Low viscosity liquid crystal material

A liquid crystal material, low viscosity technology, applied in the direction of liquid crystal materials, instruments, chemical instruments and methods, etc., can solve the problems of difficult measurement experiments, unpredictable effects, and difficulties in predicting its performance, so as to achieve the goal of reducing bulk viscosity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

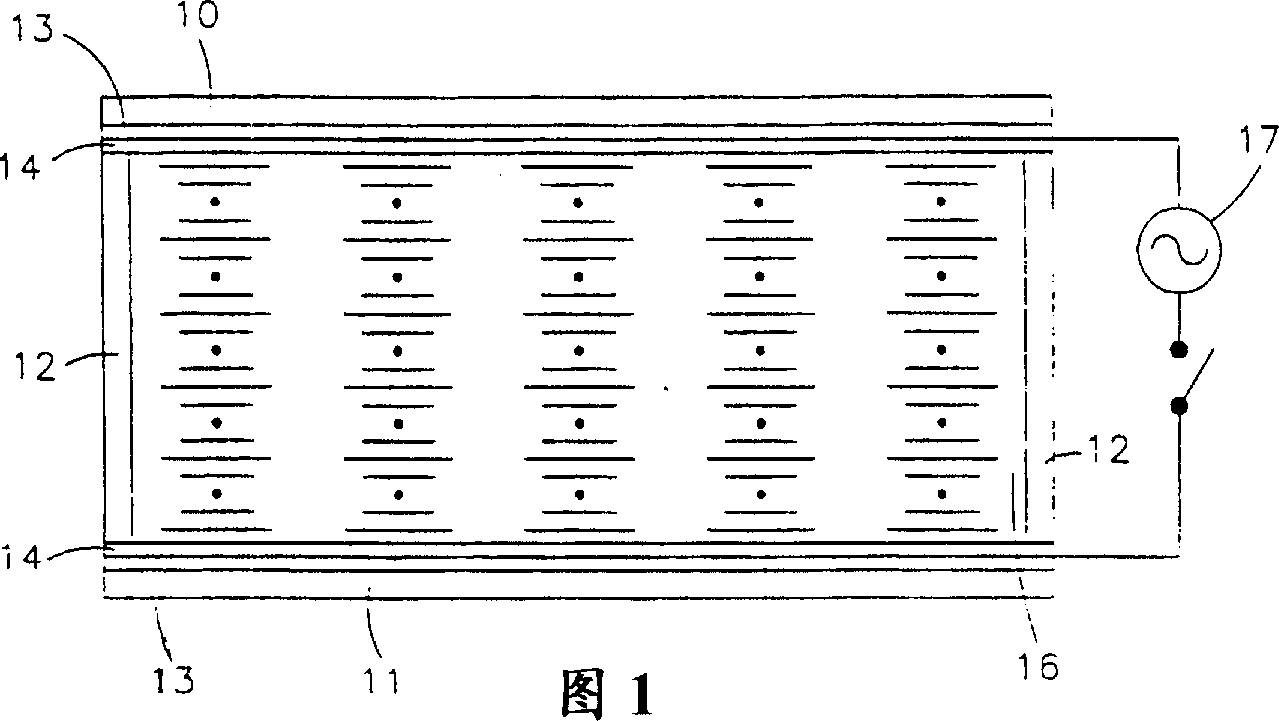

Image

Examples

Embodiment 1

[0110] Add together the following weight % materials expressed based on the total weight of the composition:

[0111] BL061 74.6%;

[0112] E44 14.9%;

[0113] p-cyanophenylpentane 10.0%;

[0114] C6 0.50%;

[0115] Dye is added to saturate the color. The helical pitch of the cholesteric liquid crystal is adjusted with the E44 nematic material so that the material reflects light at wavelengths in the visible region of the electromagnetic spectrum. These materials were mixed in a vortex mixer for 30 seconds. The mixture was then placed in an oven at 100°C until the entire mixture was in the isotropic phase. The mixture was then mixed in a vortex mixer at room temperature until returning to the cholesteric phase. The time for the second mixing varies with the concentration of the additive and the amount of the mixture.

Embodiment 2

[0117] The following components were added together and kneaded under the same conditions as in Example 1.

[0118] BL061 76.28%;

[0119] E44 16.12%;

[0120] 1-Phenylhexane 7.10%;

[0121] C6 0.50%;

Embodiment 3

[0123] The following components were added together and kneaded under the same conditions as in Example 1.

[0124] BL061 75.4%;

[0125] E44 16.1%;

[0126] p-cyanopentylbenzene 8.00%;

[0127] BAB 1.10%;

[0128] IRGACURE 651 0.30%;

[0129] C6 0.50%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com