Patents

Literature

255results about How to "Reduce driving time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

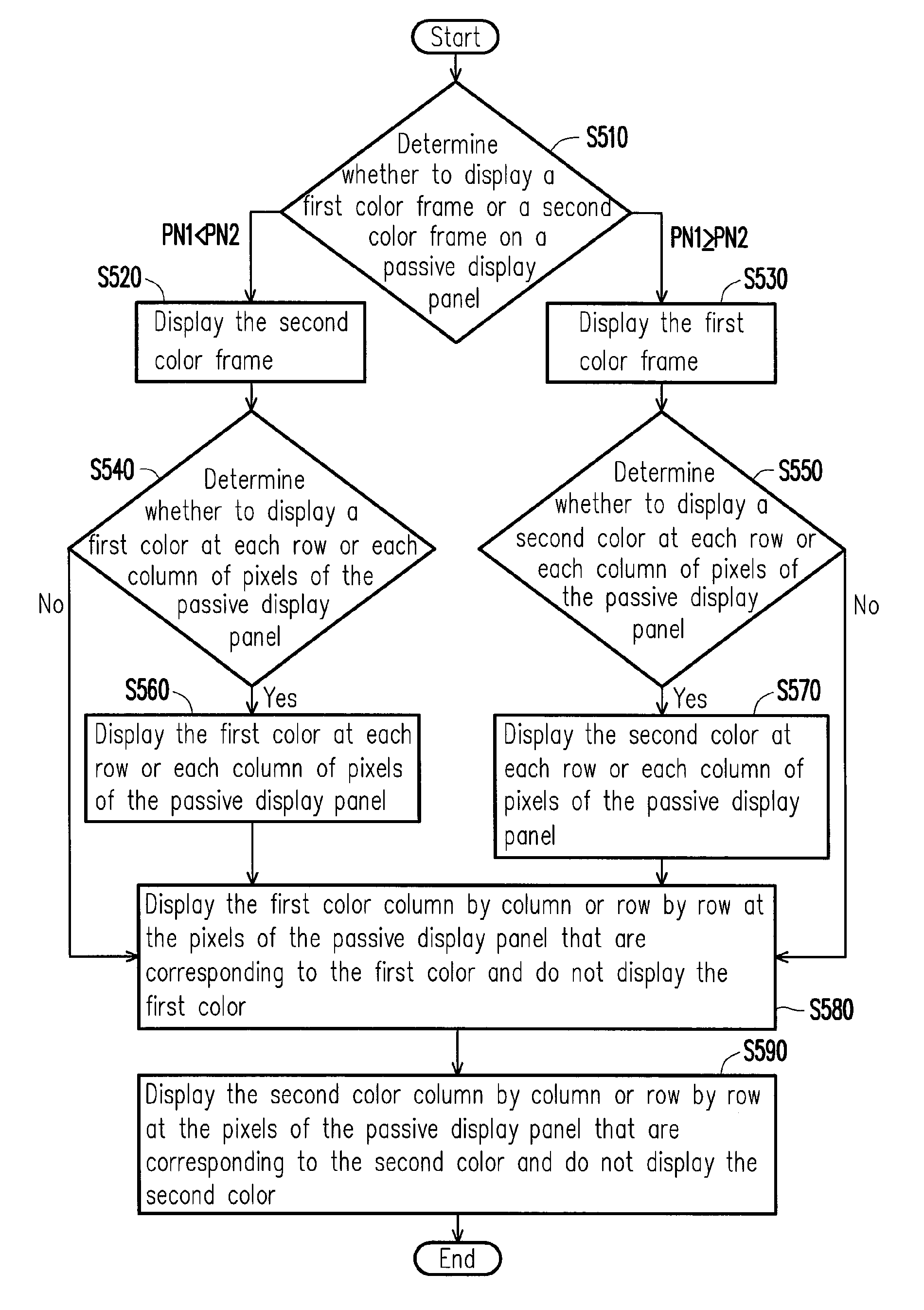

Driving method of passive display panel and display apparatus

ActiveUS9019198B2Reduce driving timeImpact of capacitive coupling effect on the display quality of the pixels can beStatic indicating devicesComputer visionComputer science

Owner:YUANHAN MATERIALS INC

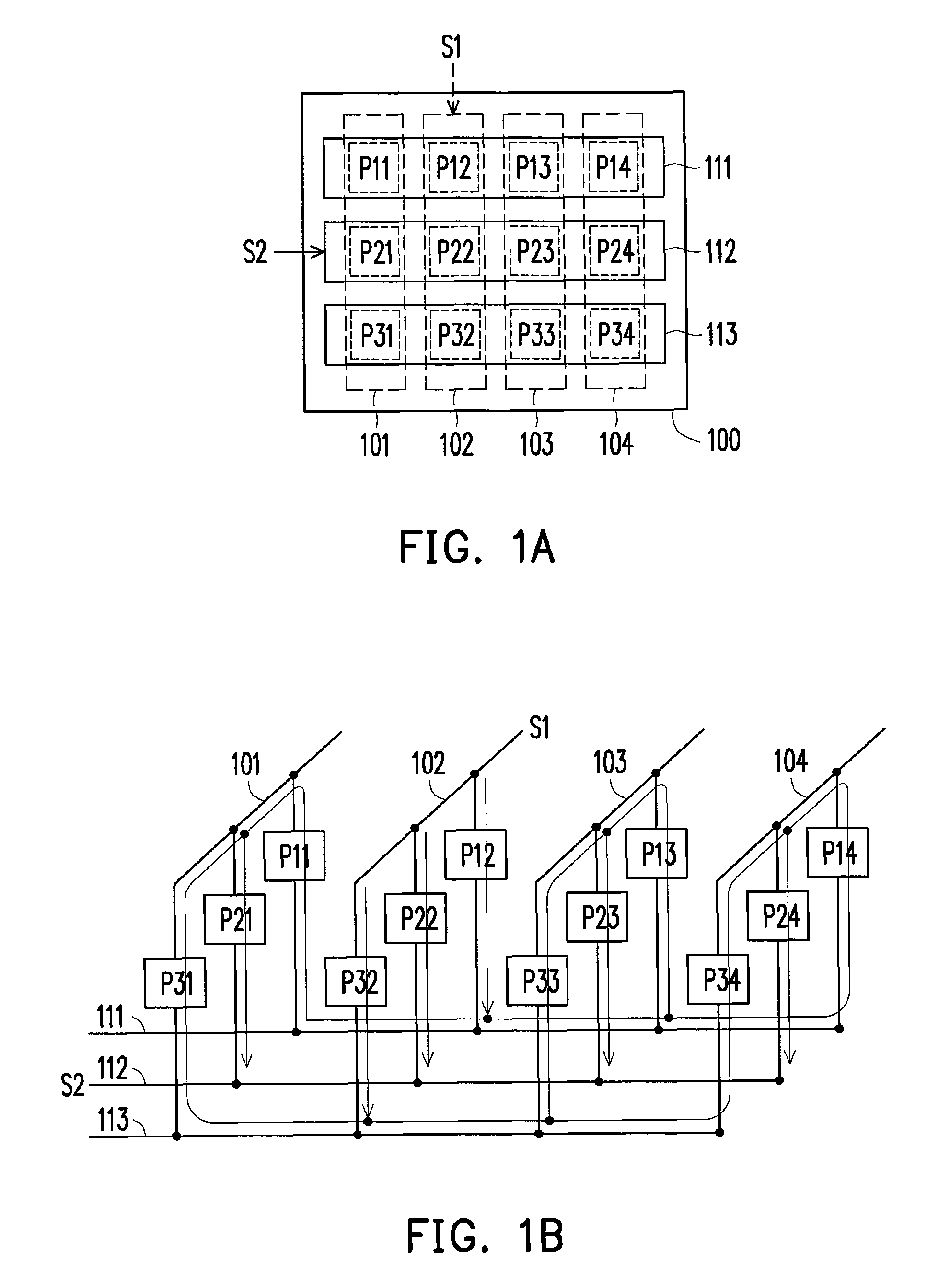

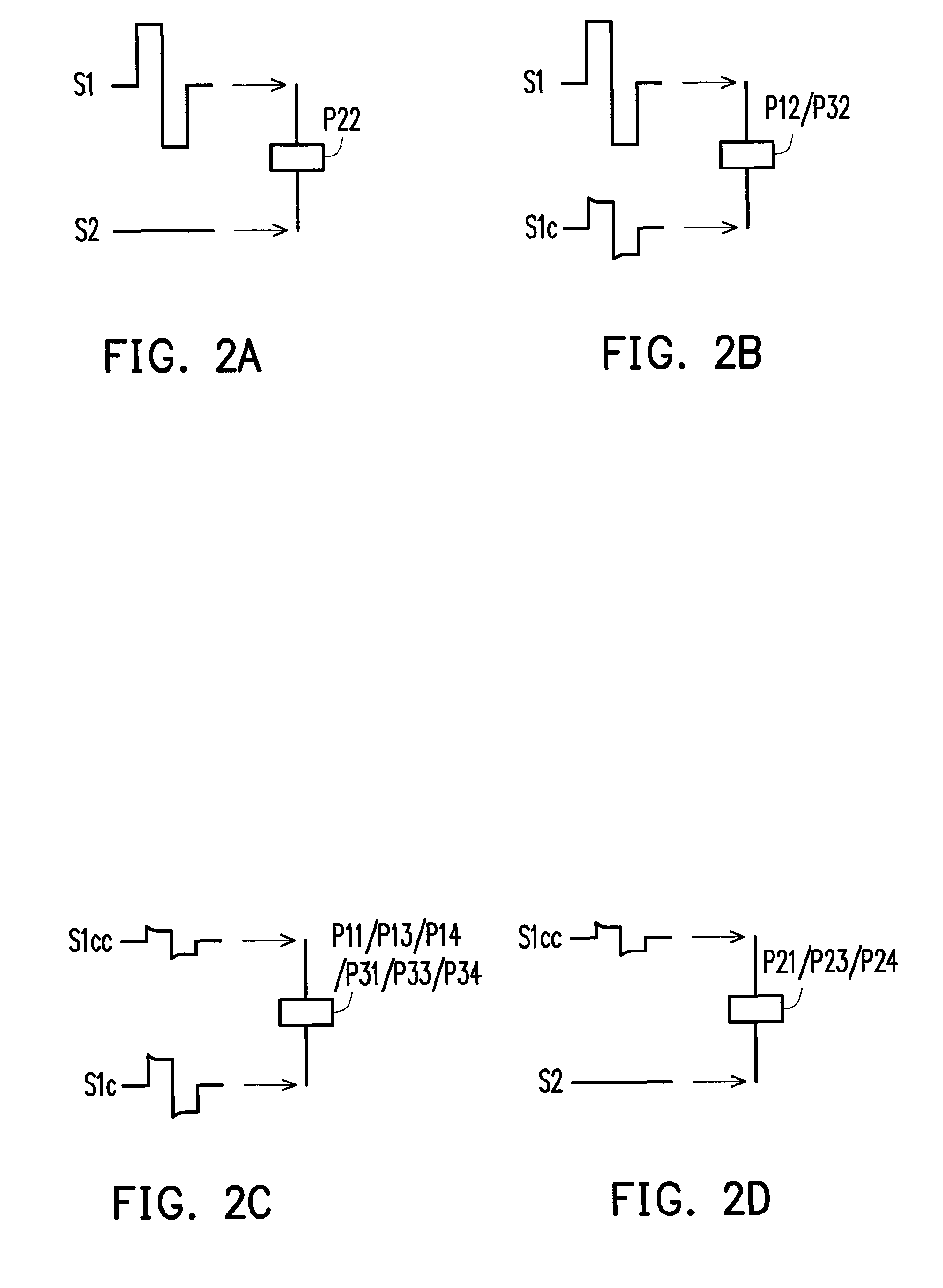

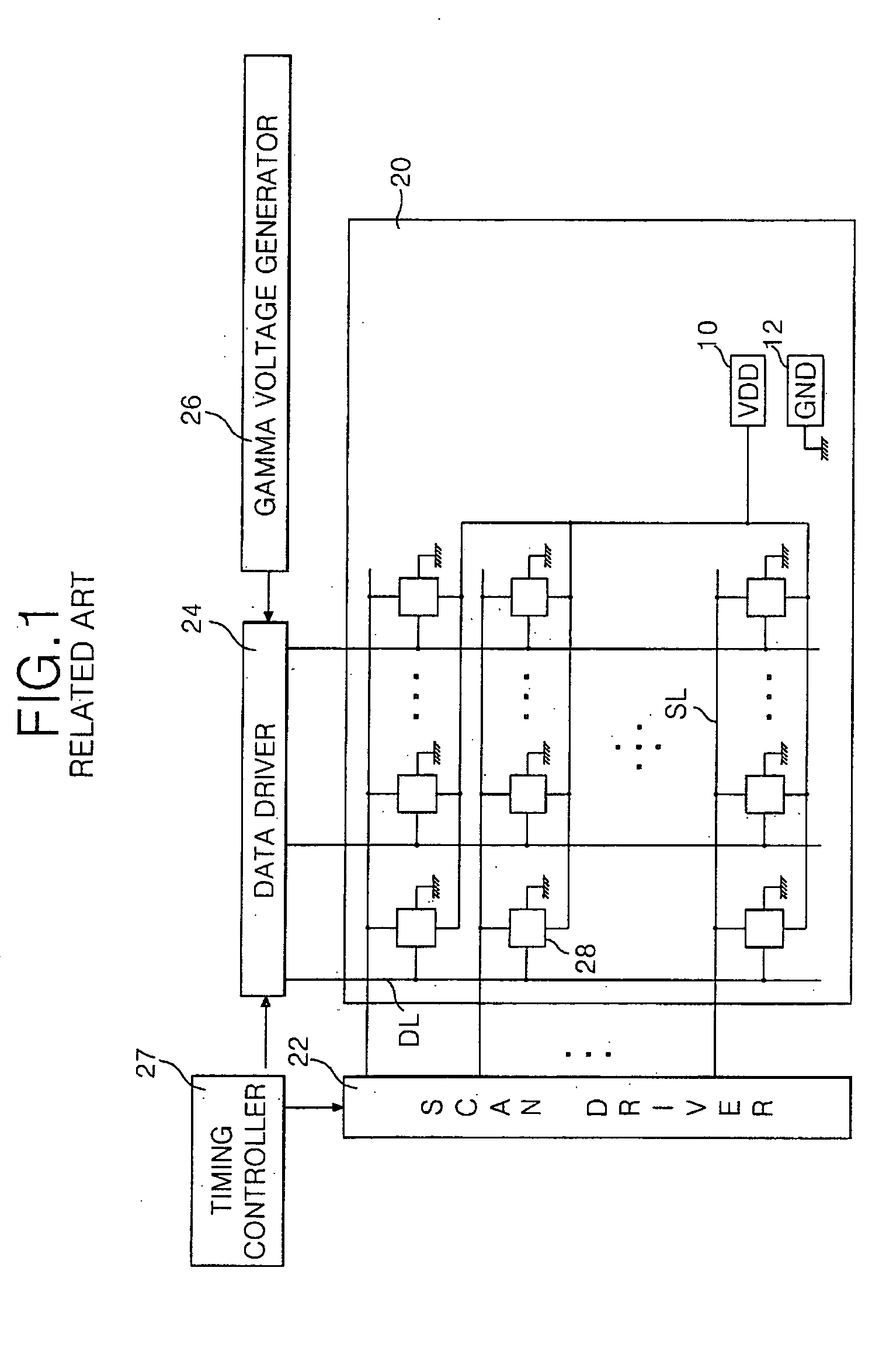

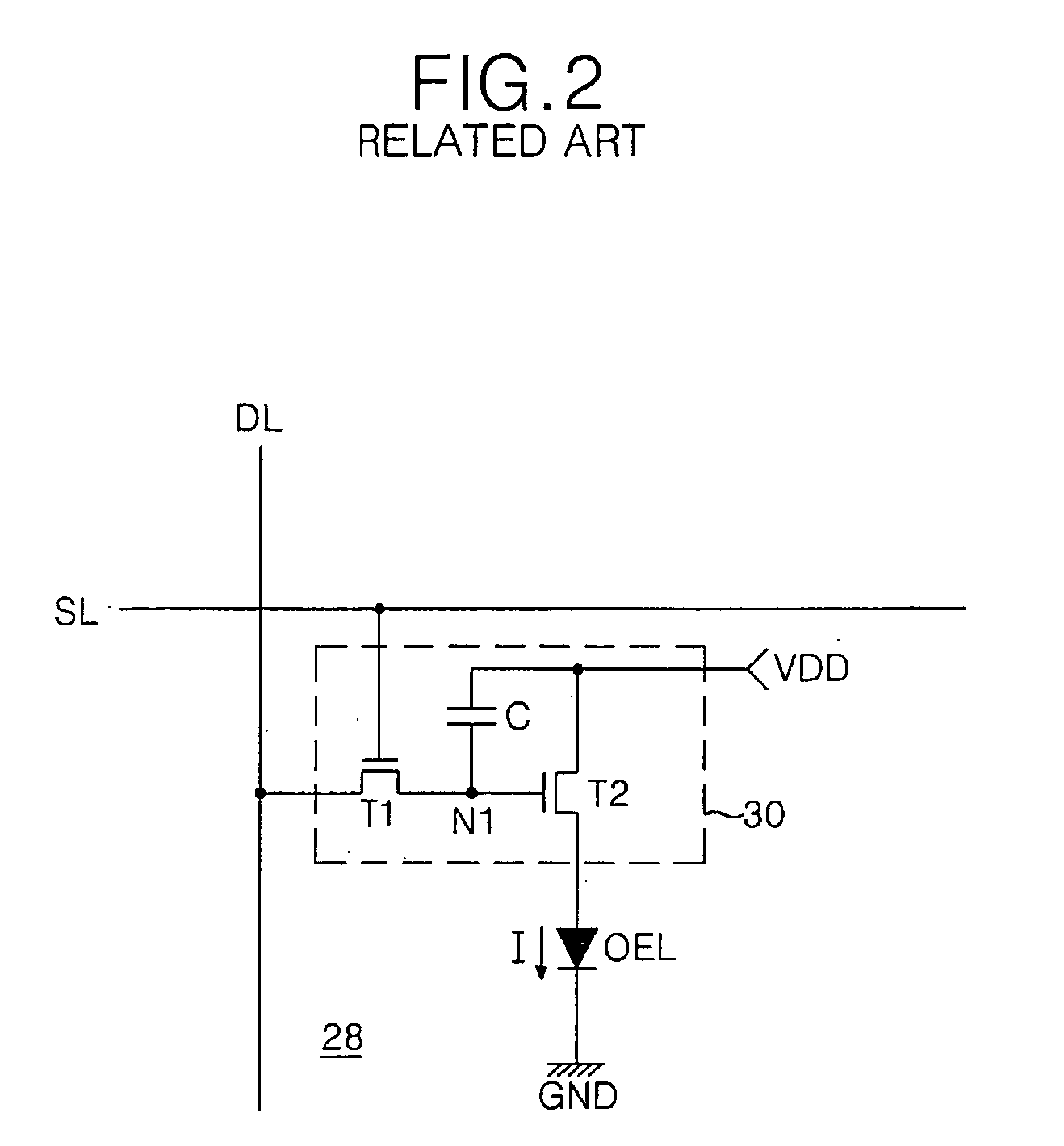

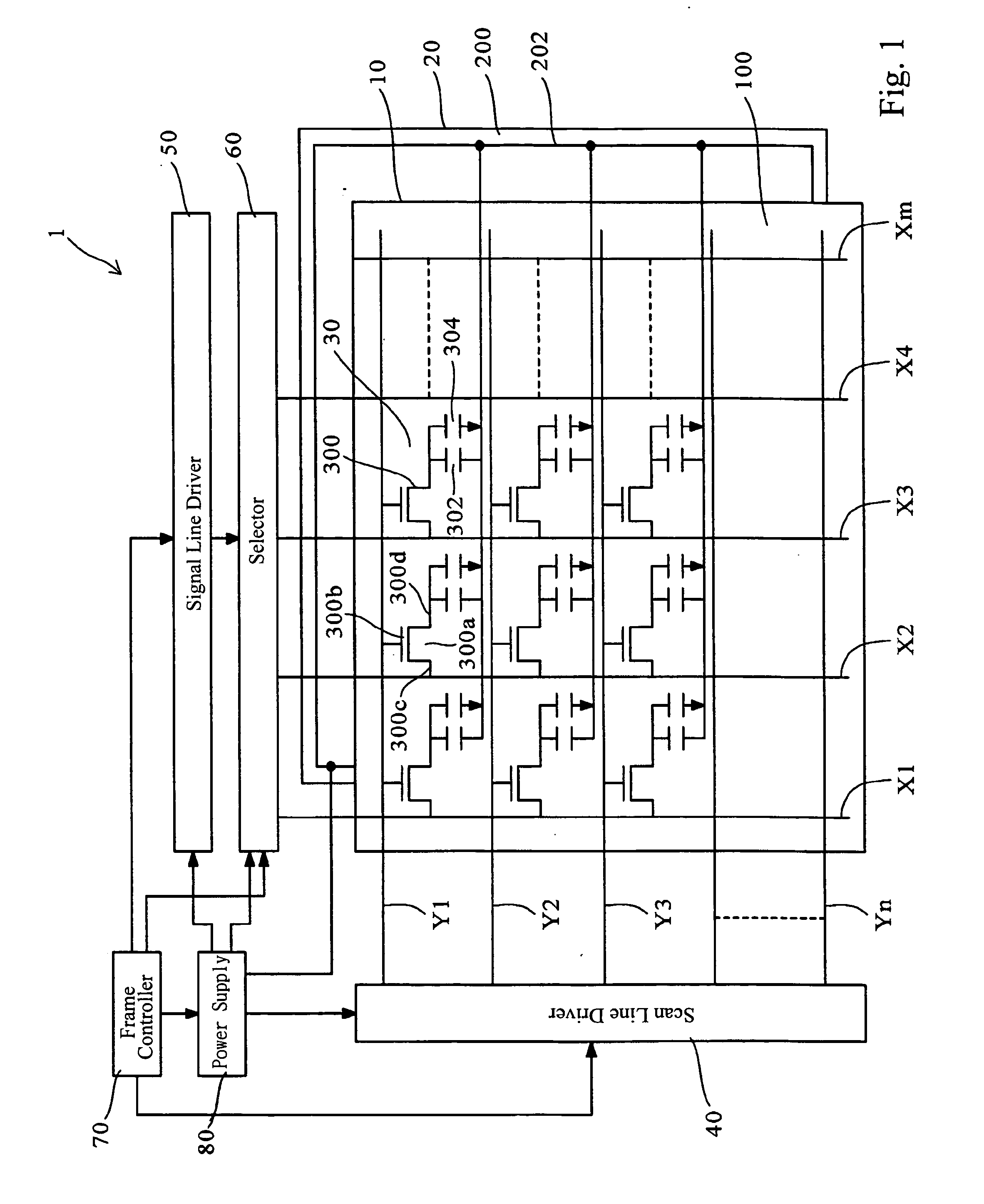

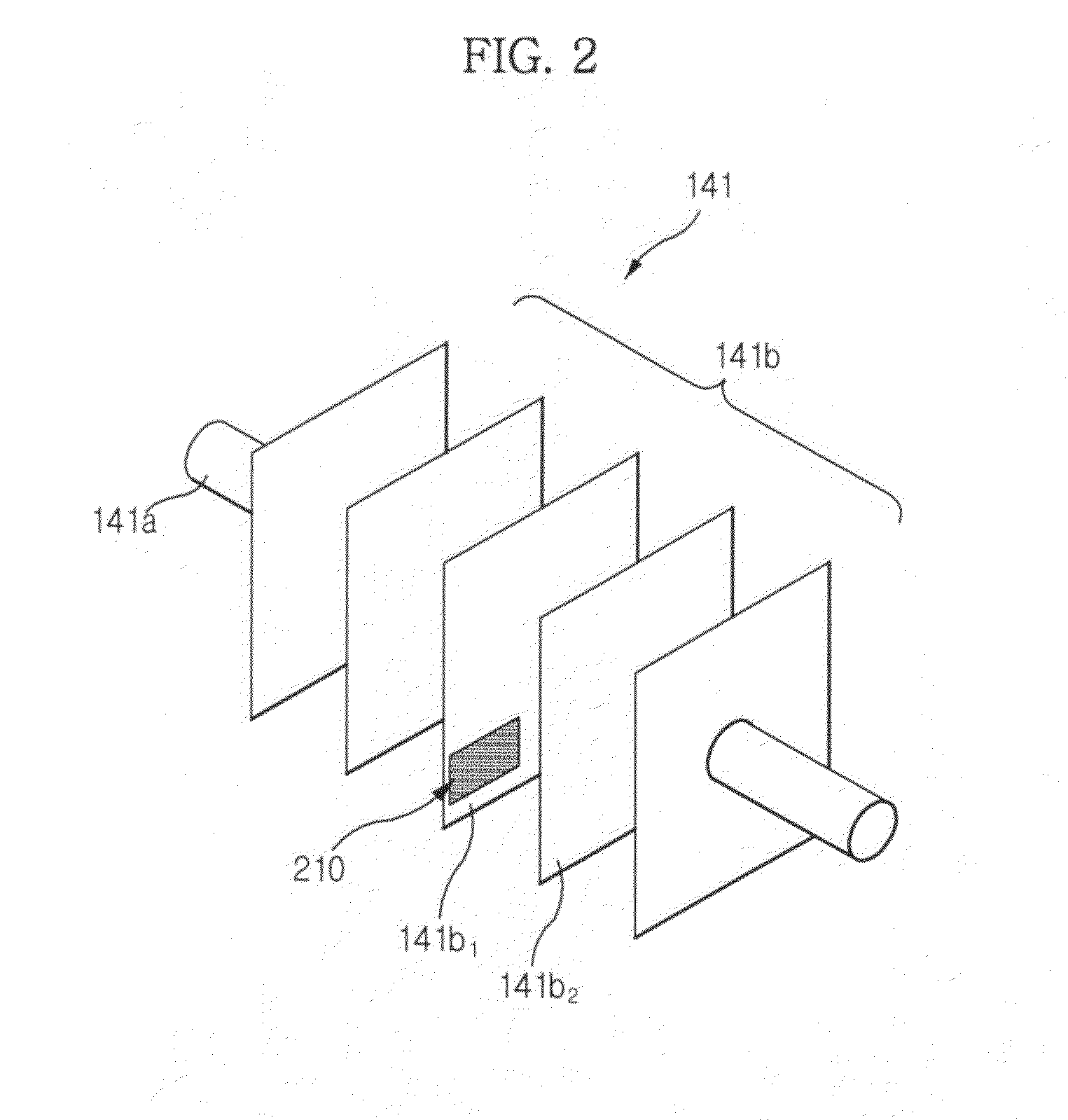

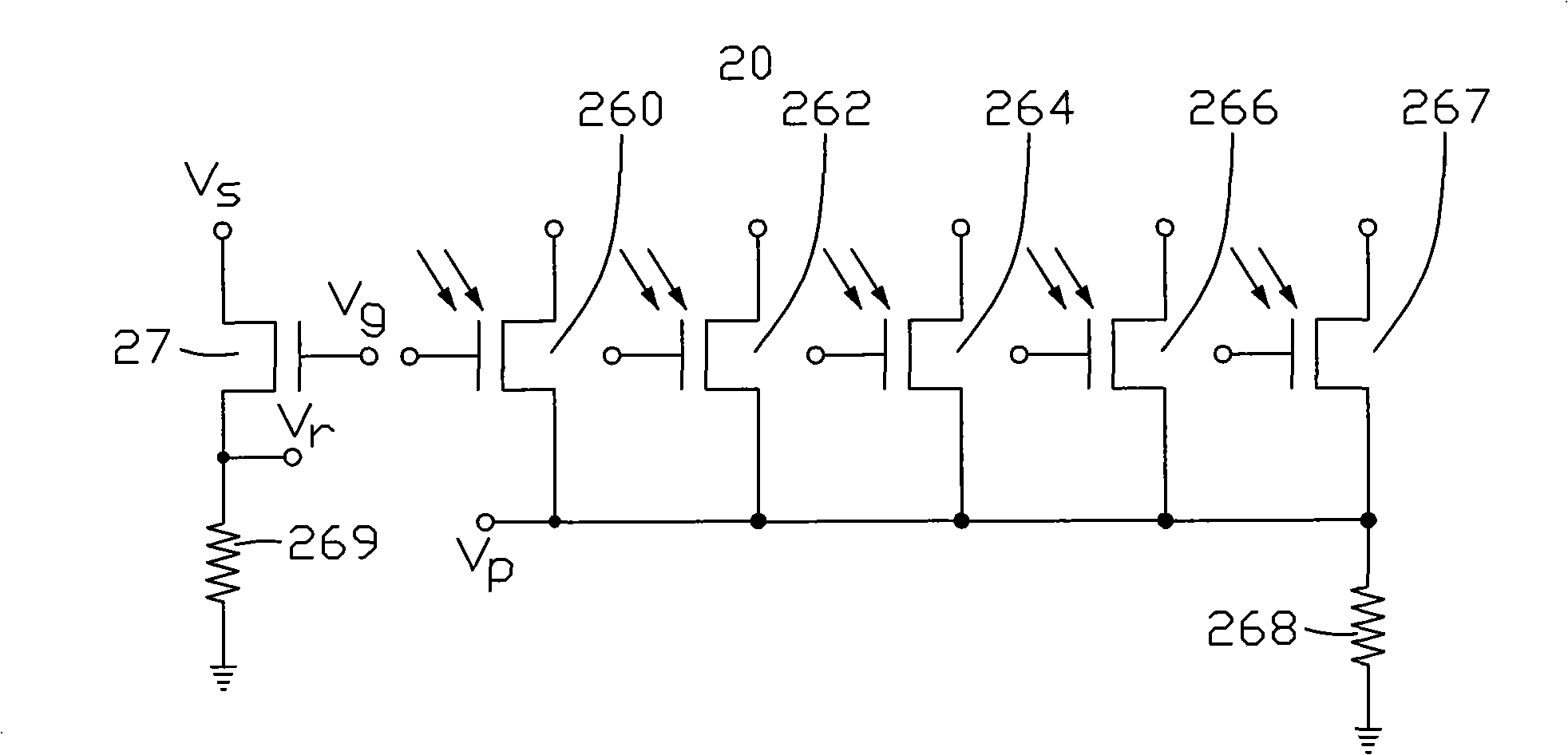

Driving of data lines used in unit circuit control

ActiveUS6989826B2Reduce driving timeSolid-state devicesSemiconductor/solid-state device manufacturingScan linePre-charge

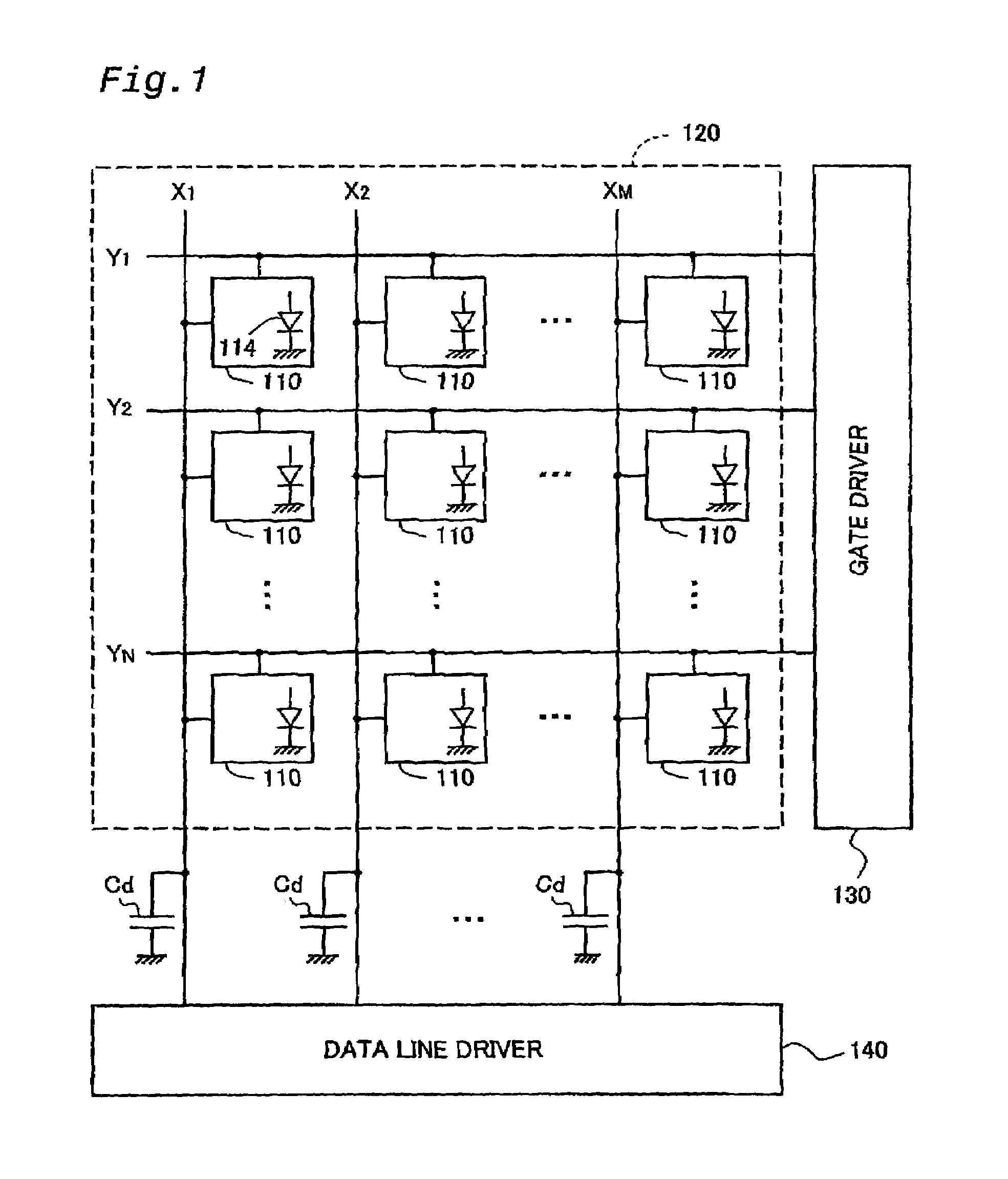

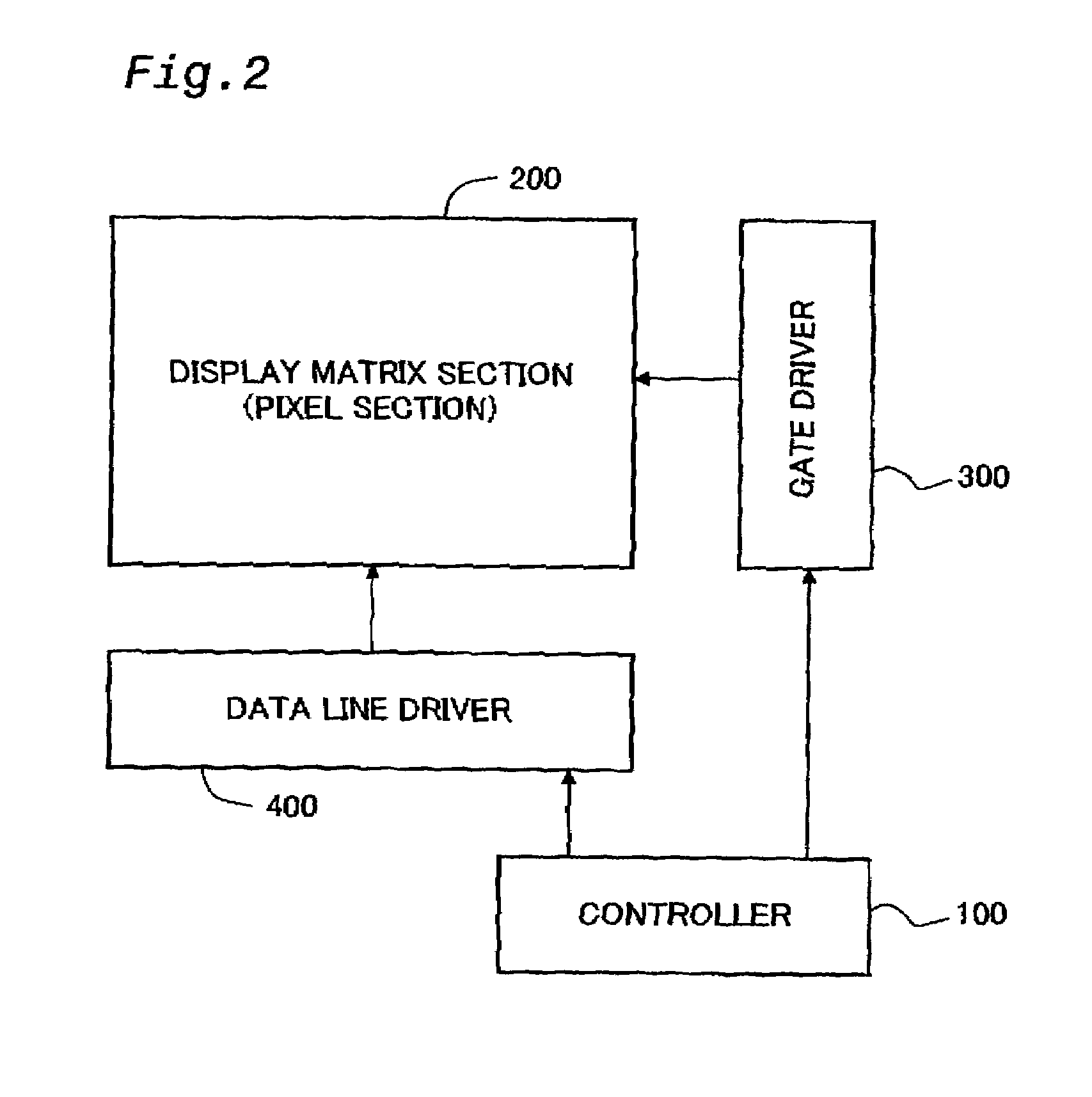

The display matrix section 200 has pixel circuits 210 arranged in the form of a matrix, a plurality of gate lines Y1, Y2 . . . that extend in the row direction, and a plurality of data lines X1, X2 . . . that extend in the column direction. The scan lines are connected to a gate driver 300, and the data lines are connected to a data line driver 400. A pre-charging circuit 600 or additional current generation circuit is installed for each data line as means for accelerating the charging or discharging of the data line. For each data line, charging or discharging is accelerated by pre-charging or current addition prior to the completion of the setting of the light emission level in the corresponding pixel circuit 210.

