Cooling apparatus and frost detecting method thereof

a technology of cooling apparatus and frost detection, which is applied in the direction of domestic cooling apparatus, refrigeration machines, defrosting, etc., can solve the problems of excessive power consumption, inefficient removal method of frost formed on the evaporator, and inability to detect so as to accurately determine the amount of frost formed, accurately determine the noise contained in the signal received, and achieve the effect of easy and accurate determination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053]Hereinafter, exemplary embodiments will be described in order to explain the present invention by referring to the figures.

[0054]Exemplary embodiments are adapted to enhance the defrosting efficiency of a cooling apparatus and thus to reduce power consumption by accurately detecting whether or not frost has been formed on an evaporator of the cooling apparatus and the amount of frost formed, and controlling driving of a heater based on the results of the detection, thereby controlling a defrosting operation.

[0055]The exemplary embodiments are described in conjunction with an example in which the cooling apparatus is applied to a refrigerator.

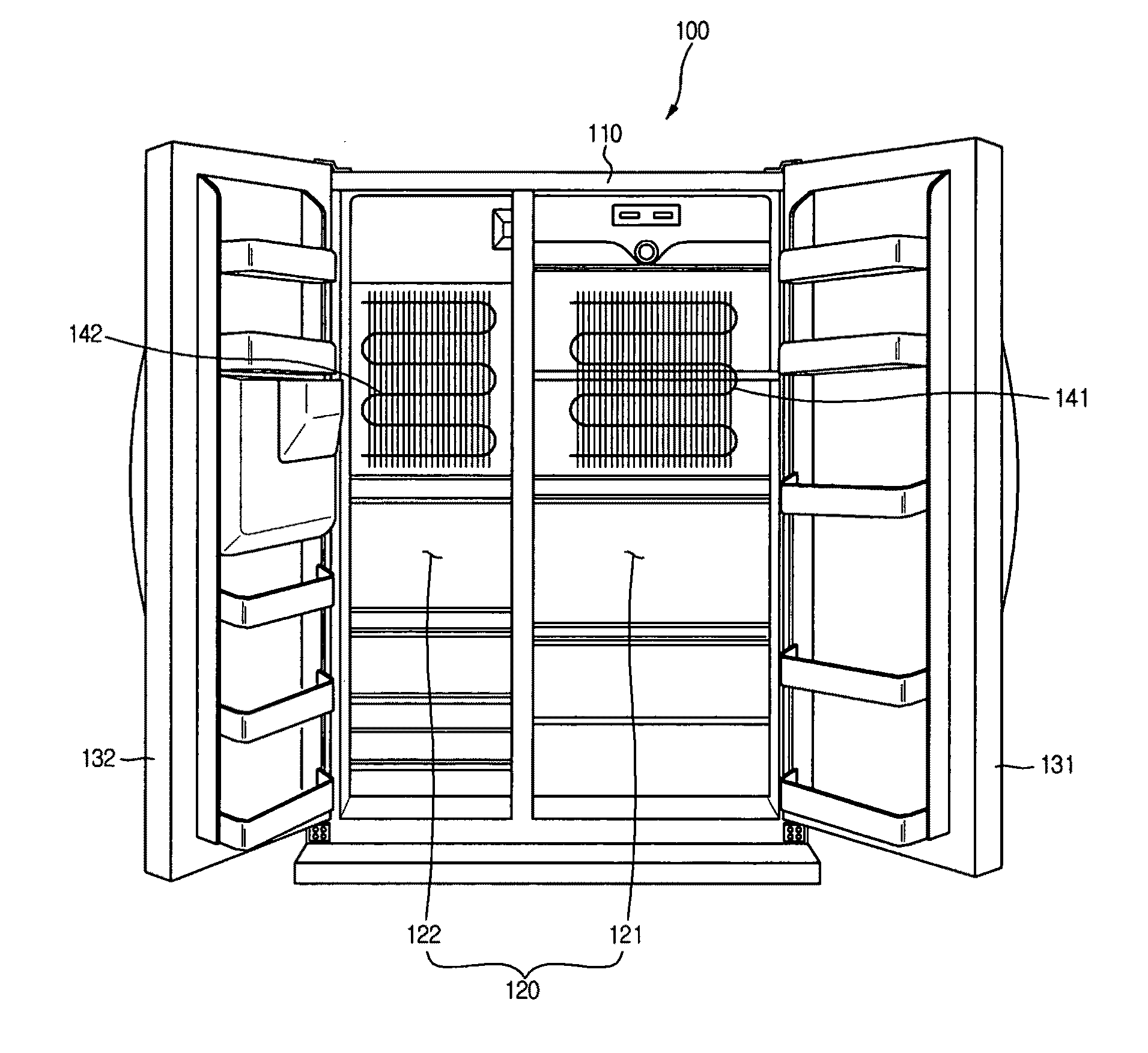

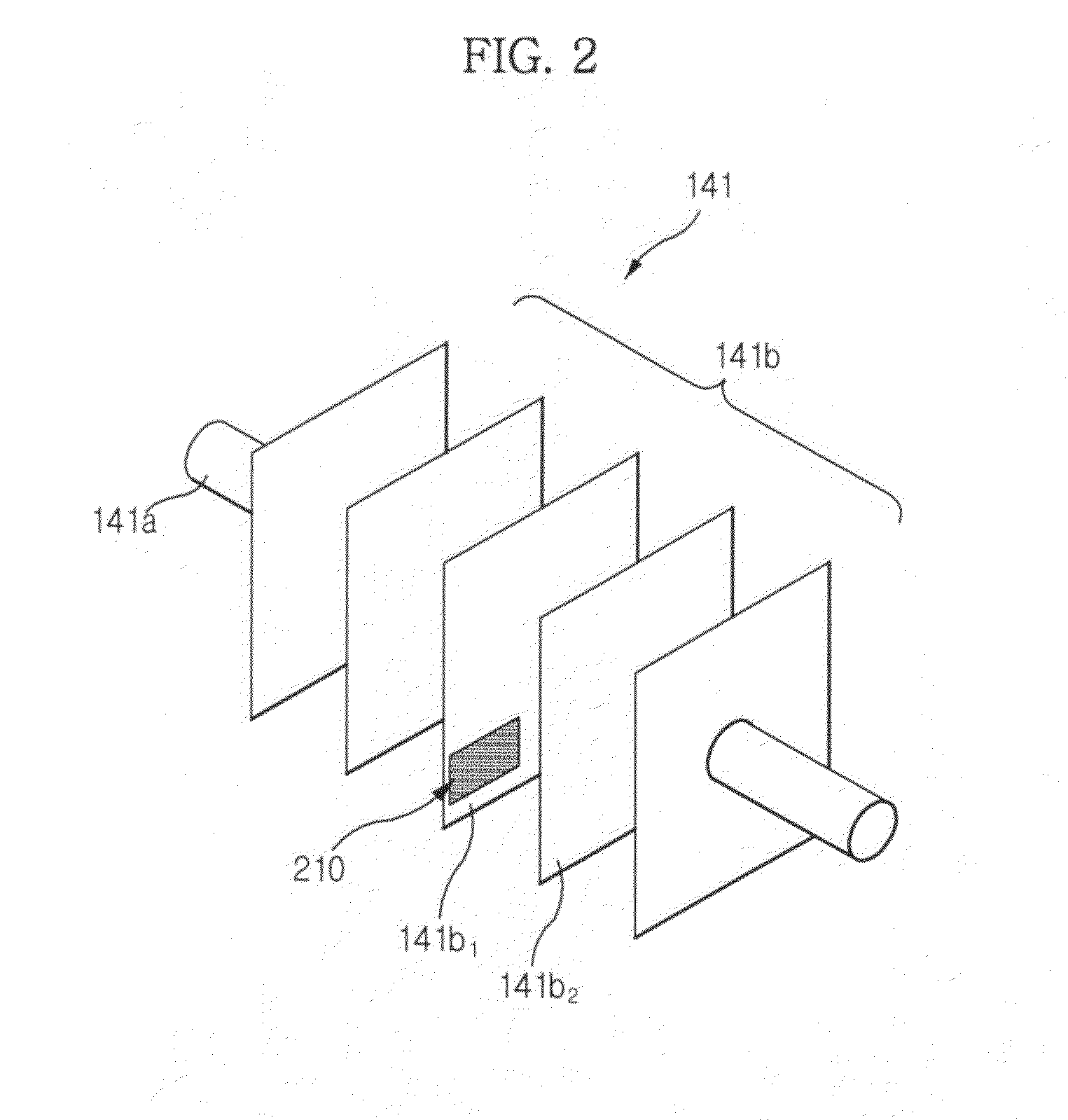

[0056]FIG. 1 is a view illustrating a refrigerator according to an exemplary embodiment. FIG. 2 is a view illustrating a detailed configuration of an evaporator provided at the refrigerator according to the illustrated embodiment. FIG. 3 is a block diagram illustrating a control configuration of the refrigerator according to an exemplary e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com