Patents

Literature

171 results about "Discotic liquid crystal" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

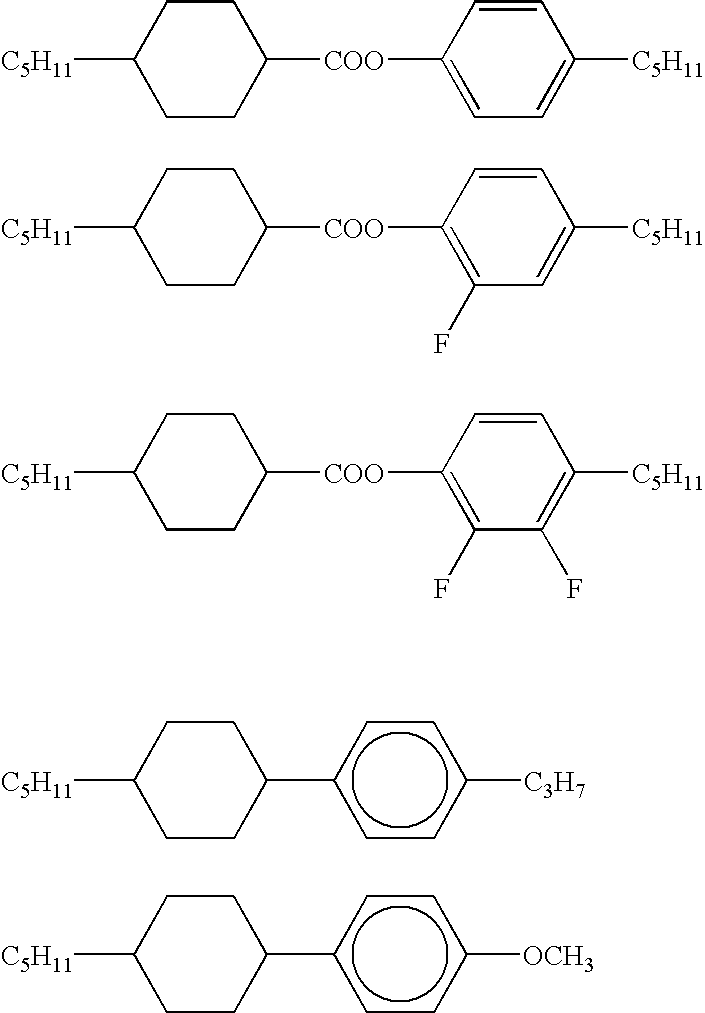

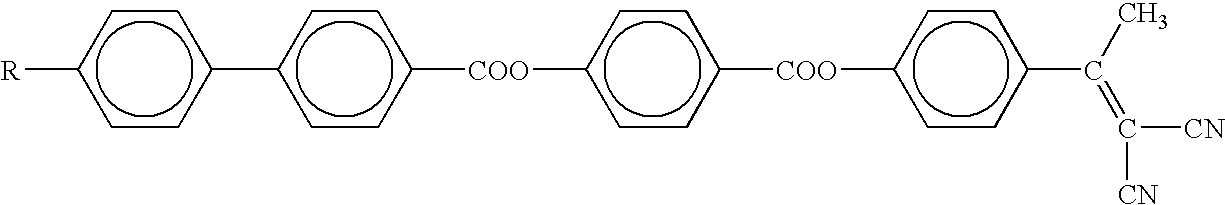

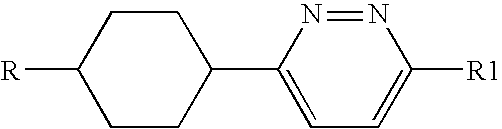

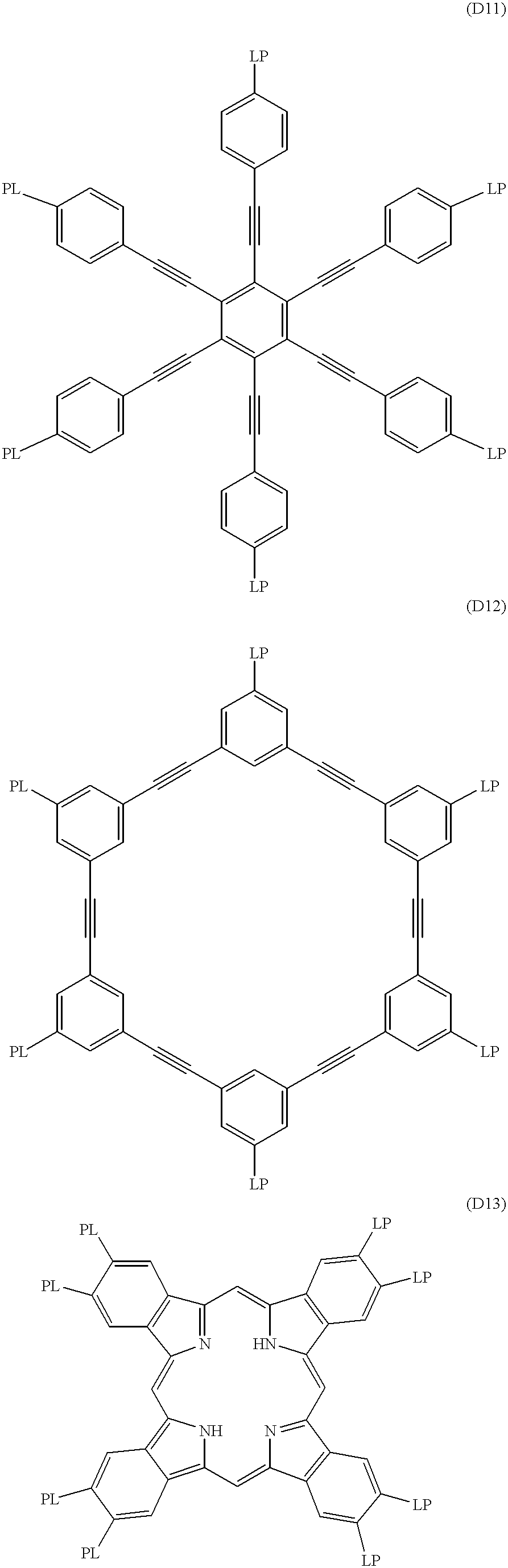

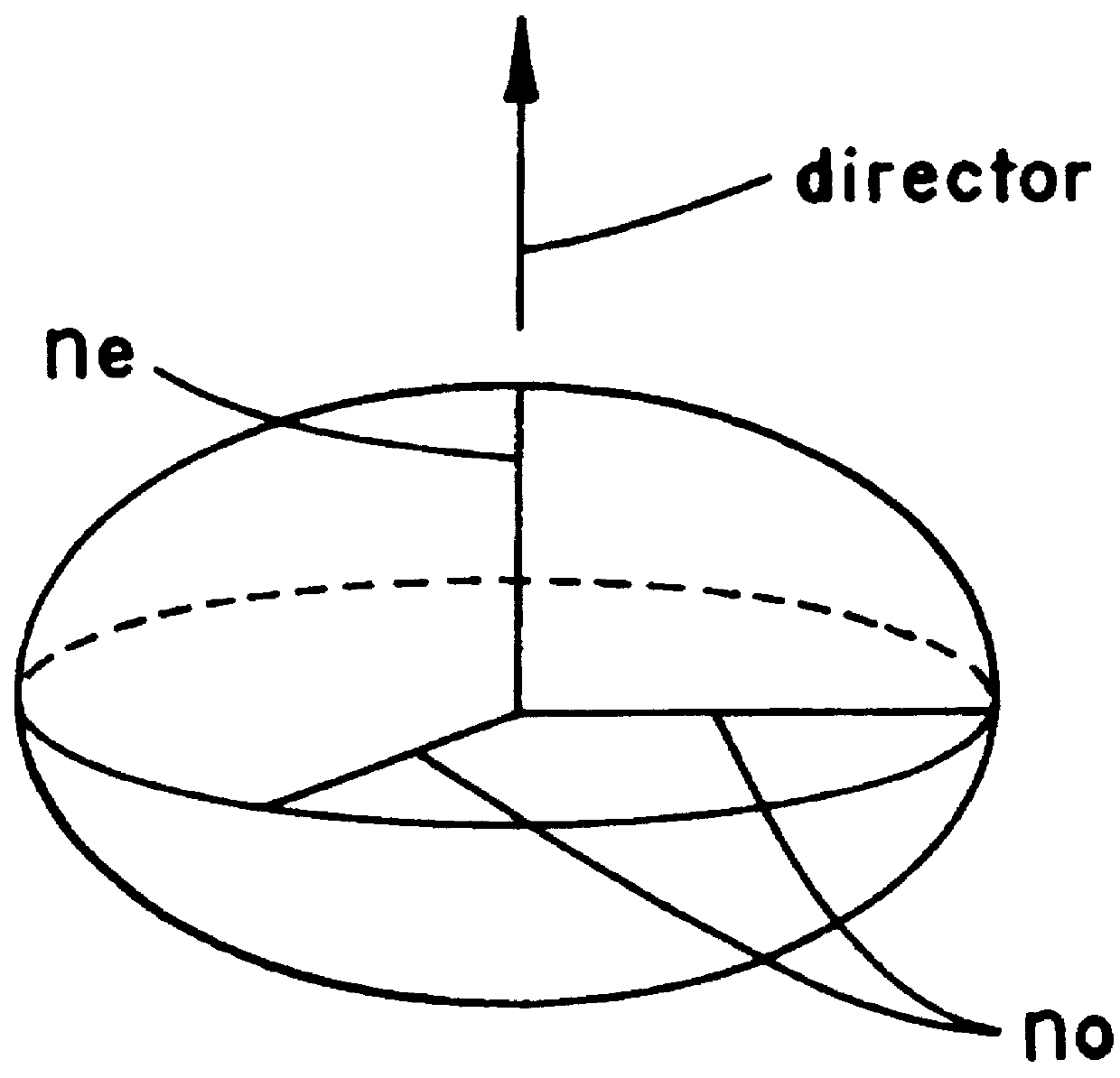

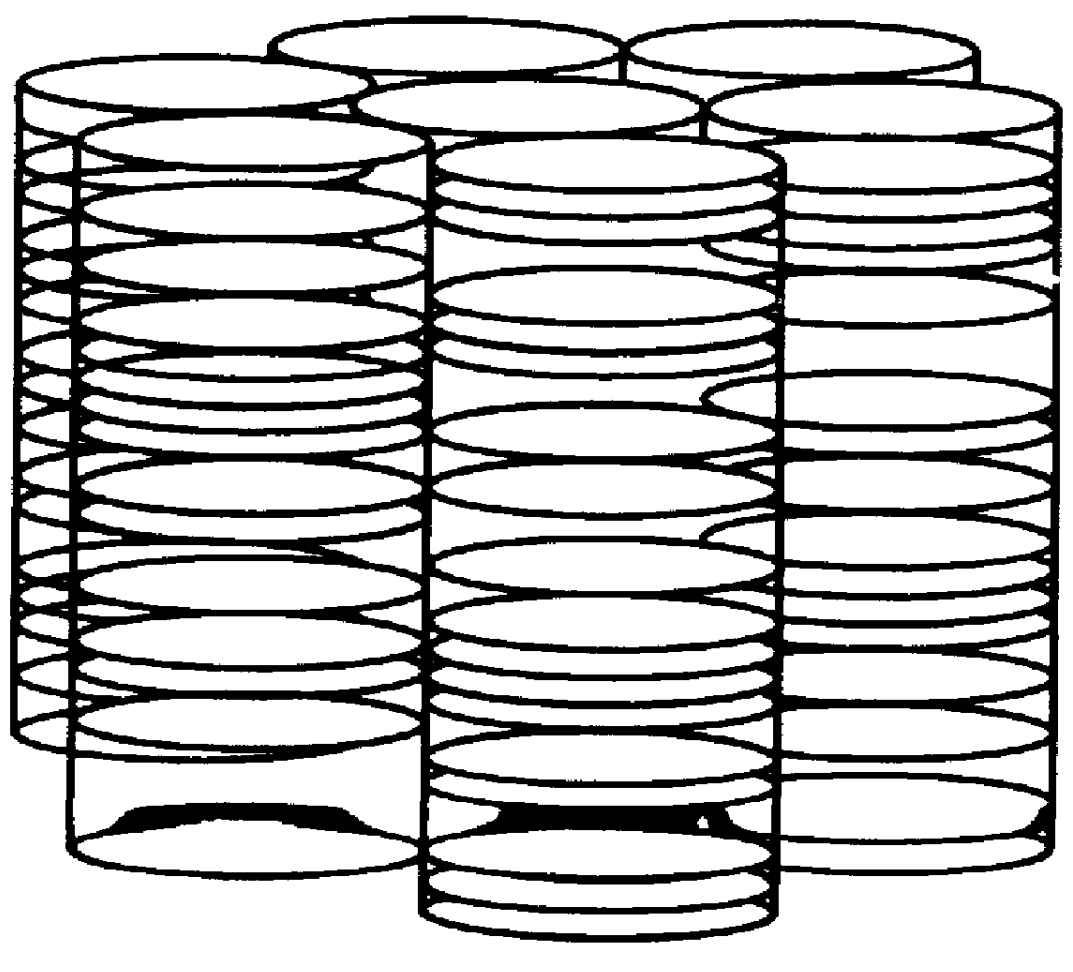

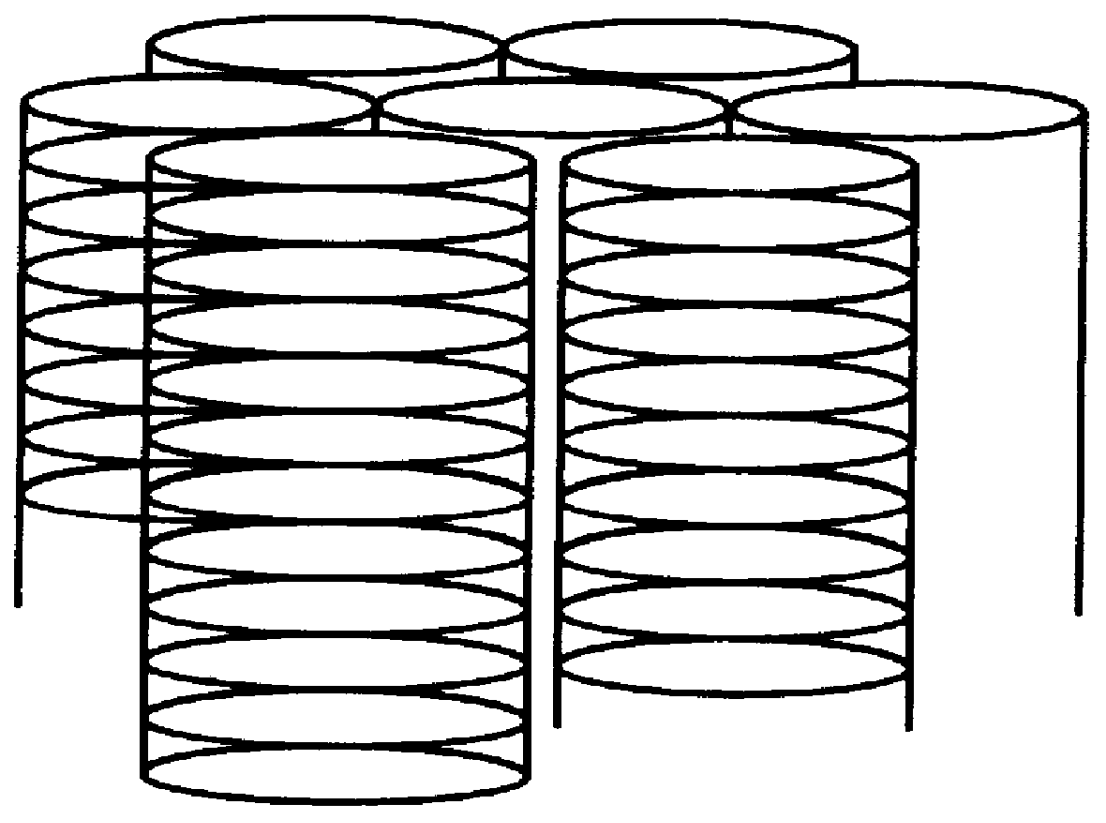

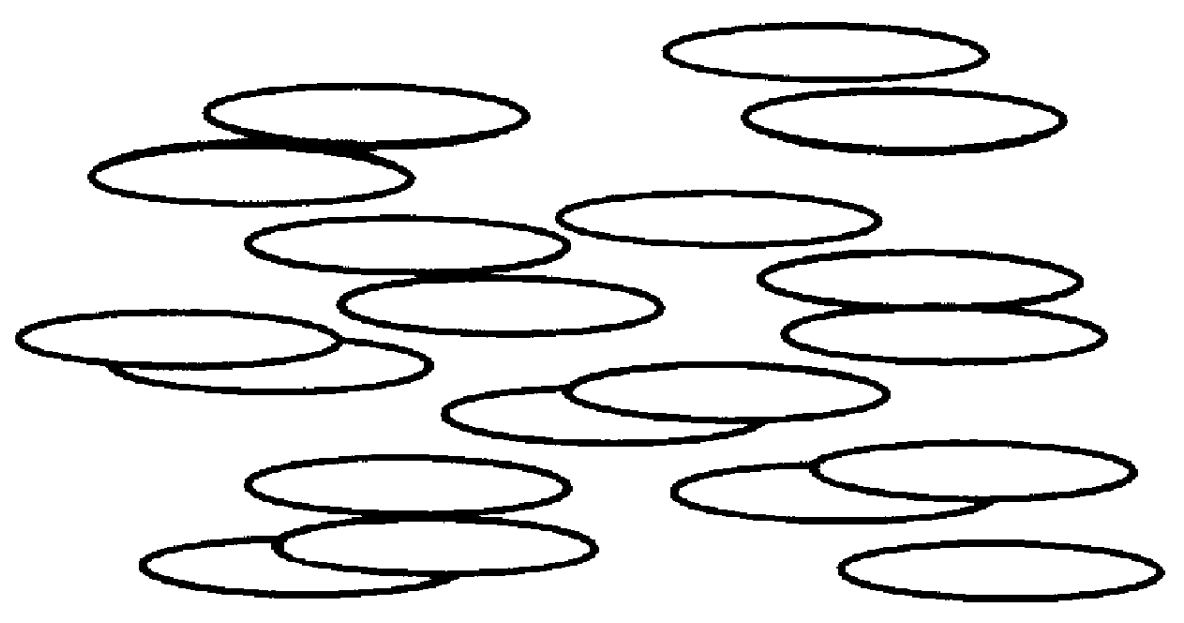

Discotic liquid crystals are mesophases formed from disc-shaped molecules known as "discotic mesogens". These phases are often also referred to as columnar phases. Discotic mesogens are typically composed of an aromatic core surrounded by flexible alkyl chains. The aromatic cores allow charge transfer in the stacking direction through the π conjugate systems. The charge transfer allows the discotic liquid crystals to be electrically semiconductive along the stacking direction. Applications have been focusing on using these systems in photovoltaic devices, organic light emitting diodes (OLED), and molecular wires. Discotics have also been suggested for use in compensation films, for LCD displays.

Electrically switchable polymer-dispersed liquid crystal materials including switchable optical couplers and reconfigurable optical interconnects

InactiveUS6821457B1Lower switching voltageDiffusing elementsPhotomechanical apparatusWavelengthOptical coupler

A new photopolymerizable material allows single-step, fast recording of volume holograms with properties that can be electrically controlled. Polymer-dispersed liquid crystals (PDLCs) in accordance with the invention preferably comprise a homogeneous mixture of a nematic liquid crystal and a multifunctional pentaacrylate monomer in combination with photoinitiator, coinitiator and cross-linking agent. Optionally, a surfactant such as octancic acid may also be added. The PDLC material is exposed to coherent light to produce an interference pattern inside the material. Photopolymerization of the new PDLC material produces a hologram of clearly separated liquid crystal domains and cured polymer domains. Volume transmission gratings made with the new PDLC material can be electrically switched between nearly 100% diffraction efficiency and nearly 0% diffraction efficiency. By increasing the frequency of the switching voltage, switching voltages in the range of 50 Vrms can be achieved. The optional use of a surfactant allows low switching voltages at lower frequencies than without a surfactant. In an alternative embodiment, a PDLC material in accordance with the invention can be utilized to form reflection gratings, including switchable reflection gratings. In still further embodiments, a PDLC material in accordance with the invention can be used to form switchable subwavelength gratings. By further processing, static transmission, reflection, and subwavelength PDLC materials can be formed. In addition, PDLC materials in accordance with the present invention can be used to form switchable slanted transmission gratings suitable for switchable optical coupling and reconfigurable optical interconnects.