Owner:ELEMENT CAPITAL COMMERCIAL CO PTE LTD

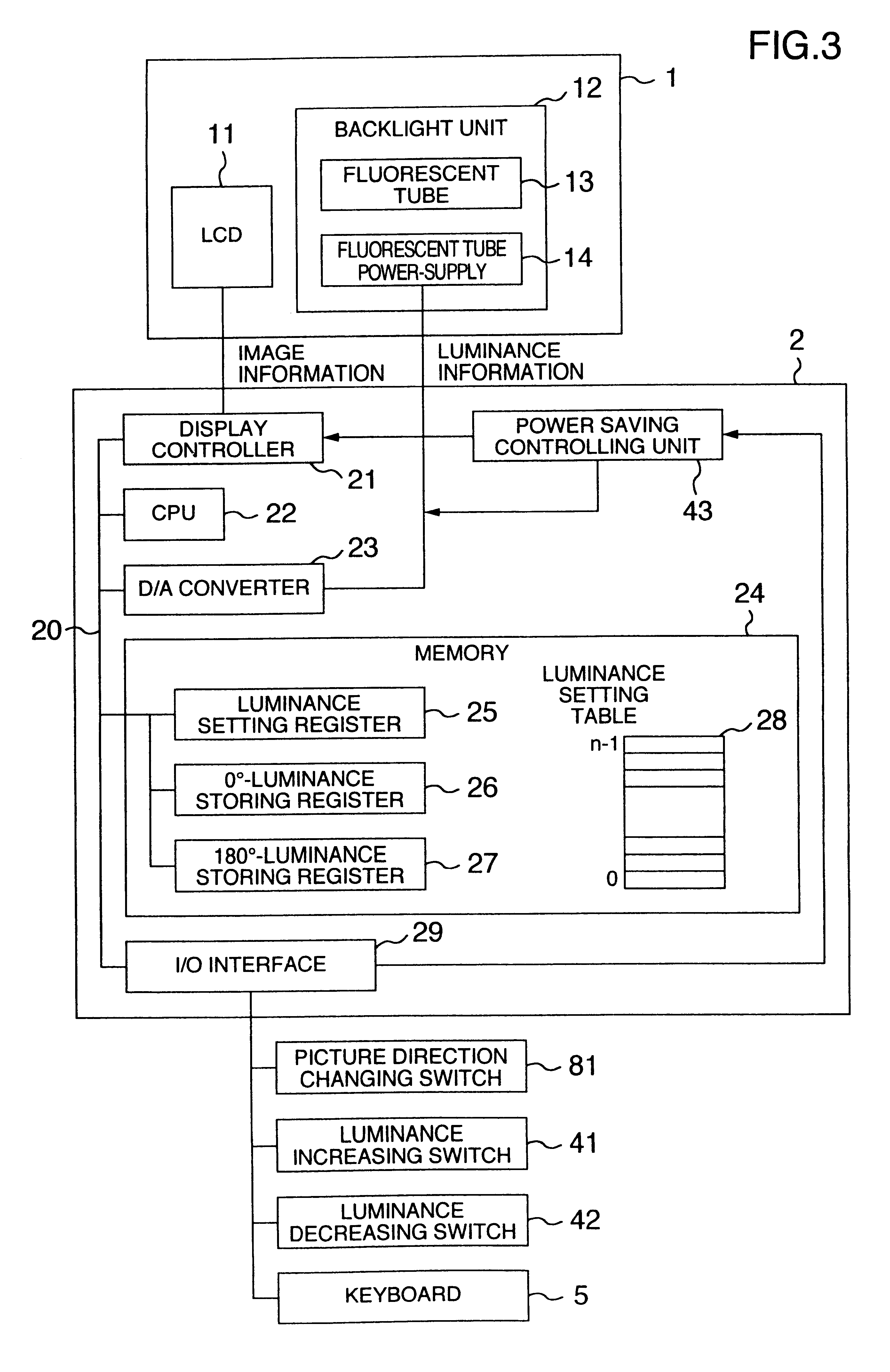

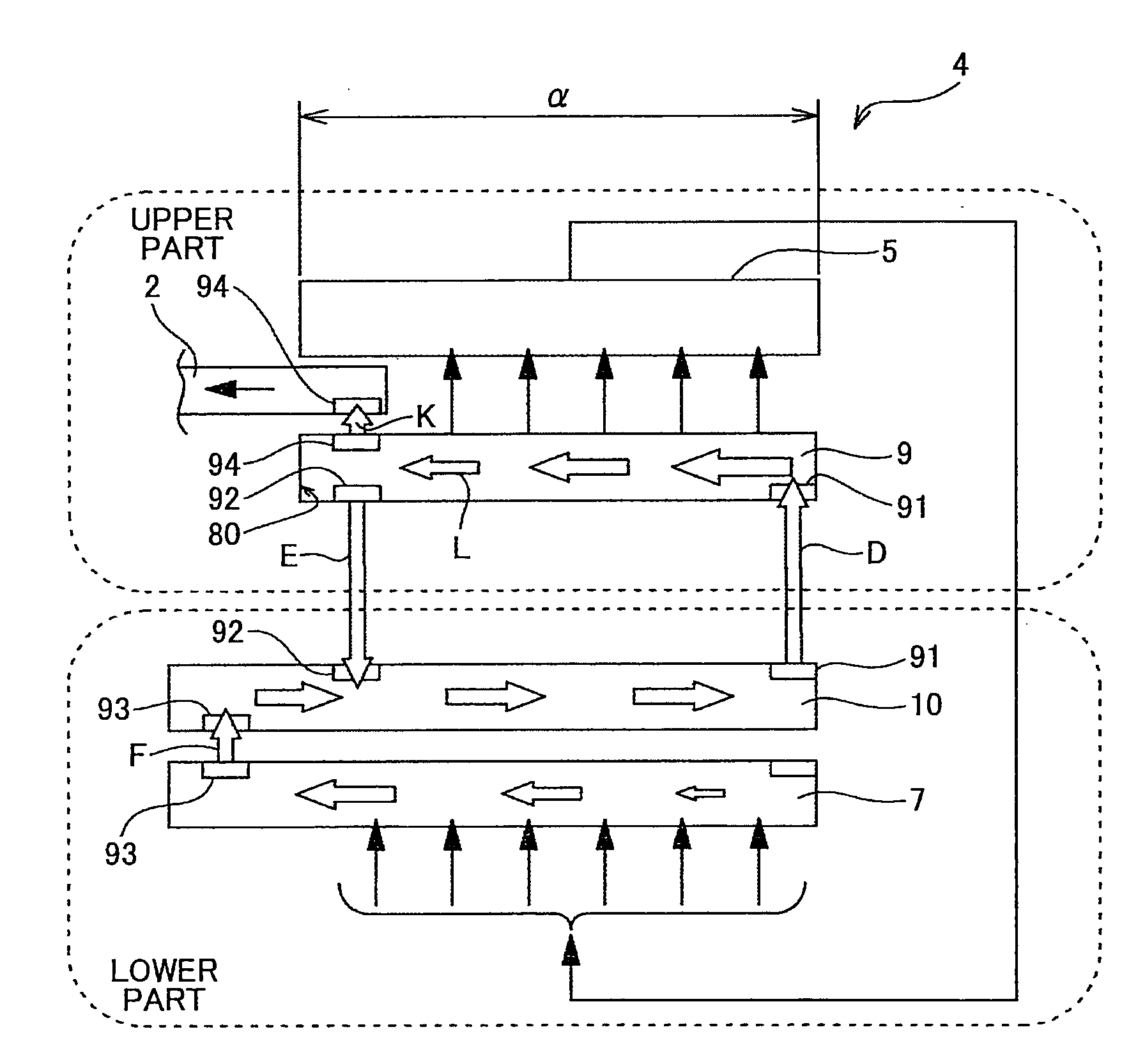

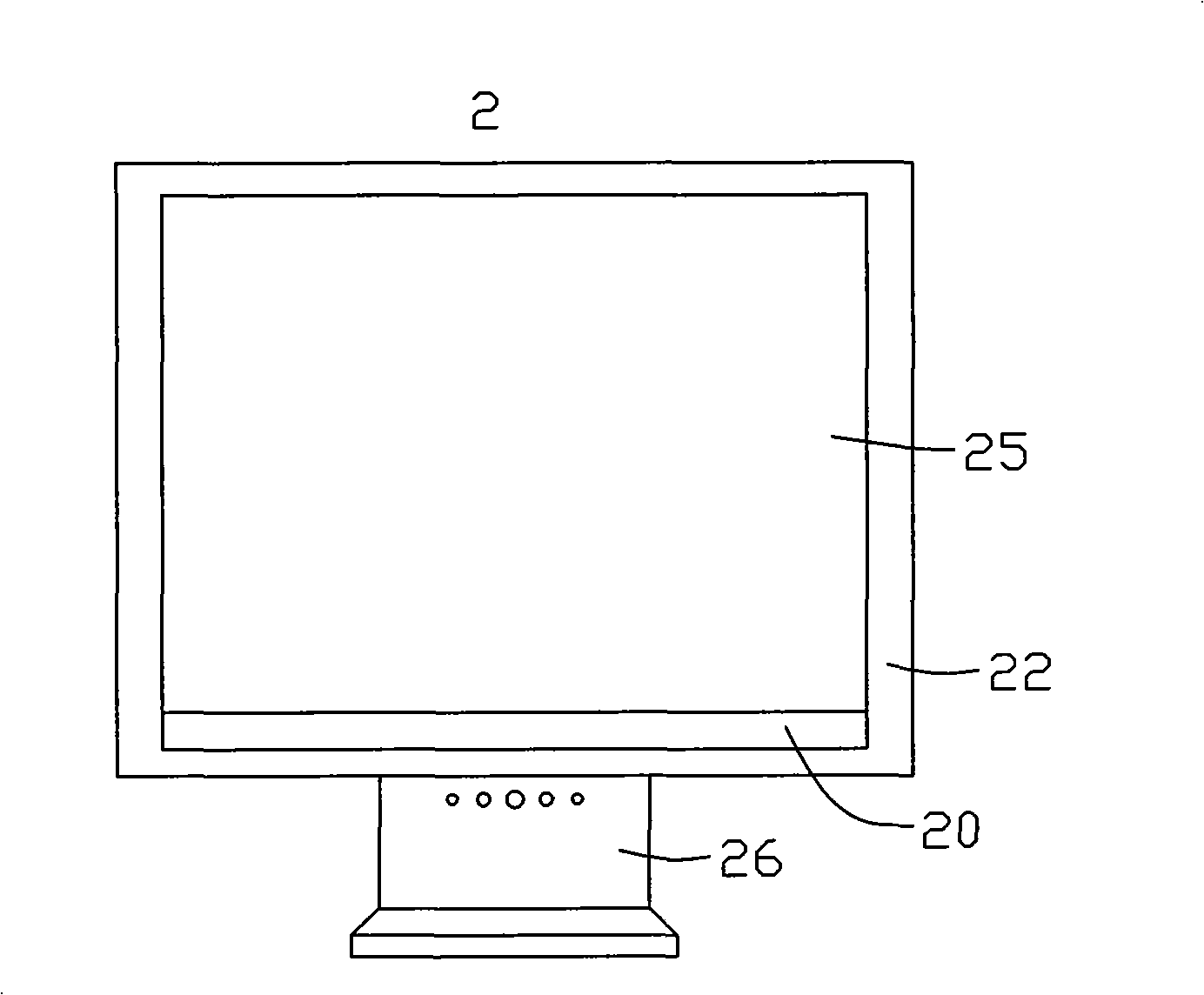

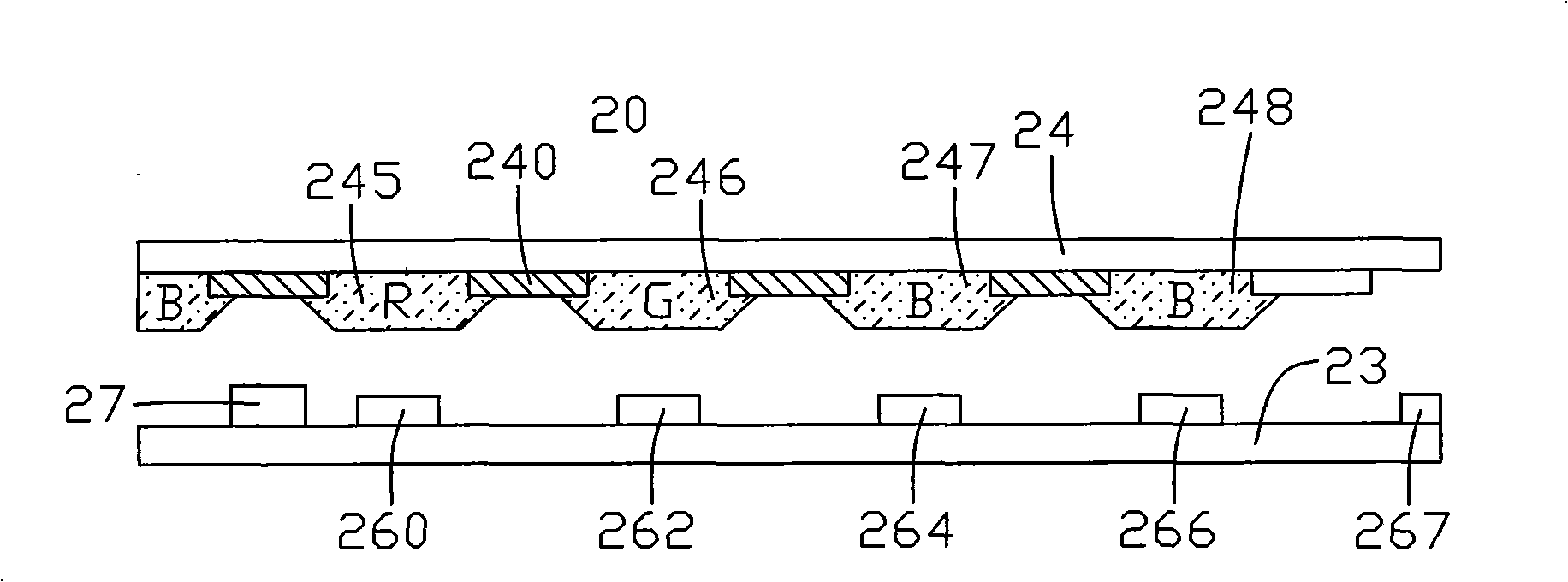

Liquid crystal display apparatus and its luminance control method

InactiveUS6693612B1Easy to seeIncrease impressionTelevision system detailsColor television detailsInformation processingLiquid-crystal display

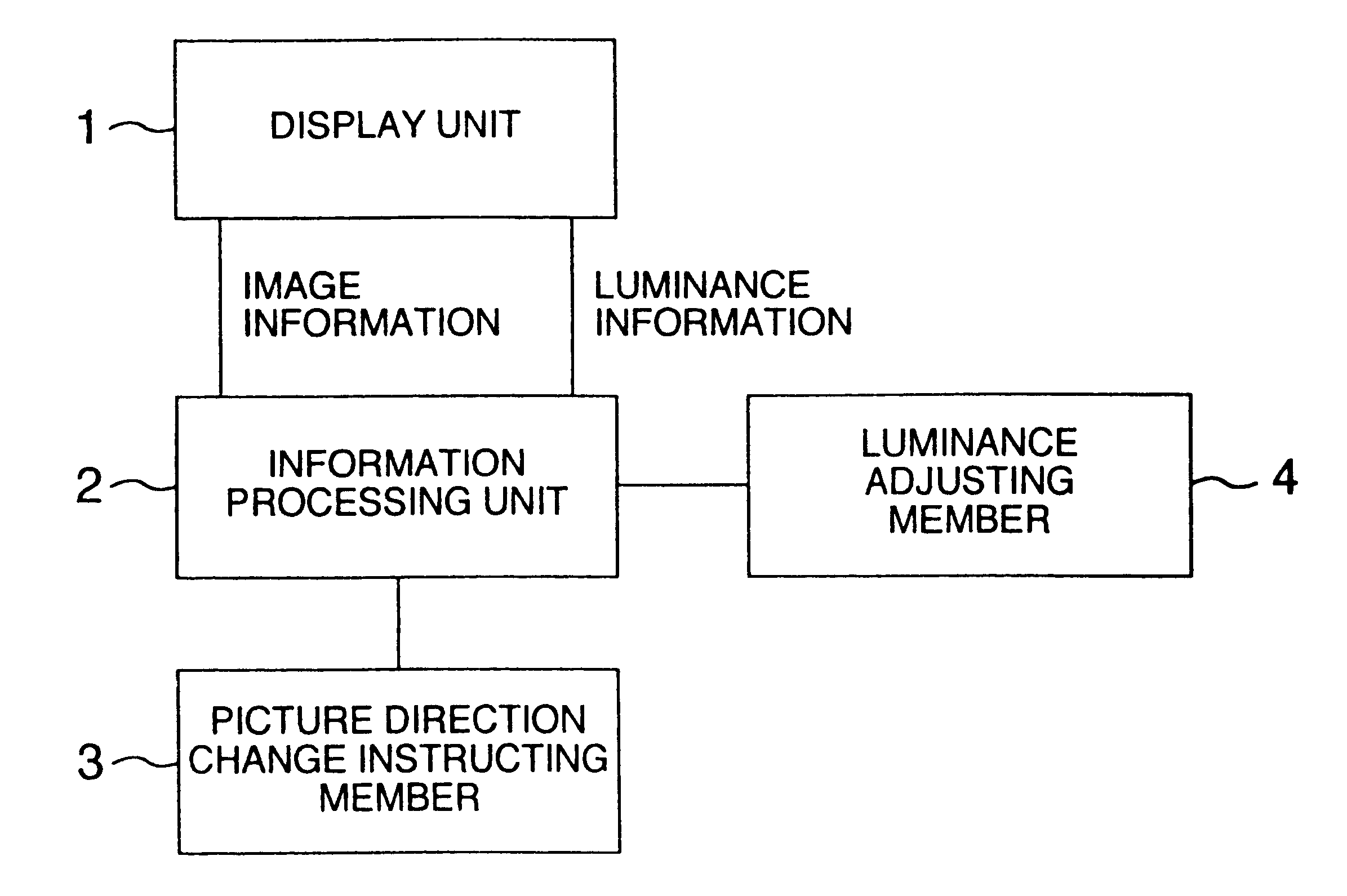

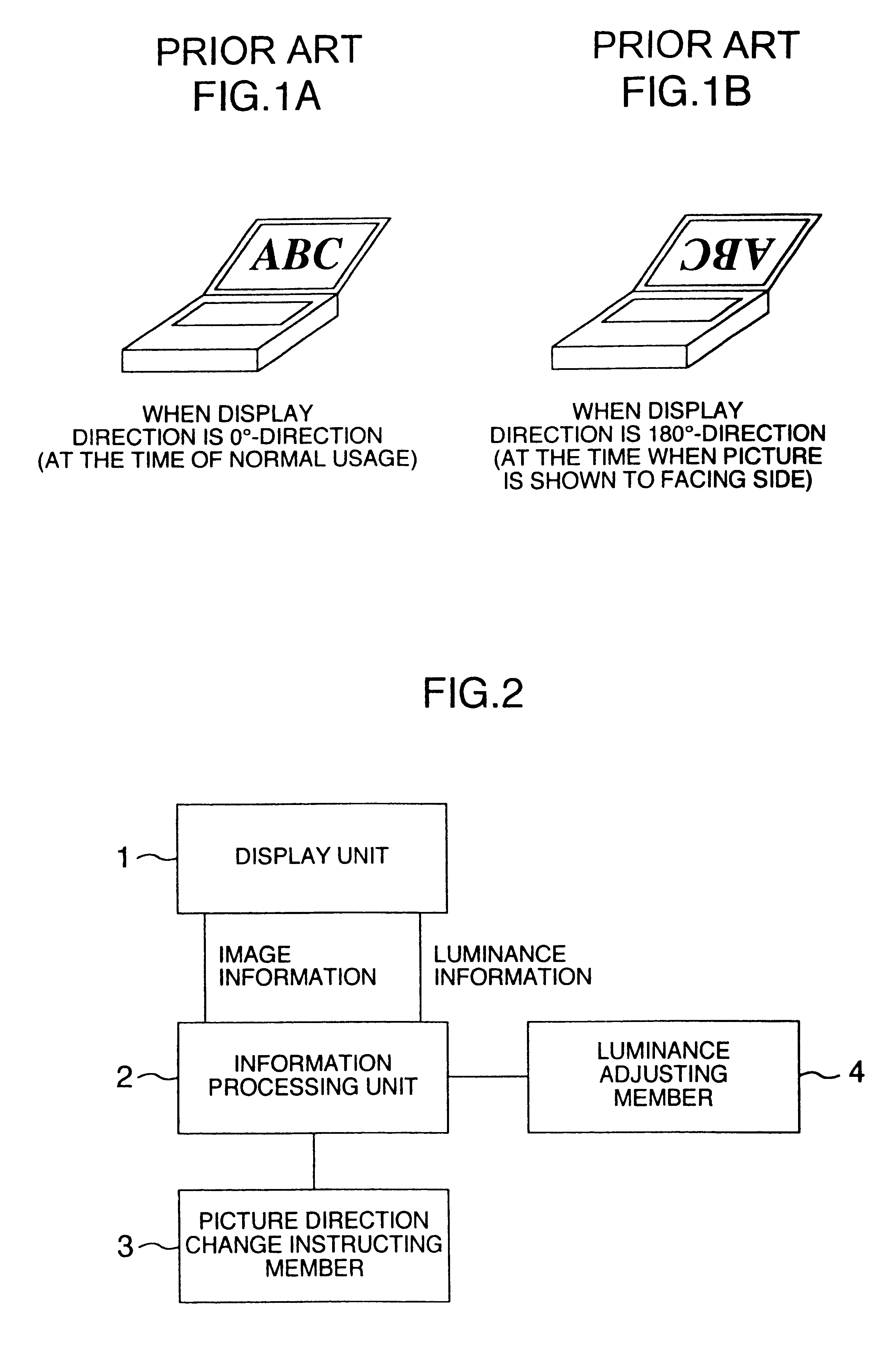

The information processing apparatus equipped with a liquid crystal display apparatus that is usable in the face-to-face usage style. When the display direction is switched into the facing direction and in a normal usage state, the liquid crystal display apparatus exhibits an excellent visual recognizability and complicated operations are unnecessary. The image information, the picture direction of which has been inverted upside down, is outputted from the information processing unit 2 to the display unit 1 in such a manner as to be coupled with the picture direction change instructing member 3. At the same time, the luminance information at the time of the picture upside-down inversion, which has been set in advance into the luminance adjusting member 4, is supplied to the display unit 1 so as to change the luminance simultaneously with the picture inversion. At this time, the luminance of the display unit 1 at the time of the picture upside-down inversion is changed to a higher luminance, thereby making it possible to enhance the visual recognizability from the facing side.

Owner:MAXELL HLDG LTD

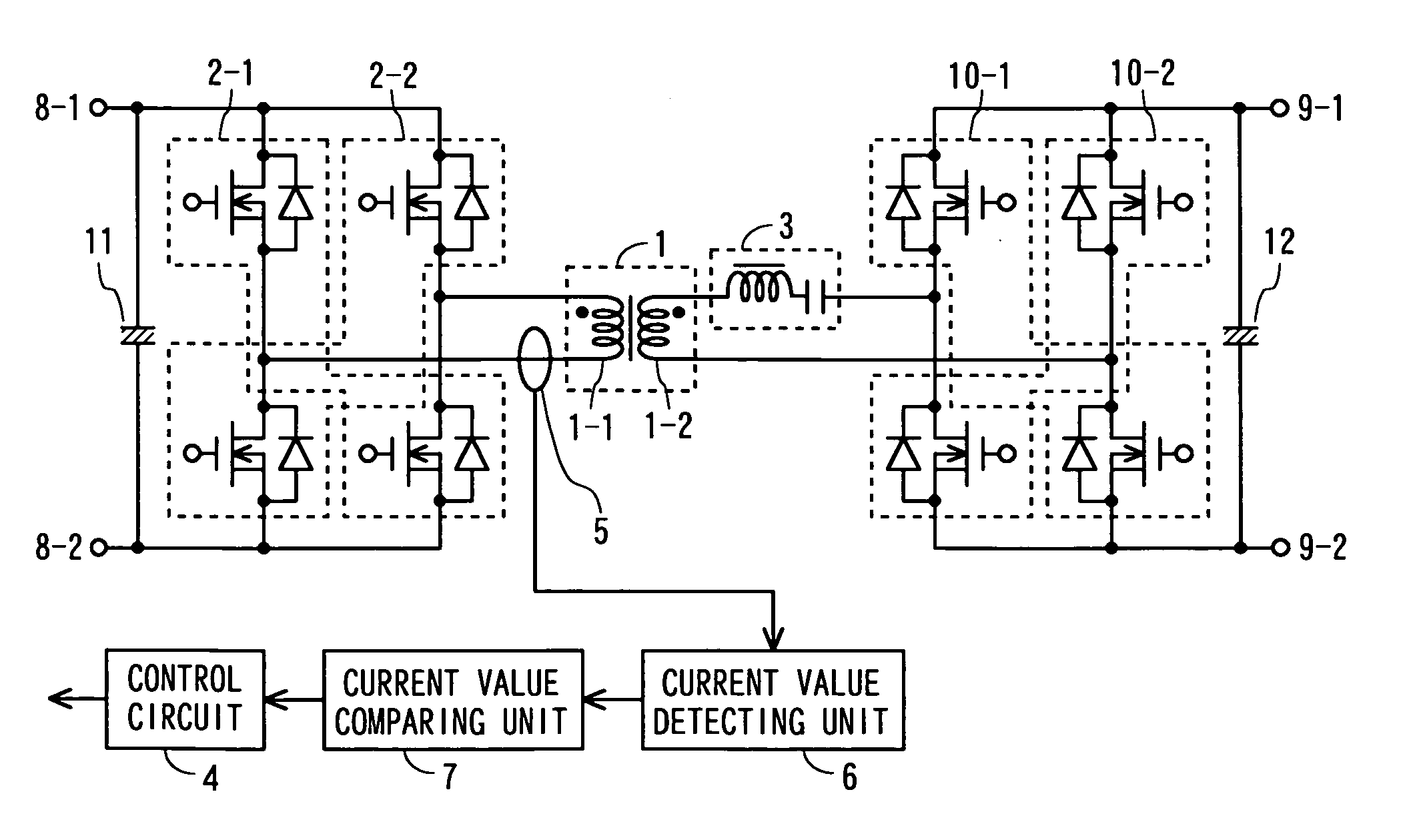

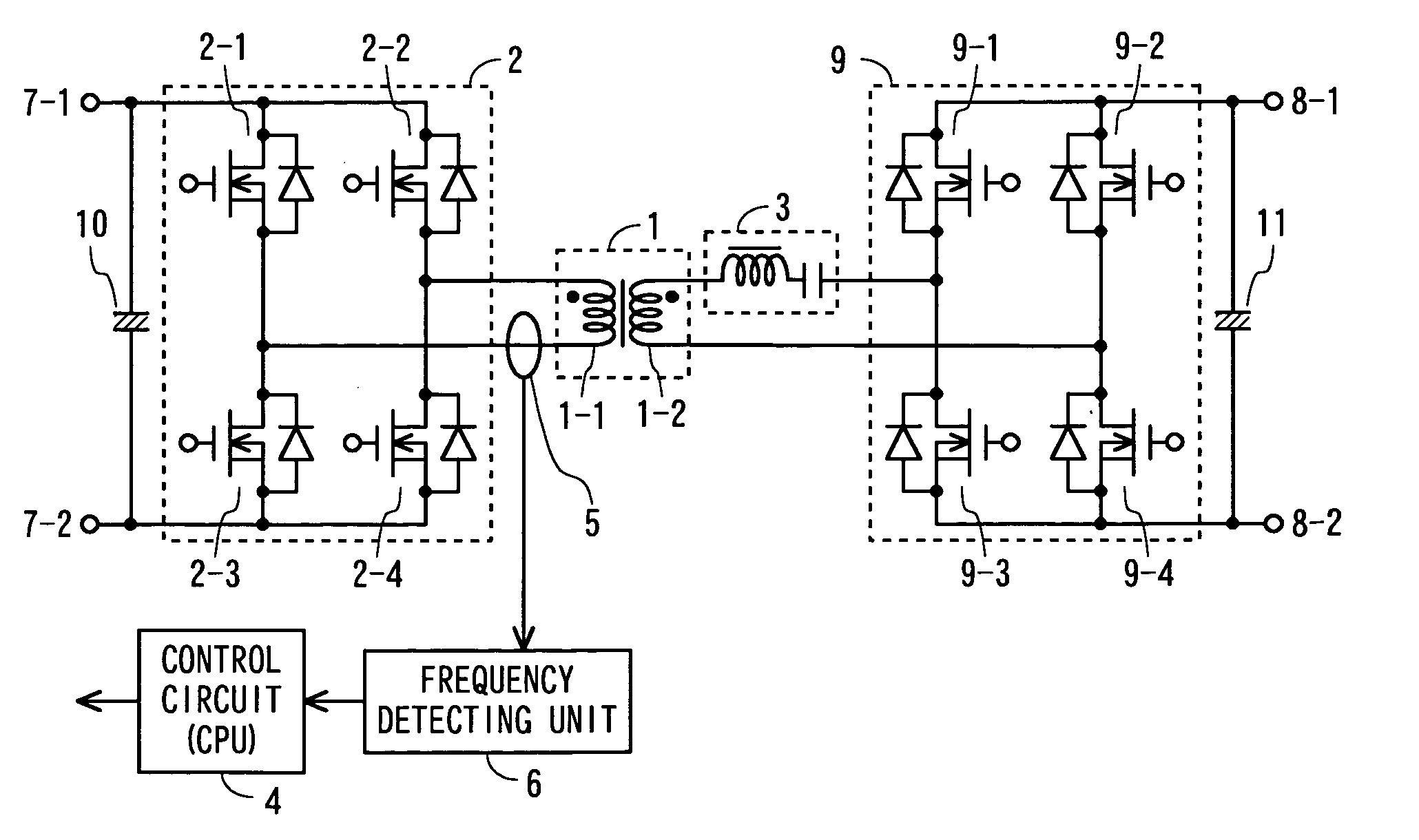

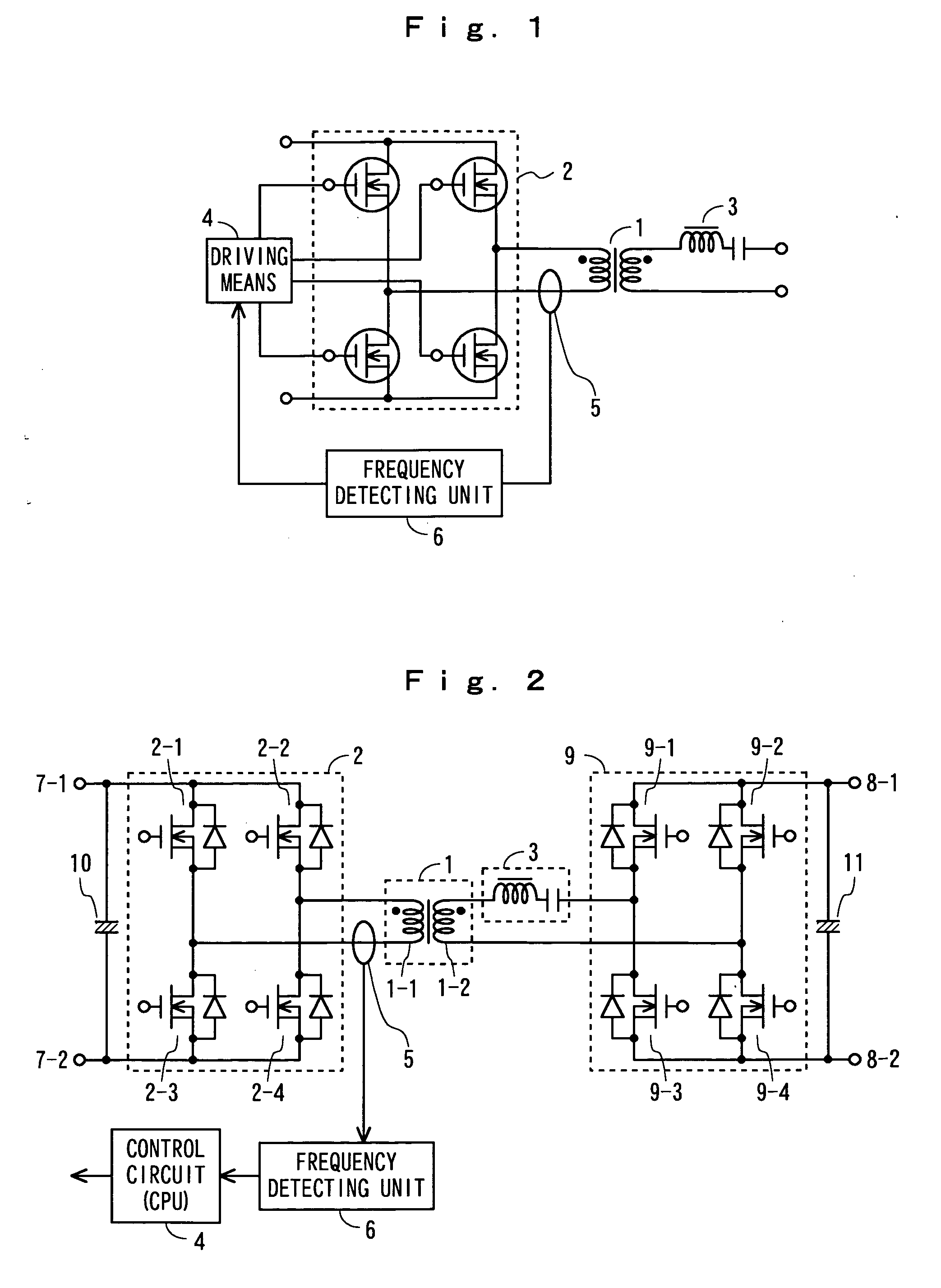

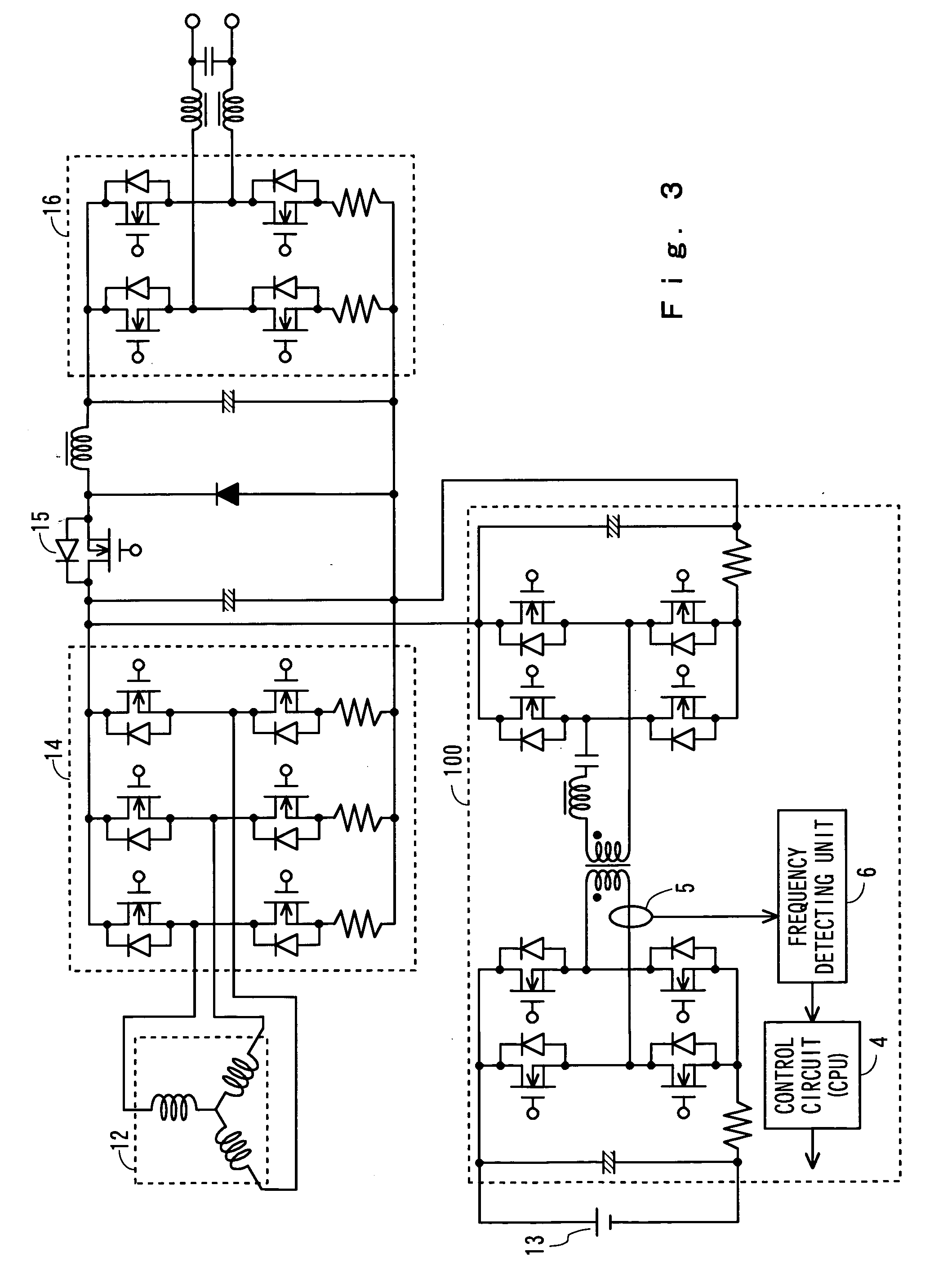

Dc-dc converter

InactiveUS20070070655A1Avoid it happening againImprove efficiencyEfficient power electronics conversionAc-dc conversionDc dc converterResonance

To provide a DC-DC converter allowing miniaturization of a voltage transformer without fear of reducing conversion efficiency due to saturation of the transformer and allowing enhancement of conversion efficiency by suppressing switching loss. An LC resonance circuit 3 is inserted on the secondary side of a transformer 1. When driving means 4 alternately turn on and off a pair of switching means 2-1, 2-2, an output is obtained on the secondary side via the transformer 1. A current transformer 5 for current detection, a current value detection portion 6 and a current value comparison portion 7 detect a difference between each resonance current value per half cycle due to the operation of the LC resonance circuit 3. In response to its result, the drive means 4 regulate automatically on-state duty ratio of the switching means 2-1, 2-2 so as to align the resonance current values per half cycle.

