Nanostructure composite LED (Light Emitting Diode) ceramic substrate and manufacturing method thereof

A nanostructure composite, ceramic substrate technology, applied in the direction of printed circuit manufacturing, electrical components, printed circuit components, etc., can solve the problems of poor adaptability, low yield, poor antistatic performance, etc., to reduce costs and product quality. Good results with low purity requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

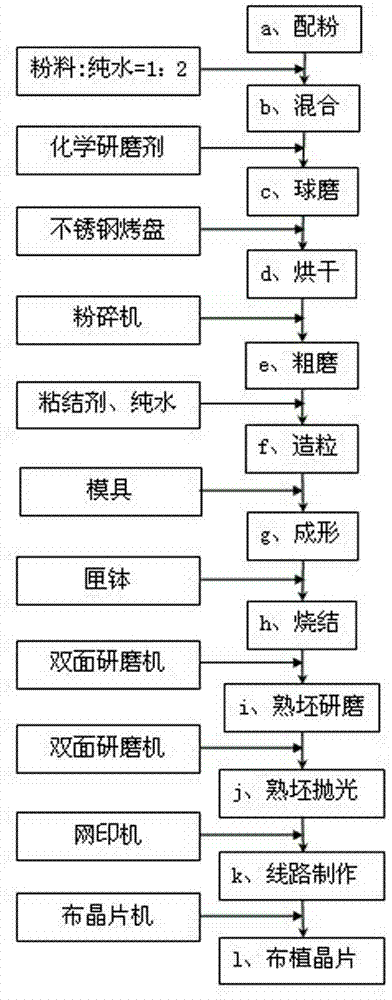

[0037] As a preferred embodiment, the technical process see figure 1 ,right figure 1 A method for manufacturing a nanostructure composite LED ceramic substrate according to the steps shown, is characterized in that it comprises the following steps:

[0038] a. Mixing powder, according to the weight percentage of the powder, 80% of alumina with a purity of >95%, 15% of zinc oxide and magnesium oxide, 5% of rare earth elements and nano-inorganic polymers, among which nano-inorganic polymers are one-dimensional Any value <100nm, the particle size of the rest of the powder is 1~2μm, the ambient temperature is maintained between 15°C~25°C, the temperature is 65%, and the circulating wind speed is less than 0.5m / s;

[0039] b. Mixing, mix the prepared powder and pure water in a ratio of 1:2 to form a slurry, and add an appropriate amount of chemical abrasive to the code name CM5, the resistance value of pure water is >5MΩ, and the pure water is allowed to stand It should not excee...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| electrical resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com