Owner:LEIDOS

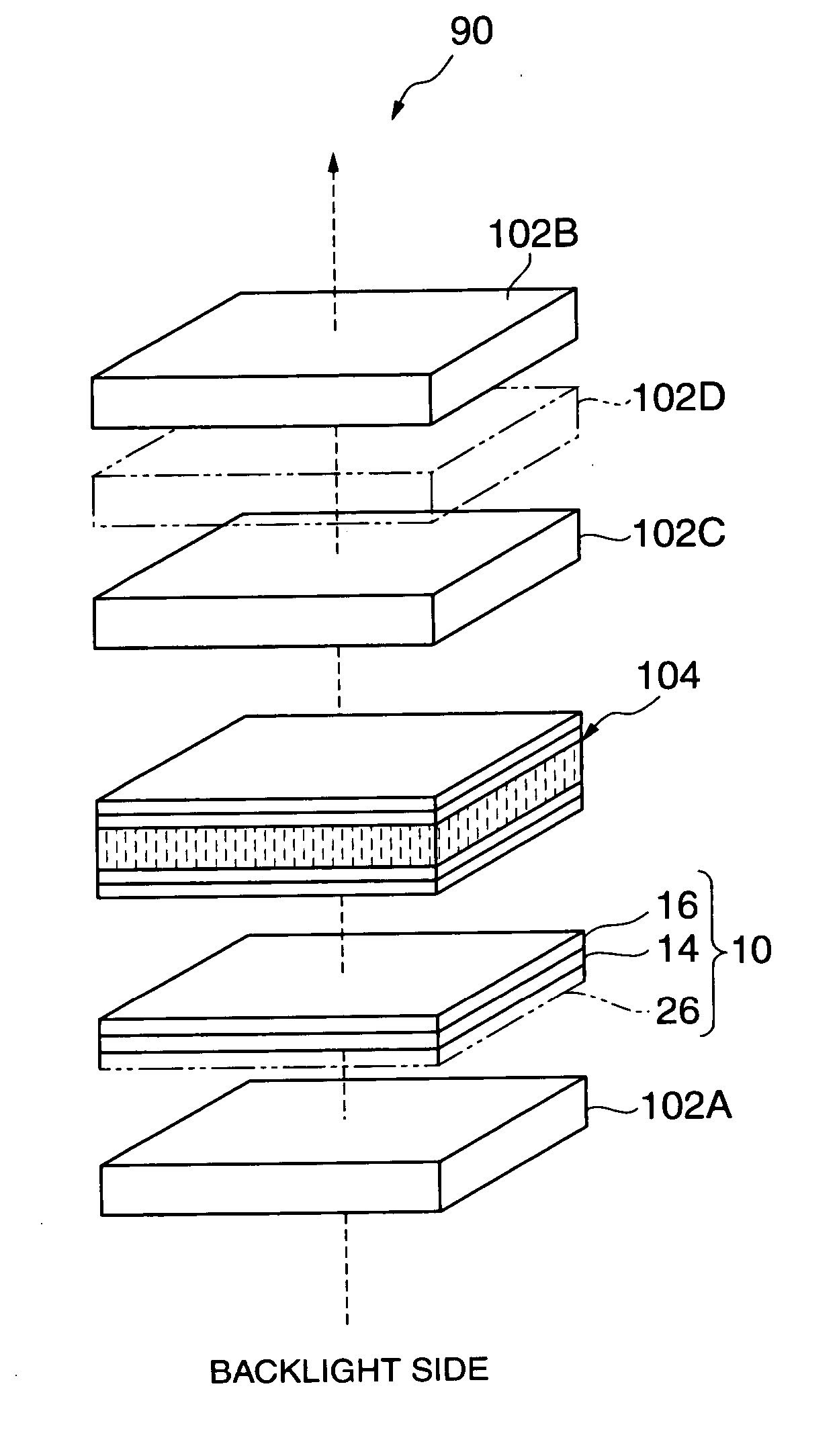

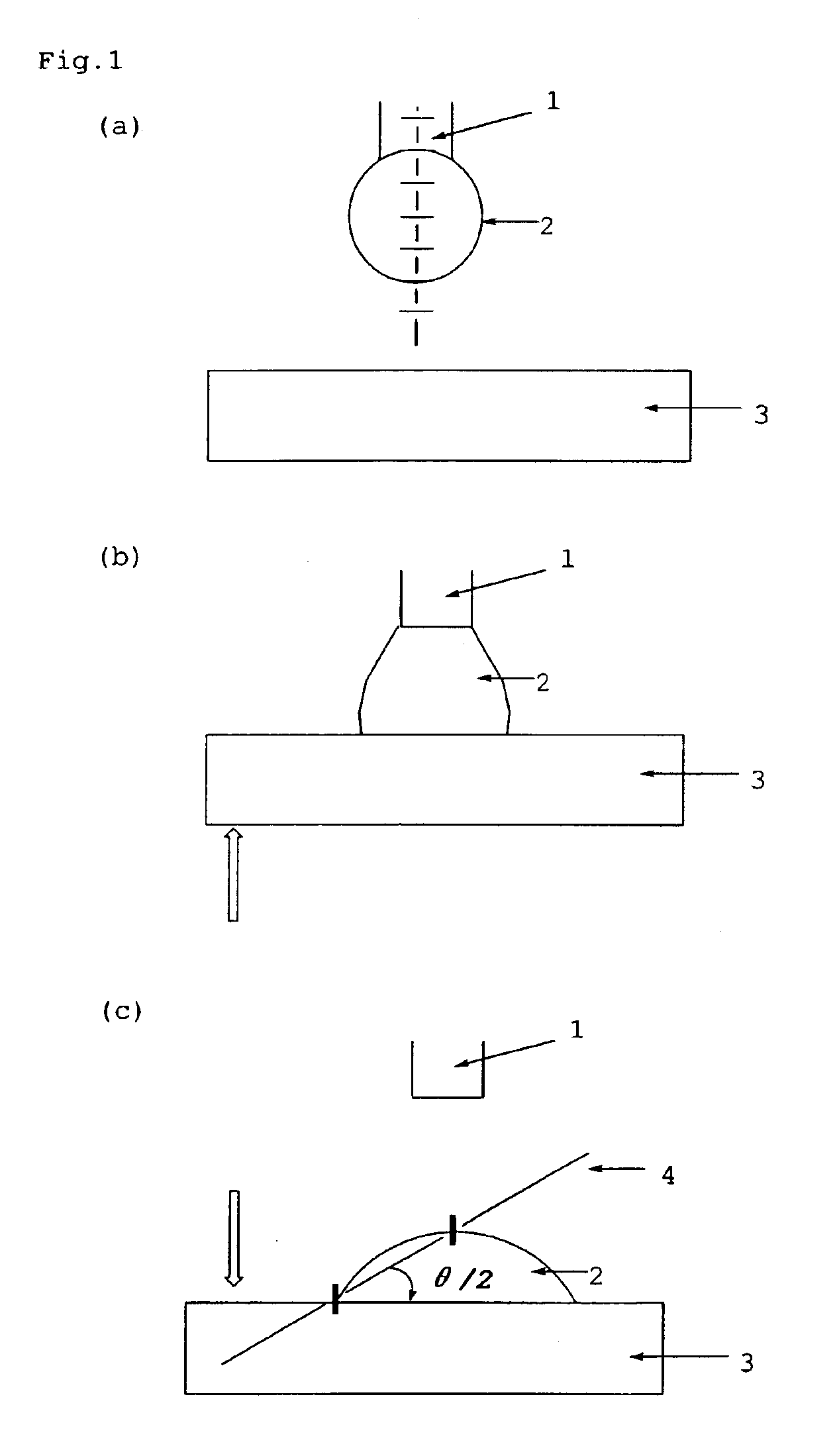

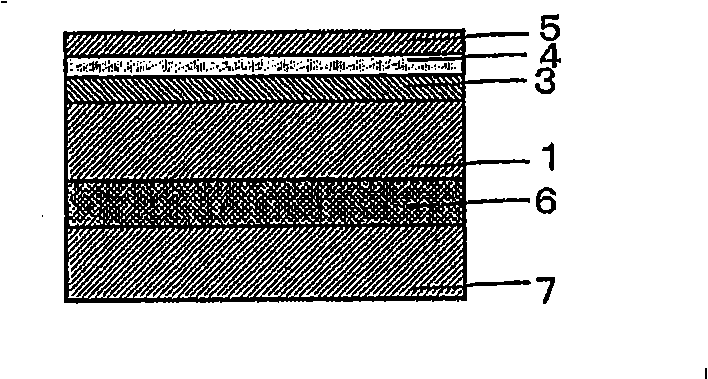

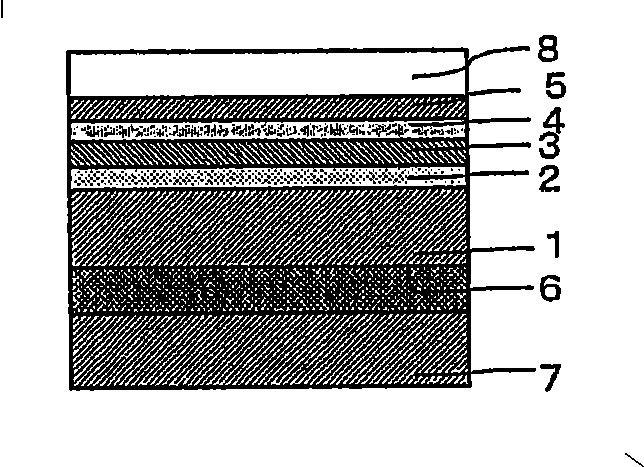

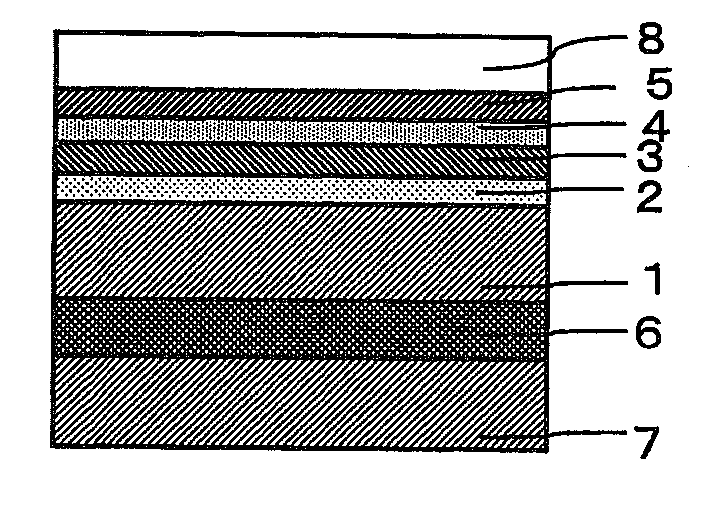

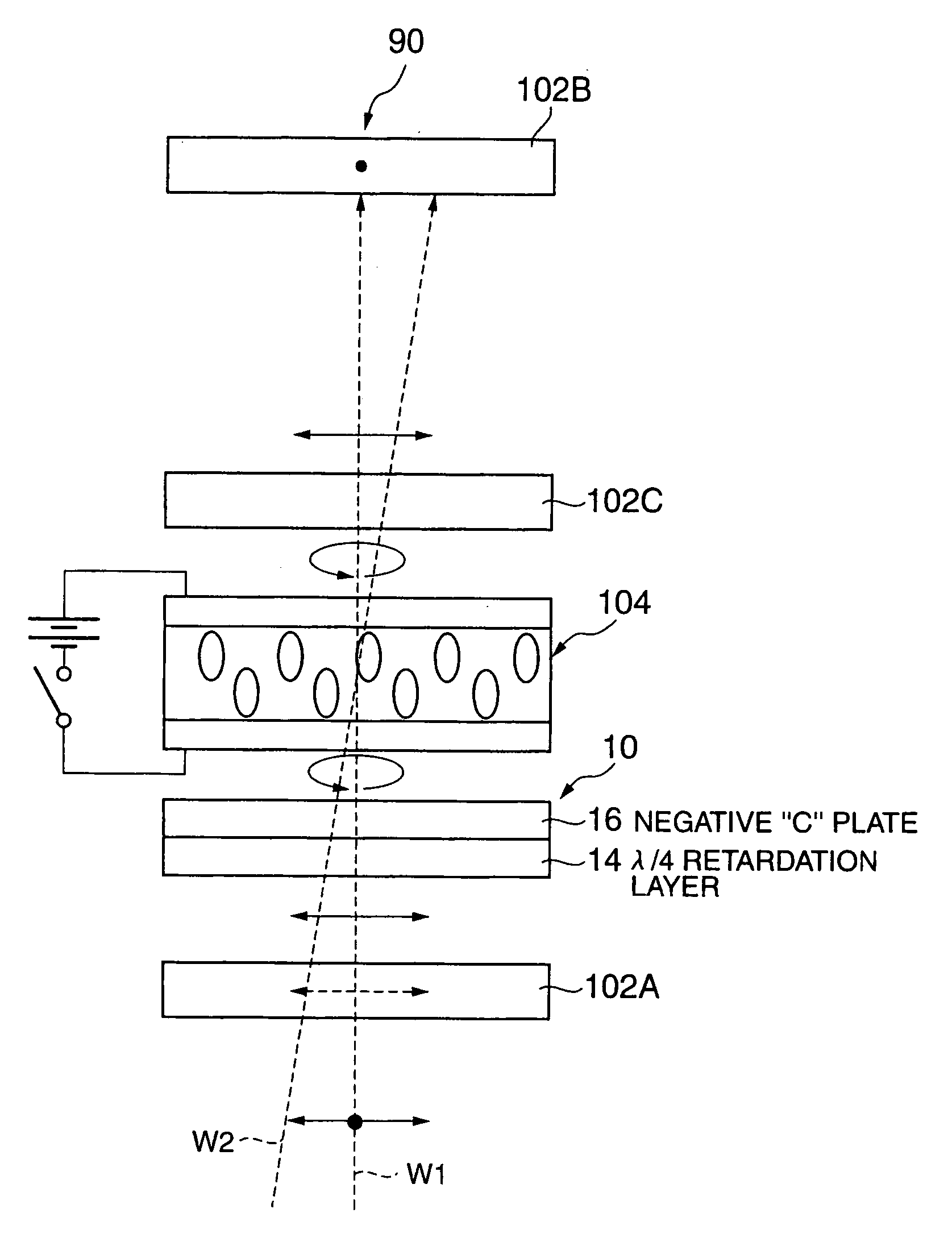

Laminated retardation optical element, process of producing the same, and liquid crystal display

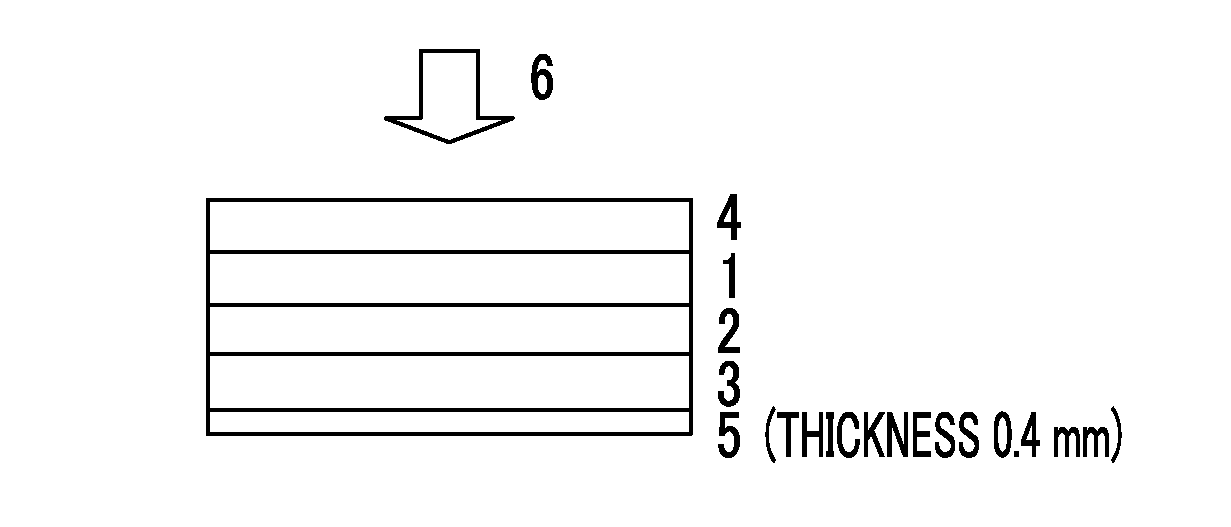

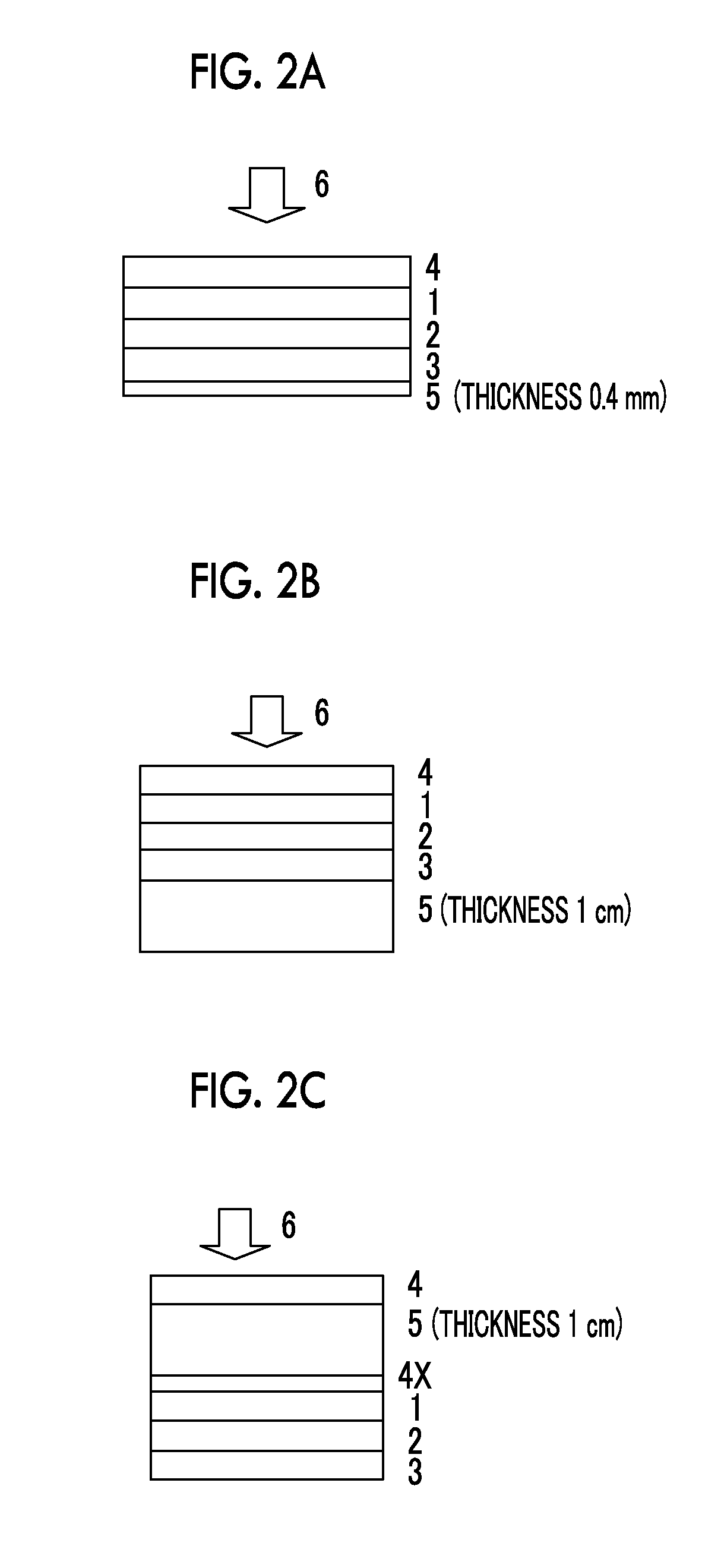

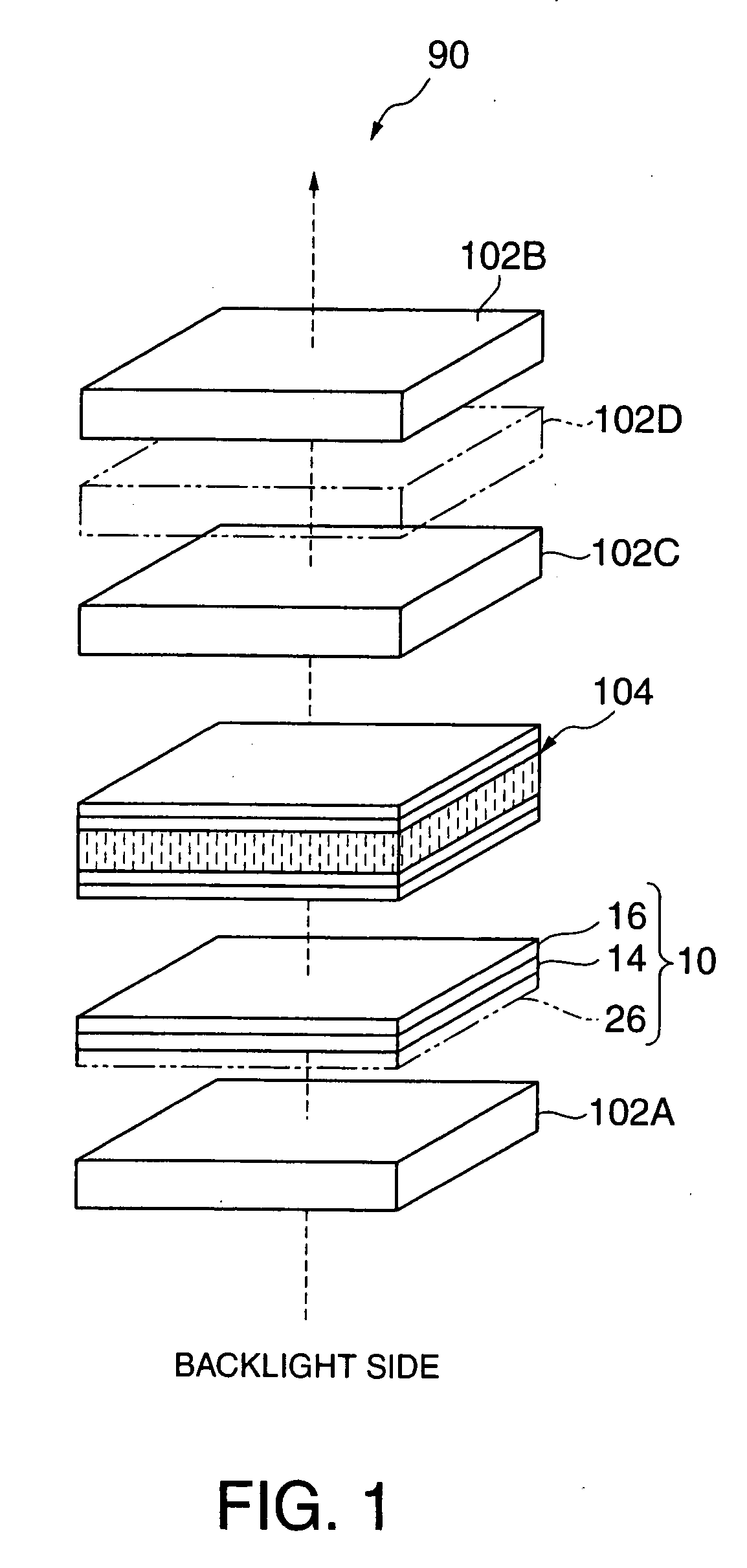

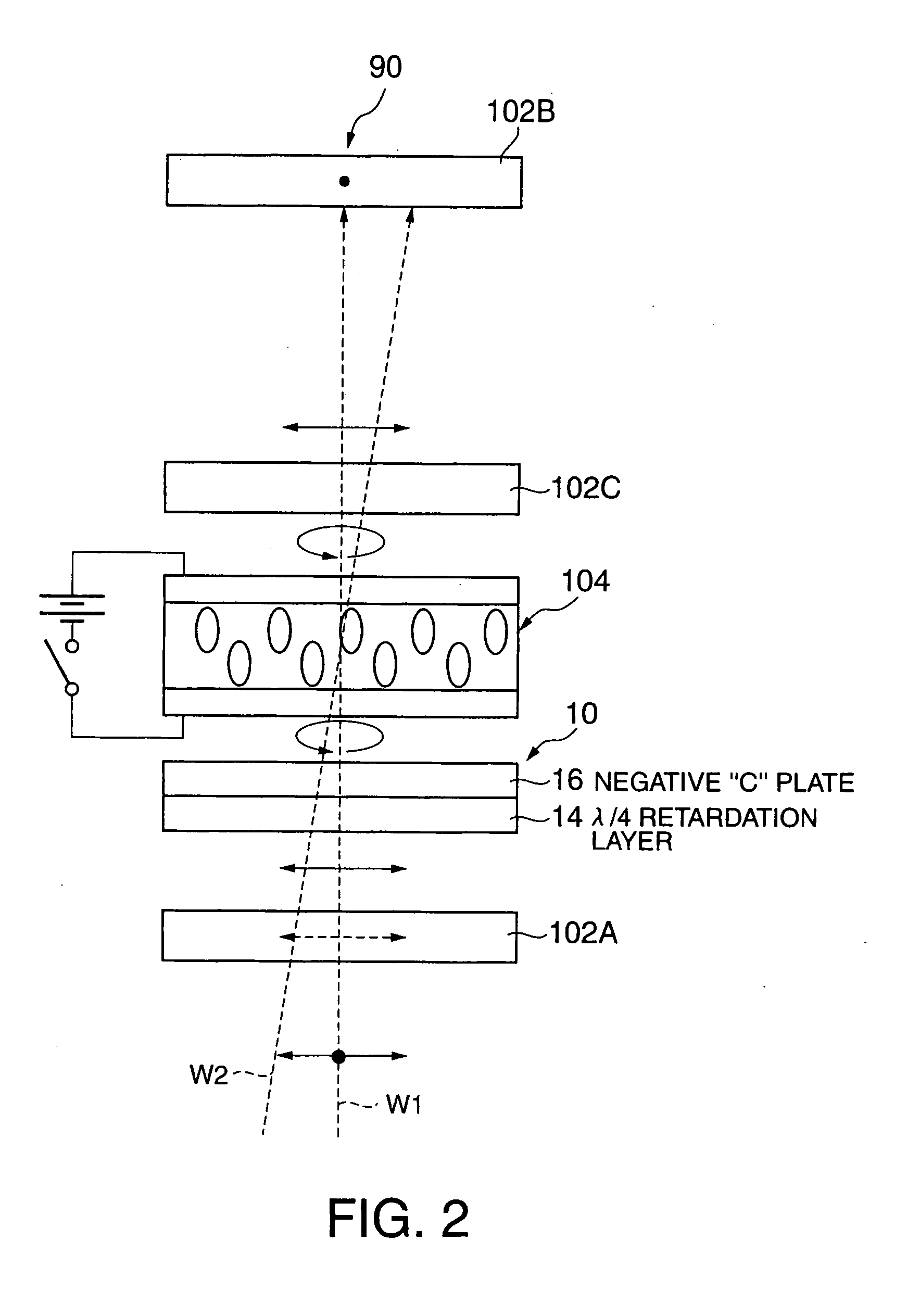

The present invention provides a laminated retardation optical element that never lowers contrast and thus never degrades display performance even when placed between a liquid crystal cell and a lambda / 4 retardation film. In a liquid crystal display 90, a laminated retardation optical element 10 is placed between a polarizer 102A on the incident side and a liquid crystal cell 104, and a lambda / 4 retardation film 102C is placed between a polarizer 102B on the emergent side and the liquid crystal cell 104. The laminated retardation optical element 10 comprises: a lambda / 4 retardation layer 14 having the function of bringing, to light that passes through this retardation layer, a phase difference corresponding to a quarter of the wavelength of the light; and a C plate-type retardation layer 16 that acts as a negative C plate. The lambda / 4 retardation layer 14 and the C plate-type retardation layer 16 are laminated to a transparent substrate 12 in the order mentioned, and are optically bonded to each other. The lambda / 4 retardation layer 14 comprises as its main component a horizontally-aligned, cross-linked nematic liquid crystal, while the C plate-type retardation layer 16 comprises as its main component a cross-linked chiral nematic liquid crystal (a cross-linked nematic liquid crystal and a cross-linked chiral agent) or cross-linked discotic liquid crystal.

Owner:DAI NIPPON PRINTING CO LTD

Optical compensatory sheet and liquid crystal display

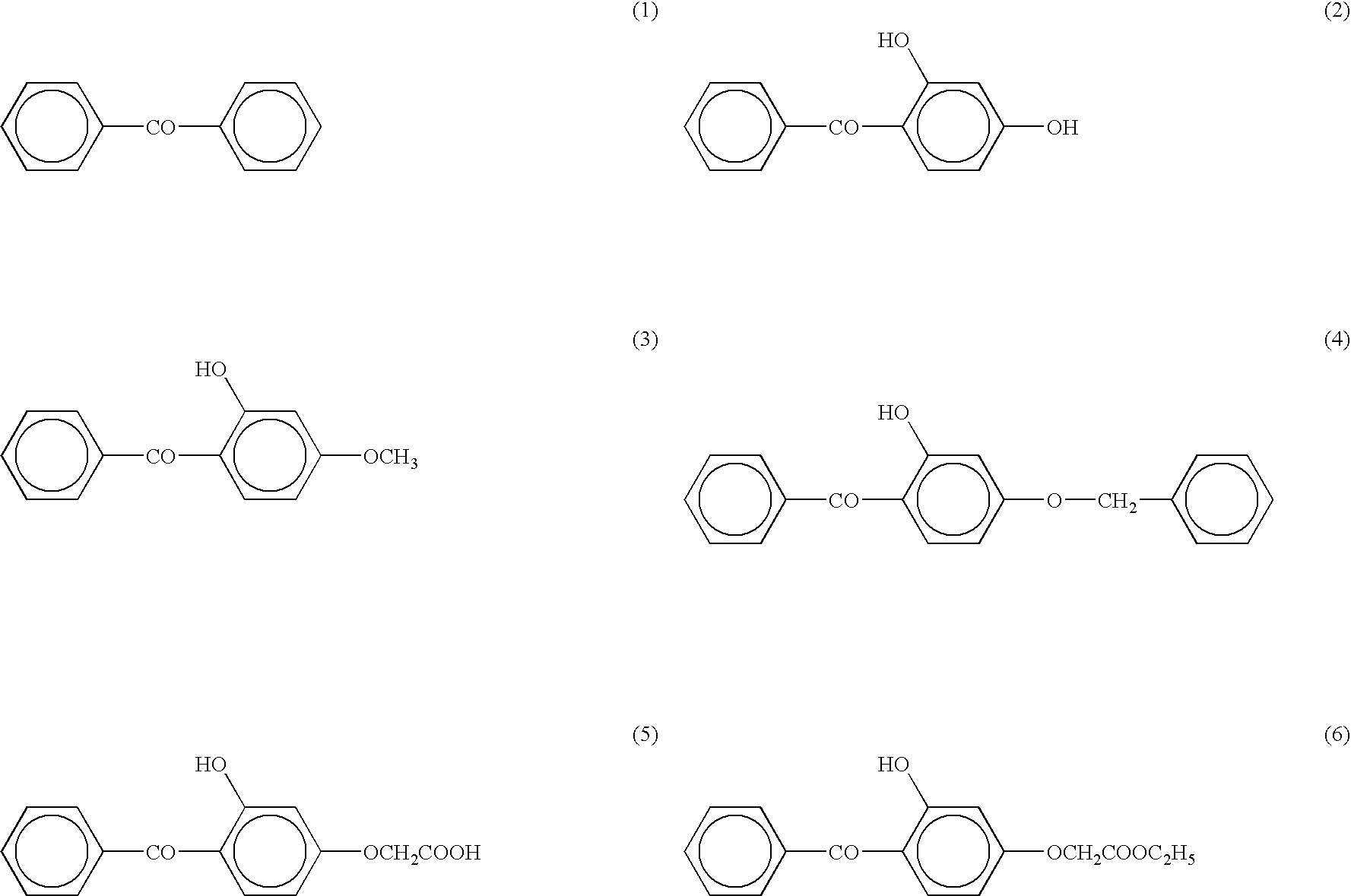

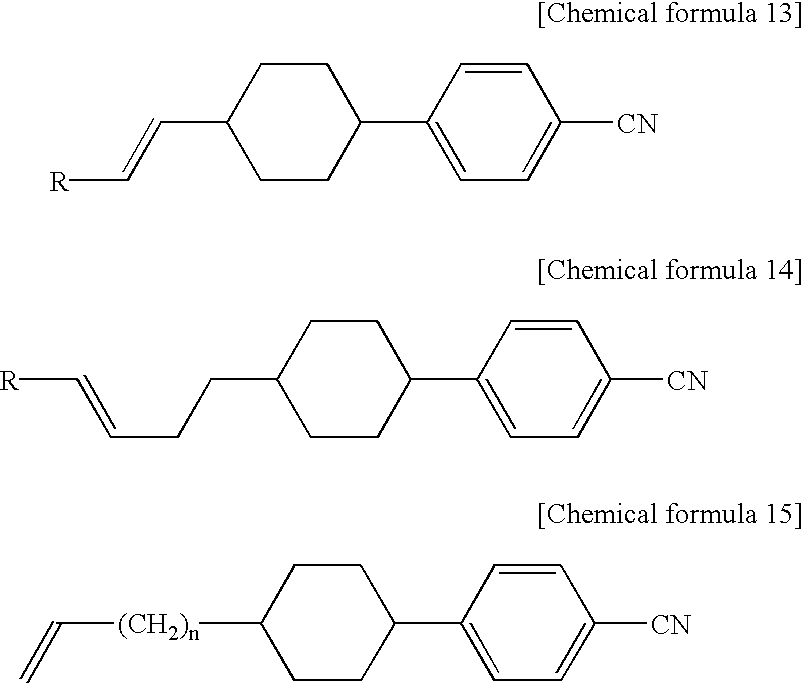

InactiveUS6380996B1Good dimensional stabilityLiquid crystal compositionsStatic indicating devicesDiscotic liquid crystalChemistry