Owner:HONDA MOTOR CO LTD

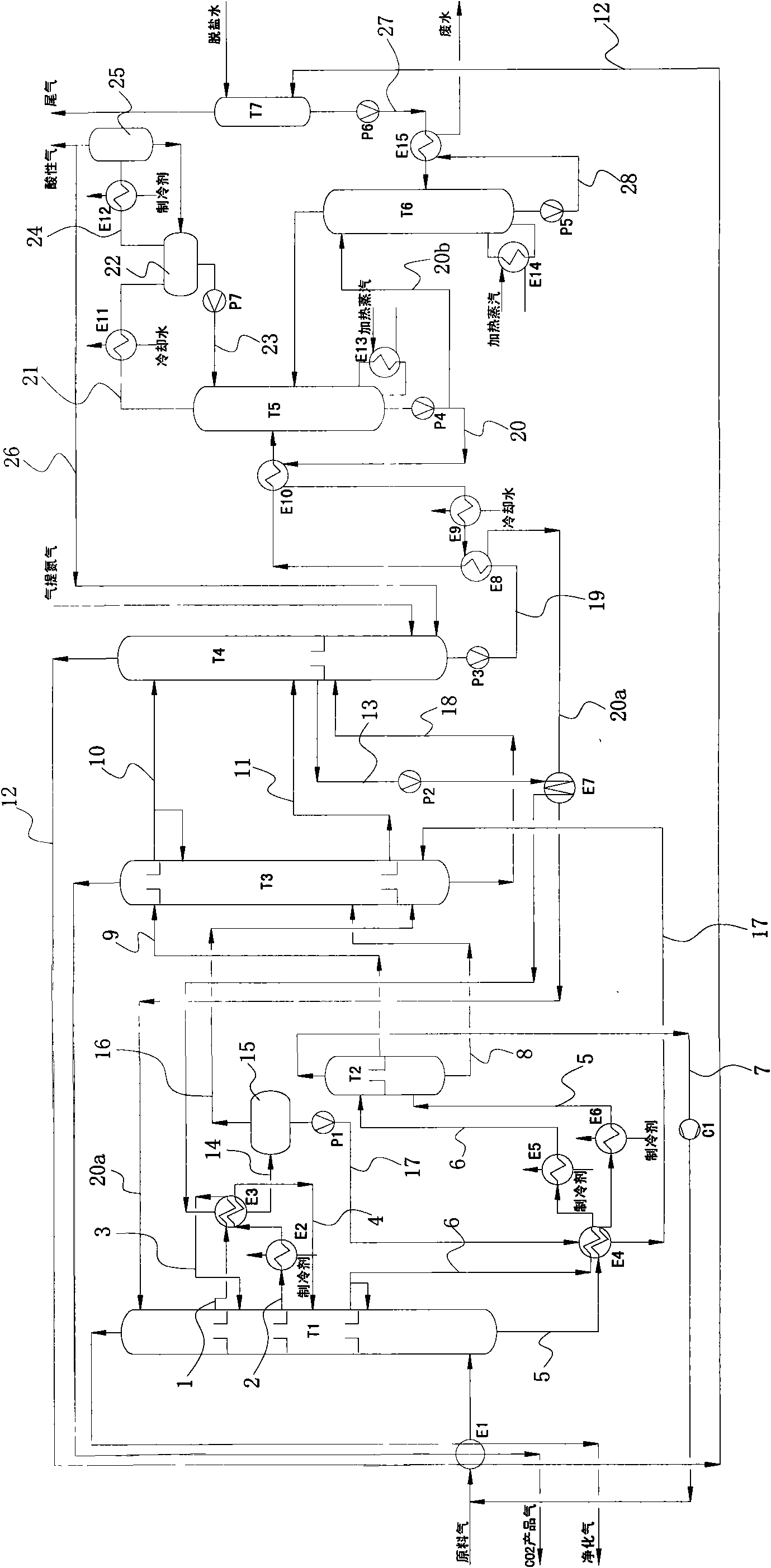

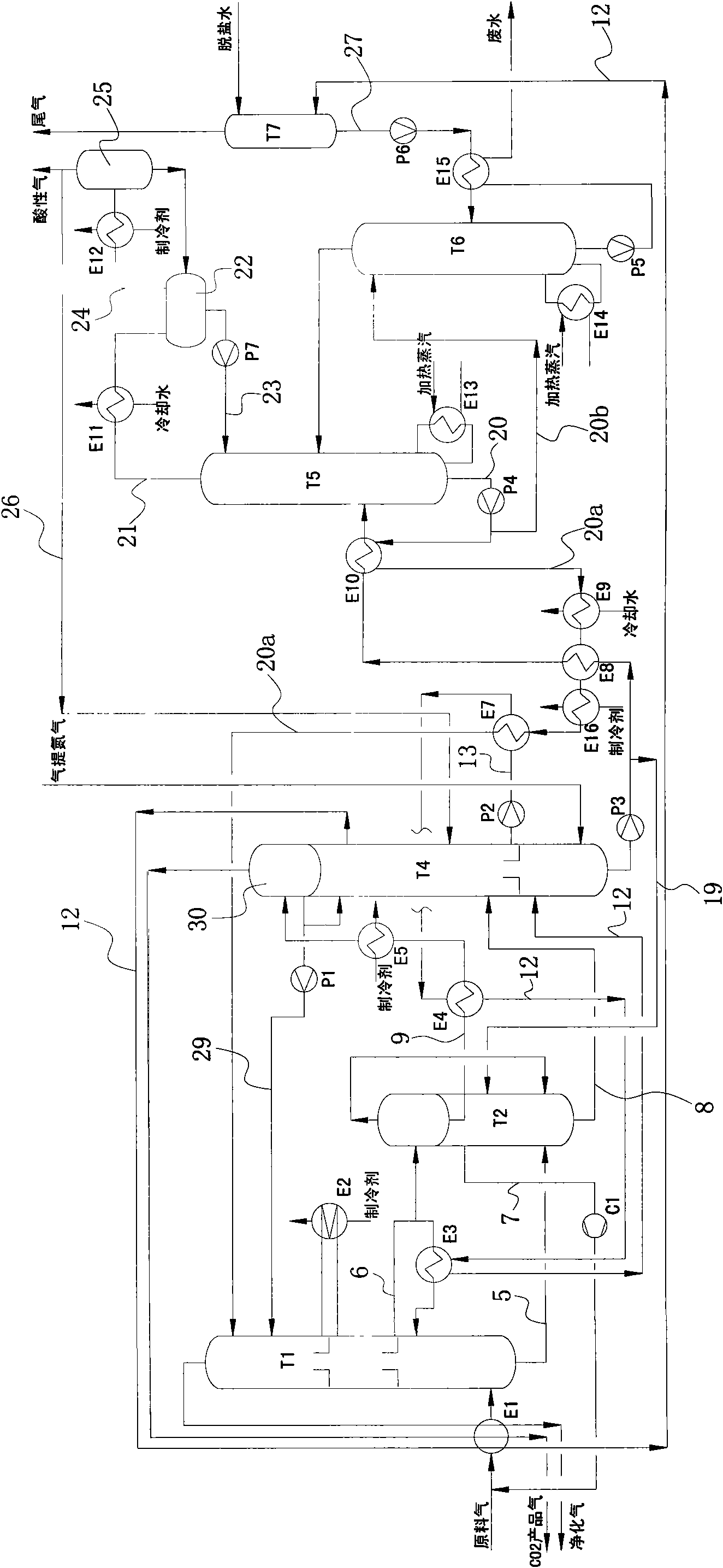

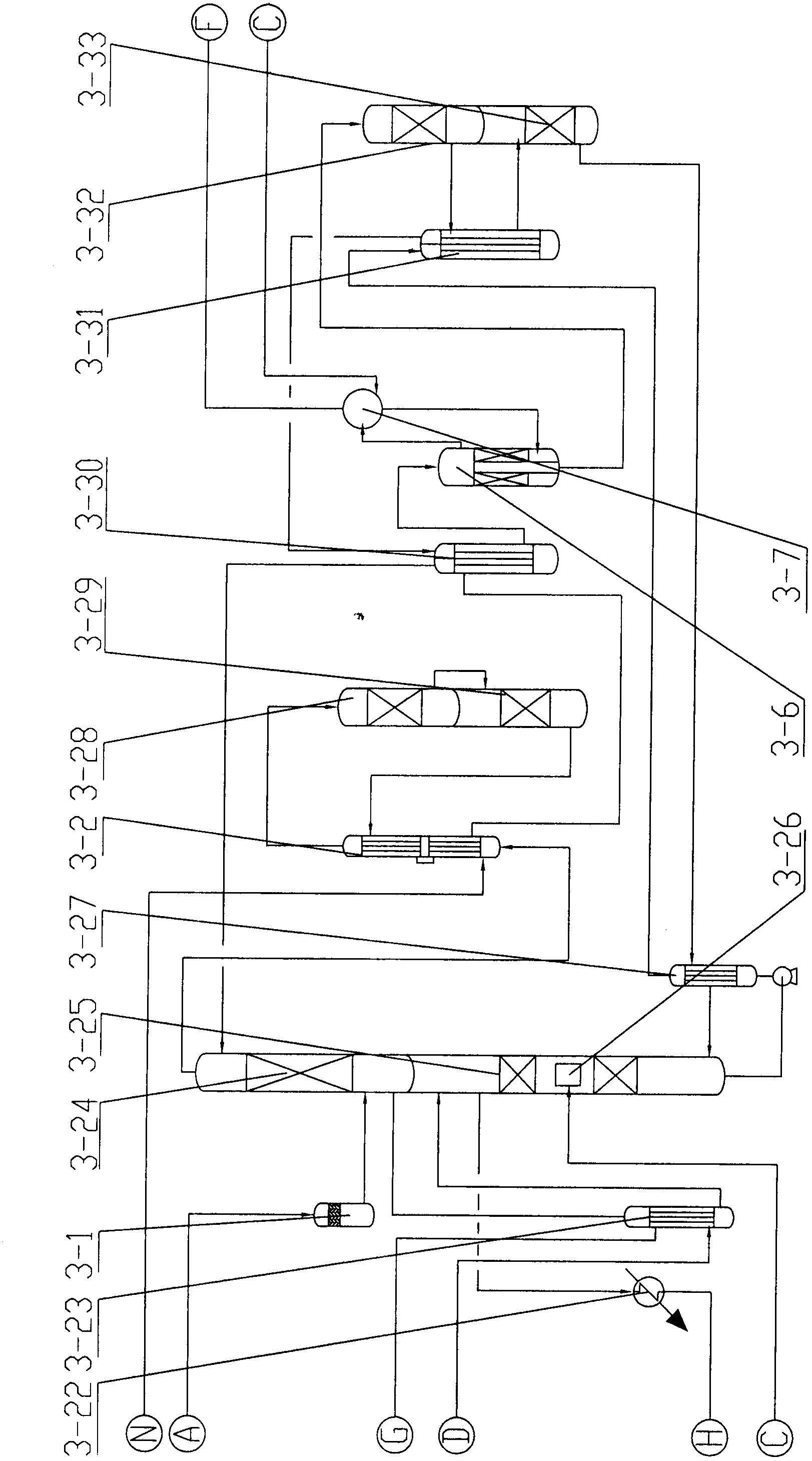

Split-flow rectisol device

The invention discloses a split-flow rectisol device, which comprises an absorption tower, a medium pressure flash tower, a reabsorber, a hot regenerating tower, a methanol water tower, a tail gas washing tower, a plurality of heat exchangers, pumps and a circulation compressor; and the upper section of the reabsorber is provided with a flash distillation section. The split-flow rectisol device is not provided with a CO2 product tower, and reduces the complexity of the flow and the investment on the premise of ensuring that CO2 product gas is qualified. The split-flow rectisol device is provided with a novel split-flow rectisol (acid gas removal) flow for absorption from a semi-lean methanol liquid feeding absorption tower on the upper section of the reabsorber, reduces the dosage of lean methanol of the absorption tower, further can reduce the energy consumption of the hot regenerating tower for hot regeneration, and saves the dosage of gas stripping nitrogen, consumption of steam, and low level cold quantity used when the lean methanol is cooled.

Owner:SHANGHAI INT ENG CONSULTING

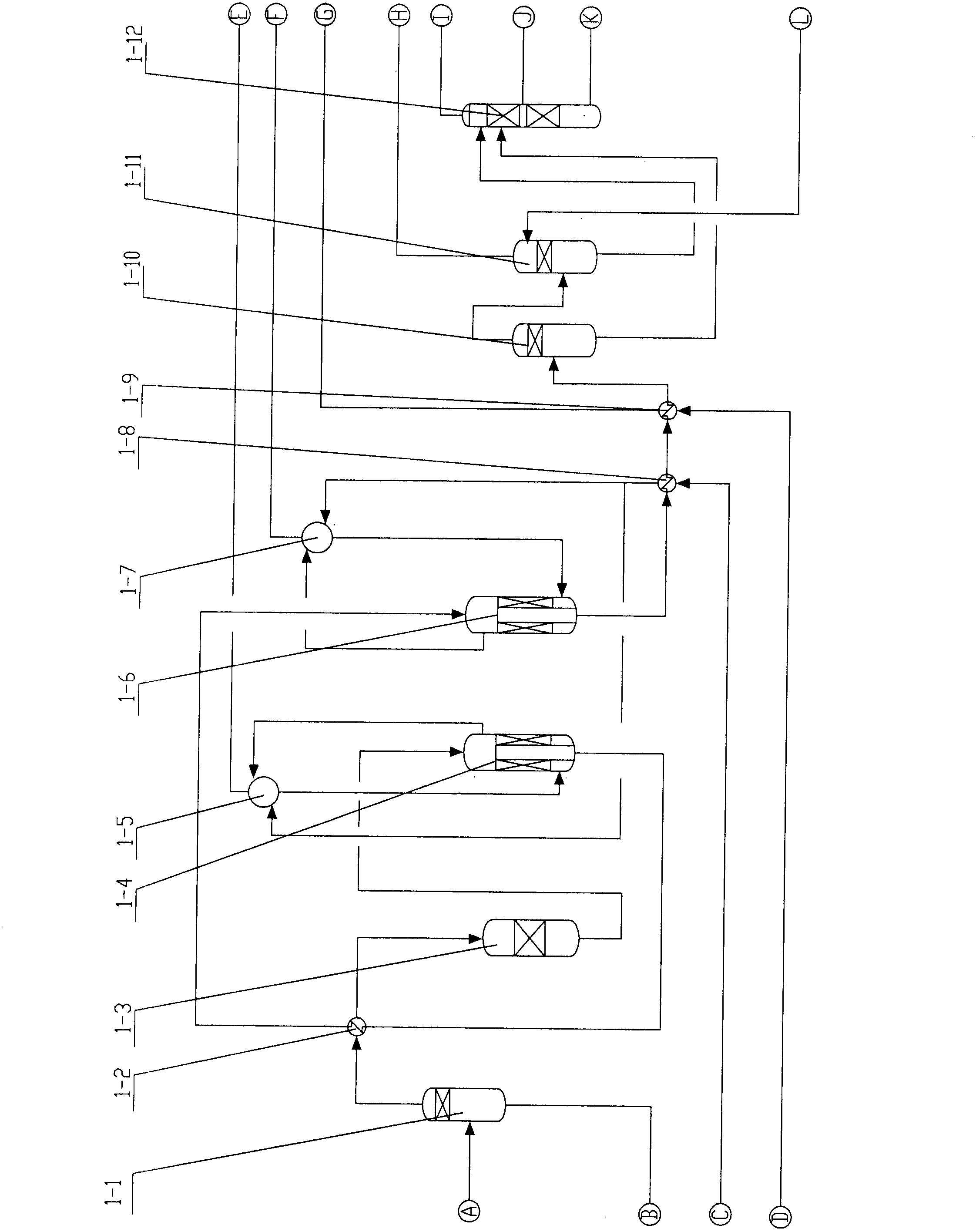

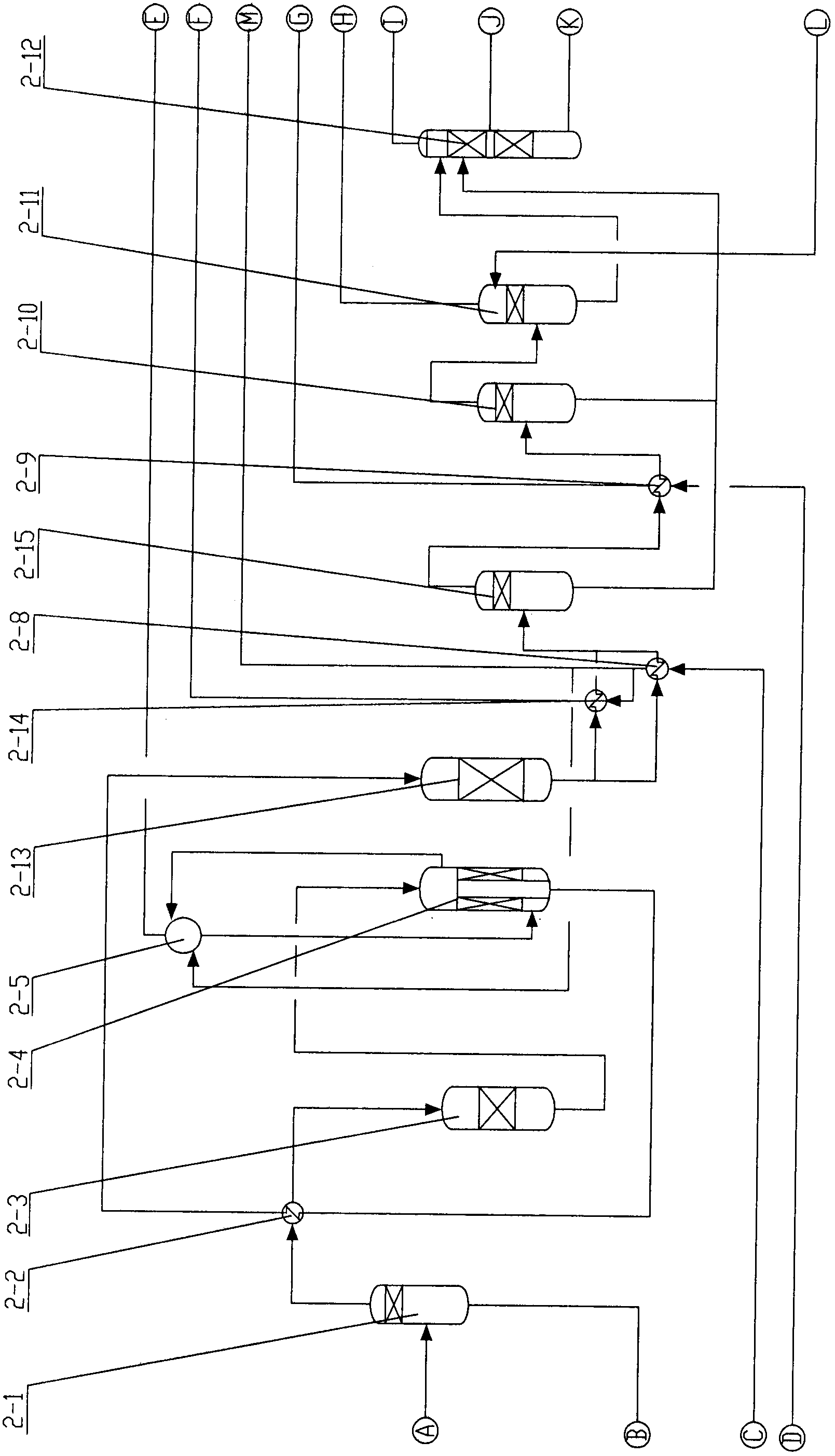

Water heat-transfer shift process for by-product high-grade steam energy-saving deep conversion

ActiveCN102701149AGuaranteed service lifeEliminate "dew point corrosion"HydrogenChemical recyclingComing outThermal energy

The invention relates to a water heat-transfer shift process for by-product high-grade steam energy-saving deep conversion. According to the process, a primary water heat-transfer shift converter and a secondary shift converter are adopted, CO in feed gas reacts with H2O to generate H2 and CO2 under the catalysis of a Co-Mo (copper-zinc) catalyst, and CO in shift gas coming out of a shift system is less than or equal to 0.1% (dry basis). In the process, CO is subject to deep conversion, the feed gas (containing water gas, semi-water gas, natural gas conversion gas or coke-oven gas conversion gas) utilization rate is high, the shift catalyst is not overheated, and the catalyst has a long service life; meanwhile, by-product saturated steam with the pressure of 0.5 to 9.0 MPa is generated, sensible heat and latent heat in the shift gas are further recovered by deoxygenated water and desalted water, low-grade heat energy is converted into high-grade heat energy, cooling water consumption is reduced, the temperature of` the shift gas coming out of a process system is lower than or equal to 40 DEG C, equipment is few, the flow is short, the investment is small, and the resistance is low (less than or equal to 0.05MPa).

Owner:NANJING DUNXIAN CHEM TECH

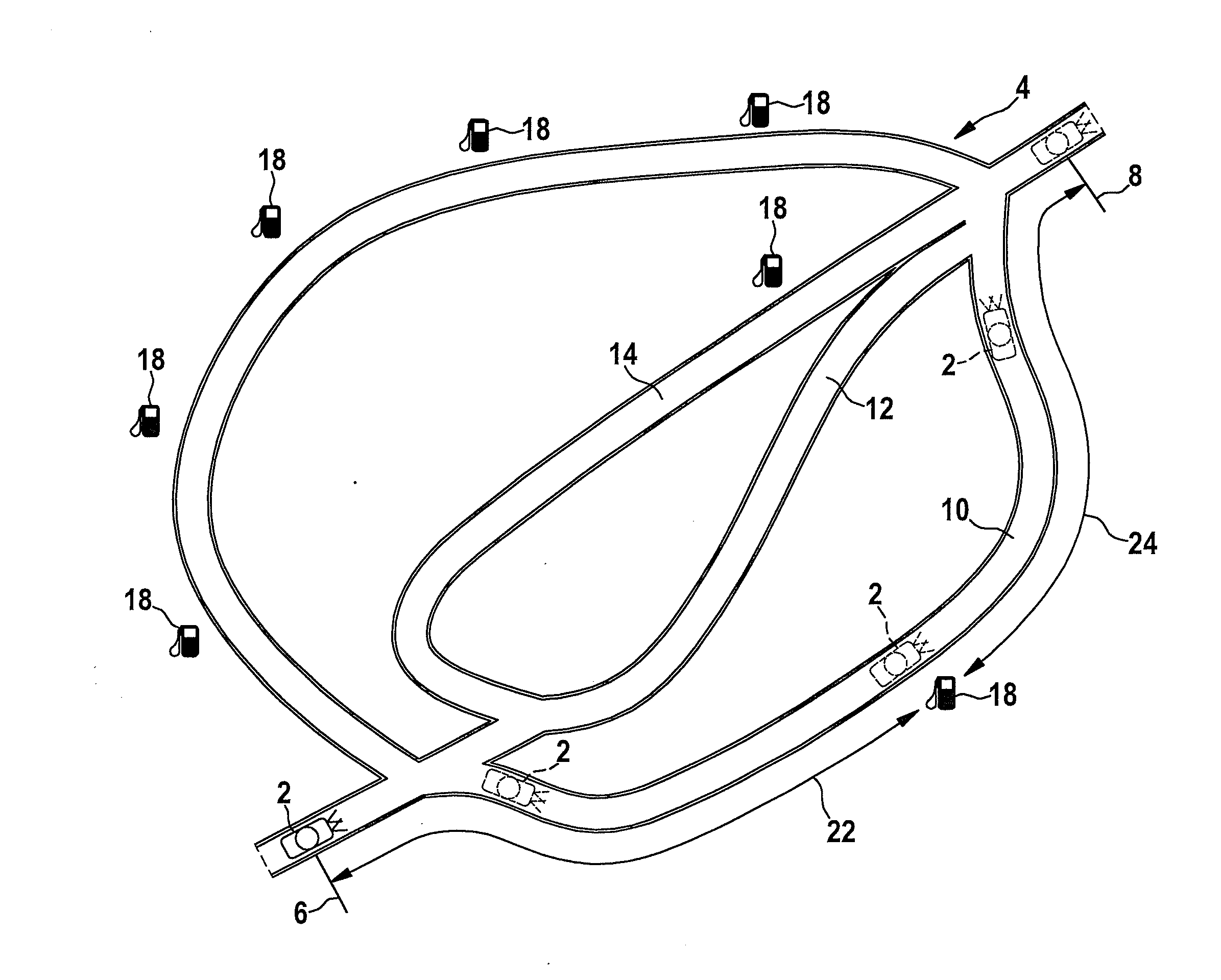

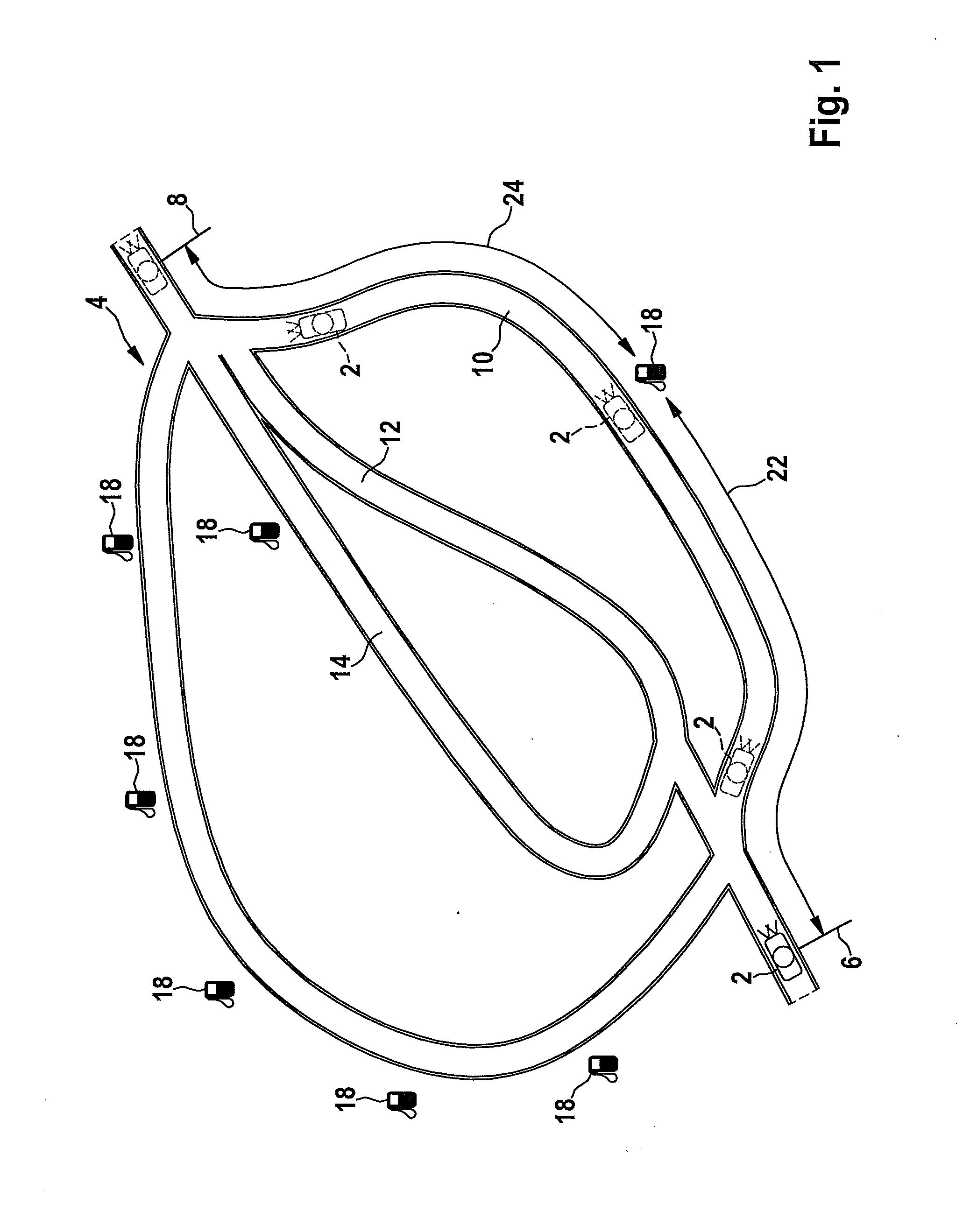

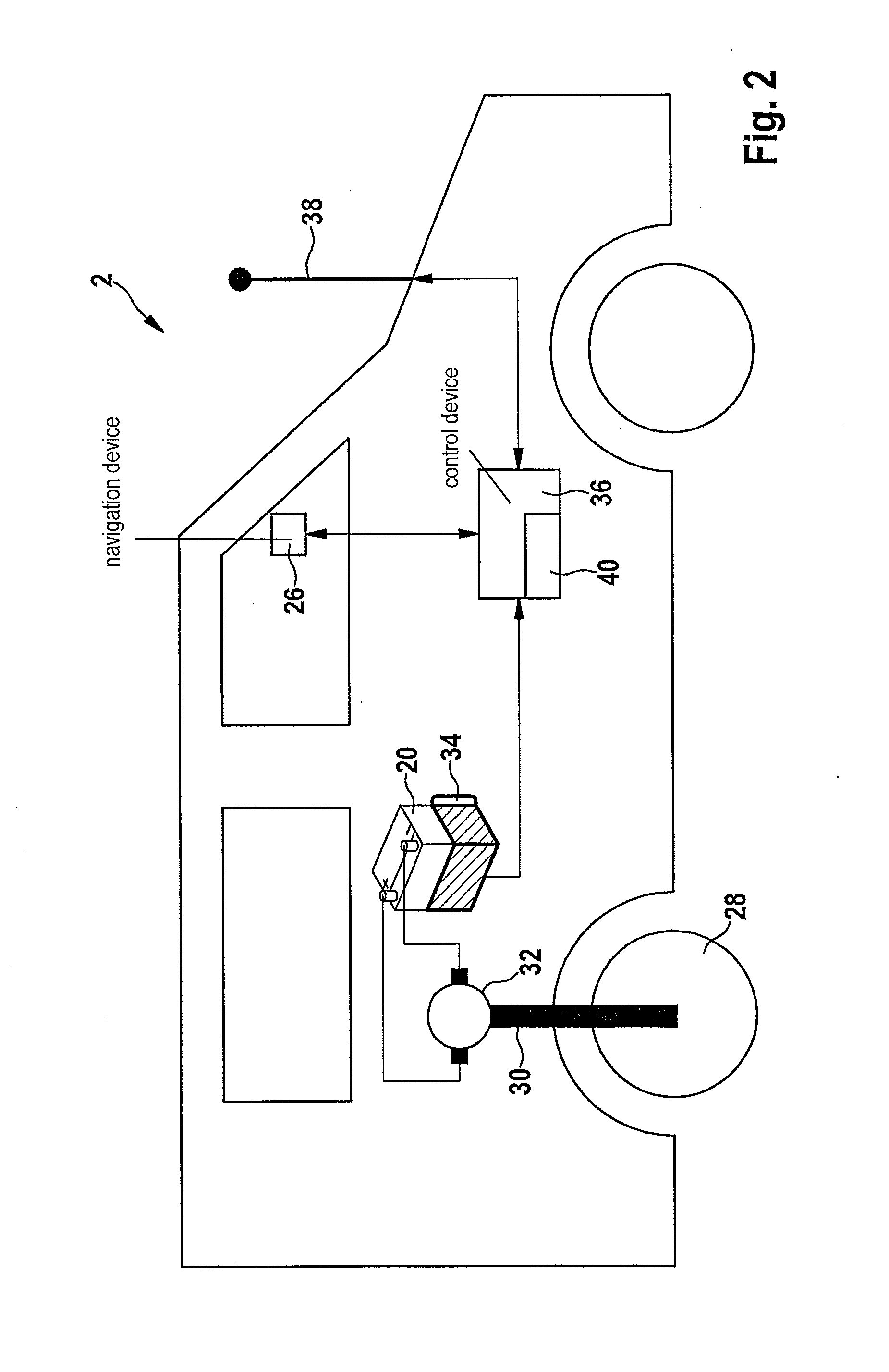

Method for implementing an energy management of a vehicle

InactiveUS20130345945A1Improve energy consumptionThe degree of freedom becomes largerAnalogue computers for vehiclesBatteries circuit arrangementsElectricityElectric drive

A method for implementing an energy management of a vehicle which is movable via an electric drive, the electric drive being able to be driven by electrical energy stored in an electrical energy store, the method including: inputting a destination; and searching for a route to the destination, on which an available electrical energy source able to be used to recharge the electrical energy store is available within a minimum distance; the minimum distance corresponding to a path along which the vehicle is minimally still able to drive using the energy stored in the electrical energy store.

Owner:ROBERT BOSCH GMBH

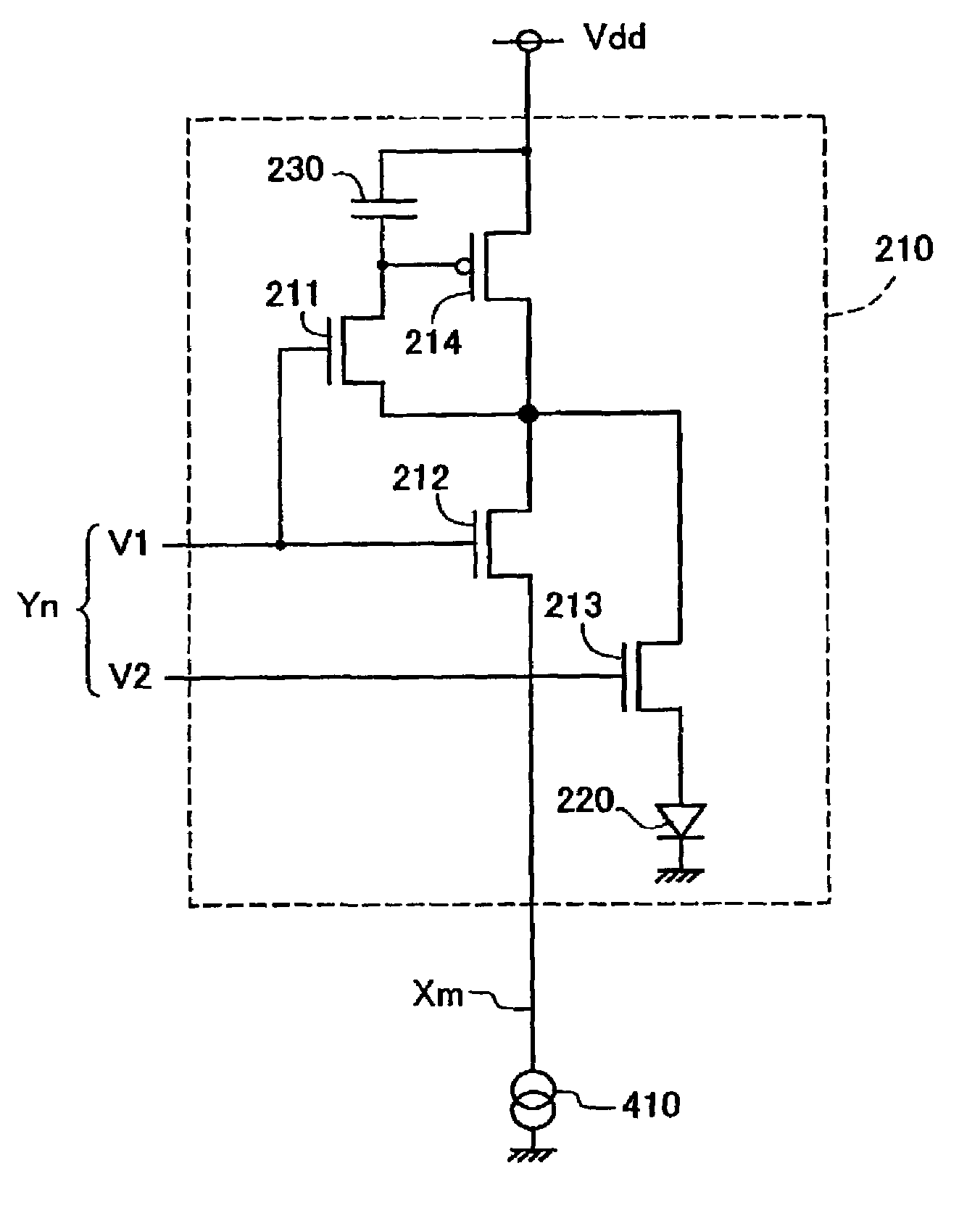

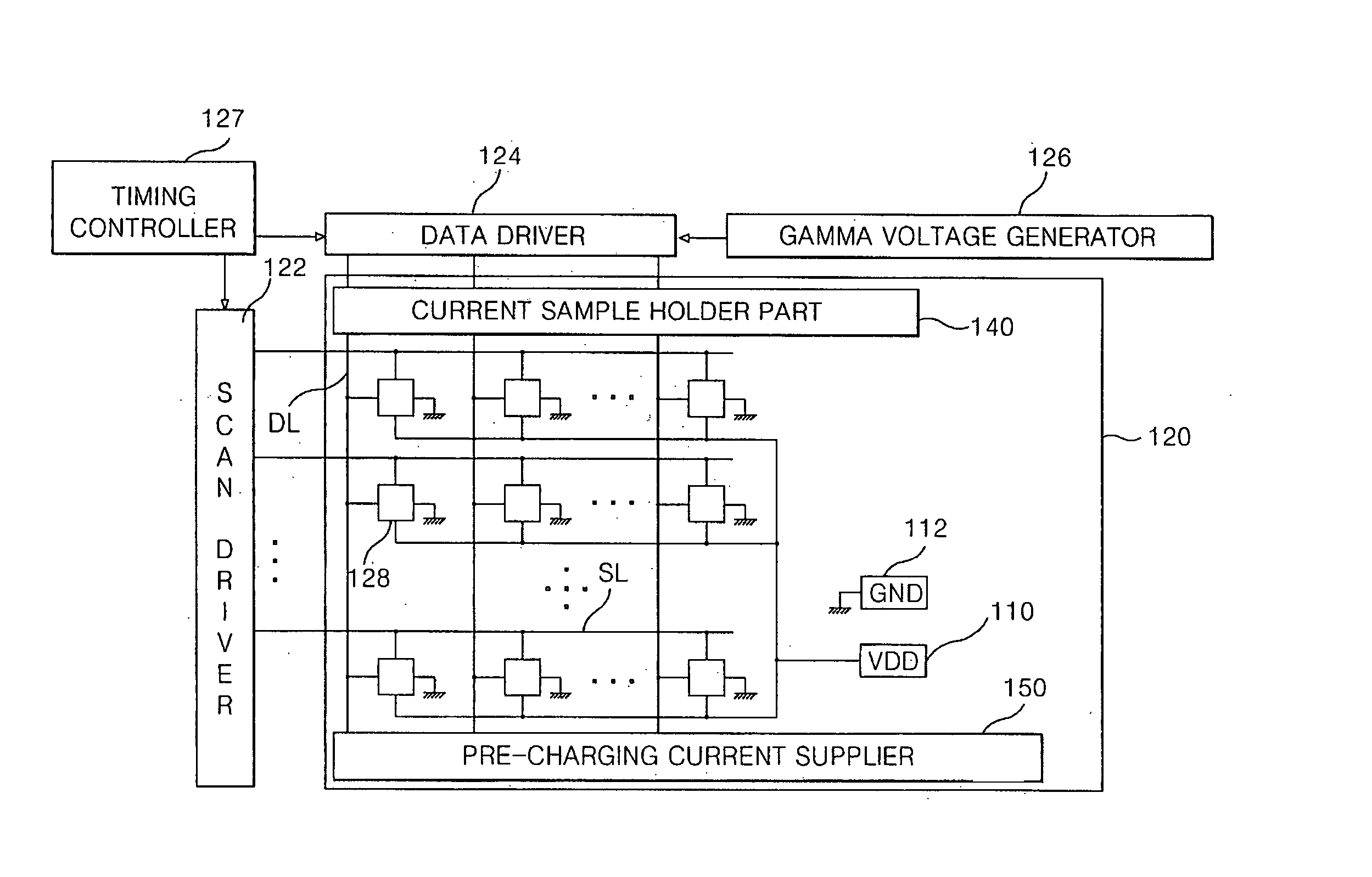

Electro-luminescence display device and driving apparatus thereof

ActiveUS20050140596A1Reducing pixel driving timeEfficient dischargeStatic indicating devicesElectroluminescent light sourcesElectricityScan line

An electro-luminescence display device includes: pixels provided between data lines and scan lines, each of the pixels including a light-emitting cell driven with a current; and a current controller for temporarily increasing the current for driving the light-emitting cells.

Owner:LG DISPLAY CO LTD

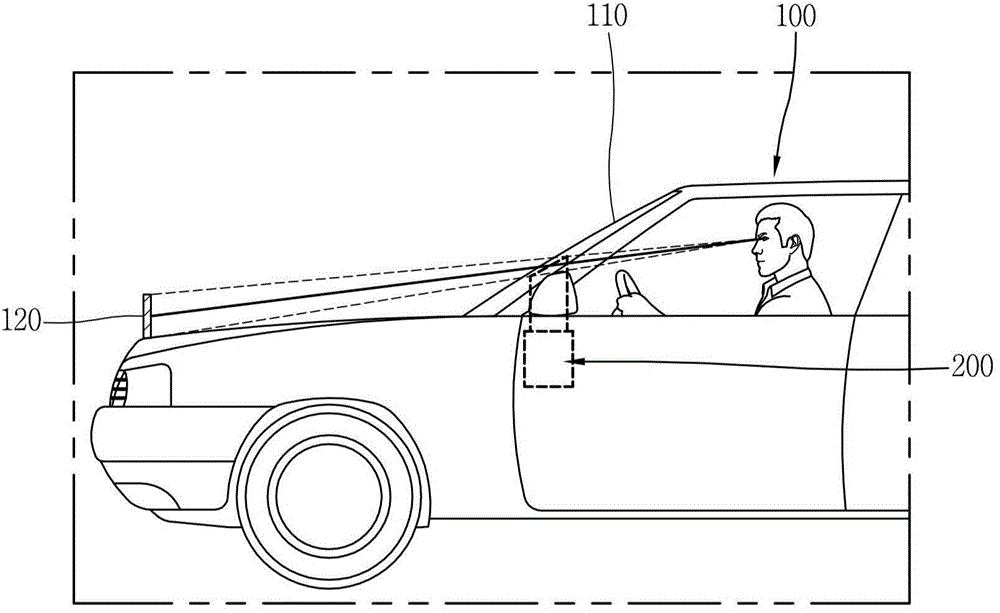

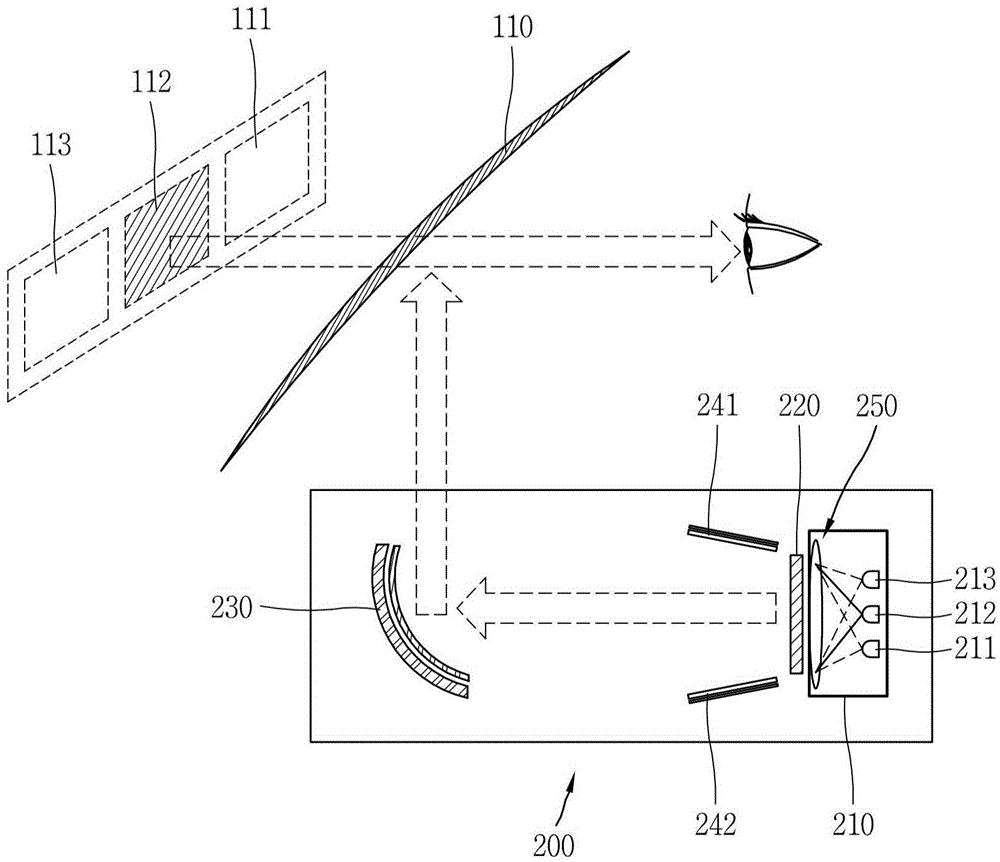

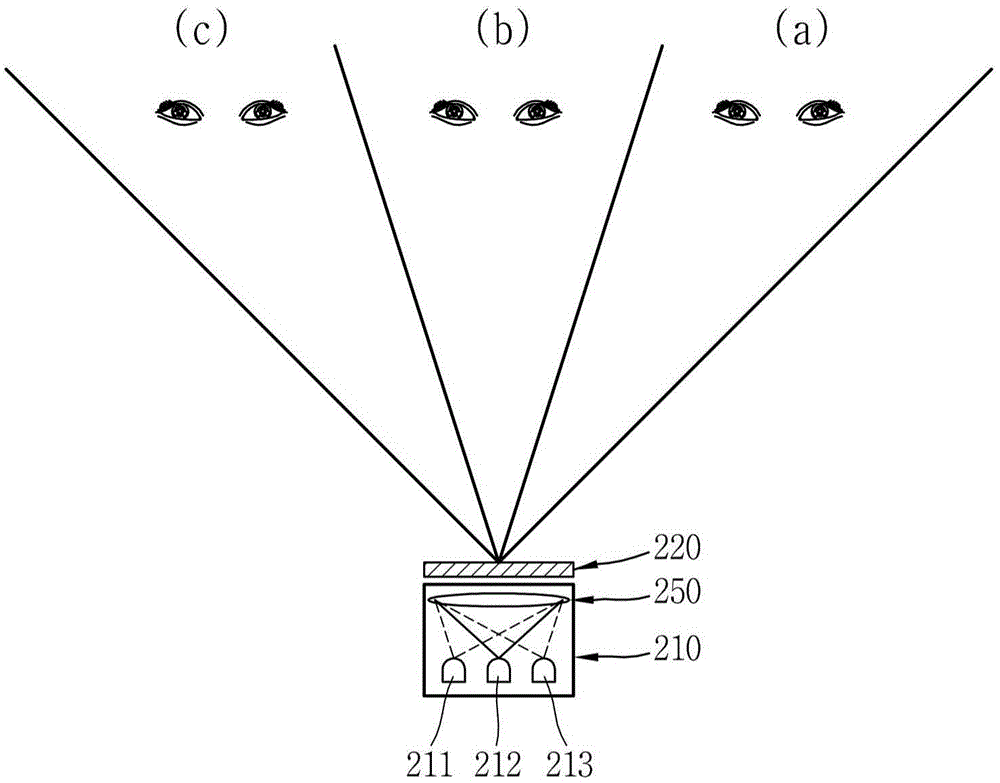

Head-up display device and vehicle having the same

ActiveCN105044910AReduce driving timeTelevision system detailsOptical signallingHead-up displayComputer science

A head-up display (HUD) device configured to project at least one of an image or a text on a windshield includes a display panel, a backlight module configured to emit light to the display panel, and an optical guide module configured to guide the at least one of the image or the text displayed on the display panel to the windshield. The backlight module includes a plurality of light sources configured to emit light to the display panel in different directions from one another such that the at least one of the image or text is independently projected on different regions of the windshield.

