Patents

Literature

73 results about "Chiral nematic liquid crystal" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

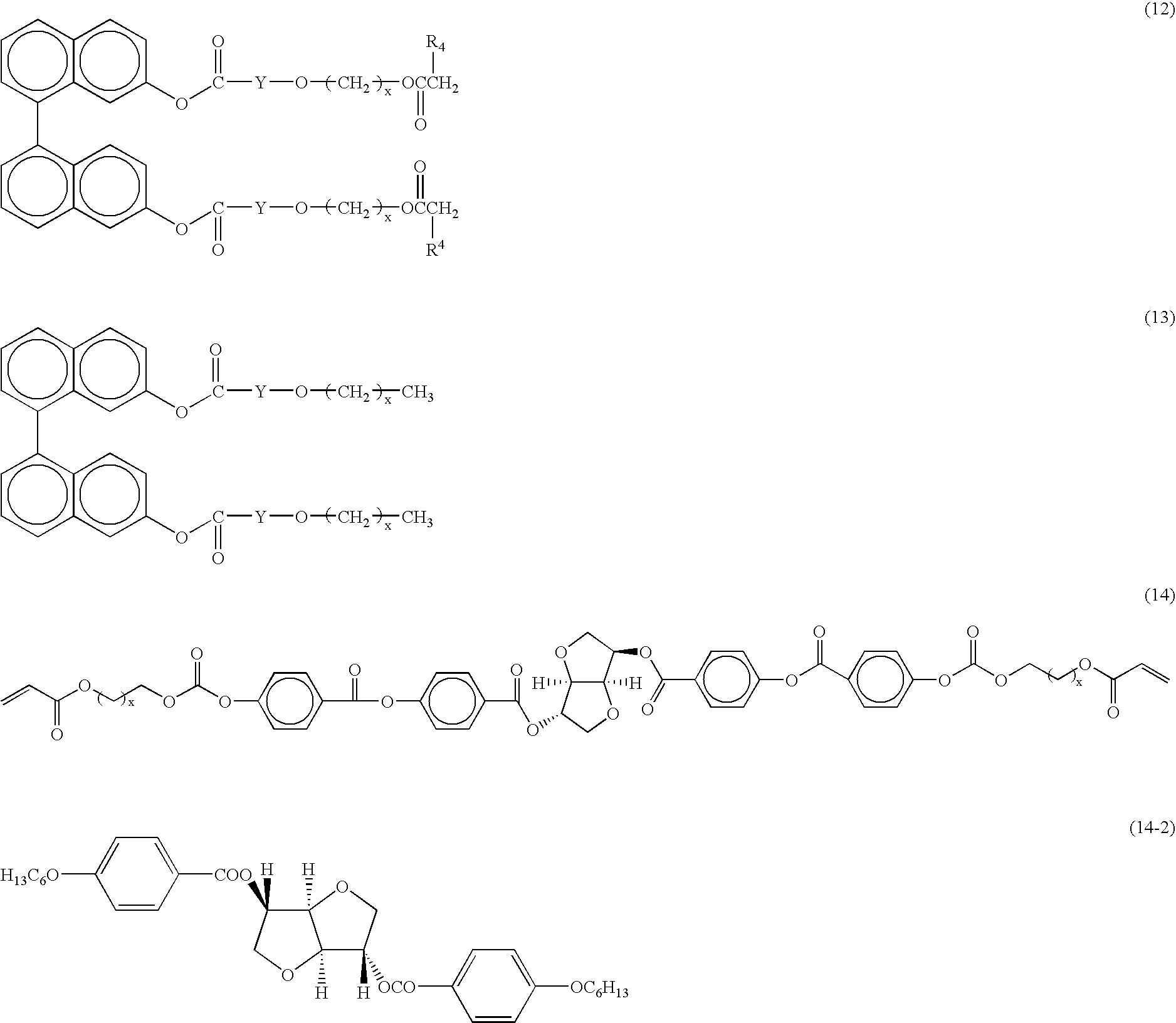

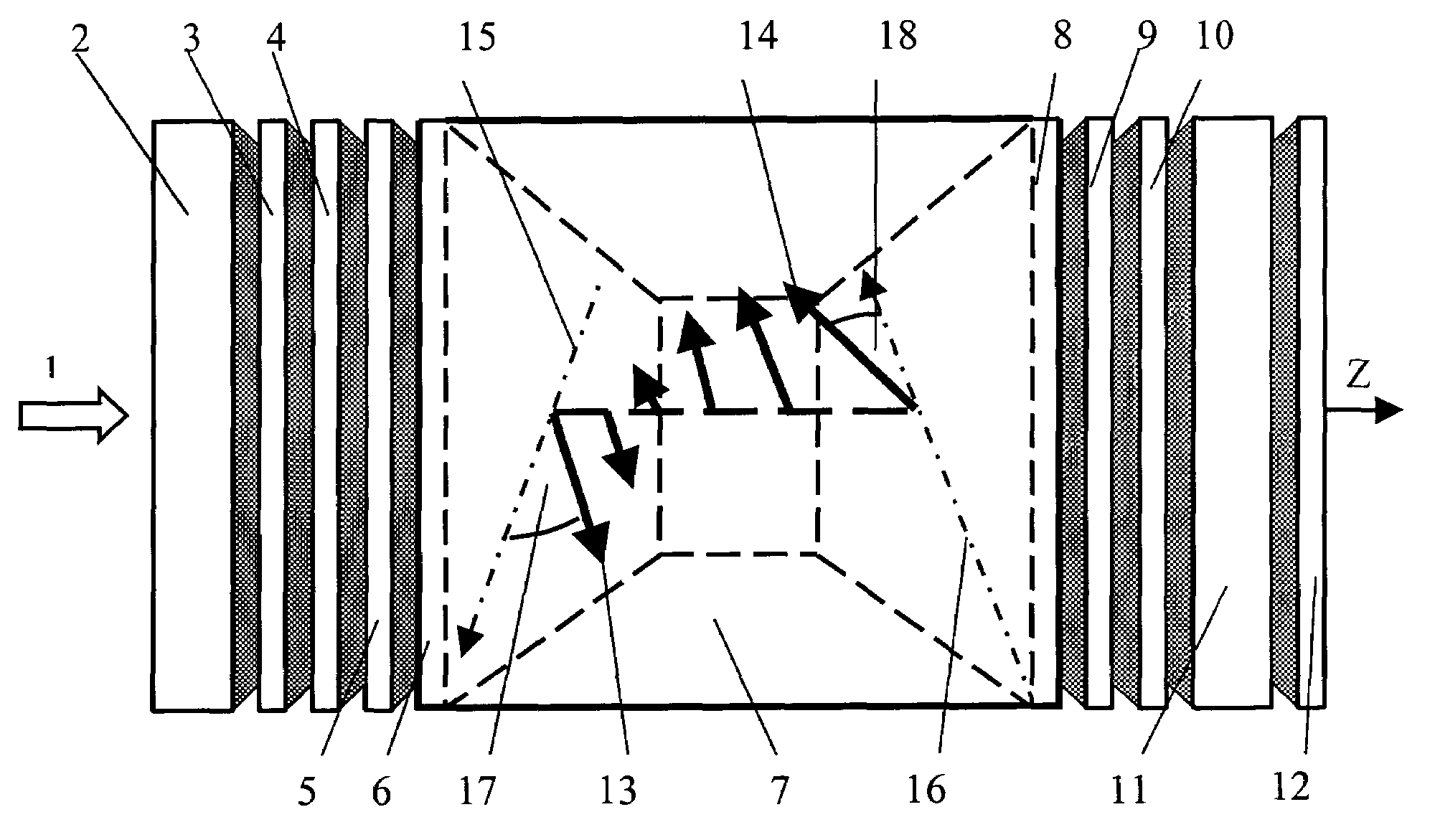

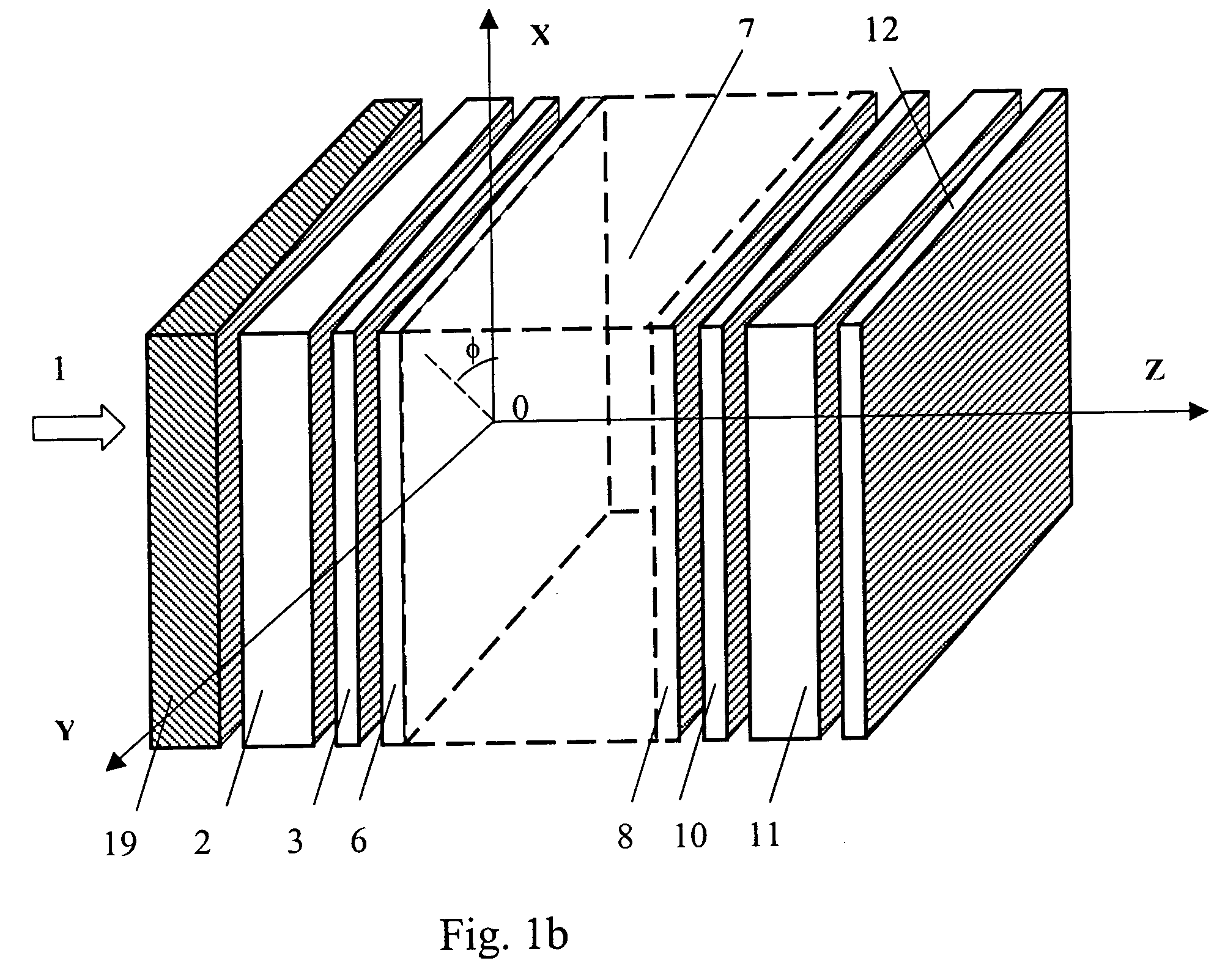

Laminated retardation optical element, process of producing the same, and liquid crystal display

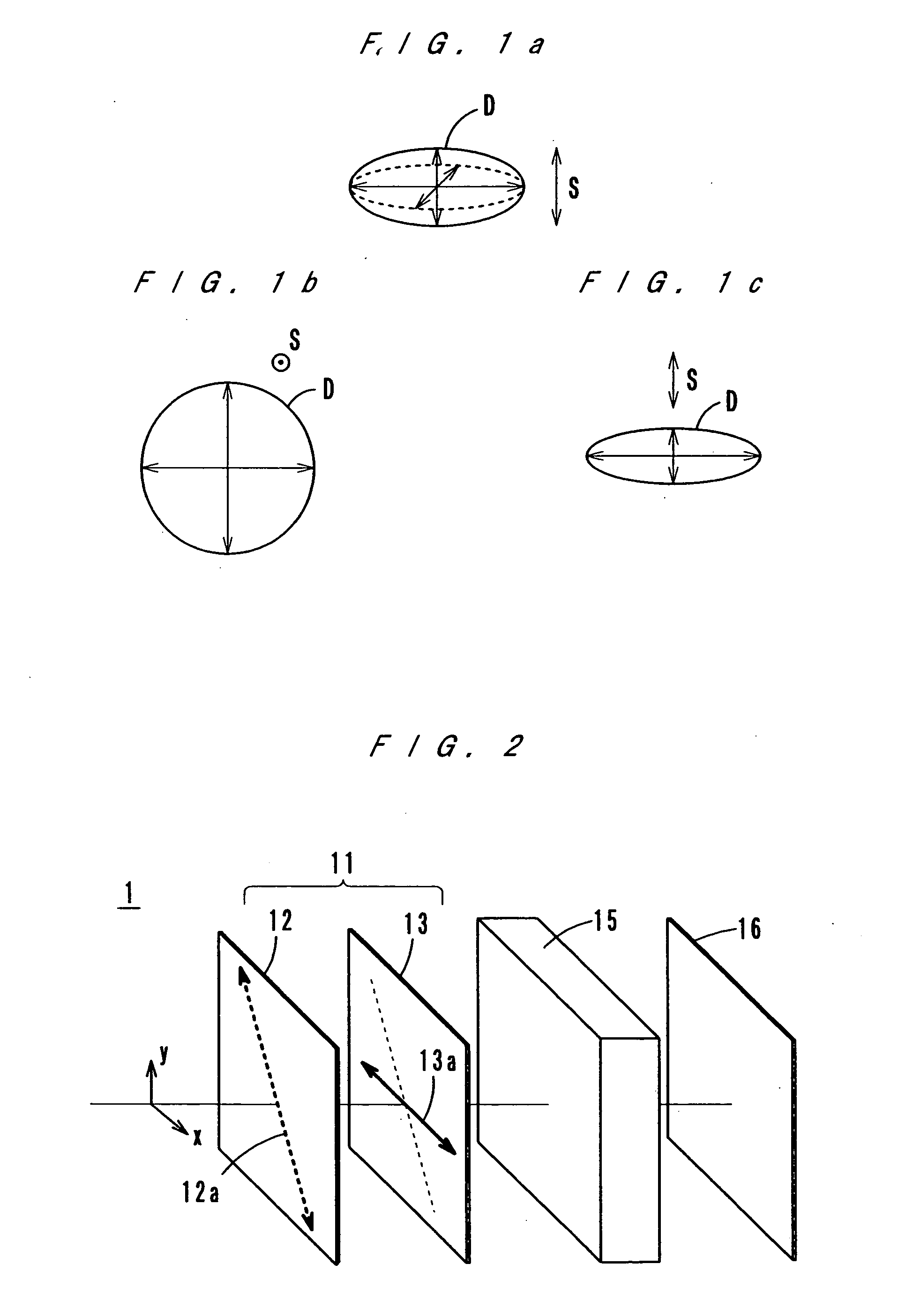

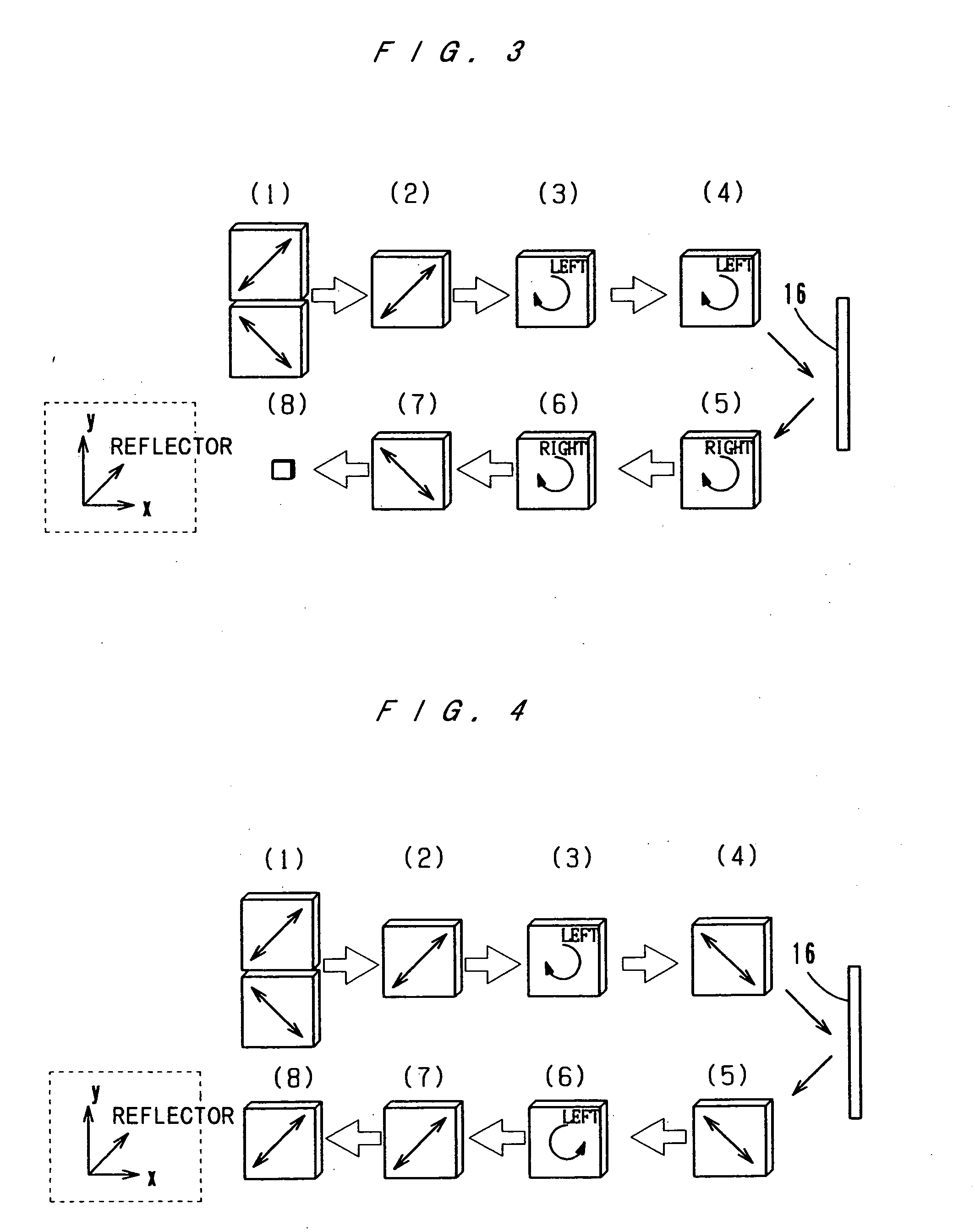

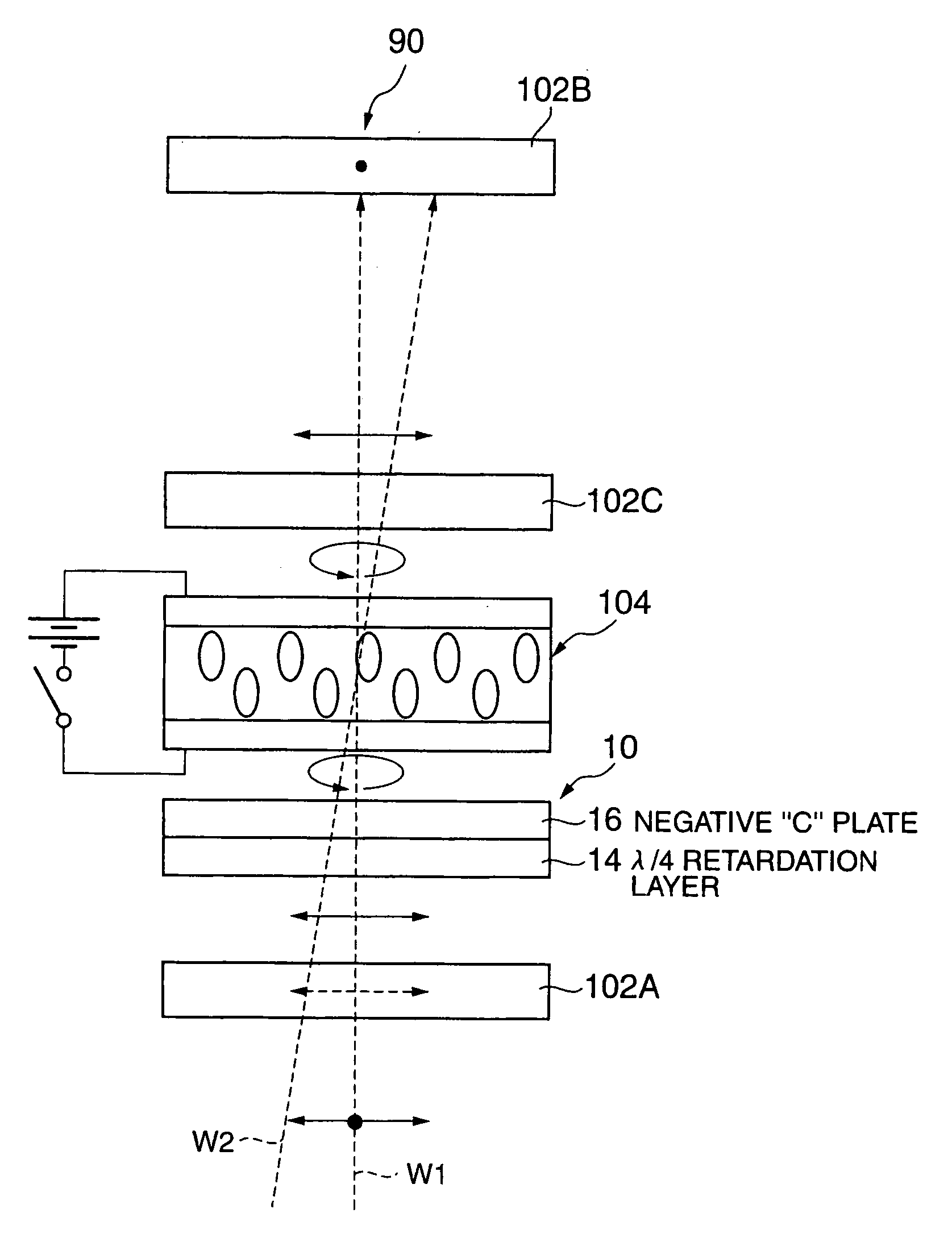

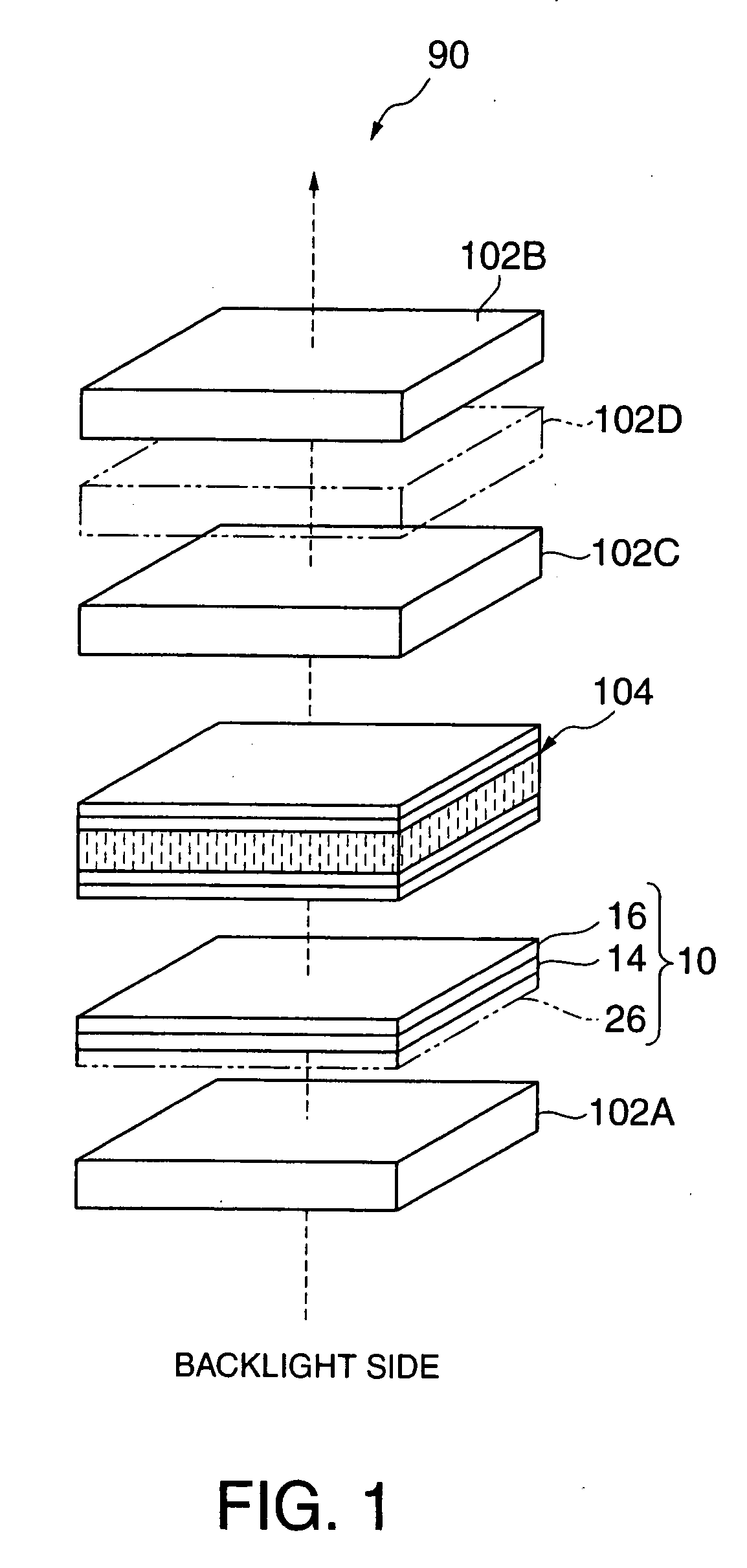

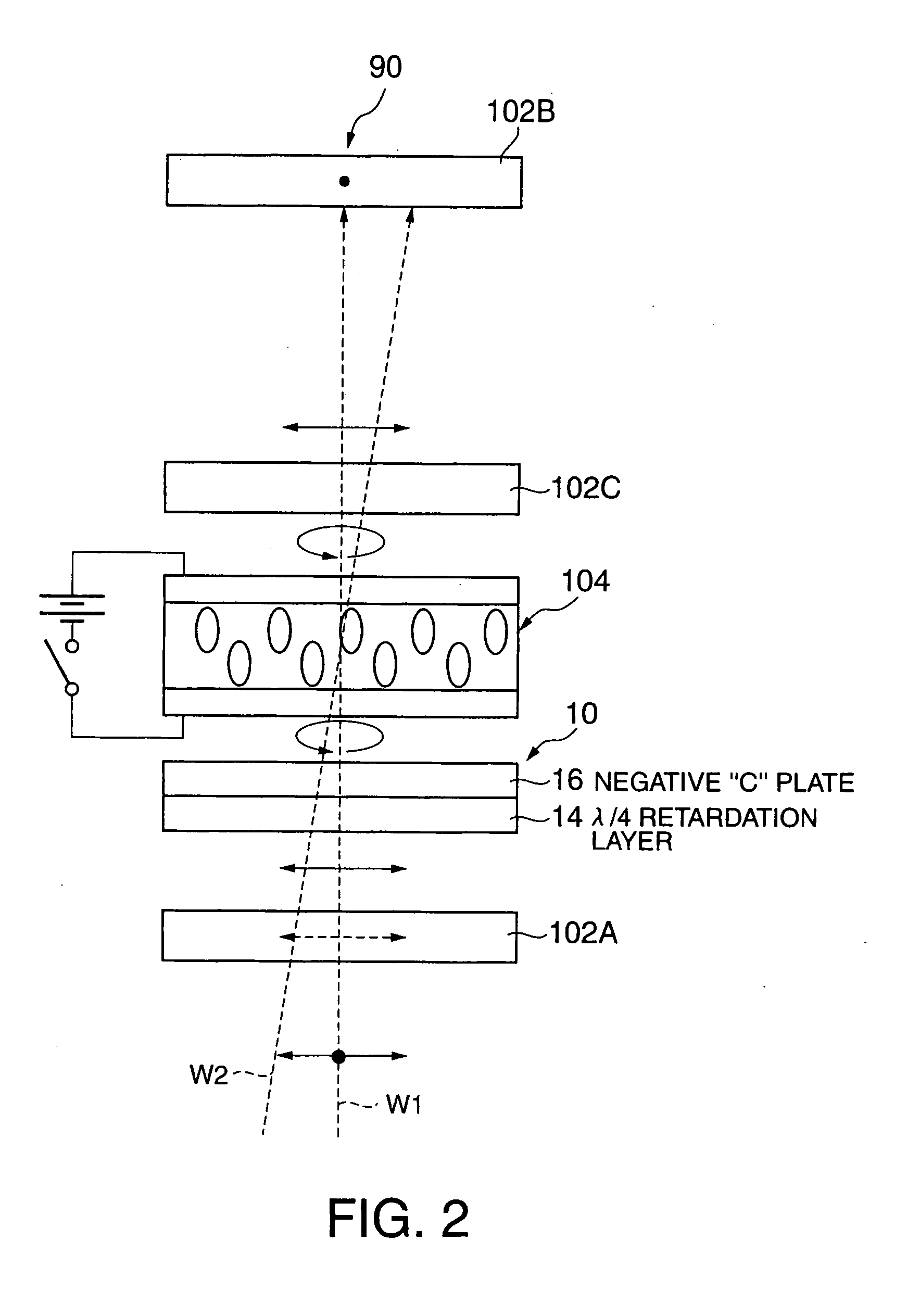

The present invention provides a laminated retardation optical element that never lowers contrast and thus never degrades display performance even when placed between a liquid crystal cell and a lambda / 4 retardation film. In a liquid crystal display 90, a laminated retardation optical element 10 is placed between a polarizer 102A on the incident side and a liquid crystal cell 104, and a lambda / 4 retardation film 102C is placed between a polarizer 102B on the emergent side and the liquid crystal cell 104. The laminated retardation optical element 10 comprises: a lambda / 4 retardation layer 14 having the function of bringing, to light that passes through this retardation layer, a phase difference corresponding to a quarter of the wavelength of the light; and a C plate-type retardation layer 16 that acts as a negative C plate. The lambda / 4 retardation layer 14 and the C plate-type retardation layer 16 are laminated to a transparent substrate 12 in the order mentioned, and are optically bonded to each other. The lambda / 4 retardation layer 14 comprises as its main component a horizontally-aligned, cross-linked nematic liquid crystal, while the C plate-type retardation layer 16 comprises as its main component a cross-linked chiral nematic liquid crystal (a cross-linked nematic liquid crystal and a cross-linked chiral agent) or cross-linked discotic liquid crystal.