Owner:FUJIFILM CORP

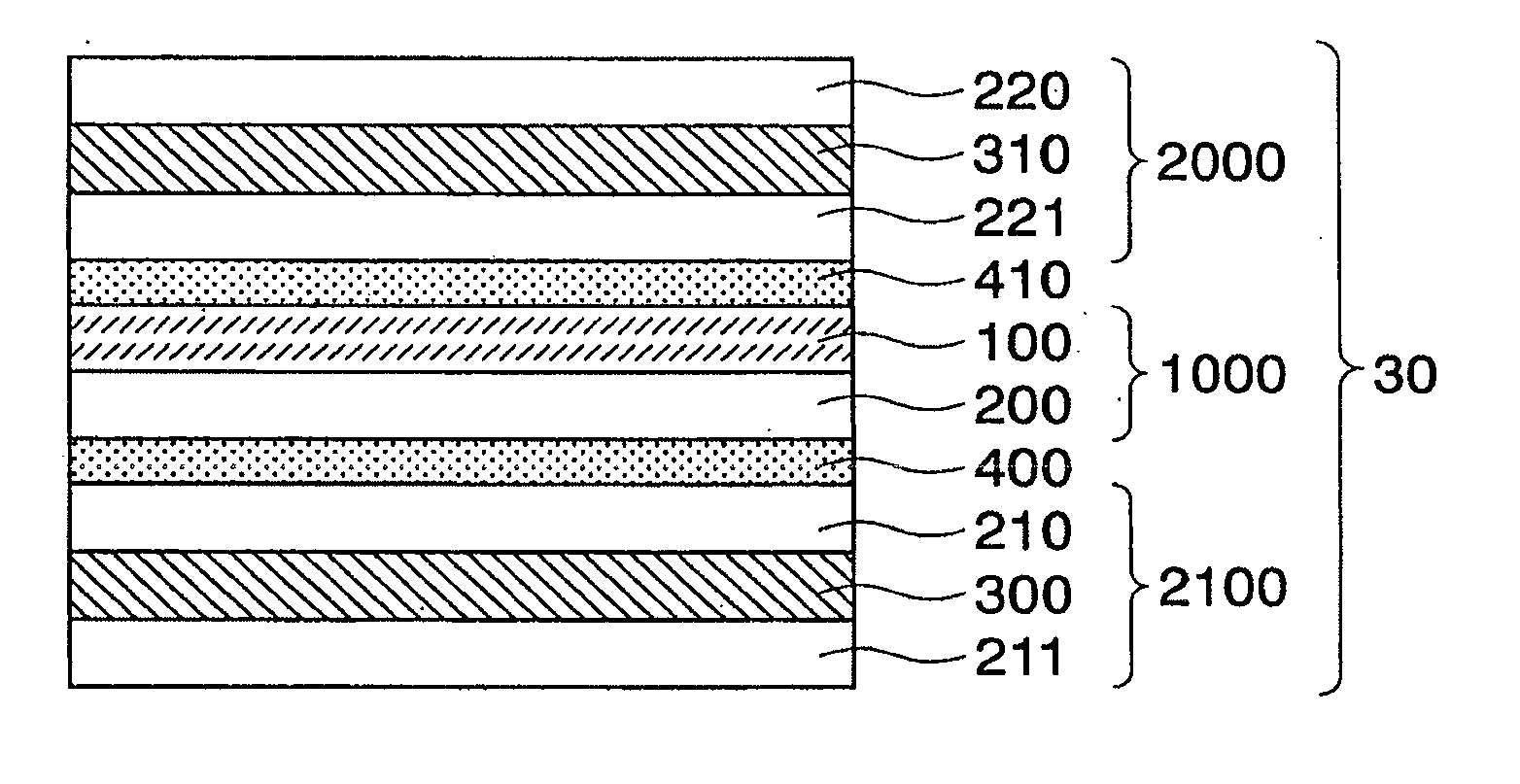

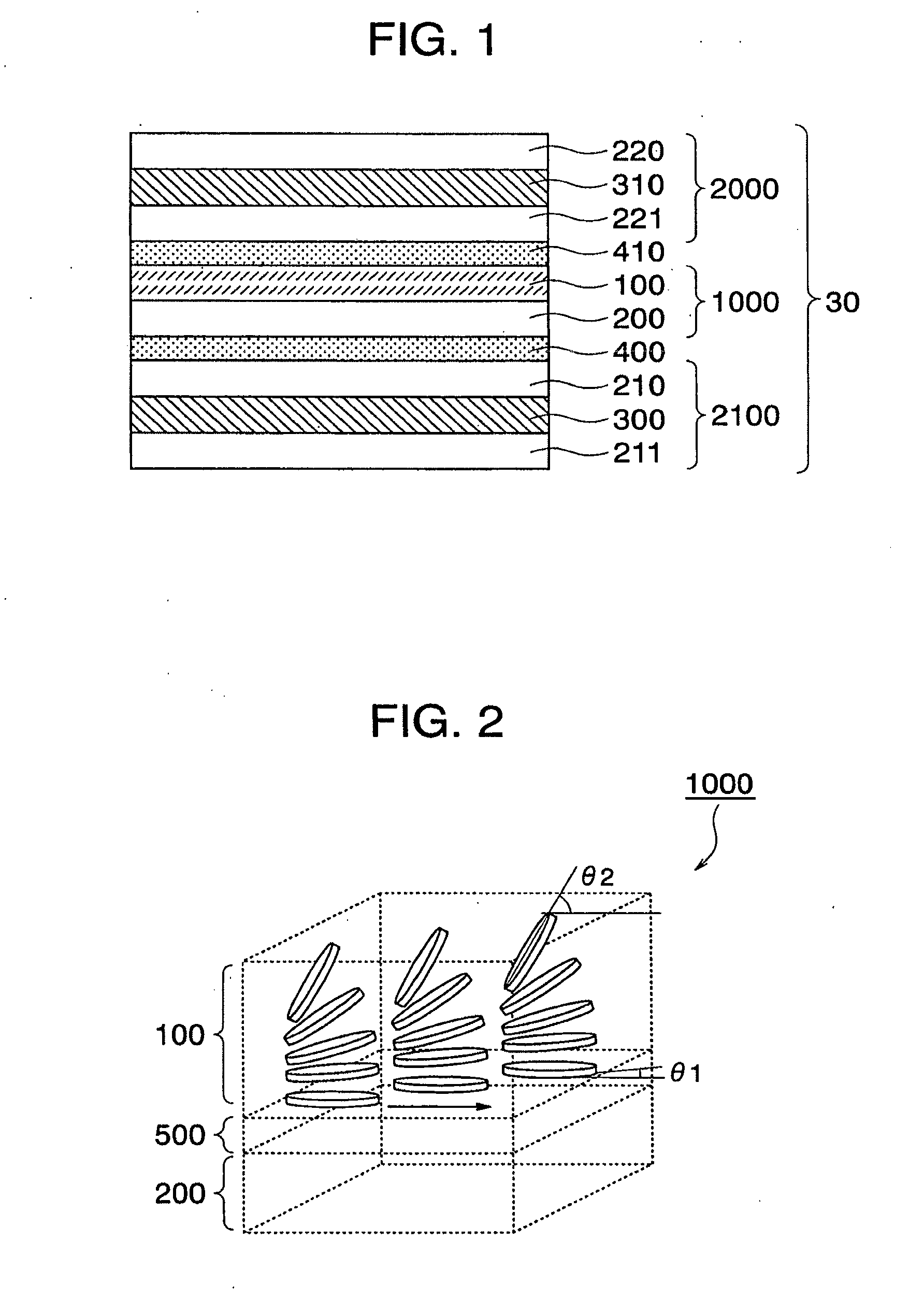

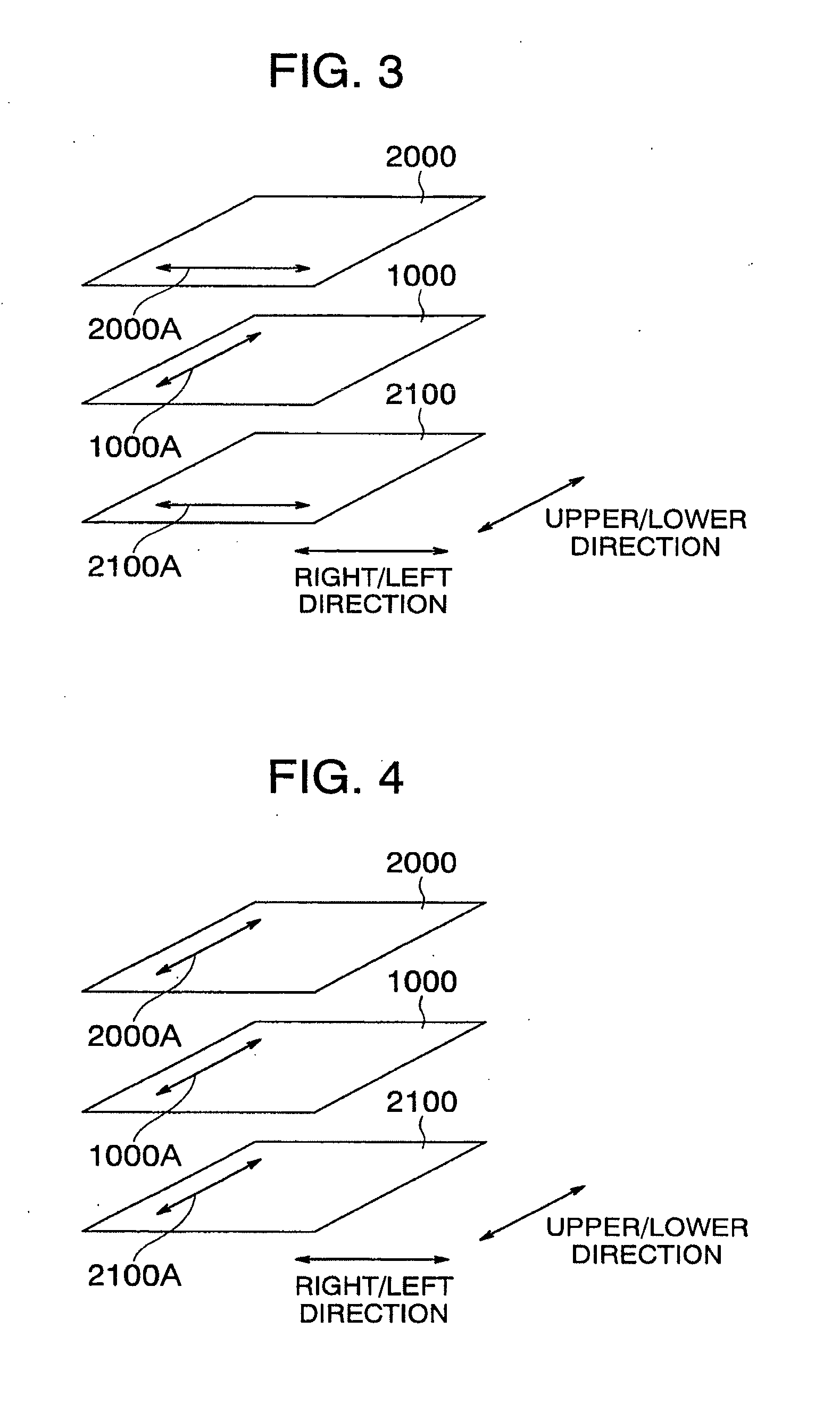

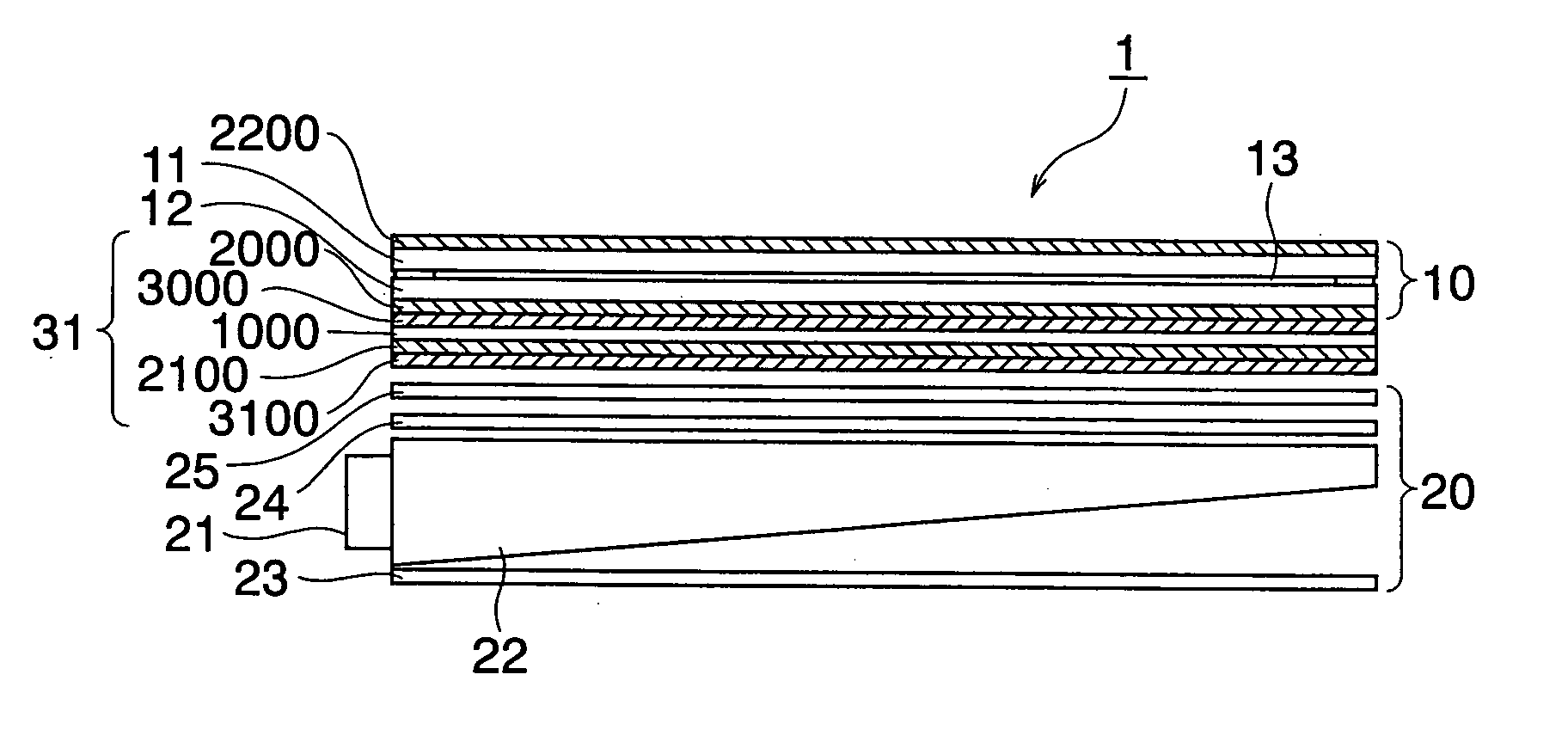

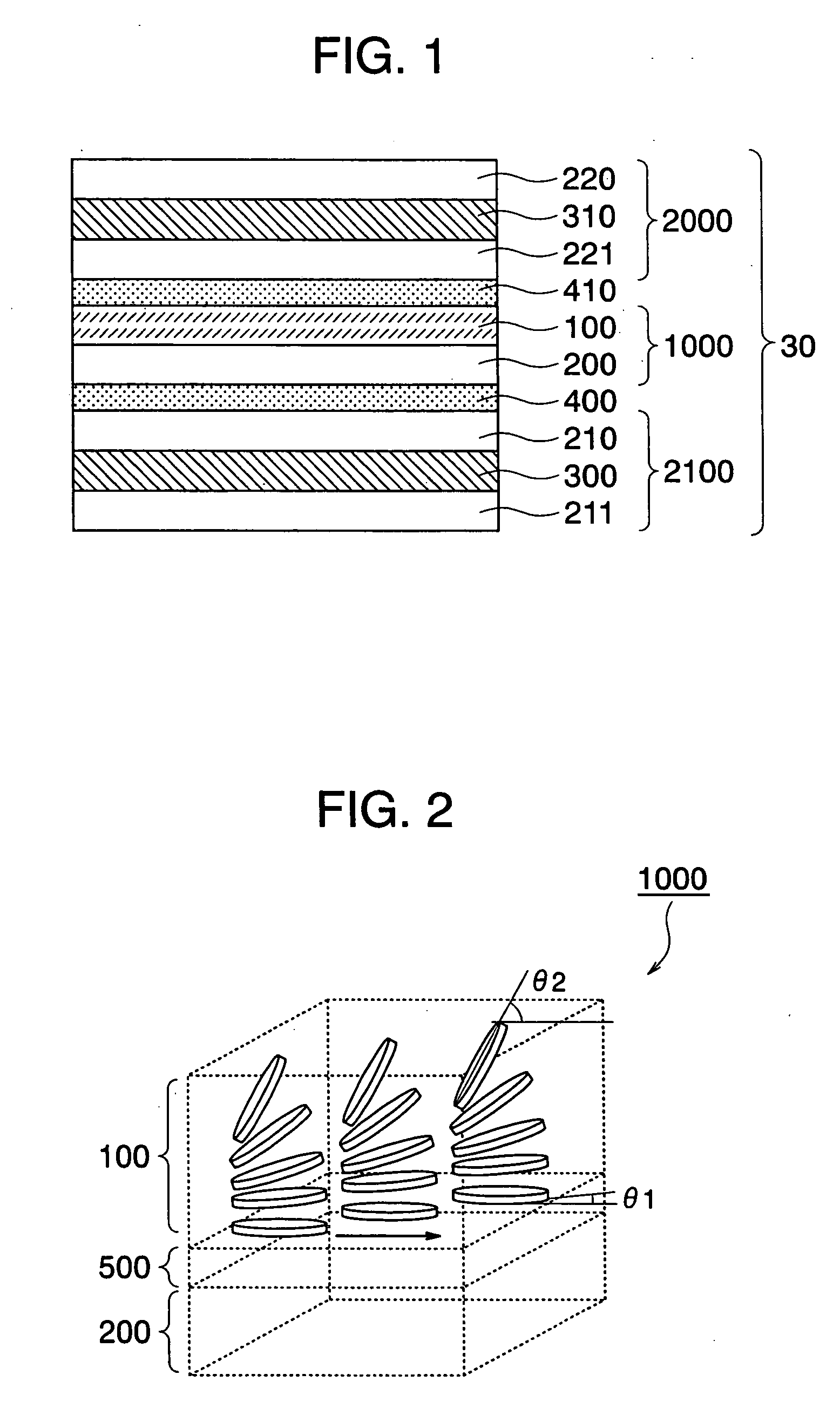

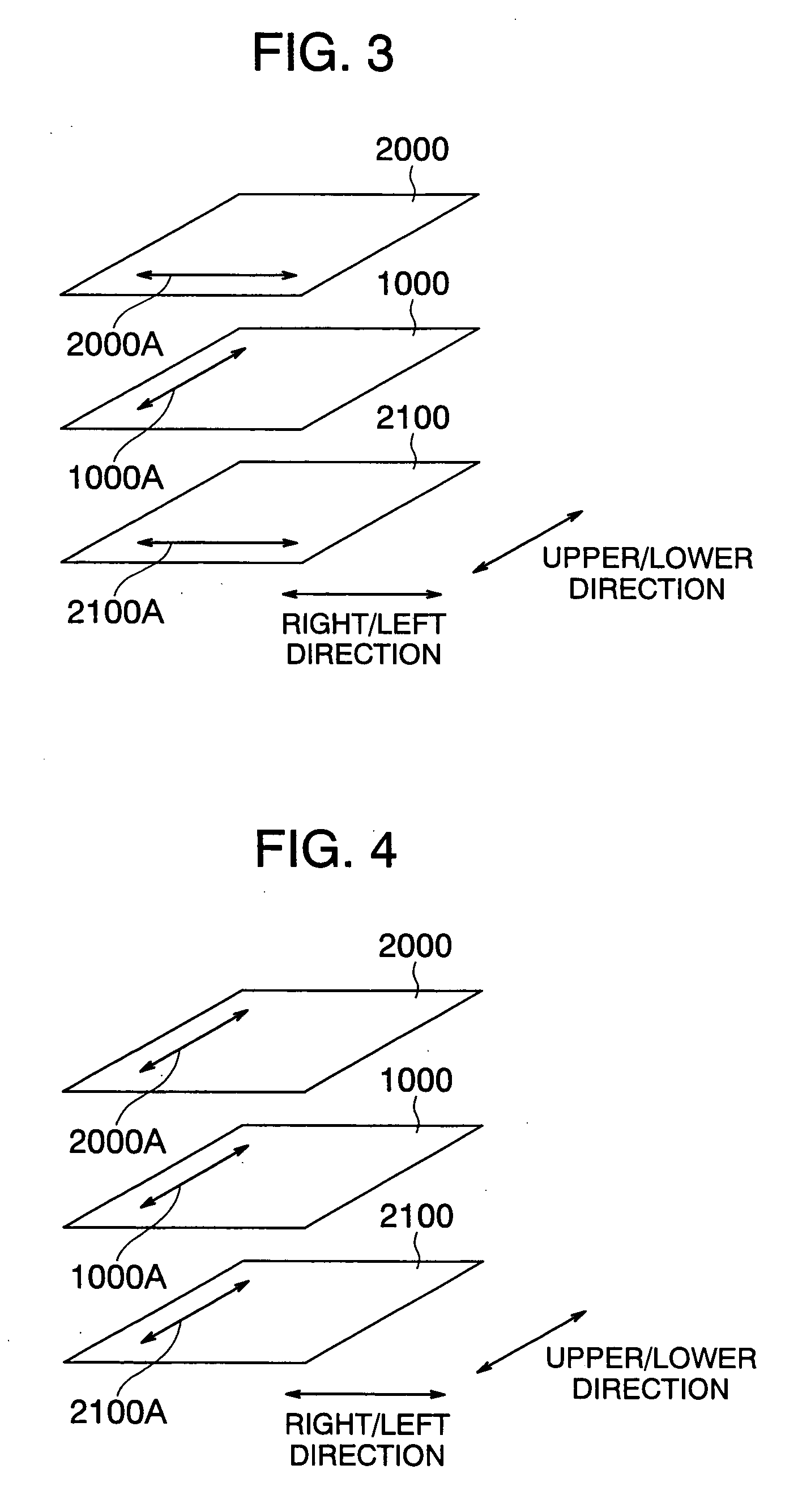

Optical element and display device using the same

ActiveUS20100289989A1High light transmittanceDeterioration of image qualityStatic indicating devicesNon-linear opticsLiquid-crystal displayImaging quality

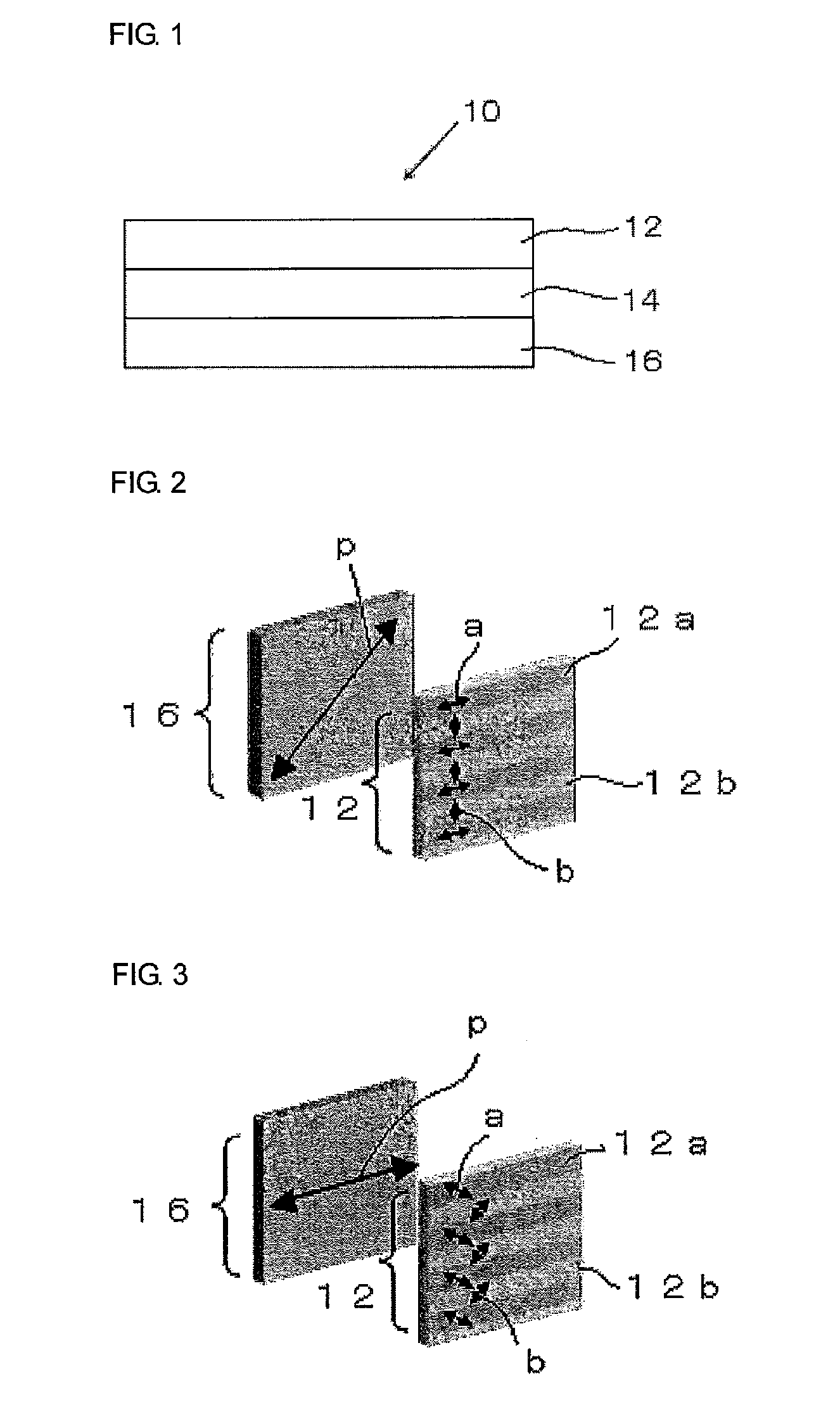

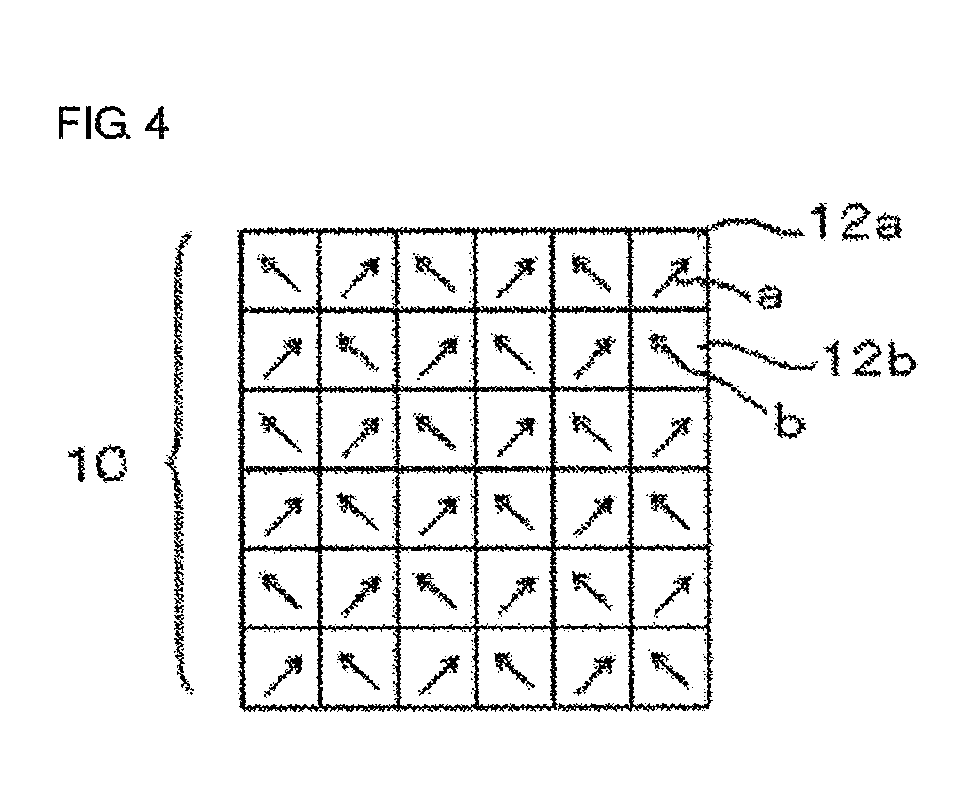

An optical element is arranged in such a manner that a screen thereof can be hardly observed from a predetermined direction, and a deterioration of an image quality caused by moire does not occur. The optical element is constituted by a first polarizing layer, a second polarizing layer, and a liquid crystal layer arranged between these two polarizing layers. In the optical element, absorption axes of the first polarizing layer and the second polarizing layer are located parallel to each other; the liquid crystal layer is made of hybrid-aligned discotic liquid crystal; and an alignment axis of the liquid crystal layer is located parallel to, or perpendicular to both absorption axes of the first polarizing layer and of the second polarizing layer.