Owner:LG ELECTRONICS INC

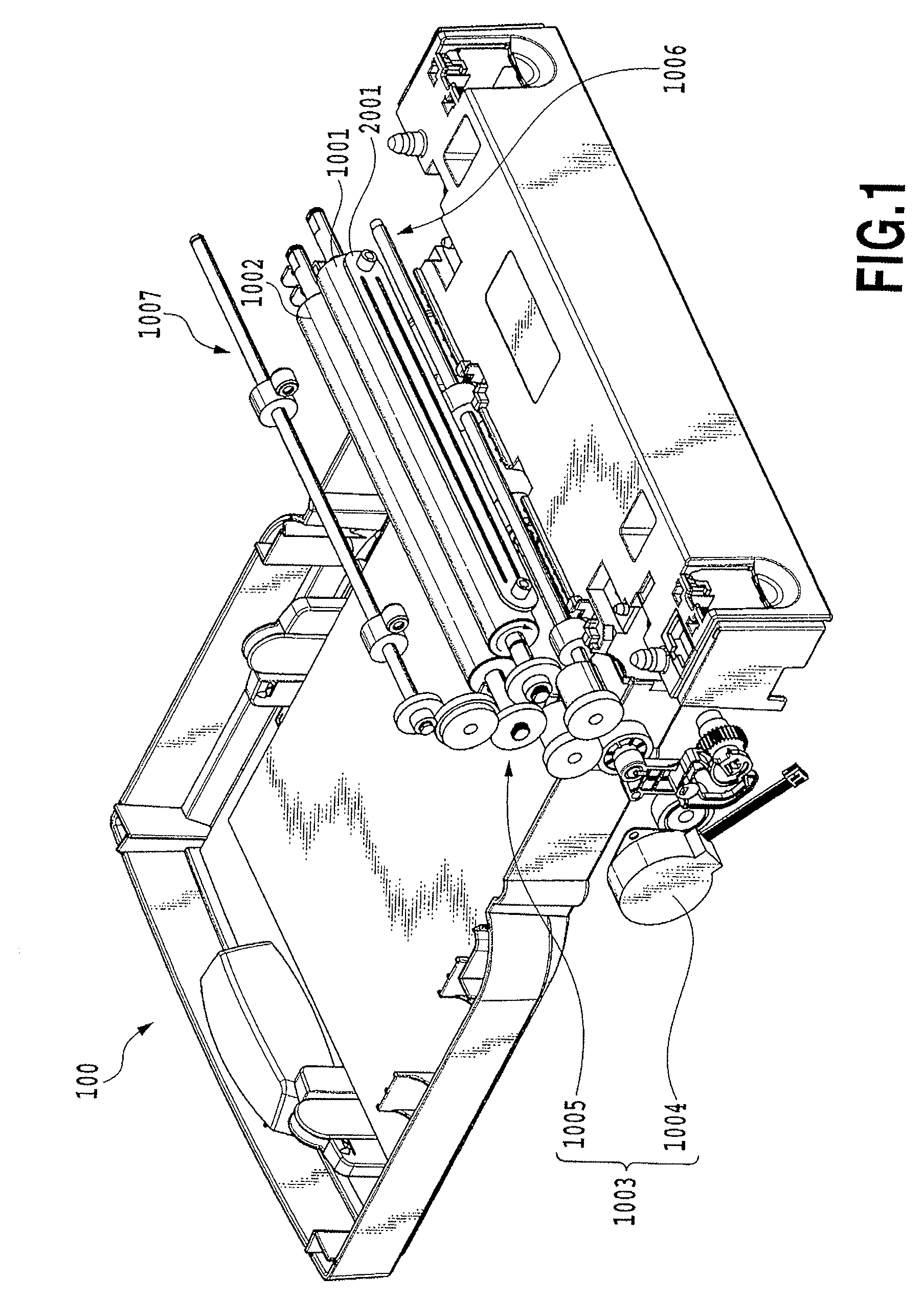

Liquid application device, inkjet recording apparatus, and method of controlling liquid application device

ActiveUS20070070163A1Reduce liquid viscosityLow viscosityMeasurement apparatus componentsOther printing apparatusStart timePre treatment

The present invention provides a liquid application device, an inkjet recording apparatus and a recording apparatus, which are capable of performing an adequate application initial operation according to the length of waiting time and power-off time, as well as a method of controlling the liquid application device. In the present invention, information on an end time of the previous processing for collecting liquid is read from a nonvolatile memory, current time information indicating the current time is obtained, and information on a lapse of time from the end time of the previous collection to a start time of the current application. Thereafter, the number of preliminary rotations R of an application roller is decided based on the information on the lapse of time with reference to a look-up table. Sequentially, the application roller is rotated by the decided number of preliminary rotations R to perform preprocessing operation.

Owner:CANON KK

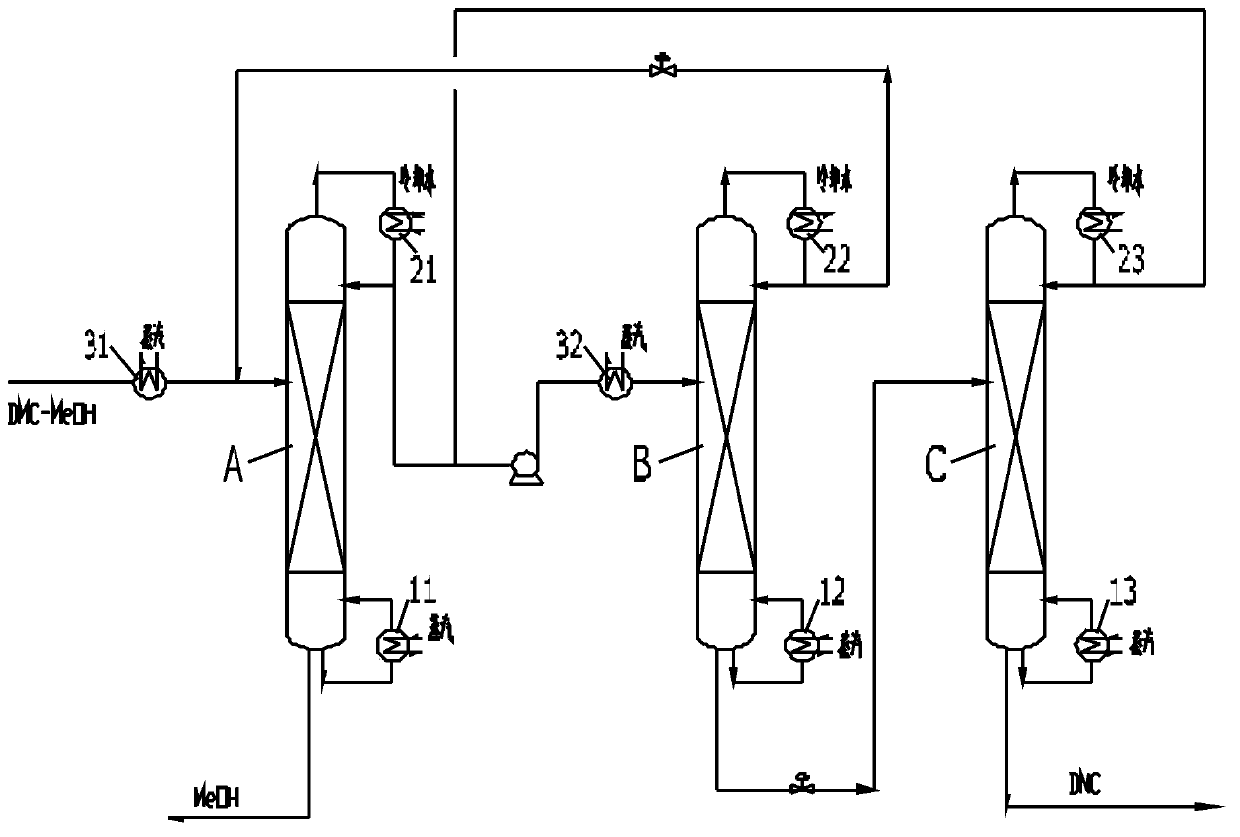

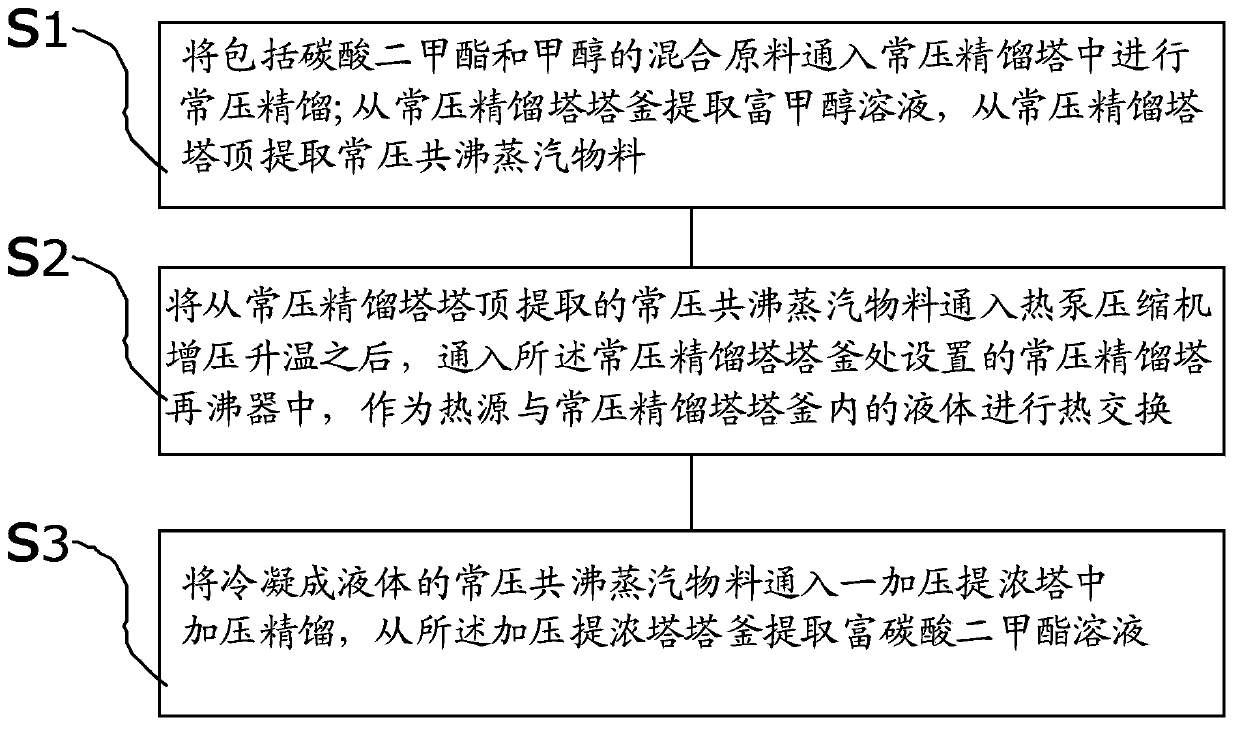

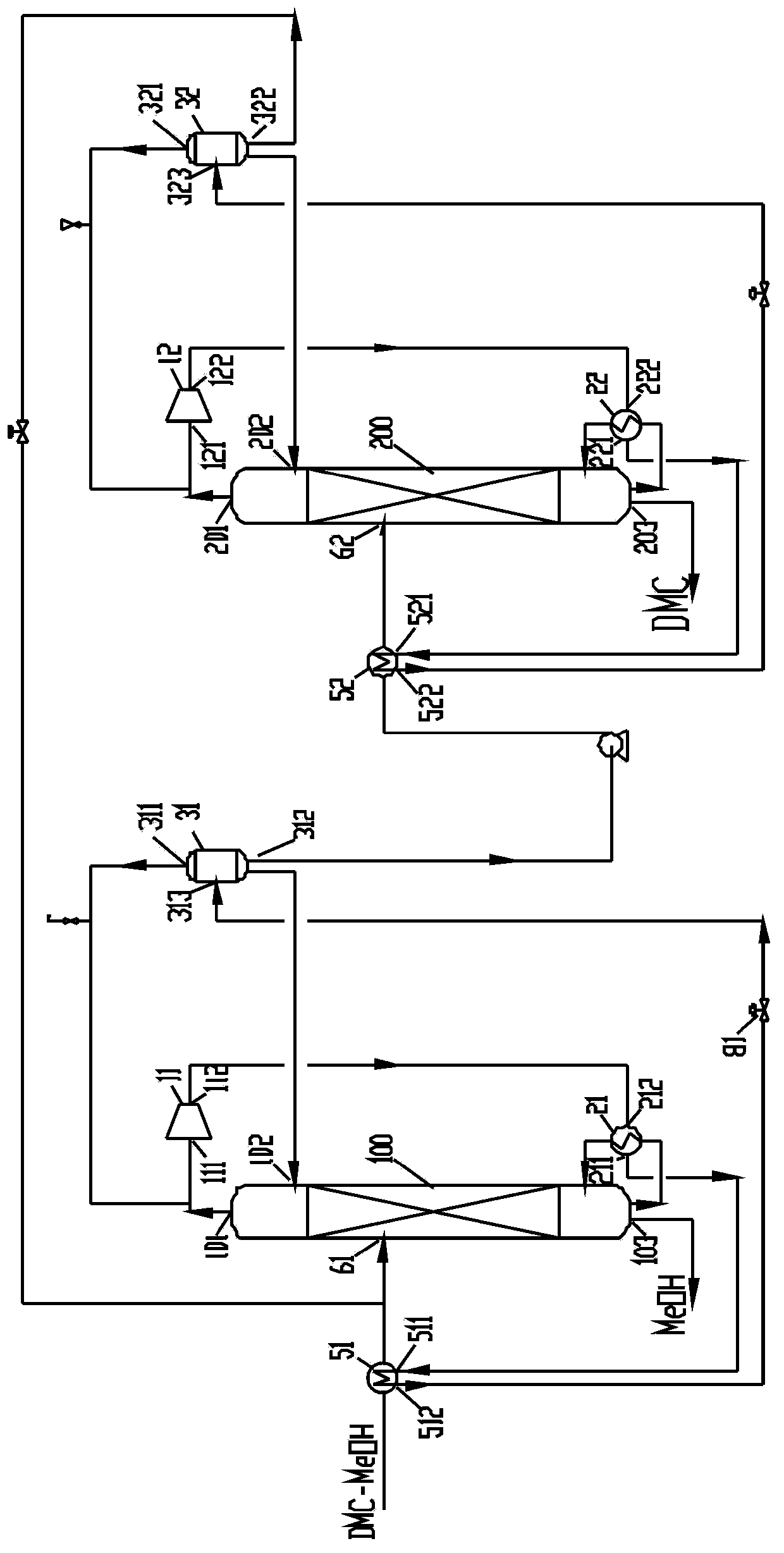

Method for separating dimethyl carbonate and methanol through pressure-swing distillation of heat pump, and apparatus thereof

InactiveCN103626656AReduce energy consumptionLow costCarbamic acid derivatives preparationOrganic compound preparationReboilerSelf-condensation

The invention provides a method for separating dimethyl carbonate and methanol through pressure-swing distillation of heat pump, and an apparatus thereof. In the dimethyl carbonate and methanol through pressure-swing distillation of the heat pump, an atmospheric azeotropic steam material obtained from the top of an atmospheric rectification tower is supercharged and heated by a heat pump compressor, and is introduced to a reboiler at the bottom of the atmospheric rectification tower as a heat source, so a liquid in the atmospheric rectification tower is heated, and the self-condensation of the atmospheric azeotropic steam material is completed. Compared with traditional atmospheric azeotropic steam material condensation through using cooling water and kettle liquid heating realized through an extra external heat source, the method in the invention properly improves the temperature and the pressure of an atmospheric azeotropic steam through the heat pump compressor to make the atmospheric azeotropic steam realize the kettle liquid heating and the reasonable and effective energy cycle as a heat source; and the cost generated by the pump heat compressor is far lower than the cost of traditional cooling water and the external heat source, so a good economic benefit is generated.

Owner:YASHENTECH CORP

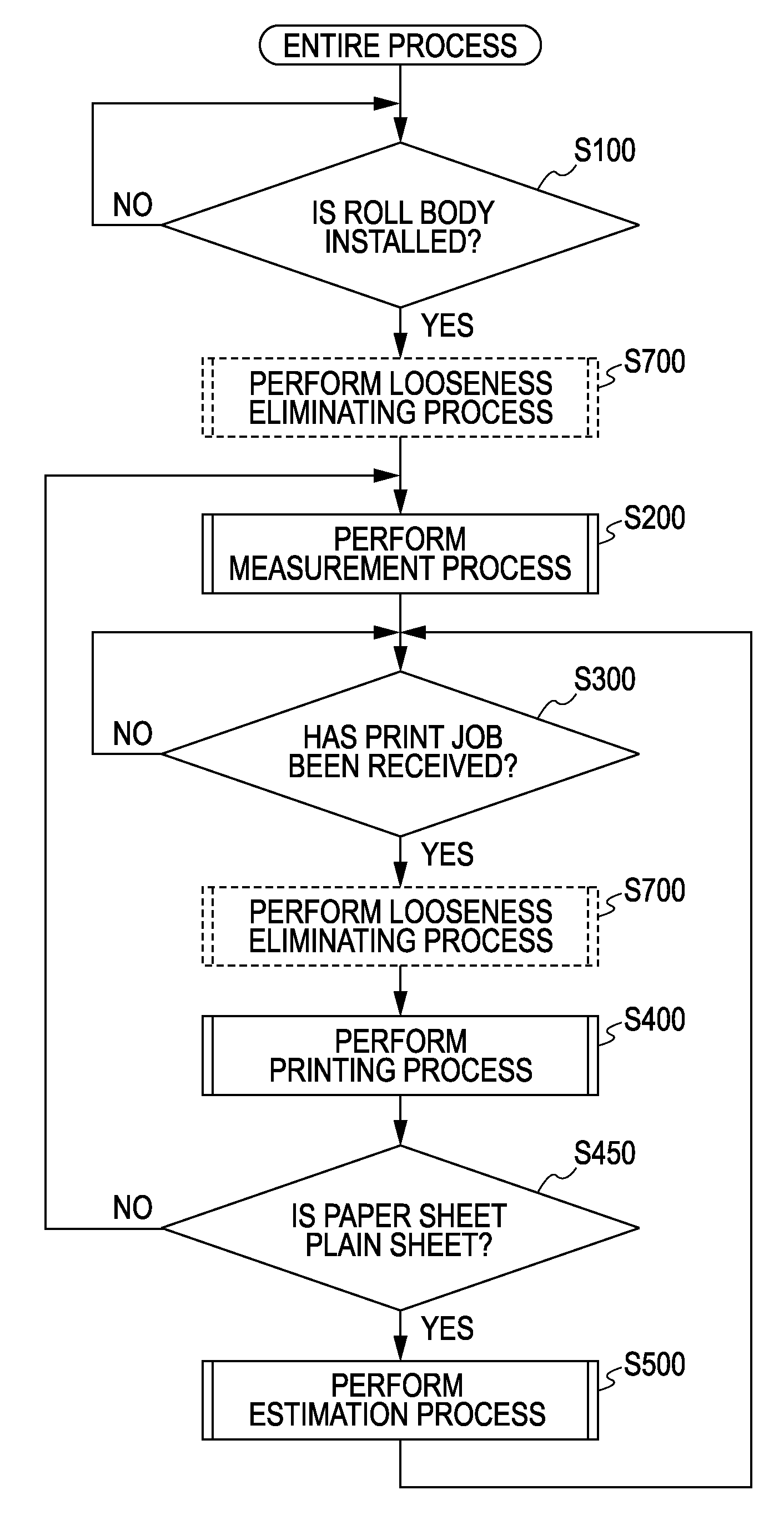

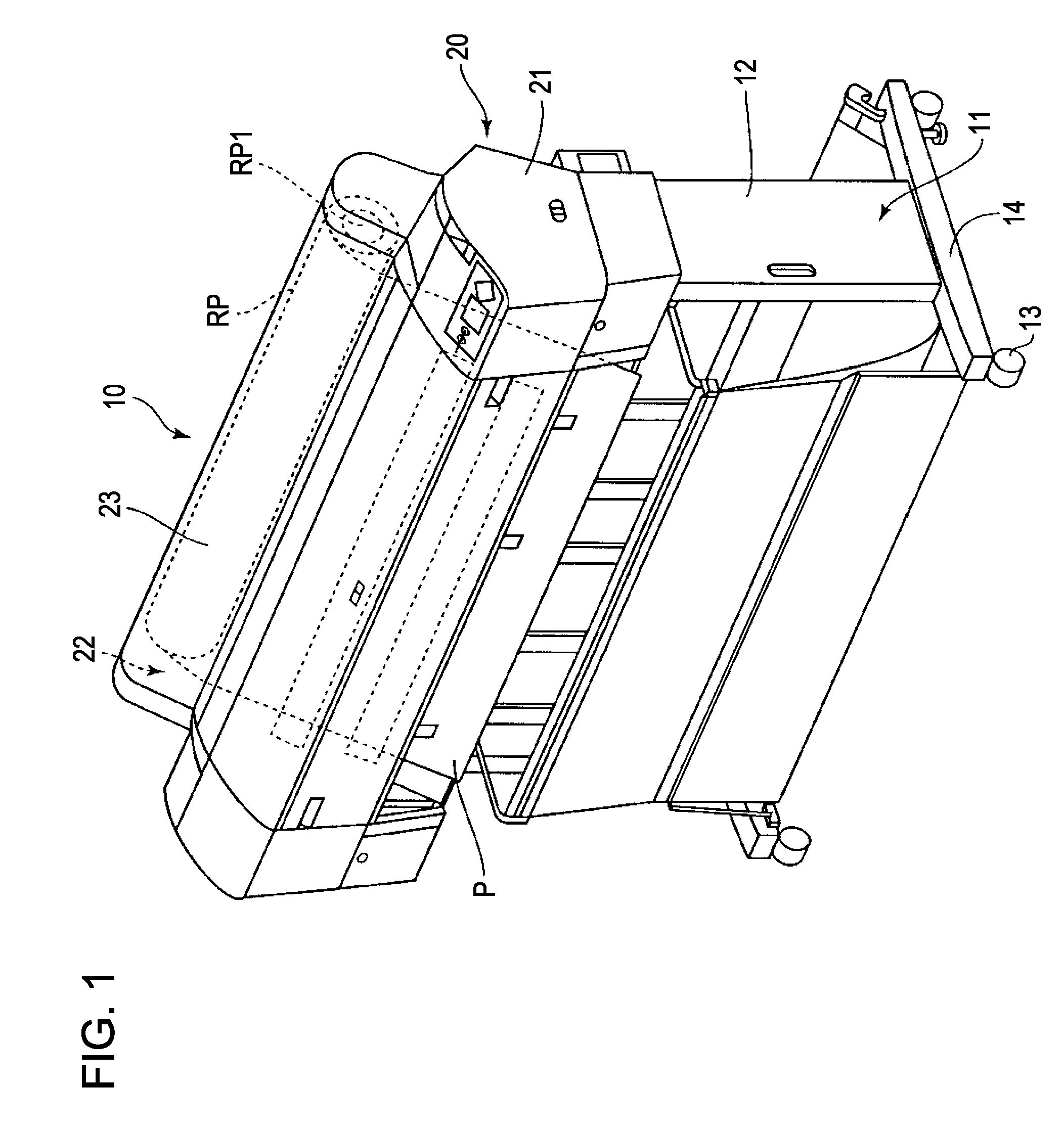

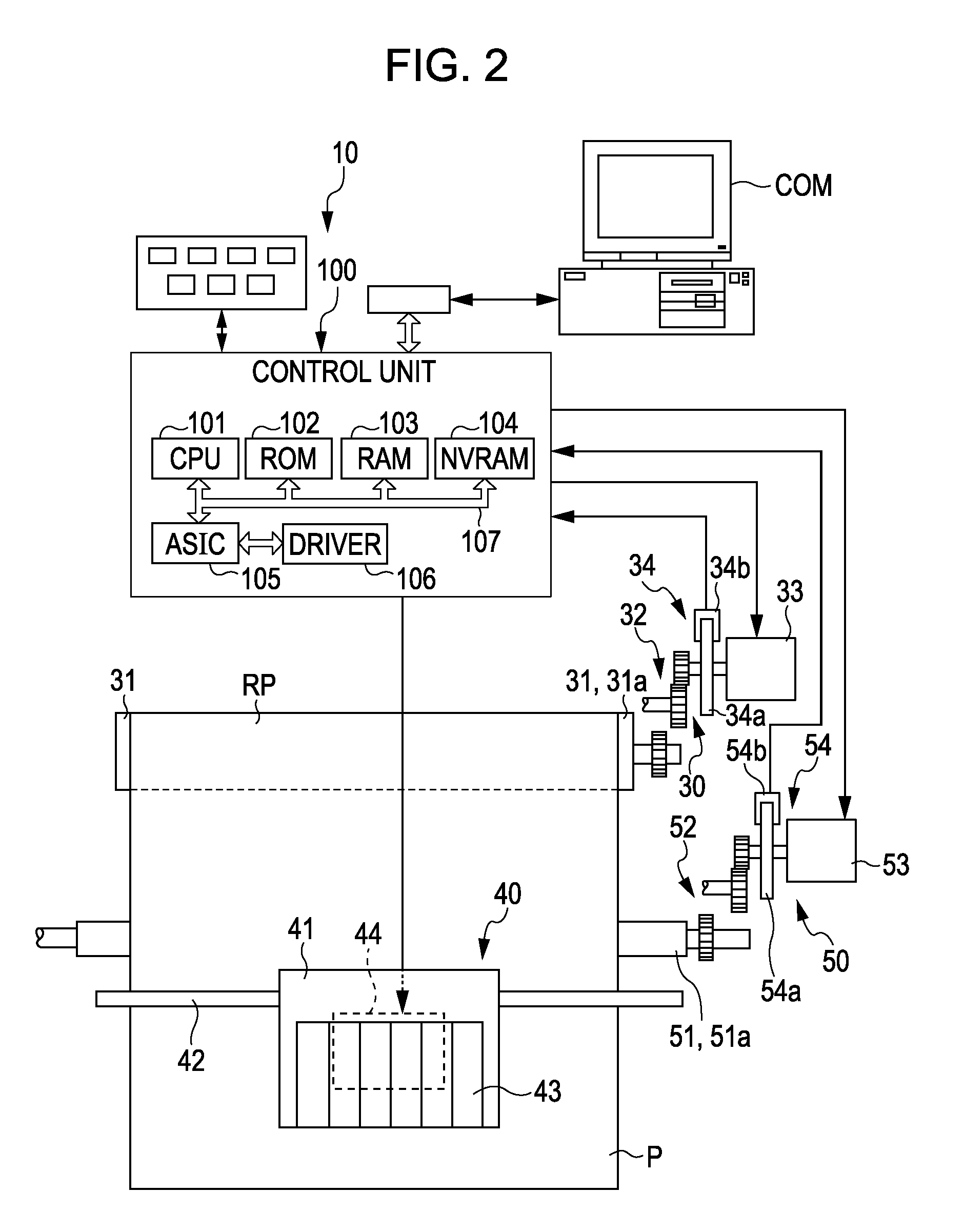

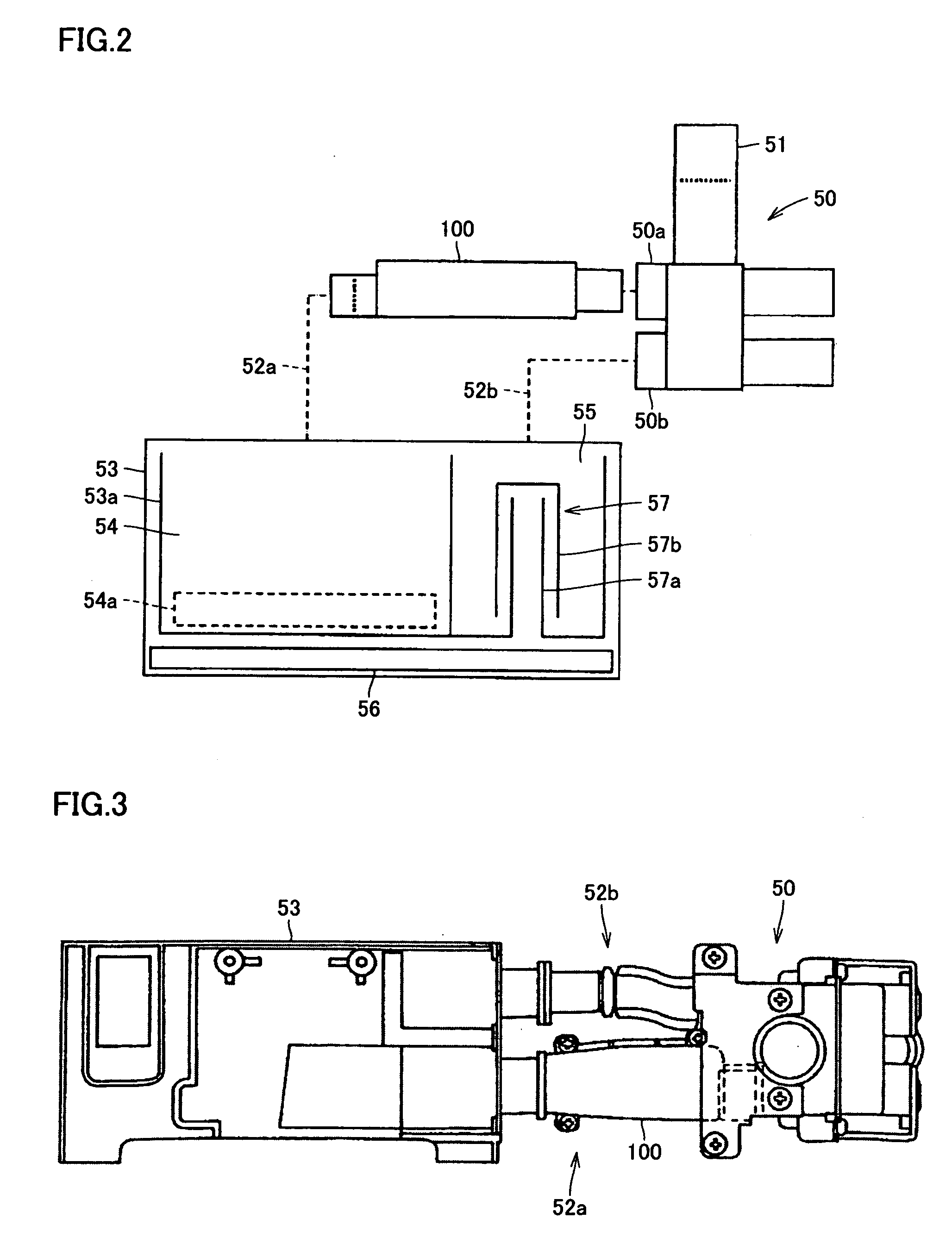

Printing method and printing apparatus

ActiveUS20100053251A1Eliminate loosenessSuppress power consumptionTypewritersOther printing apparatusEngineeringElectric motor

Owner:SEIKO EPSON CORP

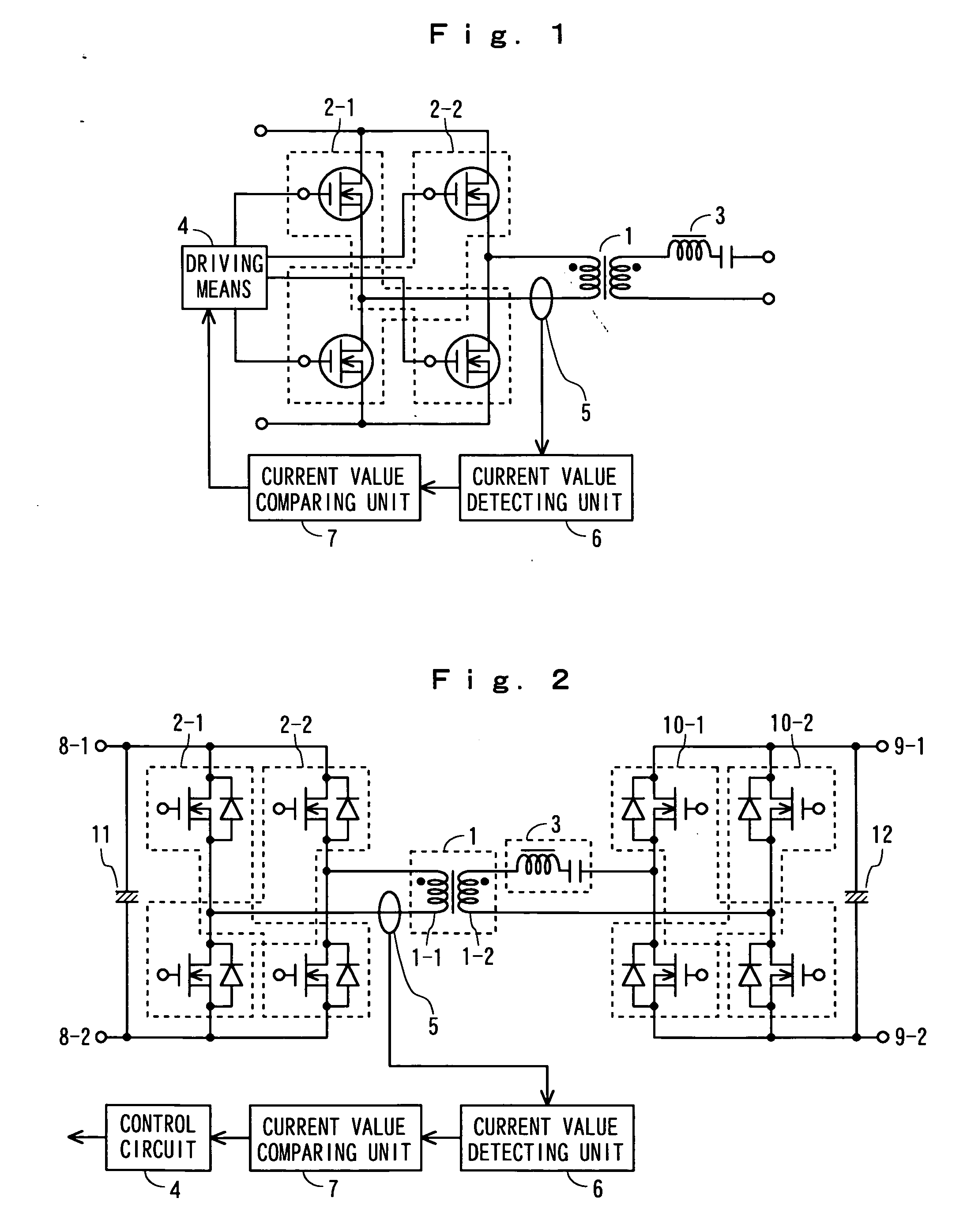

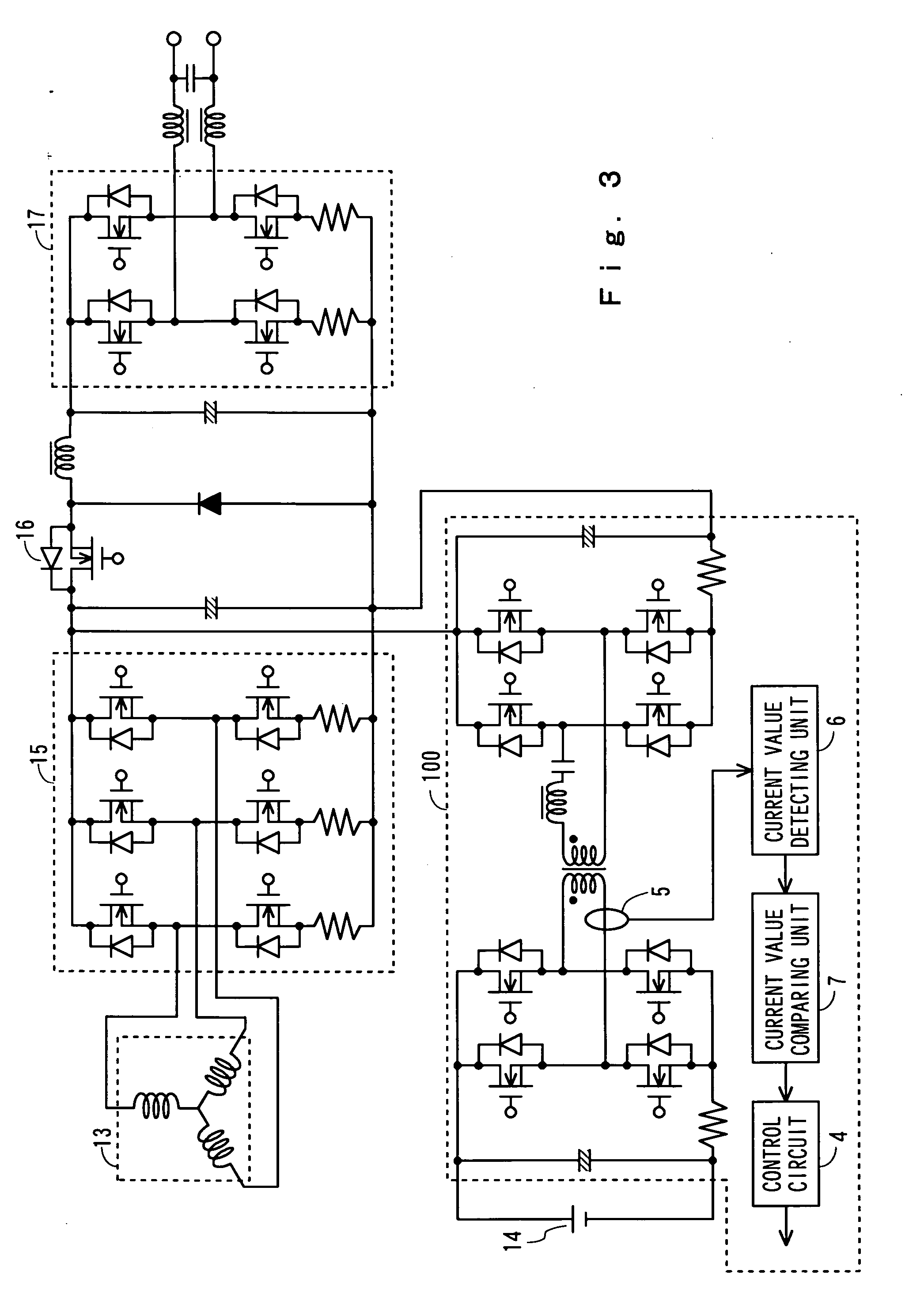

Dc-dc converter

InactiveUS20070041222A1Suppress switching lossesImprove switching efficiencyEfficient power electronics conversionAc-dc conversionDc dc converterLc resonant circuit

To provide a DC-DC converter capable of suppressing switching loss with a simple structure, and capable of enhancing converting efficiency. An LC resonant circuit 3 is inserted on a secondary side of a transformer 1. If switching means 2 is turned ON or OFF by driving means 4, output can be obtained on the secondary side through the transformer 1. A resonant current frequency detecting means comprises a current detecting current transformer 5 and a frequency detecting unit 6. The resonant current frequency detecting means detects resonant current frequency caused by operation of the LC resonant circuit 3. This frequency is fed back to the driving means. As a result, the driving means 4 turns the switching means 2 ON or OFF at a frequency corresponding to the resonant frequency of the LC resonant circuit 3.

