Method for utilizing polymer stable liquid crystal material to prepare light brightness enhancement film

A technology for stabilizing liquid crystals and polymerizing liquid crystals, applied in optics, nonlinear optics, instruments, etc., can solve the problems of difficult synthetic methods of raw materials and expensive synthetic materials, and achieve optimized light reflection performance, little influence of light scattering, and uniform surface Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Production of the glass substrate: soak the glass substrate in potassium dichromate lotion for 1 hour, take out the glass substrate, wash it with distilled water, and dry it. Soak the other glass substrate in the aqueous solution of photopolymerizable siloxane for 1 minute, take out the glass substrate, wash it with distilled water, and heat it at 100°C for 1 hour, combine the above two glass substrates, and the thickness of the spacer is 20 μm to make a liquid crystal box.

[0019]

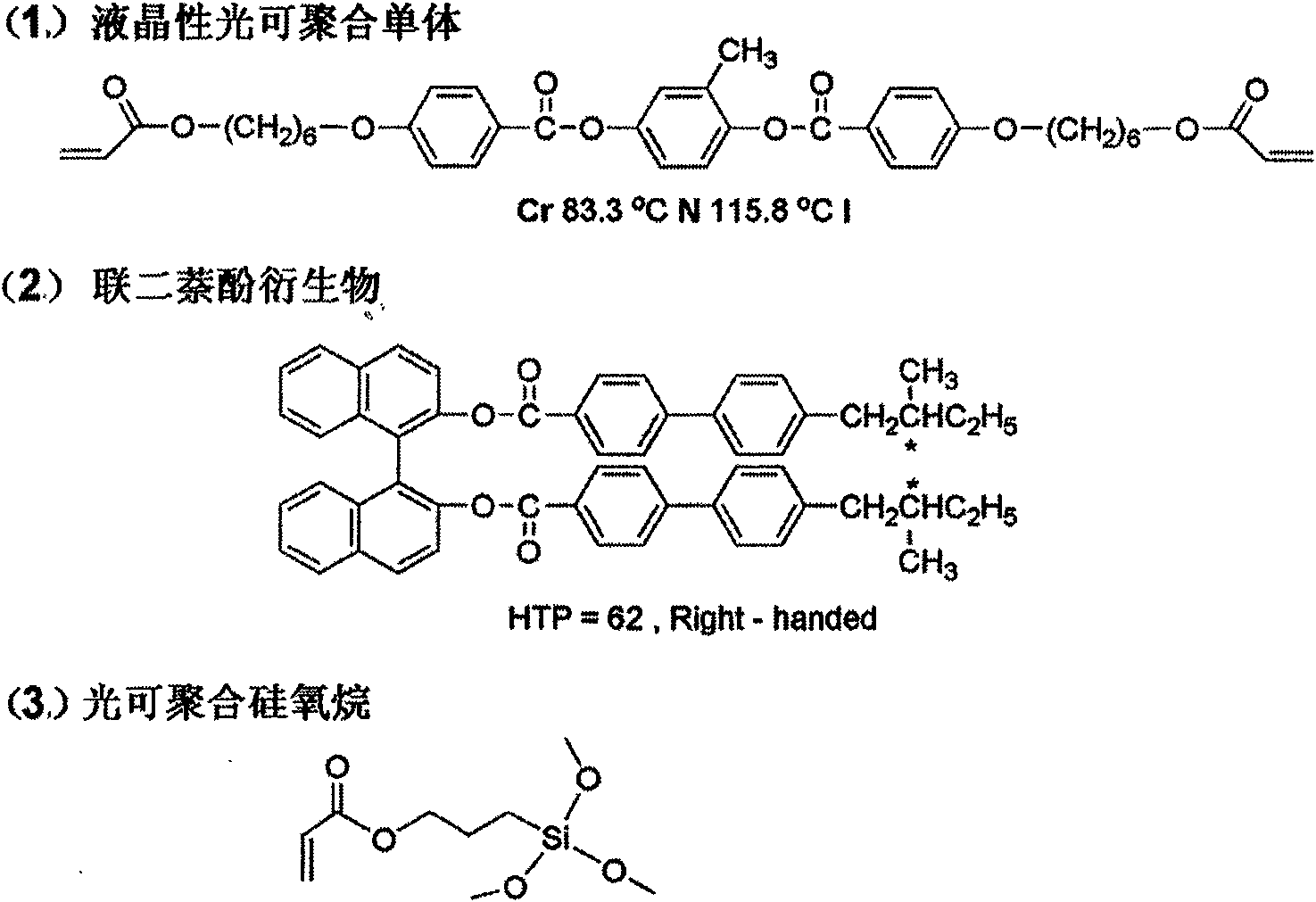

[0020] a) Mass ratio: nematic liquid crystal (SLC-1717) / chiral compound / C6M / photoinitiator

[0021] Pour sample 1 into a new liquid crystal cell after surface treatment, N * The phase liquid crystal maintains the planar texture, and the liquid crystal cell is irradiated with ultraviolet light, and the irradiation intensity is 30mW / cm 2 , and the irradiation time was 1 hour. After the irradiation, the surface treated with the potassium dichromate washing solution was peeled off from ...