Owner:DAI NIPPON PRINTING CO LTD

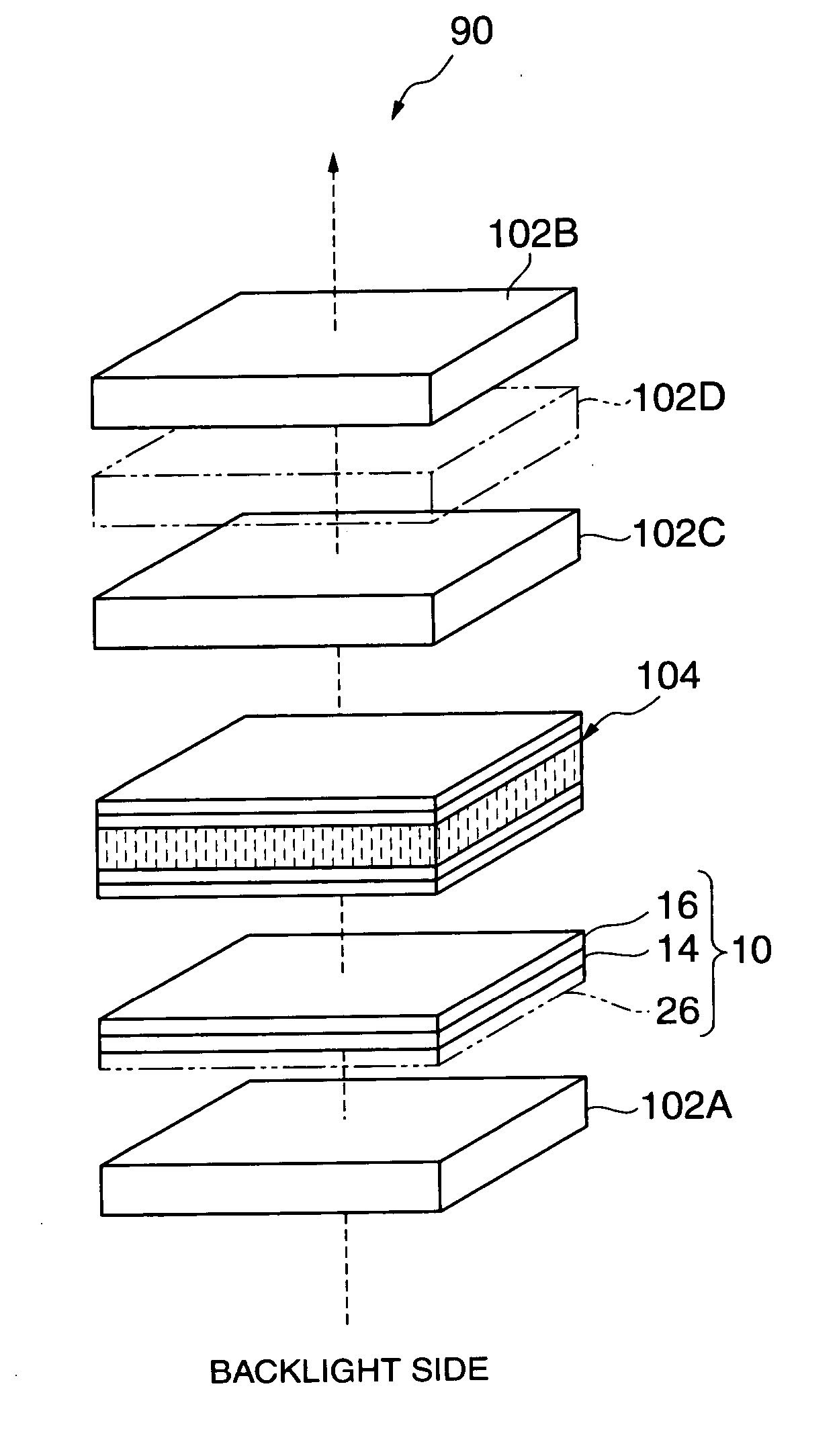

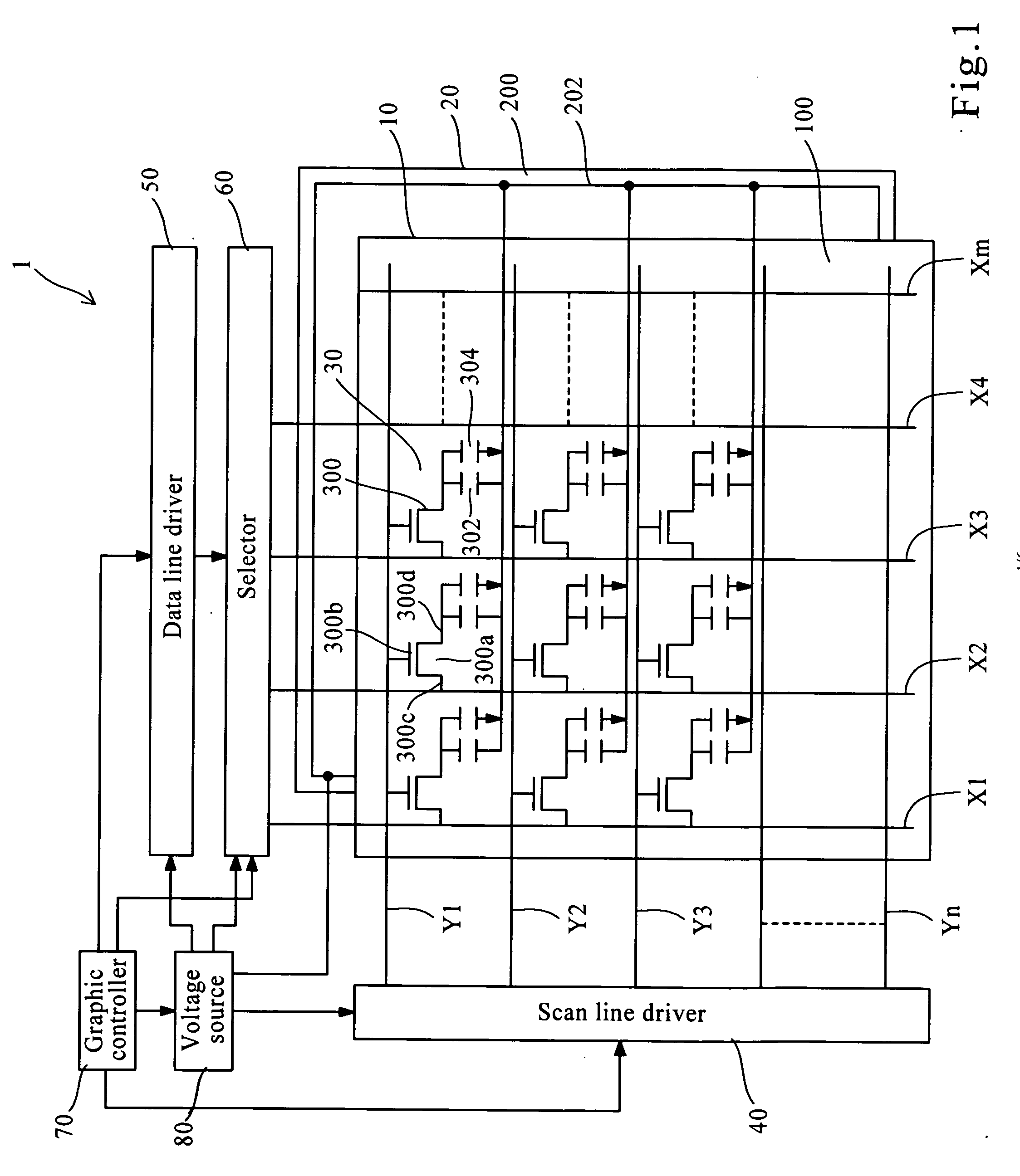

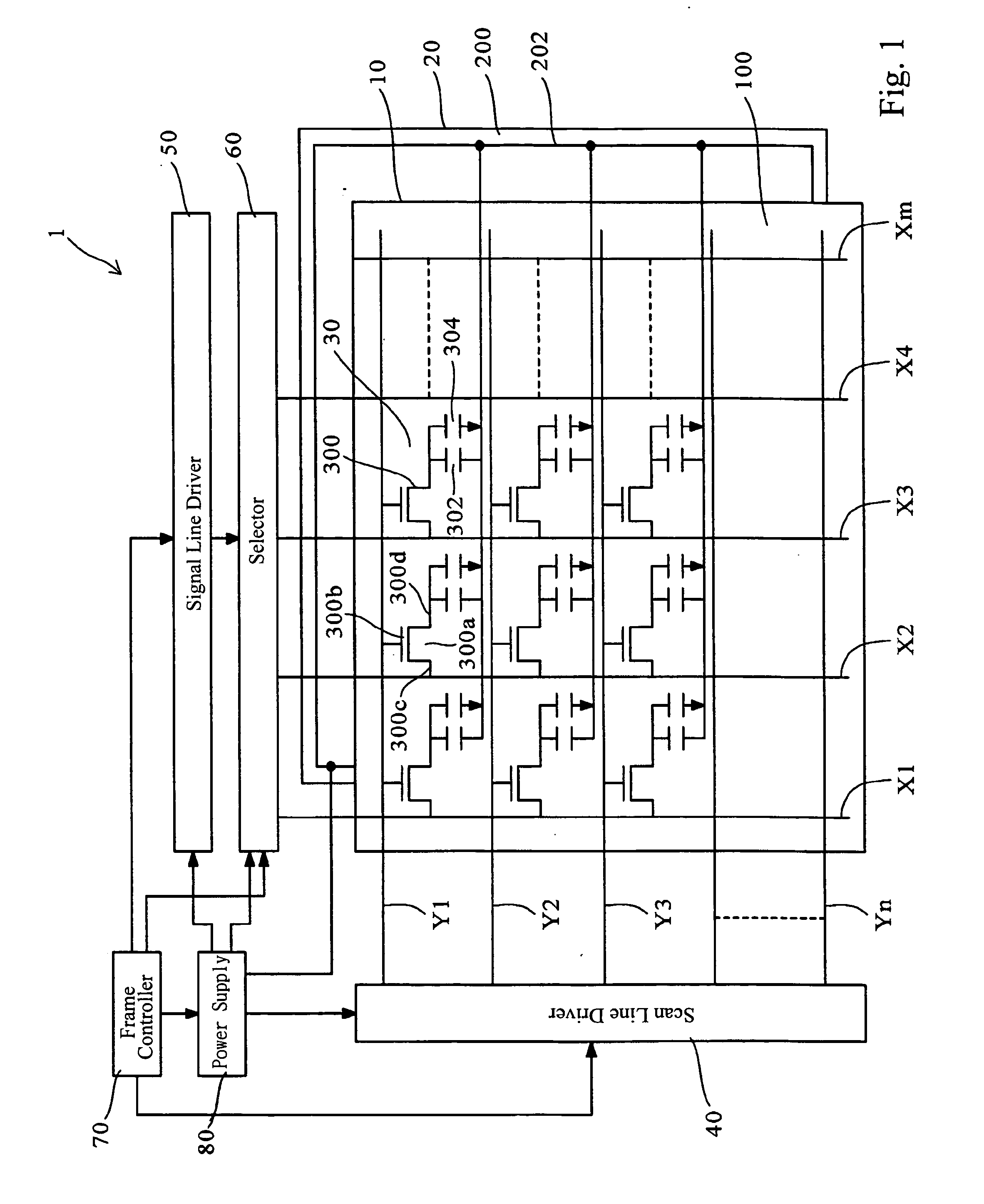

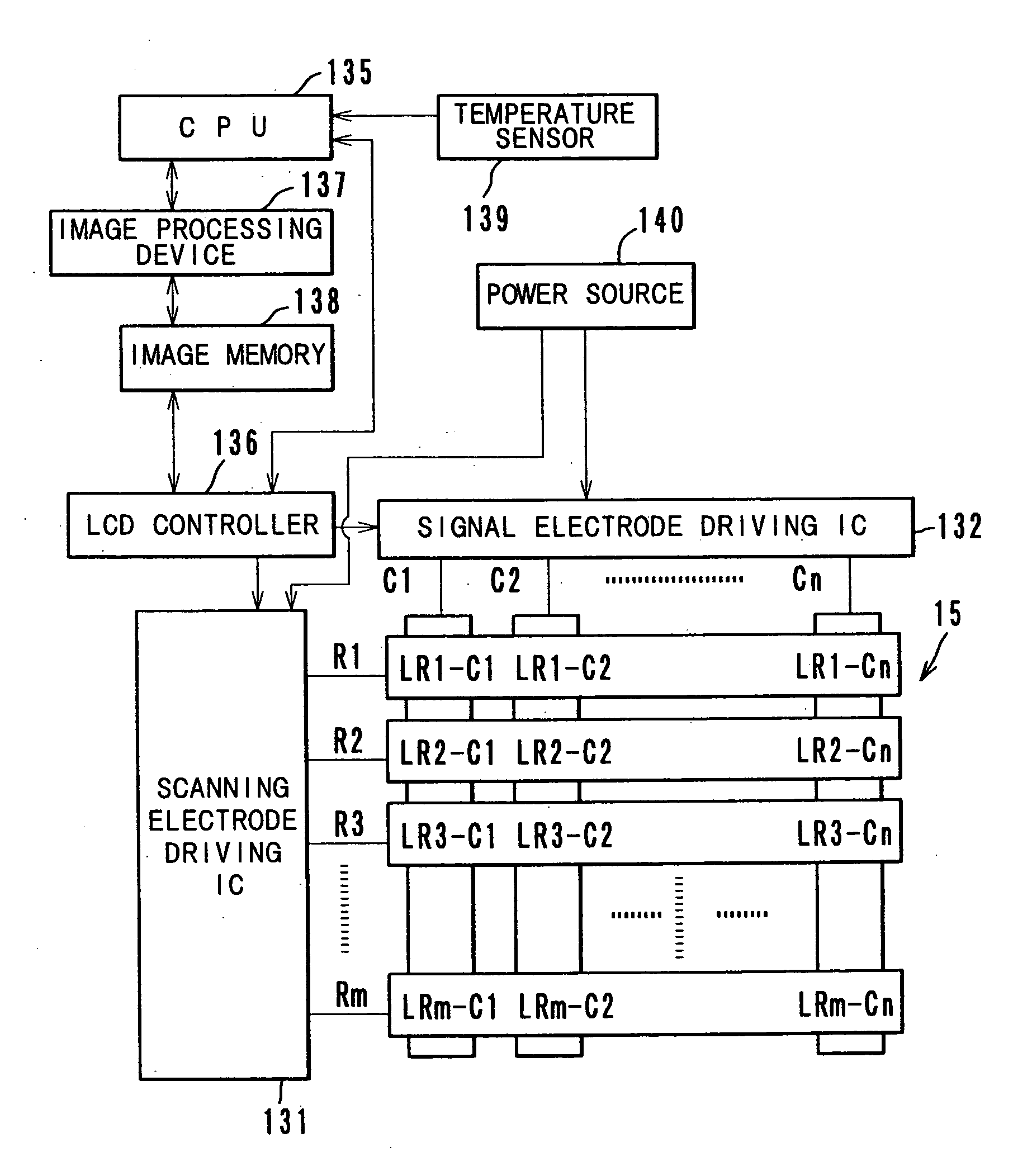

Bi-stable chiral nematic liquid crystal display and driving method for the same

InactiveUS20060279501A1Improve manufacturing yieldManufacturing costStatic indicating devicesLiquid-crystal displayEngineering

The present invention provides a bi-stable chiral nematic liquid crystal display and a driving method for the same. Each pixel of the liquid crystal display includes at least a transistor as a switch element to switch a column voltage to the pixel and a capacitor for storing a voltage of the pixel. The method for driving the bi-stable chiral nematic liquid crystal display is to divide each frame to be updated into a plurality of sub-frames. During a period of each sub-frame, the bi-stable chiral nematic liquid crystal is driven to a corresponding state in accordance with a respective driving condition.

Owner:IND TECH RES INST

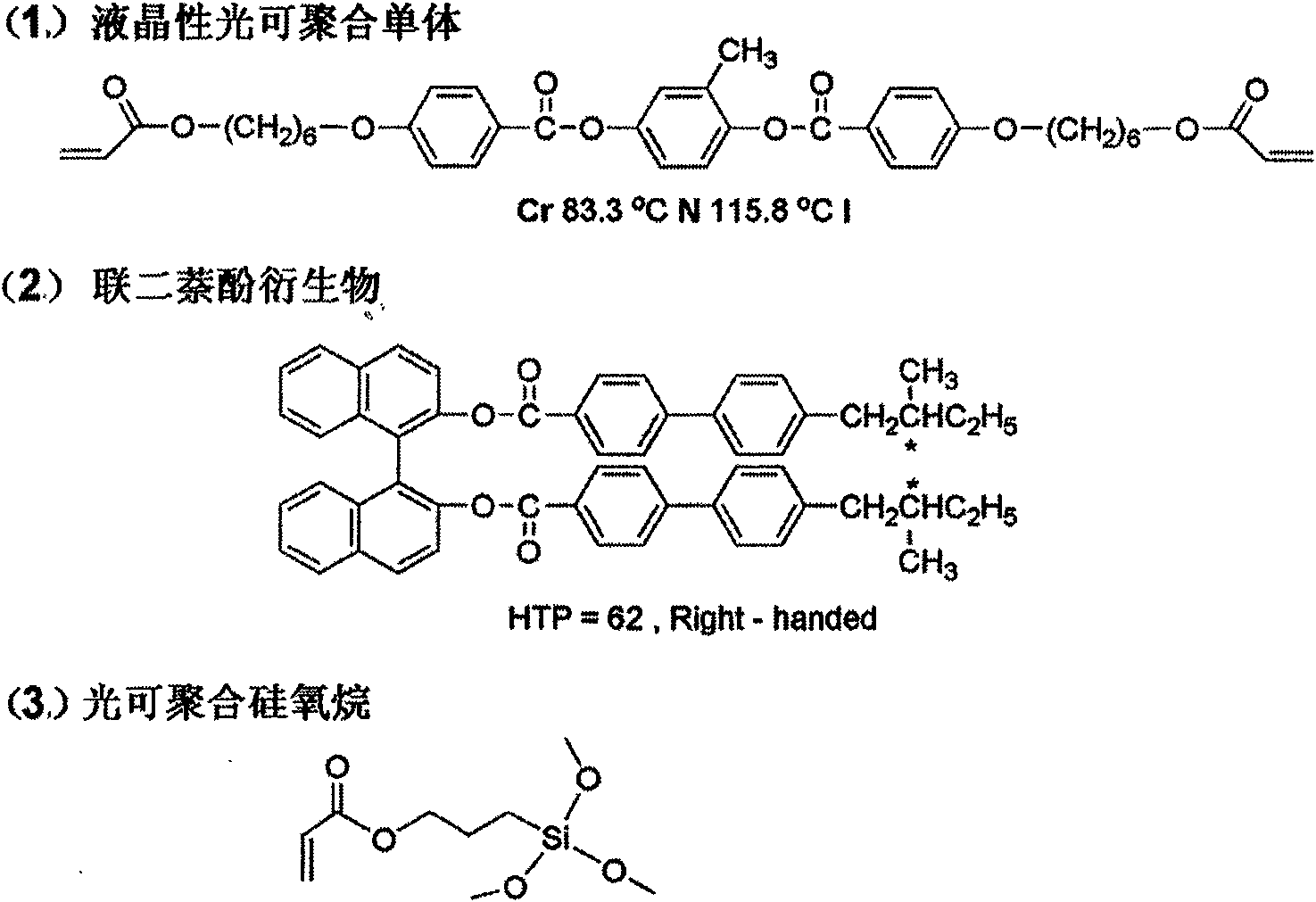

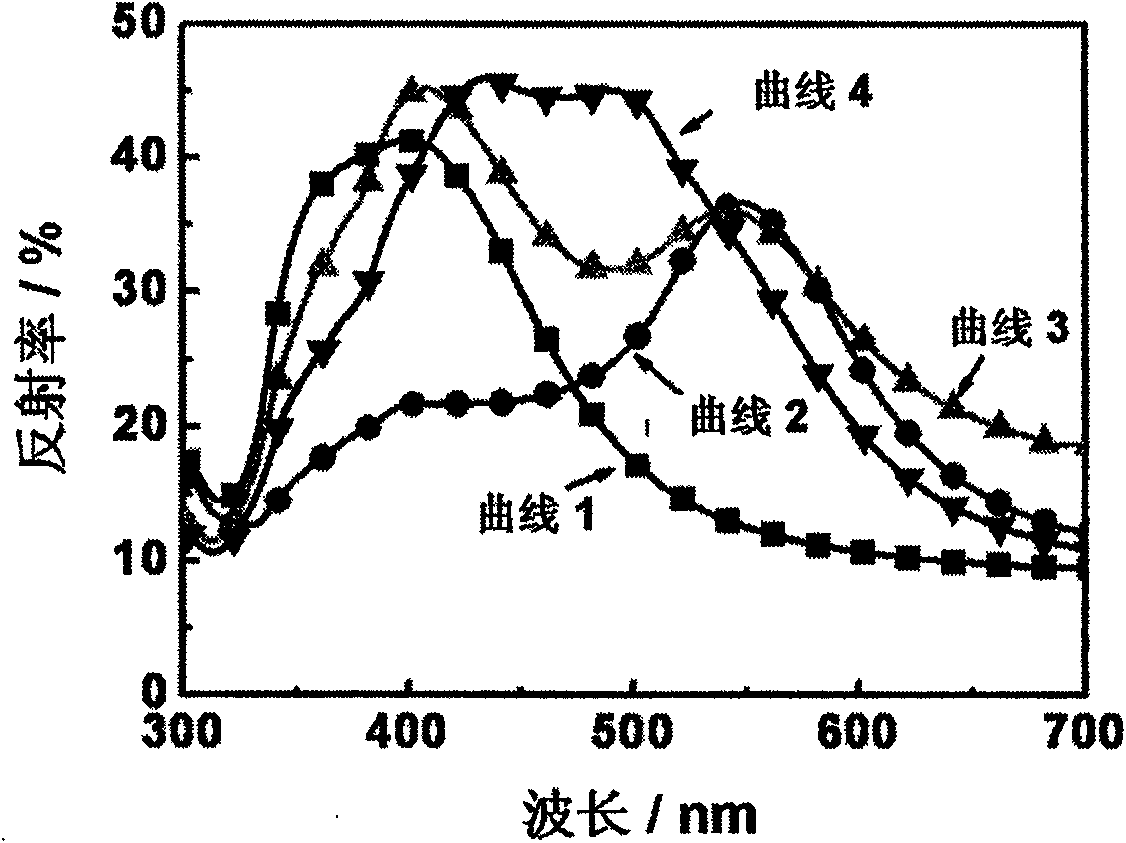

Method for utilizing polymer stable liquid crystal material to prepare light brightness enhancement film

InactiveCN101566755AImprove adhesionSpread evenlyNon-linear opticsMolecular networkHigh concentration

The invention belongs to the field of application of liquid crystal materials and provides a method for utilizing polymer stable liquid crystal material to prepare a light brightness enhancement film. The method comprises the following steps of: mixing nematic liquid crystals, chiral compounds, ultraviolet polymerizable liquid crystal monomers, ultraviolet polymerizable siloxane and photoinitiators uniformly according to a certain mass proportion, injecting the mixture into pretreated film materials combined by PSLC substrate, carrying out diffusion from the high-concentration substrate to the low-concentration substrate by the chiral compounds, generating chiral nematic liquid crystals with continuous and different screw pitches, carrying out ultraviolet radiation on the film material, leading the ultraviolet polymerizable liquid crystal monomer molecules to occur polymerization reaction, forming a high-molecular network, leading the planar texture of the liquid crystal molecules to be stabilized and finally obtaining the PSLC material with wide wave reflection characteristics. The film material can reflect circularly polarized light with the reflection wavelength of 300 to 1500nm and the range of the reflected wave width can be precisely controlled. According to the differences of the reflection wavebands, the film material can be applied to the field of light brightness enhancement films and infrared ultraviolet light screen films of liquid crystal displays and the like.

Owner:UNIV OF SCI & TECH BEIJING

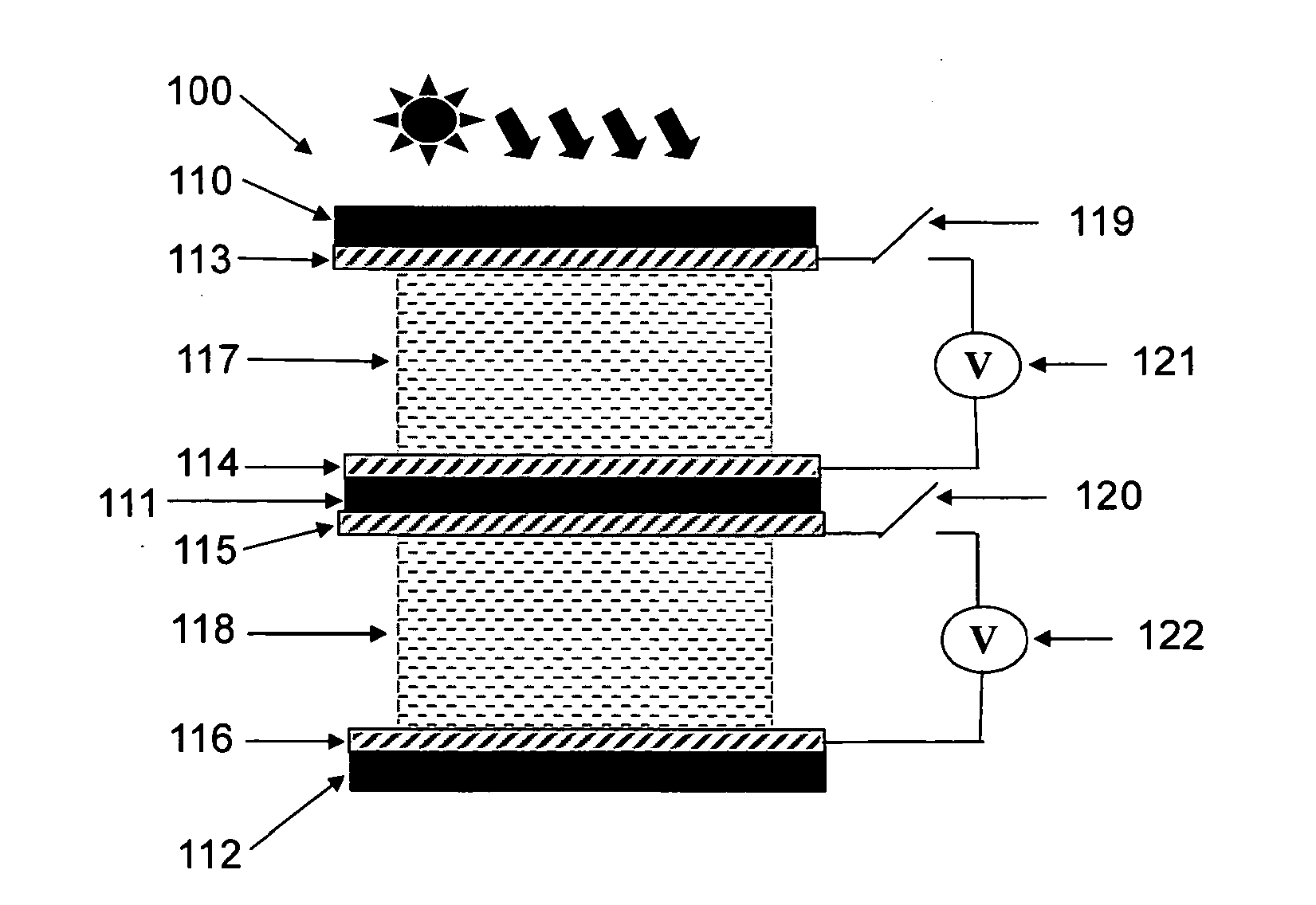

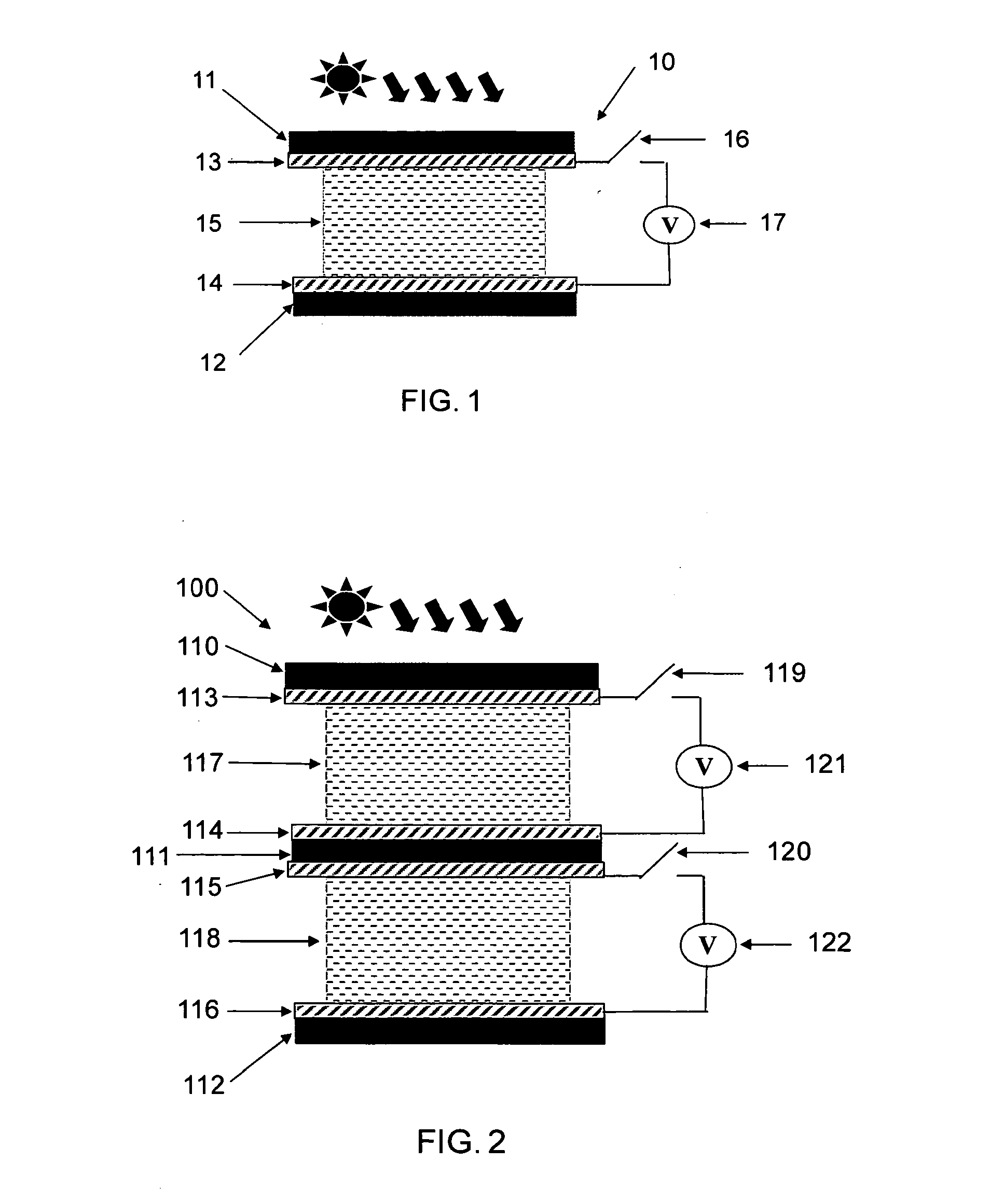

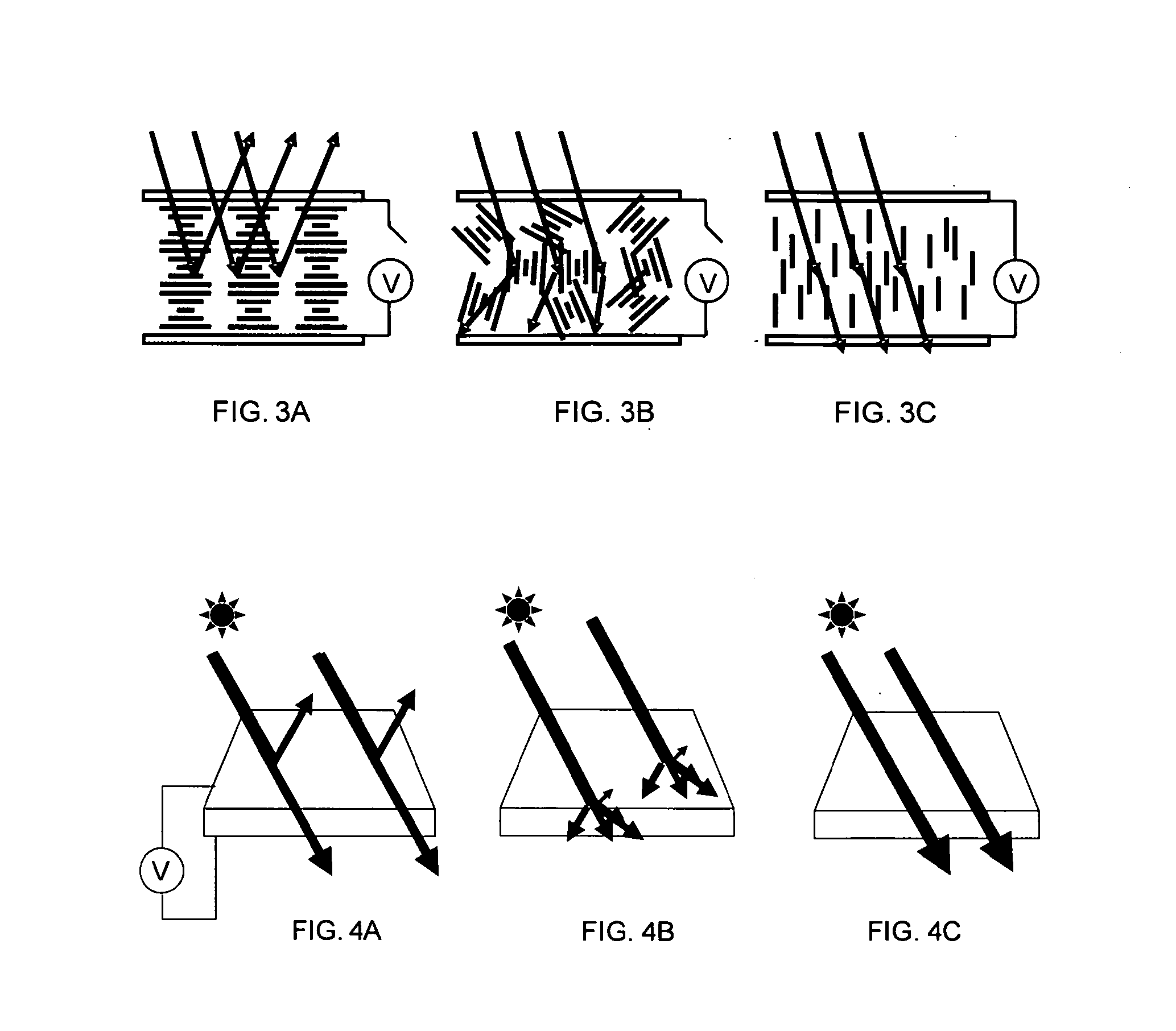

Smart photochromic chiral nematic liquid crystal window

ActiveUS20130093969A1Useful and effective to utilize energyLow costAntiglare equipmentNon-linear opticsChiral nematic liquid crystalSunlight irradiation

A multi-functional photochromic chiral nematic liquid crystal window comprises at least a photochromic chiral nematic liquid crystal layer. The windows are able to not only to darken in color upon exposure to sunlight irradiation but also control the light and the heat passing through them, which can be used as the windows of buildings, vehicles, and the like.