Owner:PANASONIC LIQUID CRYSTAL DISPLAY CO LTD +1

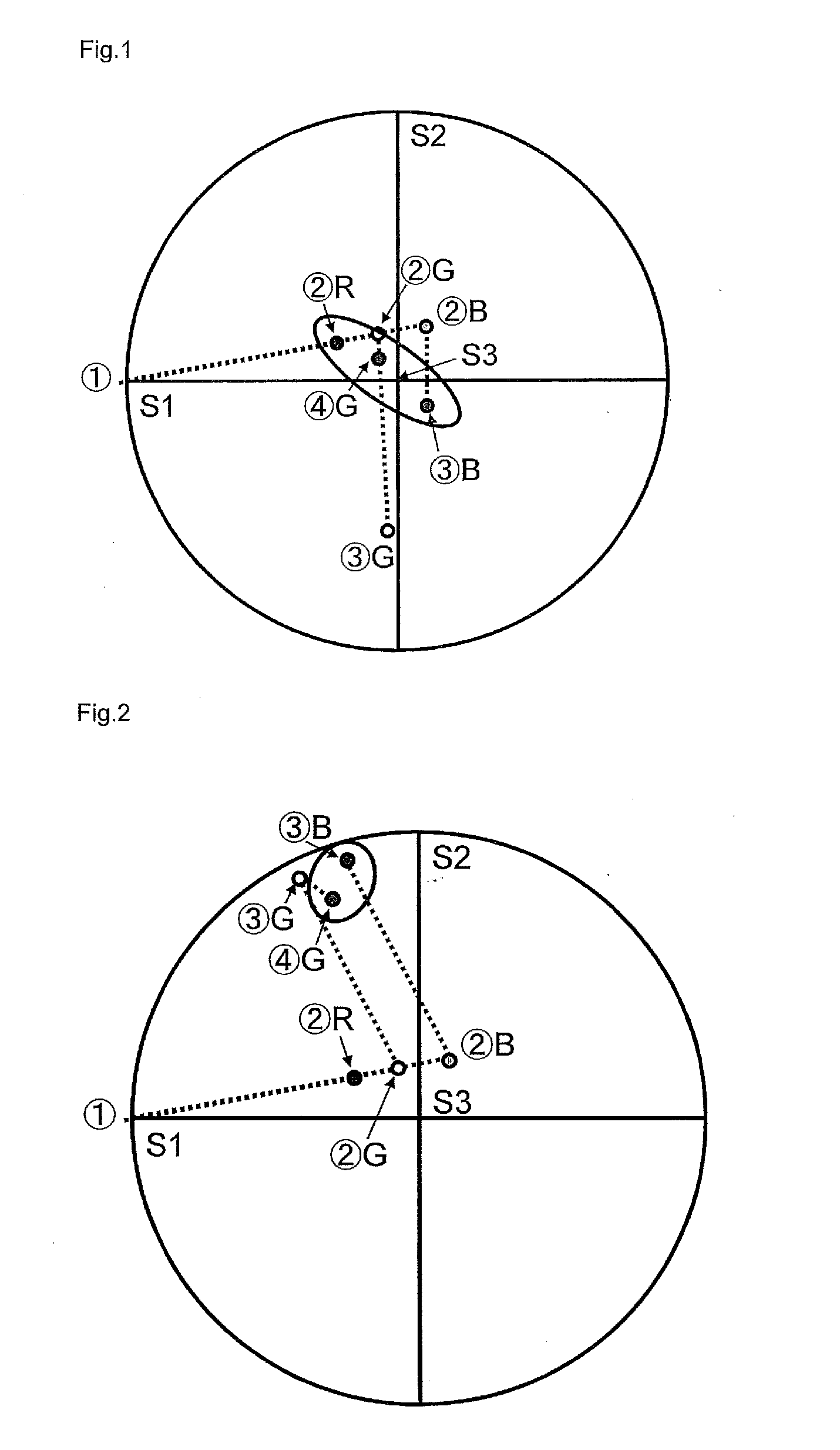

Compensating film for a liquid crystal display and an OCB mode liquid crystal display incorporating the compensating film

InactiveUS6124913AGood compensationSet freeLiquid crystal compositionsDiffusing elementsColor compensationFilm plane

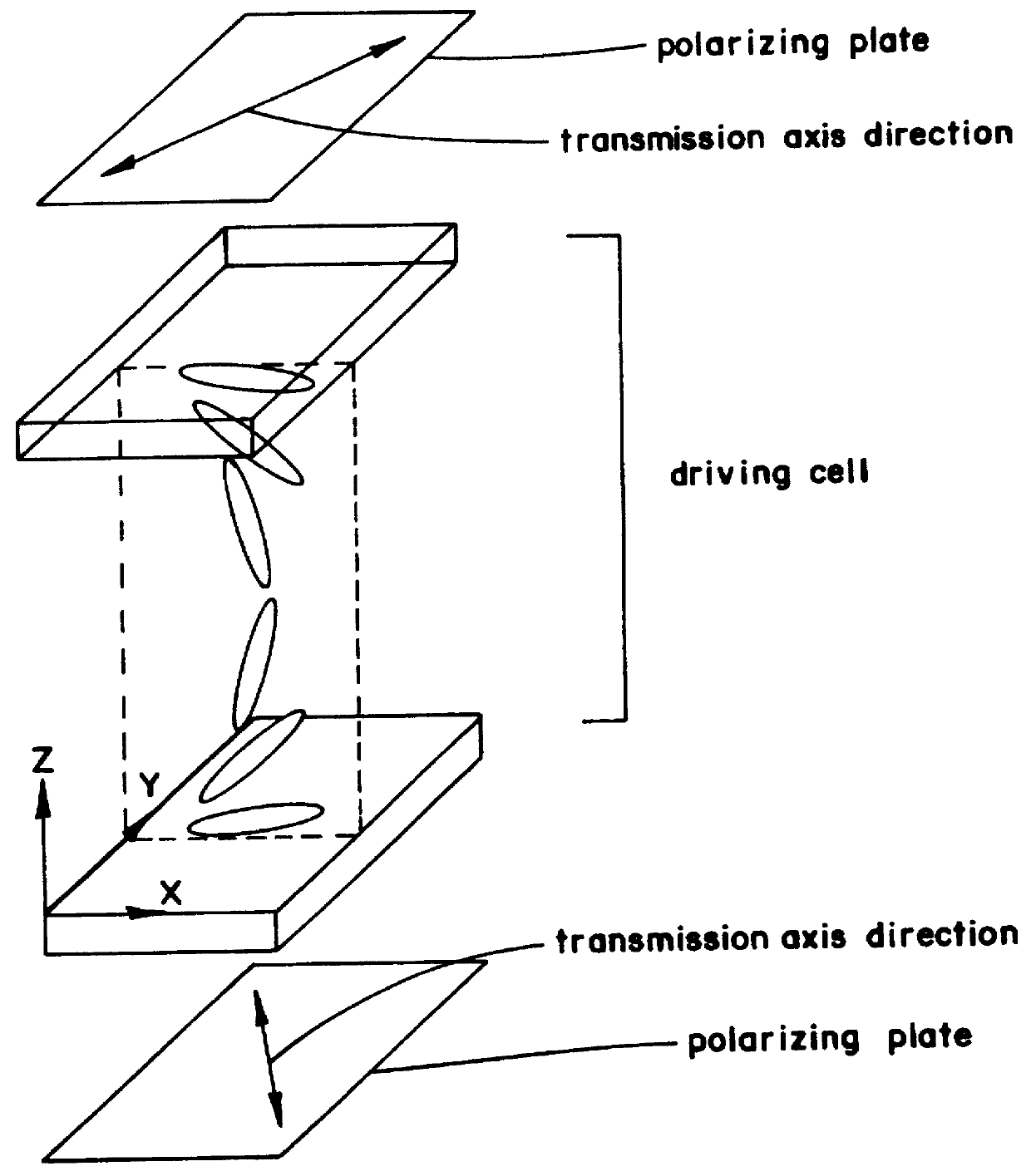

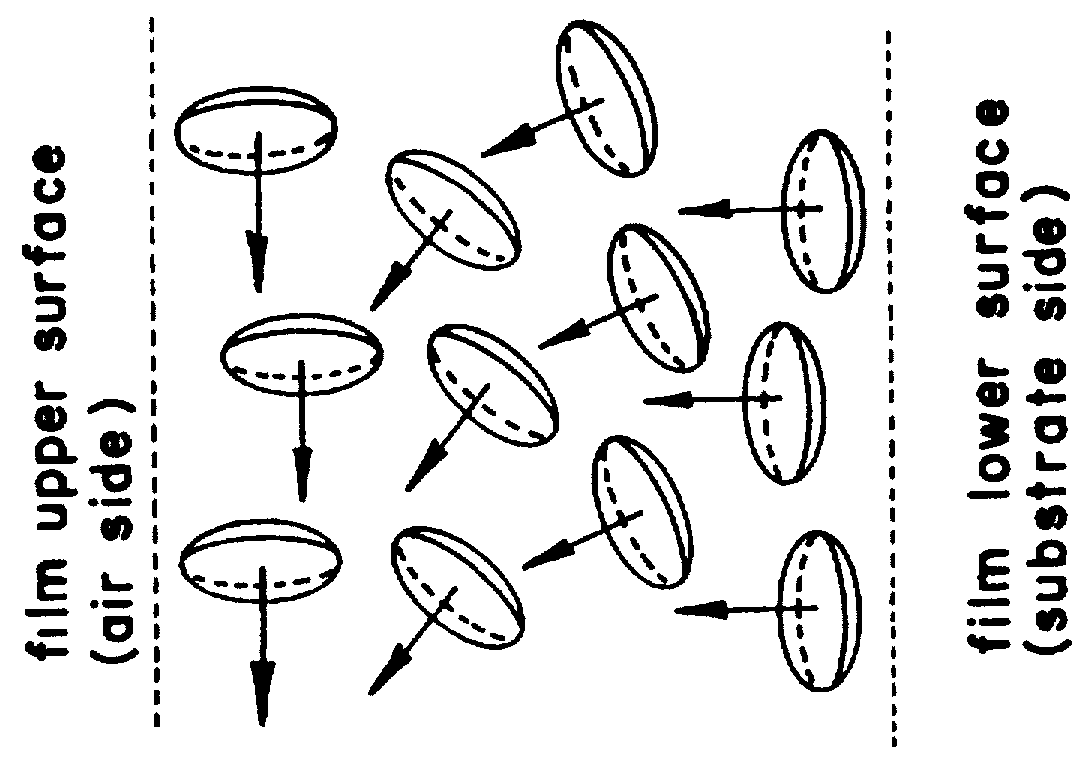

As a compensator for use in an OCB mode liquid crystal display there is provided a compensating film capable of making color compensation and attaining such a viewing angle expansion as has not been attainable heretofore. A compensating film for a liquid crystal display, constituted by at least one layer of a compensating film to be used in an OCB mode liquid crystal display, the compensating film being formed by a discotic liquid crystalline material having a fixed orientation form of a discotic liquid crystal, the compensating film being disposed between a driving liquid crystal cell and a pair of upper and lower polarizing plates, and the orientation form being a hybrid orientation in which the angle between discotic liquid crystal directors near the upper interface of the film and the film plane and the angle between discotic liquid crystal directors near the lower interface of the film and film plane are different from each other.

Owner:NIPPON MITSUBISHI OIL CORP

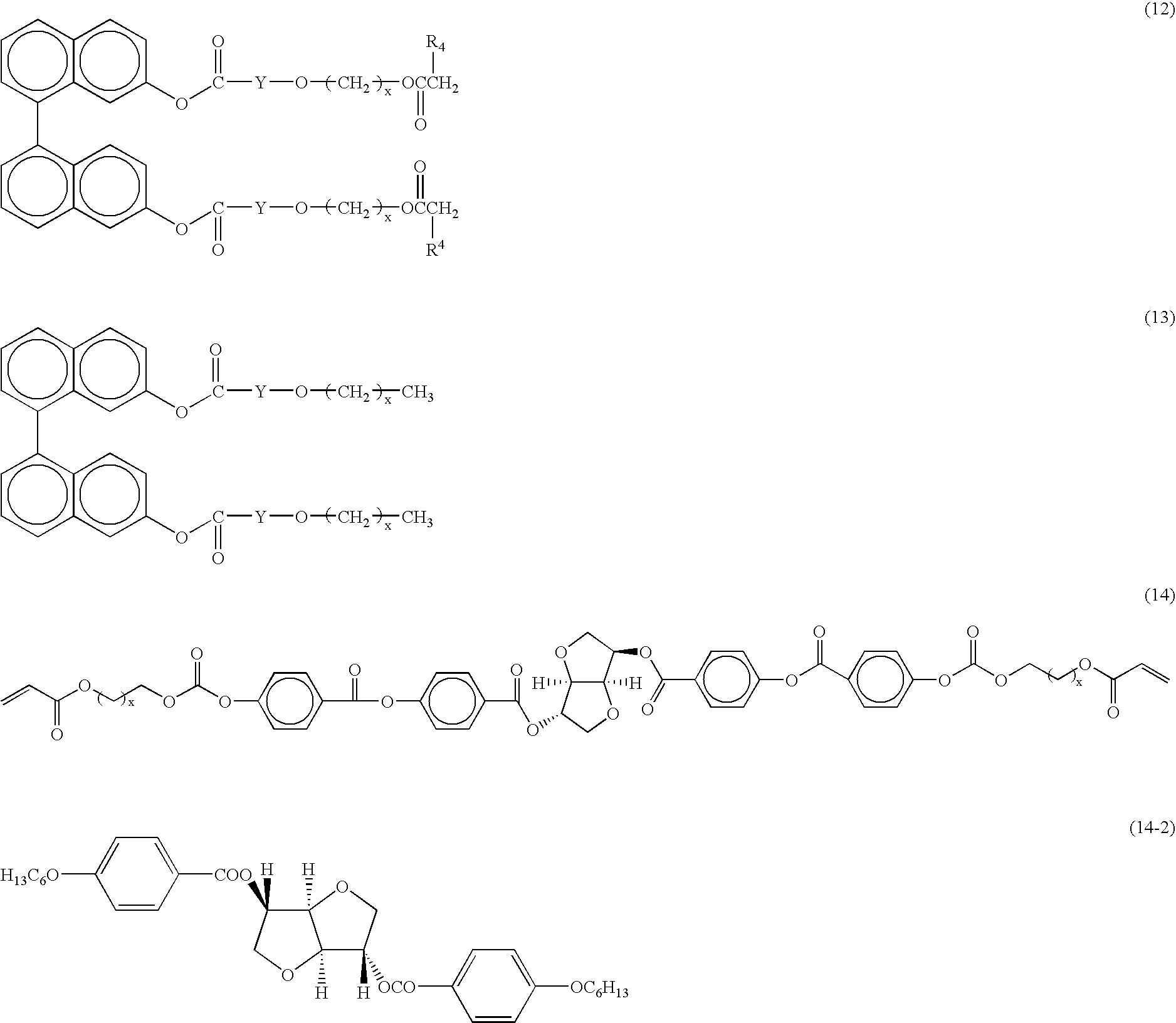

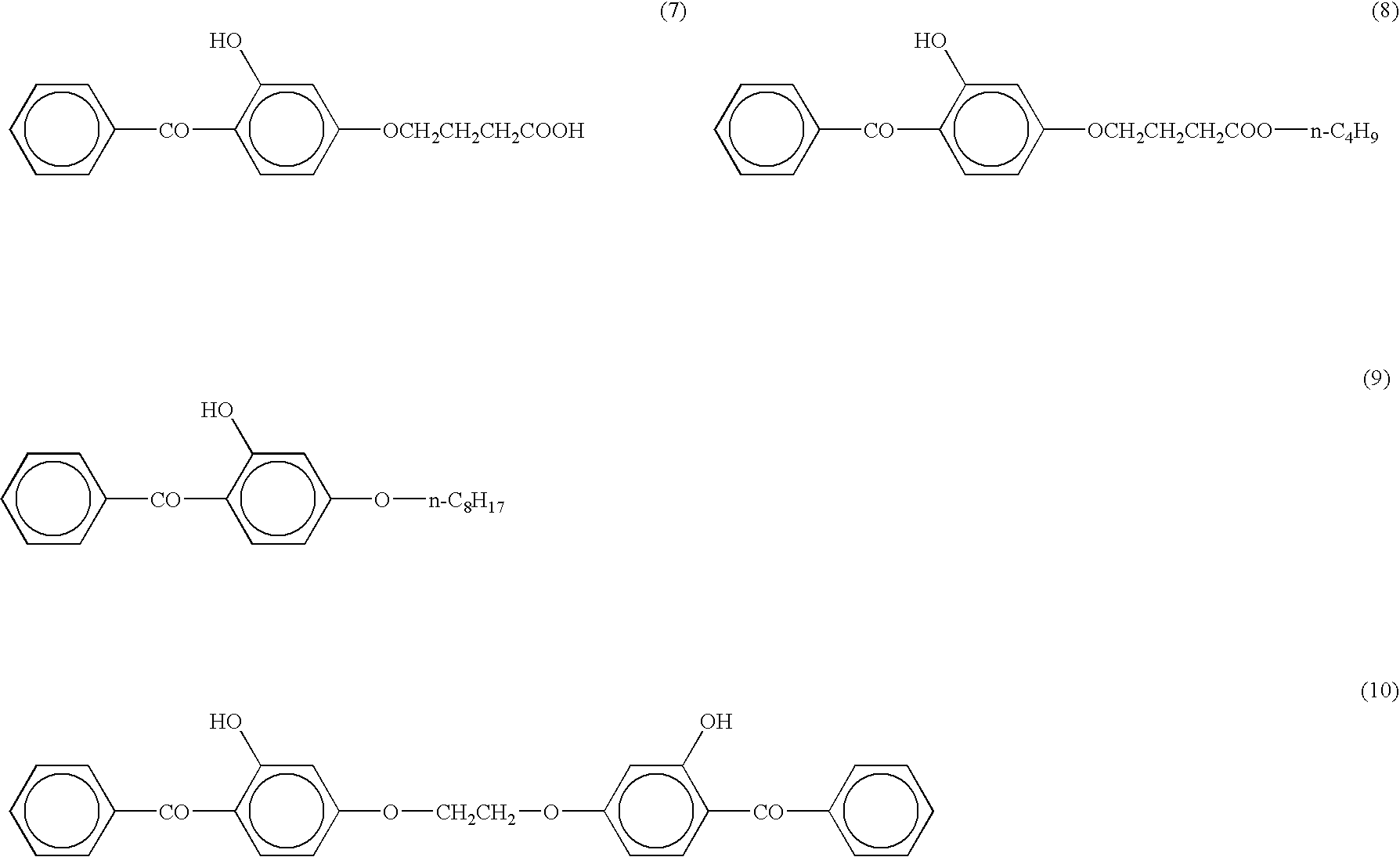

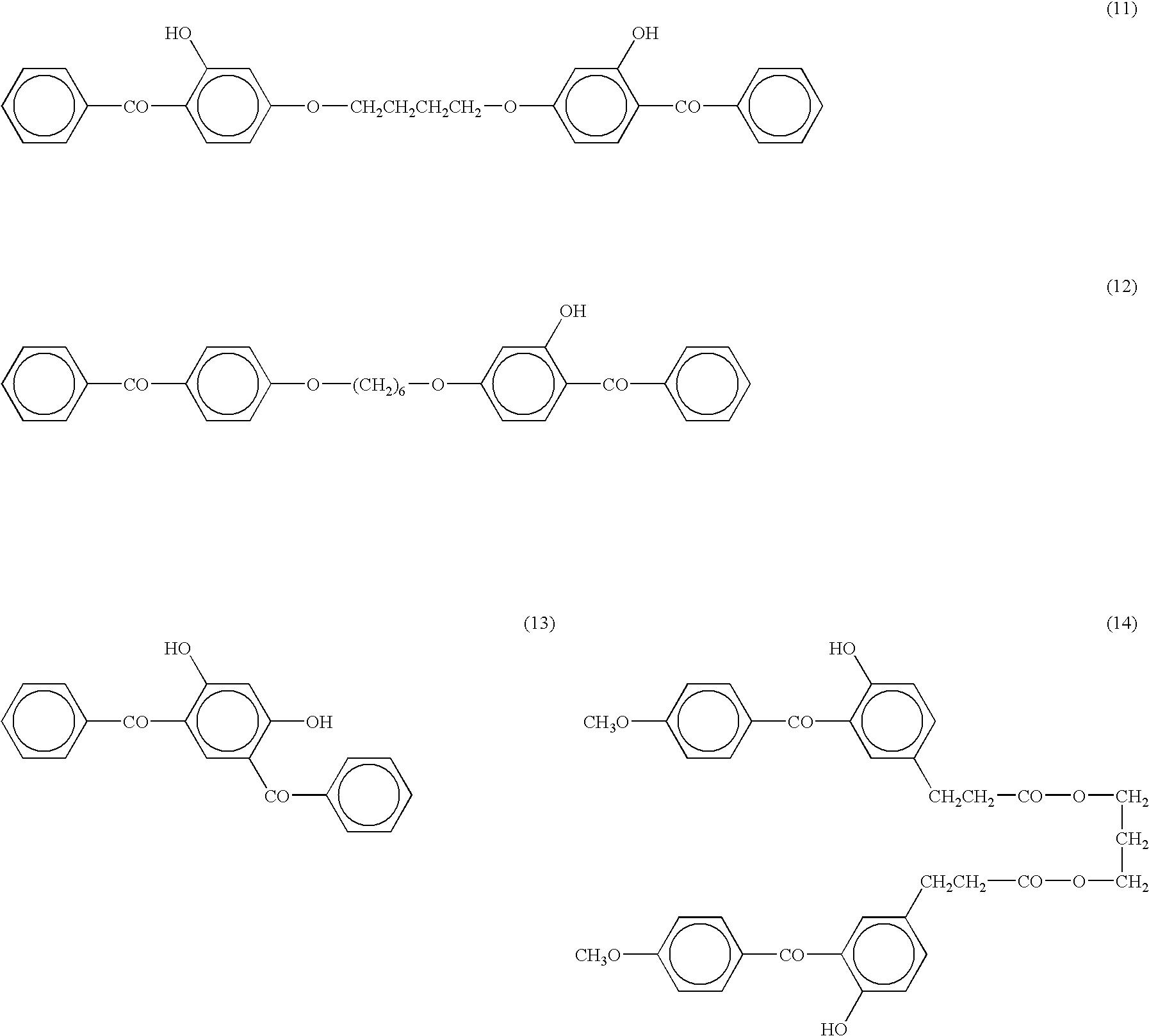

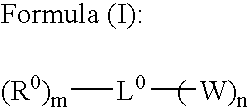

Optical compensatory sheet, liquid-crystal display and elliptical polarizing plate employing same

InactiveUS6890608B2Increase tilt angleWiden perspectiveLiquid crystal compositionsPolarising elementsLiquid-crystal displayAir interface

