Method for production of 1.0-2.2MPa water gas by fixed bed gasification

A water gas, fixed bed technology, applied in fixed bed gasification, gasification process, chemical industry and other directions, can solve the problem of high production cost, achieve the effect of small workload, reduce consumption and reduce pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

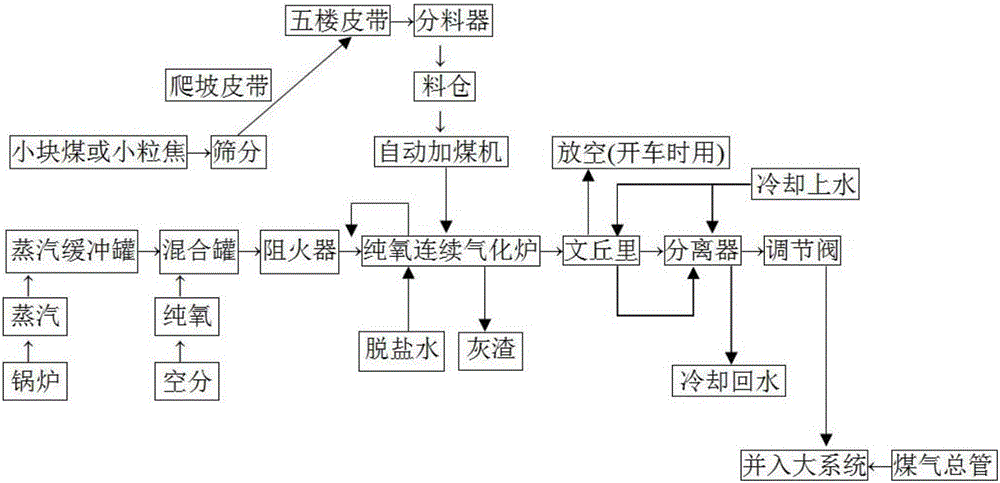

[0029] The method for producing 2.0MPa water gas by continuous gasification of pure oxygen in a fixed bed comprises the following steps:

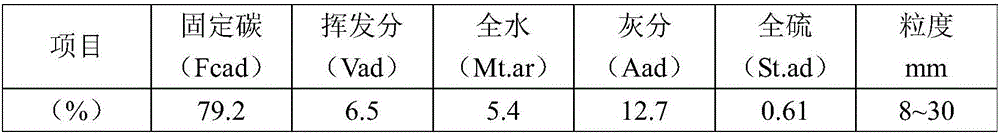

[0030] With anthracite small lump coal (analysis index sees table 1 below) (383kg / kNm 3 Coal gas) into the gasifier, while the pressure of 2.2MPa of oxygen (202Nm 3 / kNm 3 gas) and external source steam (330kg / kNm 3 Coal gas) and internal source steam with temperature 215℃ and pressure 2.1MPa are passed into the gasifier (the total amount of steam introduced is 633kg / kNm 3 Coal gas), control the temperature in the gasifier to 1100-1200°C, pressure 2.0MPa (pressure measurement on the top of the furnace), and react to generate crude gas with a temperature of about 470°C. After the crude gas is washed and cooled, clean water gas with a temperature of 200°C can be obtained .

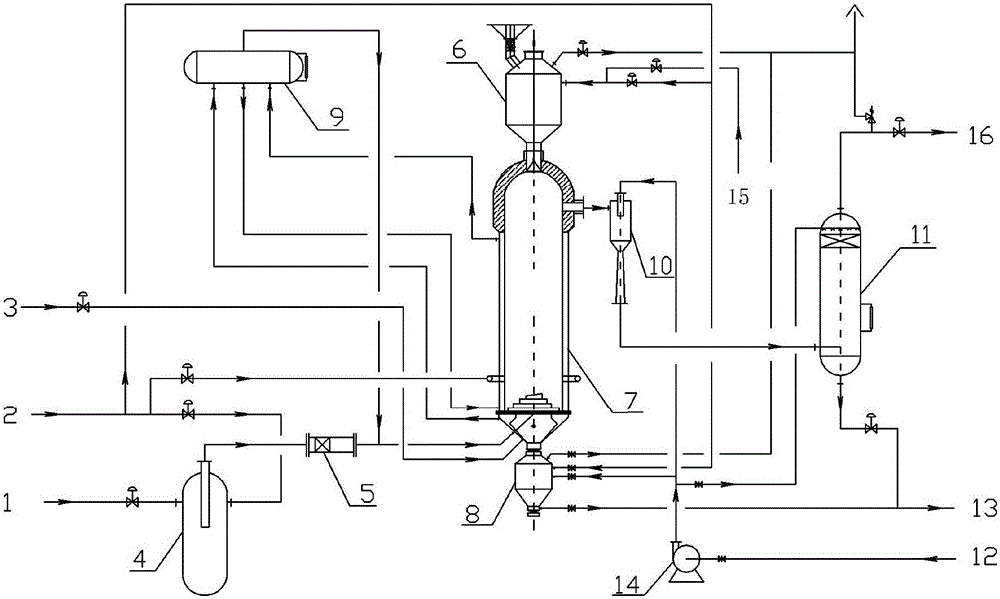

[0031] like figure 1 As shown, the water gas production system in this embodiment includes a gasifier 7 , the feed port of the gasifier 7 is connected to the coal fe...

Embodiment 2

[0044] The method for producing 2.0MPa water gas by continuous gasification of pure oxygen in a fixed bed comprises the following steps:

[0045] Small particle coke (analysis index sees table 4 below) (411kg / kNm 3 Coal gas) into the gasifier, while oxygen (219Nm 3 / kNm 3 gas) and external source steam (302kg / kNm 3 coal gas) and internal source steam at a temperature of 215°C and a pressure of 2.1MPa are passed into the gasifier (the total amount of steam introduced is 602kg / kNm 3 Coal gas), control the temperature in the gasifier to 1100-1200°C, pressure 2.0MPa (pressure measurement on the top of the furnace), and react to generate crude gas with a temperature of about 480°C. After the crude gas is washed and cooled, clean water gas with a temperature of 200°C can be obtained . The water gas production system is the same as in Example 1, the water gas composition is shown in Table 5 below, and the gasification reaction consumption index is shown in Table 6 below. Furnace...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com