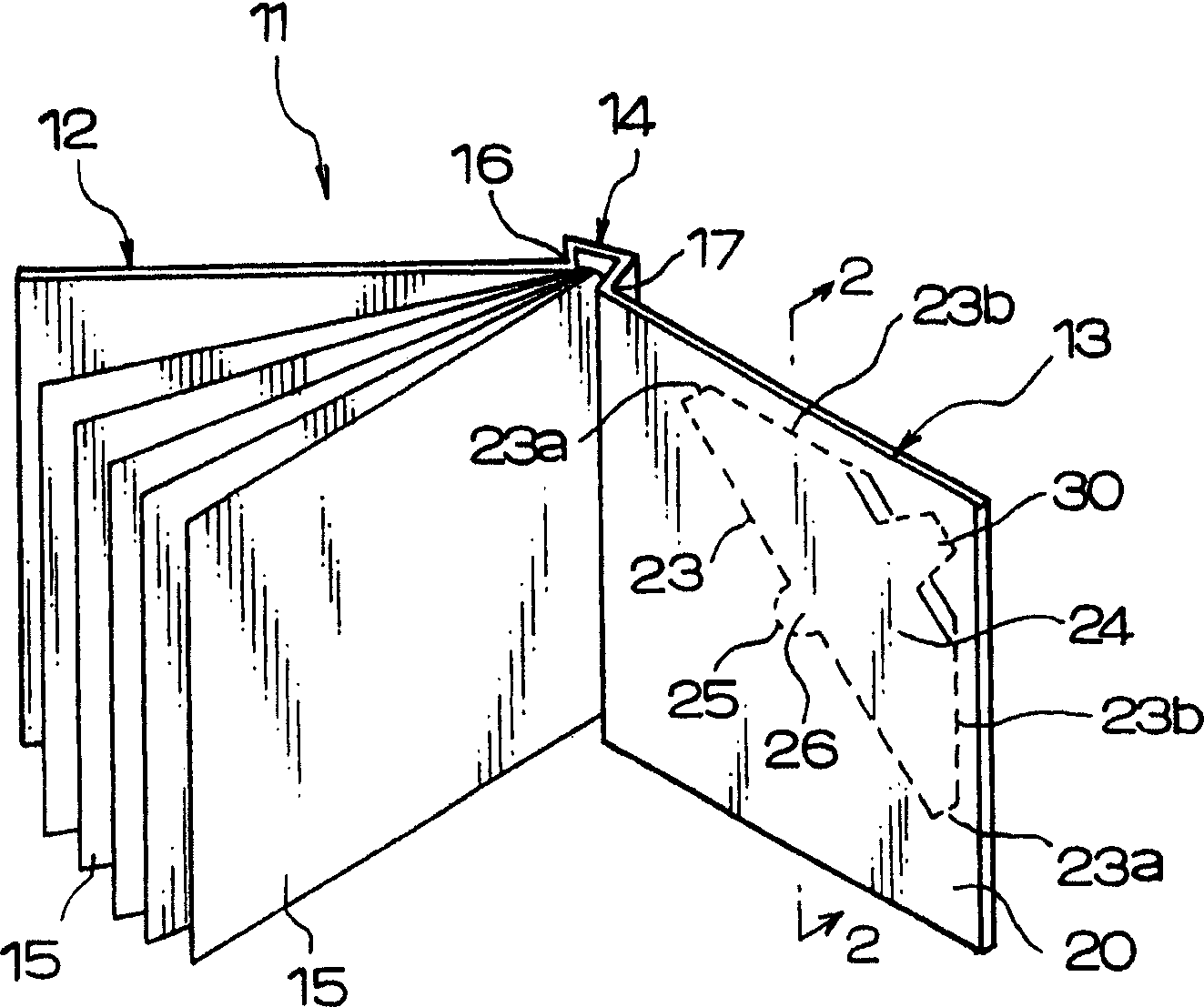

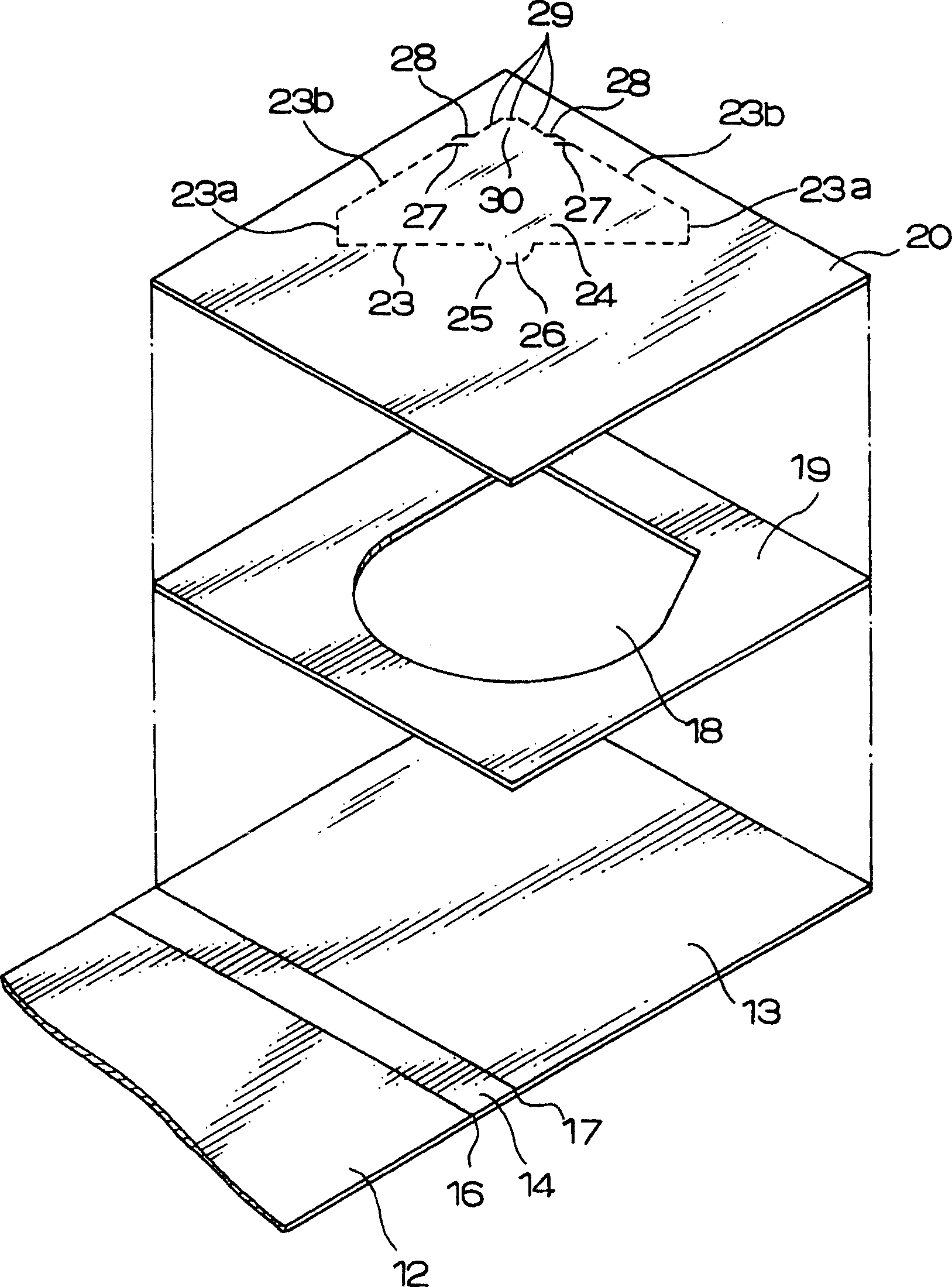

Book-type CD placing box

InactiveCN1892878ANo environmental issuesFlat record carrier containersPackagingMedial partEngineering

The book style placement box for optical disks possesses front cover, spine face, and back cover, as well as multiple paper sheets. The front cover, spine face, and back cover are folded to form book style. There are multiple paper sheets between the front cover and the back cover. At least one cover from the said front cover and the back cover possesses intermediate parts stacked each other, and medial parts in order to form stacked objects in inner side. Spaces for accepting disks are formed in the intermediate parts. There are perforation lines and creases of truncating the perforation lines on parts in inner side so as to be consistent to the spaces for accepting disks partially. Thus, aperture parts for optical disks to be fetched from the said spaces are prepared in the said parts in inner side.