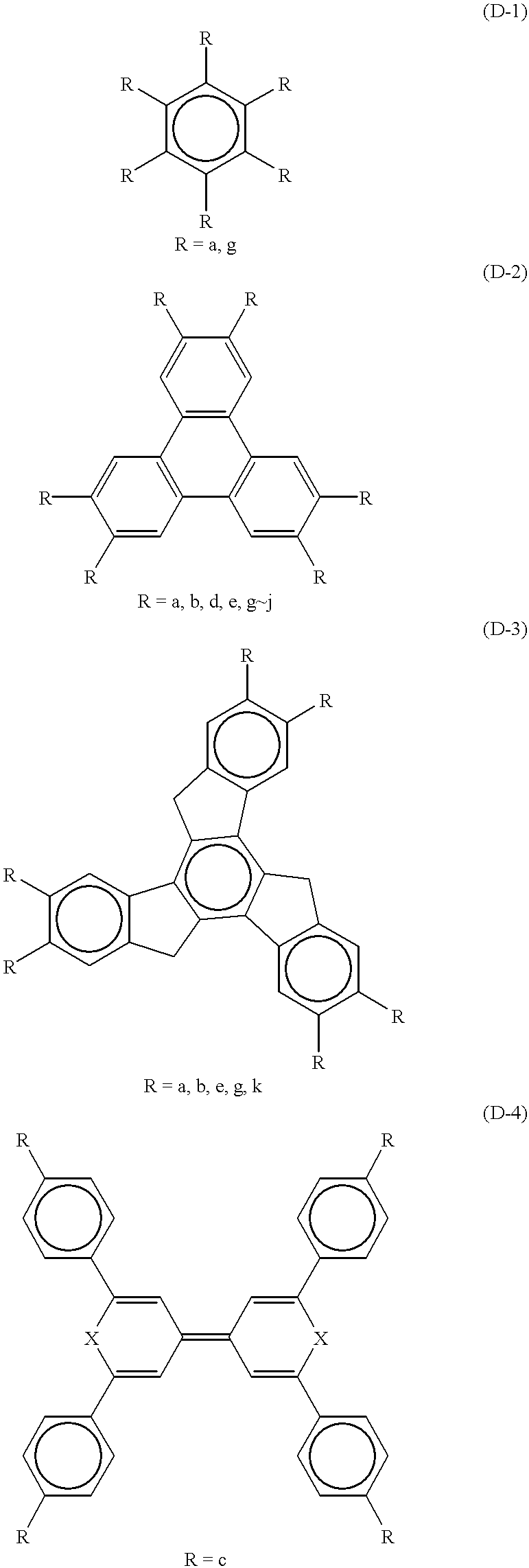

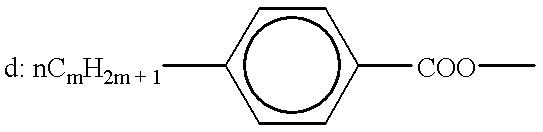

A novel optical compensatory sheet is disclosed the sheet comprises a transparent support and an optically anisotropic layer formed of discotic liquid-crystal molecules thereon. The anisotropic layer comprises at least one air interface control agent, thereby having an air interface polarity of at least 1.5-fold relative to that of a layer which does not comprise said air interface control agent. An optical compensatory sheet comprising a transparent support and an optically anisotropic layer formed of discotic liquid-crystal molecules thereon, wherein said anisotropic layer comprises at least one compound denoted by formula (I) is also disclosed

Owner:FUJIFILM CORP

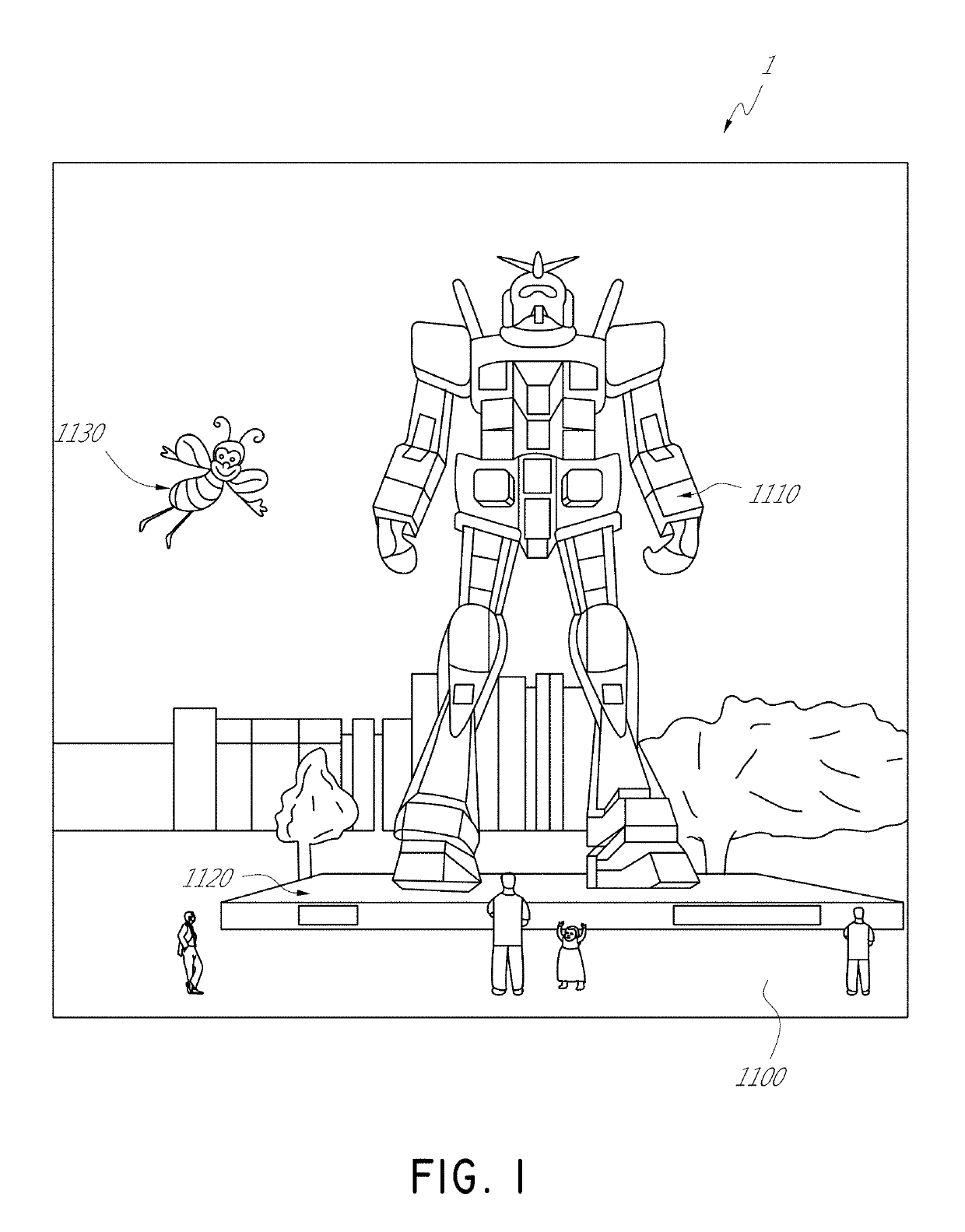

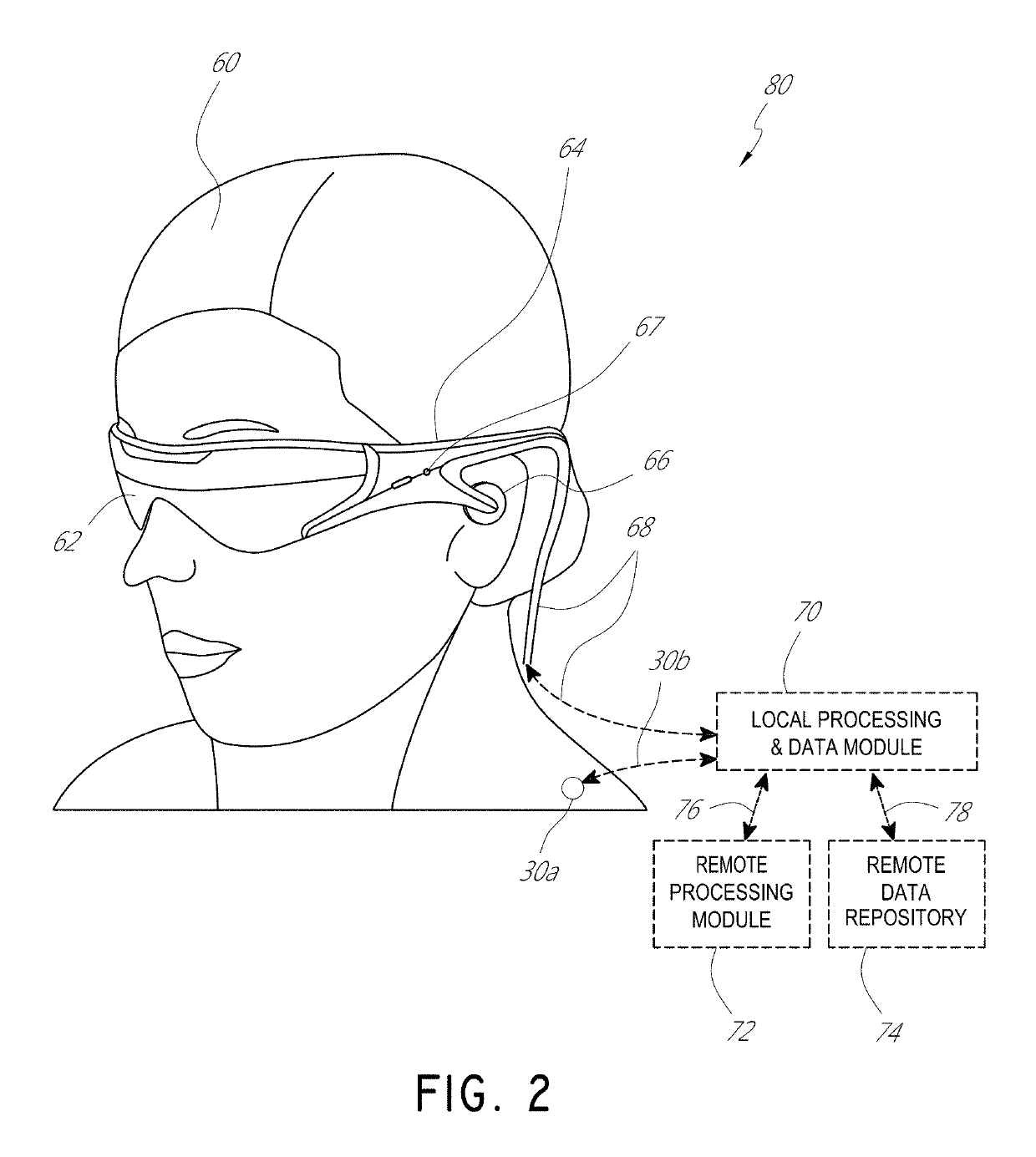

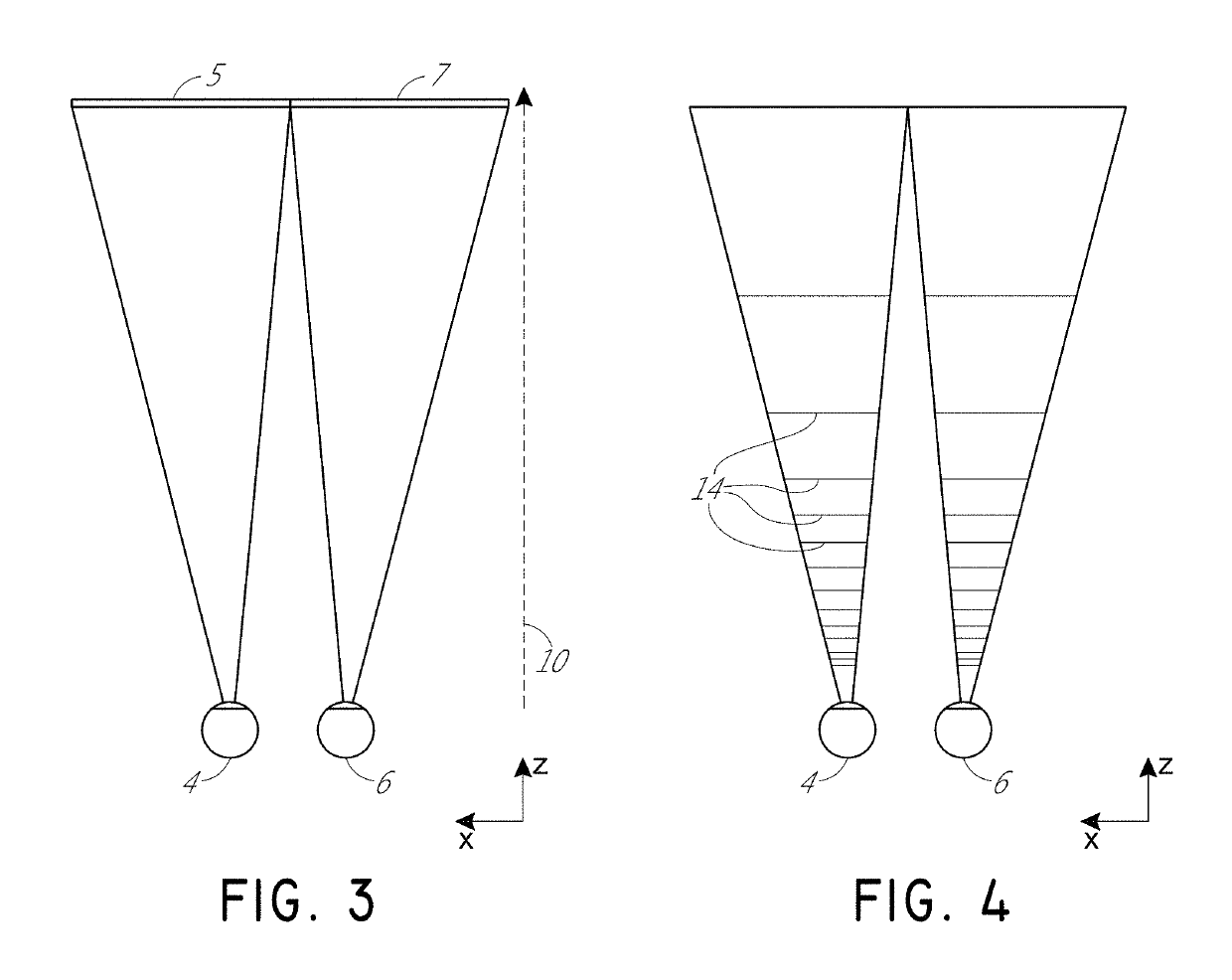

Diffractive devices based on cholesteric liquid crystal

ActiveUS10466561B2Non-linear opticsInput/output processes for data processingDepth directionWaveguide

Examples of diffractive devices comprise a cholesteric liquid crystal (CLC) layer comprising a plurality of chiral structures, wherein each chiral structure comprises a plurality of liquid crystal molecules that extend in a layer depth direction by at least a helical pitch and are successively rotated in a first rotation direction. Arrangements of the liquid crystal molecules of the chiral structures vary periodically in a lateral direction perpendicular to the layer depth direction to provide a diffraction grating. The diffractive devices can be configured to reflect light having a particular wavelength range and sense of circular polarization. The diffractive devices can be used in waveguides and imaging systems in augmented or virtual reality systems.

Owner:MAGIC LEAP INC

Optical element and display device using the same

ActiveUS20060103782A1Deterioration of image qualityTransmission limitNon-linear opticsIdentification meansImaging qualityDisplay device

An optical element is arranged in such a manner that a screen thereof can be hardly observed from a predetermined direction, and a deterioration of an image quality caused by moire does not occur. The optical element is constituted by a first polarizing layer, a second polarizing layer, and a liquid crystal layer arranged between these two polarizing layers. In the optical element, absorption axes of the first polarizing layer and the second polarizing layer are located parallel to each other; the liquid crystal layer is made of hybrid-aligned discotic liquid crystal; and an alignment axis of the liquid crystal layer is located parallel to, or perpendicular to both absorption axes of the first polarizing layer and of the second polarizing layer.

Owner:PANASONIC LIQUID CRYSTAL DISPLAY CO LTD +1

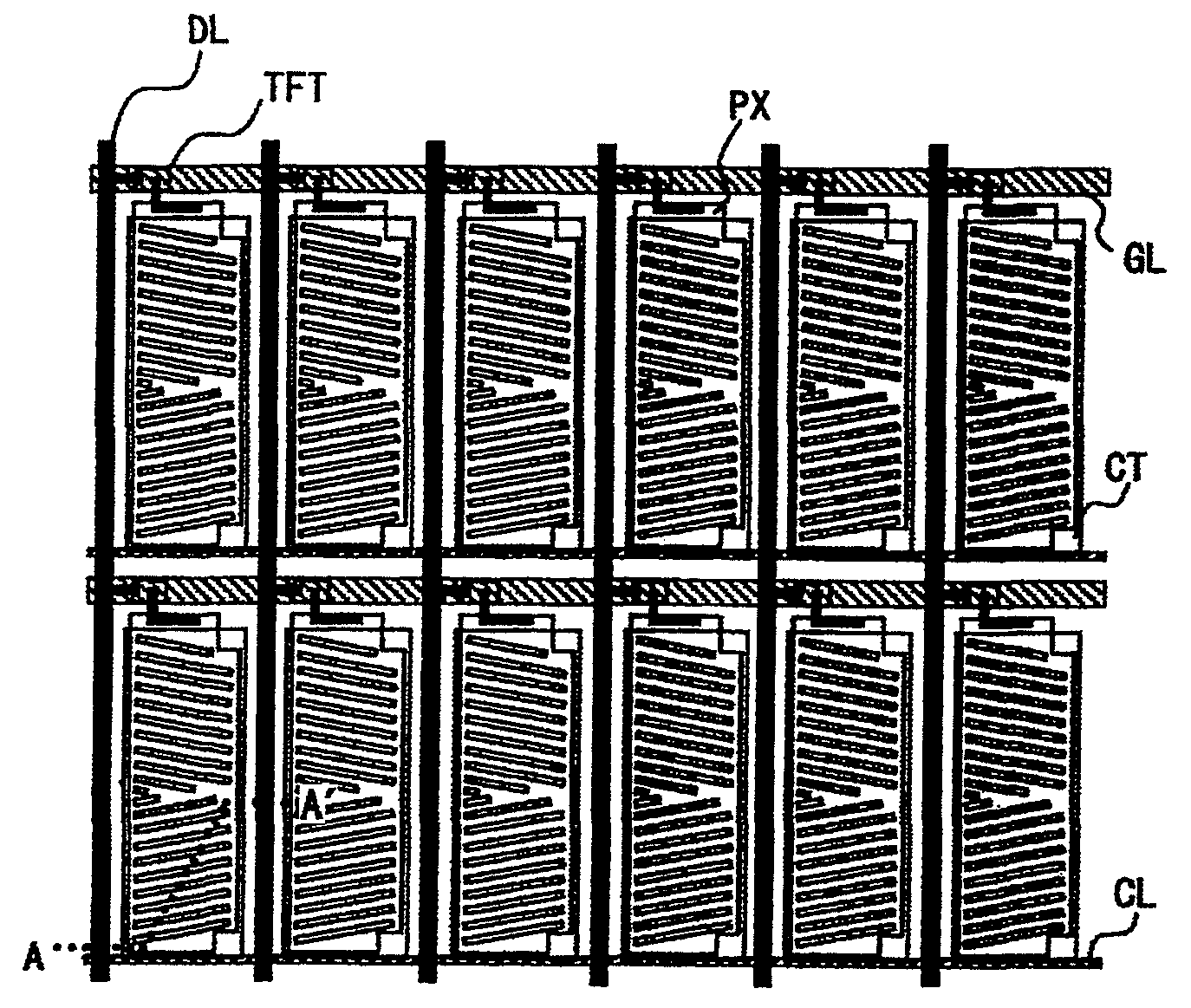

Optically isotropic liquid crystal materials and display apparatus using the same

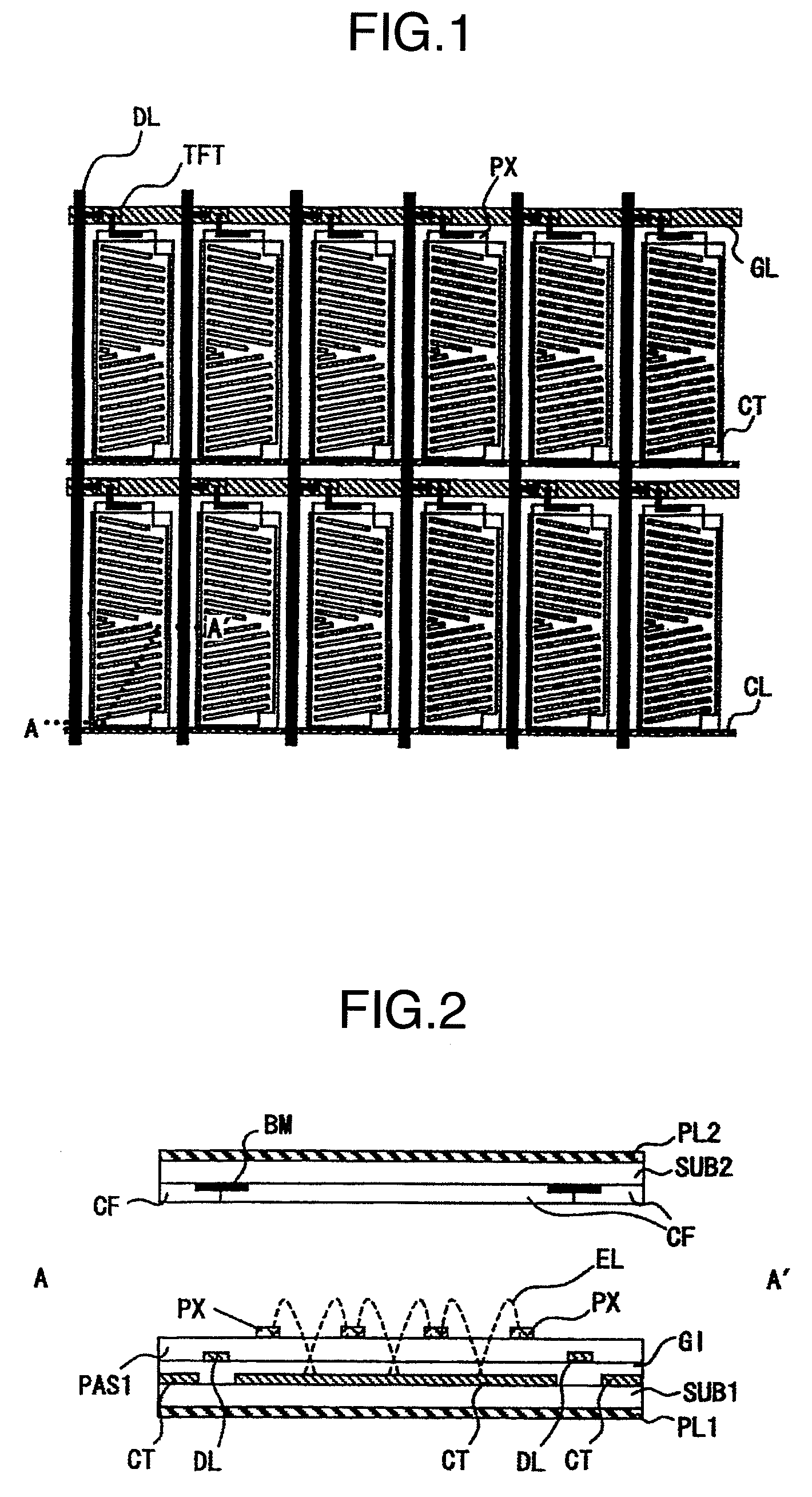

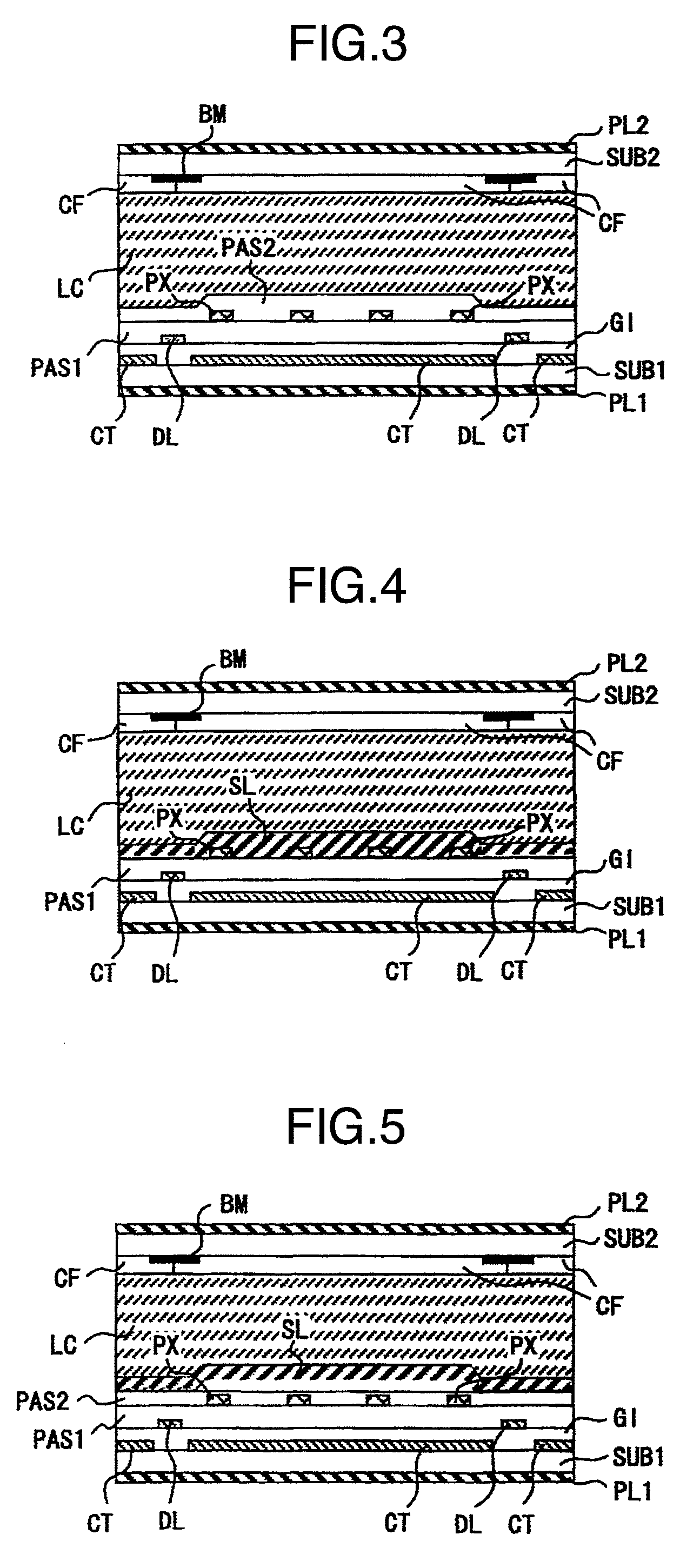

ActiveUS20080007666A1Quality improvementLiquid crystal compositionsNon-linear opticsLiquid-crystal displayPotential difference

The present invention is intended to attain an electrode structure and a pixel design which are the most suitable for effective utilization of optically isotropic liquid crystals in a device.The present invention uses a structure of liquid crystal display device comprising a first substrate, a second substrate, polarizing plates provided on the first substrate and the second substrate, respectively, a liquid crystal layer located between the first substrate and the second substrate, and pixel electrodes and common electrodes, which are provided on the first substrate, wherein the liquid crystal layer has such a property that optical anisotropy is induced therein by a change of an optically isotropic state caused by application of a voltage; either the pixel electrodes or the common electrodes are formed in an interdigital form and the other is formed in the form of a flat plate; and an electric field is applied to the liquid crystal layer by a potential difference made between the pixel electrodes and the common electrodes.