Owner:HONDA MOTOR CO LTD

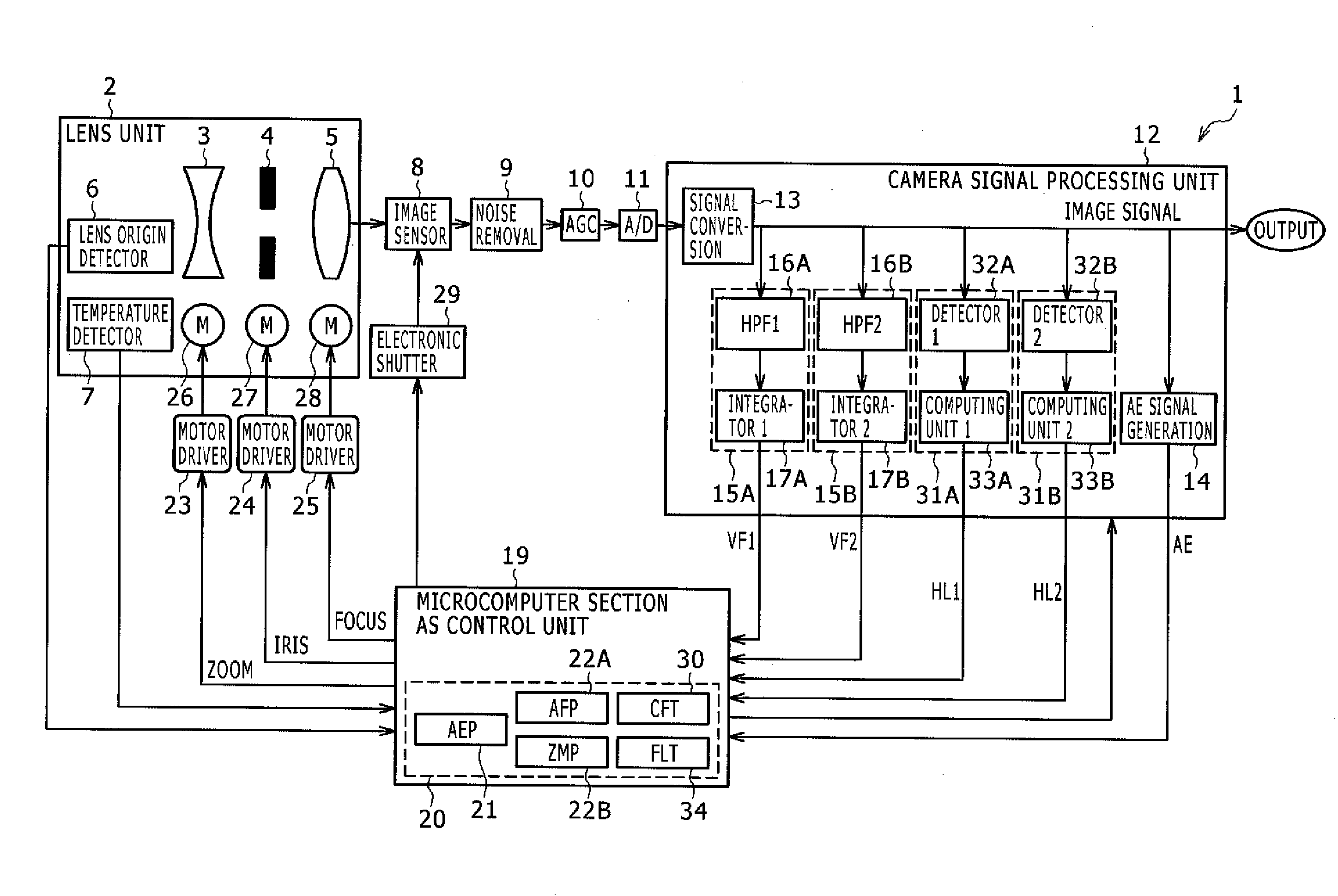

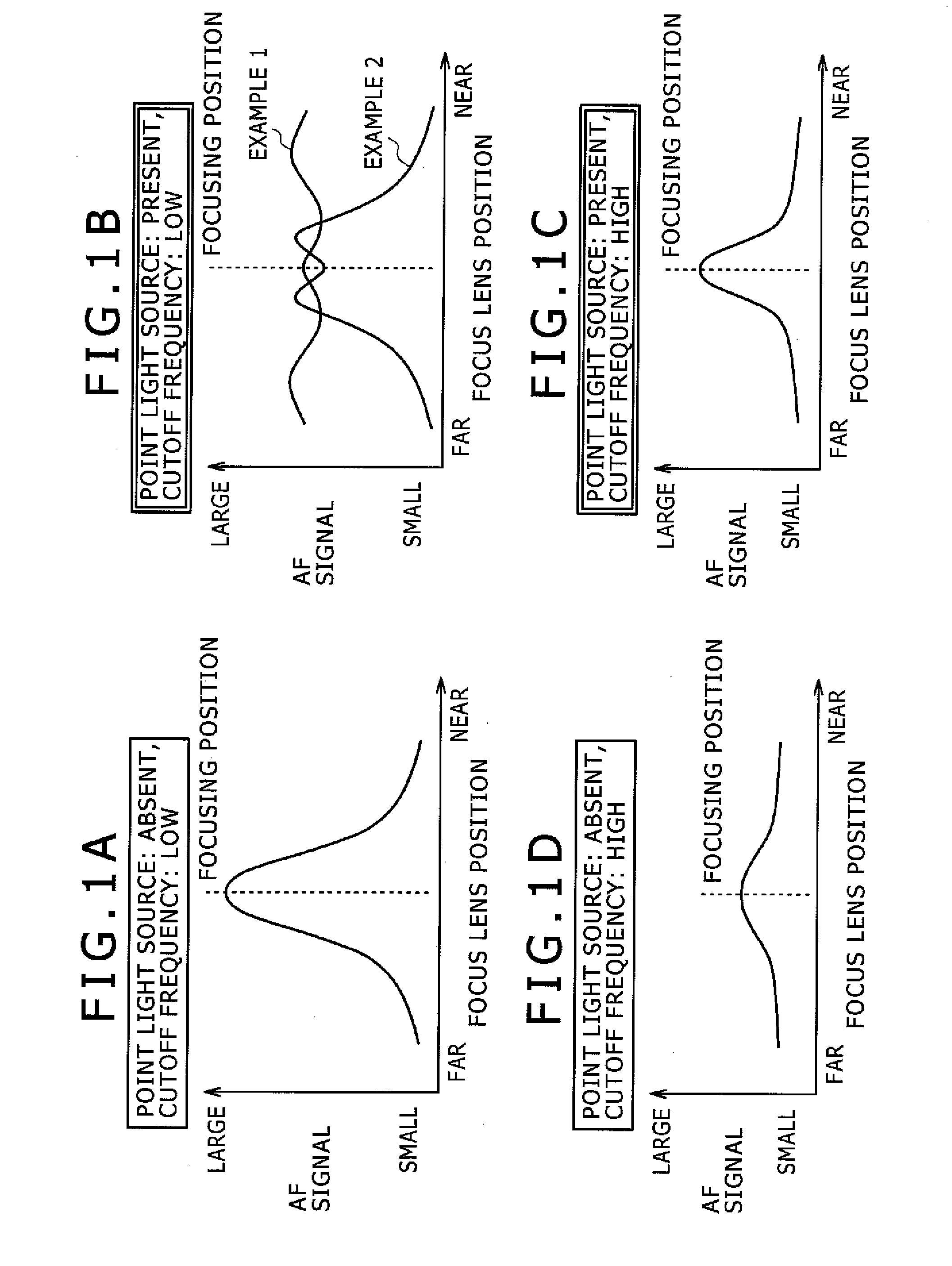

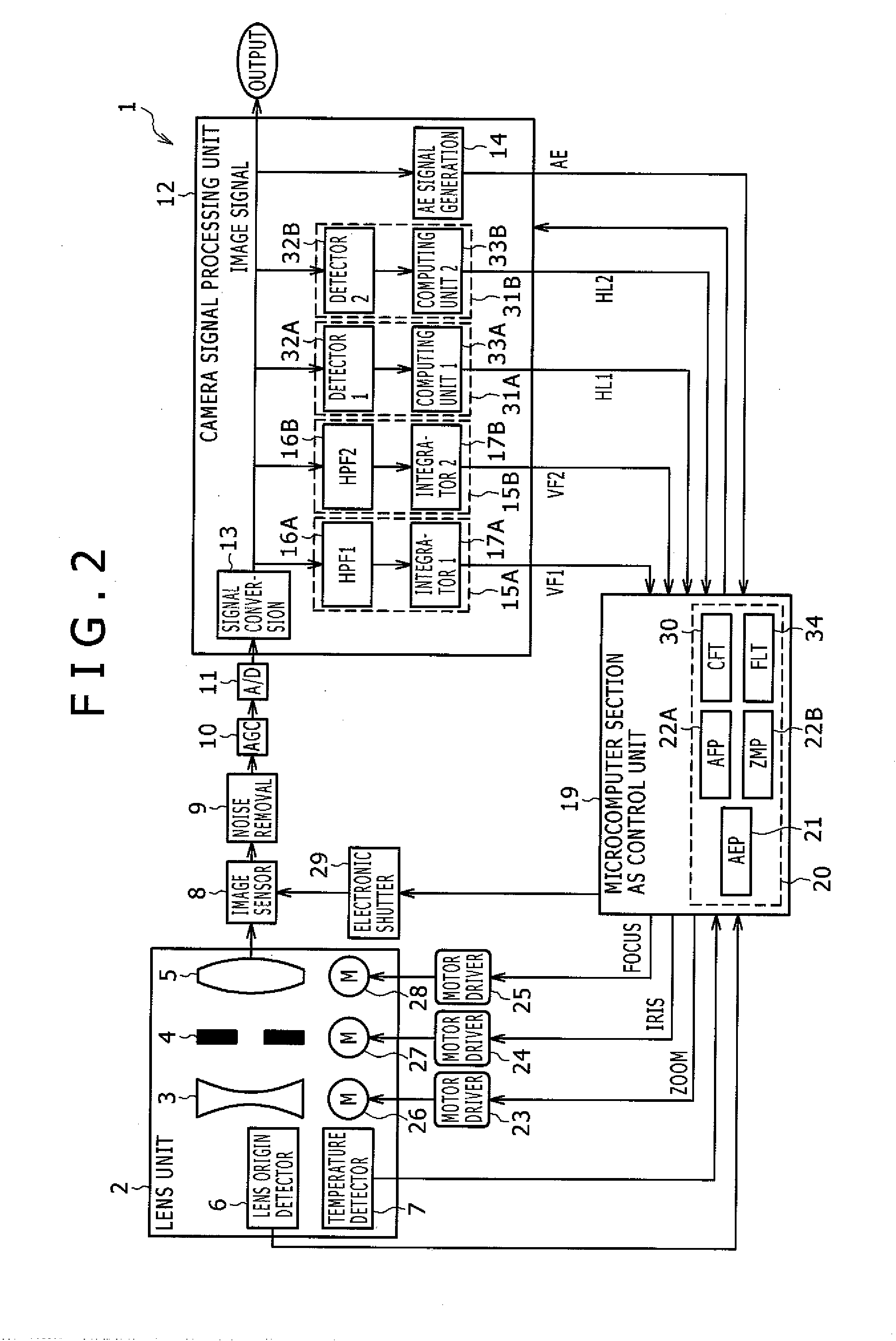

Focus Control Device and Focus Control Method

InactiveUS20100123818A1Reduce focusing timeAchieve effectTelevision system detailsTelevision system scanning detailsHigh luminanceBrightness perception

Even when a point light source is present in a subject or a normal subject is erroneously determined as a point light source in determination of the presence or absence of a point light source, the following is implemented: the driving time of a focus lens is shortened and quick focusing operation is provided. The optimum focus lens stroke is computed based on information on a high-brightness region and a low-brightness region in an image. Then the focus lens is driven while the focus lens stroke is continuously varied based on the amount of change in high-brightness region and low-brightness region.

Owner:HITACHI INFORMATION & CONTROL SOLUTIONS LTD

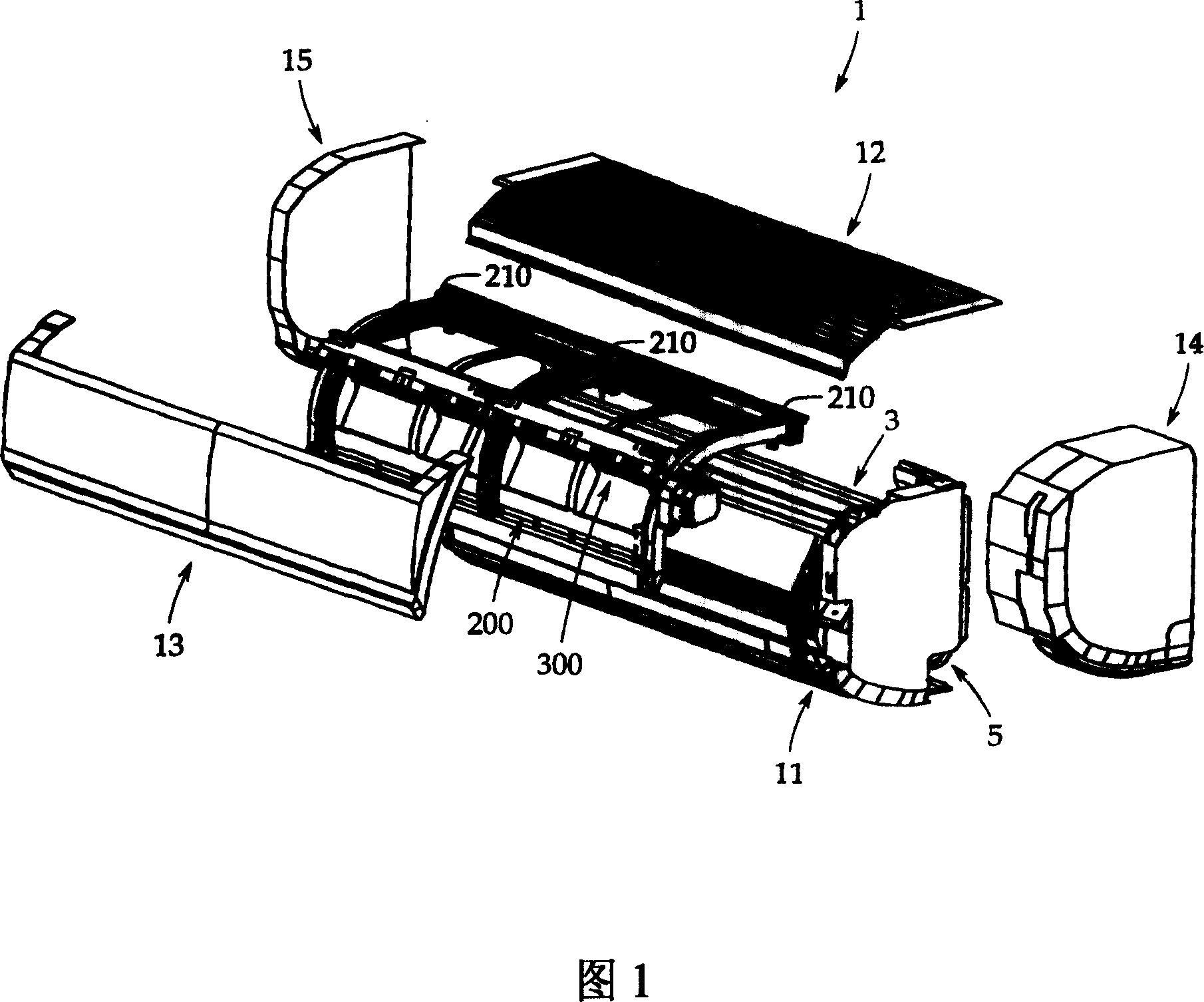

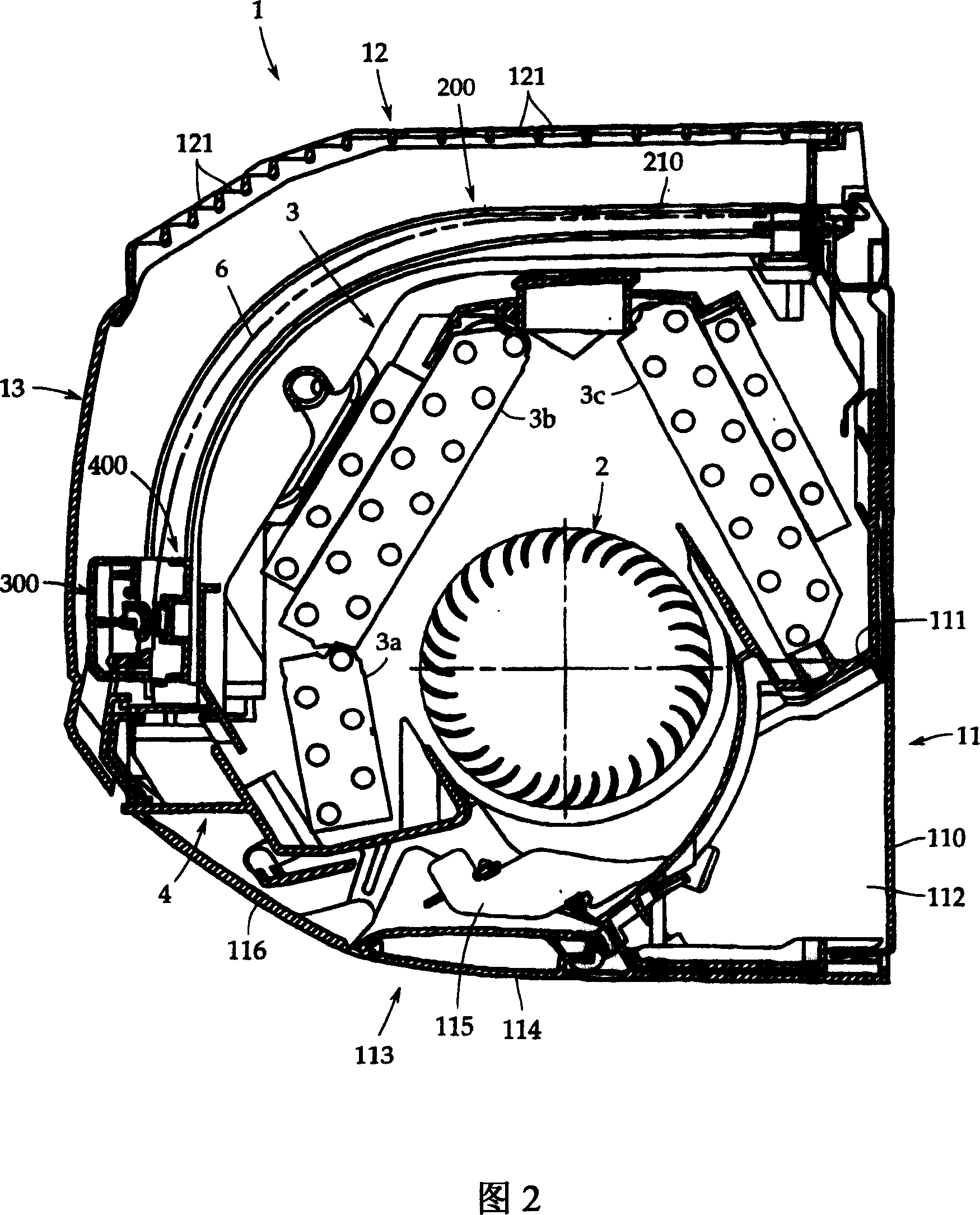

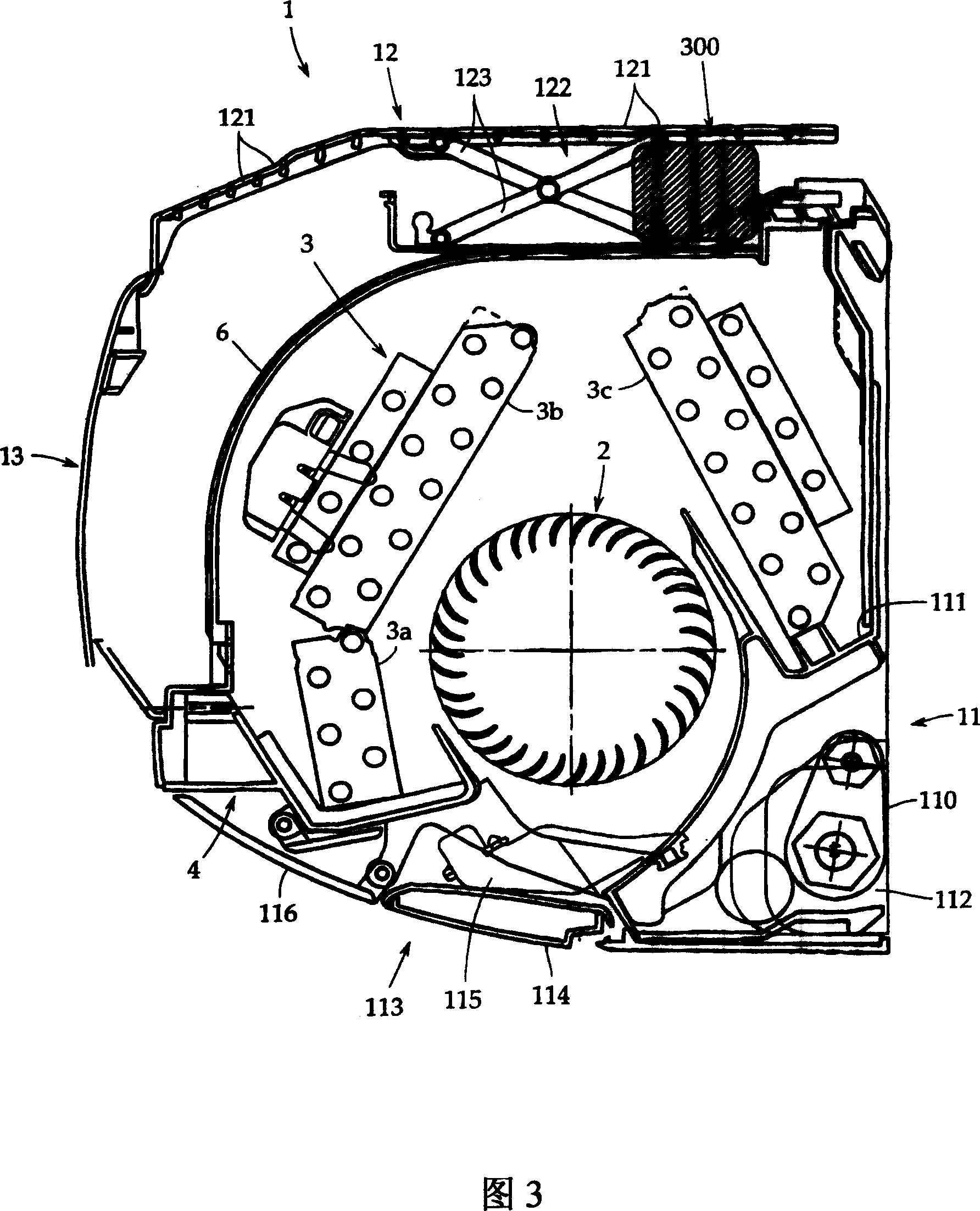

Air conditioner and method for assembling the same

InactiveCN1932396AReliable contactEasy to moveLighting and heating apparatusSpace heating and ventilation detailsAir filterEngineering

An air conditioner having a main body is provided with a panel (1001) including a front panel (1001a) a and a top panel (1001b), the main body incorporating an air passage connecting an air inlet (1002) and an air outlet (1003) , an air filter (1004), a heat exchanger (1005), a blower fan (1006), and a dedusting device (1007) attached to the front face of the air filter (1004) which is reciprocated along the surface of the air filter (1004), the top panel (1001b) is opened / closed as the dedusting device (1007) is reciprocated.

Owner:FUJITSU GENERAL LTD

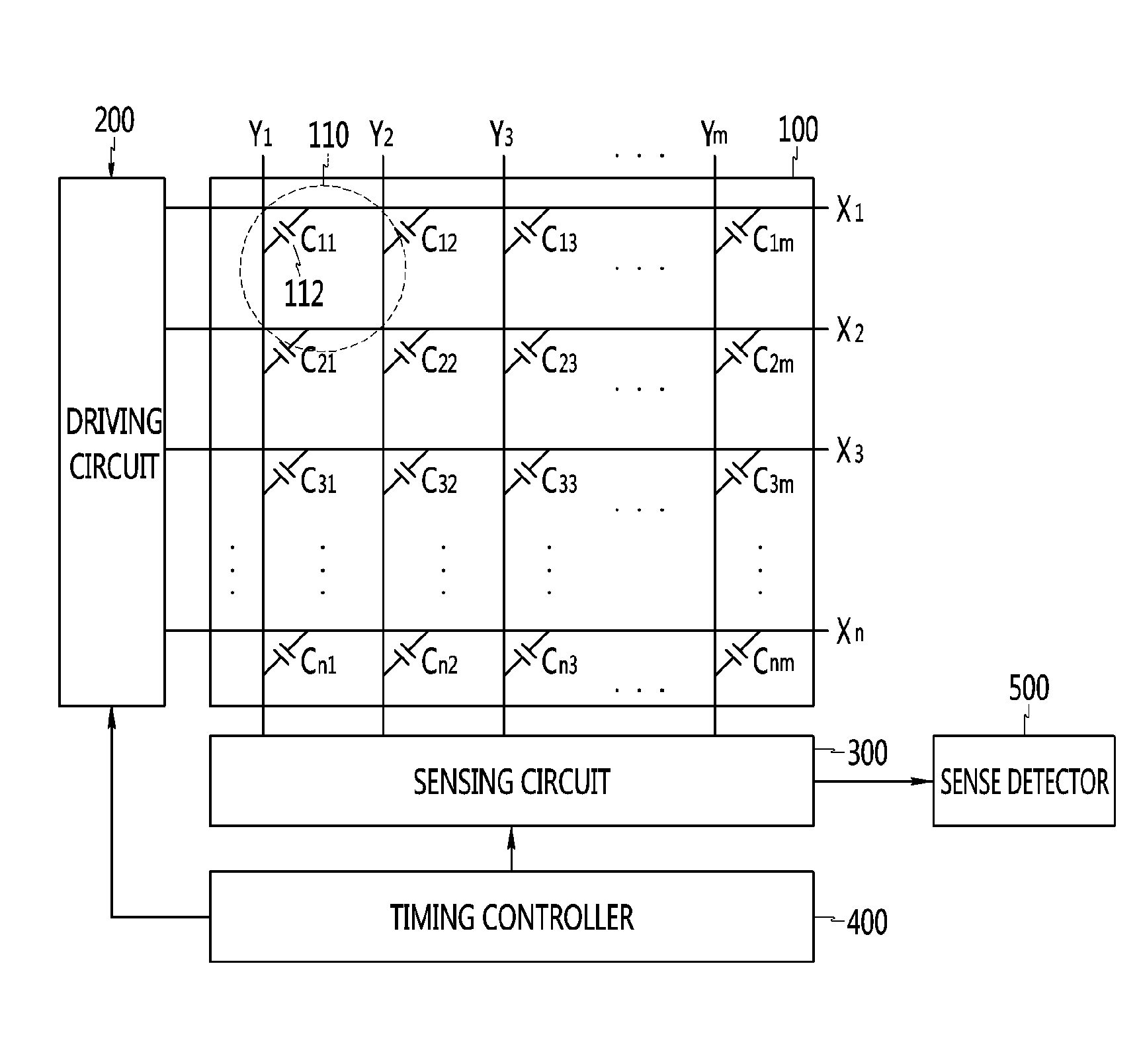

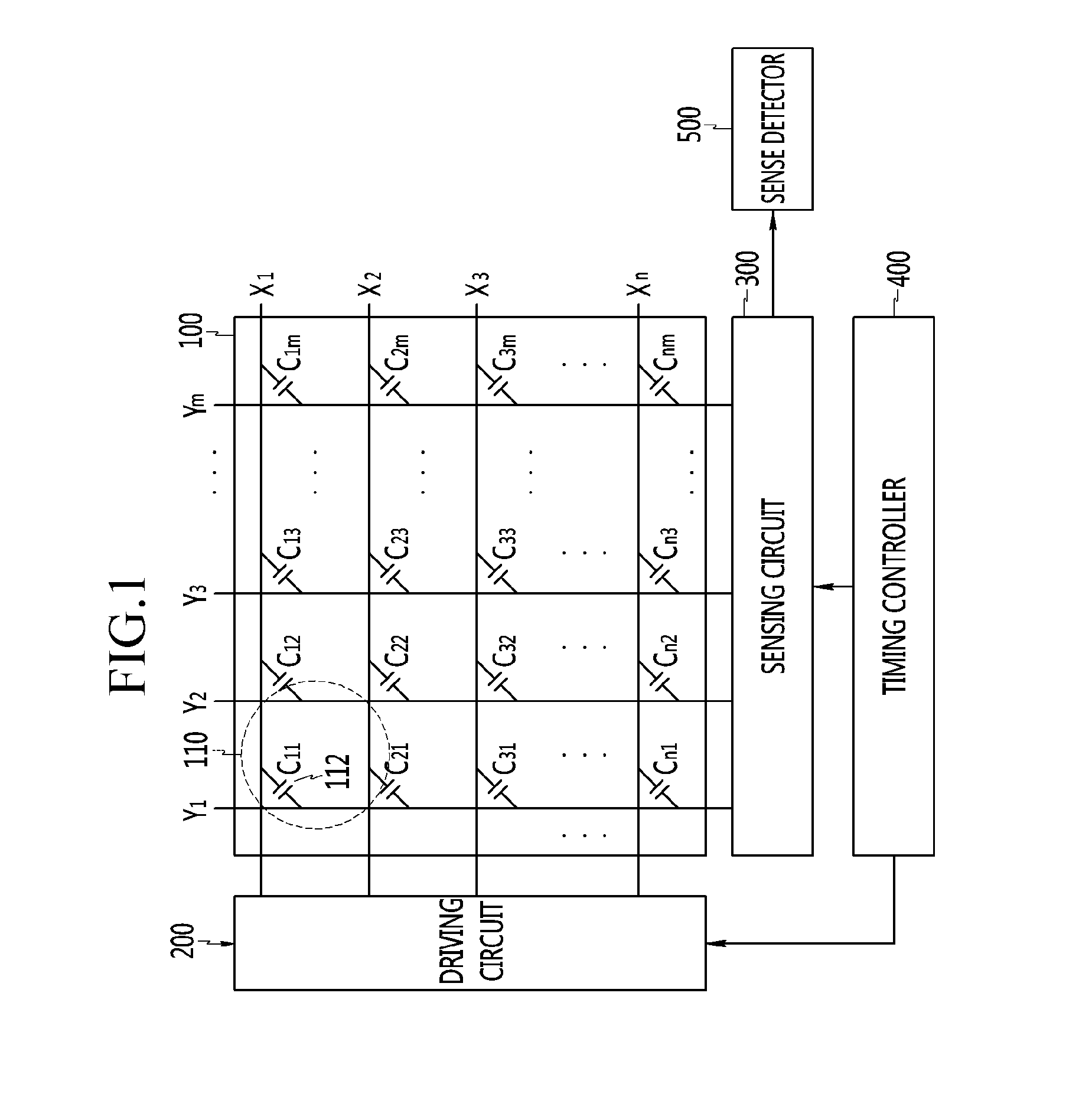

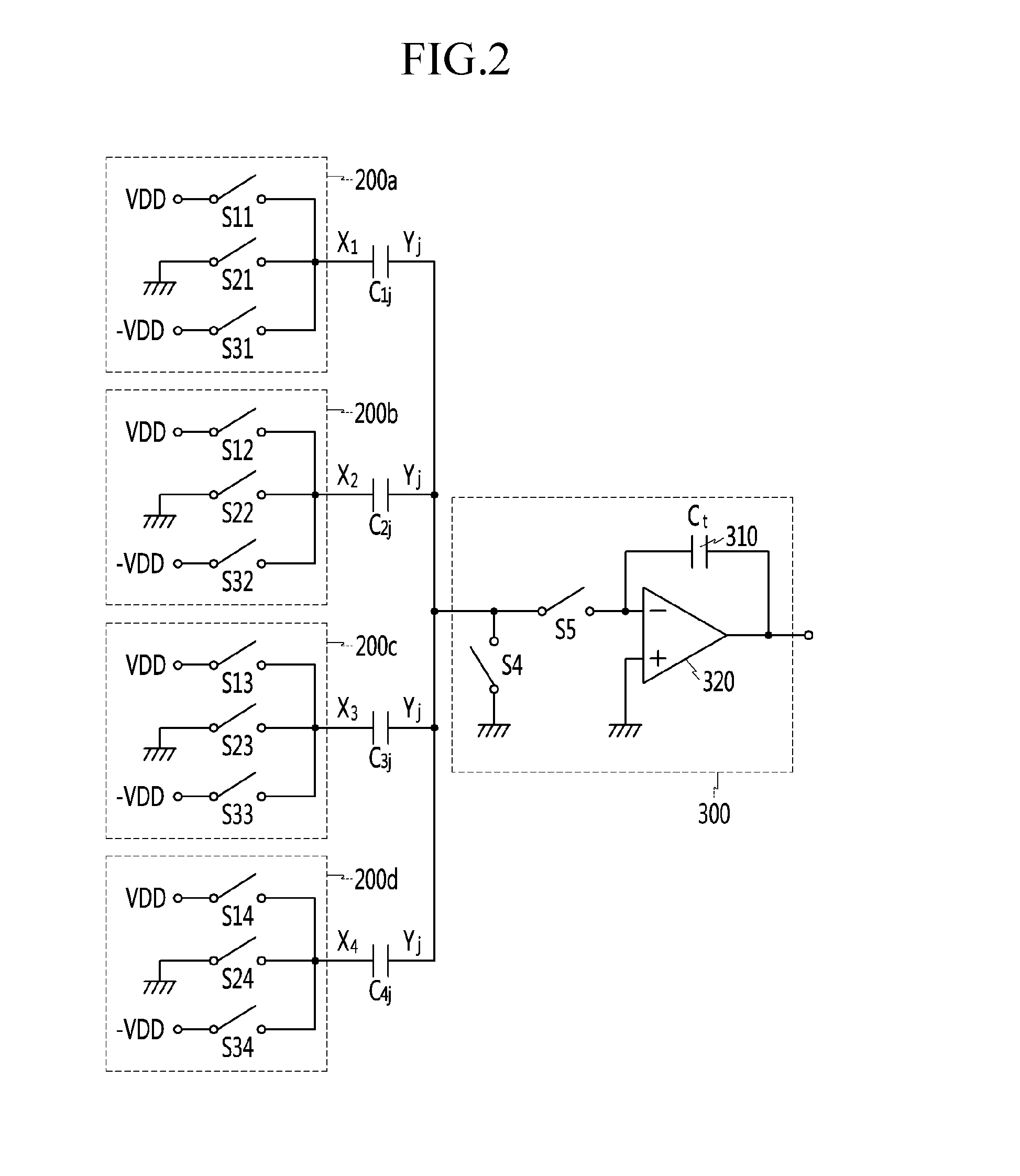

Touch screen device, and driving device and driving method for touch panel

ActiveUS20130201154A1Reduce driving timeAvoid failureInput/output processes for data processingElectricityCapacitance

A driving circuit outputs driving waveforms to operation signal lines. The waveforms are formed by combining a first-mode waveform for charging a node capacitor with a positive voltage and a second-mode waveform for charging the node capacitor with a negative voltage in a predetermined binary sequence. A sensing circuit is electrically connected with a plurality of sense signal lines and measures sense voltages delivered to one integration capacitor from a plurality of node capacitors which are electrically connected with the sense signal lines. A sense detector adds or subtracts the sense voltages which are measured by the sensing circuit at driving time points to measure capacitances of the node capacitors. Accordingly, an autocorrelation technique which is generally used in communication systems is applied to driving a touch screen device.