Owner:KENT STATE UNIV

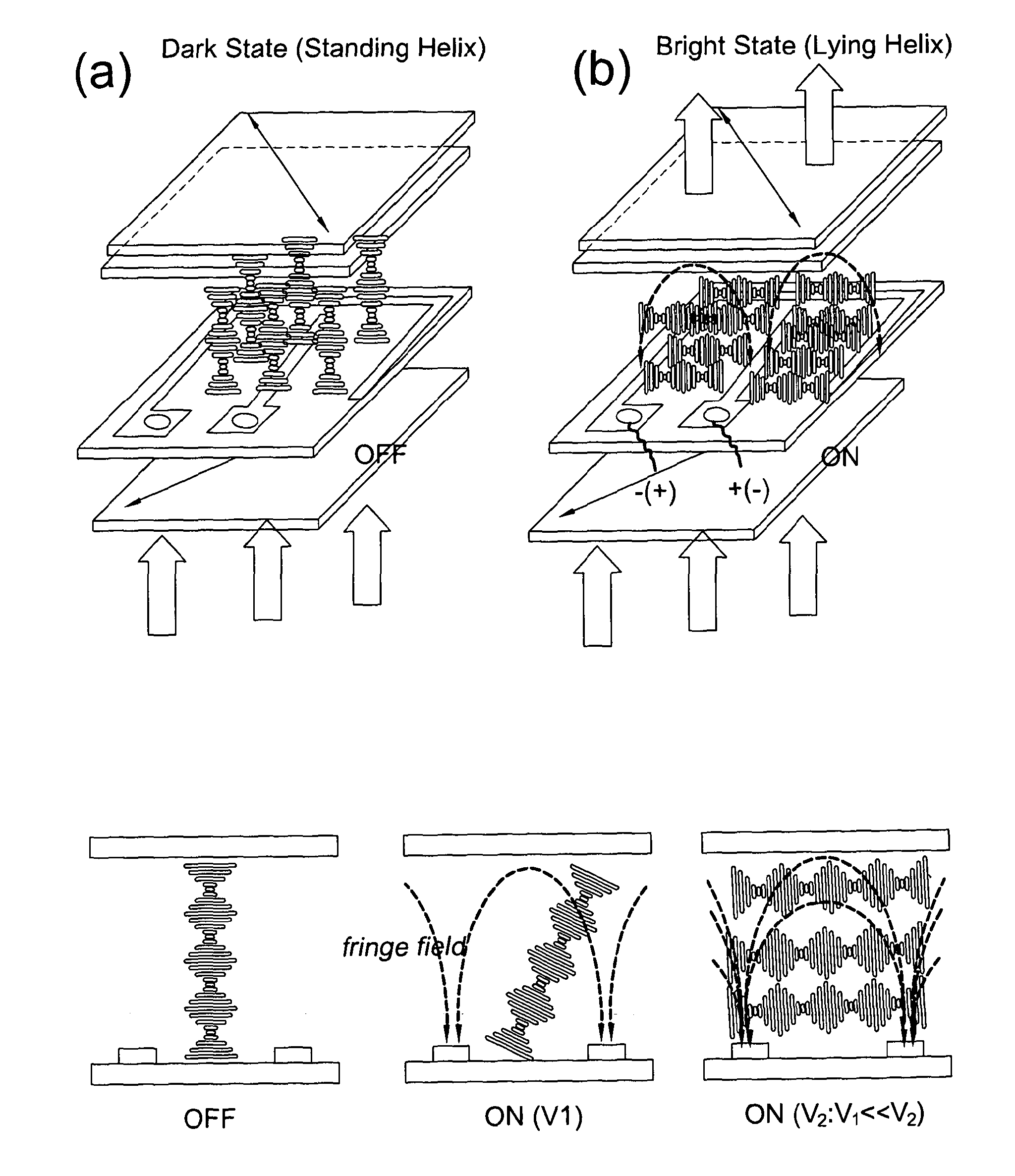

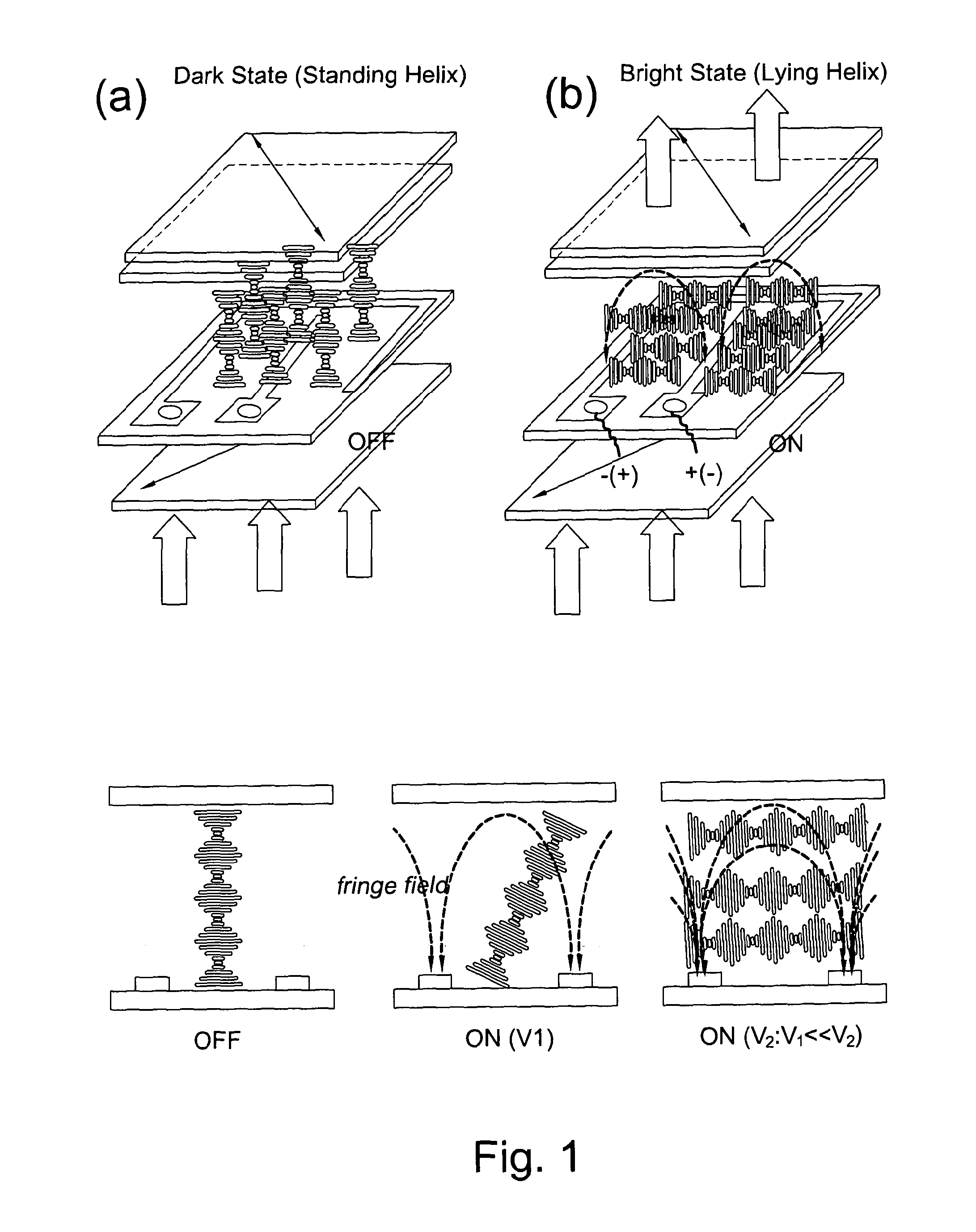

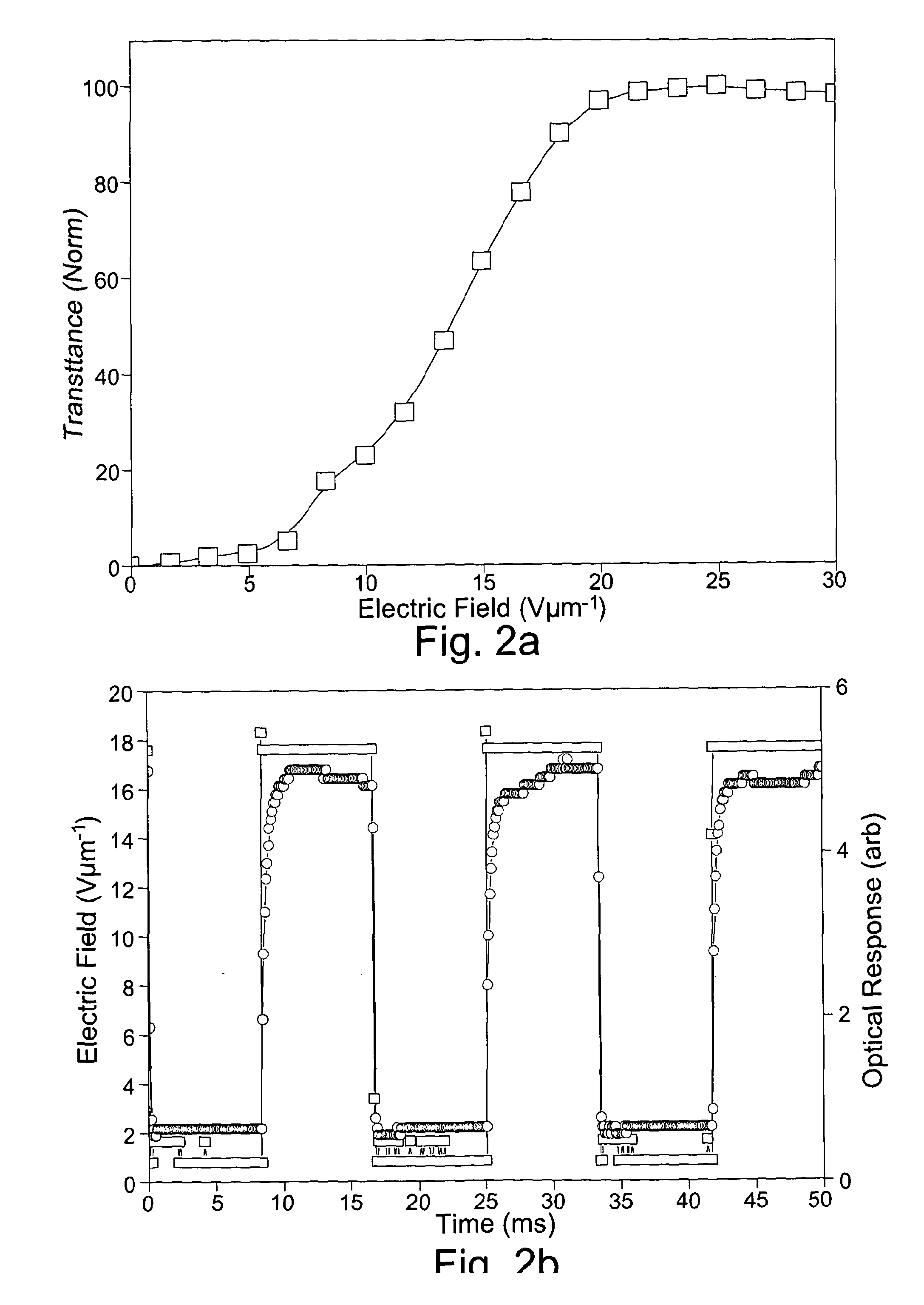

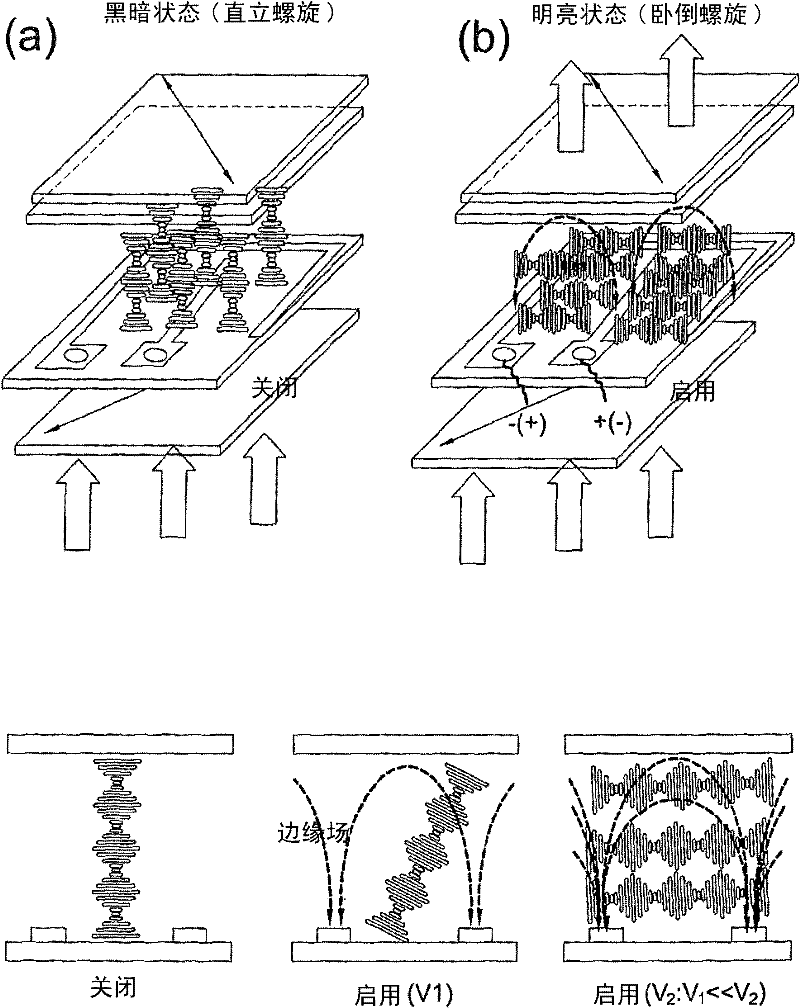

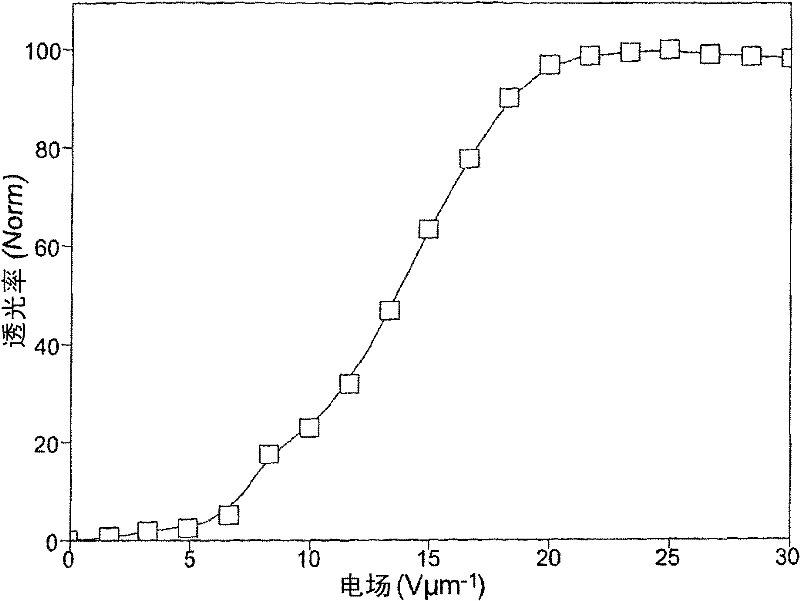

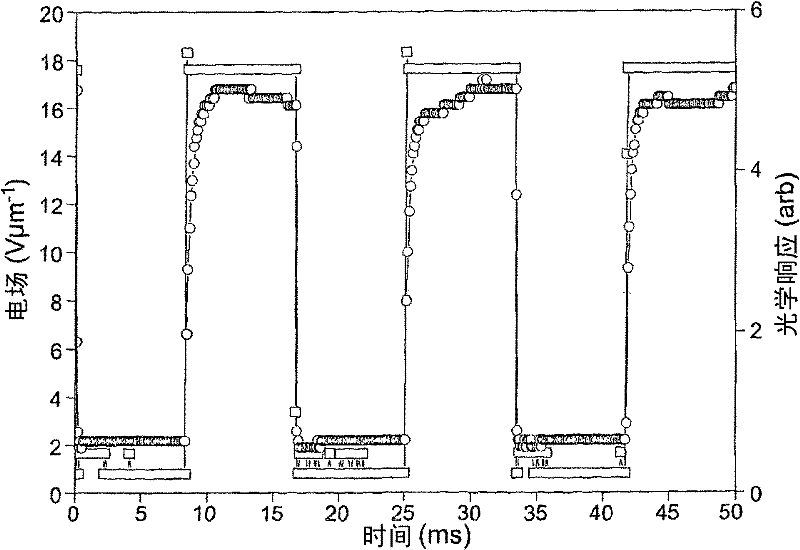

Liquid crystal device comprising chiral nematic liquid crystal material in a helical arrangement

InactiveUS20120140133A1Range of viewing angleEnhance the imageStatic indicating devicesNon-linear opticsDielectric anisotropyDisplay device

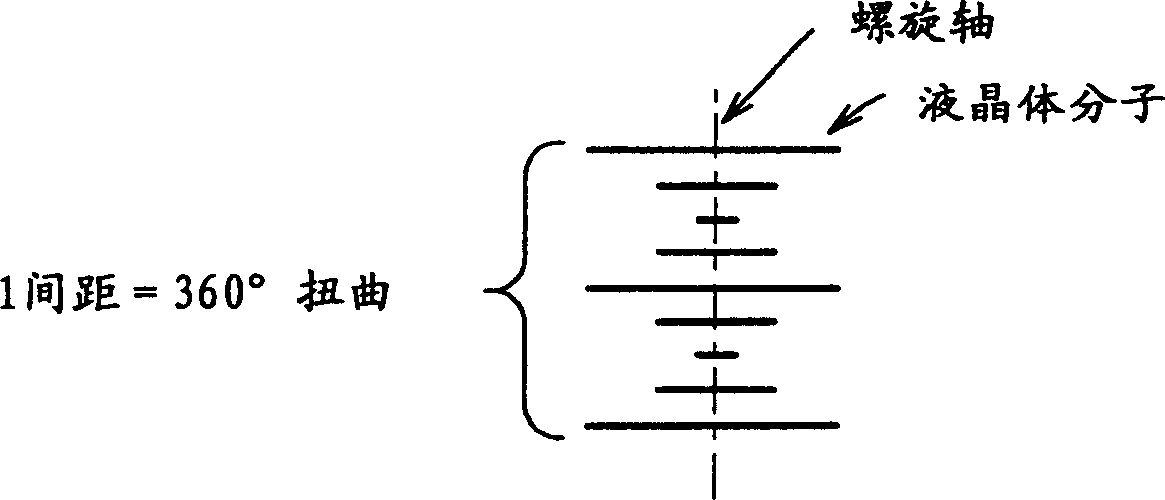

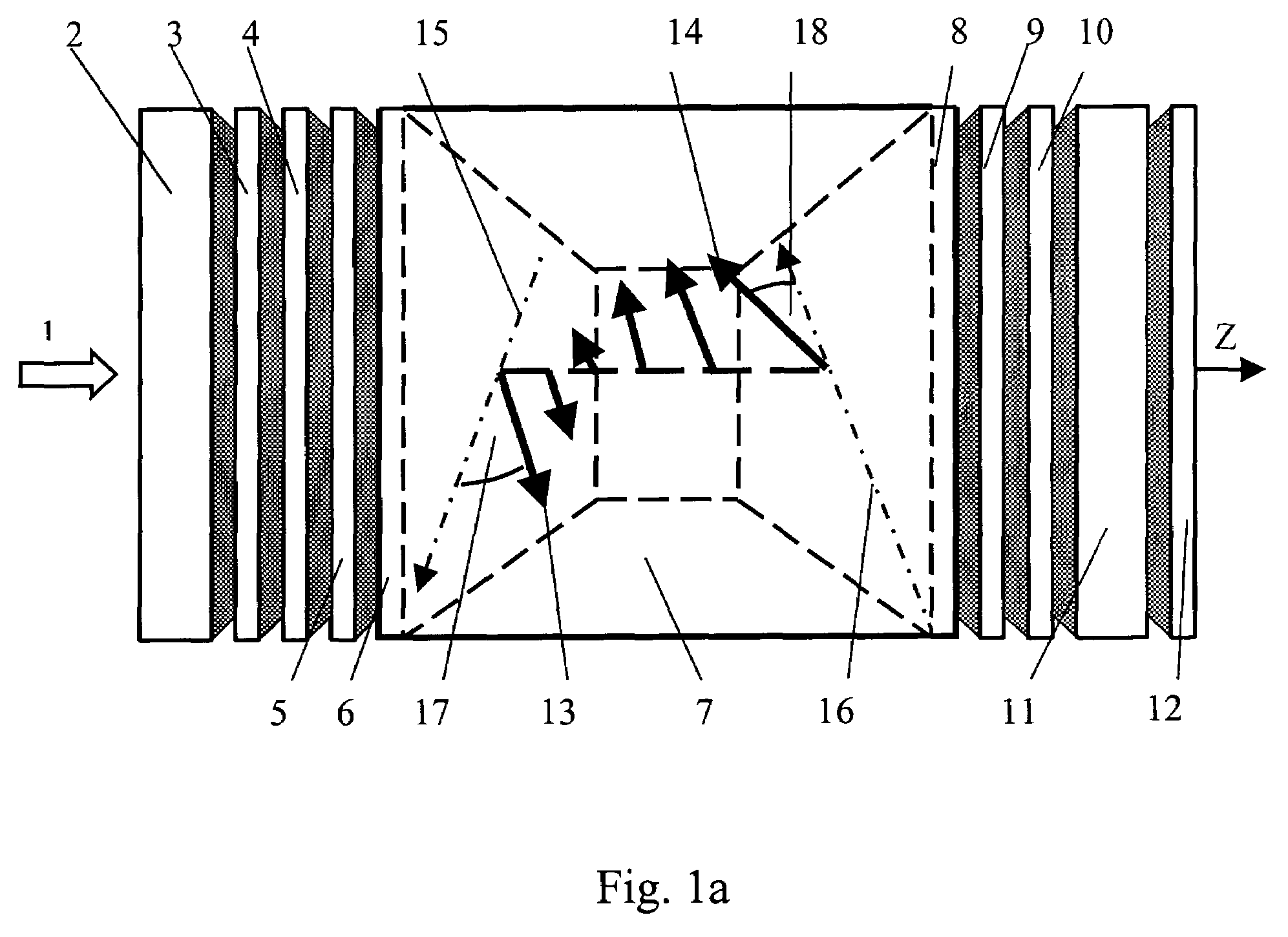

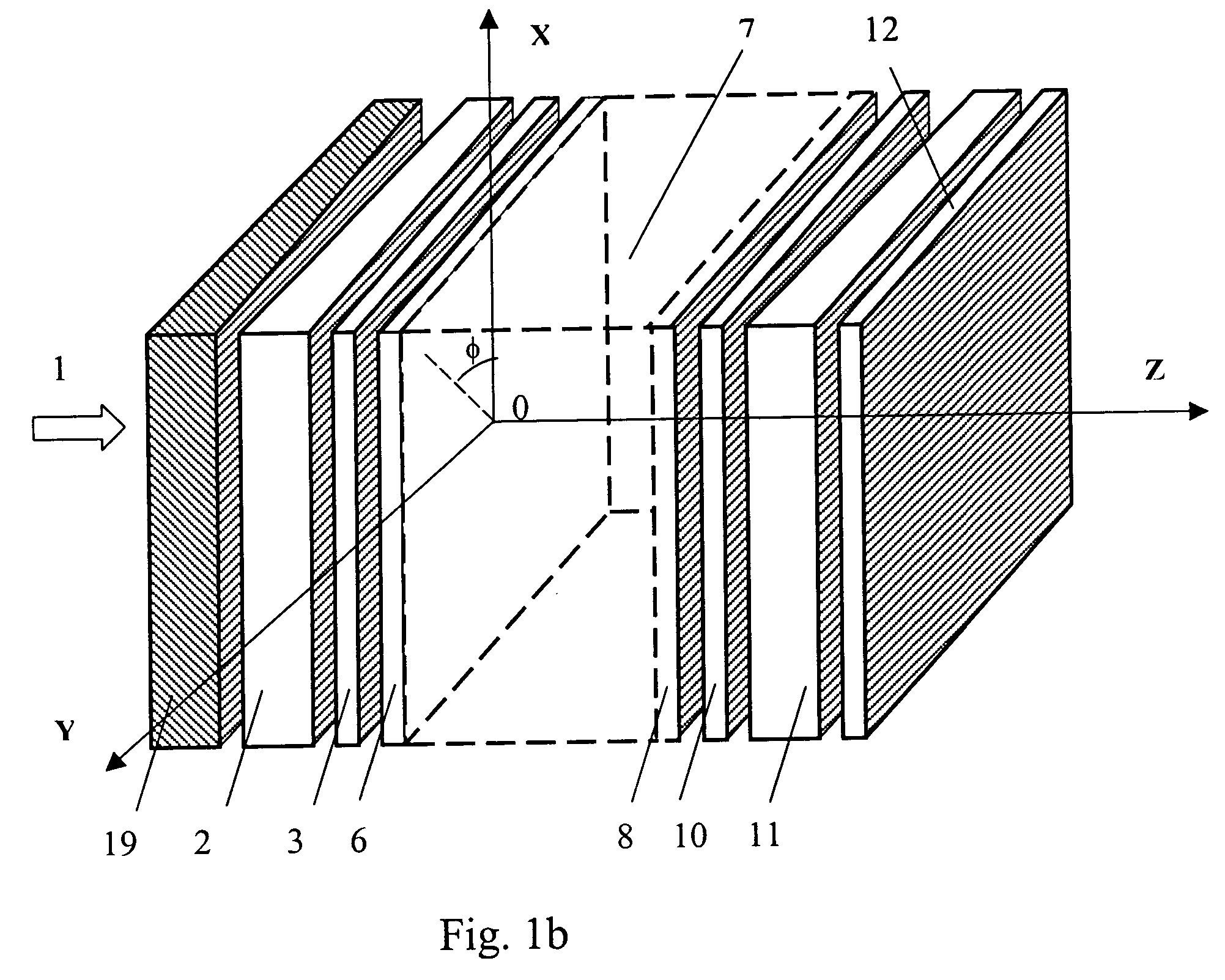

This invention generally relates to a liquid crystal device, and more particularly to such a device in the form of a liquid crystal cell such as for a display device, and further relates to a display device having the liquid crystal device, an optical waveguide device comprising the liquid crystal device, a Variable Optical Attenuator comprising the liquid crystal device, an optical switch comprising the liquid crystal device, a method of controlling transmission of polarised light, and to a further liquid crystal device. A liquid crystal device for controlling transmission of polarised light, comprising: chiral nematic liquid crystal having a helical arrangement of liquid crystal molecules in the absence of an electric field; and at least two electrodes for applying an electric field having a component normal to the helical axis of the chiral nematic liquid crystal, wherein the chiral nematic liquid crystal has negative dielectric anisotropy.

Owner:CAMBRIDGE ENTERPRISE LTD

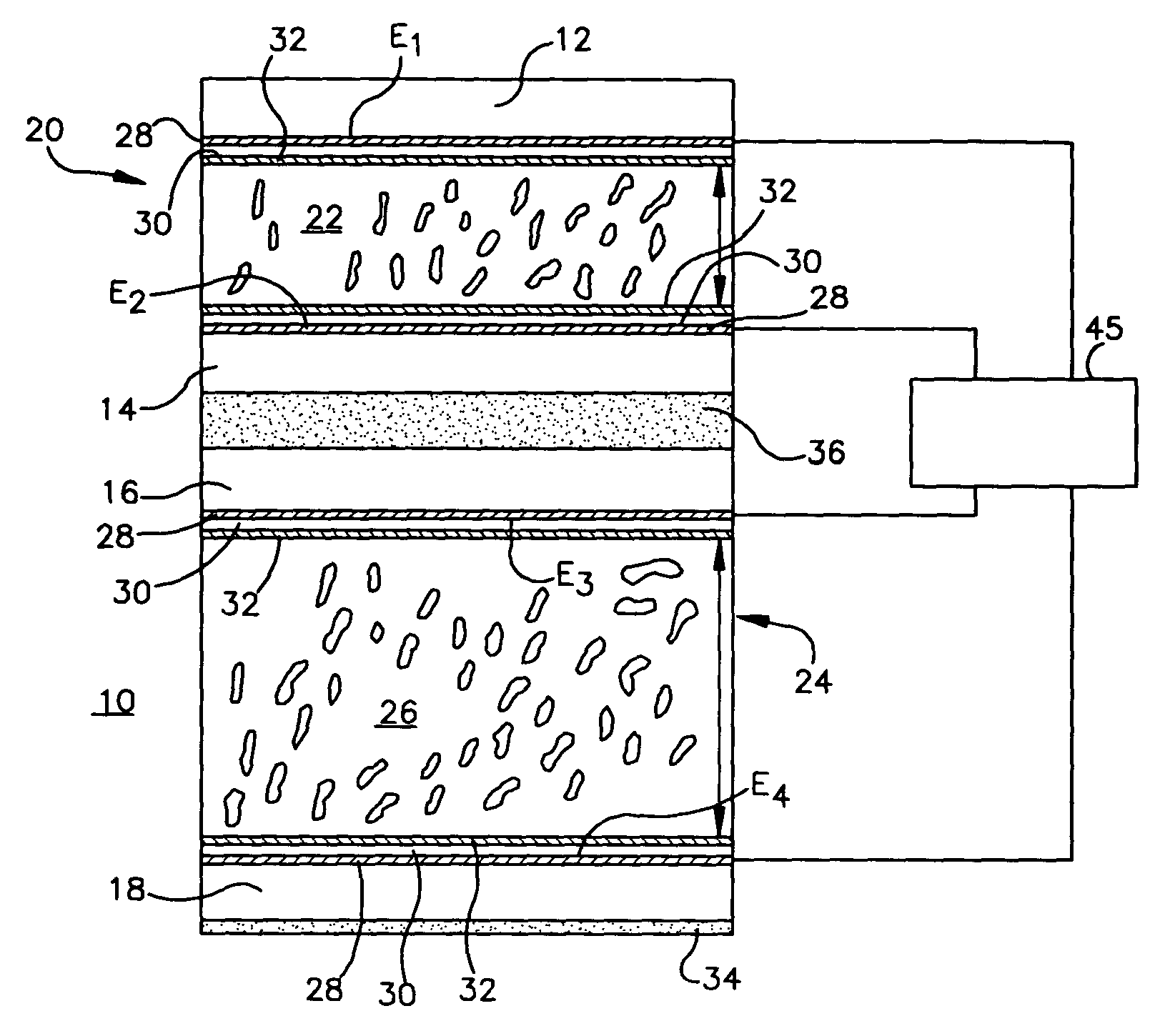

Stacked color liquid crystal display device

InactiveUS20050036077A1High bandwidthIncrease rangeLiquid crystal compositionsStatic indicating devicesDisplay devicePhotolithography

A liquid crystal display device includes cell wall structure and a chiral nematic liquid crystal material. The cell wall structure and the liquid crystal cooperate to form focal conic and twisted planar textures that are stable in the absence of a field. A device applies an electric field to the liquid crystal for transforming at least a portion of the material to at least one of the focal conic and twisted planar textures. The liquid crystal material has a pitch length effective to reflect radiation having a wavelength in both the visible and the infrared ranges of the electromagnetic spectrum at intensity that is sufficient for viewing by an observer. One liquid crystal material may be disposed in a single region or two or more liquid crystal materials may be used, each in separate regions even without the infrared reflecting layer. One aspect of the invention is directed to a photolithography method for patterning a substrate of the display. The display may also have multicolor capabilities by including separate layers of at least two or three liquid crystal materials that reflect visible light. A full color stacked display may be produced with grey scale capabilities.

Owner:KENT DISPLAY SYST

Multilayer laminates comprising chiral nematic liquid crystals

InactiveUS20090161061A1Lower energy requirementsEasy to useLiquid crystal compositionsGlass/slag layered productsCrystallographyChiral nematic liquid crystal

Provided are multilayer laminates having one or more layers comprising twisted nematic liquid crystals and one or more layers of a polymeric sheet. The twisted nematic liquid crystal layers reflect infrared radiation. Thus, the multilayer laminates are useful to reduce the transmission of infrared energy. For example, in some embodiments the multilayer laminates are useful as windows to reduce energy consumption necessary to cool the interior of a structure such as an automobile or building. Preferably, the multilayer laminates retain one or more of the beneficial properties of safety glass. The multilayer laminates may include additional layers such as infrared absorbing layers, half wave plates, and the like, to minimize the transmission of infrared energy. The multilayer laminates may also include further additional layers such as polymeric films, polymeric sheets, rigid sheets, and the like.