Owner:PANASONIC LIQUID CRYSTAL DISPLAY CO LTD +1

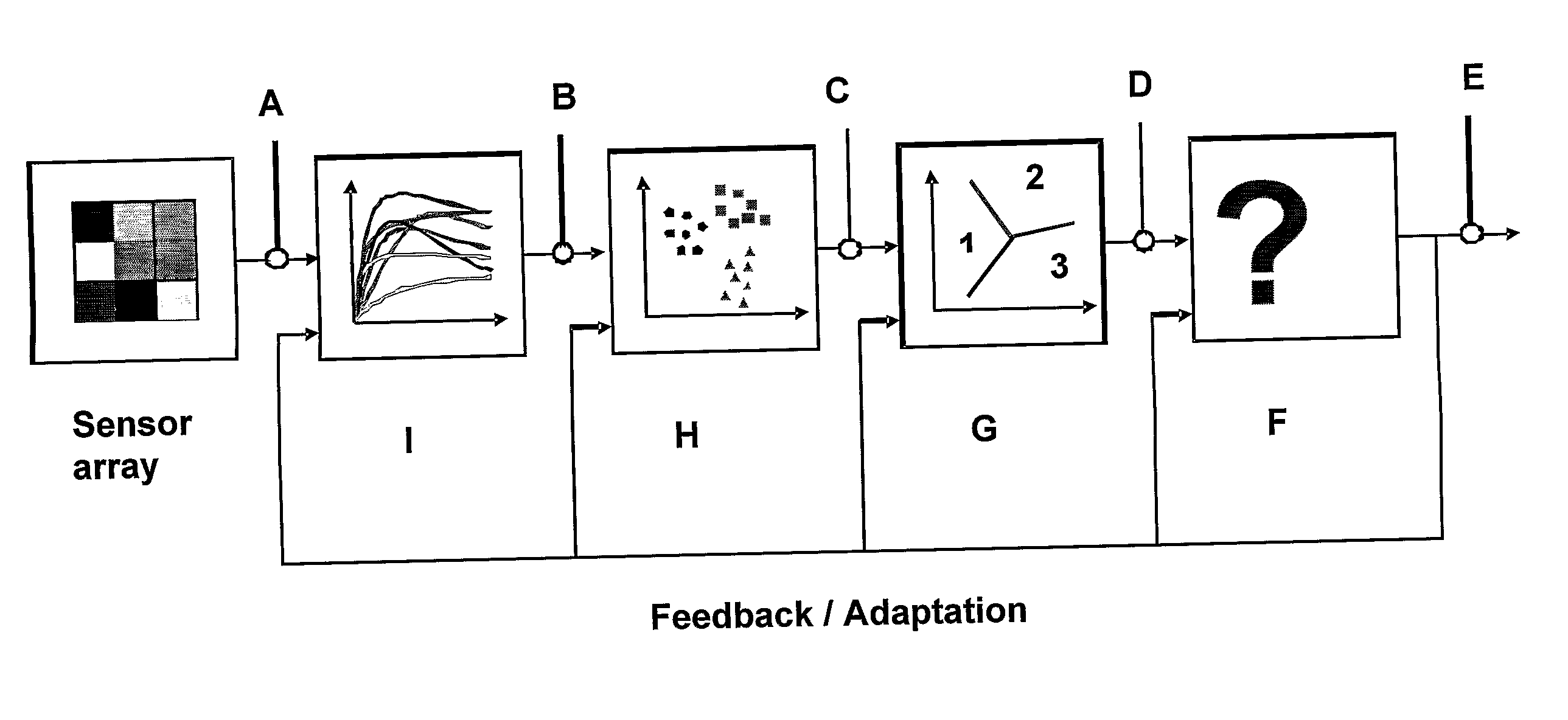

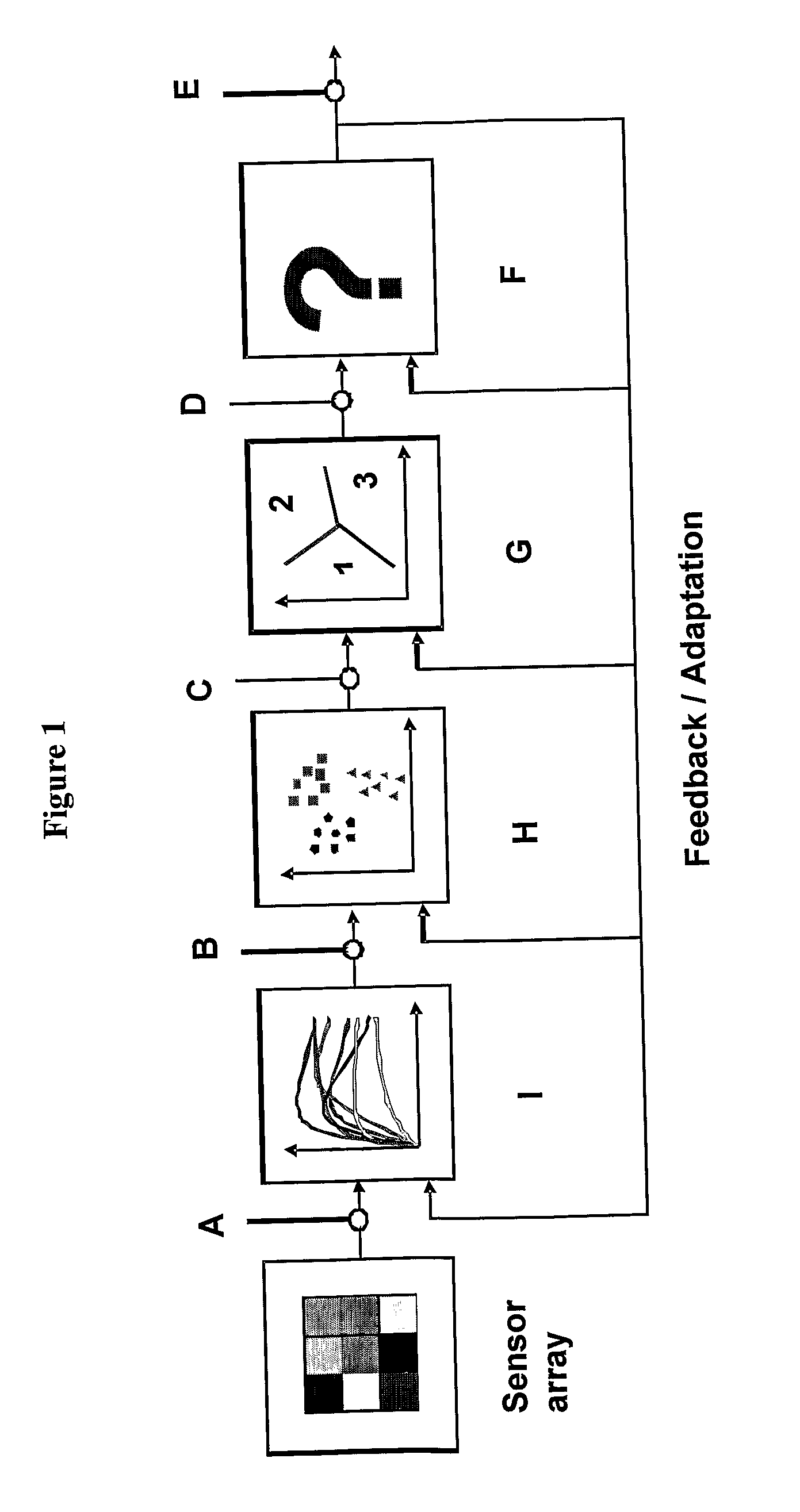

Electronic nose device with sensors composed of nanowires of columnar discotic liquid crystals with low sensititive to humidity

InactiveUS20100191474A1Improve Sensing PerformanceNo sensitivity to humidityMaterial analysis by electric/magnetic meansBiological neural network modelsNanowireMedicine

Electronic nose device having a plurality of sensors composed of nanowires of columnar discotic liquid crystals, the device having low sensitivity to humidity. The device is designed to determine the composition and concentration of volatile organic compounds in a sample with very high sensitivity. Methods for use of the device in applications such as diagnosis of disease and food quality control are disclosed.

Owner:TECHNION RES & DEV FOUND LTD

Optical film for 3D image display, 3D image display device, and 3D image display system

InactiveUS20140036175A1Improve viewing angle characteristicsIncrease brightnessSynthetic resin layered productsPolarising elementsIn planeAdditive ingredient

Disclosed is an optical film for 3D image display devices, including at least an optically-anisotropic layer formed of a composition that includes, as the main ingredient thereof, a discotic liquid crystal having at least one polymerizable group, wherein the optically-anisotropic layer is a patterned optically-anisotropic layer which includes a first retardation domain and a second retardation domain differing from each other in at least one of the in-plane slow axis direction and retardation in-plane thereof and in which the first and second retardation domains are alternately arranged in plane.

Owner:FUJIFILM CORP

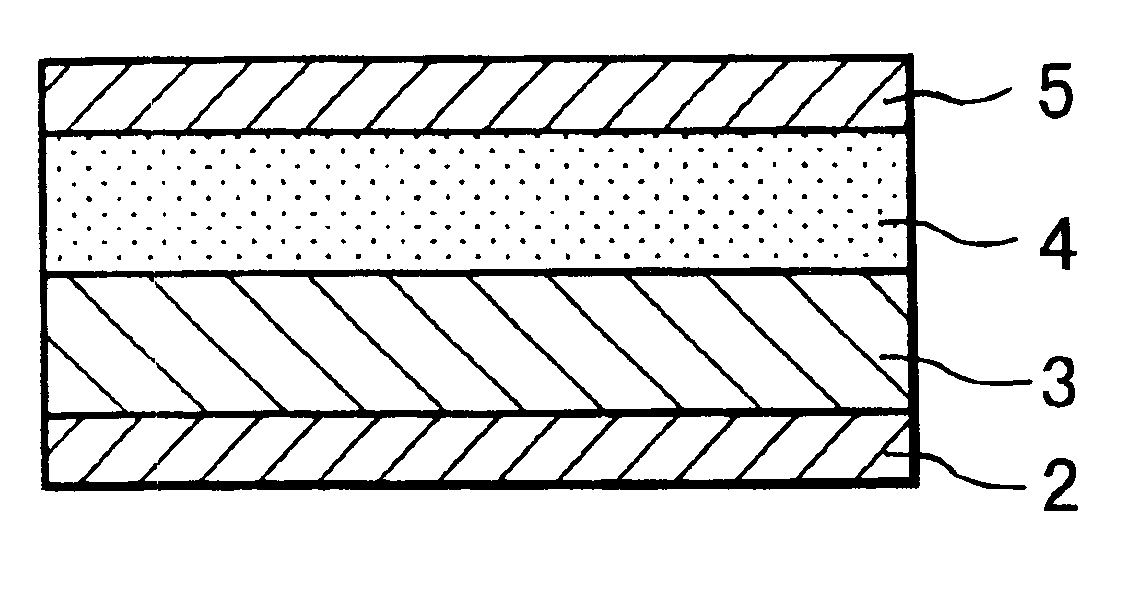

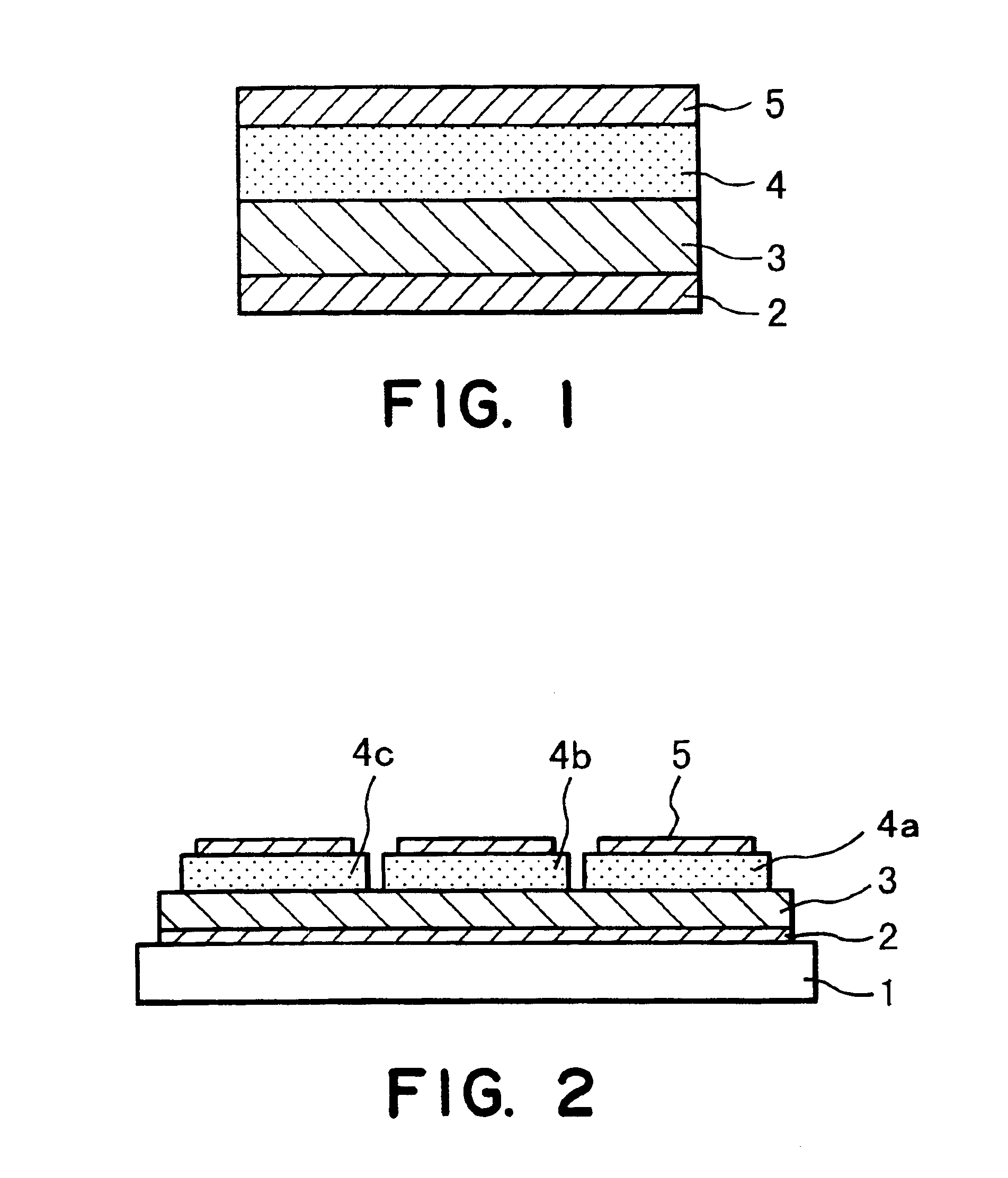

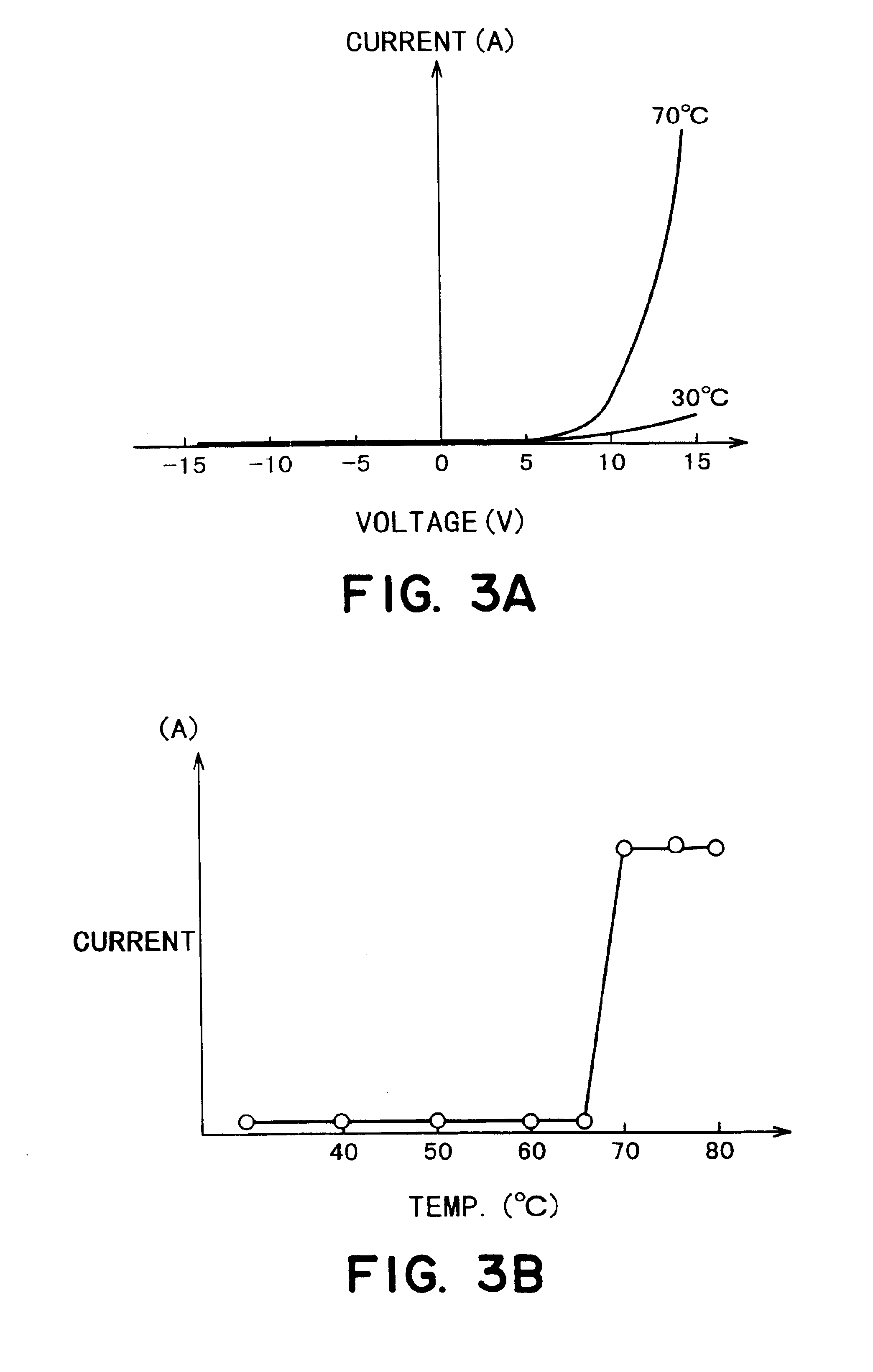

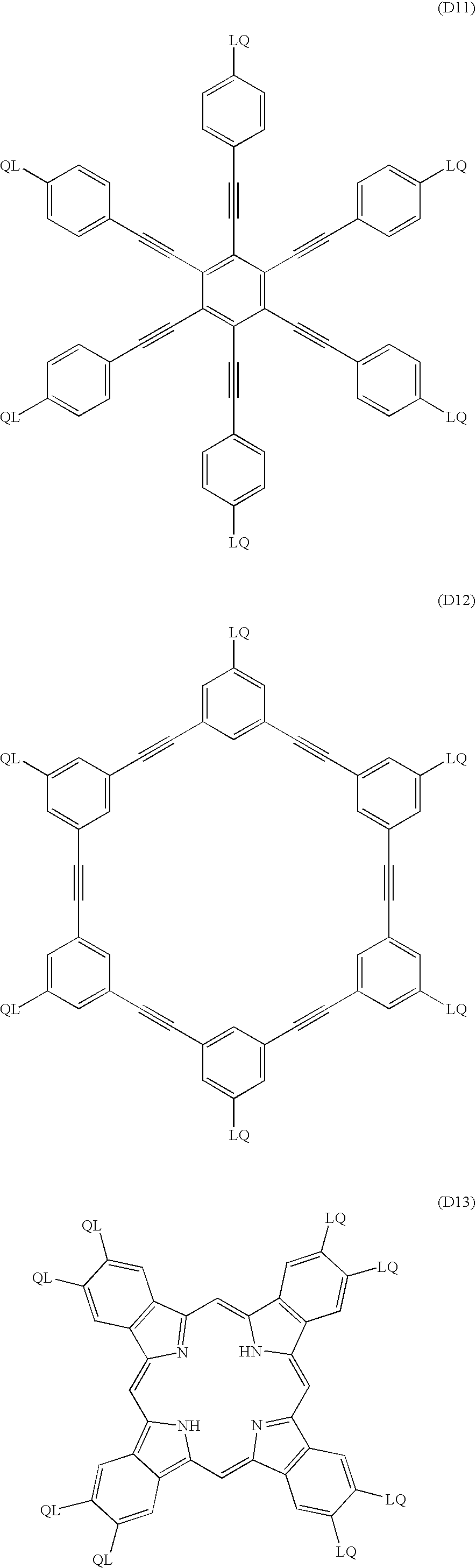

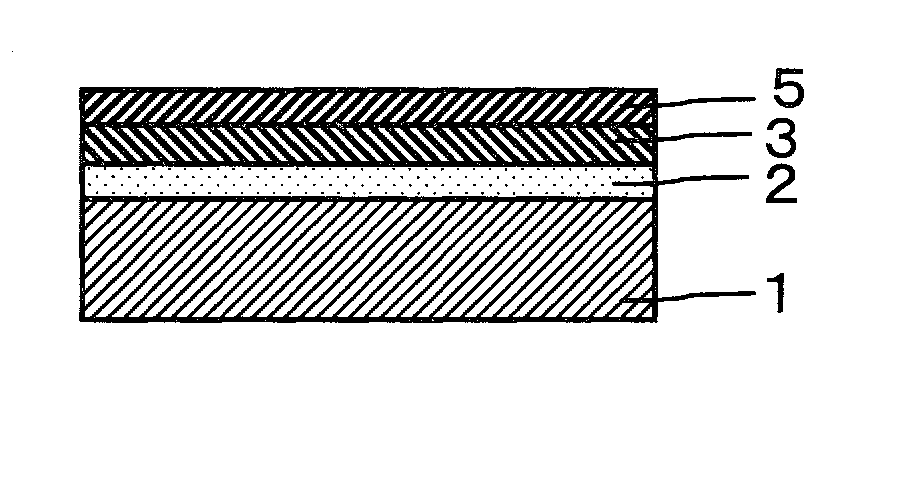

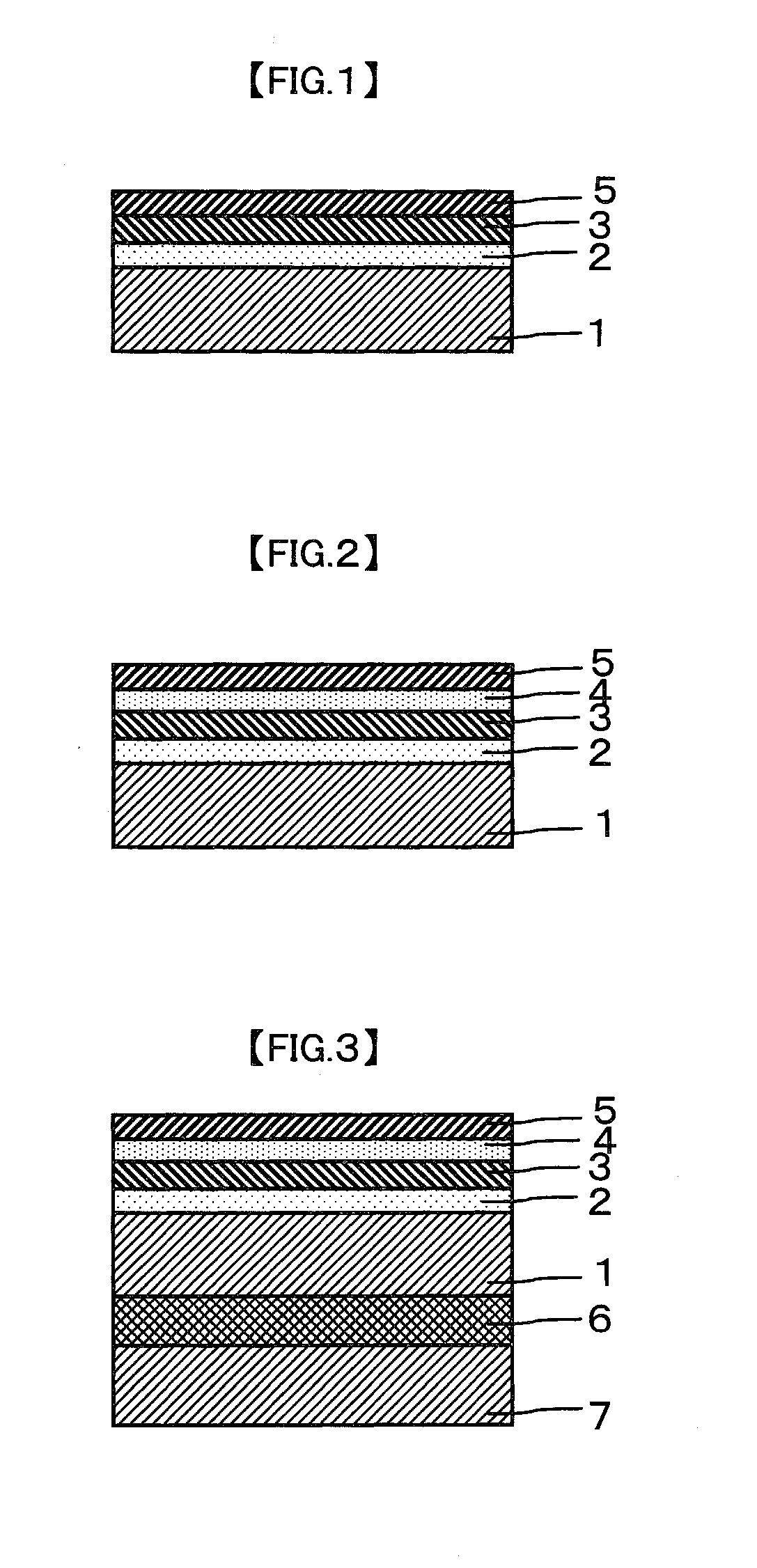

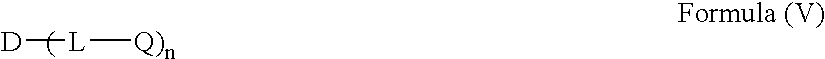

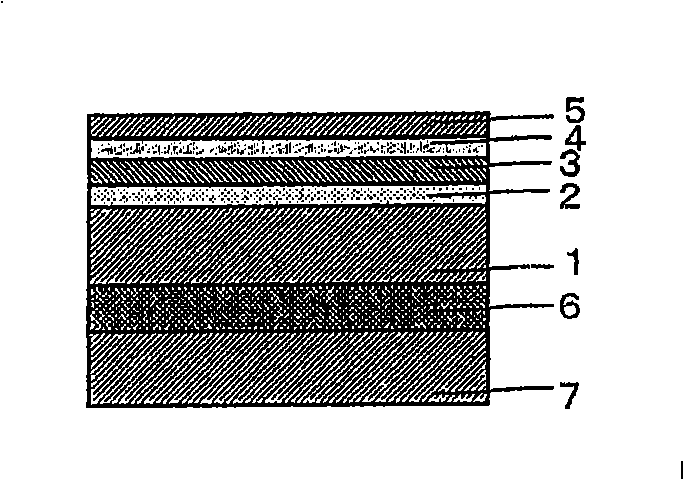

Conductive organic compound device, conductive liquid crystal device, and organic electroluminescence device

InactiveUS6858271B1Reduce power consumptionImprove carrier injection efficiencyLiquid crystal compositionsDischarge tube luminescnet screensTransport layerElectron resonance

A conductive organic compound device structure suitable for constituting an electronic device, such as an organic EL device, is formed by including a pair of oppositely spaced electrodes, and a carrier transporting layer disposed between the electrodes and in contact with one of the electrodes. The carrier transporting layer comprises a conductive organic compound having a π-electron resonance structure in its molecule. In the device, the π-electron resonance structure plane of the conductive organic compound in the carrier transporting layer is aligned substantially parallel to surfaces of the electrodes. The conductive organic compound is preferably a conductive liquid crystal, such as a discotic liquid crystal or a smectic liquid crystal, and a layer thereof is included in the device, preferably by vacuum deposition.