Owner:ZINITIX

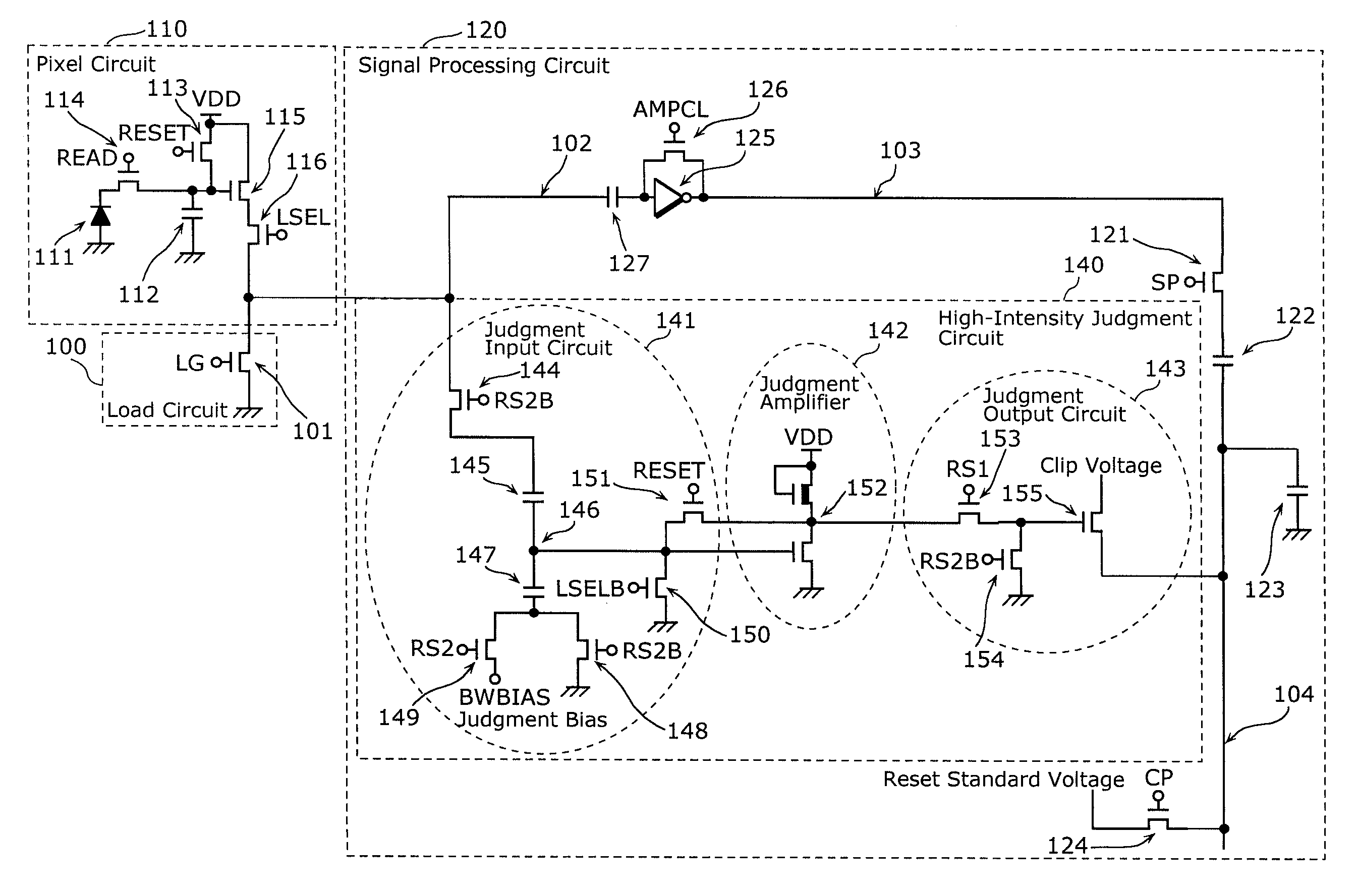

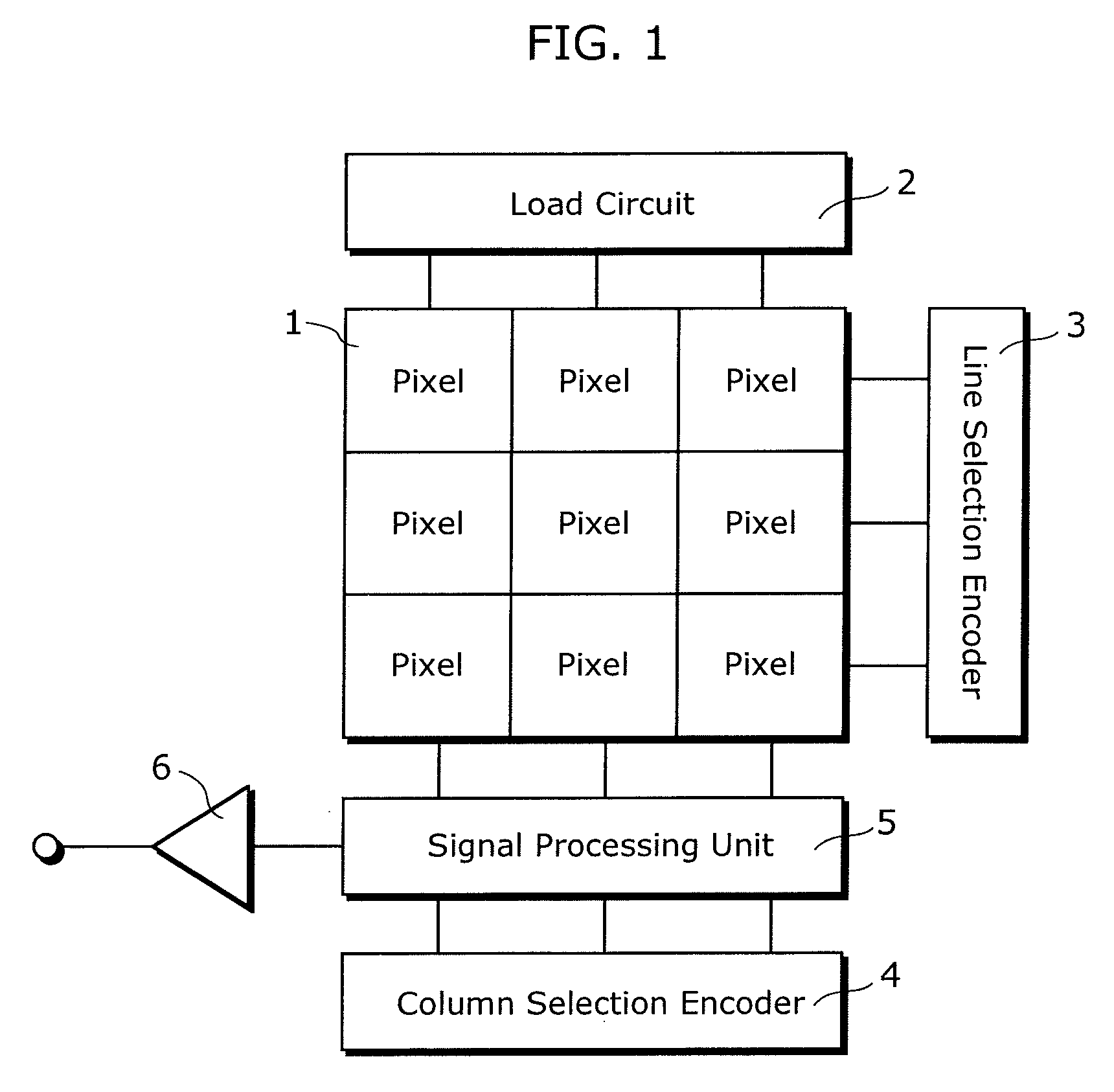

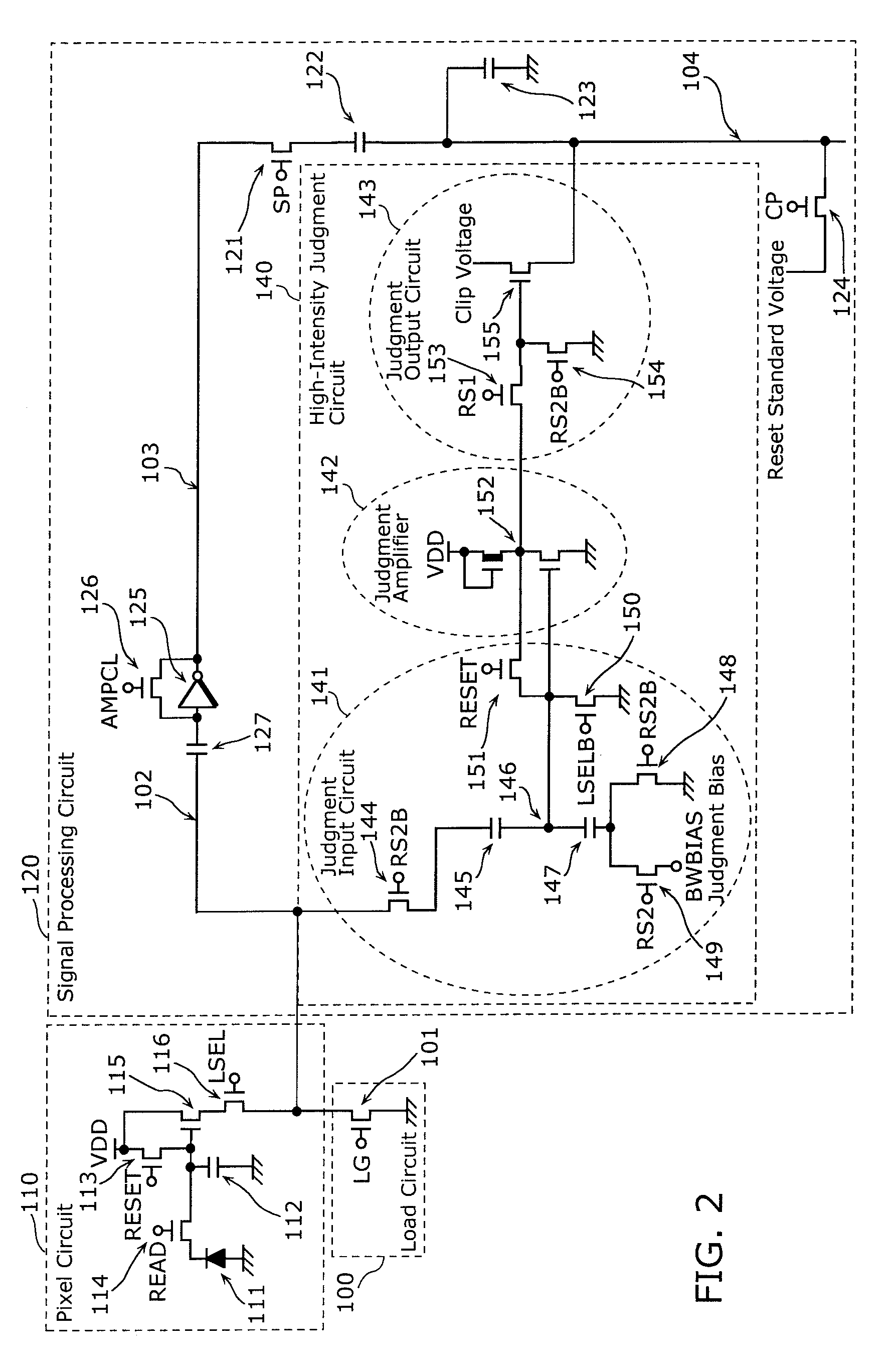

Solid-state imaging device

InactiveUS20070165117A1Simple signalReduce driving timeTelevision system detailsTelevision system scanning detailsCapacitanceHemt circuits

A solid-state imaging device which can, in response to the problem of black-crush occurring in an image when strong light is enters the device, positively detect black-crush in a state in which a variance margin has been secured. The solid-state imaging device outputs a luminance signal in accordance with an amount of received light, and includes: a pixel circuit having a light-receiving element; a signal output circuit having a sampling transistor which outputs, from a second signal output line, a luminance signal in accordance with the amount of light received by the light-receiving element, based on an output signal from the pixel circuit; and a high-intensity judgment circuit which is coupled by the pixel circuit and a judgment input coupling capacitor, judges whether or not light entering the light-receiving element is of high intensity based on the output signal from the pixel circuit, and in the case of judging the entering light to be of high intensity, outputs a luminance signal indicating high intensity.

Owner:COLLABO INNOVATIONS INC

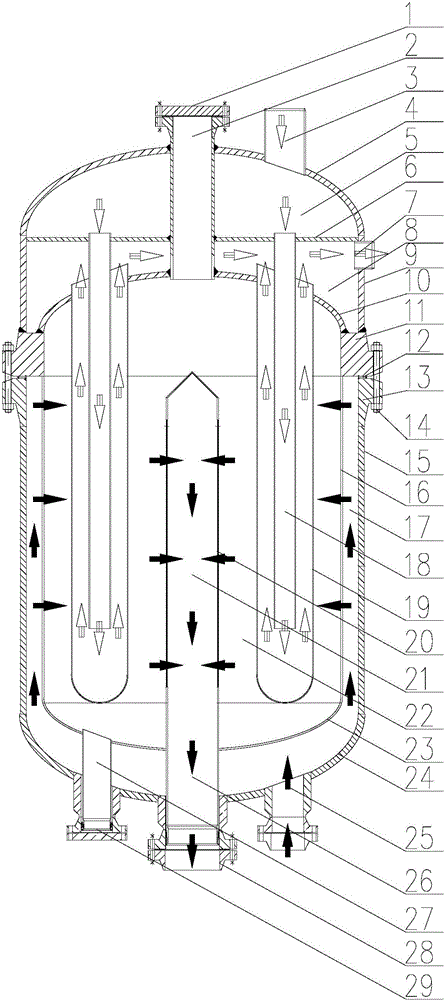

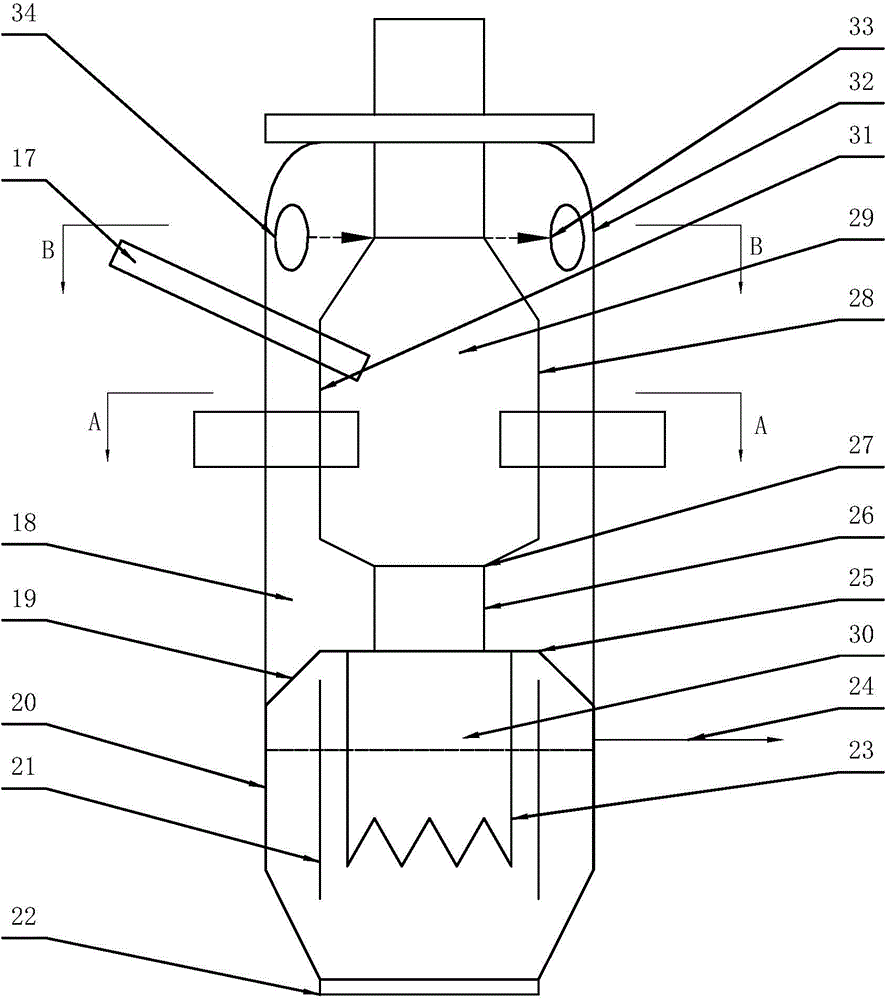

Dual-seal-head controllable water heat removing reactor

ActiveCN104645897AEasy to unloadPromote repairHydrogenHydrocarbon from carbon oxidesTemperature controlProduct gas

The invention discloses a dual-seal-head controllable water heat removing reactor. The top of a main cylinder body is connected with a lower flange; the bottom of the main cylinder body is connected with a lower outer seal head; the upper flange is connected with the lower flange; one end of a catalyst filling pipe is connected between an upper inner seal head and a gas distribution cylinder, and the other end of the catalyst filling pipe sequentially penetrates through a baffle and an upper external seal head; one end of a water guide pipe is communicated between the baffle and the upper outer seal head, and the other end of the water guide pipe sleeves a heat exchange pipe internally; a pipe body of the heat exchange pipe is positioned in a gas distribution cylinder; an outlet of the heat exchange pipe is formed between the baffle and the upper inner seal head; a cylinder body of a gas collecting cylinder is positioned in the gas distribution cylinder; an outlet of the gas collecting cylinder is connected with a gas outlet. The heat exchange pipe is buried in a catalyst bed layer so as to remove reaction heat in the catalyst bed layer timely, and the defects of short service life, easiness in overtemperature, multiple auxiliary reactants, difficulty in bed layer temperature control, long driving time, difficulty of scaling up, high running energy consumption, high project investment and the like in the prior art can be solved.

Owner:NANJING DUNXIAN CHEM TECH

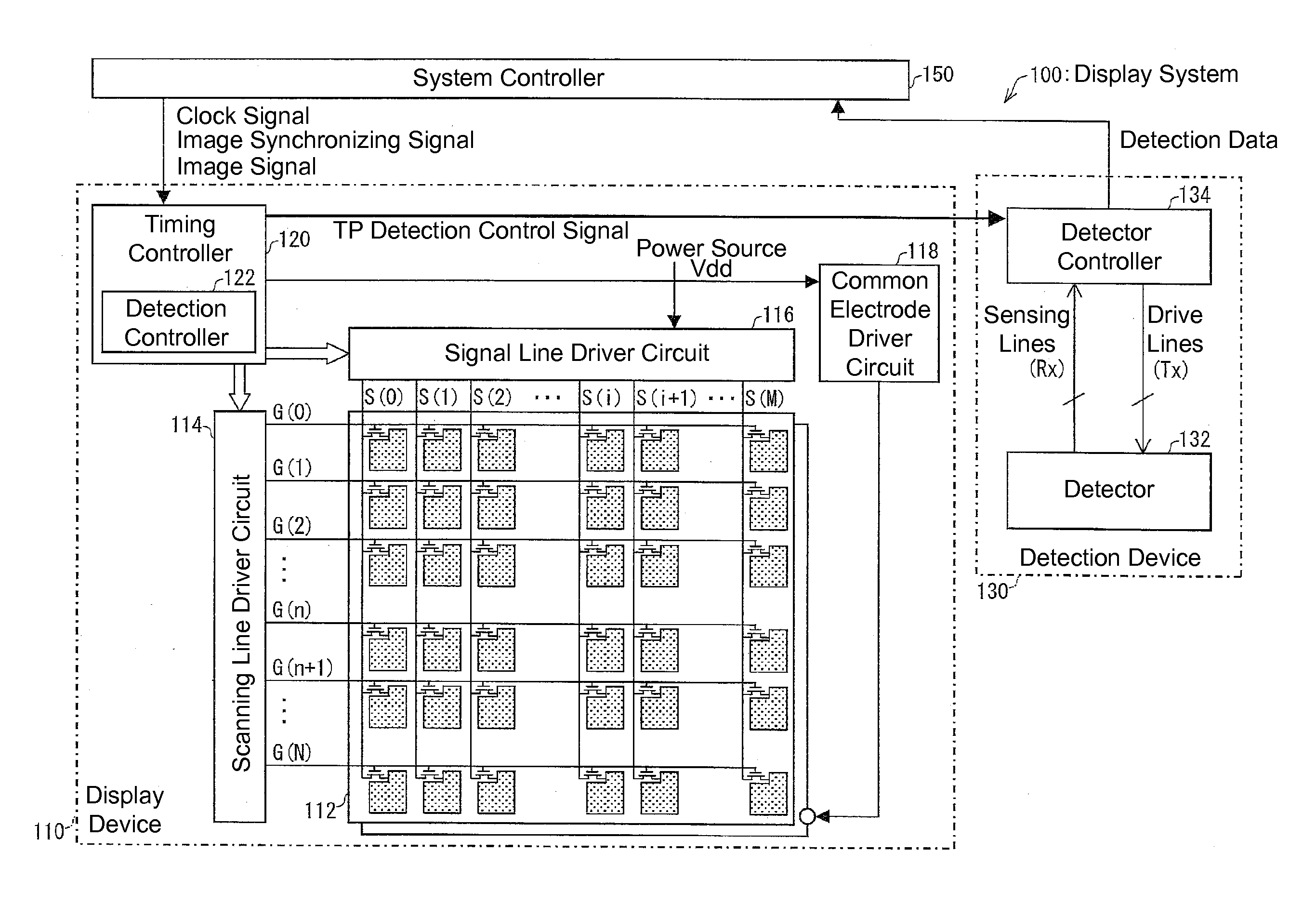

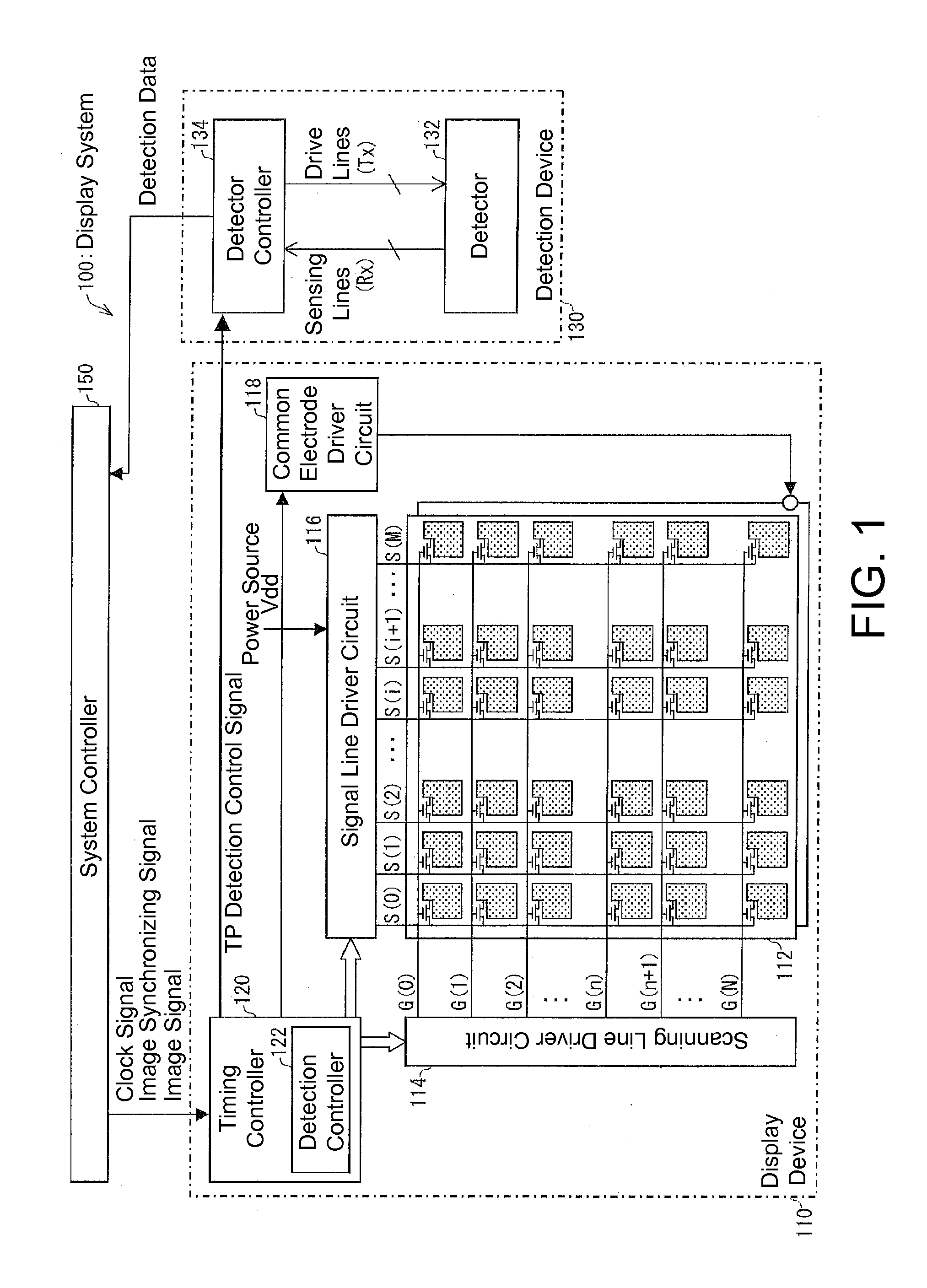

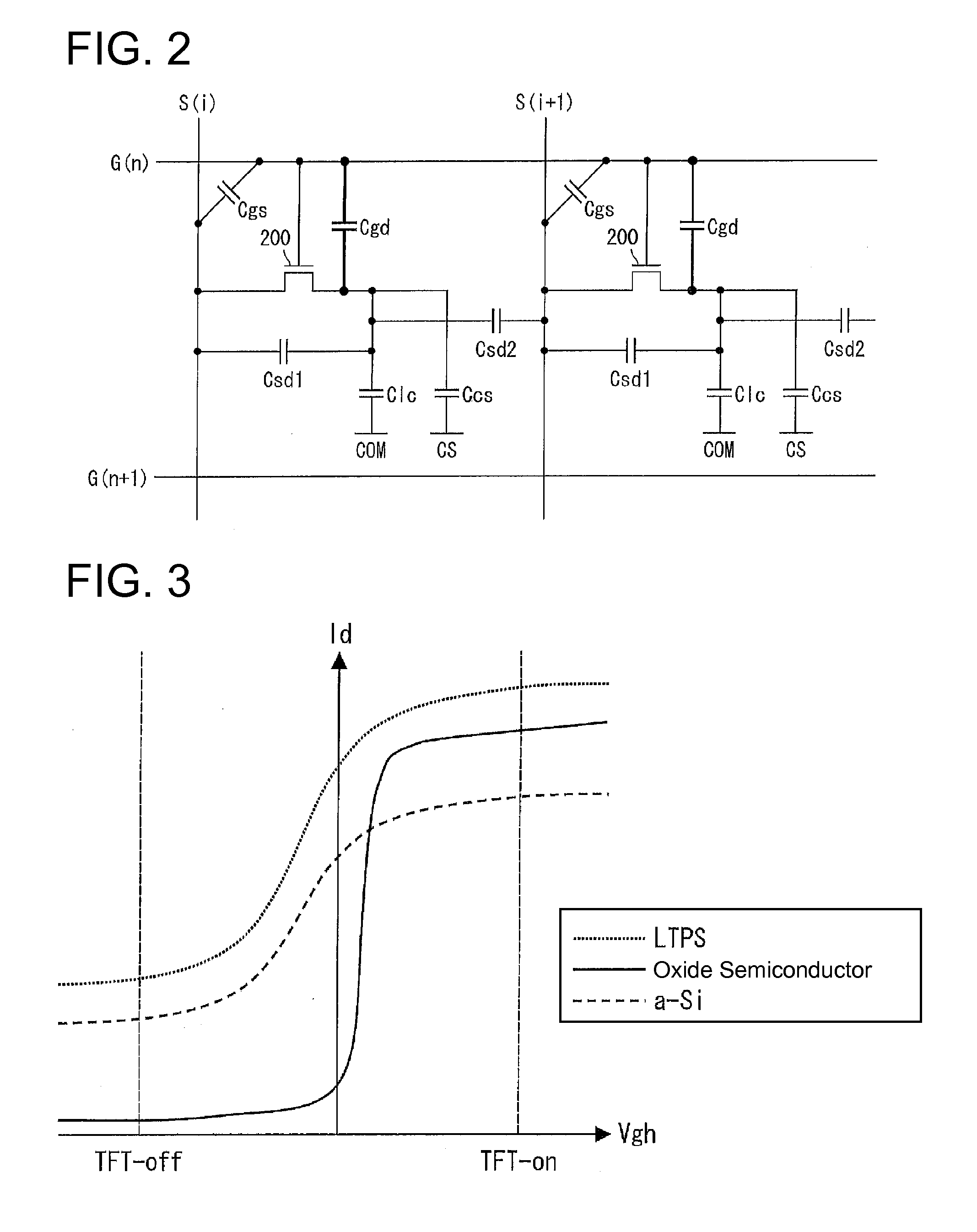

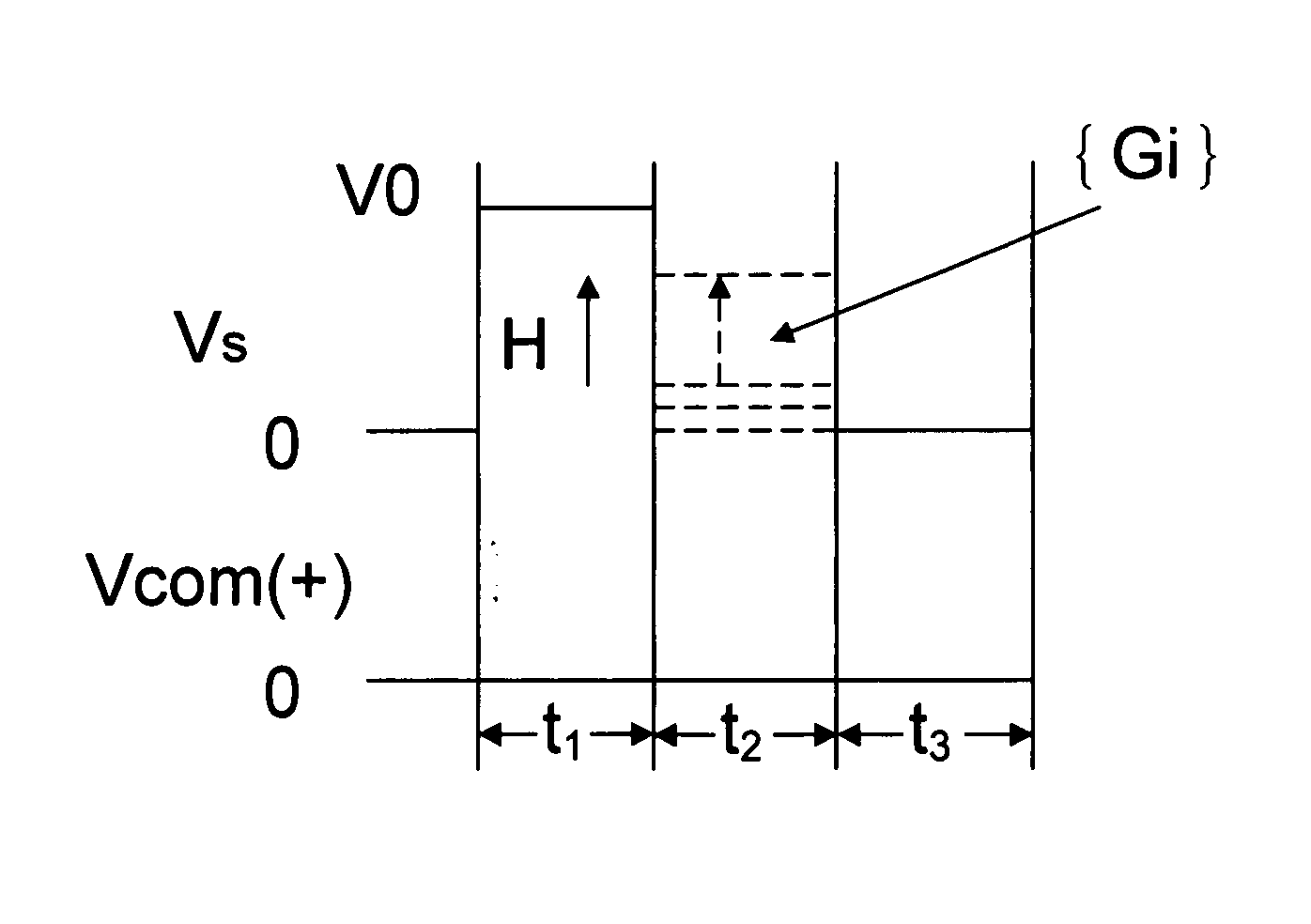

Display device and display system

InactiveUS20140333563A1Increase electron mobilityDelay periodStatic indicating devicesSolid-state devicesOxide semiconductorEngineering

A display device (110) is provided with a detection controller (122) that controls a detection device (130) such that detection is carried out within a horizontal blanking period for a display panel (112). An oxide semiconductor is used in the semiconductor layer for a TFT for each of the plurality of pixels provided in the display panel (112).

Owner:SHARP KK

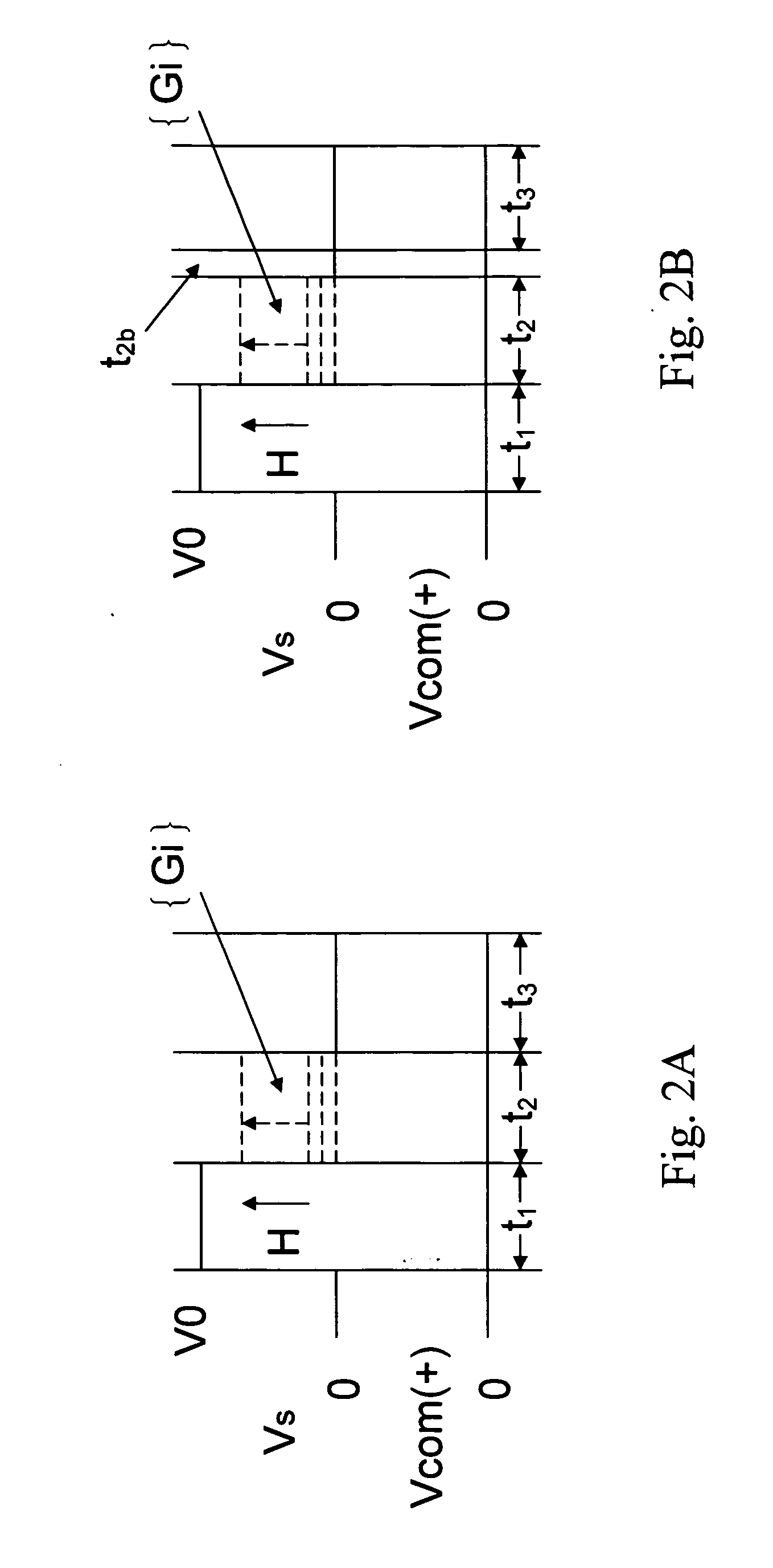

Gray-scale driving method for bistable chiral nematic liquid crystal display

InactiveUS20070075949A1High resolutionReduce driving timeStatic indicating devicesStable statePresent method

A gray-scale driving method for a bi-stable chiral nematic liquid crystal display is provided. The present method divides an updated picture into a first-section frame, a second-section frame and a third-section frame. The present invented method includes to drive the first-section frame into a predetermined initial state, and drive the second-section frame by line-by-line scanning by writing updated gray-scale frame data into the pixels, then pull the third-section frame to zero voltage for the pixels such that bi-stable chiral nematic liquid crystal relaxes to stable states corresponding to the write-in gray-scale frame data. Meanwhile, a purpose to maintain the updated picture without any consumption of power is obtained. The total power consumption can be significantly reduced.

Owner:IND TECH RES INST

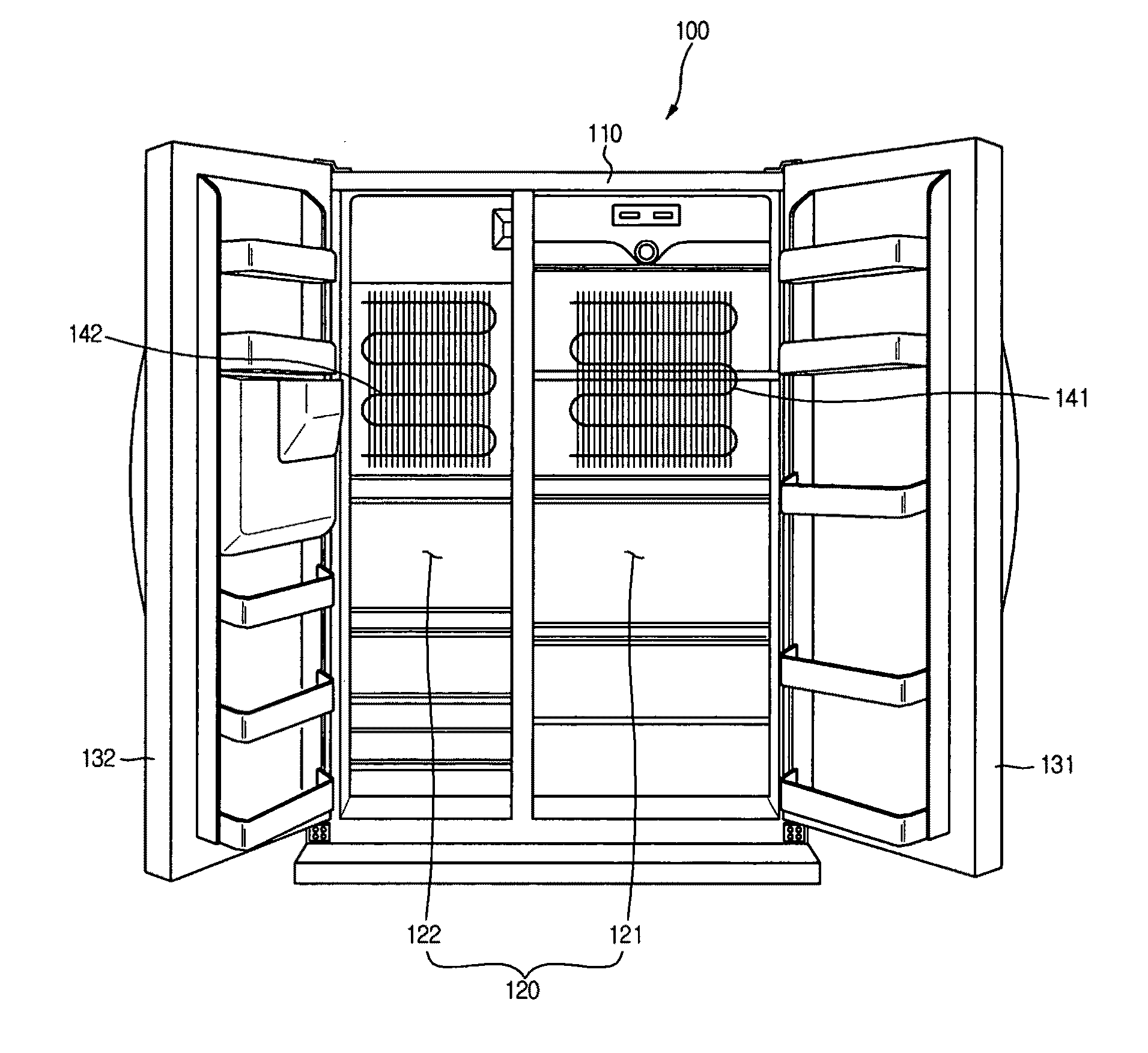

Cooling apparatus and frost detecting method thereof

InactiveUS20110185755A1Accurately determineAccurate detectionRefrigeration componentsCooling fluid circulationFrostMultiplexer

A cooling apparatus including a frost sensor to sense frost, a multiplexer having a first input terminal, to which the frost sensor is connected, and a second input terminal as a non-connected input terminal, a signal processor to subtract a signal input through the second input terminal from a signal input through the first input terminal, and to output a signal obtained by the subtraction, and a controller to detect an amount of frost sensed by the frost sensor, based on the output signal from the signal processor. It is possible to easily and accurately determine noise contained in a signal received from the frost sensor by determining, as noise, the signal received from the input terminal, to which the frost sensor is not connected, and subtracting the noise from the signal received from each input terminal, to which the frost sensor is connected.