Embodiment 2

[0023]

[0024] a) Mass ratio: nematic liquid crystal (SLC-1717) / chiral compound / C6M / photoinitiator

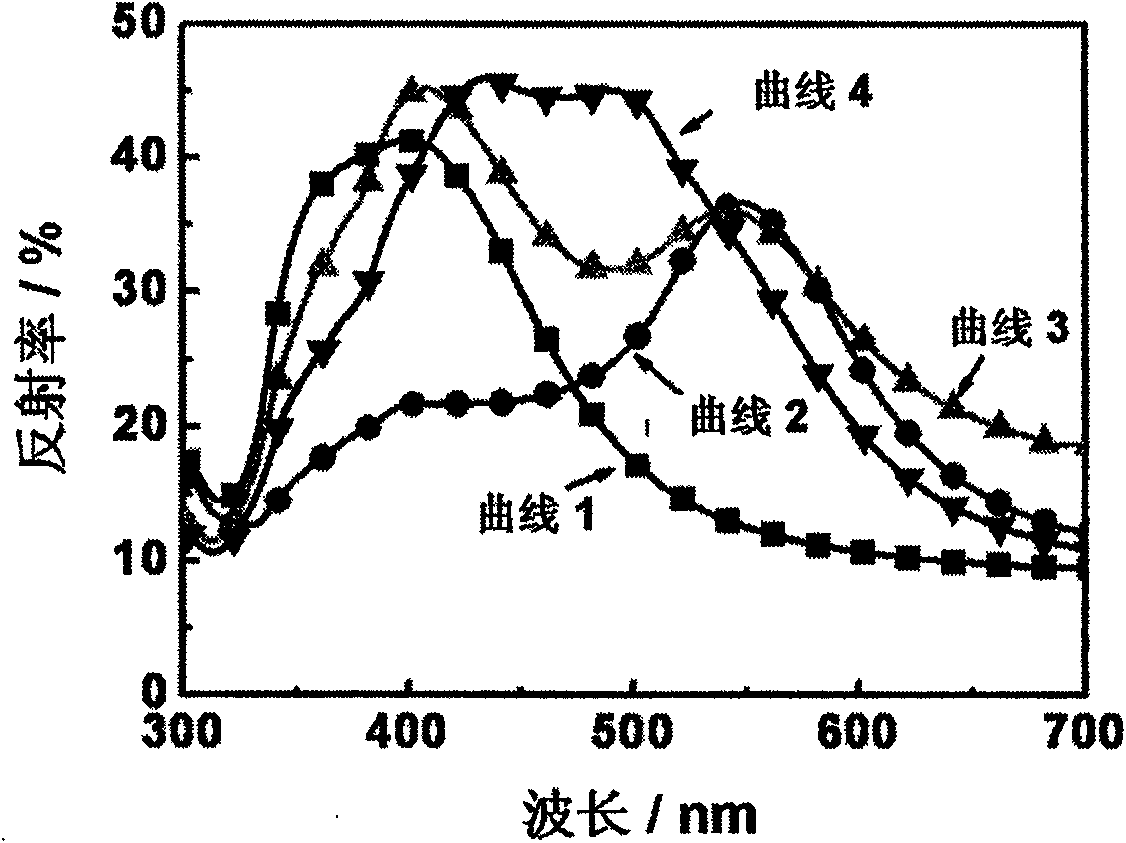

[0025] Manufacturing method is as embodiment 1, and the thickness of liquid crystal cell is 50 μ m, after the ultraviolet photopolymerization process identical with embodiment 1, promptly obtains the PSLC film material of embodiment 2, and reflection wavelength range is 400~550nm (such as figure 2 shown).

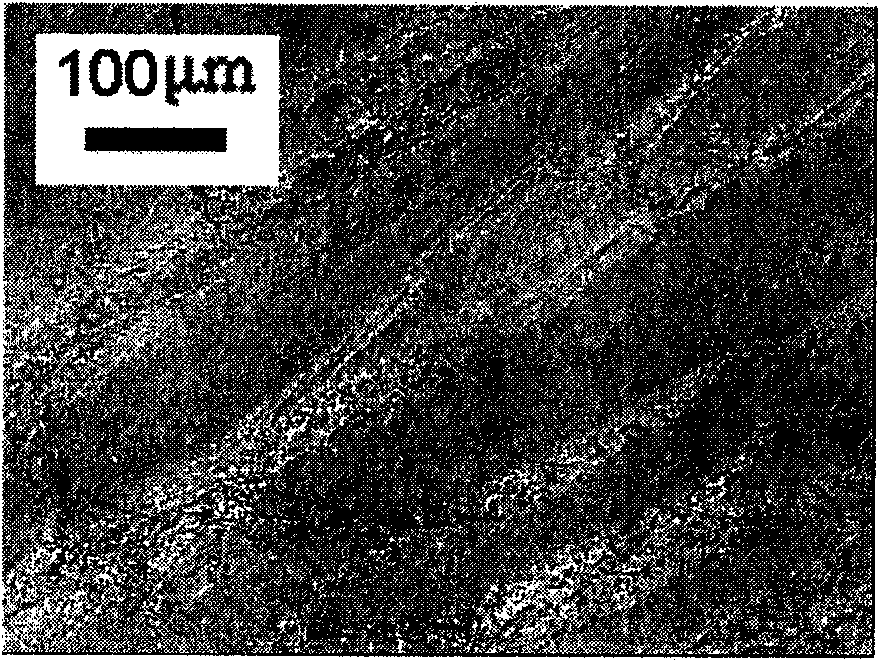

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com