Owner:CANON KK

Optical compensating sheet having optically anisotropic layer made of discotic liquid-crystalline molecules and transparent substrate comprising polymer film

InactiveUS20040036828A1Advantage of quickEasy to displayPolarising elementsNon-linear opticsLiquid crystallinePolymer science

An optical compensatory sheet comprises a transparent support and an optically anisotropic layer. The optically anisotropic layer is made from discotic liquid crystal molecules. The transparent support is made of a polymer film. The polymer film has an Re retardation value in the range of 10 to 70 nm. The polymer film also has an Rth retardation value in the range of 70 to 400 nm. The polymer film further has a standard deviation of angle of slow axis of 1.5° or less.

Owner:FUJIFILM HLDG CORP

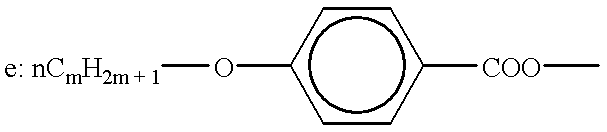

Pressure-sensitive adhesive optical film and image display

InactiveUS20080145572A1Display unevenness can be preventedSuppress display unevennessLiquid crystal compositionsFilm/foil adhesivesMeth-Display device

A pressure-sensitive adhesive optical film of the present invention comprises: an optical film comprising a transparent base film and a discotic liquid crystal layer on one side of the transparent base film; and a pressure-sensitive adhesive layer that is provided on the discotic liquid crystal layer, wherein the pressure-sensitive adhesive layer is made from a pressure-sensitive adhesive containing an acrylic polymer comprising an alkyl(meth)acrylate (a1) and a ring structure-containing (meth)acrylate (a2) as monomer units and having a weight average molecular weight of 1,000,000 to 3,000,000, and a crosslinking agent. The pressure-sensitive adhesive optical film has durability and can be prevented from causing display unevenness in a peripheral portion of a display screen.

Owner:NITTO DENKO CORP

Cellulose acetate film

InactiveUS20040233363A1Retardation valueReduce contrastLiquid crystal compositionsPolarising elementsCrystallographyRefractive index

An optical compensatory sheet comprises a cellulose acetate support and an optically anisotropic layer. The optically anisotropic layer contains a discotic liquid crystal molecule. The cellulose acetate support has a Bth<550 >birefringence in the range of 0.0007 to 0.004.

Owner:FUJIFILM CORP

Liquid crystal composition, device and apparatus

InactiveUS20020015131A1Improve performanceReduce power consumptionLiquid crystal compositionsThin material handlingProduction rateLiquid-crystal display

A liquid crystal device showing performances, such as good viewing angle characteristic, high contrast, high-speed responsiveness, high resolution and high productivity is given by forming a layer of discotic liquid crystal placed in an edge-on and uniaxial alignment state. In the liquid crystal layer, the discotic liquid crystal may preferably assume a nematic discotic layer and co-present with a rod-shaped liquid crystal in mutually separated phases.

Owner:CANON KK

Optical compensatory sheet comprising substrate and optically anisotropic layer

InactiveUS6485798B1Increase contrastClear imagingLiquid crystal compositionsStatic indicating devicesLiquid-crystal displayDiscotic liquid crystal

An optical compensatory sheet comprises a transparent substrate and an optically anisotropic layer. The optically anisotropic layer comprises discotic liquid crystal molecules. The discotic liquid crystal molecules are oriented in essentially mono domain alignment at an average inclined angle in the range of 50° to 90°. A liquid crystal display of an STN mode having the optical compensatory sheet is also disclosed.

Owner:FUJIFILM CORP

Optical compensatory sheet, liquid-crystal display and elliptical polarizing plate employing same

InactiveUS20030223026A1Liquid crystal compositionsPolarising elementsLiquid-crystal displayAir interface

A novel optical compensatory sheet is disclosed the sheet comprises a transparent support and an optically anisotropic layer formed of discotic liquid-crystal molecules thereon. The anisotropic layer comprises at least one air interface control agent, thereby having an air interface polarity of at least 1.5-fold relative to that of a layer which does not comprise said air interface control agent. An optical compensatory sheet comprising a transparent support and an optically anisotropic layer formed of discotic liquid-crystal molecules thereon, wherein said anisotropic layer comprises at least one compound denoted by formula (I) is also disclosed.

Owner:FUJIFILM CORP

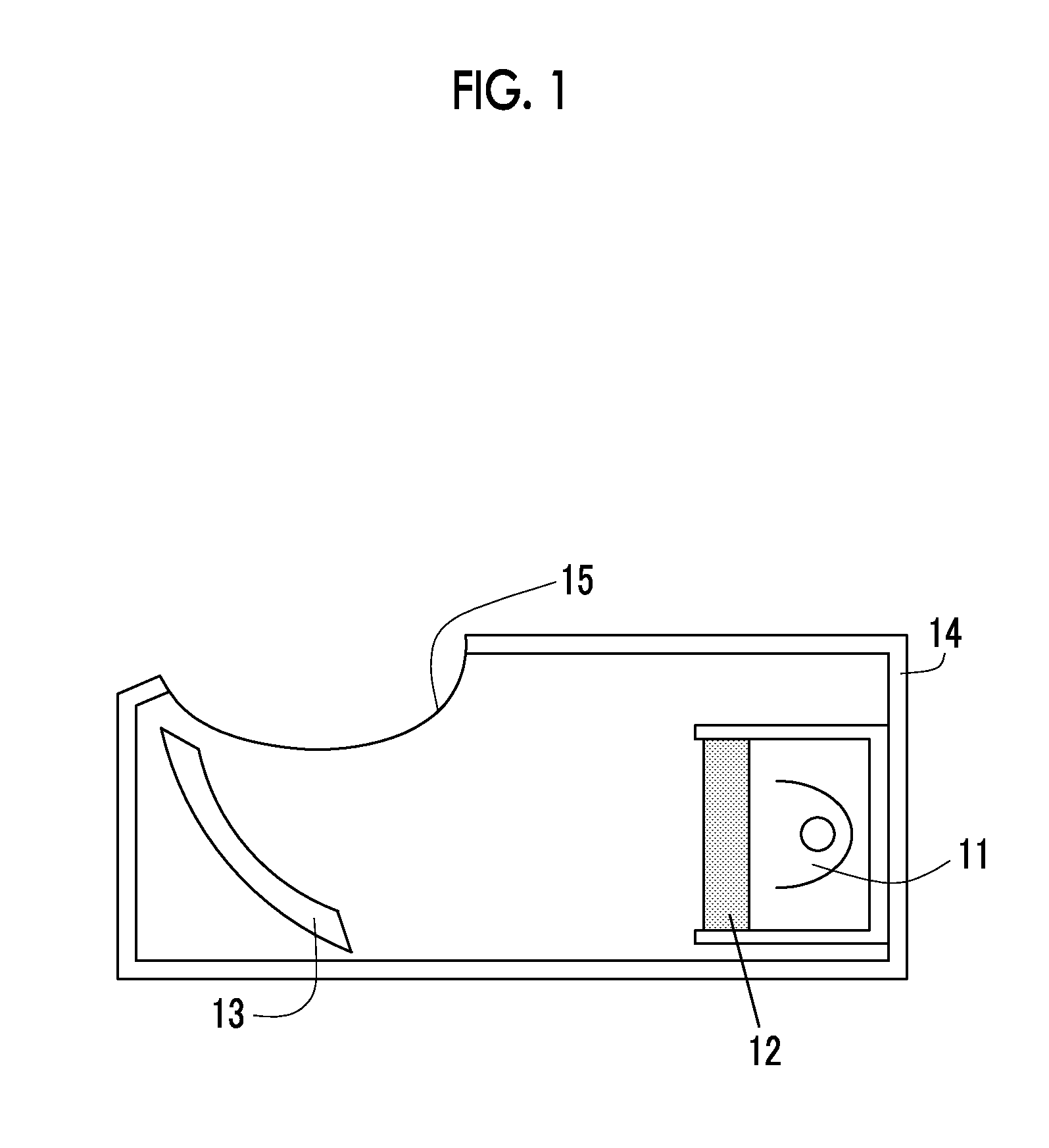

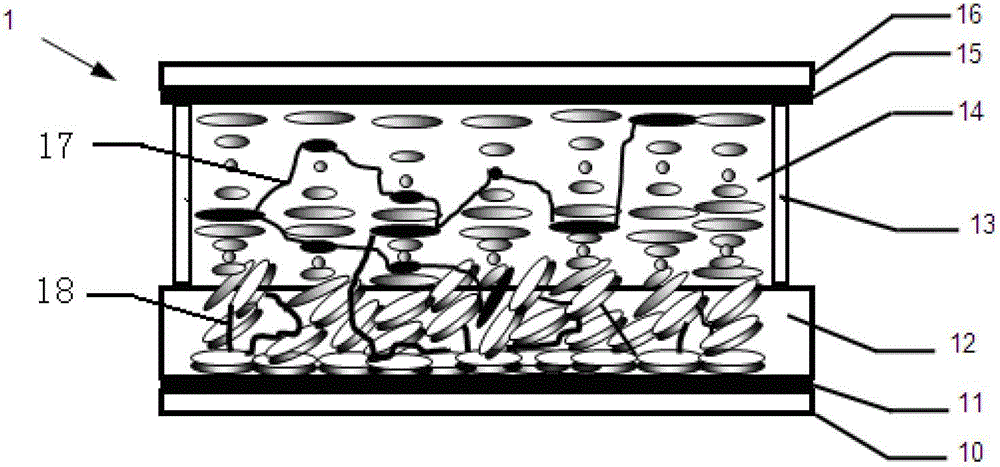

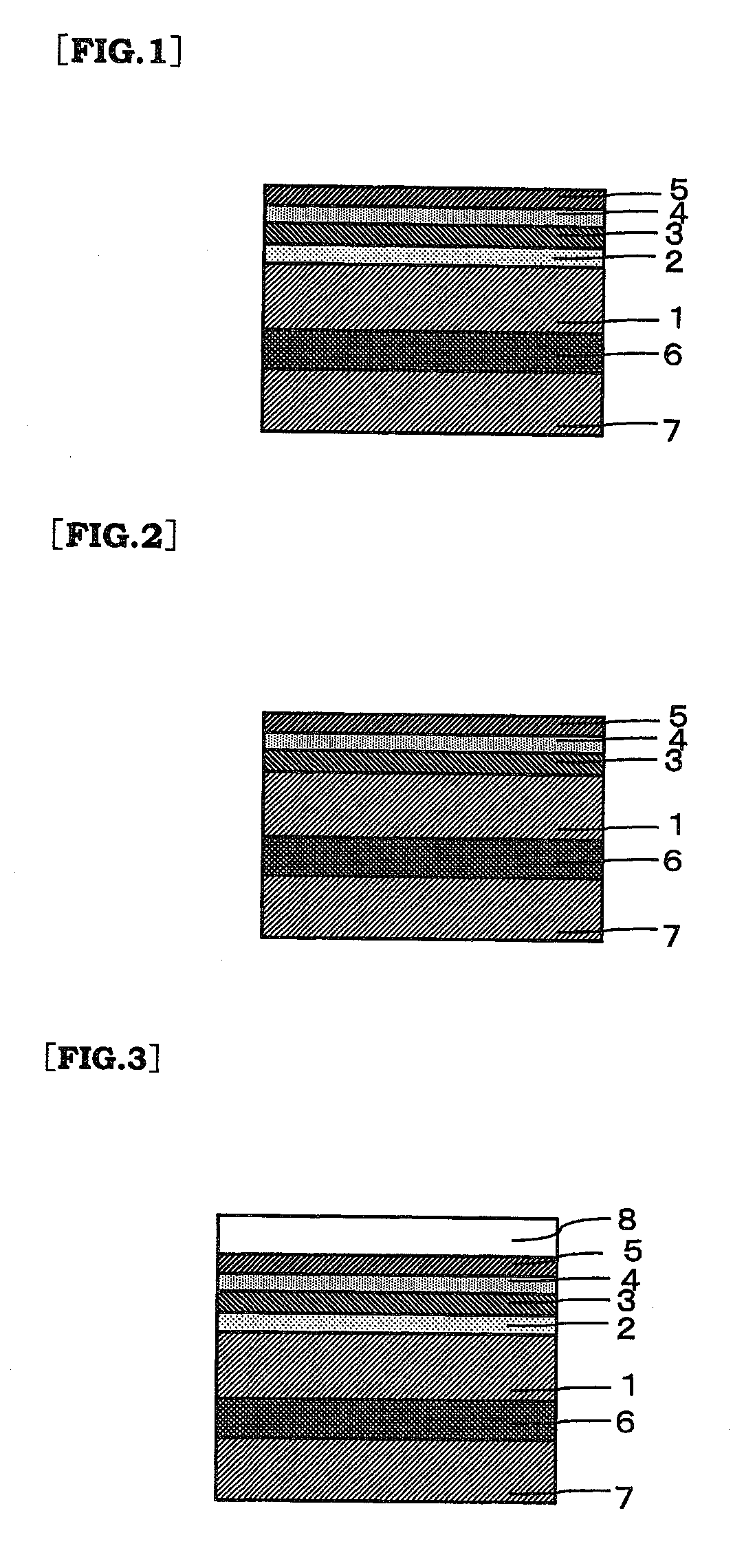

Liquid crystal display and method for producing the same

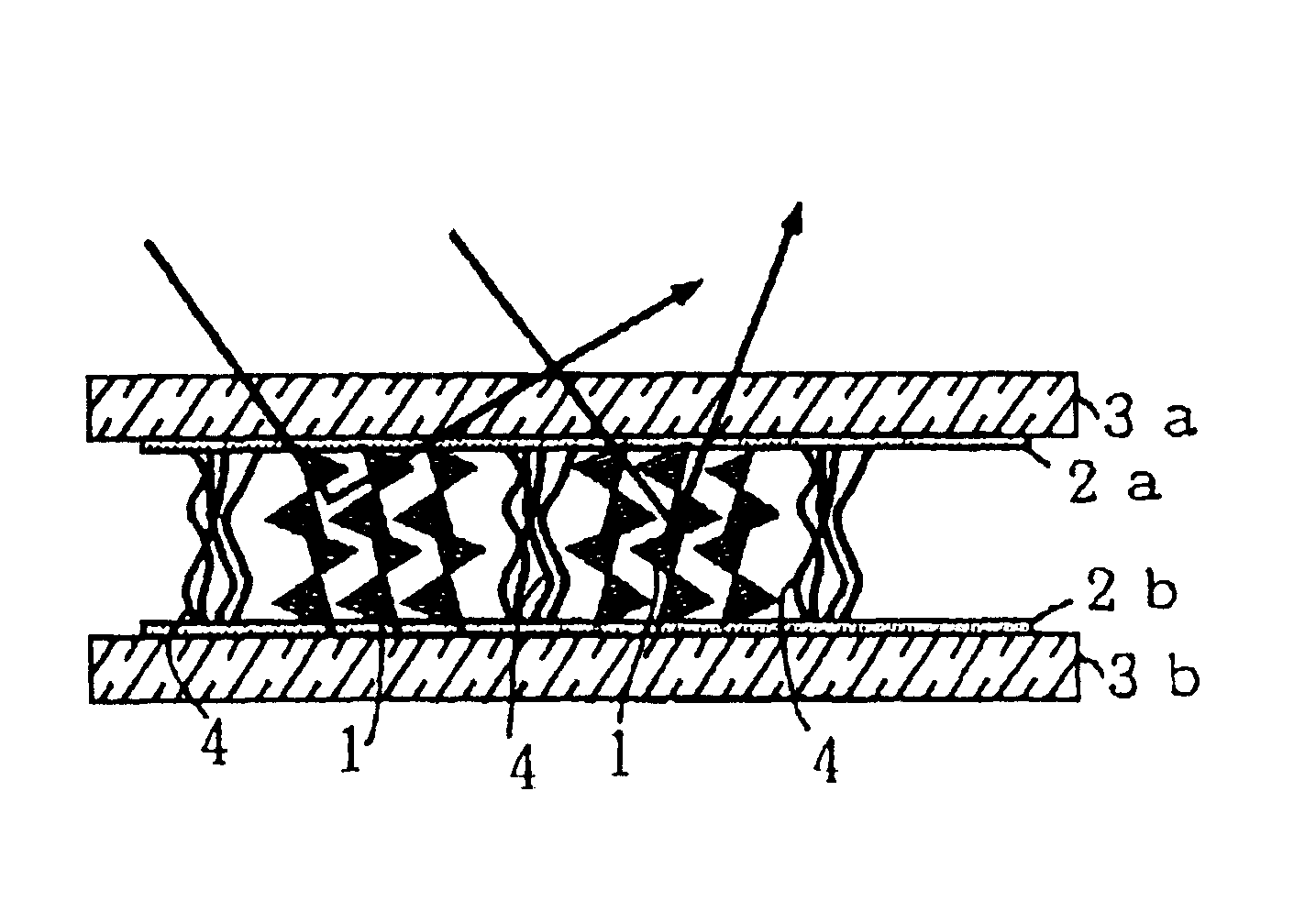

The invention provides a liquid crystal display having high reliability, which is excellent in terms of optical characteristics, heat resistance, and shock resistance, wherein a liquid crystal display consisting of a cholesteric liquid crystal, a chiral nematic liquid crystal or a liquid crystal 1 layer, being a combination thereof, which is roughly pillar-like and polygonal in section or has a roughly pillar-like form enclosed by a closed curve, and divided by said polymer network into areas whose minimum diameter measured by vernier calipers is 5 mum and whose maximum diameter measured by vernier calipers is 100 mum, is obtained by polymer networks 4 formed by polymerization of monomer, so that sufficient reflection can be obtained from the liquid crystal 1 without being optical scattering. Although the perpendicular array of the helical axes of liquid crystal 1 is slightly disordered by a polymer network 4 with respect to the plane of a pair of ITO 2a, 2b and substrates 3a,3b, wherein since almost all light entering from the substrata 3a side is reflected backwards (substrate 3a side) by Bragg's reflection, it is possible to decrease the visual angle dependency in comparison with a prior art liquid crystal display not containing any polymer constituents, and networks 4 which have been greatly established form intensive pillars (macromolcular resin walls), thereby improving the shock resistance properties.

Owner:NANOX

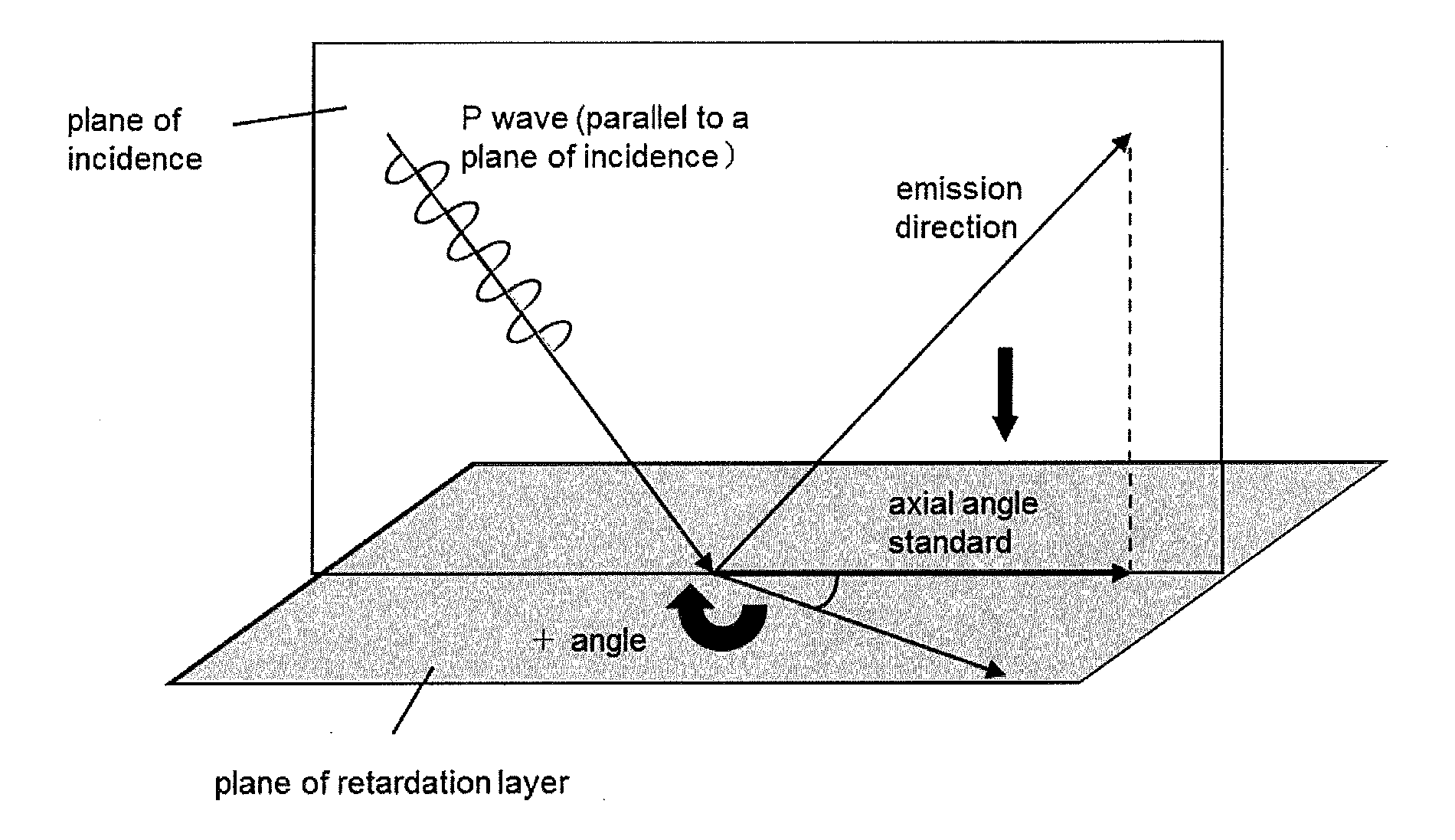

Member for projection image display and projection image display system

ActiveUS20160091756A1Improve reflectivityImprove color balanceLiquid crystal compositionsPolarising elementsSelective reflectionPhase difference

The present invention provides a member for projection image display, including a reflection layer and a retardation layer, wherein the reflection layer includes a cholesteric liquid crystal layer exhibiting selective reflection in a visible light region, the cholesteric liquid crystal layer is a layer formed from a liquid crystal composition containing a discotic liquid crystal compound, and a front phase difference of the retardation layer is in a range of 50 nm to 400 nm; and a projection image display system which includes the above member for projection image display, wherein the retardation layer is disposed on an incident light side relative to the reflection layer, and the incident light is p-polarized light that vibrates in a direction parallel to a plane of incidence, which is capable of displaying a clear image having high reflectance and high transmittance, without a problem of a double image.