Owner:SAMSUNG ELECTRONICS CO LTD

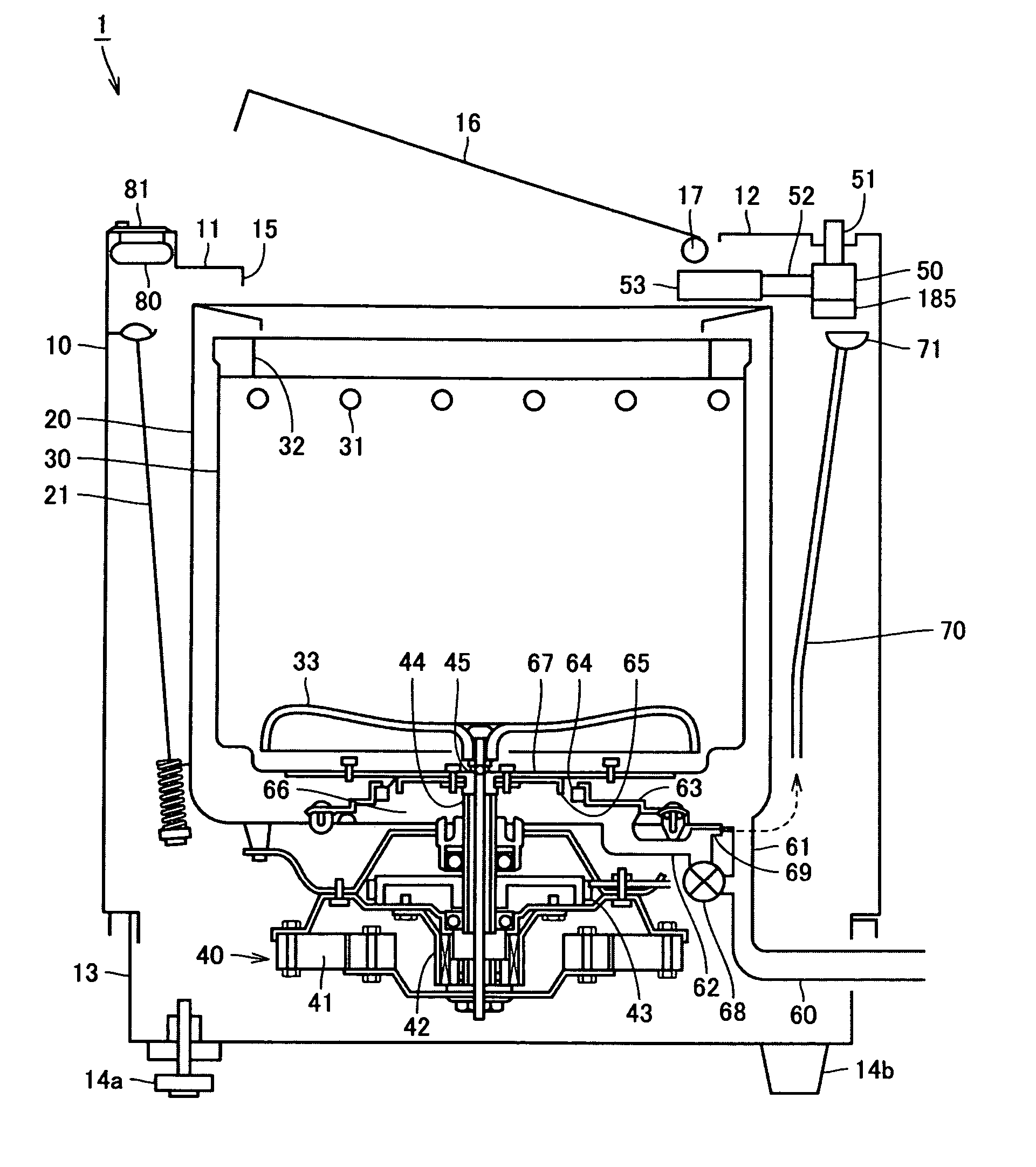

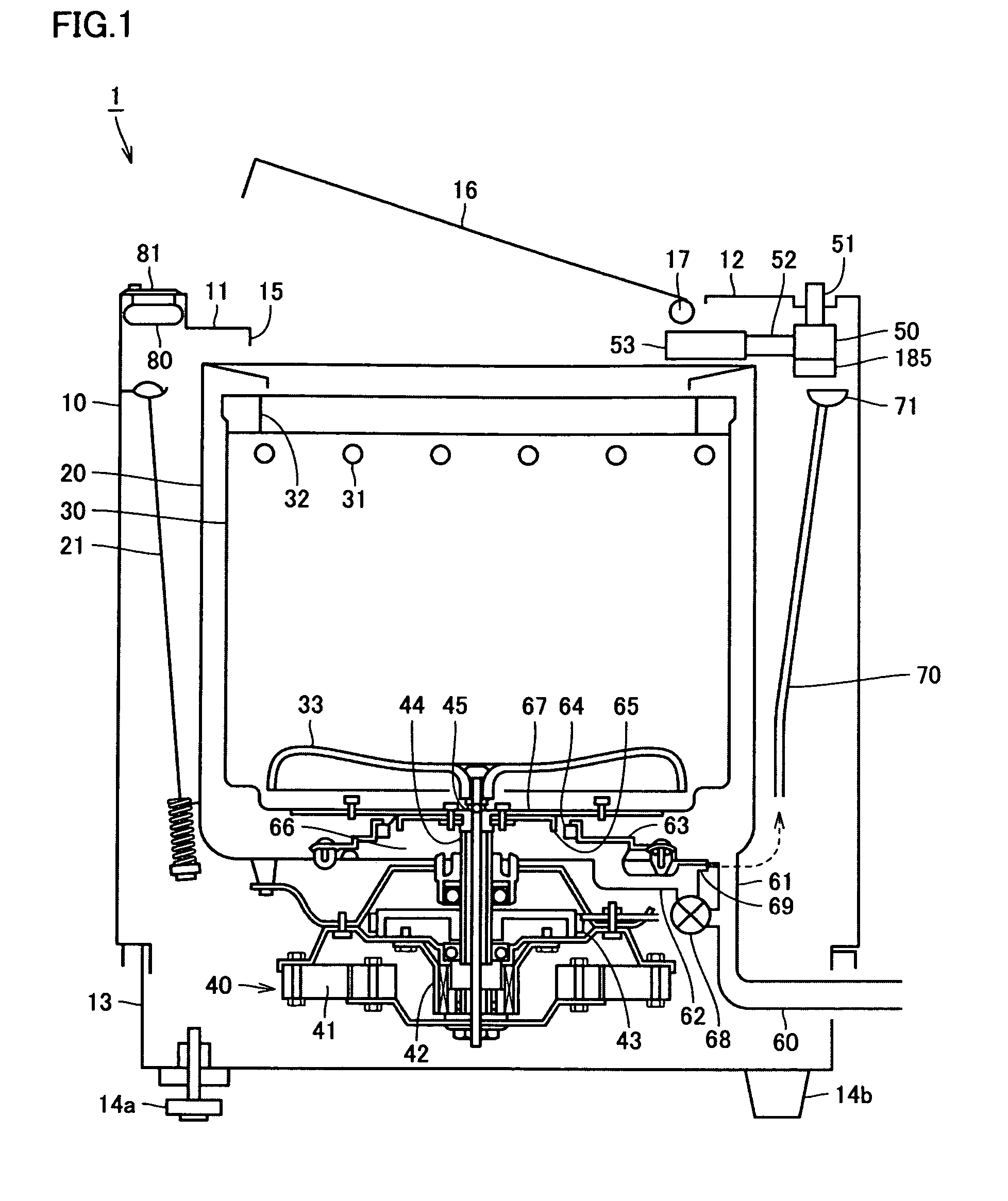

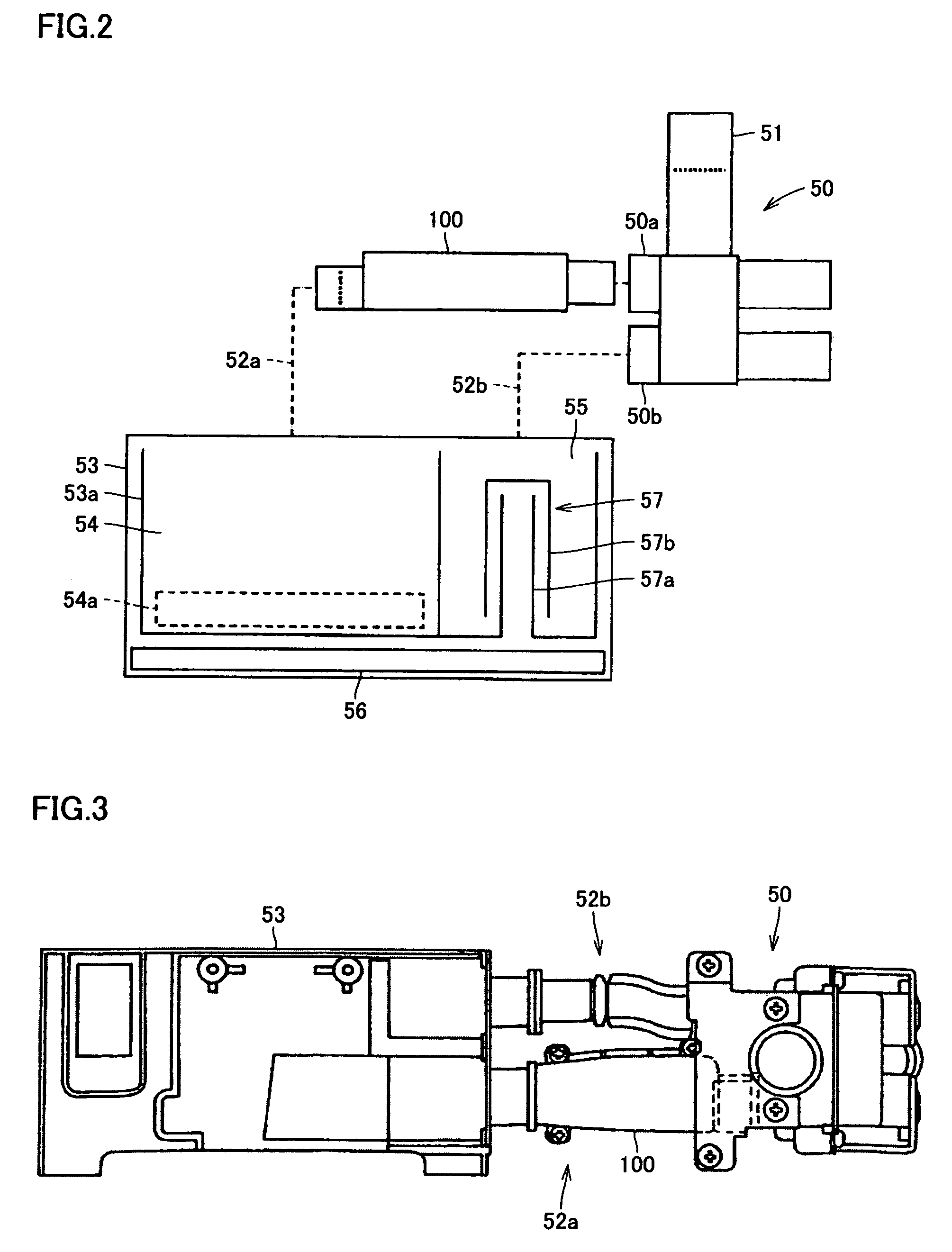

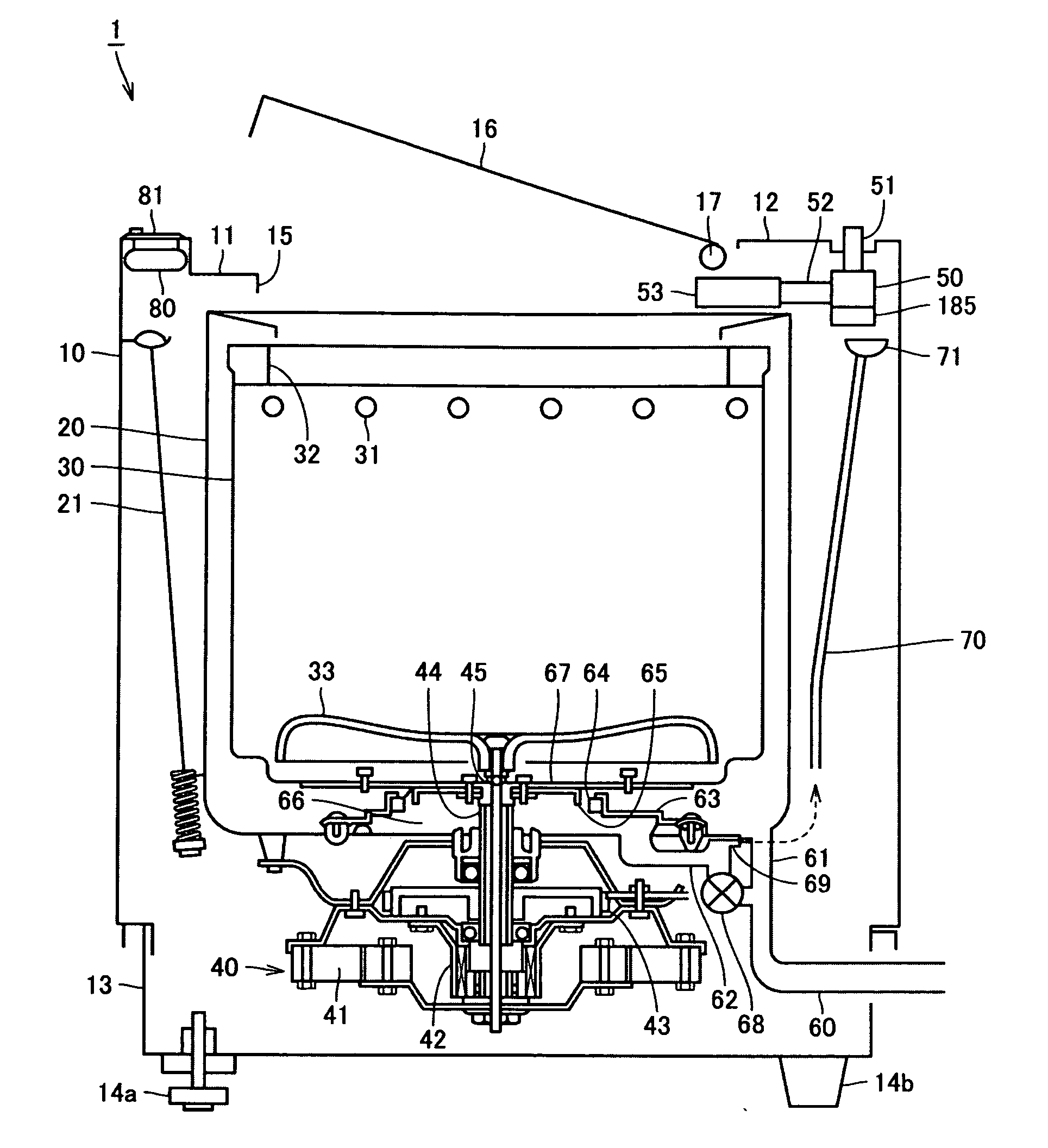

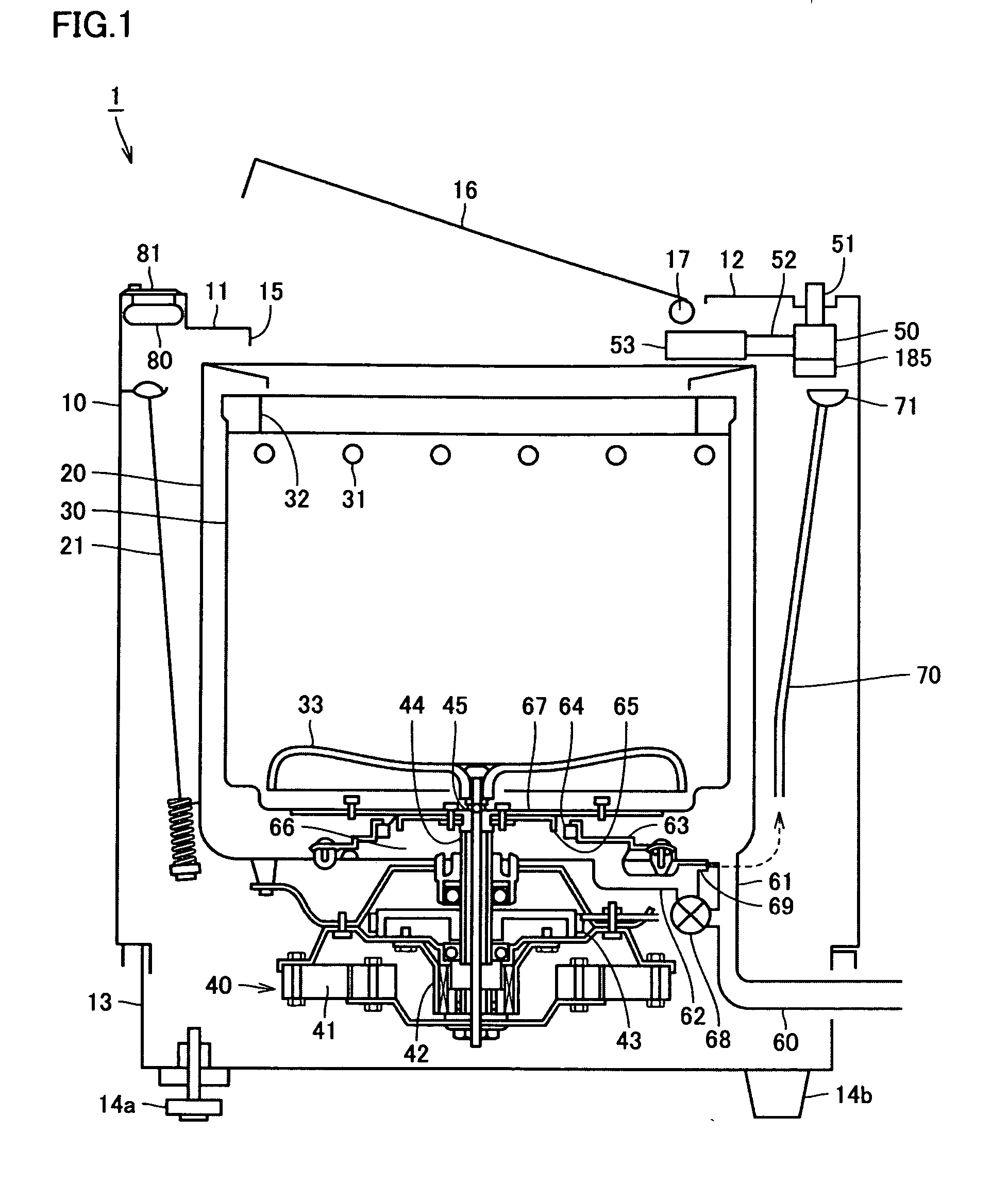

Washing machine

InactiveUS7617704B2Effect is exertedReduce driving timeOther washing machinesControl devices for washing apparatusCentrifugal forceWaste management

Owner:SHARP KK

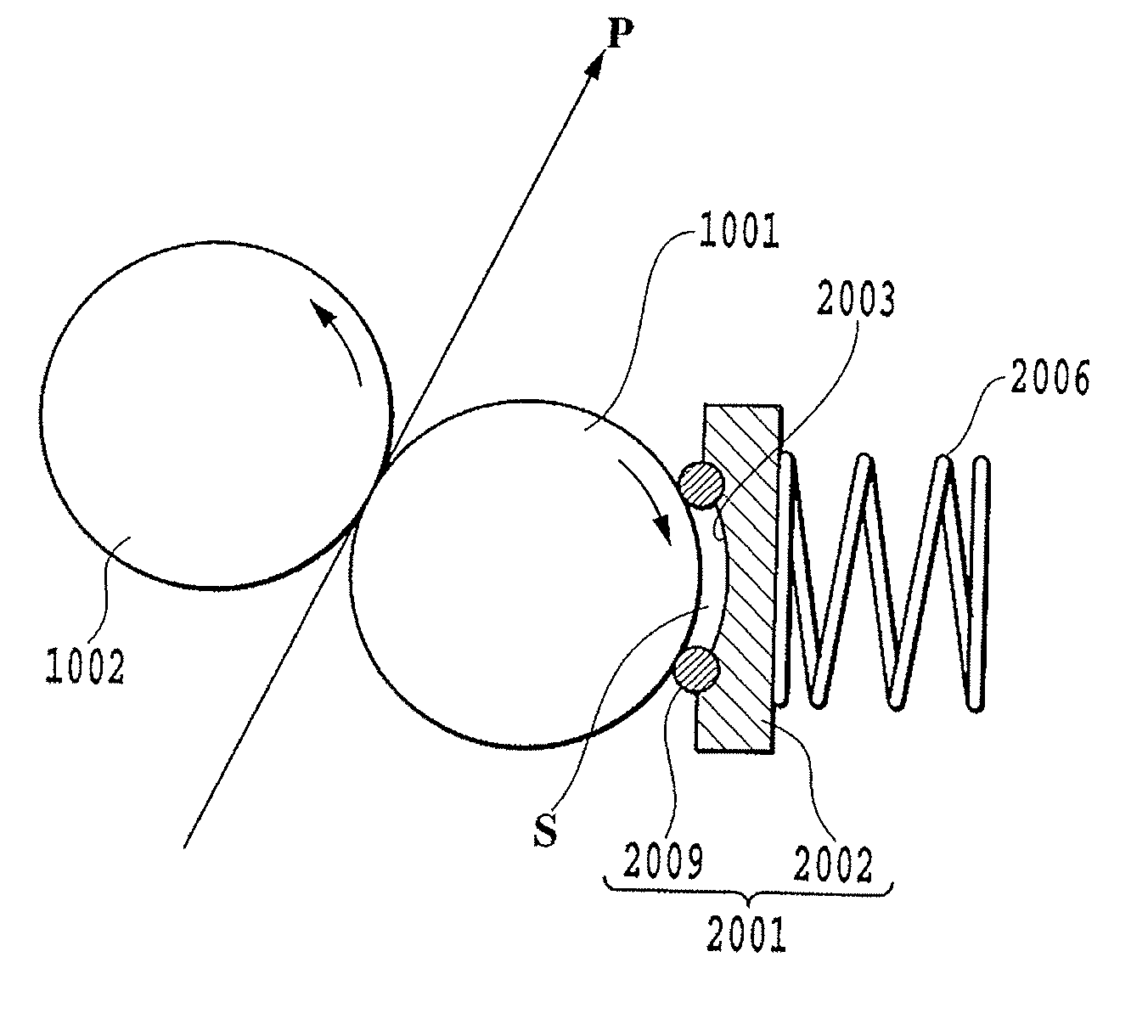

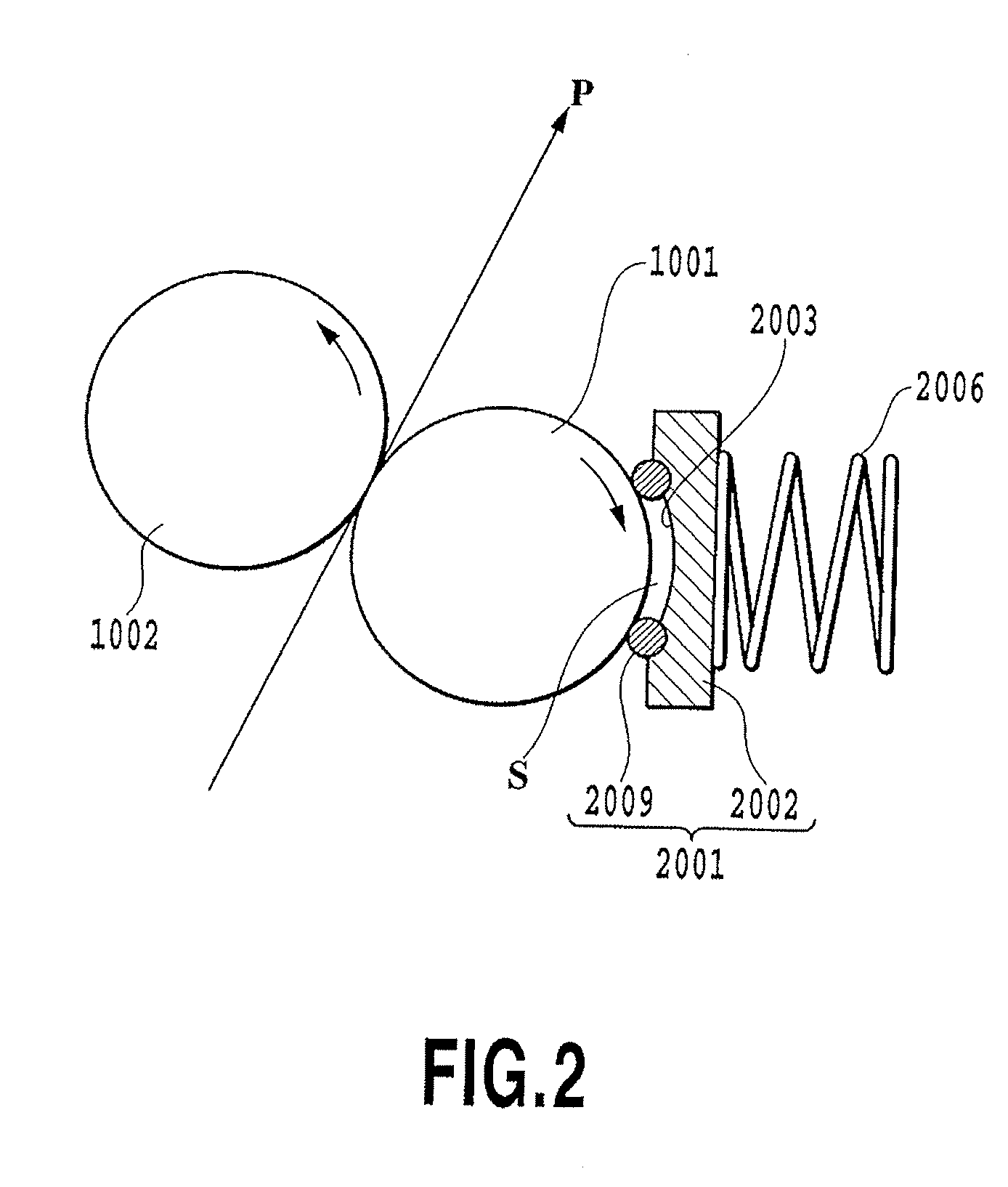

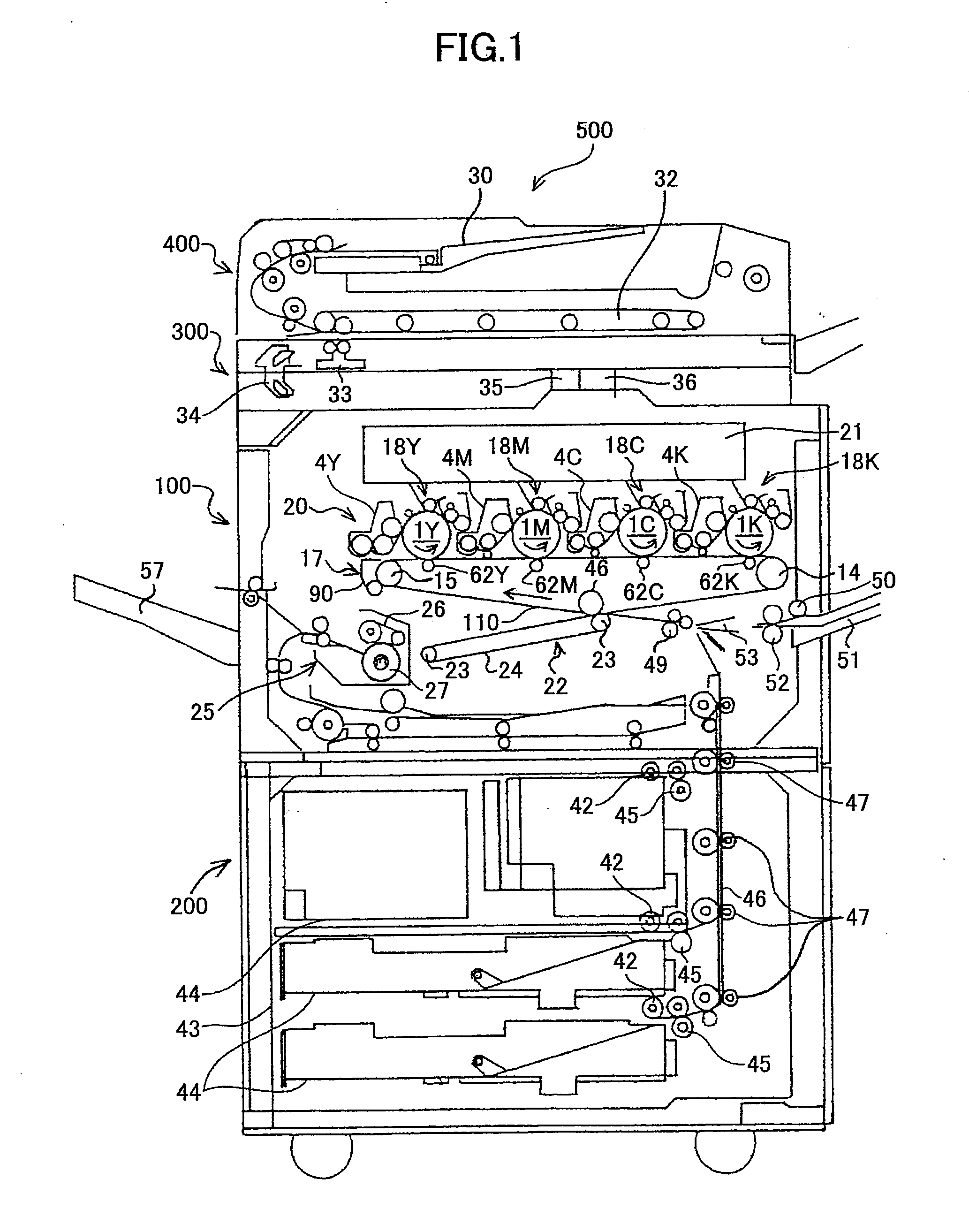

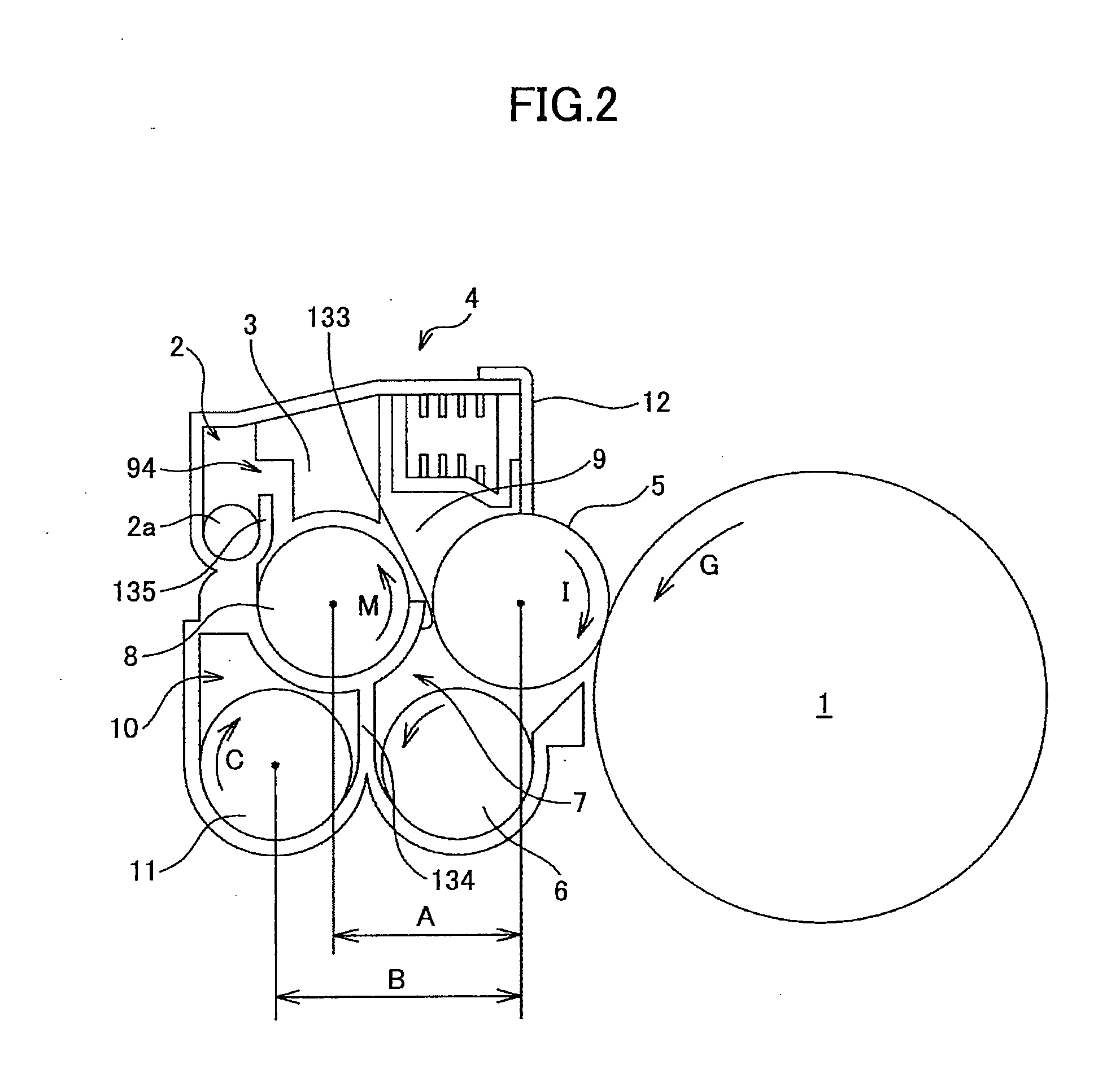

Image forming apparatus and developing device used therein

InactiveUS20110194863A1Preventing bending and breakageReduce driving timeElectrographic process apparatusLatent imageImage formation

A developing device is refilled with an initial developer while the developing device and a photoreceptor are maintained within an image forming apparatus in the same state as in an image forming process. When refilling the developing device, a control unit of the image forming apparatus first drives a stirring feed member (screw) to feed the initial developer into the developing device, and then drives a developer carrier (developing roller) and a latent image carrier (photoreceptor) to supply the developer onto the developer carrier.

Owner:RICOH KK

Liquid crystal display apparatus and display lightness regulating method thereof

InactiveCN101409049AReduce driving timeReduced photoelectric conversion efficiencyCathode-ray tube indicatorsPhotometry electrical circuitsLiquid-crystal displayComputer science

The invention relates to an LCD device and a display brightness adjusting method thereof. The LCD device comprises a sensitizing device, a processing unit and a brightness adjusting unit. The sensitizing device comprises at least two sensitizing units; the processing unit correspondingly selects to drive one sensitizing unit according to the ambient light luminance to cause the sensitizing unit to output a sensing signal, and the processing unit correspondingly outputs a brightness adjusting signal according to the sensing signal; and the brightness adjusting unit adjusts the display brightness of the LCD device according to the brightness adjusting signal. The LCD device has higher reliability in the display brightness adjustment.

Owner:INNOCOM TECH SHENZHEN +1

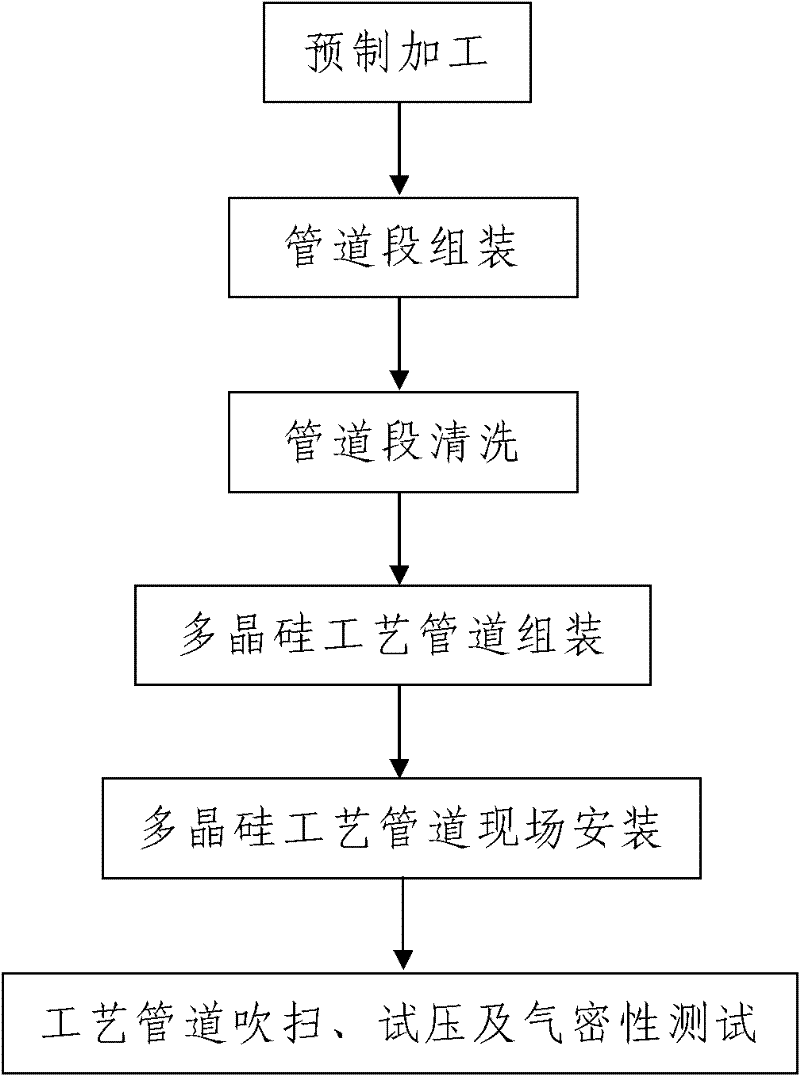

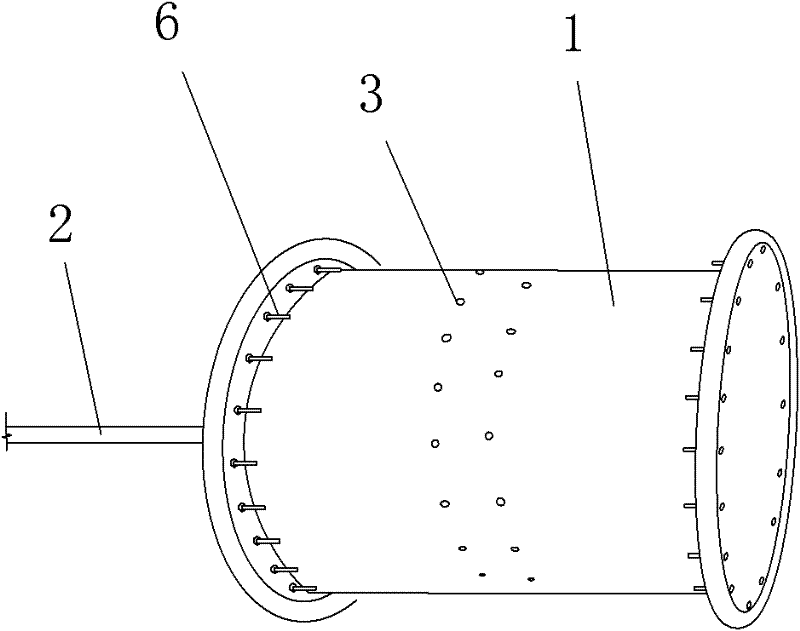

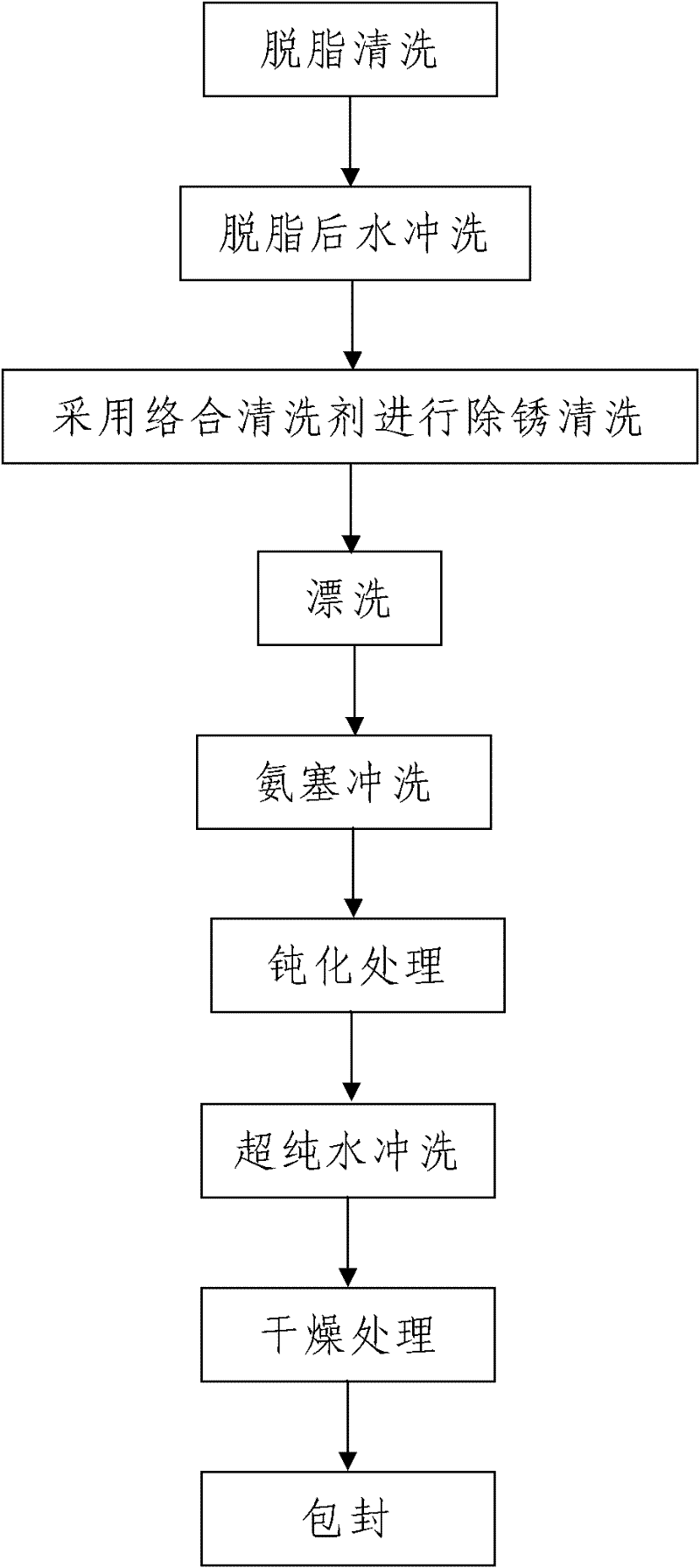

Construction method for controlling cleanliness of electronic-grade multicrystal-silicon process pipe

ActiveCN102231357AReasonable designEasy and simple to implementHollow article cleaningSemiconductor/solid-state device manufacturingEngineeringAmmonia

The invention discloses a construction method for controlling the cleanliness of an electronic-grade multicrystal-silicon process pipe. The construction method comprises the following steps of: (1) prefabrication machining; (2) pipe section assembling: finishing an assembly procedure of pipe sections by utilizing an interior gas protection device and an argon arc welding machine; (3) pipe section cleaning comprising the following steps of: degrease cleaning, water flushing after degreasing, complexing and derusting, rinsing, ammonia-plugging flushing, passivation processing, ultra-pure water flushing, dry processing and packaging; (4) multicrystal-silicon process pipe assembling; (5) field assembling of the multicrystal-silicon process pipe; and (6) process pipe blowing, pressure testing and airtightness testing. The invention has the advantages of reasonable design, simplicity and convenience in operation, convenience for realizing and good pipe cleanliness control effect, can solve various problems such as complex factors influencing the cleanliness of the interior of the multicrystal-silicon process pipe, difficulty in control of the cleanliness of the interior of the pipe, poor control effect of the cleanliness and the like in a multicrystal-silicon process pipe construction process.