Owner:EI DU PONT DE NEMOURS & CO

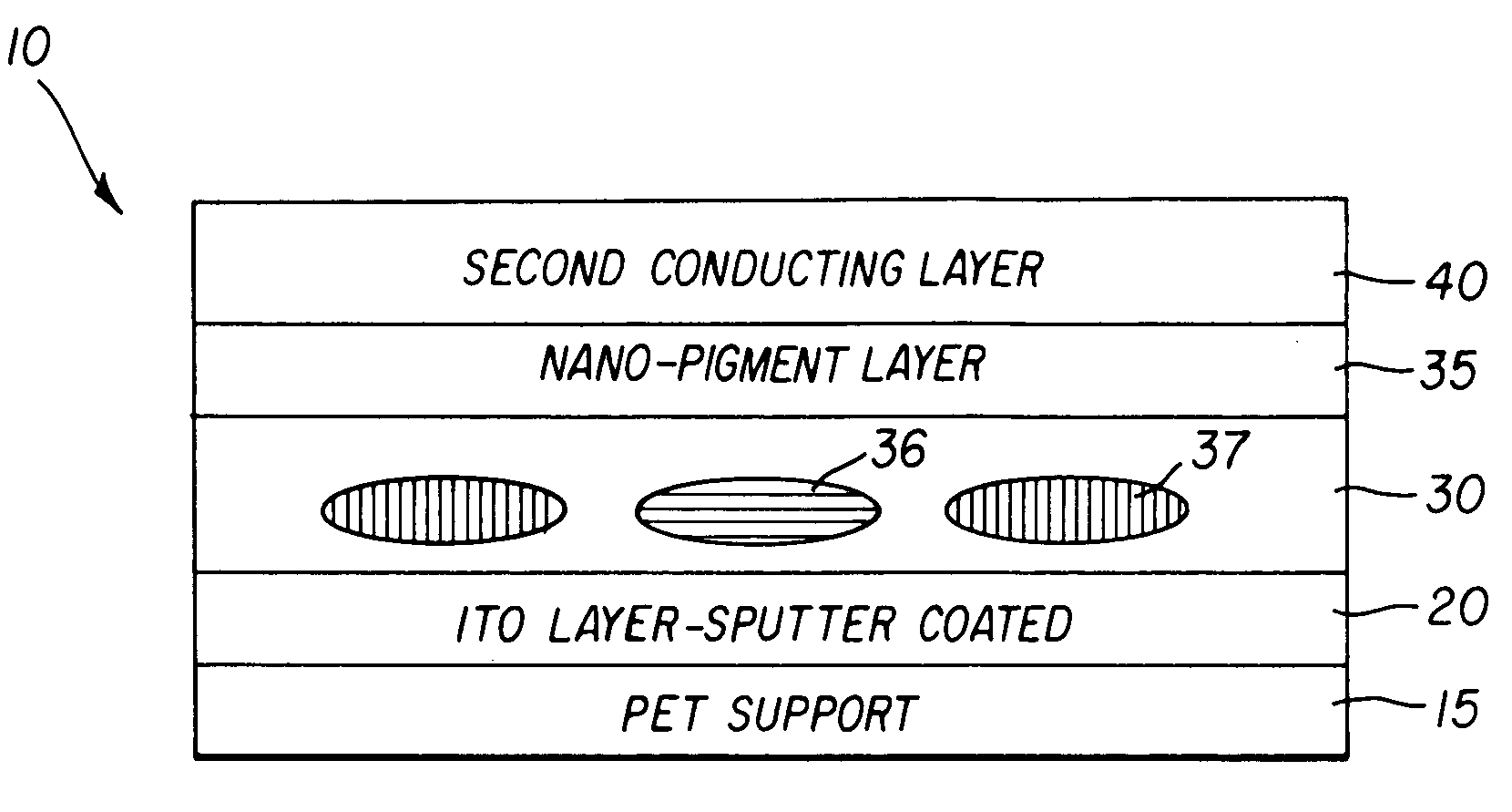

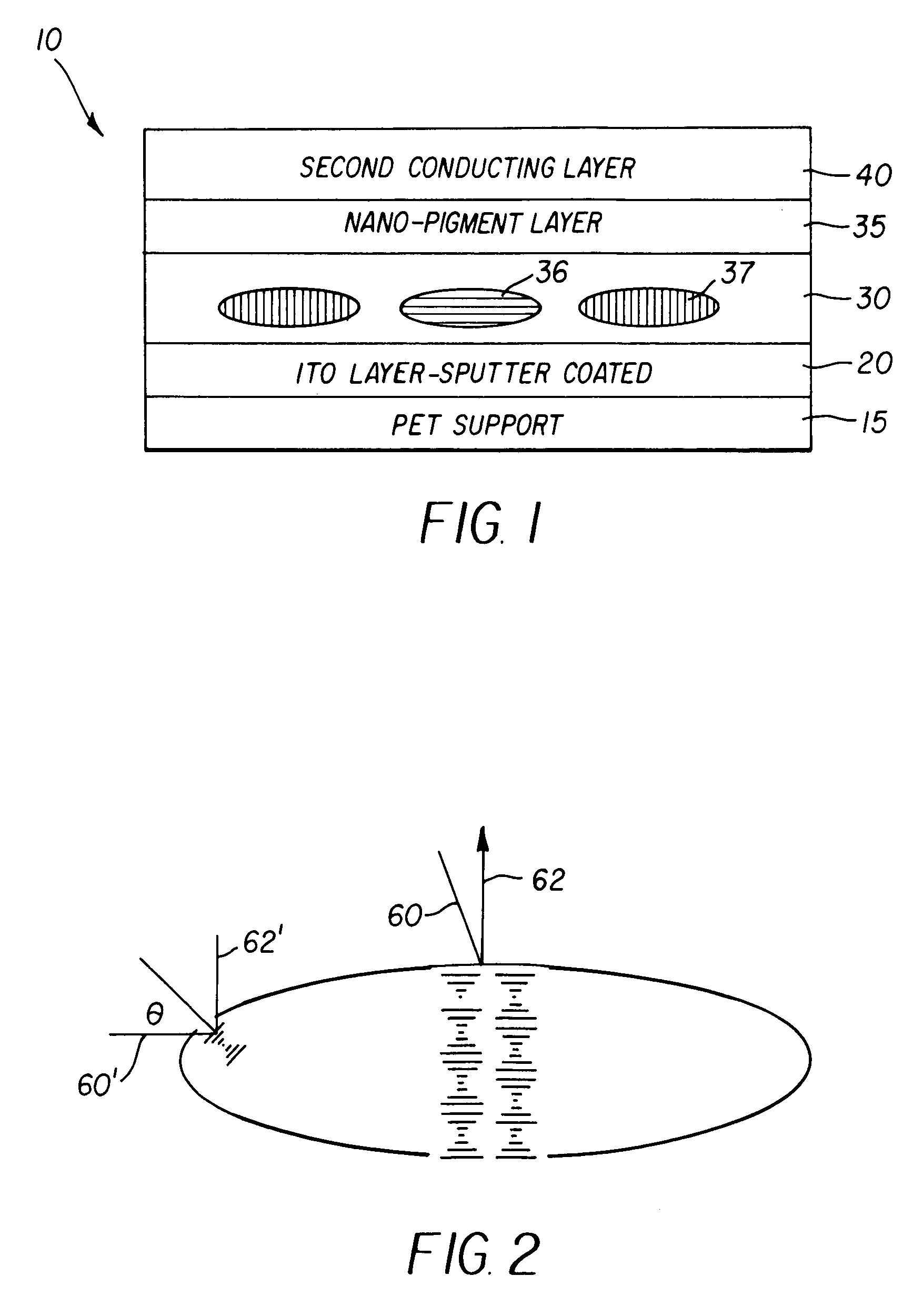

Reflective chiral-nematic liquid crystal display with broadband reflection

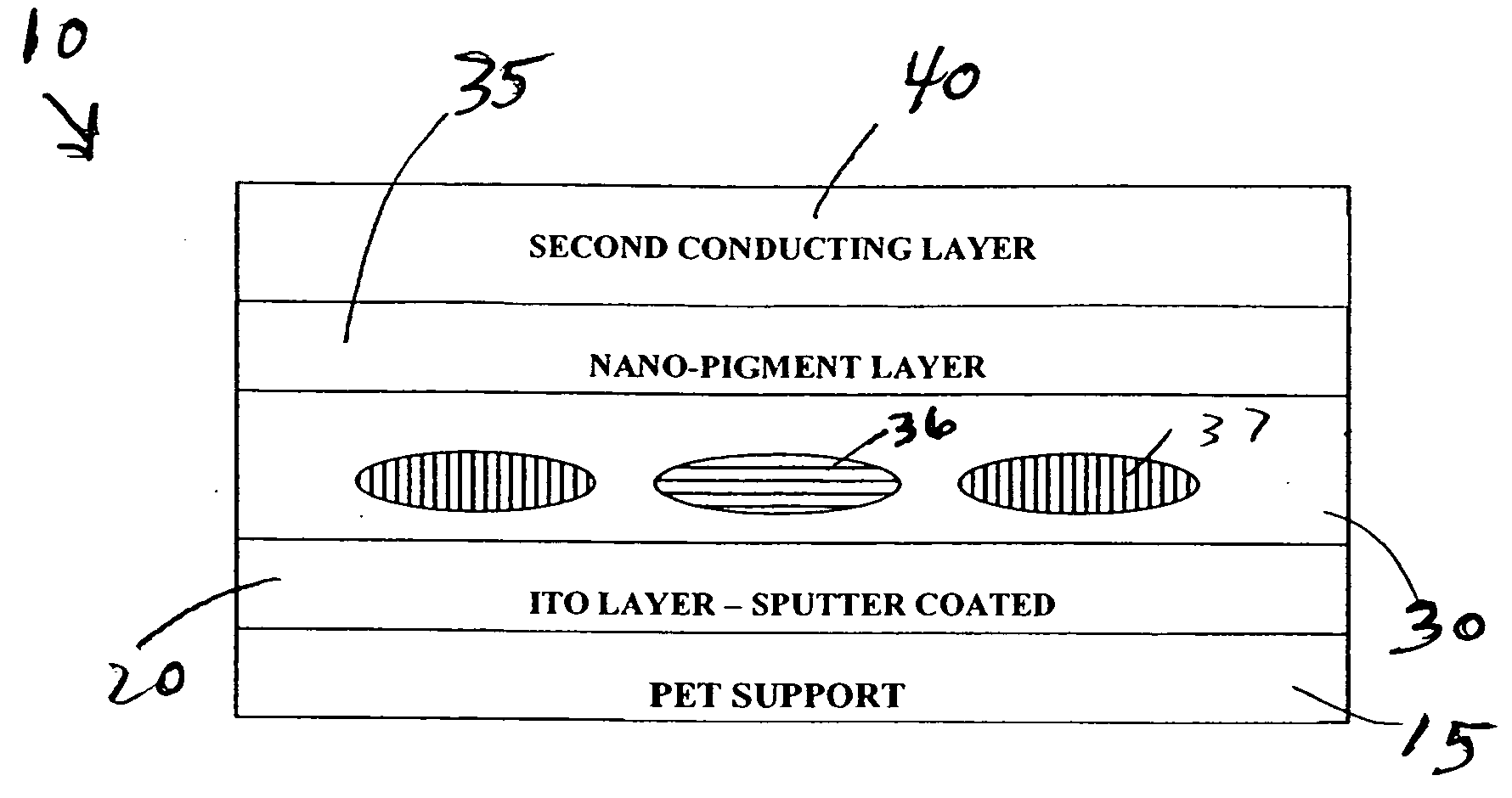

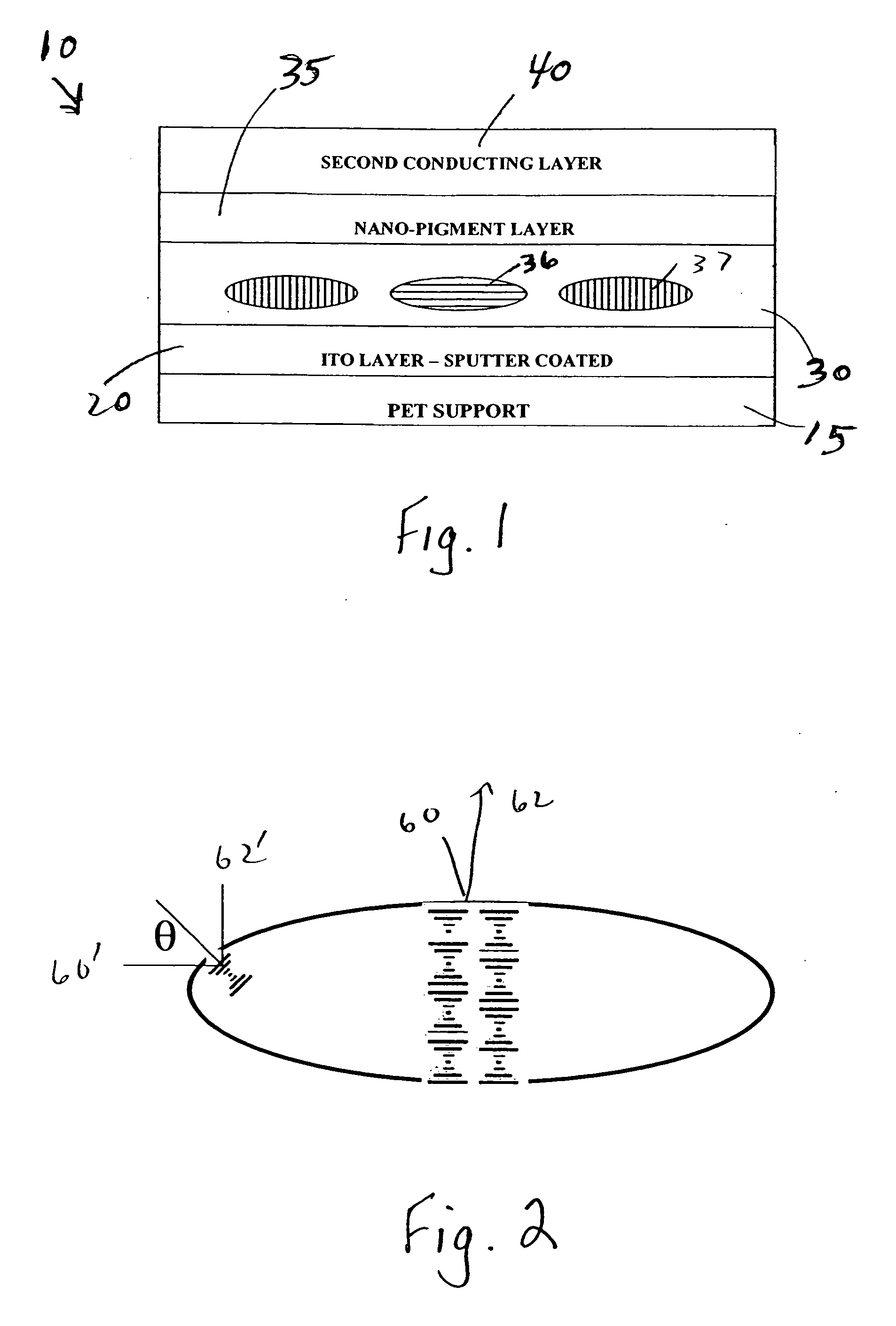

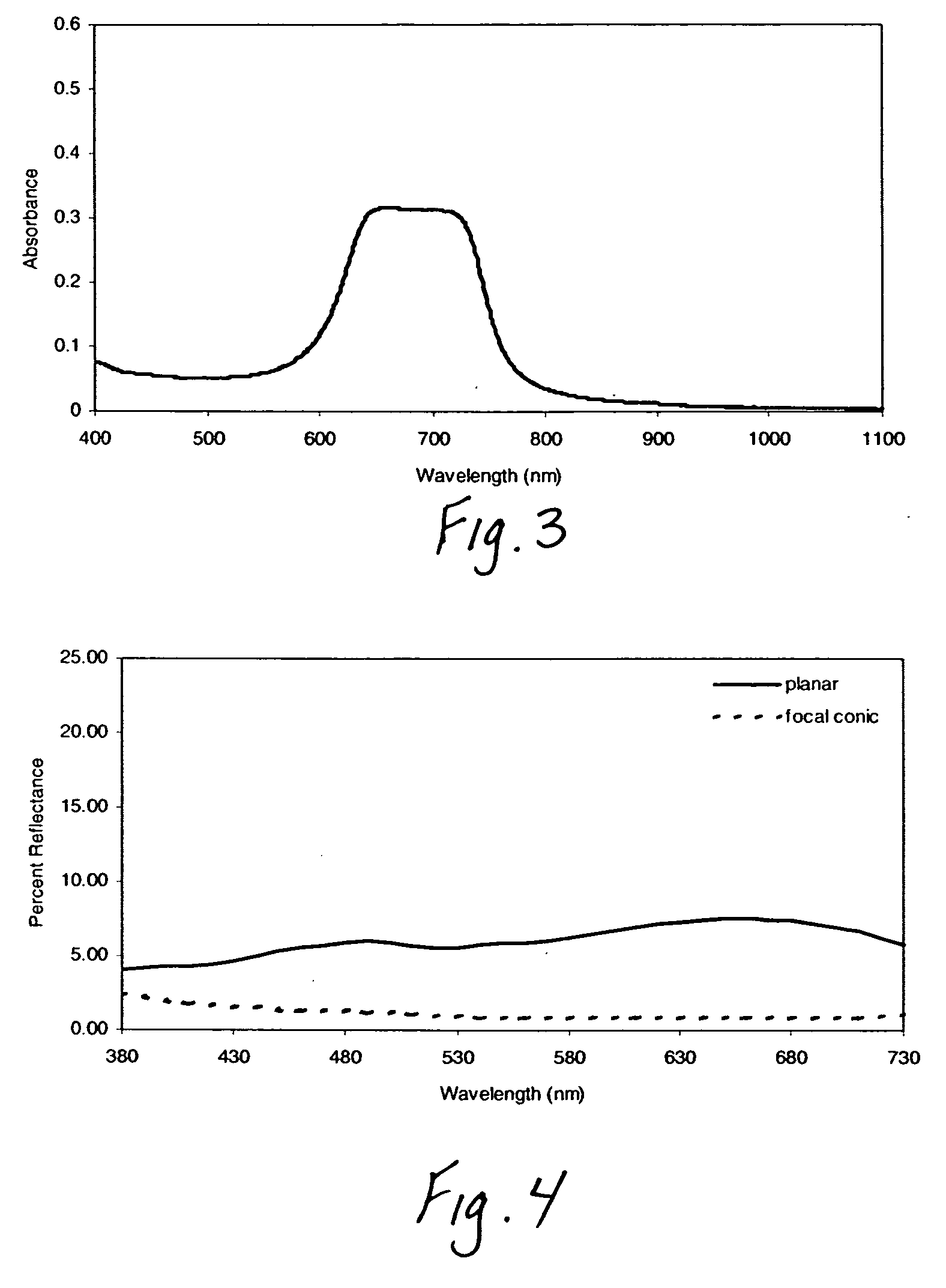

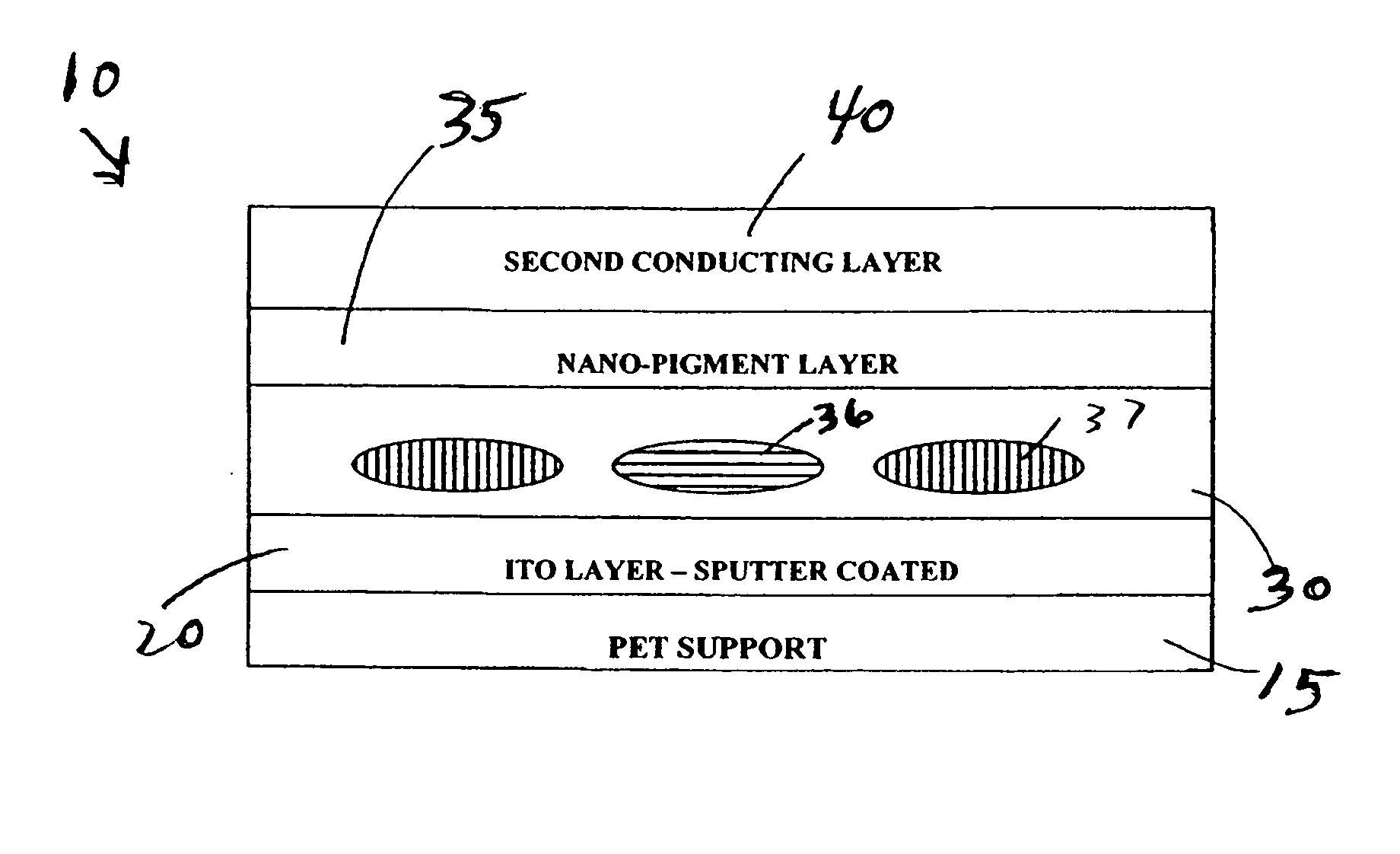

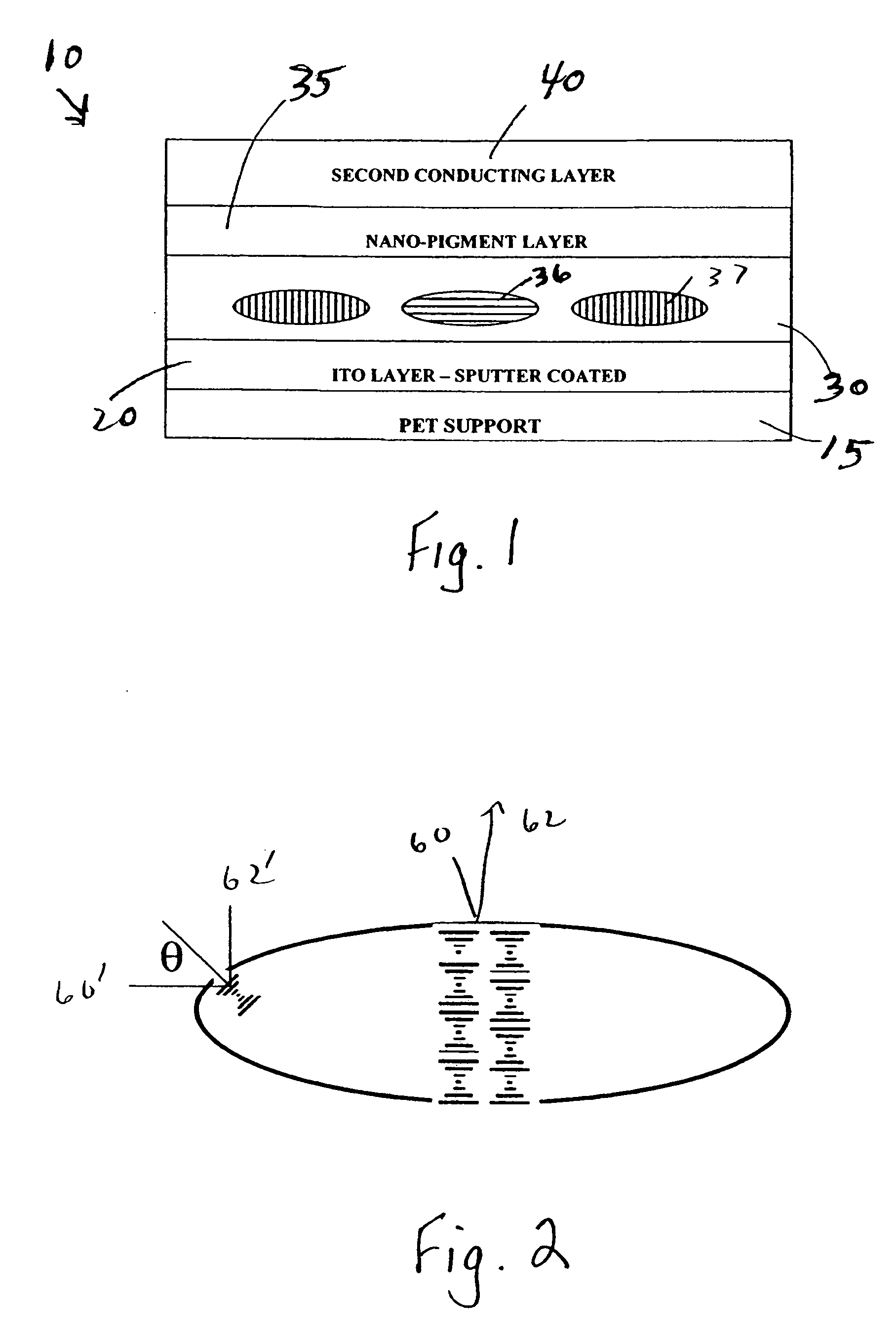

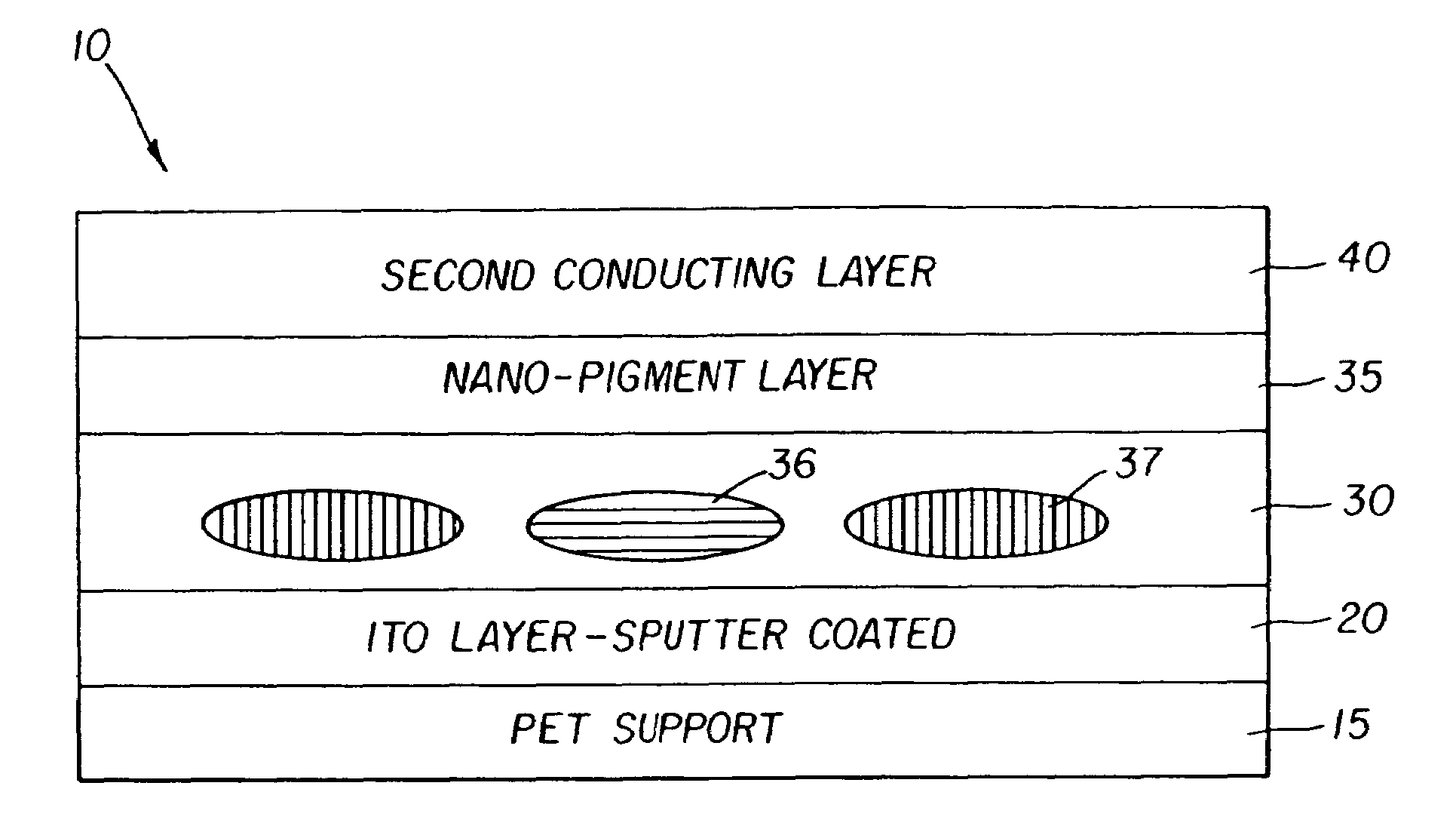

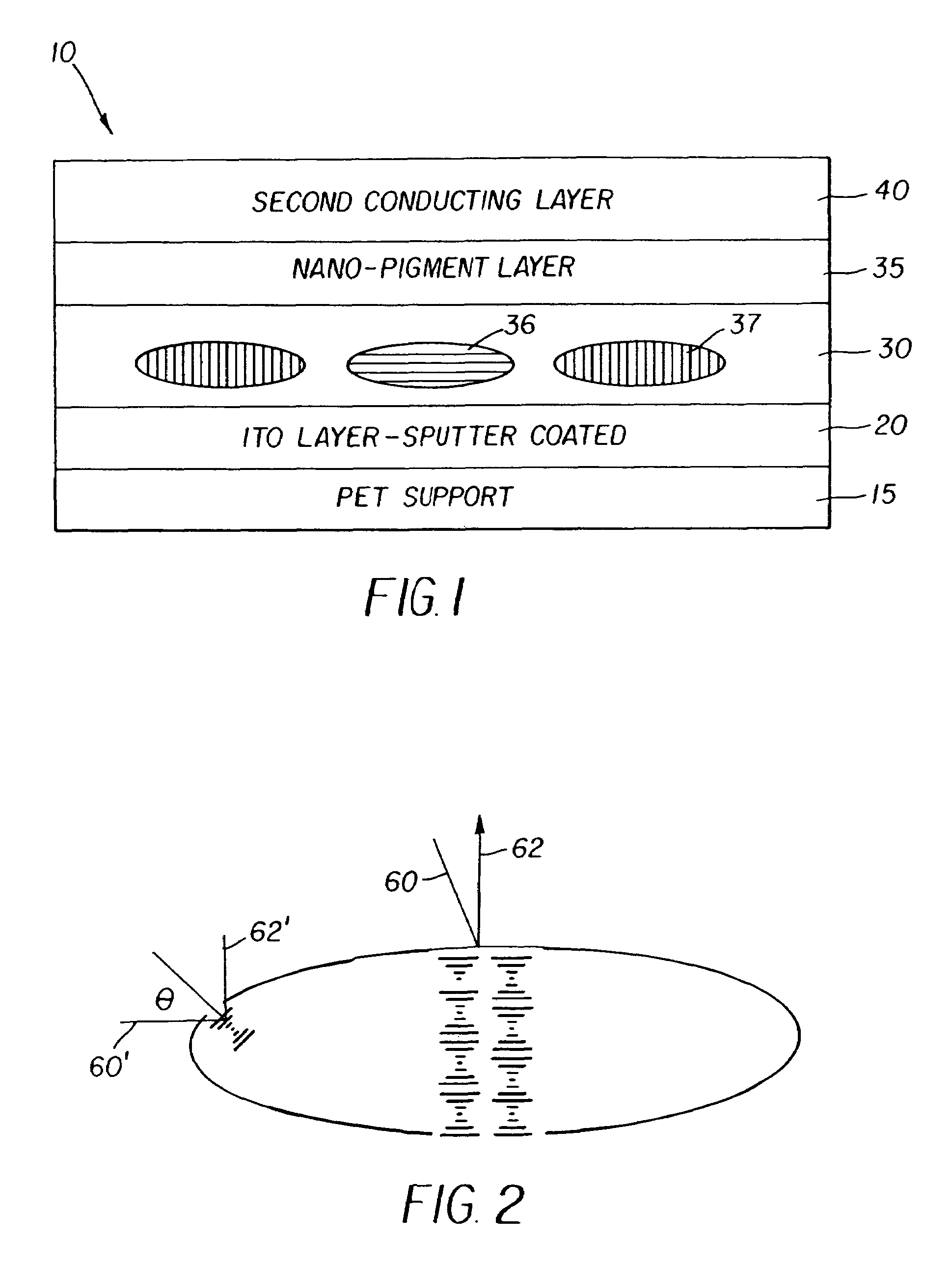

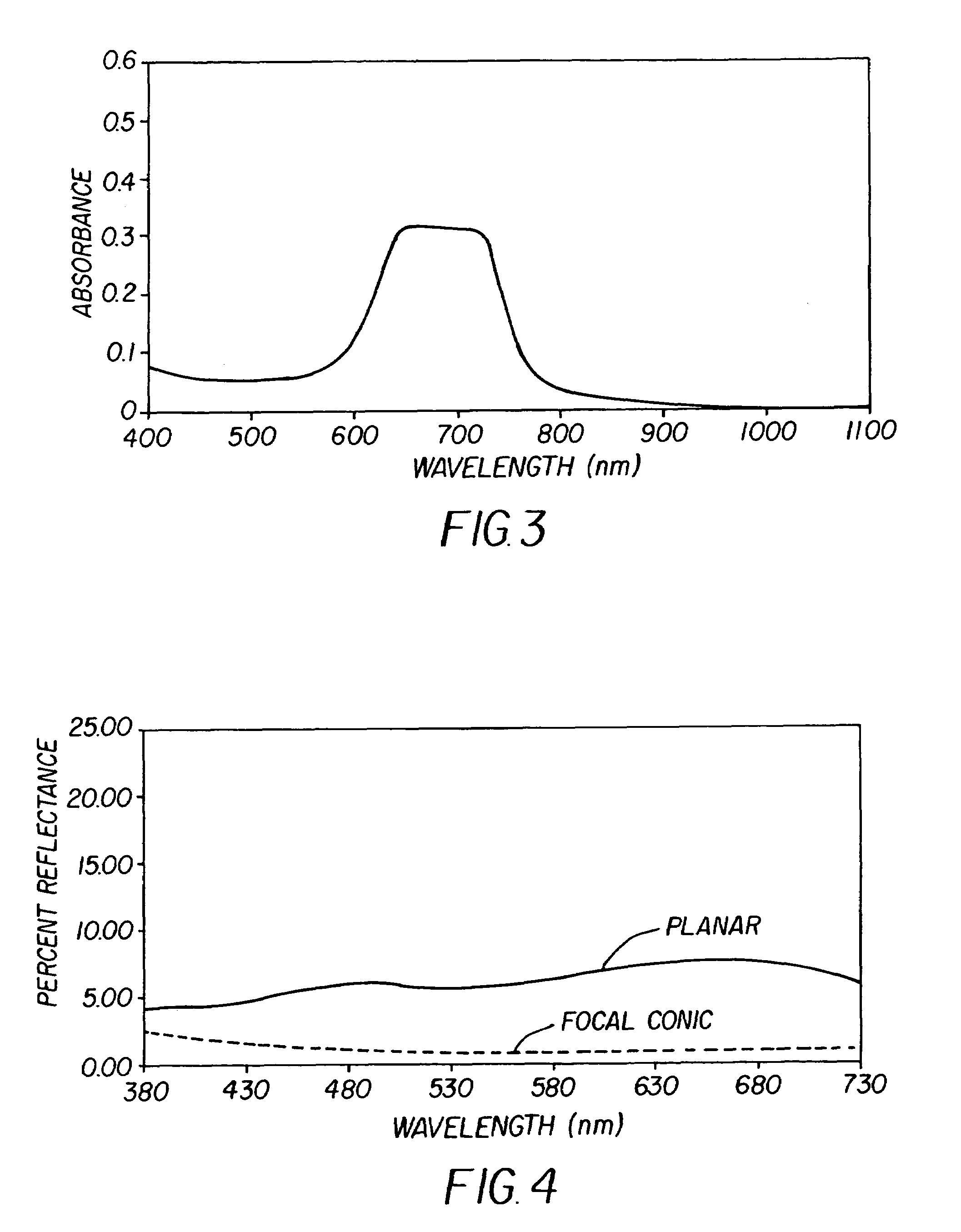

ActiveUS20050110925A1Good colorIncrease dependenceLiquid crystal compositionsNon-linear opticsDisplay boardElectrical conductor

A display sheet comprising a substrate carrying layers of material; including a polymer-dispersed chiral-nematic liquid-crystal layer having a first high reflection state within the visible light spectrum and a second less-reflective state in said spectrum, said states being changeable by an electric field, which states can be maintained in the absence of an electric field; a first transparent conductor disposed over said polymer-dispersed chiral-nematic liquid-crystal layer; and a second conductor, wherein said imaging layer is substantially a monolayer of said domains comprises a mixture of at least two differently reflecting liquid crystal materials, in which the λ maximums of the two materials are separated by 100 to 250 nm.

Owner:IRIS OPTRONICS CO LTD

Liquid crystal display and method for producing the same

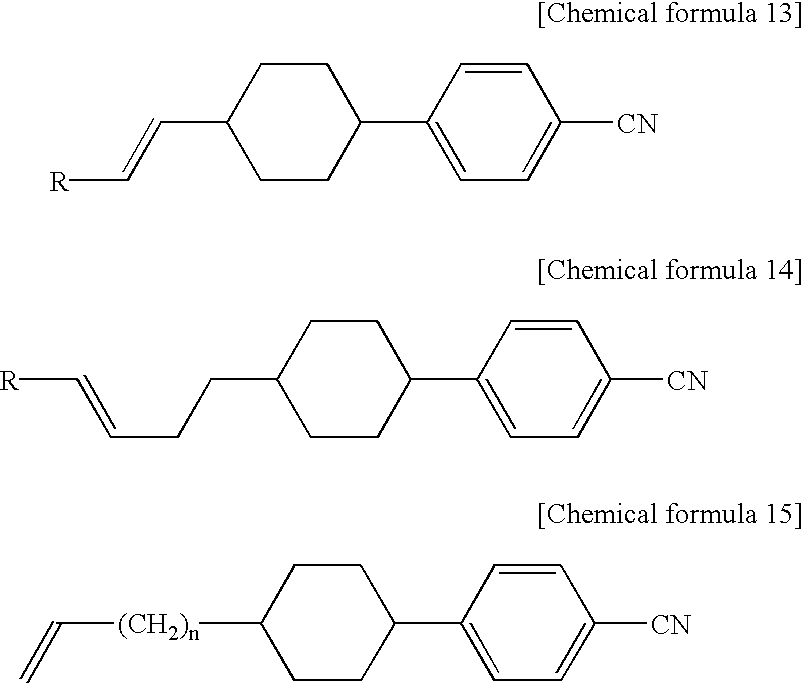

The invention provides a liquid crystal display having high reliability, which is excellent in terms of optical characteristics, heat resistance, and shock resistance, wherein a liquid crystal display consisting of a cholesteric liquid crystal, a chiral nematic liquid crystal or a liquid crystal 1 layer, being a combination thereof, which is roughly pillar-like and polygonal in section or has a roughly pillar-like form enclosed by a closed curve, and divided by said polymer network into areas whose minimum diameter measured by vernier calipers is 5 mum and whose maximum diameter measured by vernier calipers is 100 mum, is obtained by polymer networks 4 formed by polymerization of monomer, so that sufficient reflection can be obtained from the liquid crystal 1 without being optical scattering. Although the perpendicular array of the helical axes of liquid crystal 1 is slightly disordered by a polymer network 4 with respect to the plane of a pair of ITO 2a, 2b and substrates 3a,3b, wherein since almost all light entering from the substrata 3a side is reflected backwards (substrate 3a side) by Bragg's reflection, it is possible to decrease the visual angle dependency in comparison with a prior art liquid crystal display not containing any polymer constituents, and networks 4 which have been greatly established form intensive pillars (macromolcular resin walls), thereby improving the shock resistance properties.