Owner:东京美术纸工事业协同组合

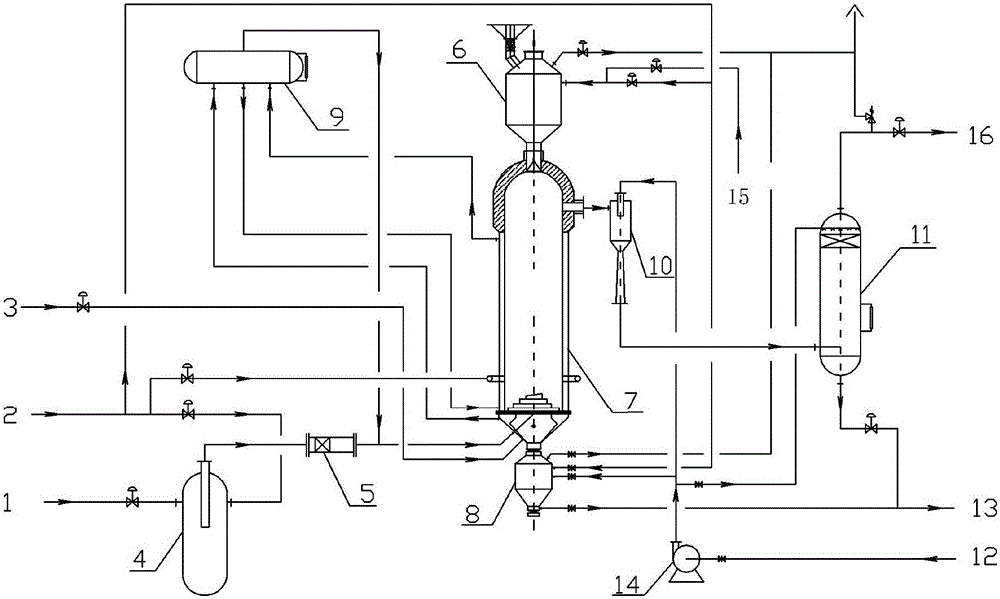

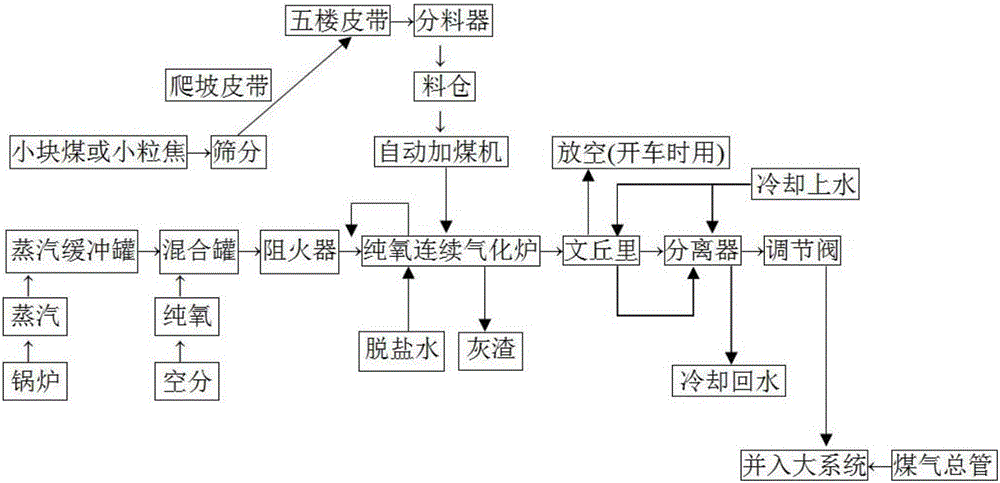

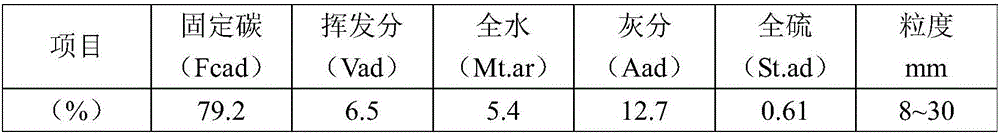

Method for production of 1.0-2.2MPa water gas by fixed bed gasification

InactiveCN105802672AReduce consumptionReduce pollutionChemical industryGasification processes detailsFixed bedProcess engineering