Owner:SCEGC EQUIP INSTALLATION GRP COMPANY

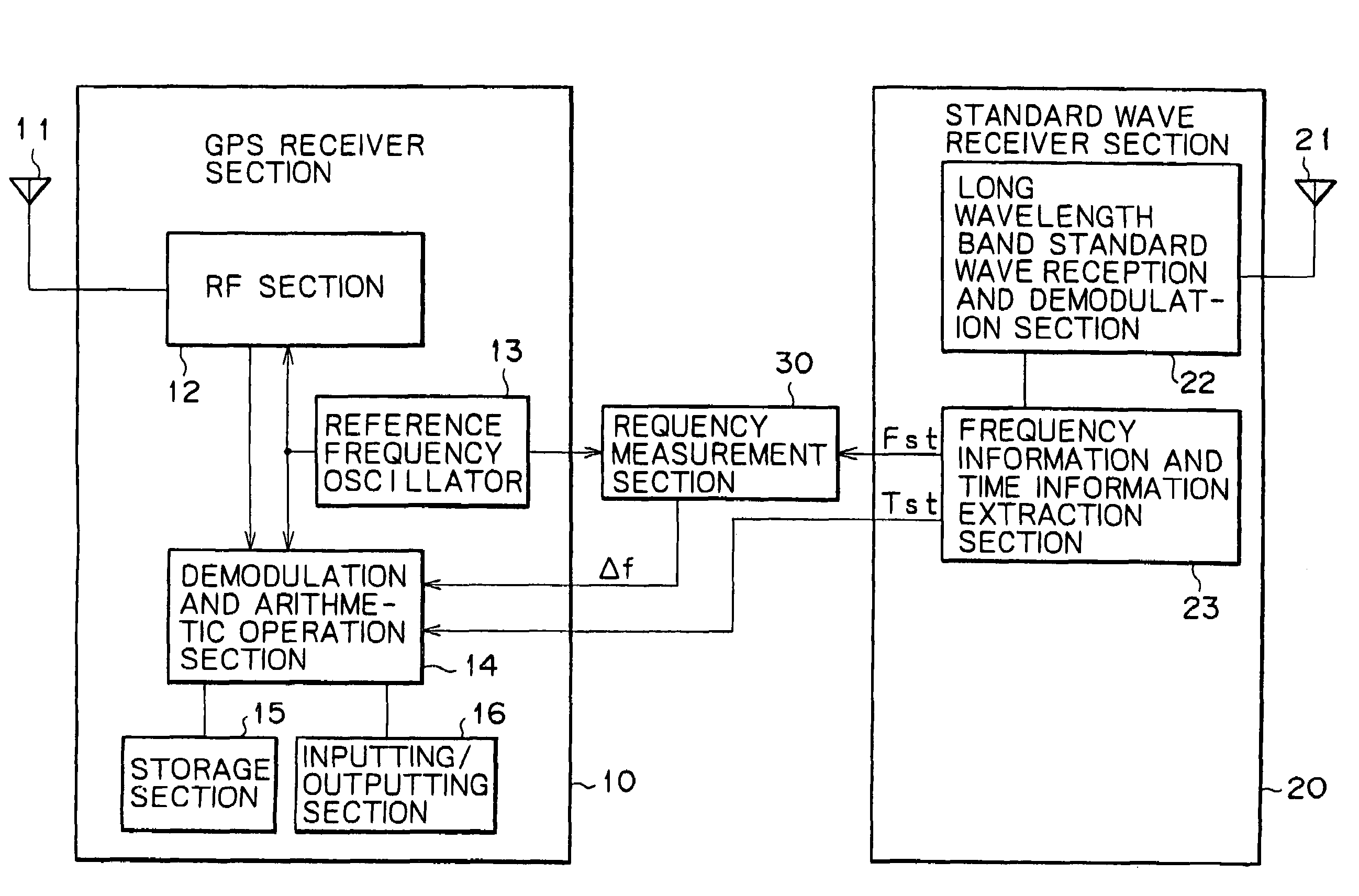

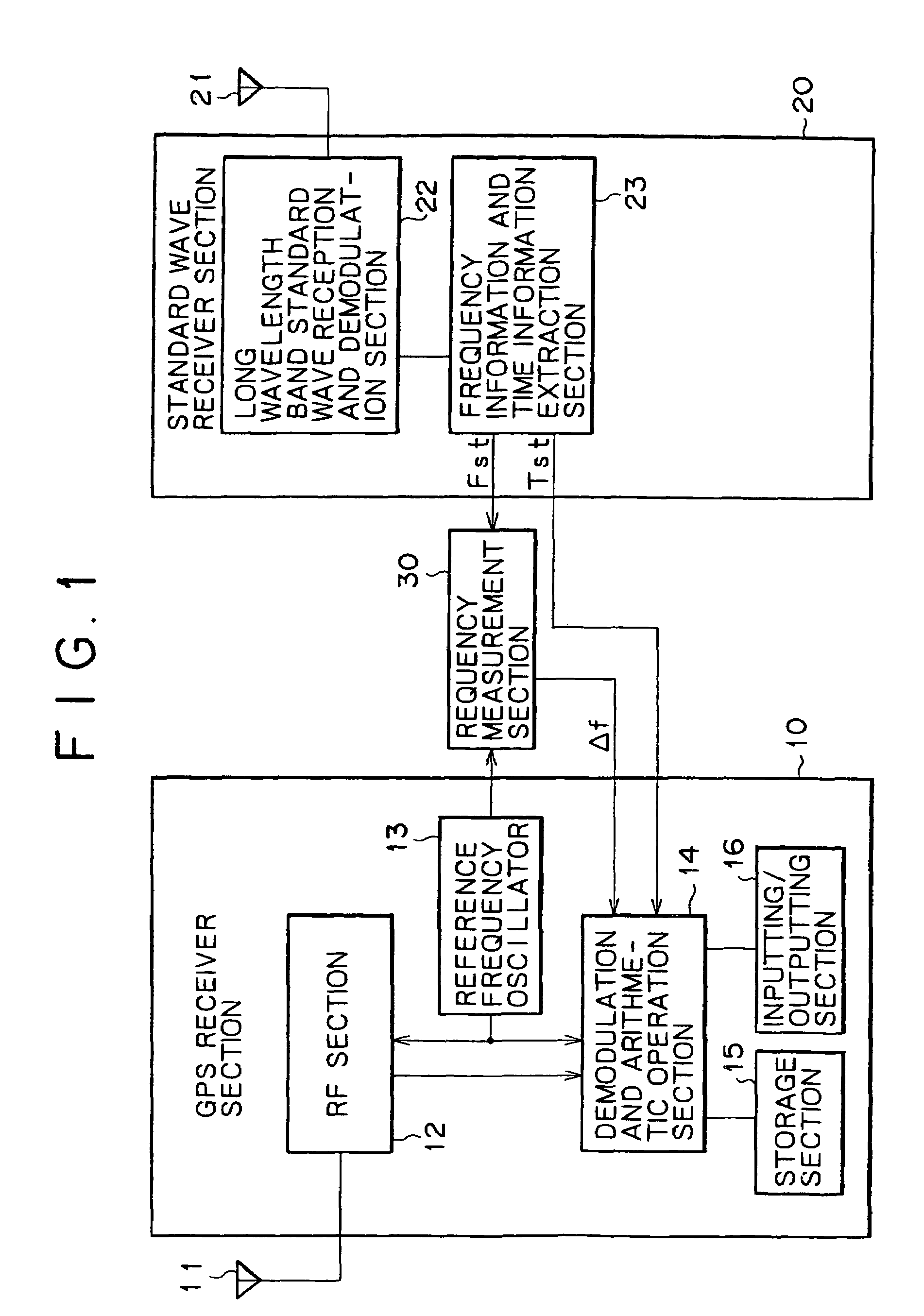

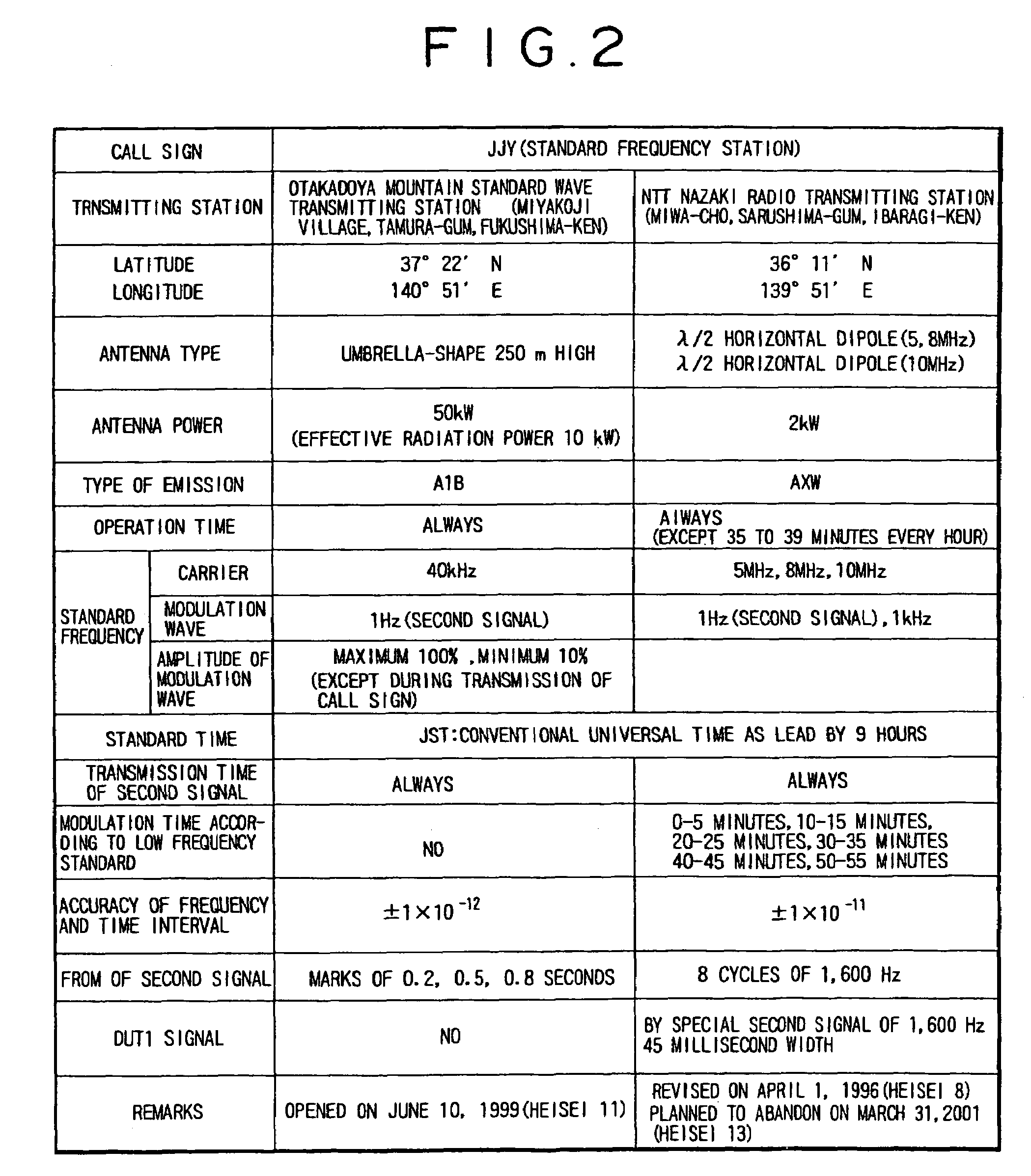

GPS positioning method and GPS reception apparatus

InactiveUS7266140B1Shorten the timeSave powerPosition fixationBeacon systemsTime informationGps receiver

A GPS positioning method is disclosed which can shorten the time required until positioning arithmetic operation is started after power is made available. An oscillation frequency of a reference frequency oscillator used in a GPS receiver section or a frequency variation of the oscillation frequency is measured using high precision frequency information provided by a standard wave. A result of the measurement is utilized to catch a signal from a GPS satellite. Further, a synchronization timing of a spread code of the spread spectrum signal from the satellite is detected to detect a small time component for time synchronization. After synchronization of the spread code is completed, a time of the boundary of one period of the spread code is detected from time information provided by a standard wave, and a time component greater than the small time component for time synchronization is detected based on the time of the boundary. Time synchronism is established using the detected small time component and the time component greater than the small time component.

Owner:SONY CORP

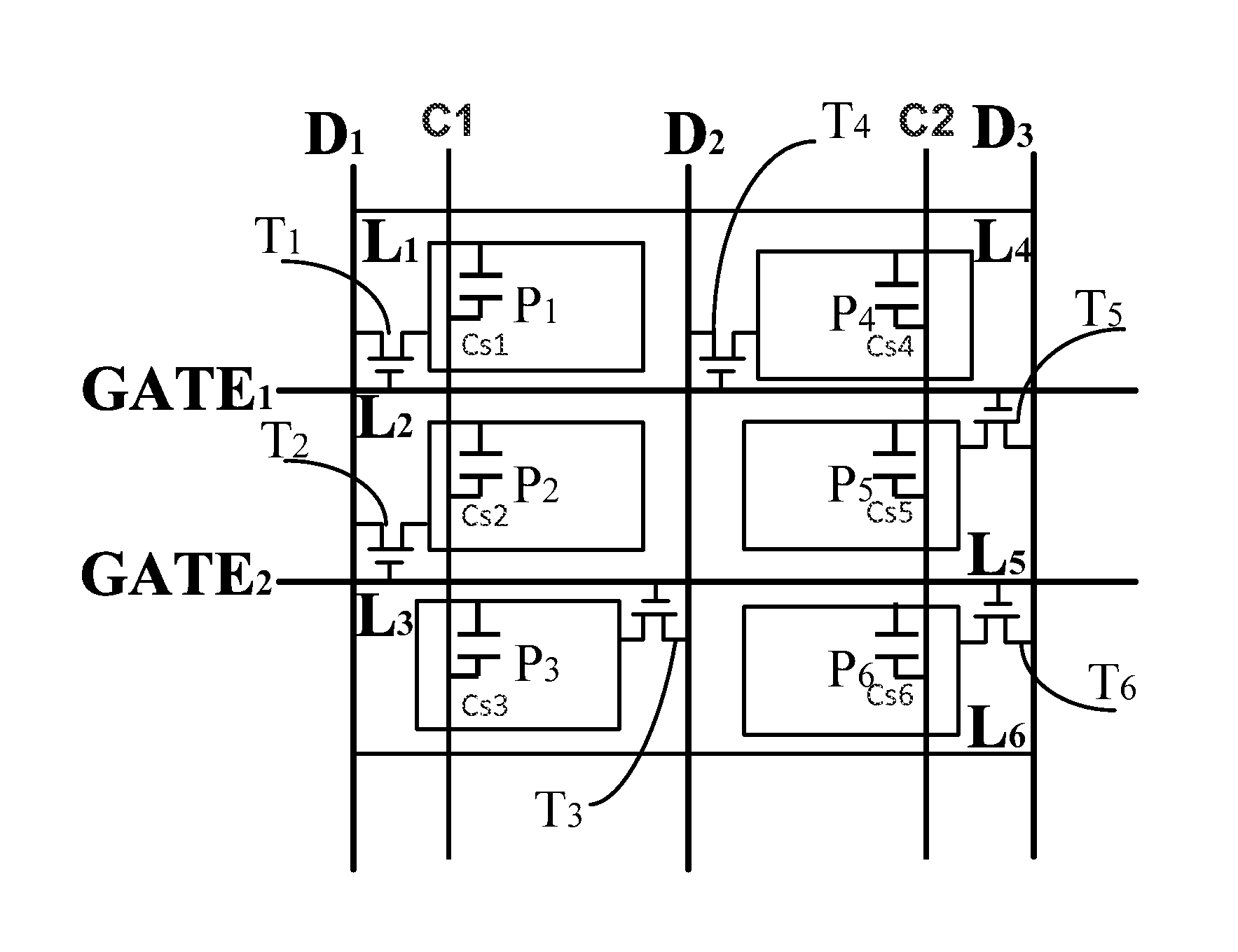

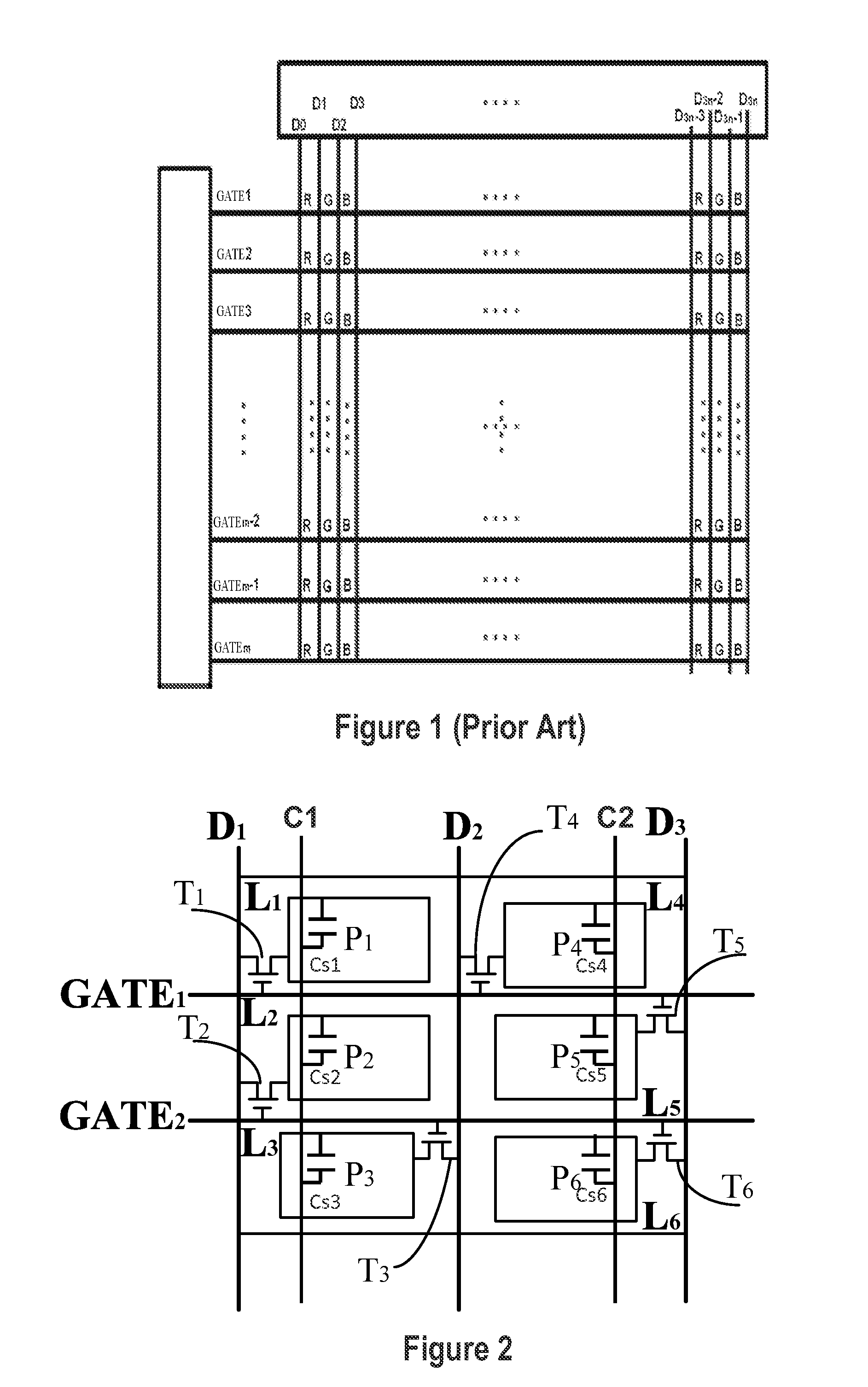

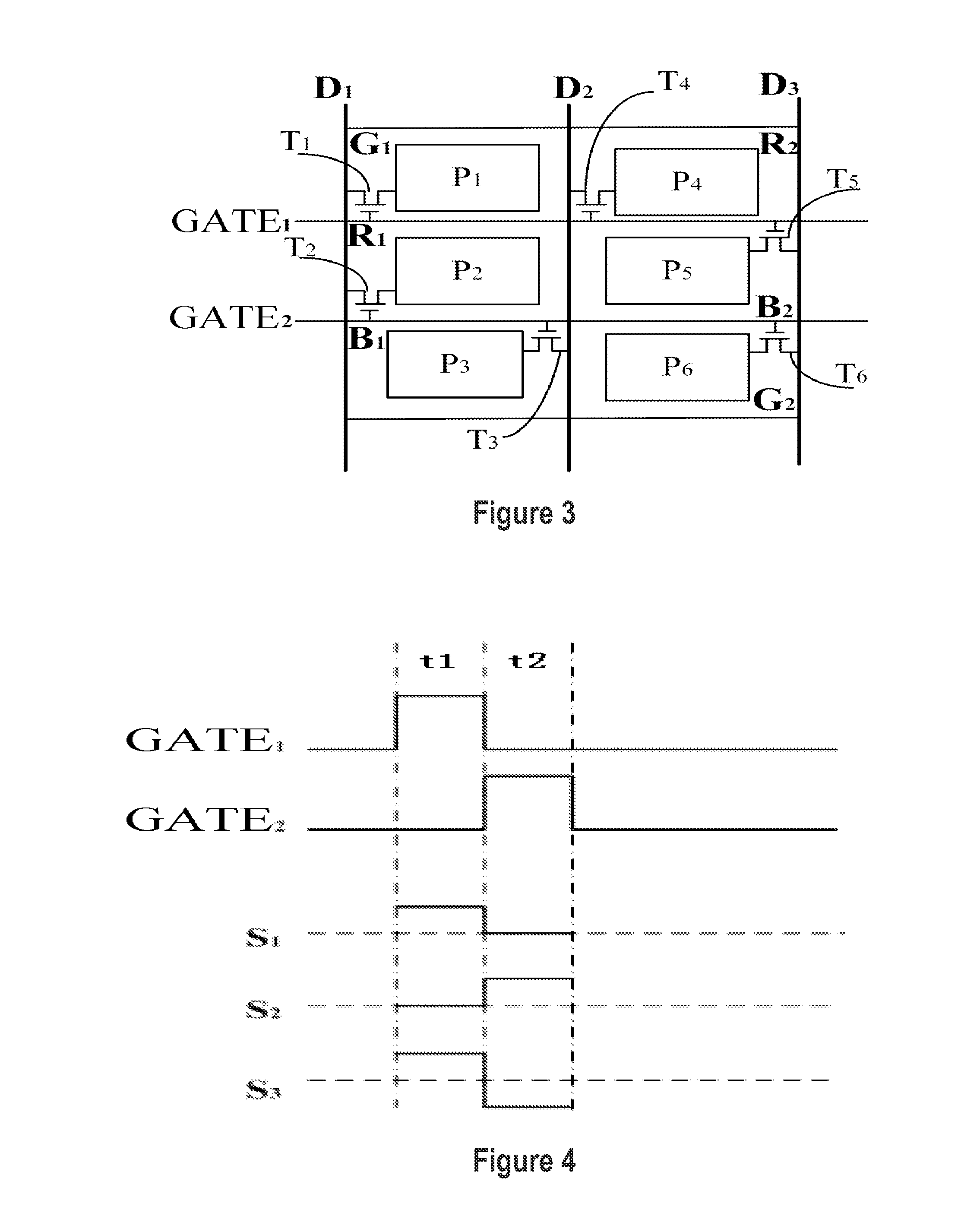

Dual-gate driven lateral pixel arrangement structure and display panel

ActiveUS20140078032A1Reduce driving timeMeet the requirementsStatic indicating devicesSolid-state devicesEngineeringTransistor

A dual-gate-driven lateral pixel arrangement structure includes two horizontally adjacent primary pixel regions having each three vertically adjacent secondary pixel regions forming a grid of six secondary pixel regions, and six thin-film transistors disposed in each of the six secondary pixel areas. The structure also includes two gate lines and three data lines crossing each other and electrically isolated from each other. Each data line is connected to the source of two thin-film transistors having the gate connected to a different gate line. The two gate lines are interposed between the three secondary pixel regions or arranged along a side or opposite sides of the primary pixel regions in a first direction. The three data lines are arranged between the primary pixel regions and along a side or opposite sides of the primary pixel regions in a second direction different from the first direction.

Owner:SHANGHAI AVIC OPTOELECTRONICS

Washing machine

InactiveUS20070186595A1Effect is exertedReduce driving timeOther washing machinesWashing machine with receptaclesWater supplyCentrifugal force

Provided is a washing machine that makes it possible to effectively exert a sterilizing effect onto all the inner wall face from a lower portion to an upper portion of a washing tank, to shorten a driving time required for washing the washing tank and also to reduce an amount of water to be used for the washing process. The washing machine is provided with a rotatable washing tank that has no hole in the tank wall, and is formed so that a diameter of the inner wall face becomes gradually greater toward an opening portion, as well as a water supply valve, a water supply pipe and an water supply inlet that serve as a water supply unit capable of supplying water having a sterilizing effect to the washing tank, and in this structure, silver ion-containing water, supplied to the washing tank by the water supply unit, is allowed to move and flow along the inner wall face of the washing tank by the centrifugal force derived from the rotation of the washing tank so as to sterilize the inner wall face of the washing tank.

Owner:SHARP KK

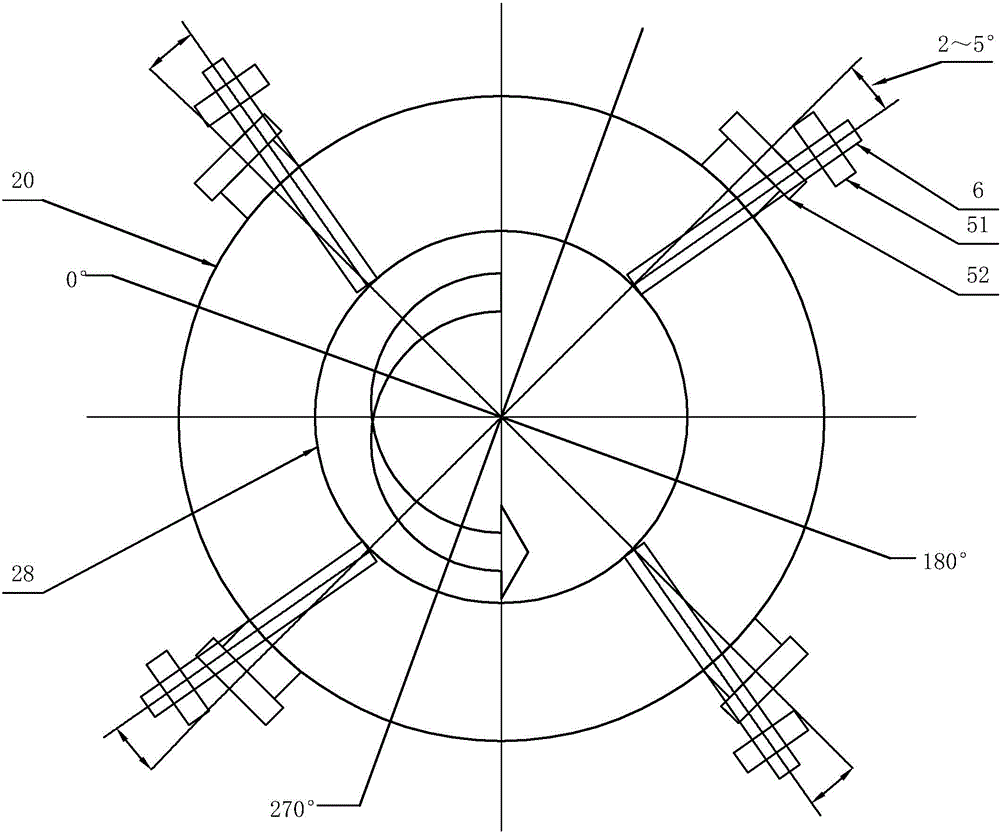

Pressure gasification process for simultaneously gasifying powdered coal and coal water slurry

ActiveCN104531219ASimple structureHigh failure rateGasification apparatus detailsGranular/pulverulent flues gasificationCoal waterBrick

The invention relates to a pressure gasification process for simultaneously gasifying powdered coal and coal water slurry. The pressure gasification process is characterized in that a purpose-made gasification furnace is used, the gasification furnace is provided with a purpose-made powdered coal burner and a start-up burner and capable of simultaneously processing the coal water slurry and the powdered coal; gasification comprises the following steps of carrying out ignition start-up, igniting the powdered coal burner, increasing the temperature and pressure of the gasification furnace and a carbon washing tower, igniting a coal water slurry burner, increasing the pressure inside a gasification chamber, and controlling continuous gasification under a specific reaction condition. The pressure gasification process disclosed by the invention can be used for solving the problems of low effective component, high requirement on the quality of coal fed into the furnace, short life of the coal water slurry burner, short operation time of a single furnace, short life of a refractory brick, low coal slurry concentration and the like of a synthetic gas obtained through the traditional coal water slurry and solving the problems of large investment, complex equipment, high comprehensive energy consumption and the like of the traditional powdered coal gasification process.

Owner:SINOPEC NINGBO ENG +2

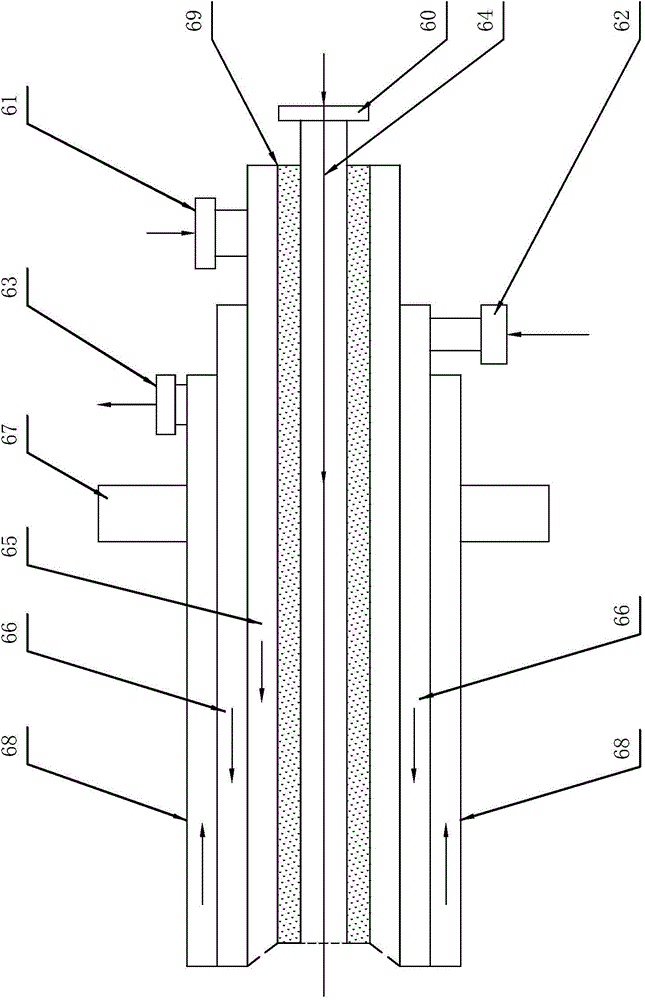

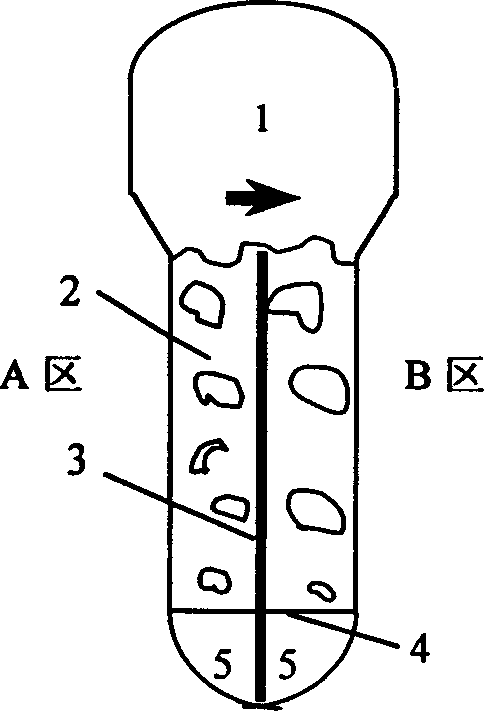

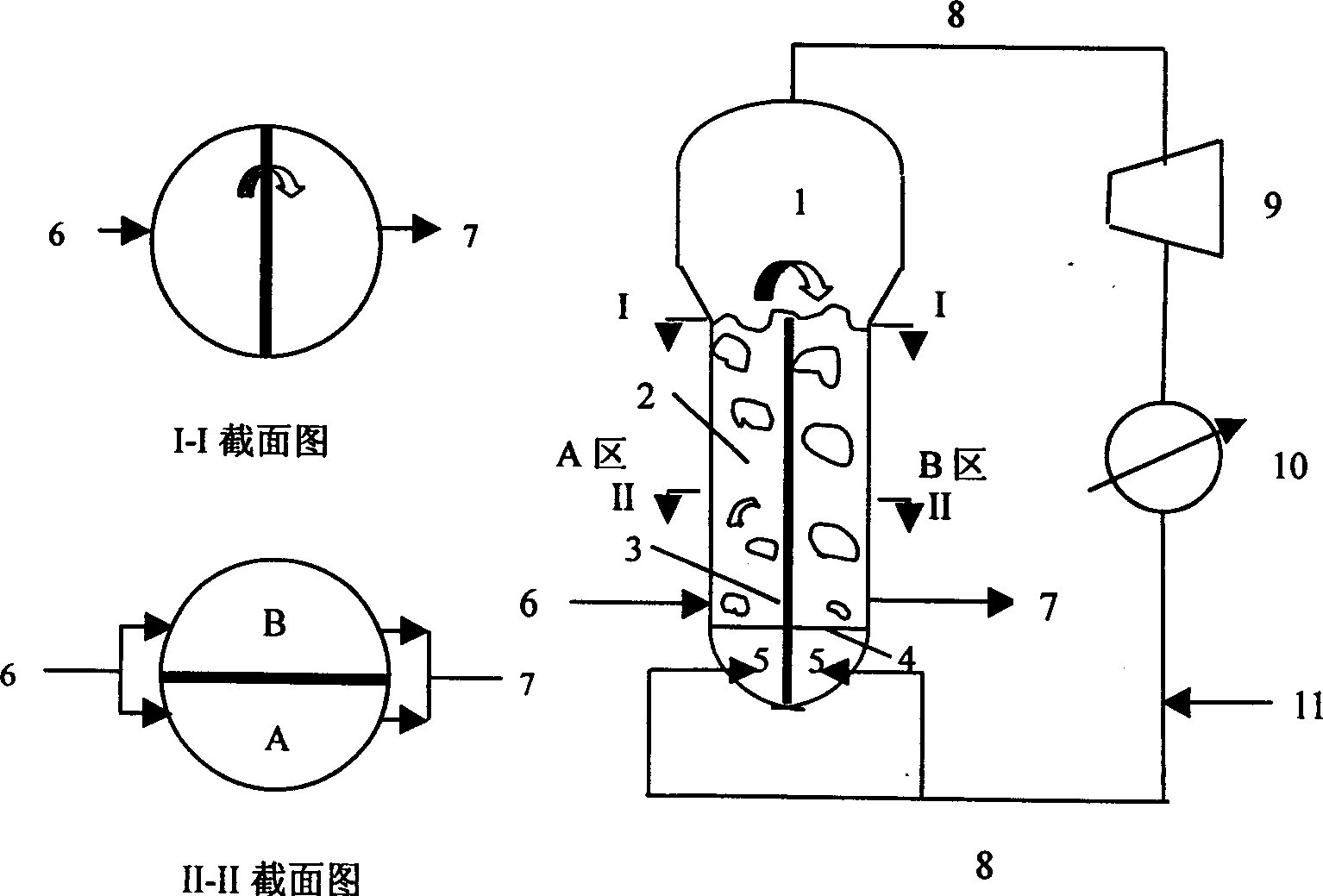

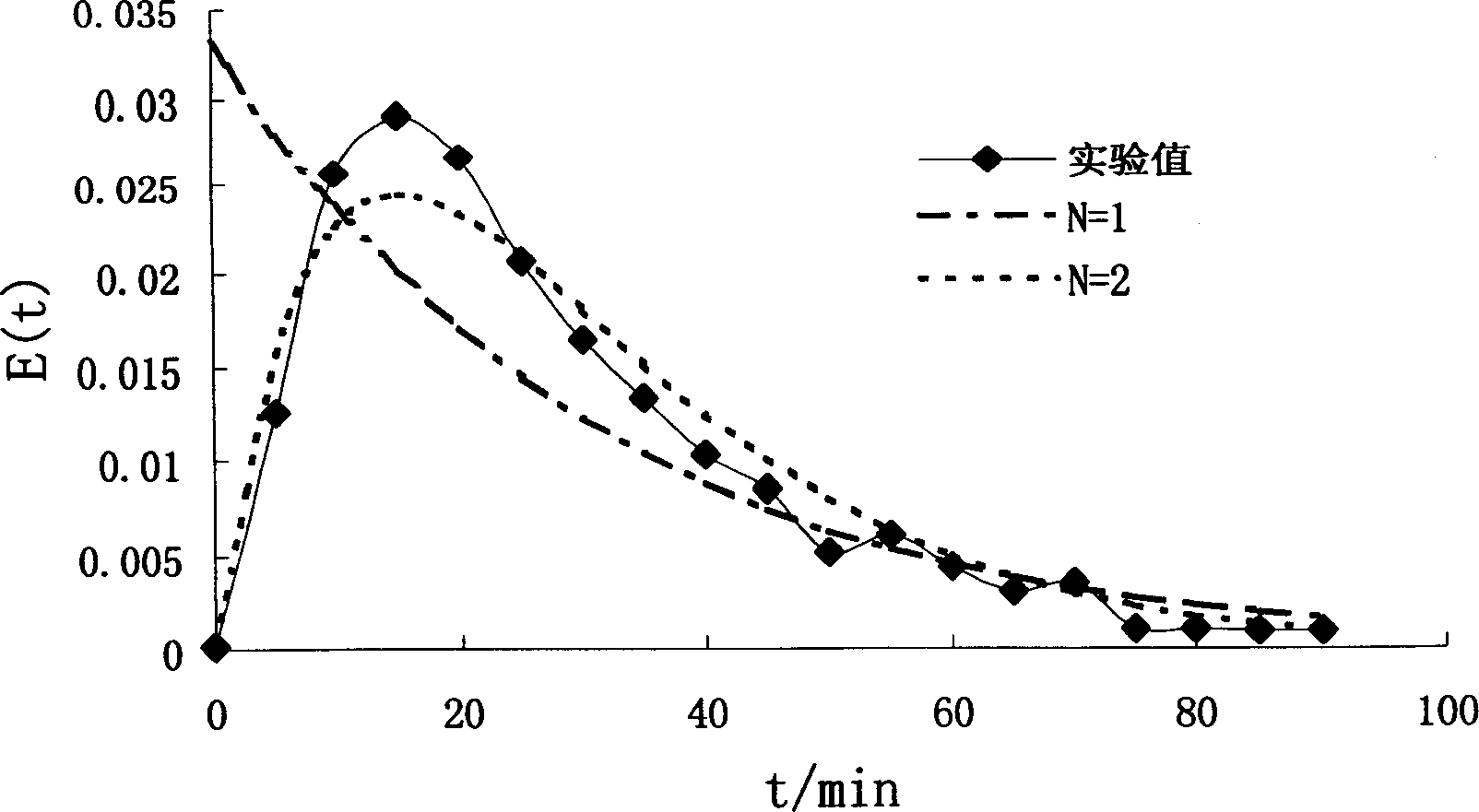

Fluidized-bed polymerization method and polymerization reactor

InactiveCN1438249AImproved dwell time distributionReduced dynamic reaction volumeFluidized bedProduct gas

The invention discloses a fluid bed polymerizaing method and the reactor. Polymerized monomer, copolymerized monomer, molecular-weight adjusting gas, nitrogen gas, condensate, catalyzer as well as aid-catalyzer enter in the reactor to make polymerization, part of gas stream from the top of the reactor circulates by compressor and is cooled to liquefacient temperature by heat exchanger, the obtained two streams enter in A and B areas of the reactor; the two streams return to the reactor in gas-liquid mode, and the liquid is separated out and directly leaded into the fluid bed; the polymerization: temperature 70-130 deg.C, pressure 1-10 MPa.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com