Owner:NANOX

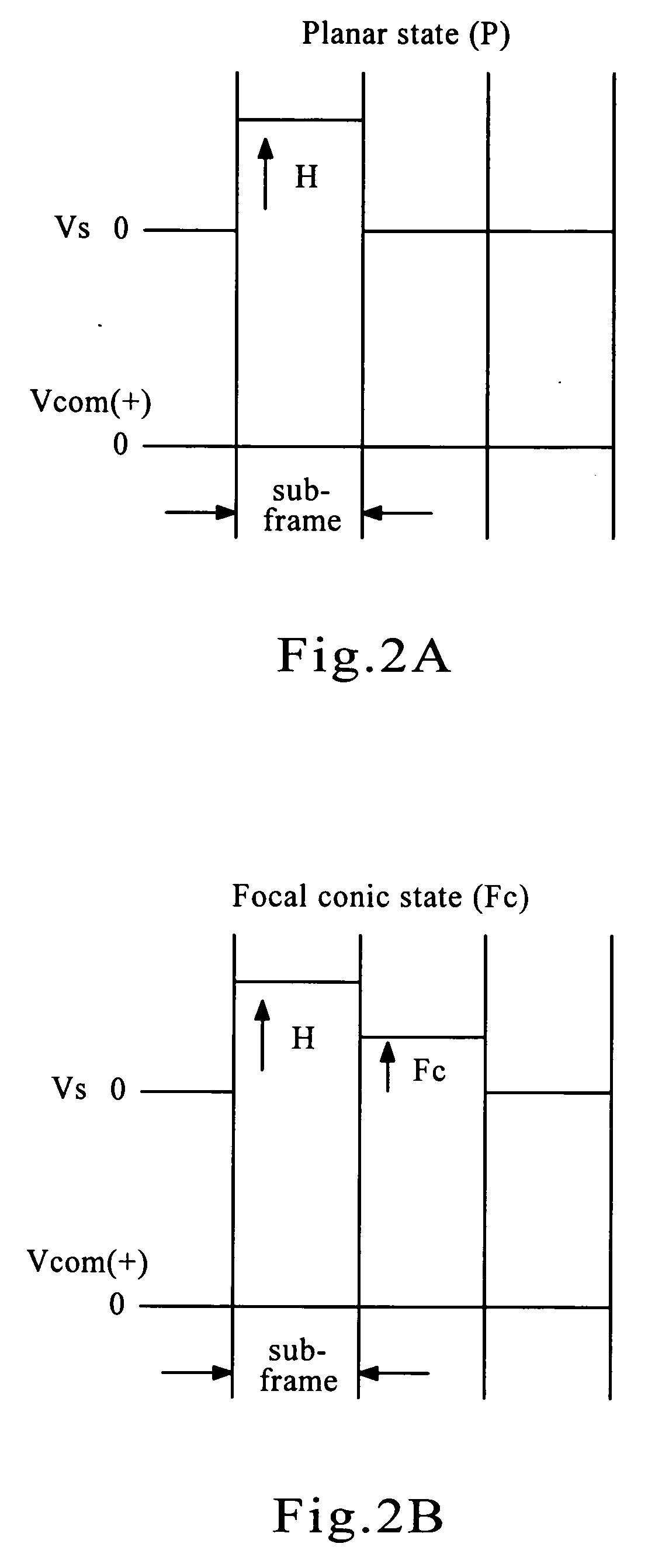

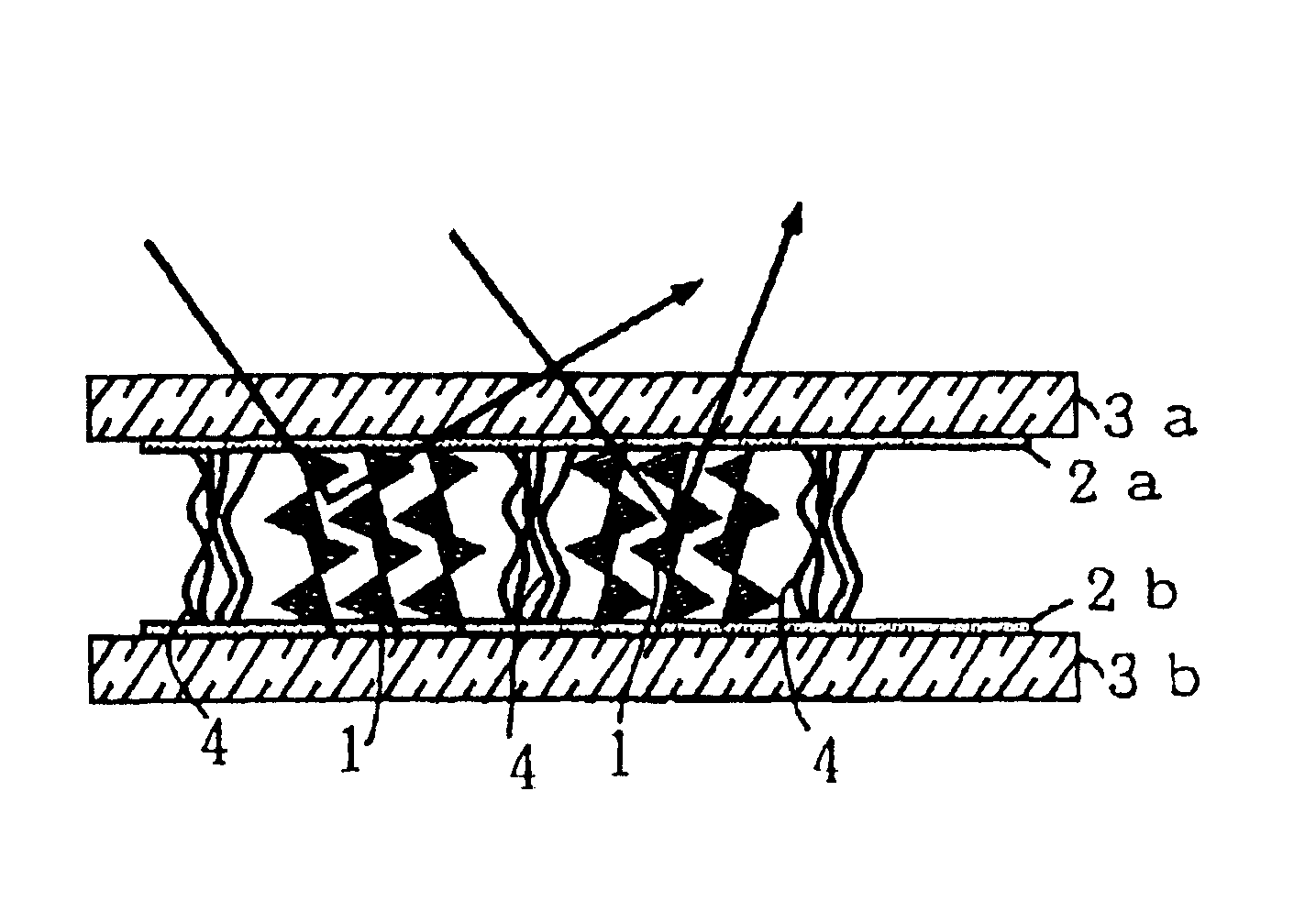

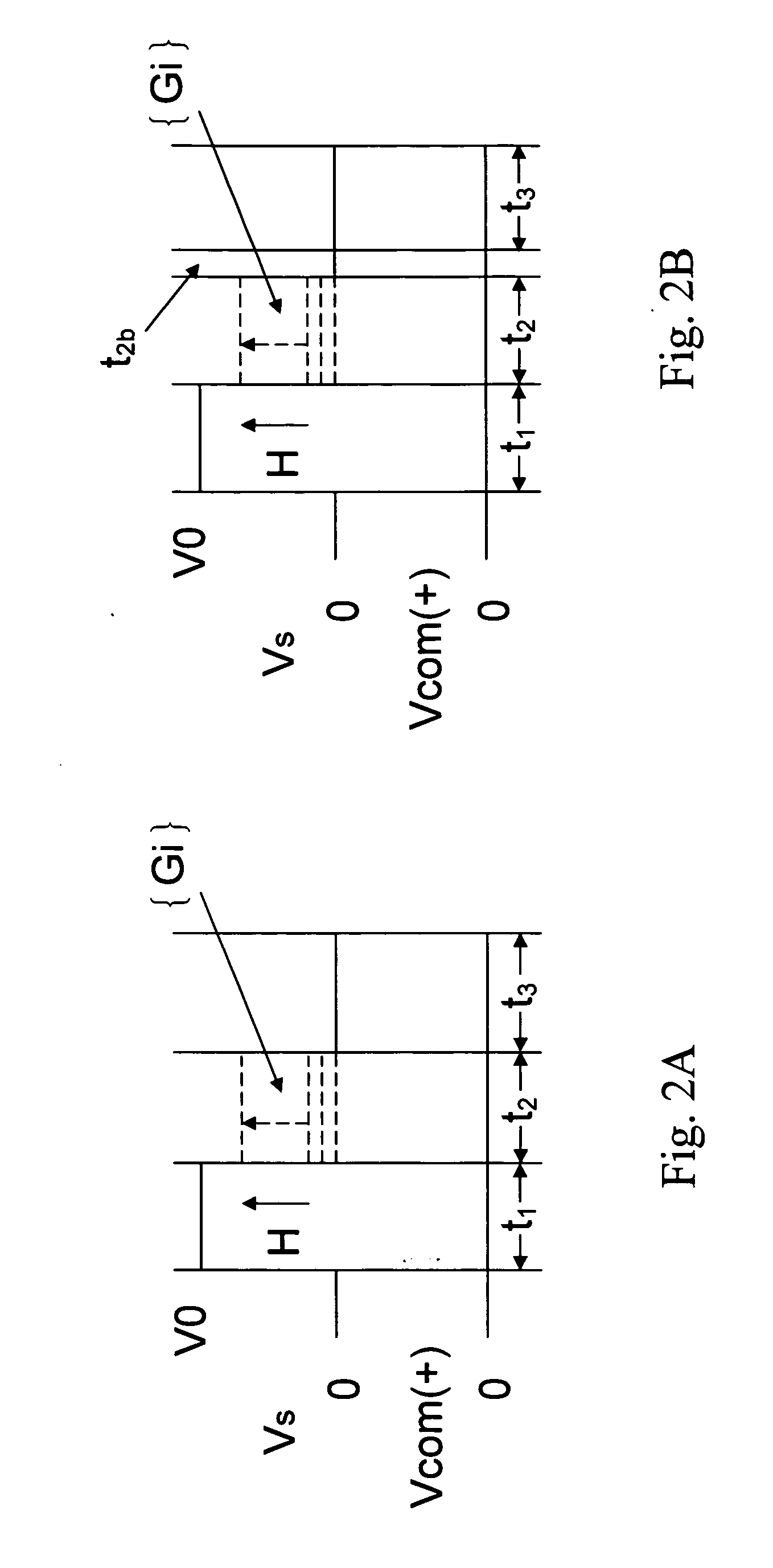

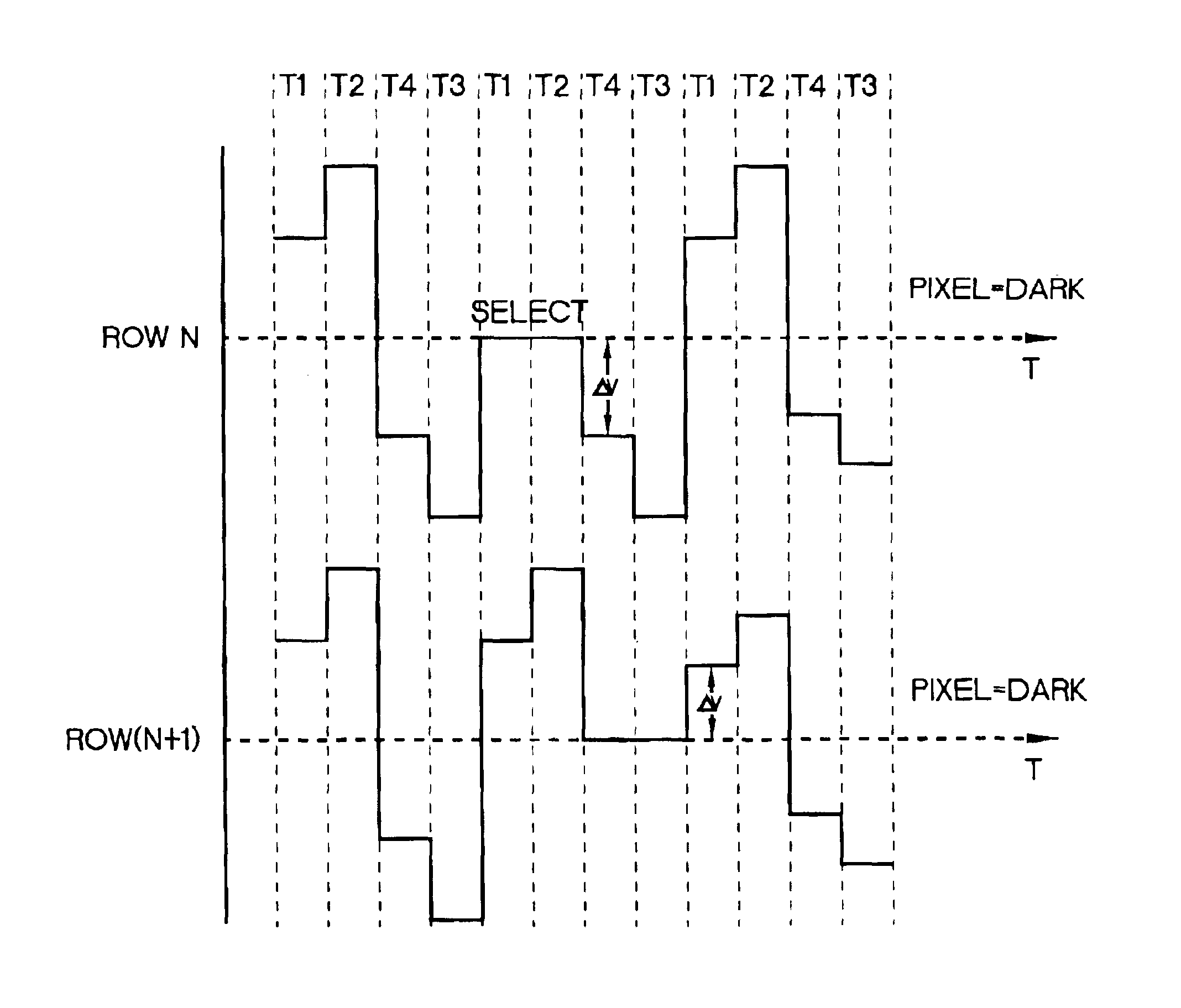

Gray-scale driving method for bistable chiral nematic liquid crystal display

InactiveUS20070075949A1High resolutionReduce driving timeStatic indicating devicesStable statePresent method

A gray-scale driving method for a bi-stable chiral nematic liquid crystal display is provided. The present method divides an updated picture into a first-section frame, a second-section frame and a third-section frame. The present invented method includes to drive the first-section frame into a predetermined initial state, and drive the second-section frame by line-by-line scanning by writing updated gray-scale frame data into the pixels, then pull the third-section frame to zero voltage for the pixels such that bi-stable chiral nematic liquid crystal relaxes to stable states corresponding to the write-in gray-scale frame data. Meanwhile, a purpose to maintain the updated picture without any consumption of power is obtained. The total power consumption can be significantly reduced.

Owner:IND TECH RES INST

Contrast chiral nematic liquid crystal displays

ActiveUS7119859B2Improvement in contrast and in purity of its reflected colorNon-linear opticsElectrical conductorLiquid-crystal display

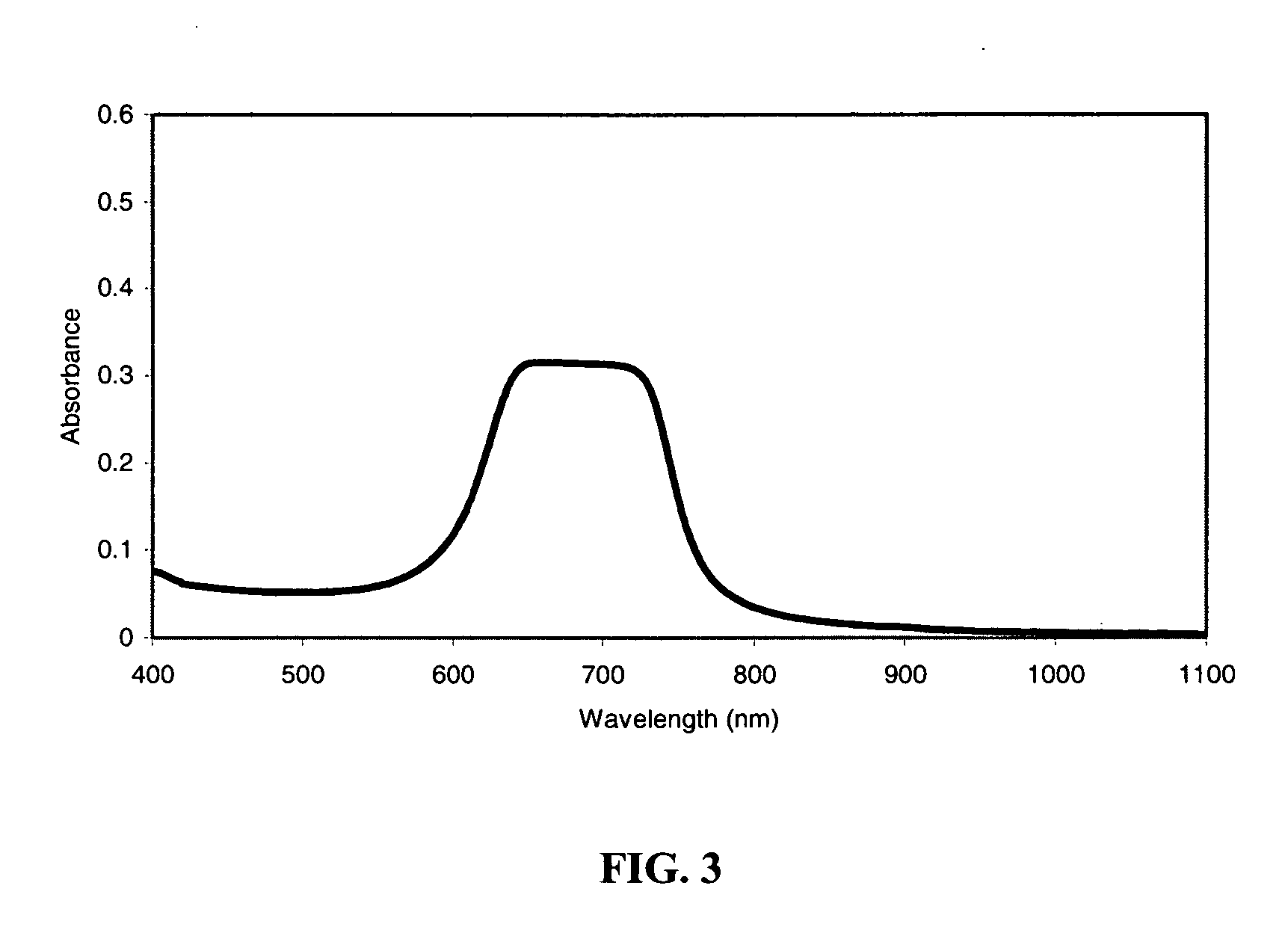

The present invention relates to a bistable polymer dispersed liquid crystal display comprising a support, at least one patterned first conductor layer having thereon at least one dried imaging layer comprising a substantial monolayer of isolated domains of liquid crystal material dispersed in a continuous polymer matrix, wherein said dried imaging layer further comprises at least one absorber colorant, and wherein said isolated domains have a size distribution such that the coefficient of variation (cv) is less than 0.35.

Owner:HKC CORP LTD

Color liquid crystal display device

InactiveUS20050248714A1Improve color displayInhibition of temperature dependenceLiquid crystal compositionsNon-linear opticsLiquid-crystal displayEngineering

A color liquid crystal display device includes a pair of oppositely disposed substrates each of which is provided with an electrode and has been subjected to homeotropic alignment treatment, and chiral nematic liquid crystal disposed between the pair of oppositely disposed substrates. The chiral nematic liquid crystal is capable of causing birefringence leading to a change in brightness and a change in hue depending on a voltage applied between the electrodes. The liquid crystal is twistedly aligned under electric field application to change a twisted angle, so that a fluctuation in birefringence with temperature is compensated.

Owner:CANON KK

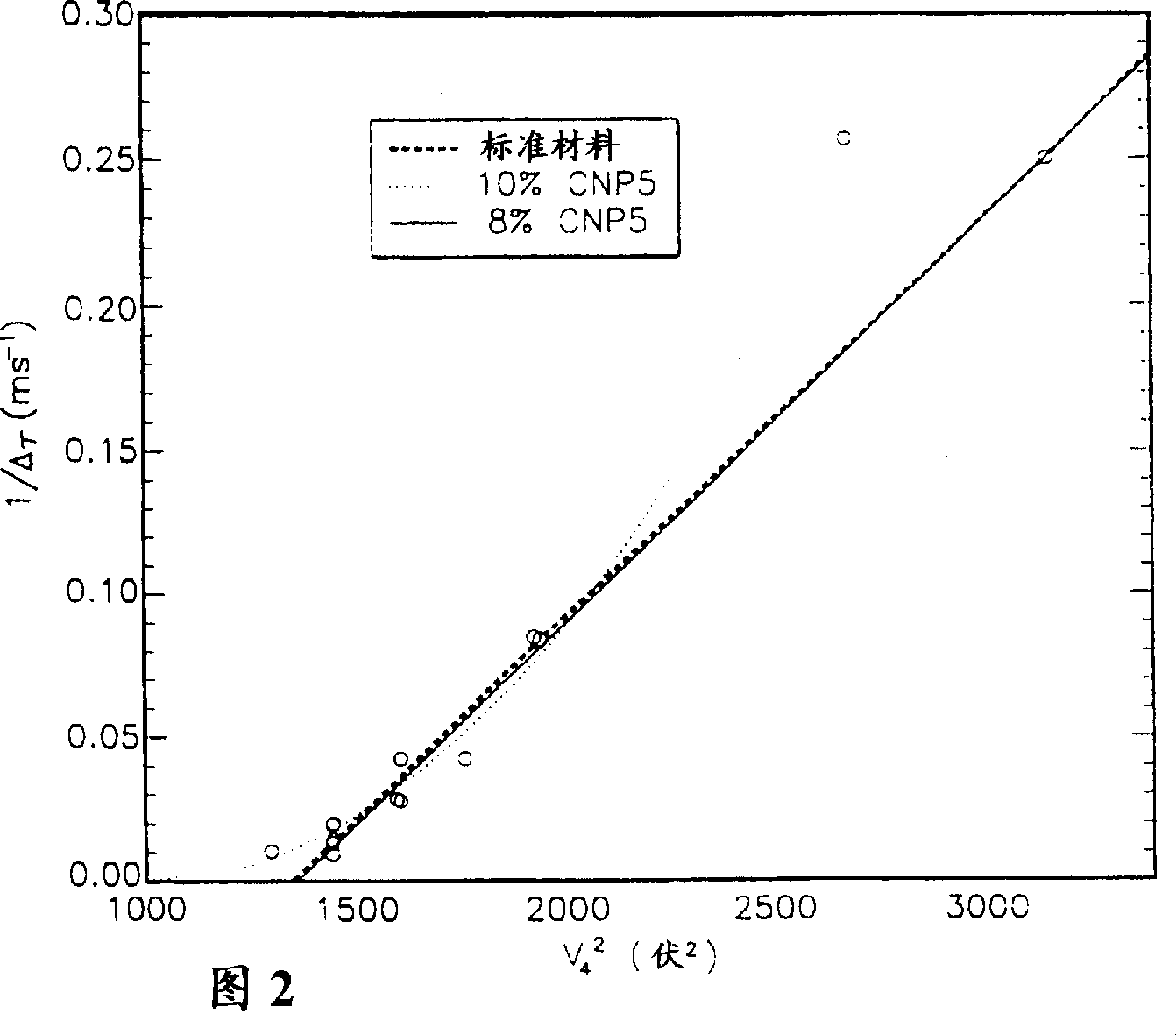

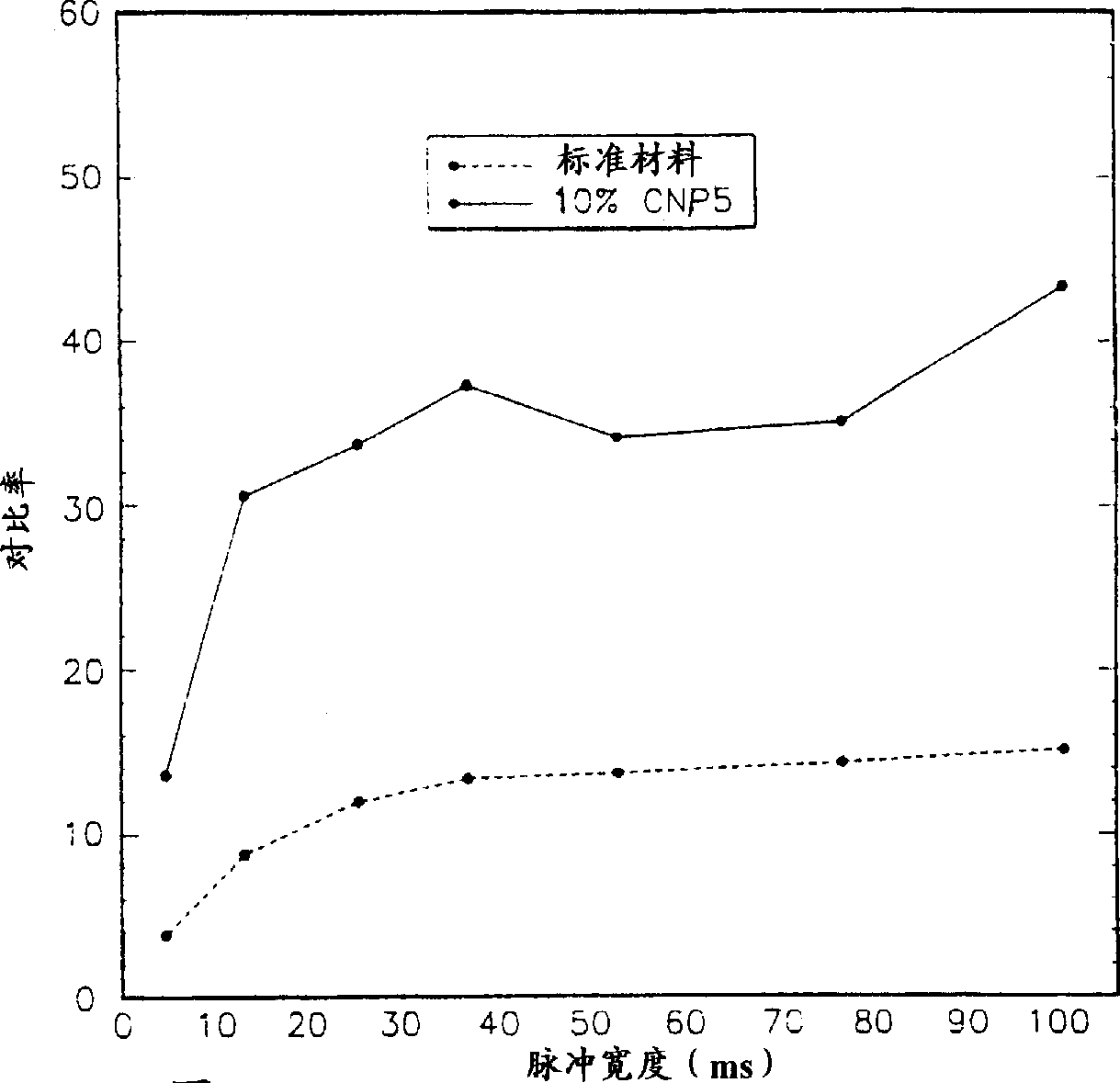

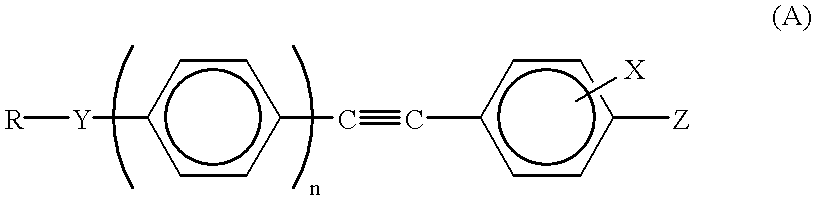

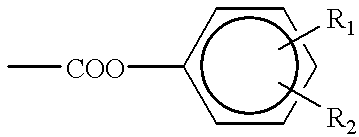

Low viscosity liquid crystal material

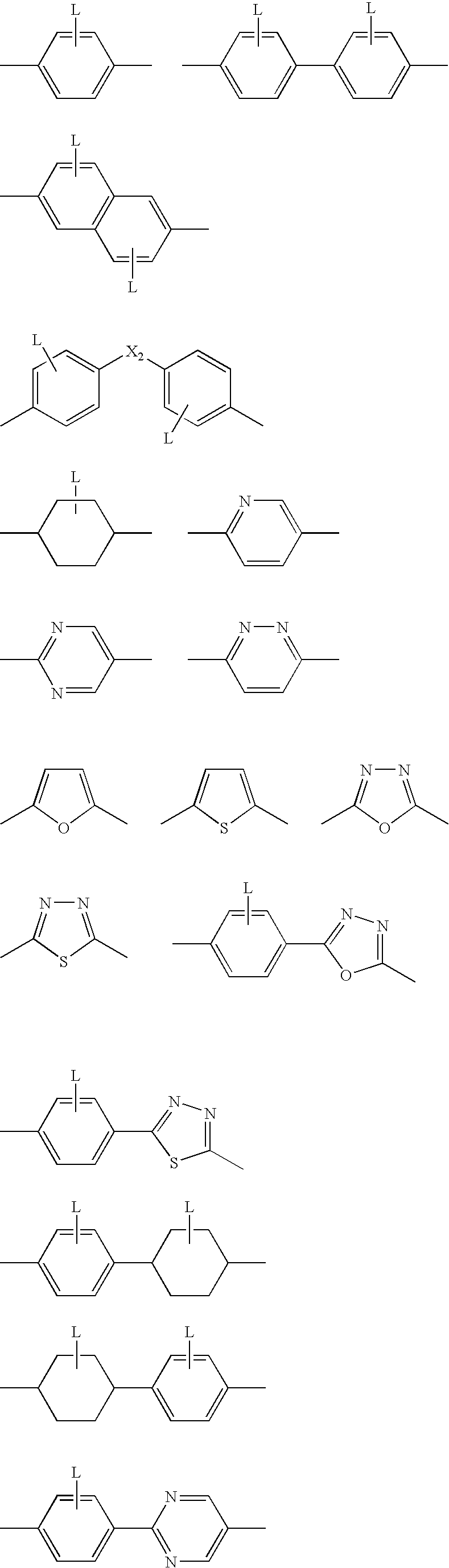

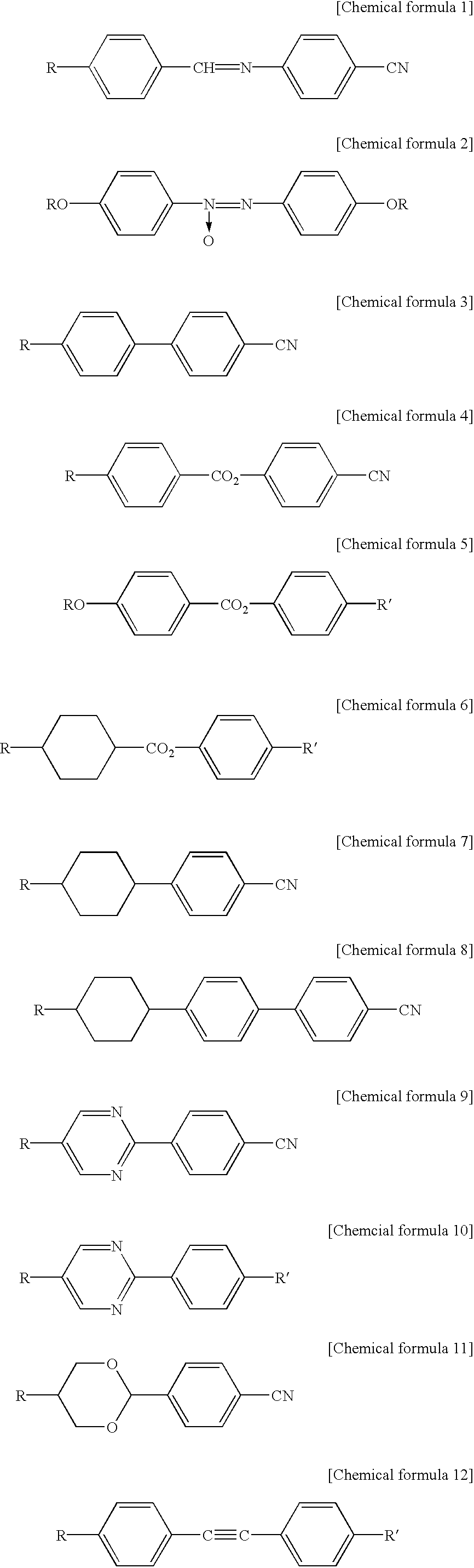

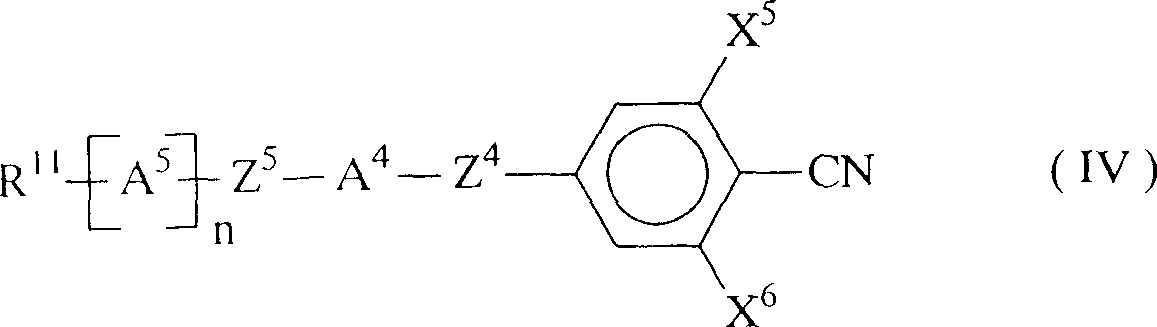

InactiveCN1257532AReduce bulk viscosityLow viscosityLiquid crystal compositionsStatic indicating devicesLiquid crystallineDielectric anisotropy

A liquid crystal material for a display device includes a first chiral nematic liquid crystal component and a second component that exhibits no liquid crystalline phase at any temperature. The second component is present in an amount effective to reduce the bulk viscosity of the liquid crystal material by at least about 26 % at room temperature or is present in an amount of at least about 5 % by weight based upon the total weight of the liquid crystal material. The liquid crystal material may have a positive dielectric anisotropy. The second component may have a molecular weight not exceeding 205 grams / mole. Embodiments relate to a display device comprising the present material. Another aspect includes a method of increasing the switching speed in a display that employs the present material.

Owner:KENT DISPLAY SYST

Liquid crystal display apparatus

InactiveUS20050174317A1Simple processHigh-accuracy displayLiquid crystal compositionsStatic indicating devicesLiquid-crystal displayVoltage pulse

A liquid crystal display apparatus which have a circular polarizer and a liquid crystal display in a stack. The liquid crystal display has a chilral nematic liquid crystal layer between substrates, and on the mutually opposite sides of the substrates, electrodes and aligning layers are formed. The liquid crystal switches between a planar alignment state and a focal-conic alignment state depending on the voltage applied thereto through the electrodes. In a planar state, light reflected by the electrodes is absorbed by the circular polarizer, and a black display is made. In a focal-conic state, light reflected by the electrodes passes through the circular polarizer, and a white display is made. The liquid crystal is driven by a chain of voltage pulses including a reset step of resetting the liquid crystal to a homeotropic state, a selection step of selecting the alignment state of the liquid crystal under zero-volt application and an evolution step of causing the liquid crystal to evolve to the selected alignment state.

Owner:KONICA MINOLTA INC

Contrast chiral nematic liquid crystal displays

ActiveUS20050270441A1Increase contrastImprovement in contrast and in purity of its reflected colorNon-linear opticsElectrical conductorLiquid-crystal display

The present invention relates to a bistable polymer dispersed liquid crystal display comprising a support, at least one patterned first conductor layer having thereon at least one dried imaging layer comprising a substantial monolayer of isolated domains of liquid crystal material dispersed in a continuous polymer matrix, wherein said dried imaging layer further comprises at least one absorber colorant, and wherein said isolated domains have a size distribution such that the coefficient of variation (cv) is less than 0.35.

Owner:HKC CORP LTD

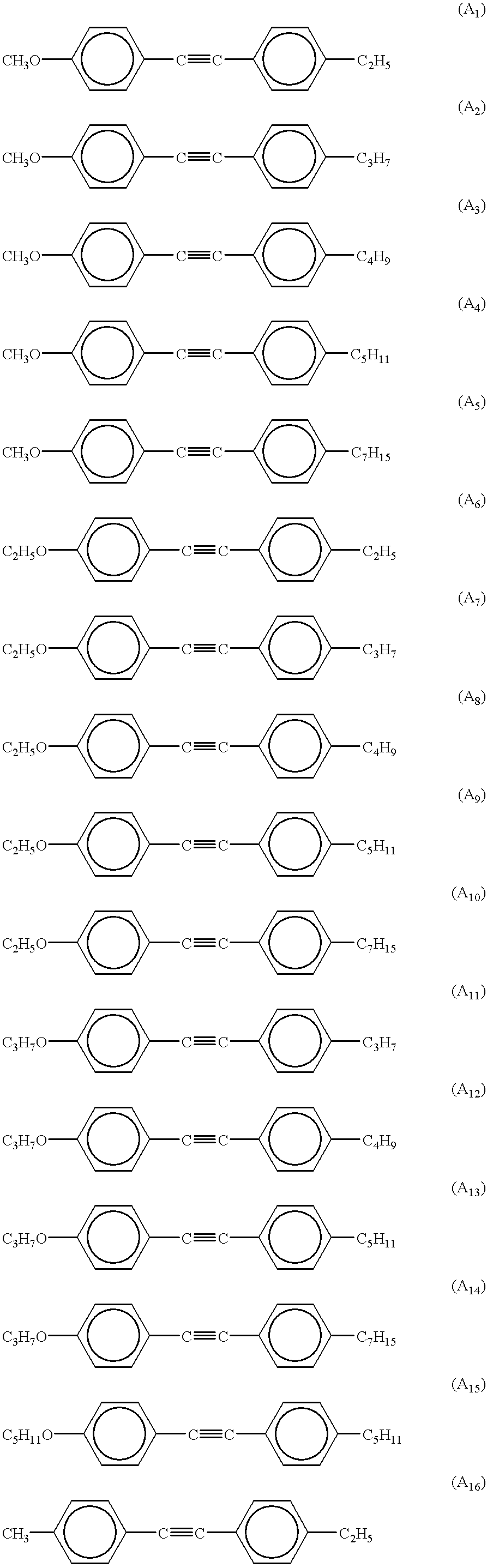

Liquid crystal display device and its production method

InactiveUS6924873B2Quick responseLiquid crystal compositionsNon-linear opticsPolymerCholesteric liquid crystal