The invention belongs to the field of coal and coke chemical gasification and discloses a method for production of 1.0-2.2MPa water gas by fixed bed gasification. The method includes steps: adding feed coal and / or coke into a gasification furnace; feeding oxygen and steam into the gasification furnace, wherein the oxygen is 1.2-2.4MPa in pressure, concentration of the oxygen is larger than or equal to 99.6%, and the steam is 240-270 DEG C in average temperature and 1.2-2.2MPa in pressure; controlling the gasification furnace to be 1100-1250 DEG C in internal temperature and 1.0-2.2MPa in pressure, reacting to generate crude gas, washing and cooling to obtain the water gas. The supply quantity of the feed coal and / or coke is 380-420kg per kNm<3> of gas, the oxygen feeding quality is 190-220Nm<3> per kNm<3> of gas, and the steam feeding quantity is 600-650Nm<3> per kNm<3> of gas. By the method for production of 1.0-2.2MPa water gas by fixed bed gasification, the conversion rate of the feed coal and / or coke can be increased to further increase the content of effective ingredients in the gas, and the water gas produced according to the method can be directly sent to a conversion section without compression, so that remarkable energy saving and consumption reduction effects are achieved.

Owner:HENAN CHANGYU IND

Method for preparing titanium dioxide doped platinum catalyst

InactiveCN107732259AGood acid and alkali stabilityImprove photoelectric performanceCell electrodesPlatinum catalystPolyvinylpyrrolidone

The invention discloses a method for preparing a titanium dioxide doped platinum catalyst. The method comprises the following steps: preparing a platinum ion alcohol solution, namely, preparing the platinum ion alcohol solution from polyvinylpyrrolidone as an additive, performing a sealed reaction for 4-8 hours, and naturally cooling to the room temperature so as to obtain a reaction alcohol solution; putting the reaction alcohol solution into a vacuum distillation device, performing vacuum distillation for 2-8 hours so as to obtain a concentrated solution; slowly putting distilled water intothe concentrated solution, uniformly stirring till stable suspended precipitate is formed, and filtering so as to obtain nano platinum granules; stirring nano titanium dioxide, putting into the nano platinum granules, putting into deionized water, performing ball-milling, and performing a stirring reaction for 2-5 hours under radiation of an ultraviolet lamp so as to obtain a suspension; filteringthe suspension so as to obtain precipitate, and sequentially washing the precipitate with absolute ethyl alcohol, methanol and deionized water, thereby obtaining the titanium dioxide doped platinum catalyst. The catalyst prepared by using the method is good in acid-alkali stability and excellent in photoelectric property, and the catalysis efficiency of a noble metal catalyst is improved.

Owner:SHAOXING UNIVERSITY

Method for treating straw in microorganism and earthworm coupled system

InactiveCN106810308AReduce processing timeNo fermentationBio-organic fraction processingClimate change adaptationBiotechnologyFeces

The invention belongs to the technical field of agricultural solid organic waste biological treatment, and specifically relates to a method for treating straw in a microorganism and earthworm coupled system. According to the method, the straw is treated while an earthworm feed is prepared without fermentation by using powdery waste crop straw, broken and dried fruit peel and vegetable as well as a microbial agent. The preparation parameters are as follows: (1) uniformly mixing 80% of the powdery waste crop straw and 20% of the broken and dried fruit peel and vegetable; (2) adding the high microbial agent into the earthworm mixed feed. The earthworm feed produced by the method is popular for earthworm, high in quality and high in efficiency; the problems that the crop straw remains and pollution is generated by incineration can be effectively solved, meanwhile the straw treatment time is shortened without fermentation, and generated earthworm excrement is converted into efficient bio-organic fertilizer, so that the development prospect is extremely wide.

Owner:HEILONGJIANG UNIVERSITY OF SCIENCE AND TECHNOLOGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com