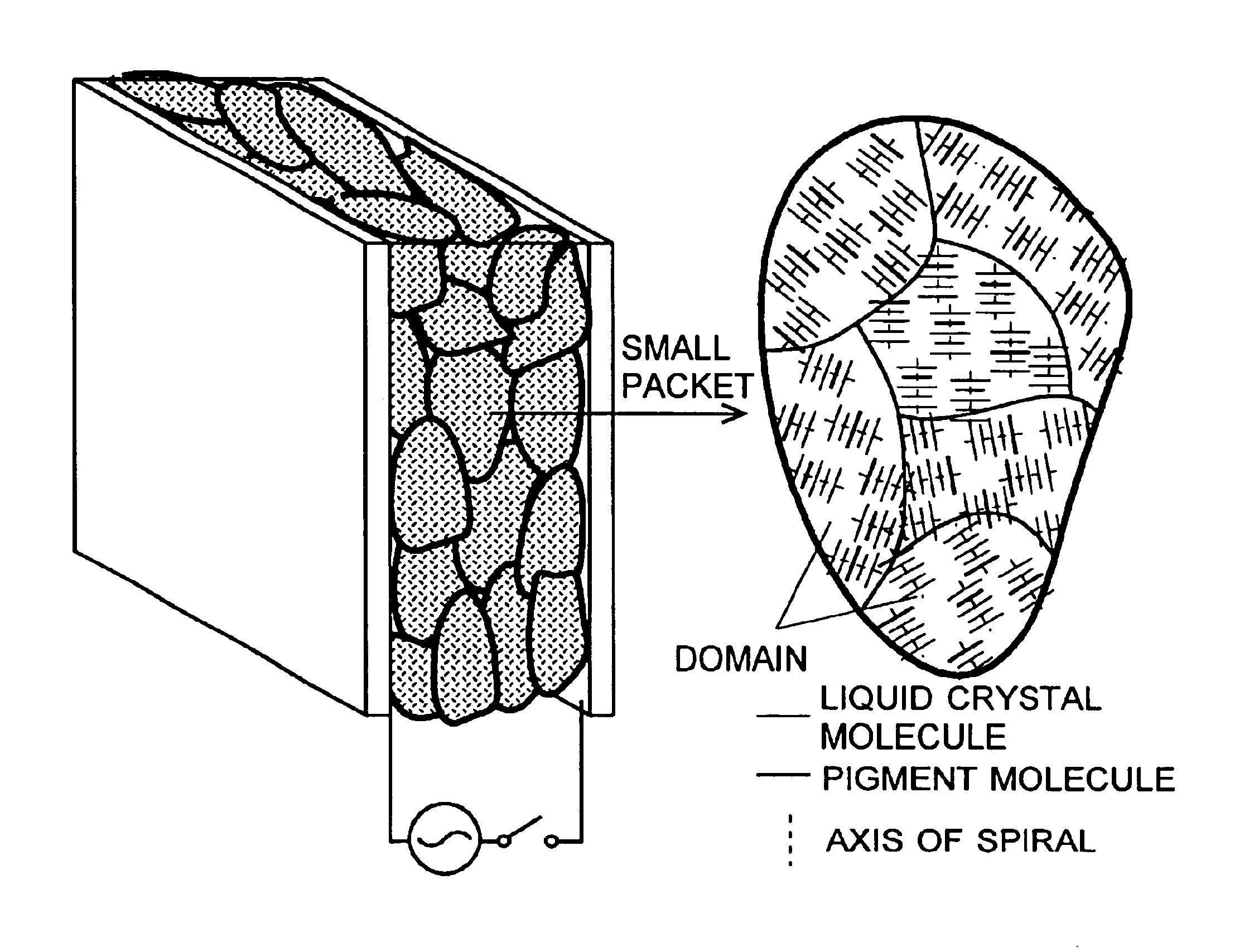

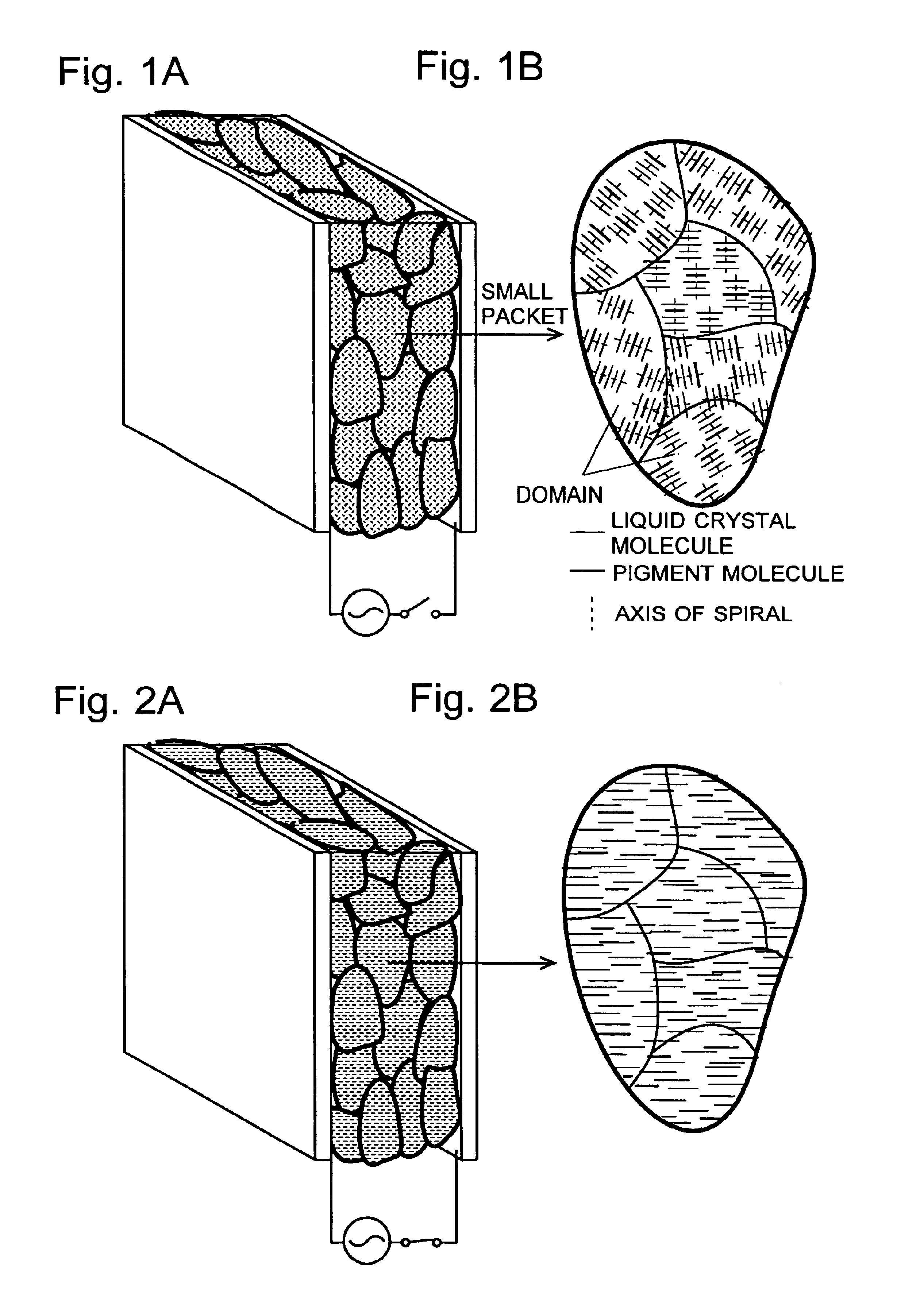

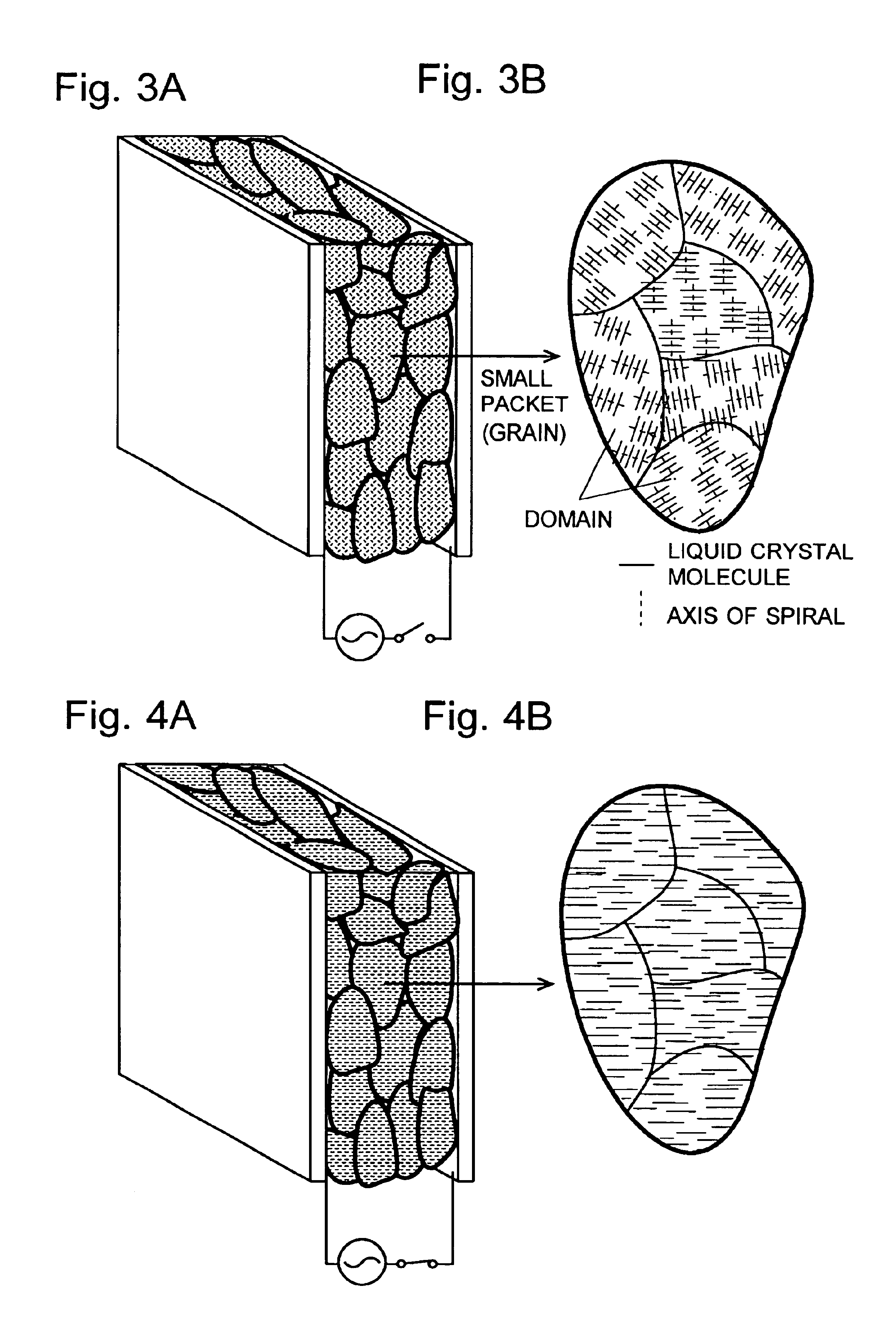

The objective of the present invention is to provide a liquid crystal display device for displaying colors by transmission and reflection modes and a method for producing such devices, whereby the additive color mixing can be used, the structure is simplified, the driving-voltage is lower, the contrast is higher, the response speed is higher, and the screen can be larger. This objective can be achieved by a method including the following steps: mixing 0.001 to 20 wt % of dichromatic melanotic pigment into chiral nematic liquid crystal mixed with chiral dopant; preparing a mixture of the liquid crystal and prepolymer to be polymerized into transparent polymeric solid; inserting the mixture into the space between two conductive substrates, wherein at least one of which is transparent; and irradiating ultra-violet light or neighboring short-wavelength light onto the mixture. This process creates an accumulation of small packets composed of the liquid crystal packed with a thin film of the transparent polymeric solid within a light-controlling layer between the two conductive substrates. When no voltage is applied, the pigment molecules absorb light because they are distributed within the space with their longitudinal axis randomly directed. When a voltage is applied, elongated liquid crystal molecules are oriented perpendicular to the substrates, and the pigment molecules are also oriented in a similar manner. In this state, the black color of the pigment molecules does not appear, so that light is allowed to pass therethrough.

Owner:ASADA TADAHIRO

Liquid crystal composition and liquid crystal light modulating device

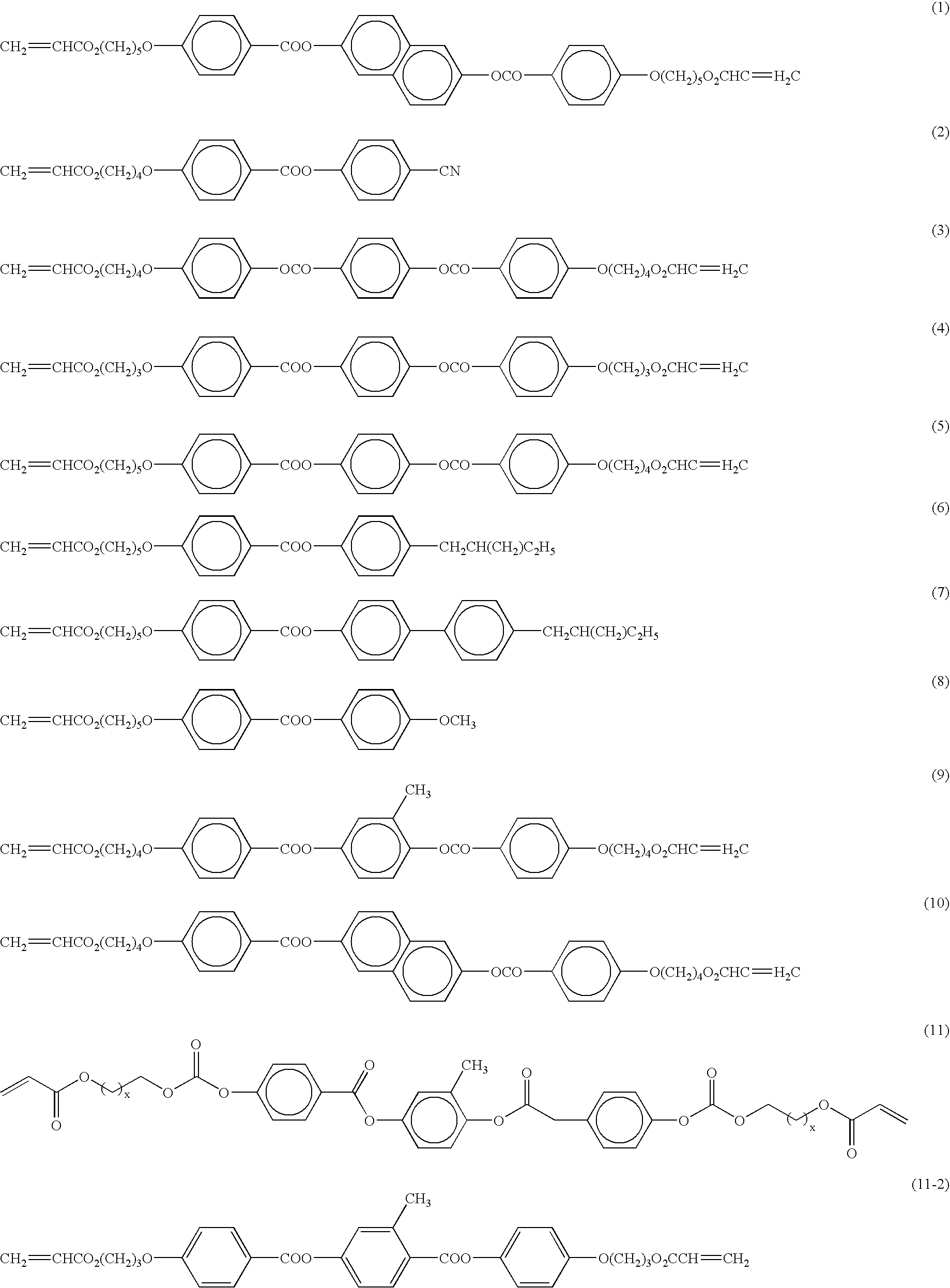

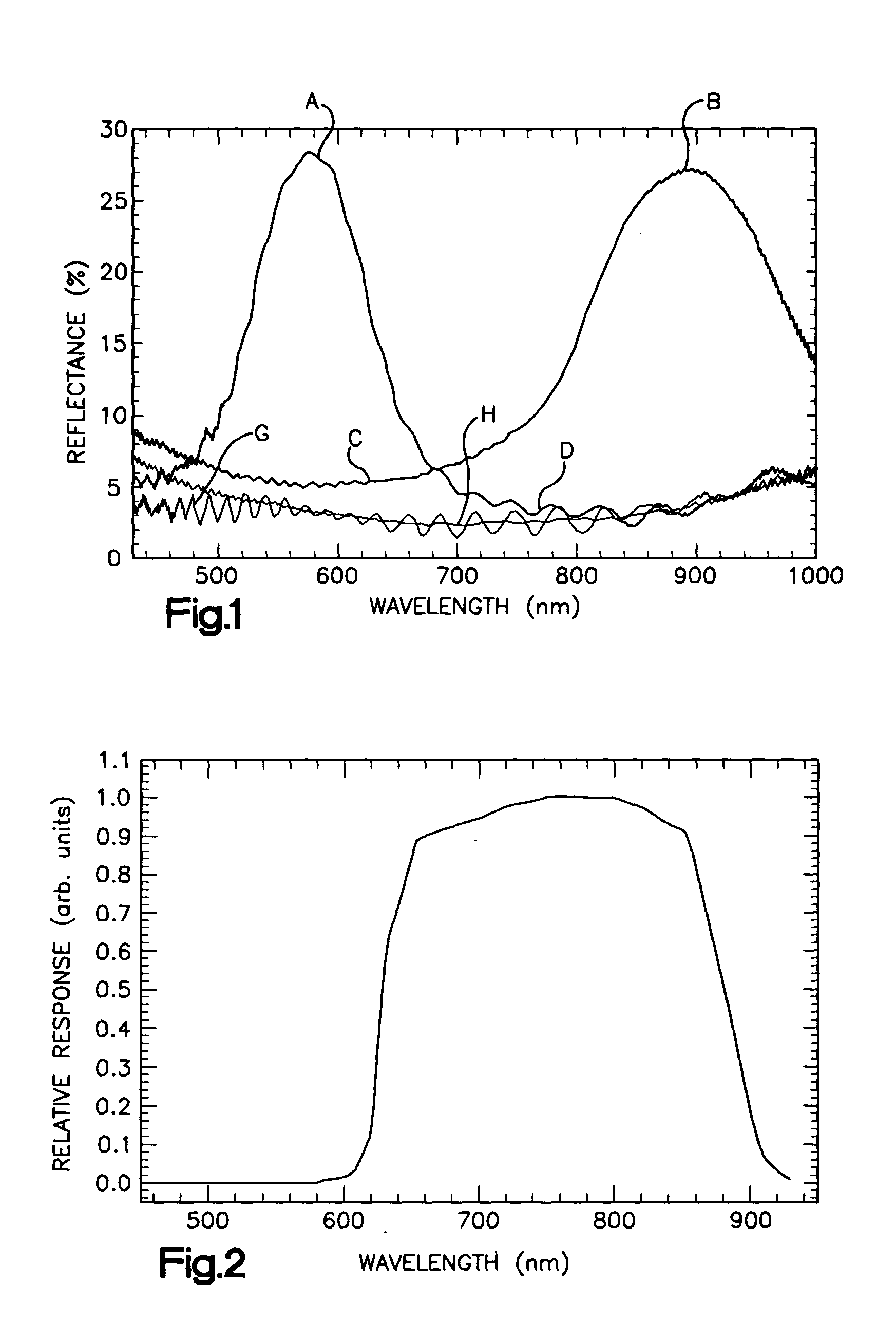

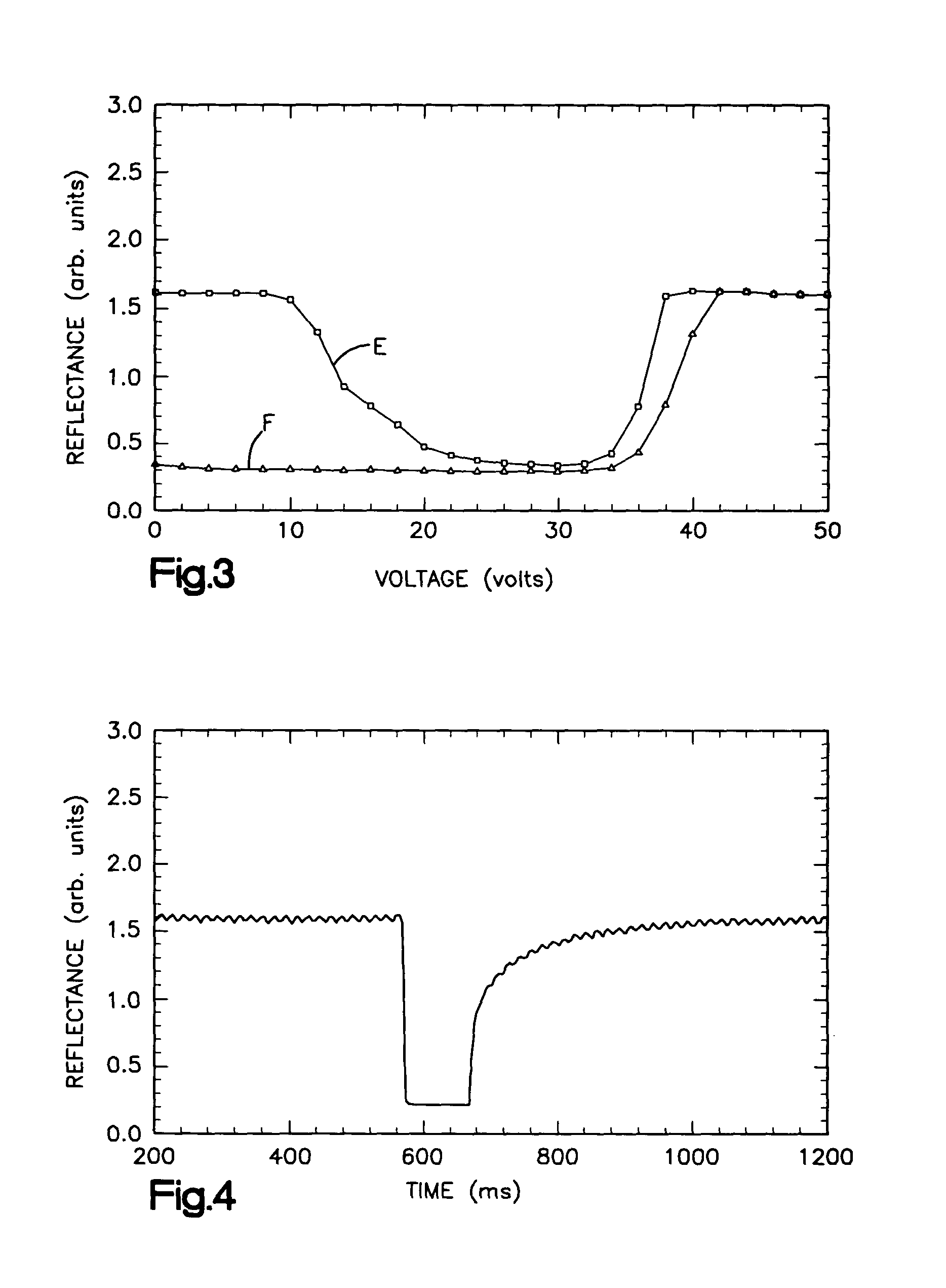

InactiveUS6348961B2High purityGood in reflectanceLiquid crystal compositionsNon-linear opticsCrystallographyLiquid-crystal display

A reflective type liquid crystal display which has a liquid crystal composition exhibiting a cholesteric phase in a room temperature and a columnar structure between substrates with ITO electrodes thereon. The liquid crystal composition is a chiral nematic liquid crystal composition which is produced by adding a chiral agent at a ratio within a range from 10 wt % to 45 wt % to nematic liquid crystal which contains a nematic liquid crystal component with a polar group at not less than 25 wt % and of which transition temperature to isotropic phase is within a range from 70° C. to 150° C. The anisotropy of refractive index of the liquid crystal composition is 0.10 to 0.22, and the anisotropy of dielectric constant is 5 to 30.

Owner:MINOLTA CO LTD

Liquid crystal optical element comprising a resin layer having a surface hardness of b or less

InactiveUS7253861B2Liquid crystal compositionsStatic indicating devicesScreen printingLiquid-crystal display

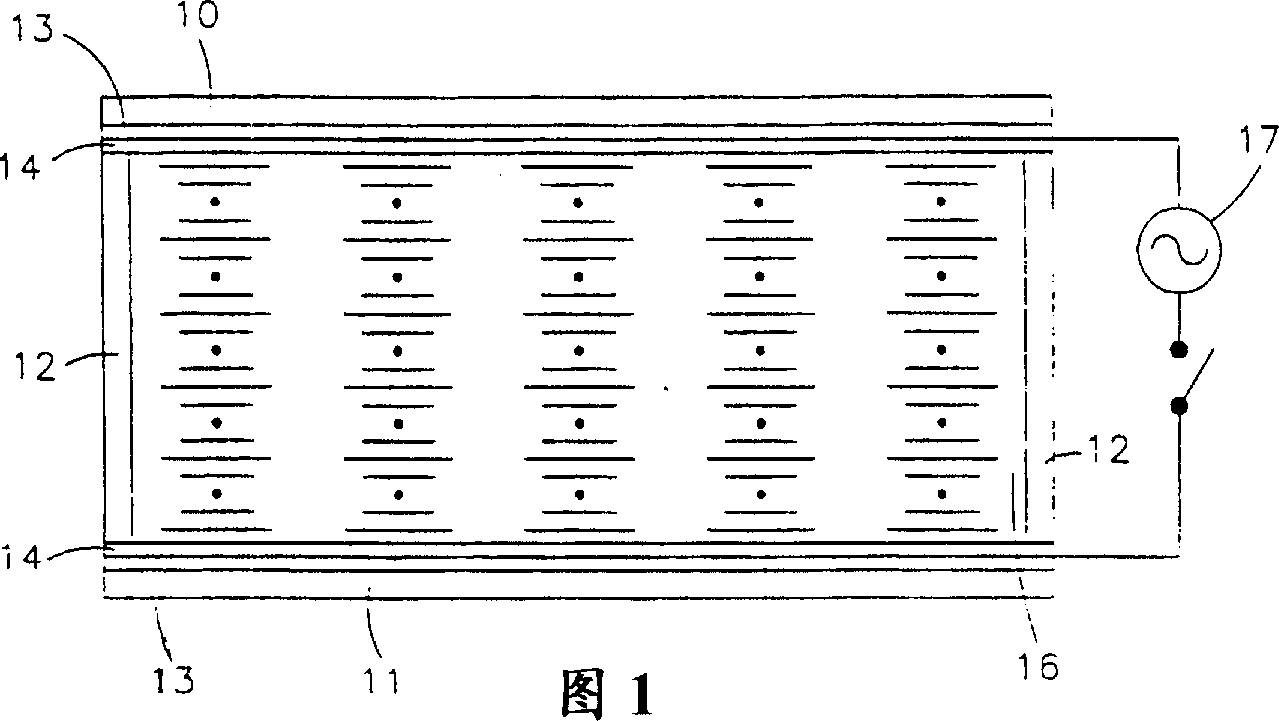

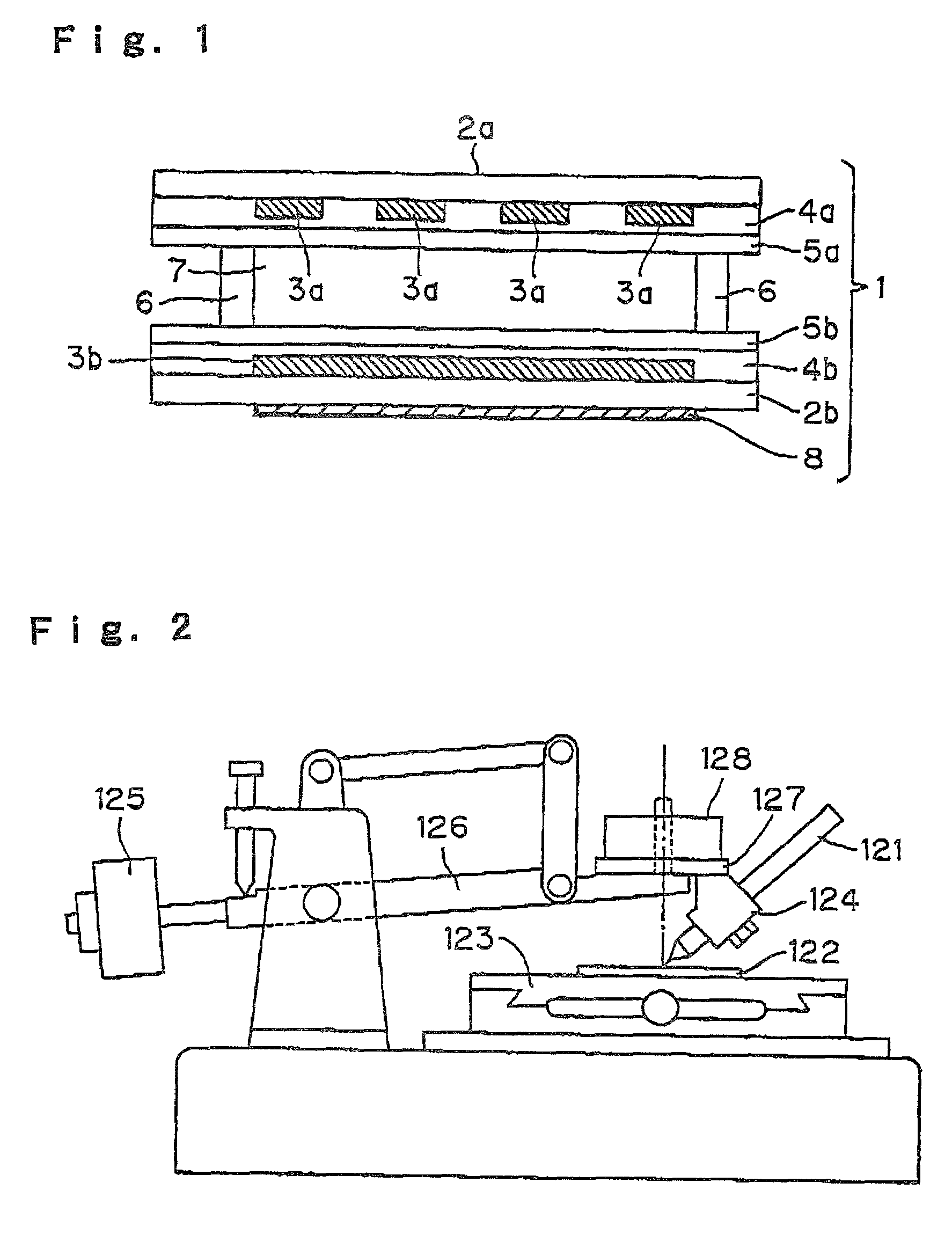

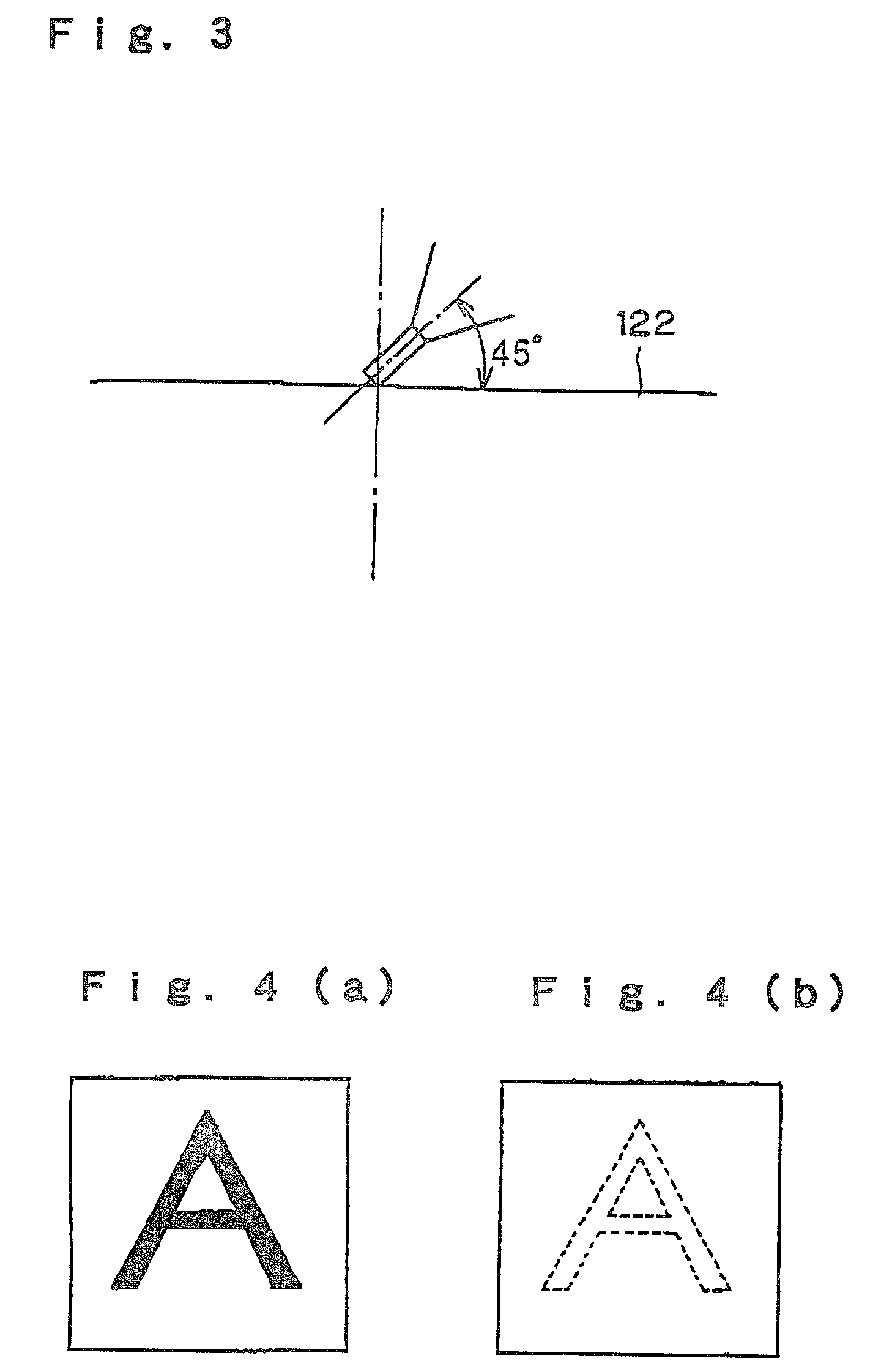

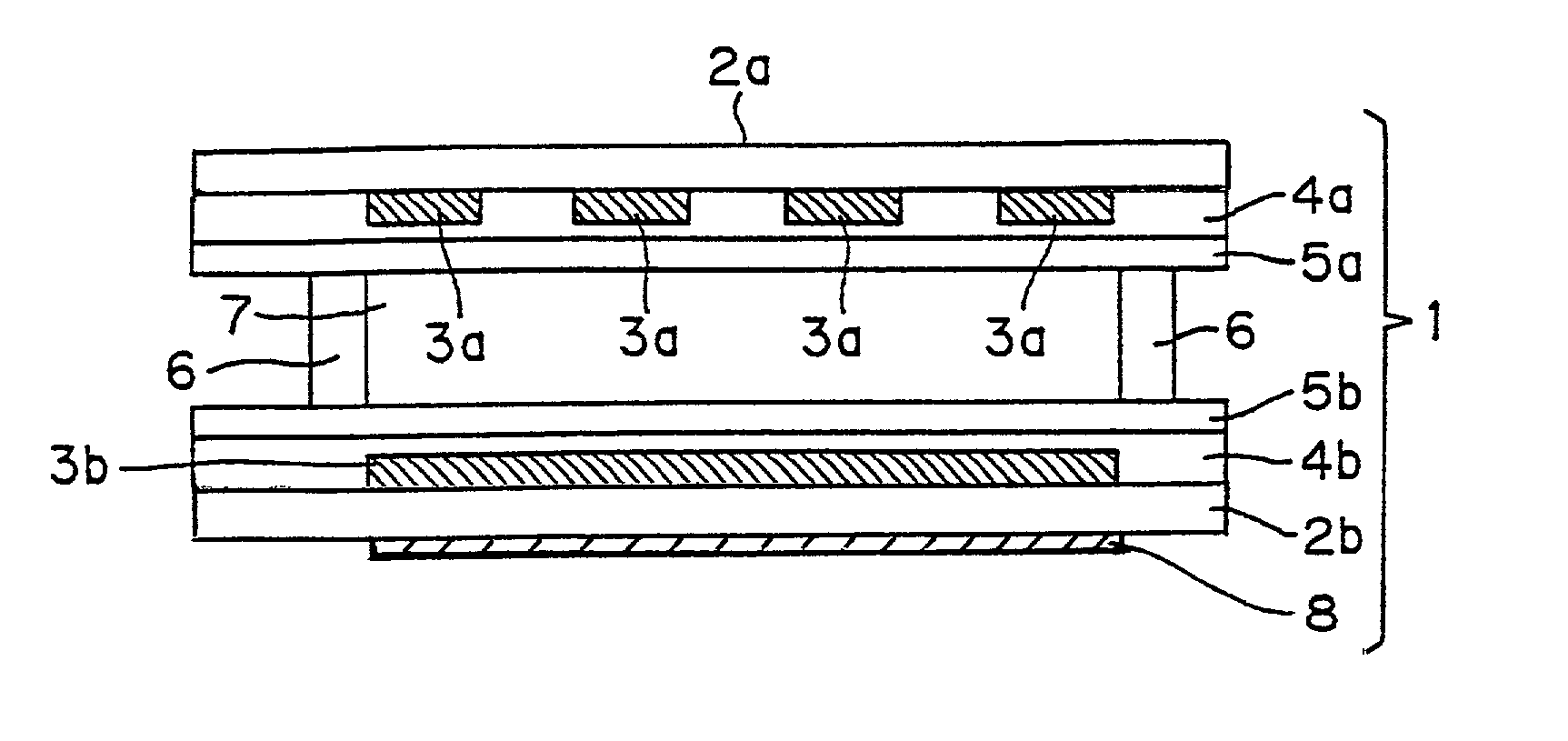

On substrates 2a, 2b of a chiral nematic liquid crystal optical element 1, transparent electrodes 3a, 3b and electrical insulation layers 4a, 4b are formed, and further, resin layers 5a, 5b hating a pencil hardness of “B” or less are formed on the electrical insulation layers by a spin coating method so as to be in contact with a liquid crystal layer 7. When the surface hardness of the resin layers is to be measured, a glass substrate on which a resin layer is formed by screen-printing is prepared as a test piece, and the test piece is fitted to a pencil-scratching tester. The surface hardness is measured by scratching the test piece with two kinds of testing pencil selected from testing pencils having 17 grades of density.

Owner:ASAHI GLASS CO LTD

Preparation method of chiral nematic liquid crystal composition and liquid crystal display

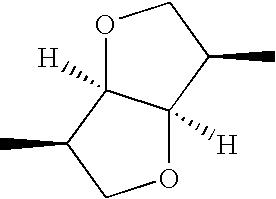

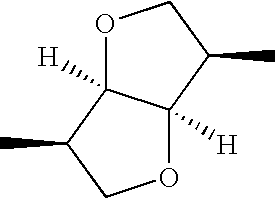

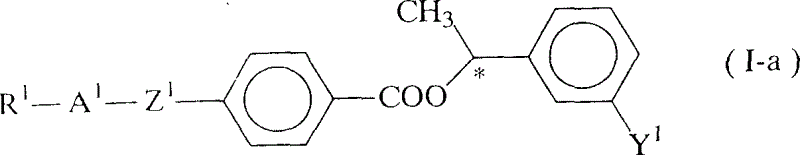

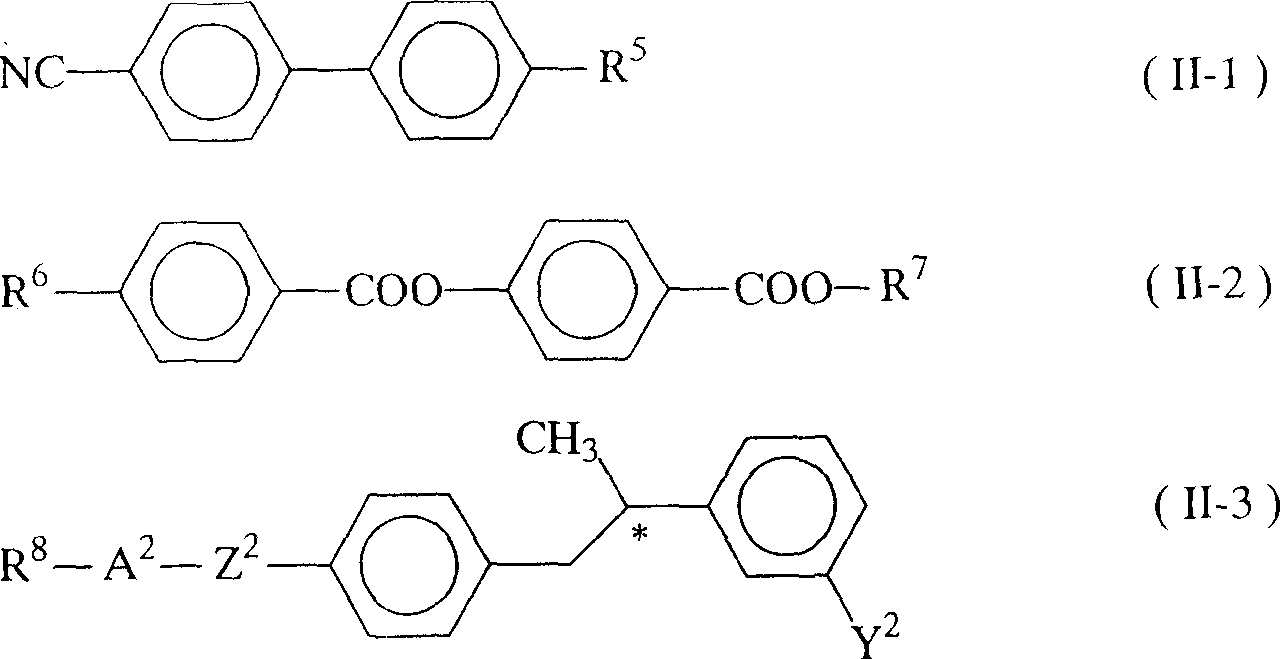

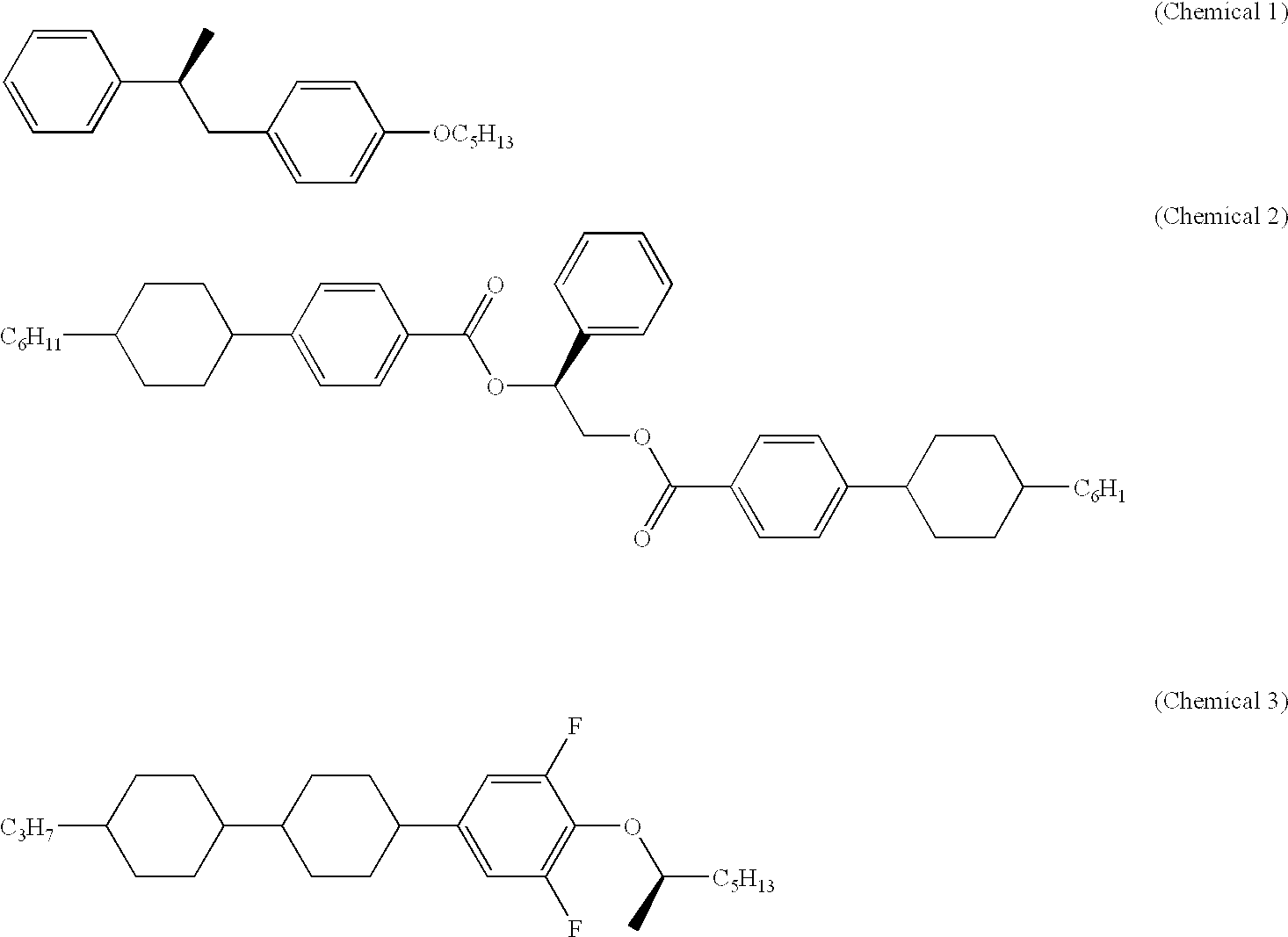

InactiveUS6852375B2Facilitates temperature compensationEasy to adjustLiquid crystal compositionsThin material handlingCrystallographyLiquid-crystal display

The present invention is based on a chiral nematic liquid crystal composition which shows cholesteric liquid crystal phase and be able to reflect light in visible region selectively, comprising:a nematic liquid crystal material;a first chiral material with shift direction of selective reflection wavelength toward long wavelength direction depending on temperature;and a second chiral material with shift direction of selective reflection wavelength toward short wavelength direction depending on temperature;wherein at least one chiral material between the first chiral material and the second chiral material comprises two or more chiral compounds, and relates to a preparation method of the above chiral nematic liquid crystal composition and a (layered-type) liquid crystal display using the same.

Owner:MINOLTA CO LTD

Laminated retardation optical element, process of producing the same, and liquid crystal display

The present invention provides a laminated retardation optical element that never lowers contrast and thus never degrades display performance even when placed between a liquid crystal cell and a λ / 4 retardation film. In a liquid crystal display 90, a laminated retardation optical element 10 is placed between a polarizer 102A on the incident side and a liquid crystal cell 104, and a λ / 4 retardation film 102C is placed between a polarizer 102B on the emergent side and the liquid crystal cell 104. The laminated retardation optical element 10 comprises: a λ / 4 retardation layer 14 having the function of bringing, to light that passes through this retardation layer, a phase difference corresponding to a quarter of the wavelength of the light; and a C plate-type retardation layer 16 that acts as a negative C plate. The λ / 4 retardation layer 14 and the C plate-type retardation layer 16 are laminated to a transparent substrate 12 in the order mentioned, and are optically bonded to each other. The λ / 4 retardation layer 14 comprises as its main component a horizontally-aligned, cross-linked nematic liquid crystal, while the C plate-type retardation layer 16 comprises as its main component a cross-linked chiral nematic liquid crystal (a cross-linked nematic liquid crystal and a cross-linked chiral agent) or cross-linked discotic liquid crystal.

Owner:DAI NIPPON PRINTING CO LTD

Liquid crystal display apparatus

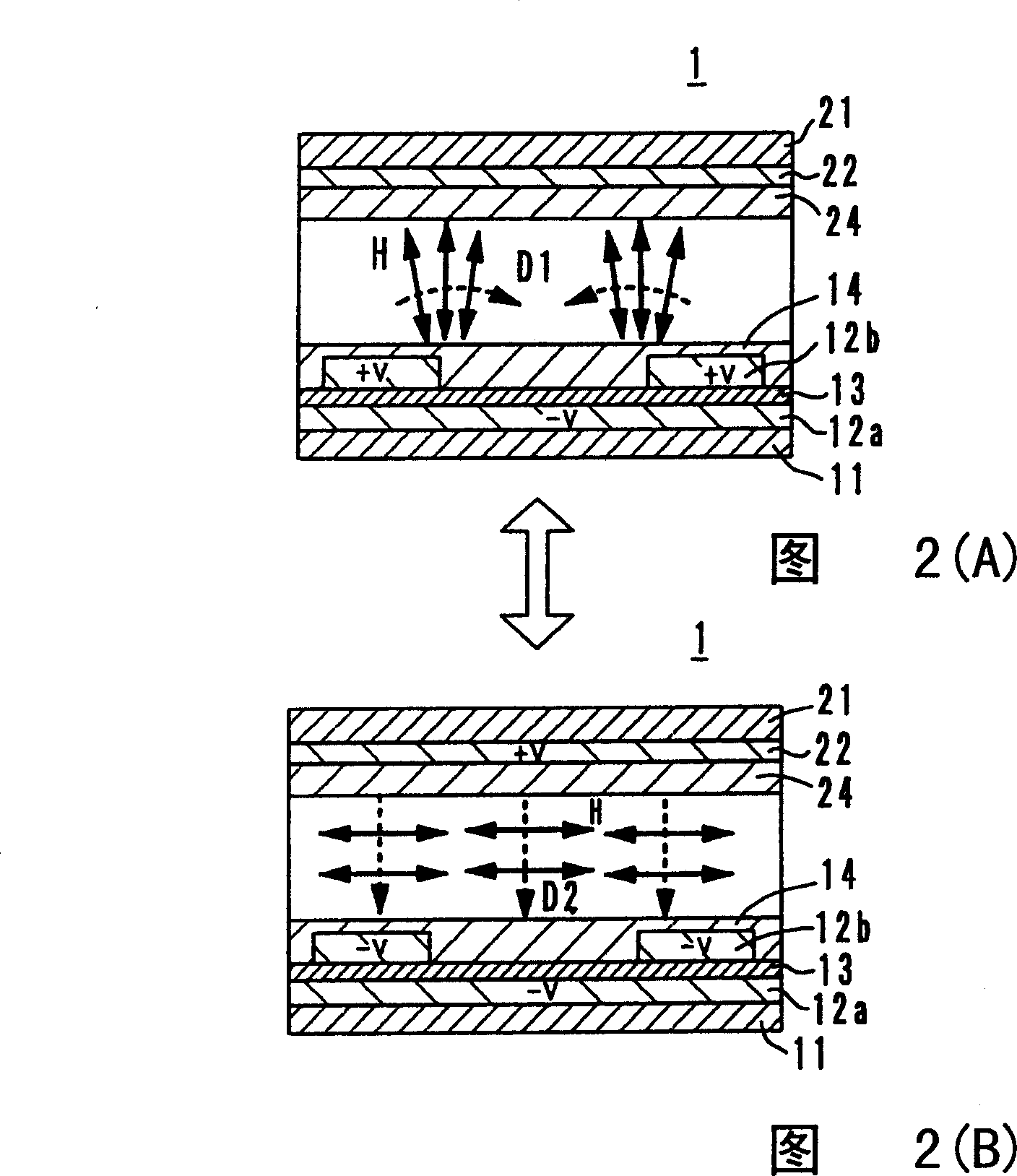

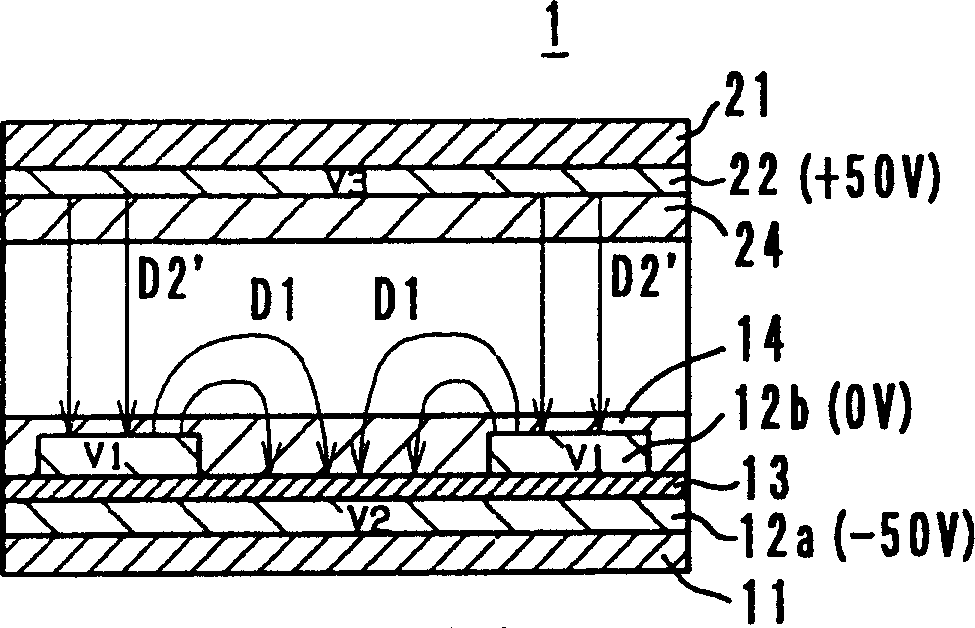

InactiveCN1460199AStatic indicating devicesNon-linear opticsLiquid-crystal displaySelective reflection

A liquid crystal display apparatus which has: a liquid crystal display which has chiral nematic liquid crystal between a pair of substrates with electrodes thereon and which makes a display by use of selective reflection of the liquid crystal; and a driving circuit for driving the liquid crystal by applying voltages to the electrodes. When an electric field of a specified strength is applied to the chiral nematic liquid crystal, the liquid crystal changes the direction of the helical axis without untwisting. By using this characteristic, the direction of the helical axis of the liquid crystal is changed by changing the direction of the electric field applied thereto, and thereby, the liquid crystal is set to a planar state or a focal-conic state. In this way, writing on the liquid crystal is carried out.

Owner:MINOLTA CO LTD

Normally white, supertwist nematic liquid crystal display of reflective type

InactiveUS7084939B2Significant light lossComplex designLiquid crystal compositionsNon-linear opticsLiquid-crystal displayDisplay device

A normally white supertwist nematic liquid crystal display of reflective type is provided. This display comprises a reflector, a layer of chiral nematic liquid crystal having a front aligning surface facing a light source and a rear aligning surface facing the reflector, and a front polarizer. The nematic liquid crystal has an optical retardation (Δnd) of the layer and a distribution of directors, wherein the chiral nematic liquid crystal has a twist angle (Φ) between an alignment direction of the director at the front aligning surface and an alignment direction of the director at the rear aligning surface. The front polarizer is disposed between the layer of chiral nematic liquid crystal and the light source. The front polarizer has a transmission axis forming an angle (α) with the alignment direction of the director at the front aligning surface of the chiral nematic liquid crystal layer. The optical retardation (Δnd) and the angle (α) are defined by the following formulas:α((Φ)=sign(Φ)·(47.0−0.4936|Φ|+2.6786×10−3·Φ2)±5, deg, andΔnd(Φ)=−11.674+0.1915·|Φ|−9.8393×10−4·Φ21.6667×10−6·|Φ|3±0.05, μm.

Owner:NITTO DENKO CORP

Liquid crystal composition and liquid crystal display element

InactiveCN1513947ALiquid crystal compositionsNon-linear opticsLiquid-crystal displaySelective reflection

Owner:DAINIPPON INK & CHEM INC

Reflective chiral-nematic liquid crystal display with broadband reflection

InactiveUS7382424B2Good colorIncrease dependenceLiquid crystal compositionsNon-linear opticsElectrical conductorLighting spectrum

A display sheet comprising a substrate carrying layers of material; including a polymer-dispersed chiral-nematic liquid-crystal layer having a first high reflection state within the visible light spectrum and a second less-reflective state in said spectrum, said states being changeable by an electric field, which states can be maintained in the absence of an electric field; a first transparent conductor disposed over said polymer-dispersed chiral-nematic liquid-crystal layer; and a second conductor, wherein said imaging layer is substantially a monolayer of said domains comprises a mixture of at least two differently reflecting liquid crystal materials, in which the λ maximums of the two materials are separated by 100 to 250 nm.

Owner:IRIS OPTRONICS CO LTD

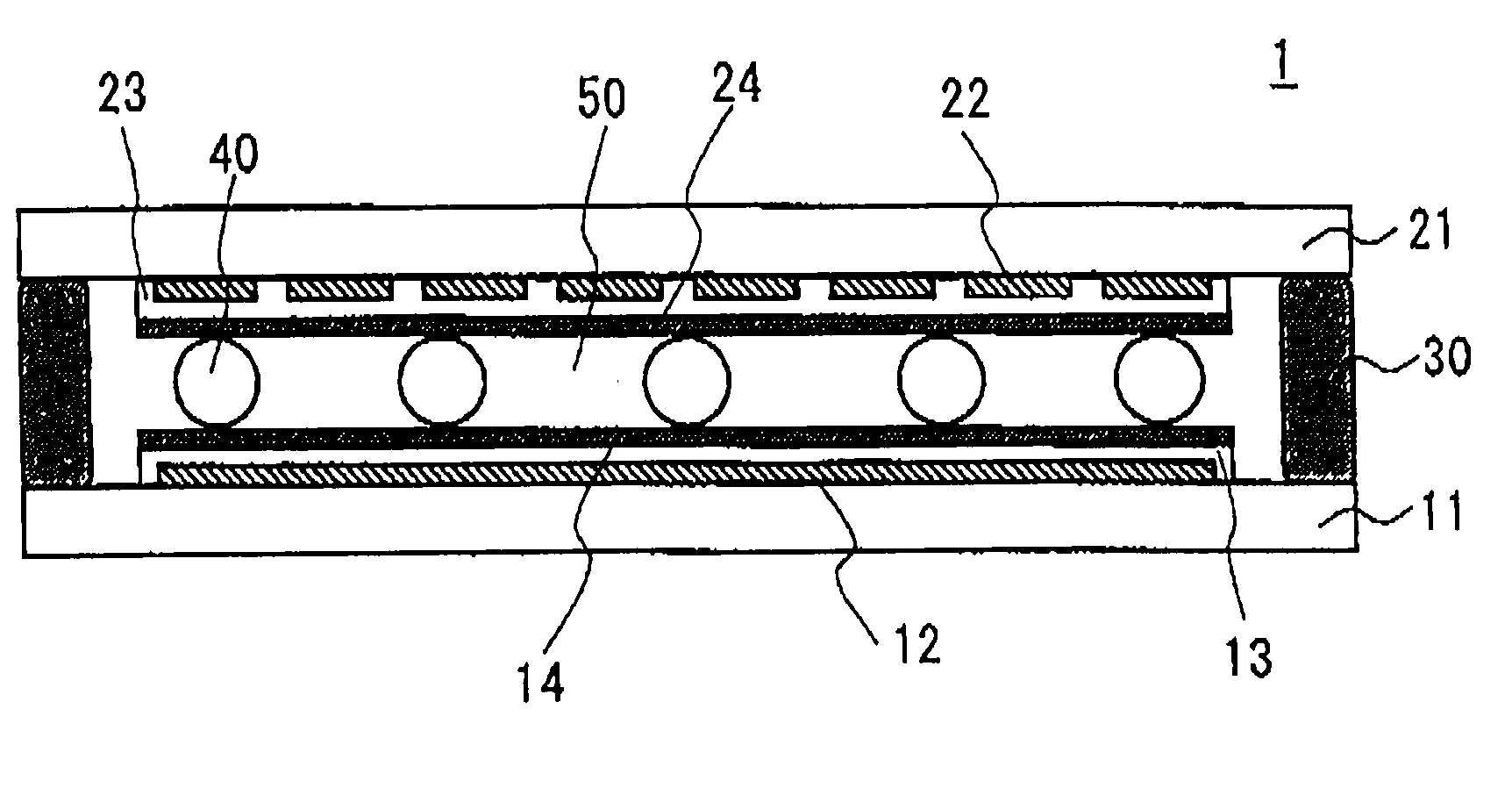

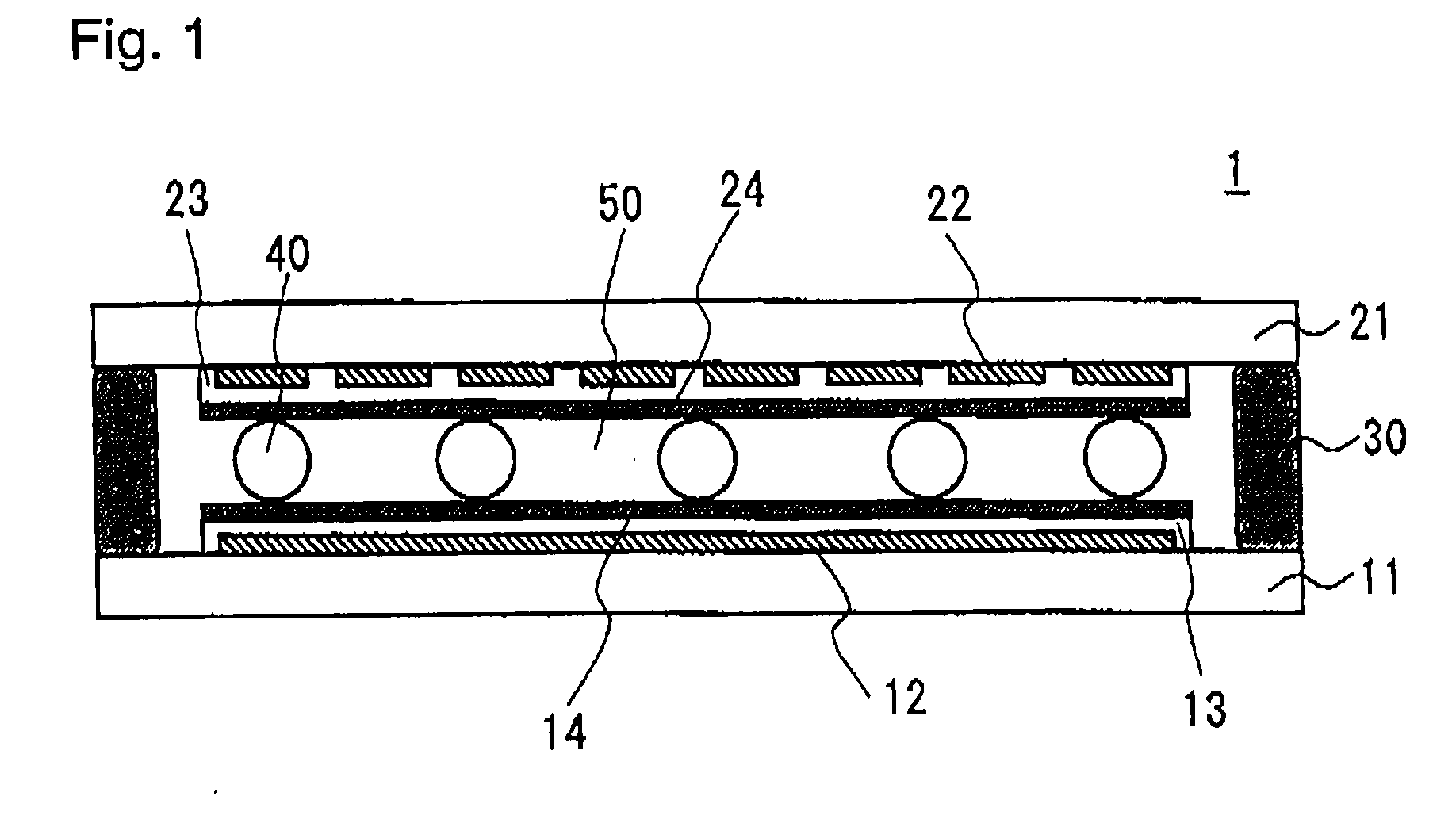

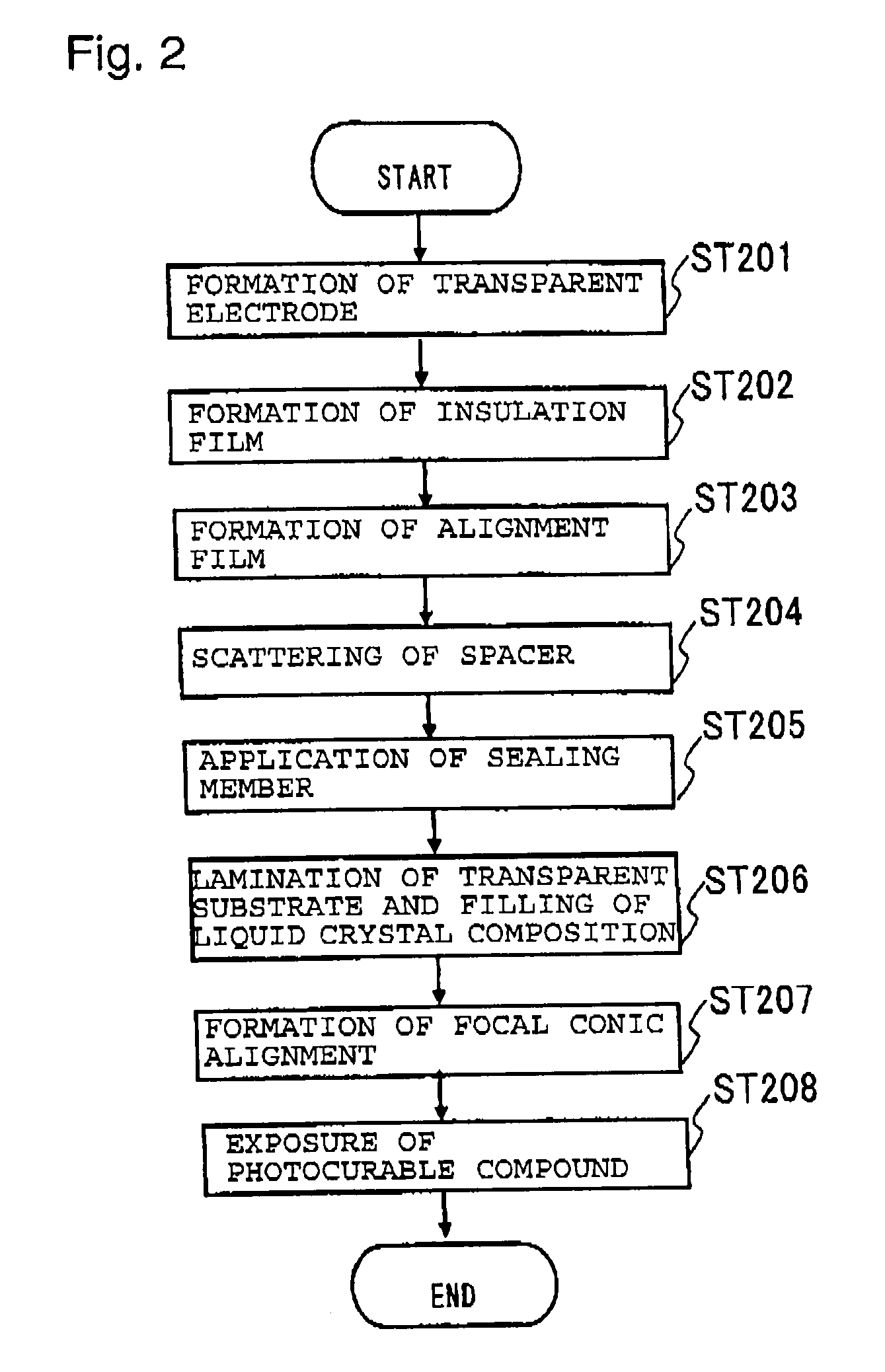

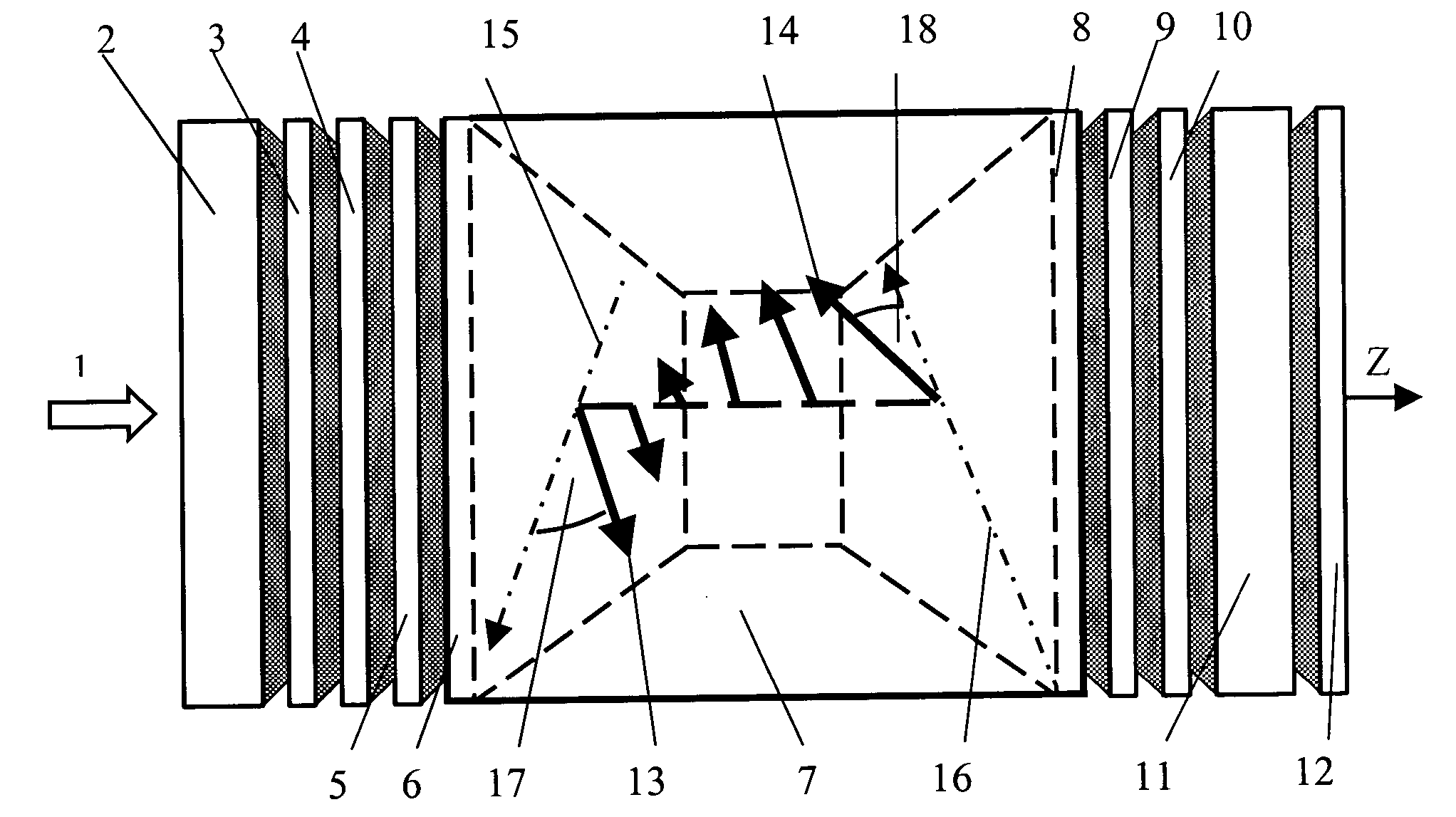

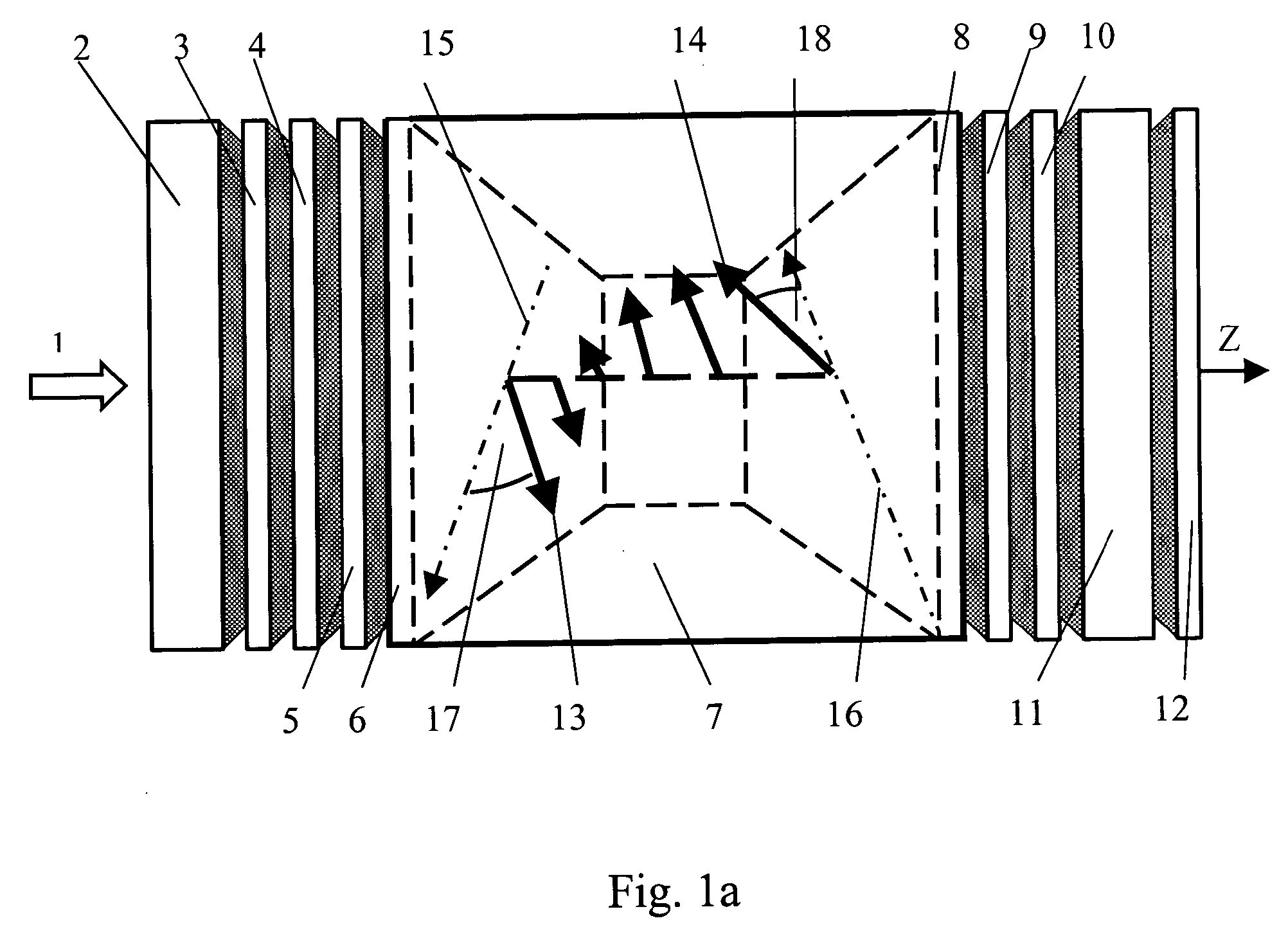

Liquid crystal optical device and process for its production

InactiveUS20090147211A1Low haze valueExcellent characteristicsLiquid crystal compositionsNon-linear opticsRotatory powerProduction rate

To provide a liquid crystal optical device showing a low haze value in the transparent state, further an excellent stability in the transparent-scattering characteristics and productivity, and to provide a production process thereof.The liquid crystal optical device in the embodiment 1 of the present invention is a liquid crystal optical device 1 comprising a pair of insulating substrates 11 and 21, of which at least one is transparent, electrodes 12 and 22 formed on respective inner faces of the substrates, and a composite 50 comprising nematic liquid crystal and a cured material, interposed between the inner faces of the substrates. The composite 50 is obtained by curing the following curable compound in the following chiral nematic liquid crystal composition in a state where the liquid crystal composition is interposed between the inner faces of the insulating substrates and the liquid crystal is aligned:chiral nematic liquid crystal composition: a liquid crystal composition showing a chiral nematic phase, comprising nematic liquid crystal and a curable compound, wherein at least a part of the curable compound is an optically active material having an optical rotatory power, and the optically active material having an optical rotatory power consists substantially solely of the curable compound.

Owner:ASAHI GLASS CO LTD

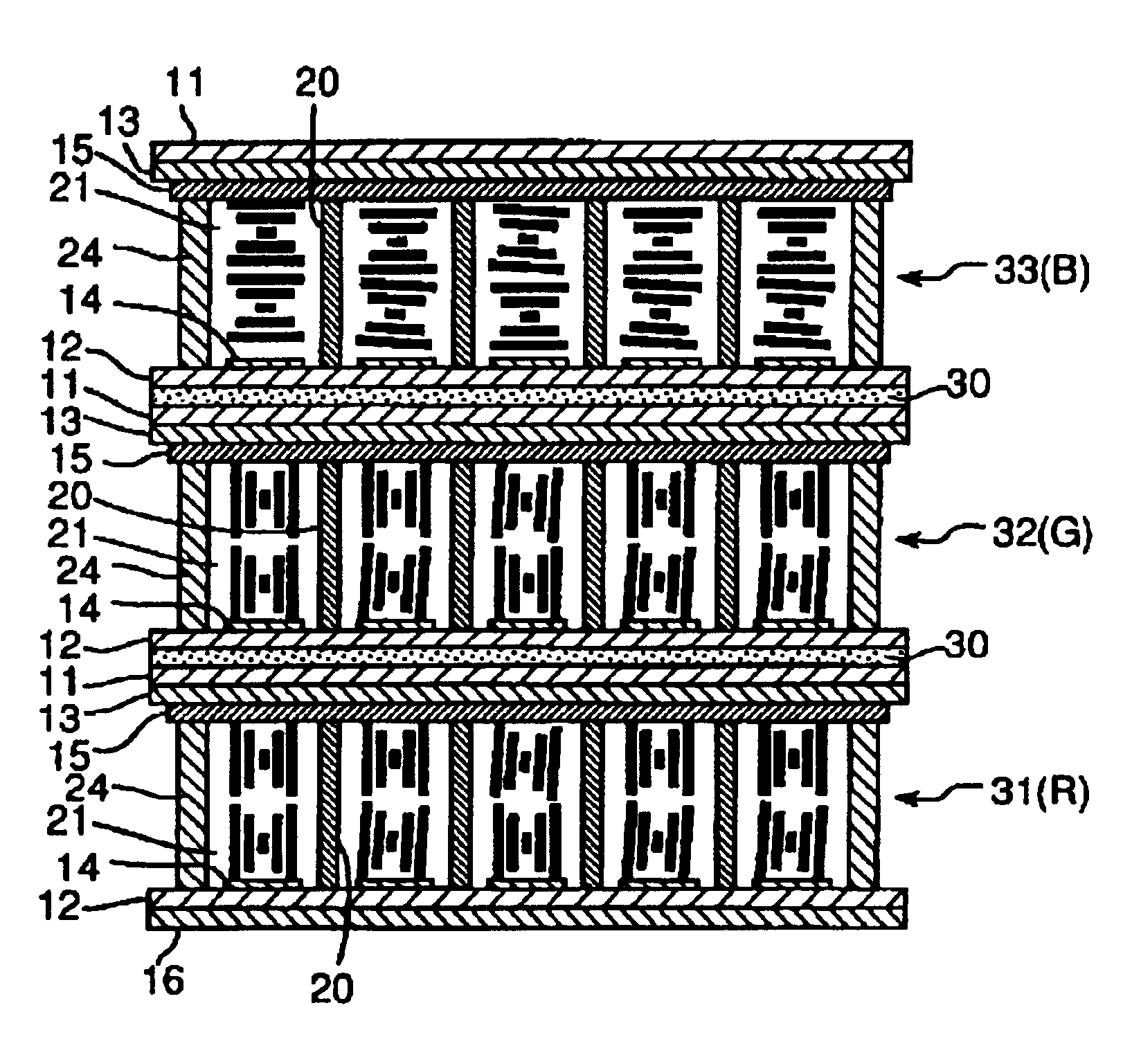

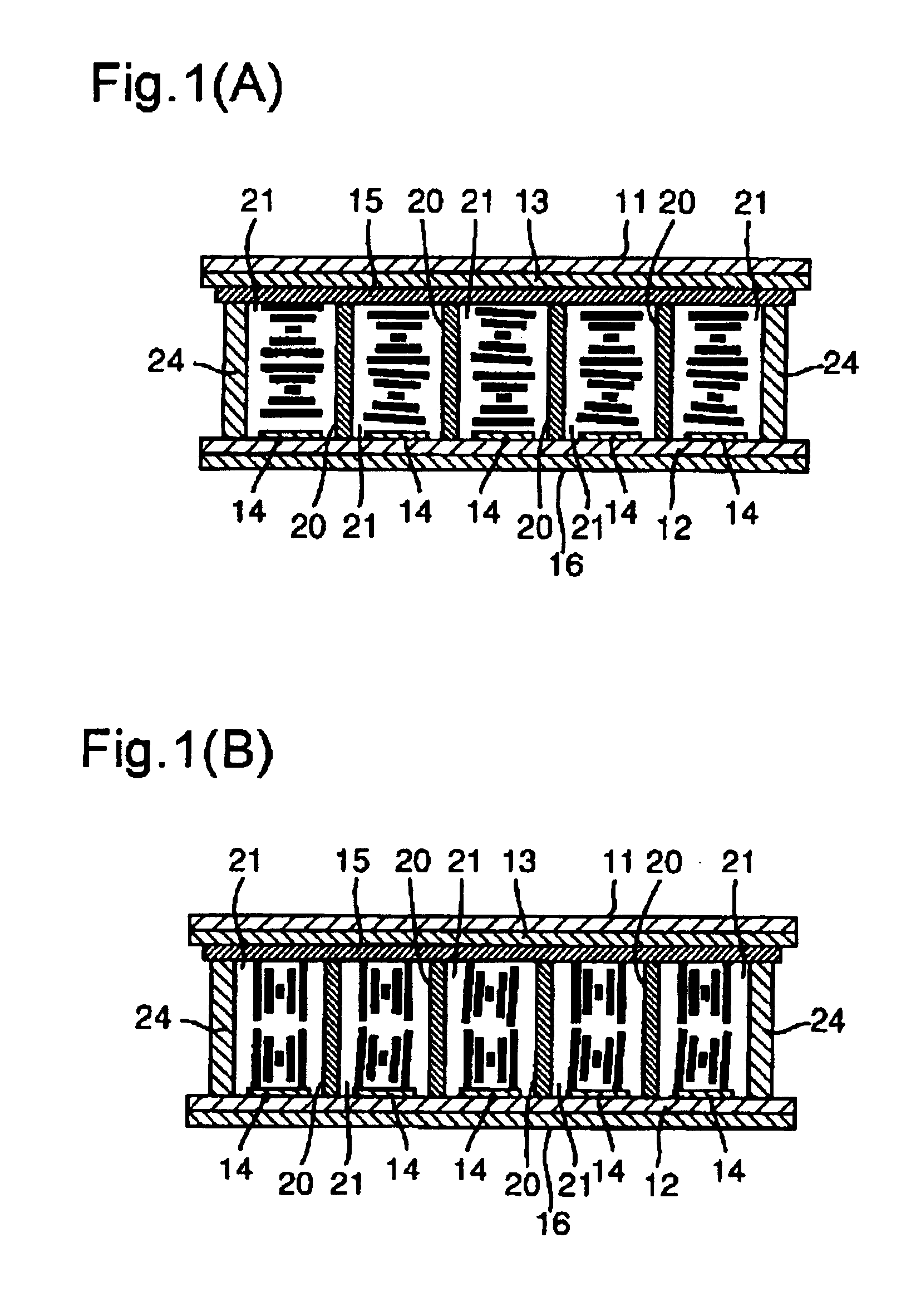

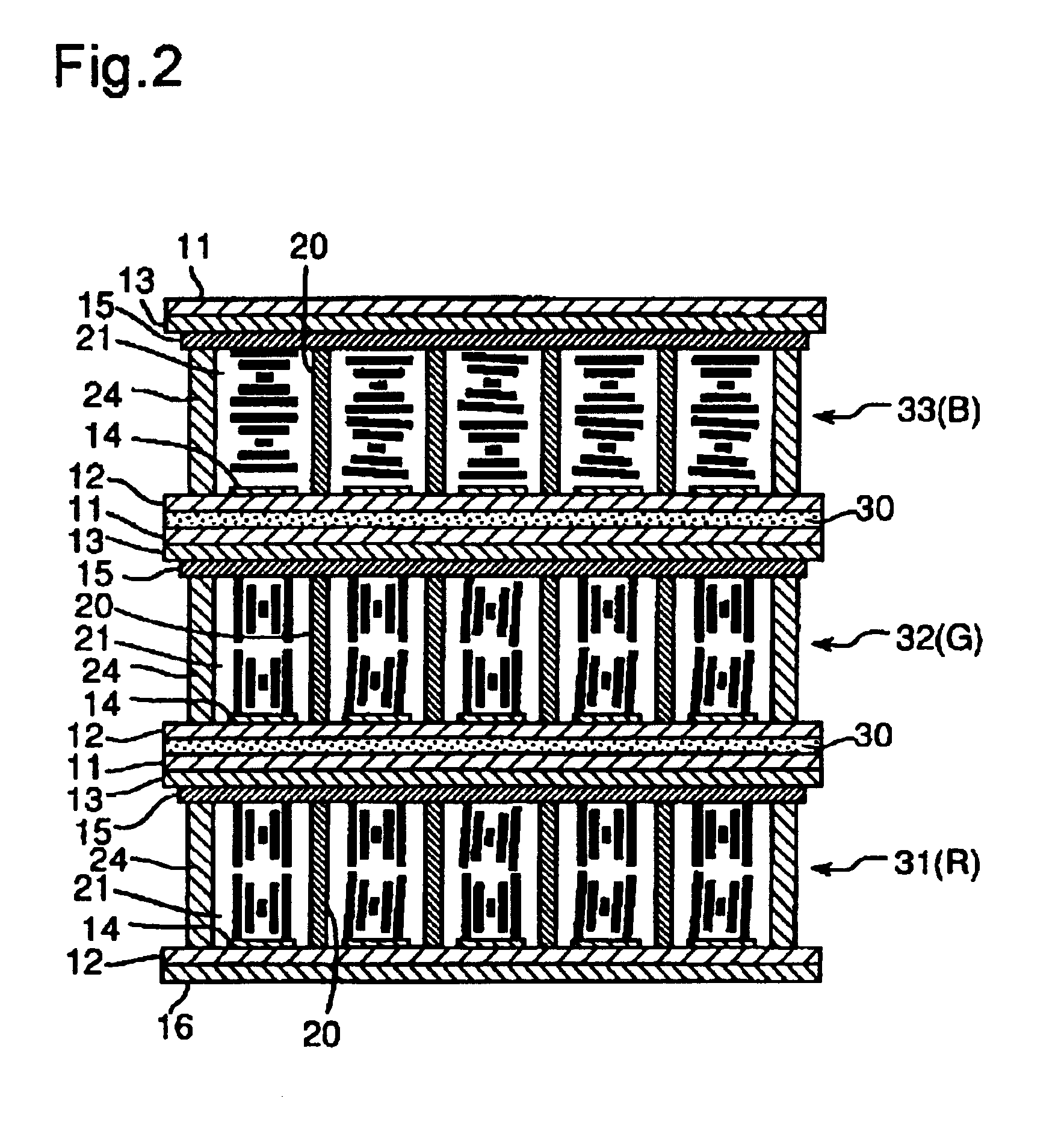

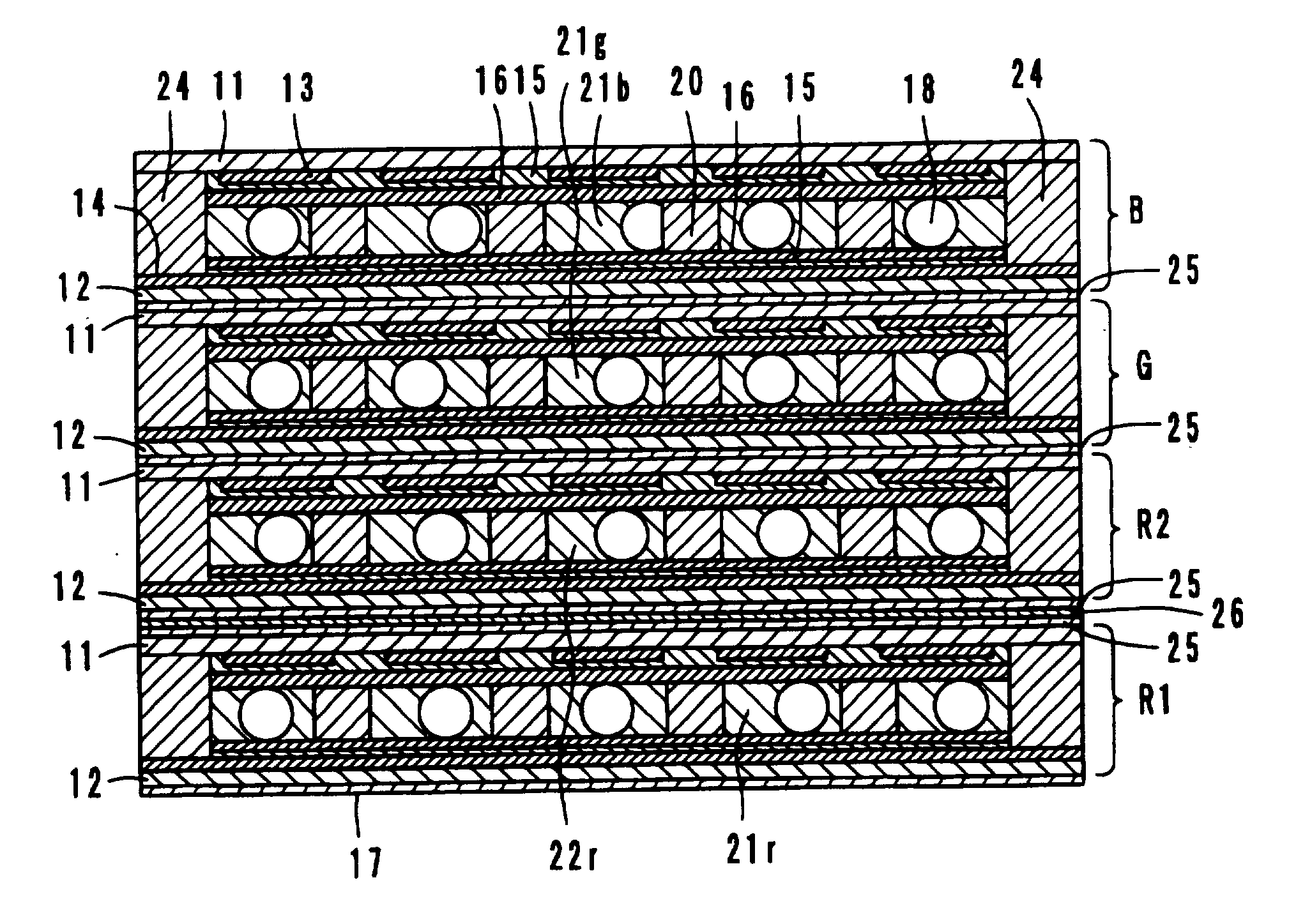

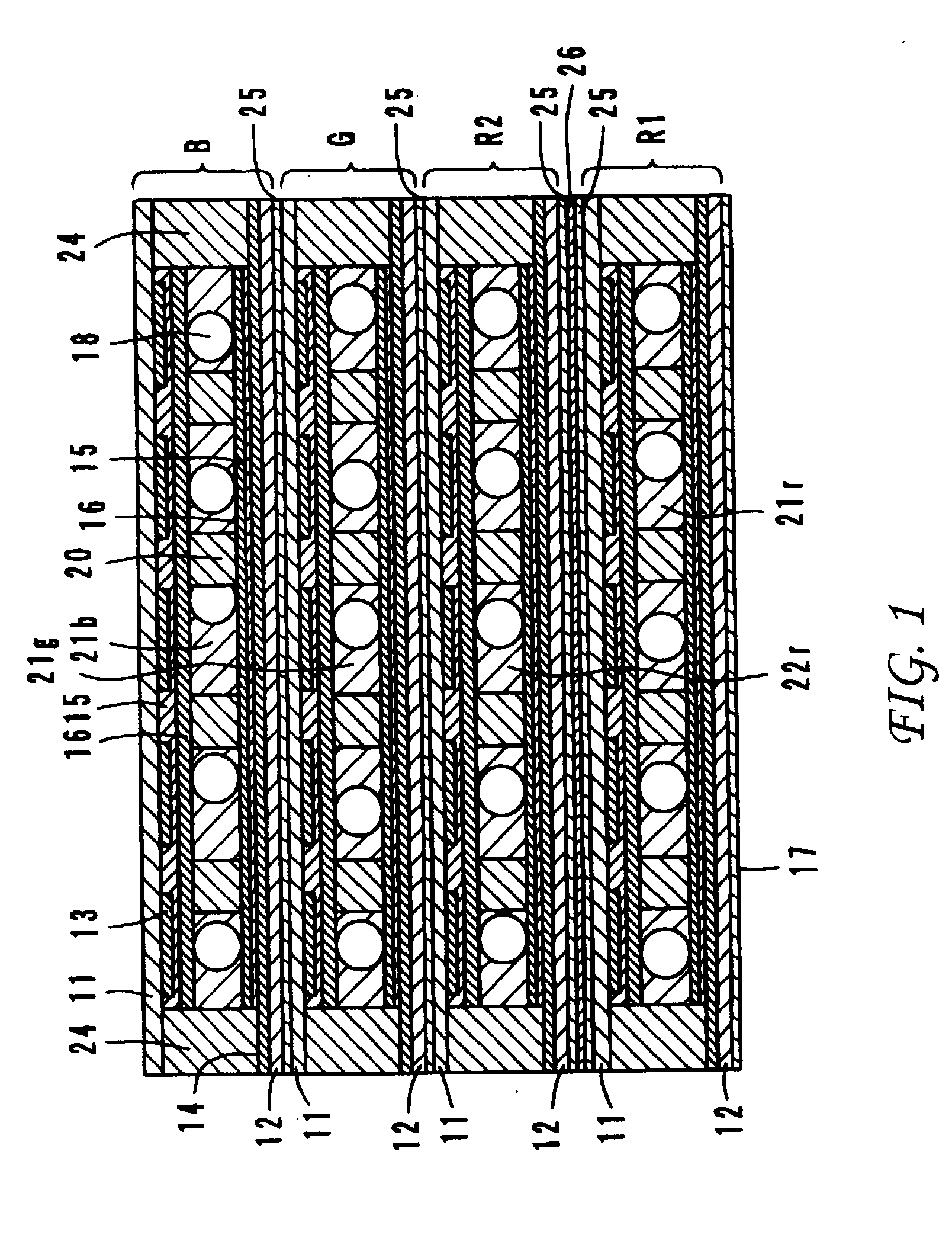

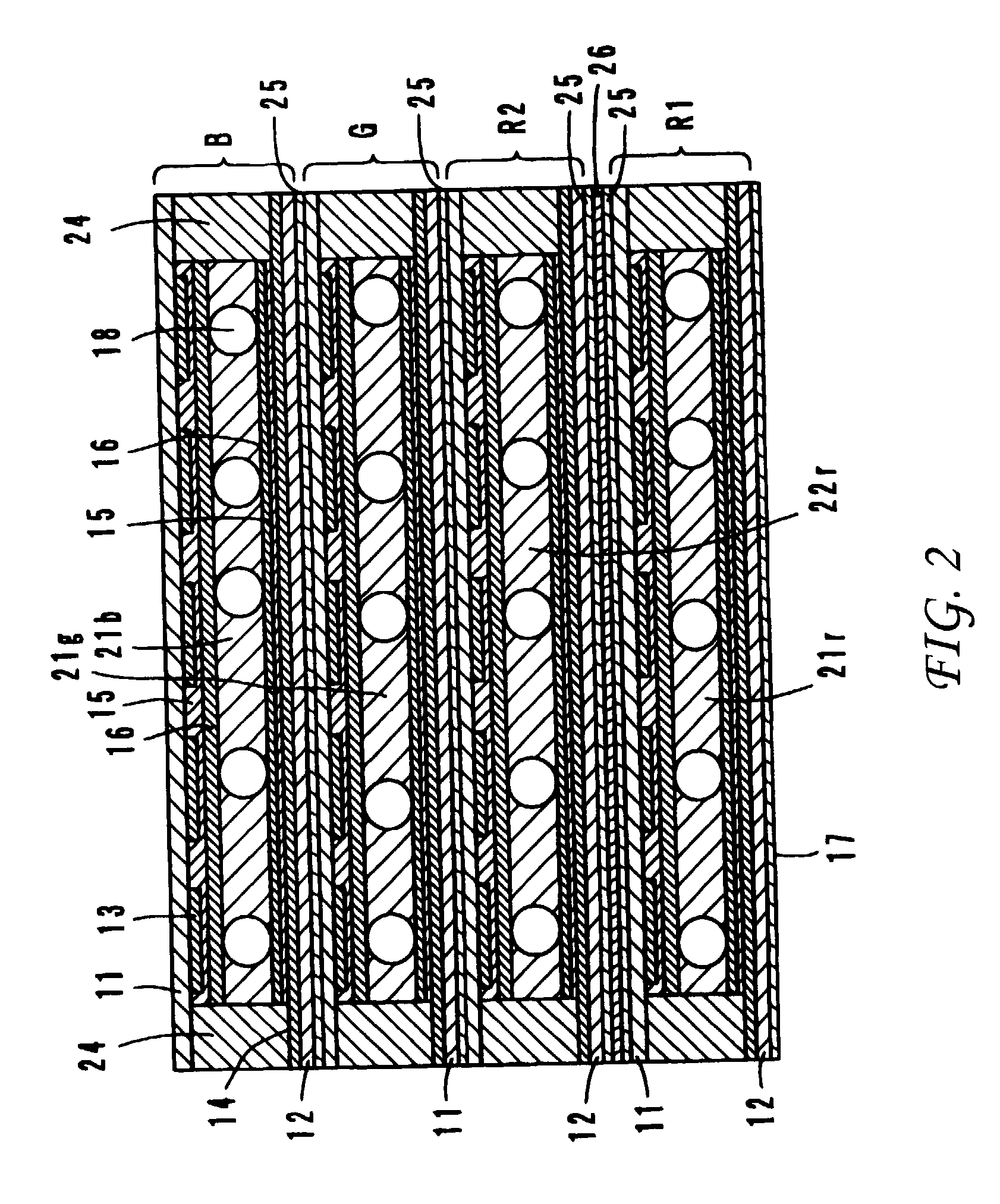

Layered type reflective full-color liquid crystal display element and display device having the element

InactiveUS20020171789A1Reduce display effectLow priceNon-linear opticsPhase differenceDisplay device

Disclosed is a reflective color liquid crystal display element having a four layered structure. The display element specifically comprises the following layers from an observation side: a single layer of a liquid crystal cell which comprises a chiral nematic liquid crystal composition for the blue color reflection; a single layer of a liquid crystal cell which comprises a chiral nematic liquid crystal composition for the green color reflection; and two layers of liquid crystal cells each of which comprises a chiral nematic liquid crystal composition for the red color reflection. In some of the embodiments, a phase difference plate is inserted between the two liquid crystal cells for the red color reflection.

Owner:MINOLTA CO LTD

Normally white, supertwist nematic liquid crystal display of reflective type

InactiveUS20040085508A1Significant light lossComplex designLiquid crystal compositionsNon-linear opticsLiquid-crystal displayDisplay device

A normally white supertwist nematic liquid crystal display of reflective type is provided. This display comprises a reflector, a layer of chiral nematic liquid crystal having a front aligning surface facing a light source and a rear aligning surface facing the reflector, and a front polarizer. The nematic liquid crystal has an optical retardation (Deltand) of the layer and a distribution of directors, wherein the chiral nematic liquid crystal has a twist angle (Phi) between an alignment direction of the director at the front aligning surface and an alignment direction of the director at the rear aligning surface. The front polarizer is disposed between the layer of chiral nematic liquid crystal and the light source. The front polarizer has a transmission axis forming an angle (alpha) with the alignment direction of the director at the front aligning surface of the chiral nematic liquid crystal layer. The optical retardation (Deltand) and the angle (alpha) are defined by the following formulas: alpha((Phi)=sign(Phi).(47.0-0.4936|Phi|+2.6786x10<-3>.Phi<2>)±5, deg, and Deltand(Phi)=-11.674+0.1915.|Phi|-9.8393x10<-4>.Phi<2>1.6667x10<-6>.|Phi|<3>±0.05, mum.

Owner:NITTO DENKO CORP

Liquid crystal device comprising chiral nematic liquid crystal material in a helical arrangement

This invention generally relates to a liquid crystal device, and more particularly to such a device in the form of a liquid crystal cell such as for a display device, and further relates to a display device having the liquid crystal device, an optical waveguide device comprising the liquid crystal device, a Variable Optical Attenuator comprising the liquid crystal device, an optical switch comprising the liquid crystal device, a method of controlling transmission of polarised light, and to a further liquid crystal device. A liquid crystal device for controlling transmission of polarised light, comprising: chiral nematic liquid crystal having a helical arrangement of liquid crystal molecules in the absence of an electric field; and at least two electrodes for applying an electric field having a component normal to the helical axis of the chiral nematic liquid crystal, wherein the chiral nematic liquid crystal has negative dielectric anisotropy.

Owner:CAMBRIDGE ENTERPRISE LTD

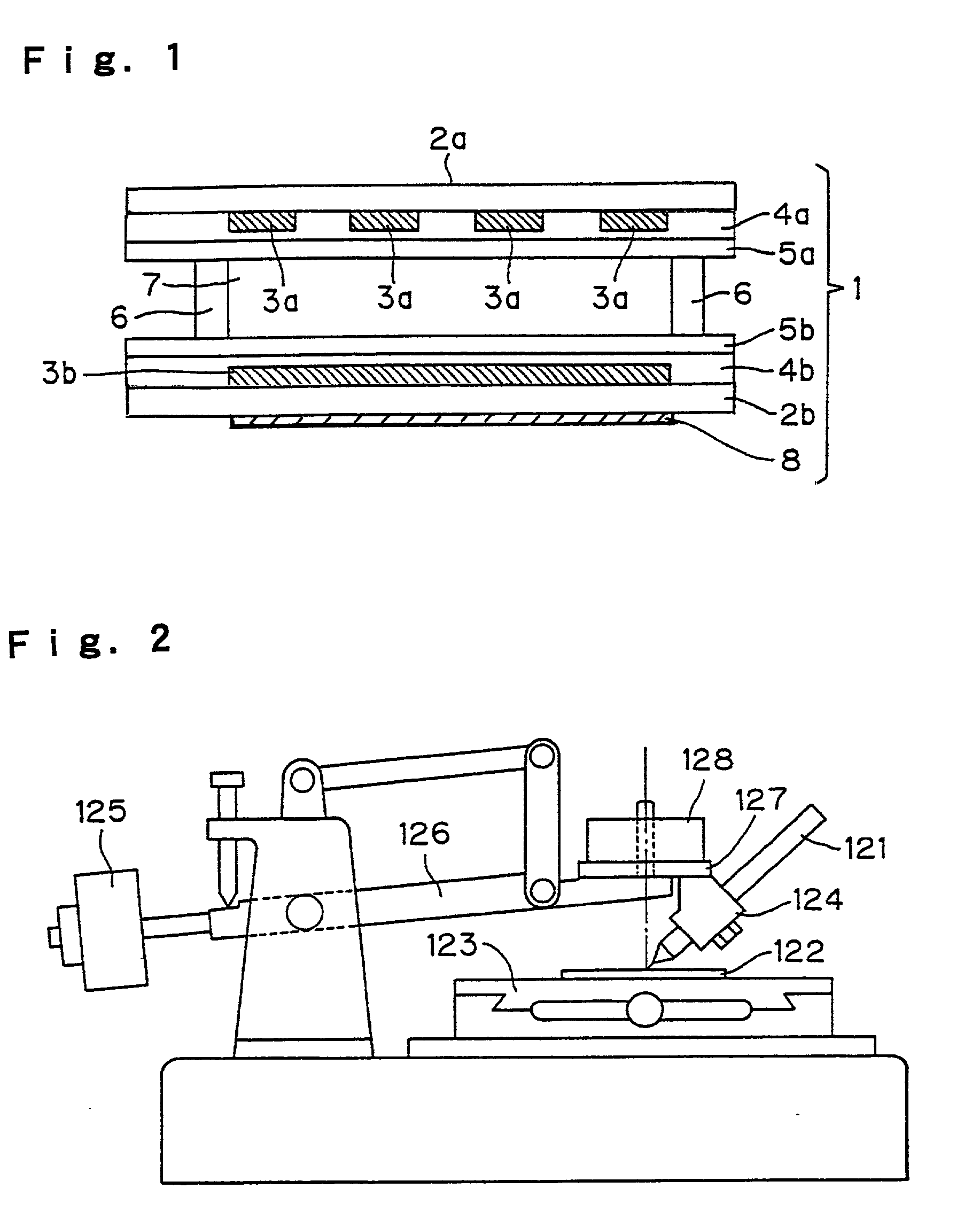

Liquid crystal optical element and test method for its boundary layer

InactiveUS20020122148A1Easy to confirmLiquid crystal compositionsNon-linear opticsScreen printingWire gauze

On substrates 2a, 2b of a chiral nematic liquid crystal optical element 1, transparent electrodes 3a, 3b and electrical insulation layers 4a, 4b are formed, and further, resin layers 5a, 5b having a pencil hardness of "B" or less are formed on the electrical insulation layers by a spin coating method so as to be in contact with a liquid crystal layer 7. When the surface hardness of the resin layers is to be measured, a glass substrate on which a resin layer is formed by screen-printing is prepared as a test piece, and the test piece is fitted to a pencil-scratching tester. The surface hardness is measured by scratching the test piece with two kinds of testing pencil selected from testing pencils having 17 grades of density.

Owner:ASAHI GLASS CO LTD

Waveform sequencing method and apparatus for a bistable cholesteric liquid crystal display

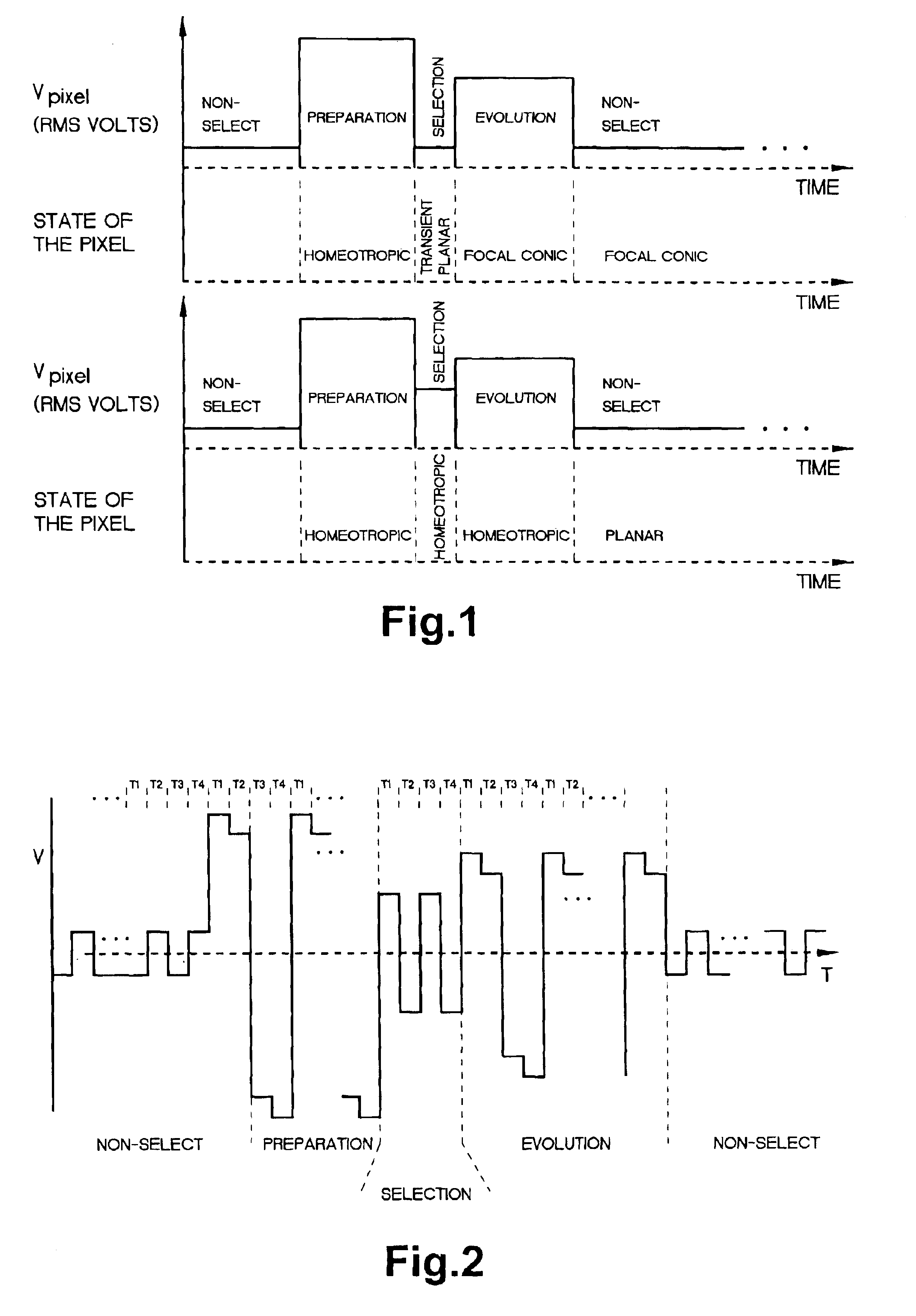

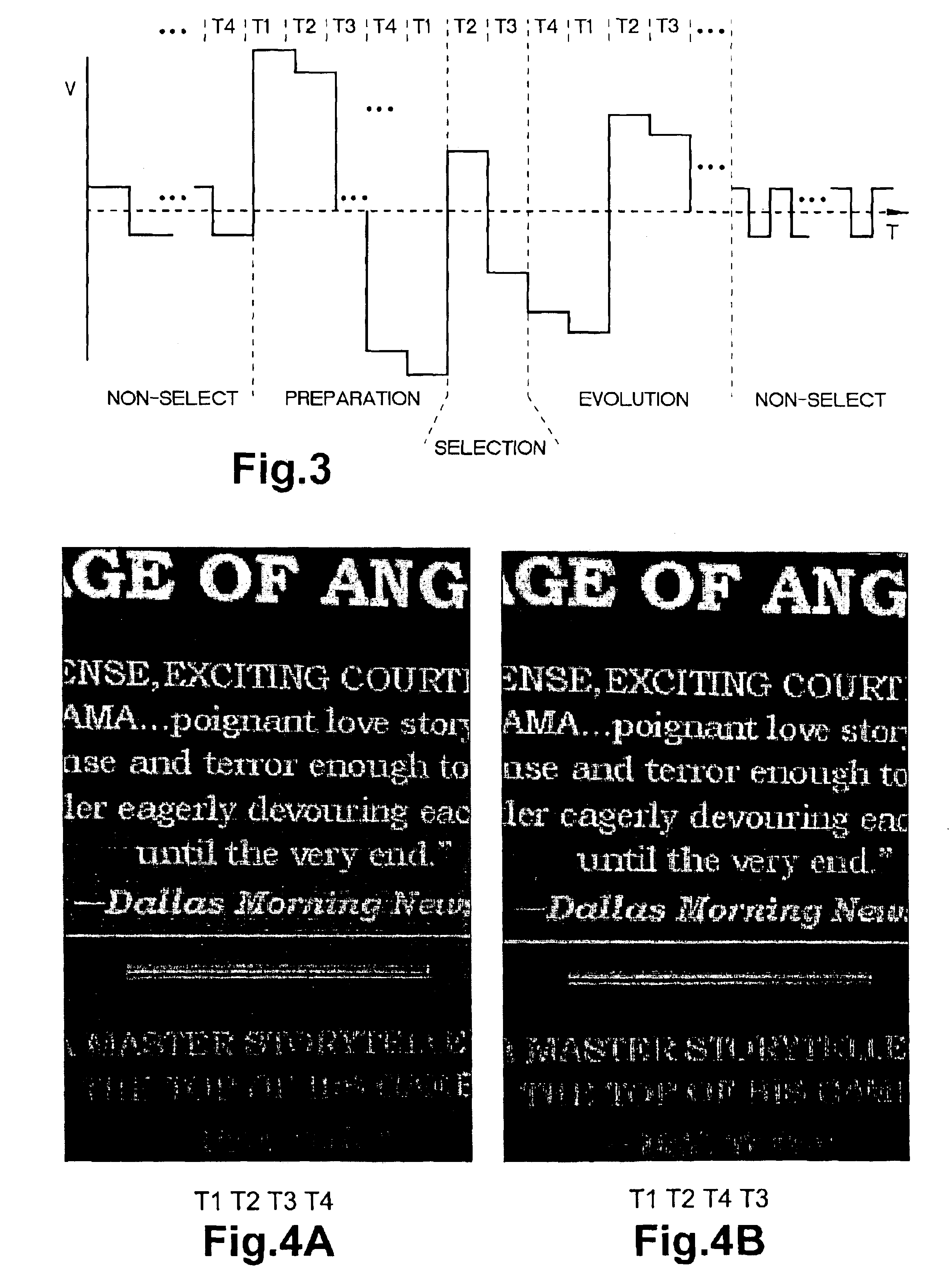

ActiveUS6911965B2Rapid update timeGood image uniformityStatic indicating devicesLiquid-crystal displayEngineering

Reflective chiral nematic liquid crystal material is disposed between a first set of electrodes and a second set of electrodes arranged on opposed sides of the material to define a collection of pixels. Fast updating dynamic drive scheme is implemented by selectively applying an electric field via the electrodes through the pixels in four phases of energization: preparation, selection, evolution, and non-select. Each phase is made up of a series of voltages having varying amplitudes. The voltage waveform is for each phase controlled based on the selection phase to achieve image uniformity. For example, the evolution voltages that are established across adjacent pixels having the same final state have initial amplitudes that are equal for both pixels to increase image uniformity.

Owner:KENT DISPLAY SYST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com