Owner:FUJIFILM CORP

Liquid crystal display

InactiveCN1800936ATransfer is fast and stableIncrease viewing angleNon-linear opticsEngineeringDiscotic liquid crystal

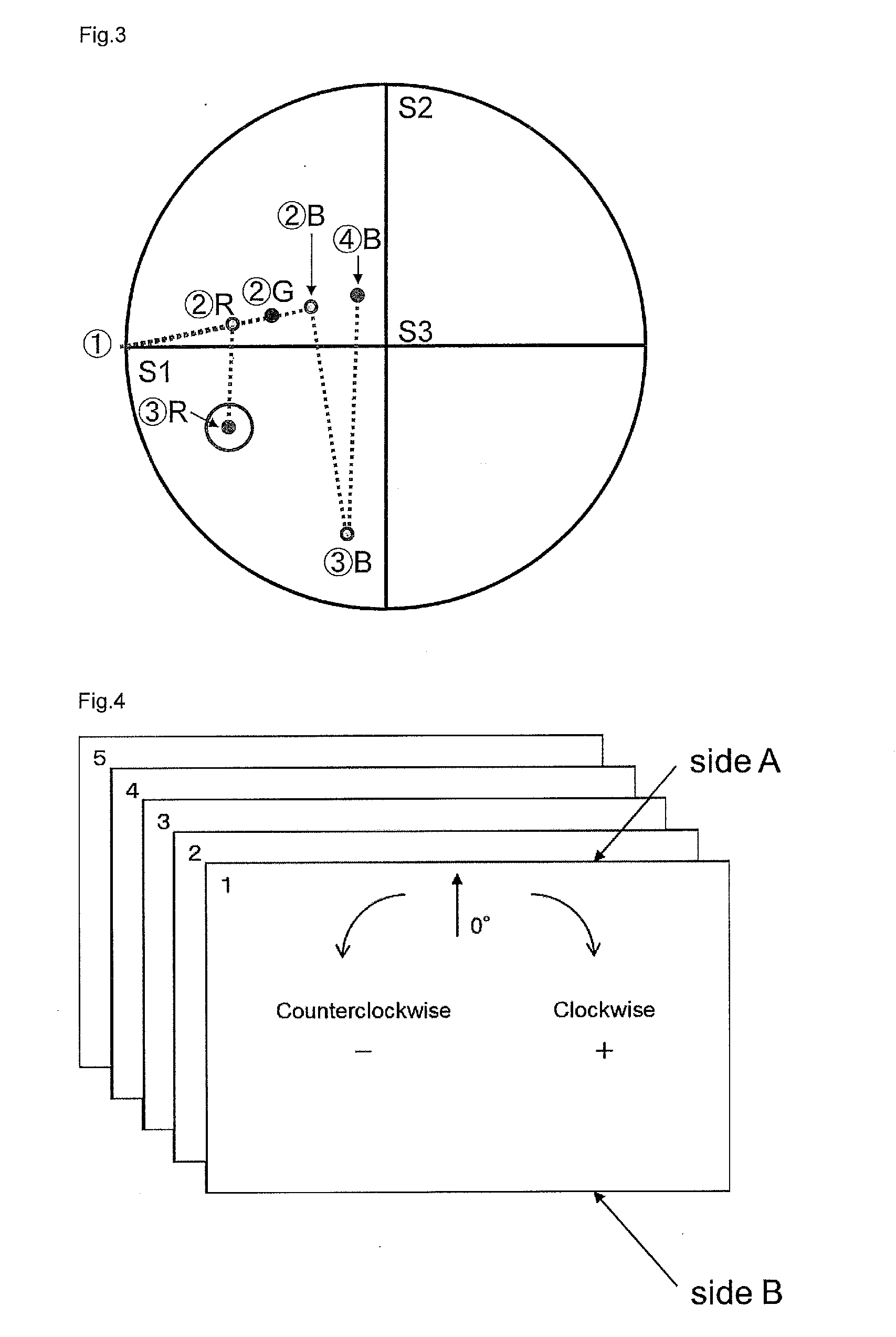

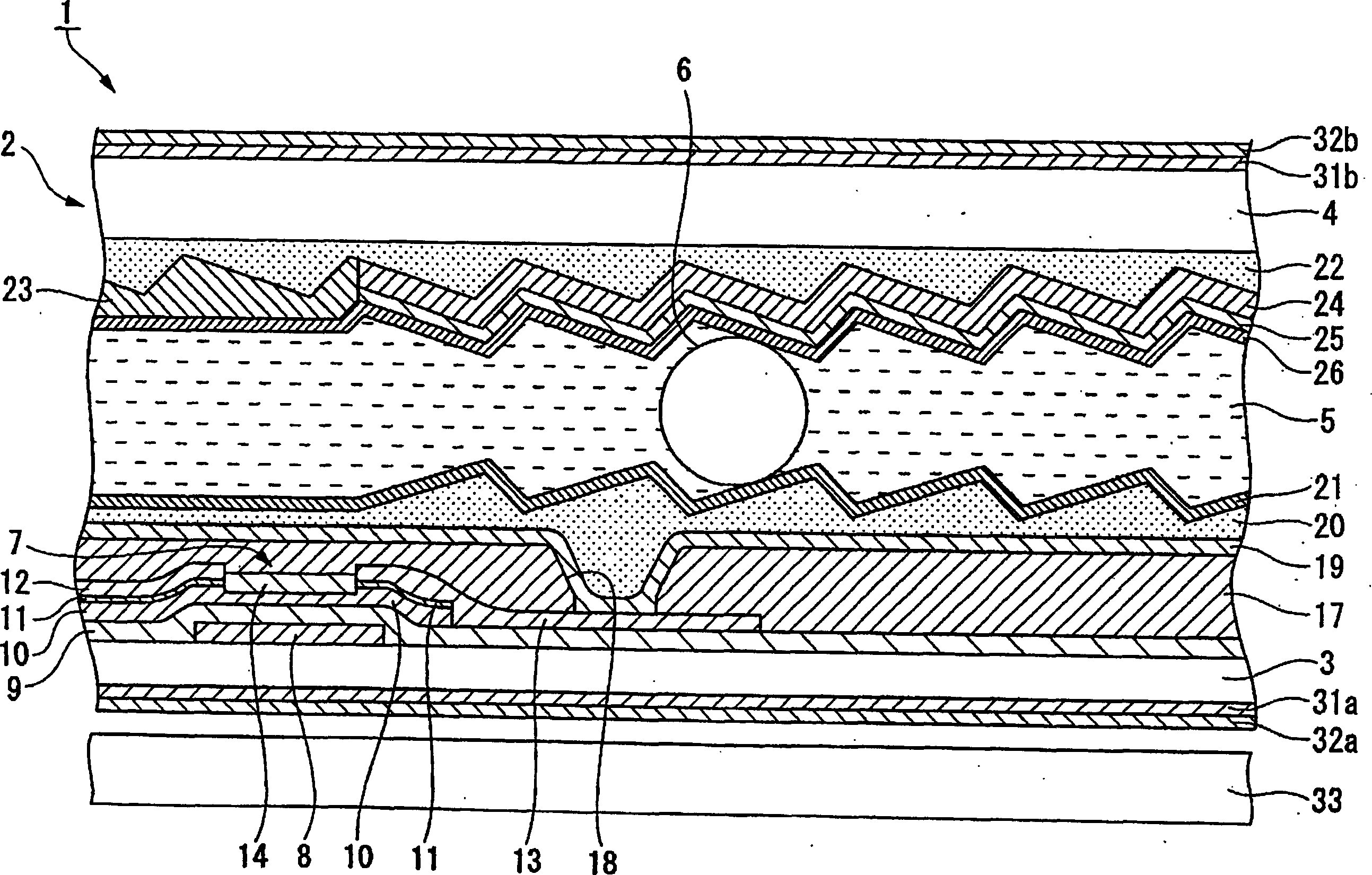

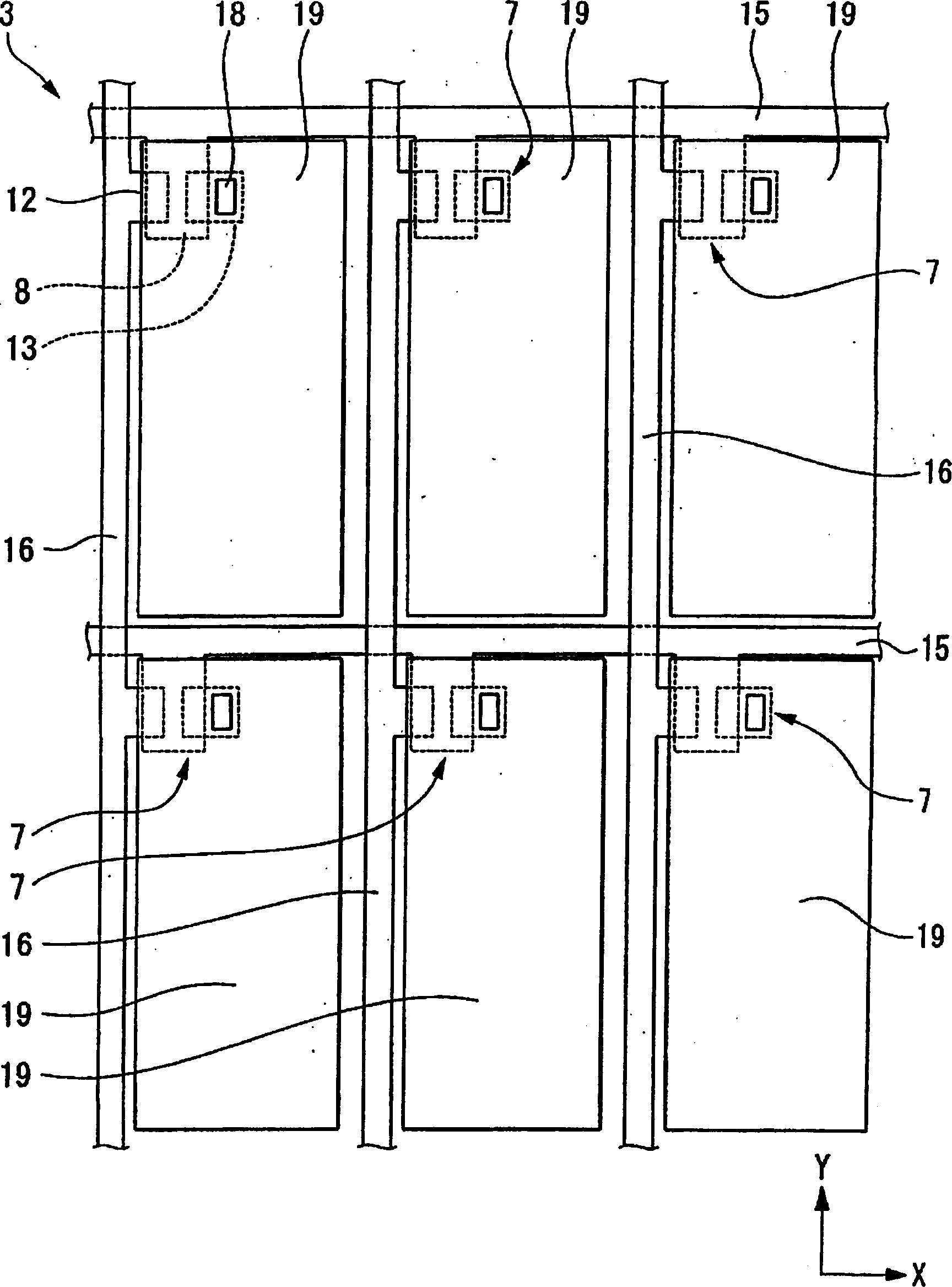

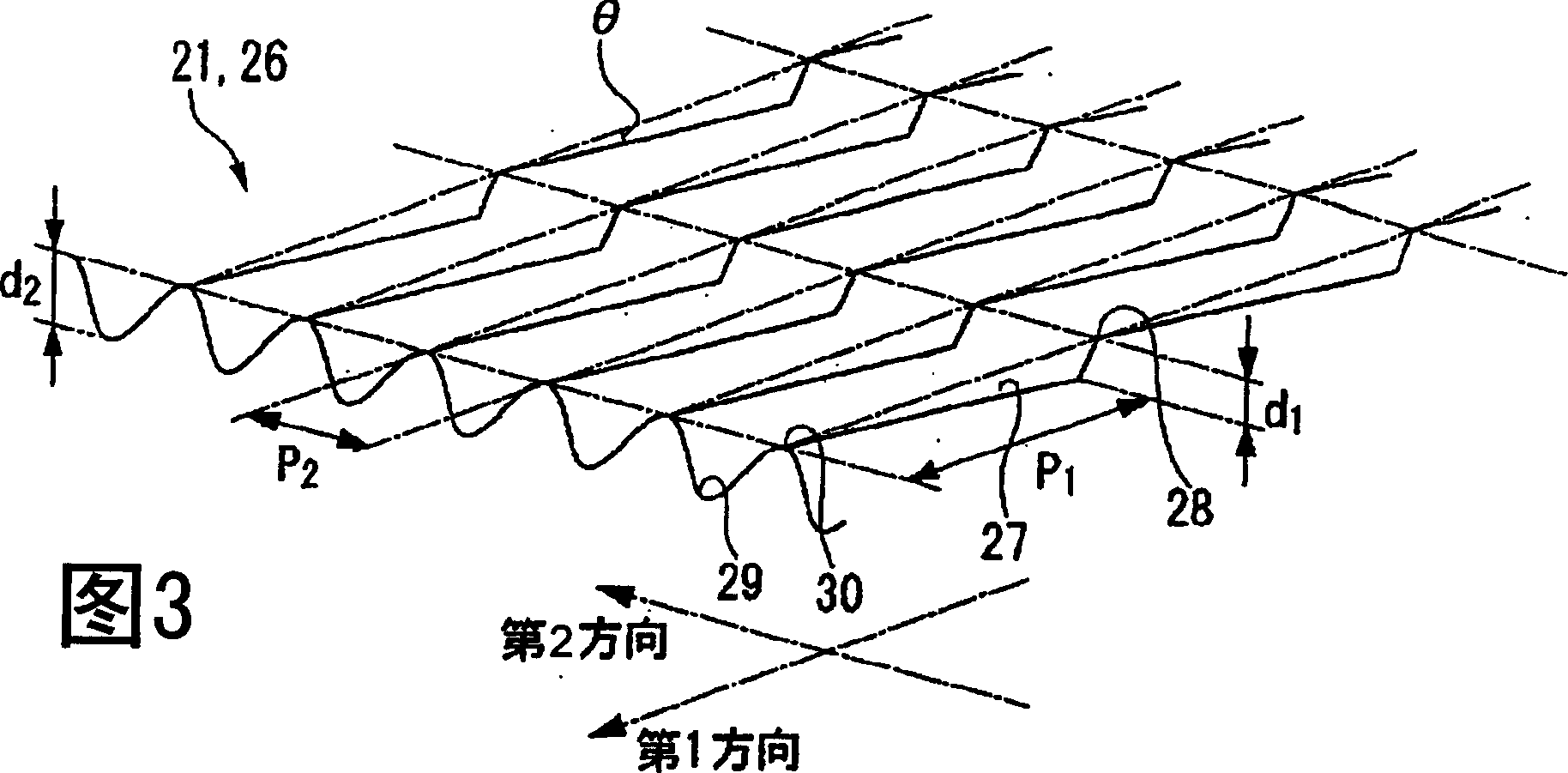

To provide a liquid crystal display device capable of generating the transition of a liquid crystal layer from a splay alignment state to a bend alignment state quickly and stably without applying a high driving voltage.The liquid crystal display device is provided with a liquid crystal panel 2 having: a pair of substrates 3, 4 , which are arranged oppositely to each other and in which electrodes 19, 25 and alignment layers 21, 26 are formed on respective counter surfaces thereof; an OCB mode liquid crystal layer 5 in which a nematic liquid crystal sealed in between the pair of substrates 3, 4 is splay aligned with the alignment layers 21, 26 and the splay aligned nematic liquid crystal is subjected to the transition to the bend aligned state with the driving voltage applied between the electrodes 19, 25; and spacers 6 arranged inside the liquid crystal layer 5 and retaining a gap between the pair of mutually opposing substrates 3, 4 uniform. The spacers 6 are subjected to a surface treatment for accelerating the transition of the liquid crystal layer 5 from the splay aligned state to the bend aligned state.

Owner:ALPS ALPINE CO LTD

Reflection member, projection screen, combiner, and heat shield member

ActiveUS20160377776A1Favorable selective reflection characteristicImprove featuresProjectorsPolarising elementsSelective reflectionProjection image

Due to the present invention, a reflection member including two or more layers of fixed cholesteric liquid crystal phases, in which the two or more layers of fixed cholesteric liquid crystal phases exhibit central wavelengths of mutually different selective reflection, and the two or more layers of fixed cholesteric liquid crystal phases include a layer formed of a composition including a disc-like liquid crystal compound and a layer formed of a composition including a rod-like liquid crystal compound and a projected image display member and a heat shield member which include the reflection member are provided. The reflection member of the present invention has favorable selective reflection characteristics with respect to oblique incidence rays.

Owner:FUJIFILM CORP

Pressure-sensitive adhesive optical film and image display

ActiveCN101303419AUneven suppressionLow moisture permeabilityLiquid crystal compositionsSynthetic resin layered productsMeth-Antioxidant

A pressure-sensitive adhesive optical film of the present invention comprises: an optical film comprising a transparent base film and a discotic liquid crystal layer provided on one side of the transparent base film; an undercoat layer; and a pressure-sensitive adhesive layer provided on the discotic liquid crystal layer with the undercoat layer interposed therebetween, the undercoat layer comprises a polymer and an antioxidant; and the pressure-sensitive adhesive layer comprises a (meth)acrylic polymer (A) comprising 80 to 99.5% by weight of an alkyl (meth)acrylate monomer unit and 0.05 to 3% by weight of a hydroxyl group-containing monomer unit and having a weight average molecular weight of 1,000,000 to 2,500,000; ; a (meth)acrylic oligomer (B) comprising 80 to 99.9% by weight of an alkyl (meth)acrylate monomer unit and 0.1 to 3% by weight of a carboxyl group-containing monomer unit and having a weight average molecular weight of 3,000 to 8,000; a crosslinking agent (C); and a silane coupling agent (D), and the pressure-sensitive adhesive layer comprises 10 to 40 parts by weight of the (meth)acrylic oligomer (B) based on 100 parts by weight of the (meth)acrylic polymer (A). The pressure-sensitive adhesive optical film has durability and can suppress display unevenness in a peripheral portion of a display screen and window frame unevenness in a state that a backlight is on.

Owner:NITTO DENKO CORP

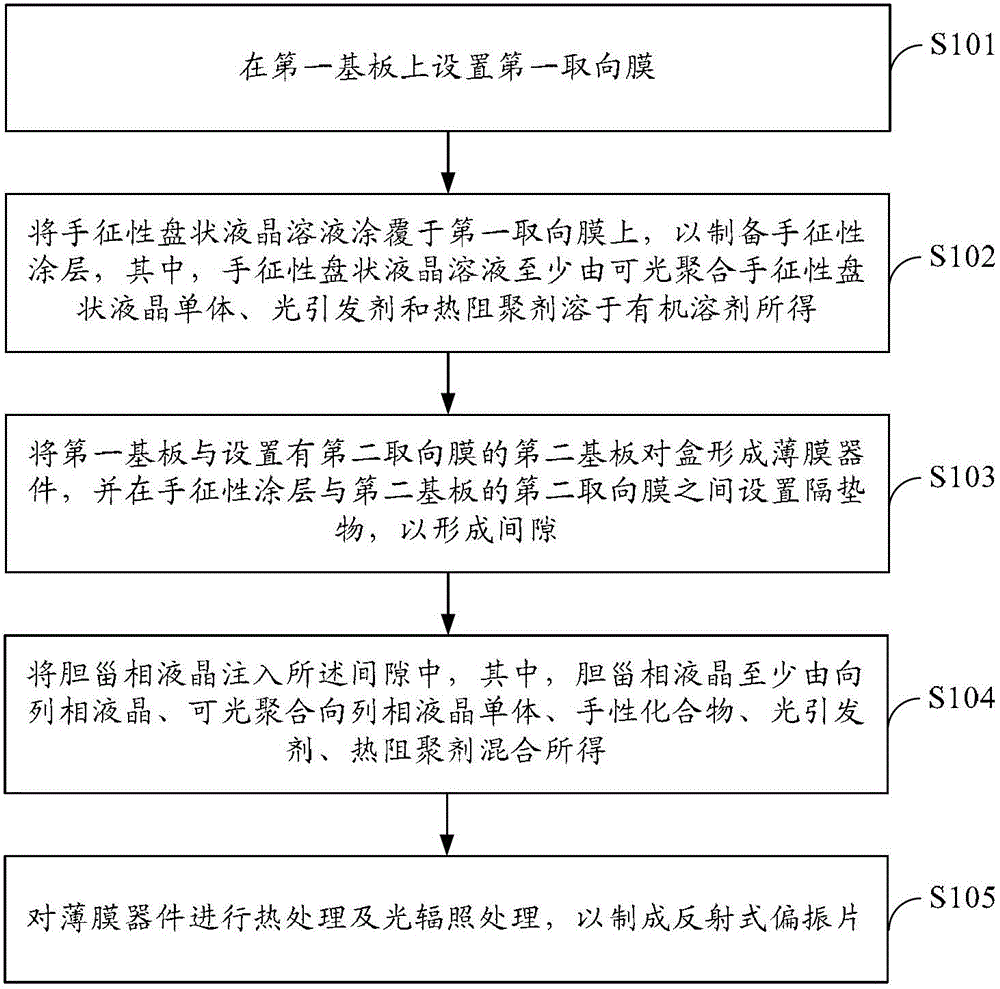

Reflecting polaroid, method for producing same and liquid crystal display device

InactiveCN102749669AIncrease the reflection widthPolarising elementsNon-linear opticsLiquid-crystal displayBroadband

The embodiment of the invention provides a reflecting polaroid, a method for producing the same and a liquid crystal display device, which relate to the technical field of liquid crystal display, and the reflecting Polaroid which has both optical compensation performance and broadband reflection performance can be produced. The reflecting polaroid comprises a first substrate, a first alignment layer which is arranged on the first substrate, a chiral coating which is formed on the first alignment layer, a second substrate which is arranged with the first substrate in a box manner and is provided with a second alignment layer, and cholesteric liquid crystals which are filled in a clearance, wherein the chiral coating is formed by coating chiral discotic liquid crystal solution onto the first alignment layer; spacers are arranged between the chiral coating and the second alignment layer for forming the clearance; and the cholesteric liquid crystals are produced by mixing at least nematic liquid crystals, photopolymerization nematic liquid crystal monomers, chiral compound, photoinitiator and thermal polymerization inhibitor.

Owner:BOE TECH GRP CO LTD +1

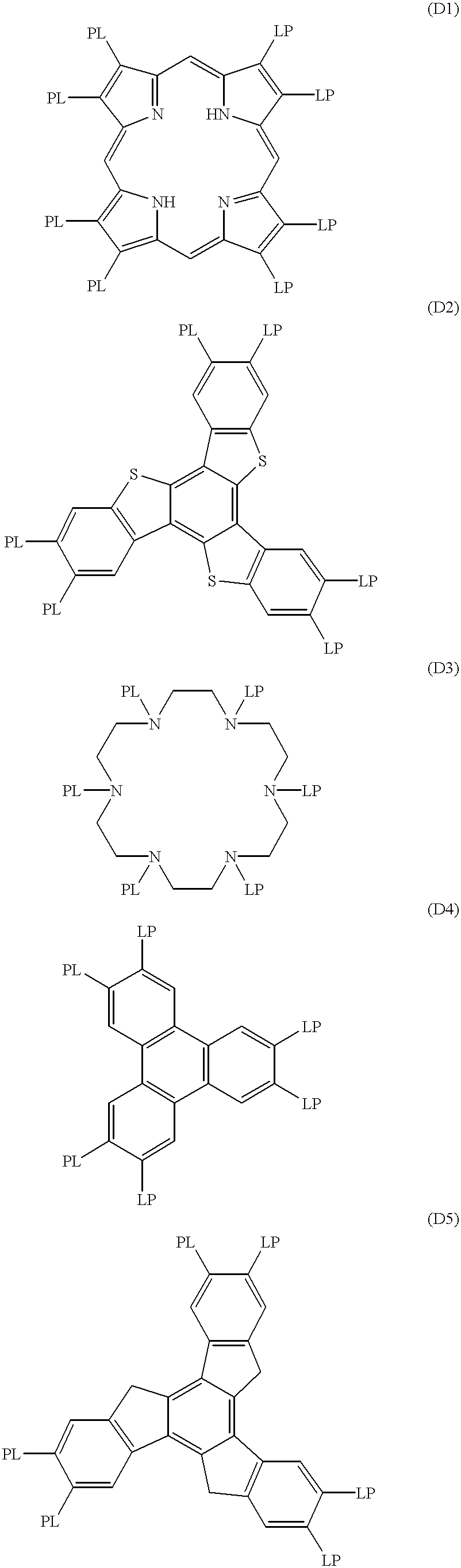

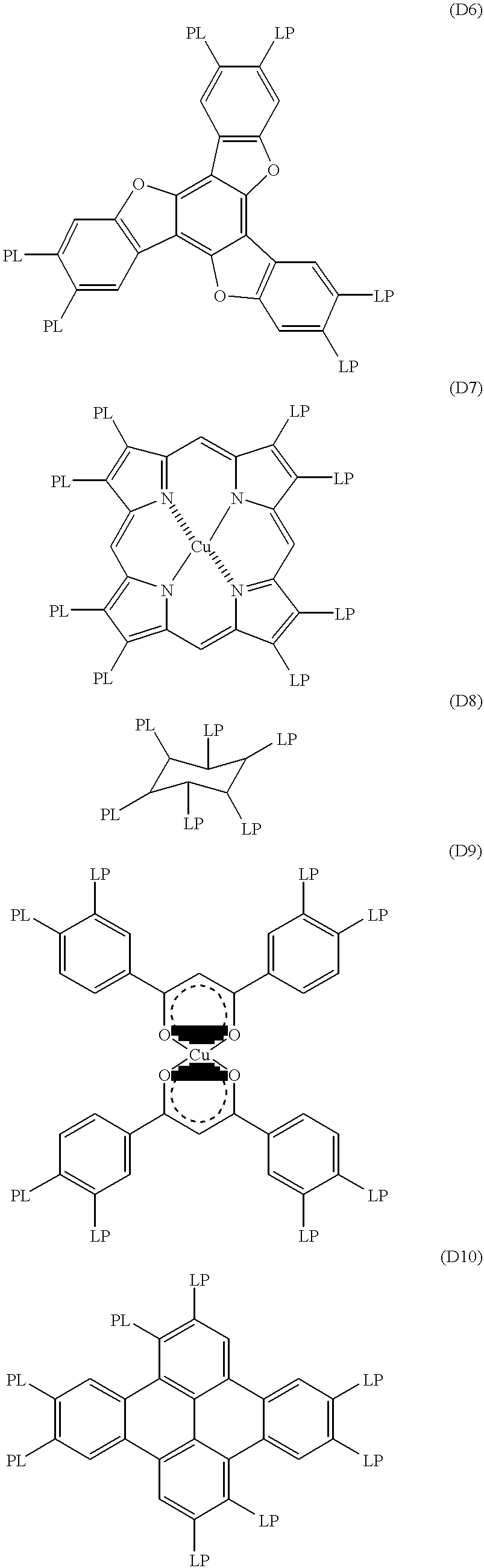

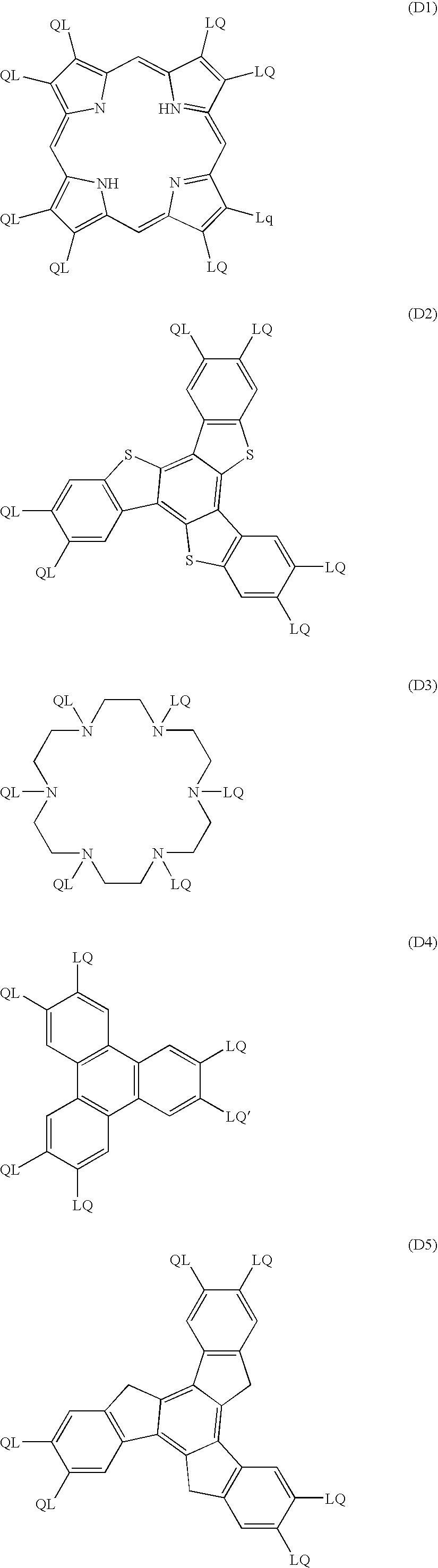

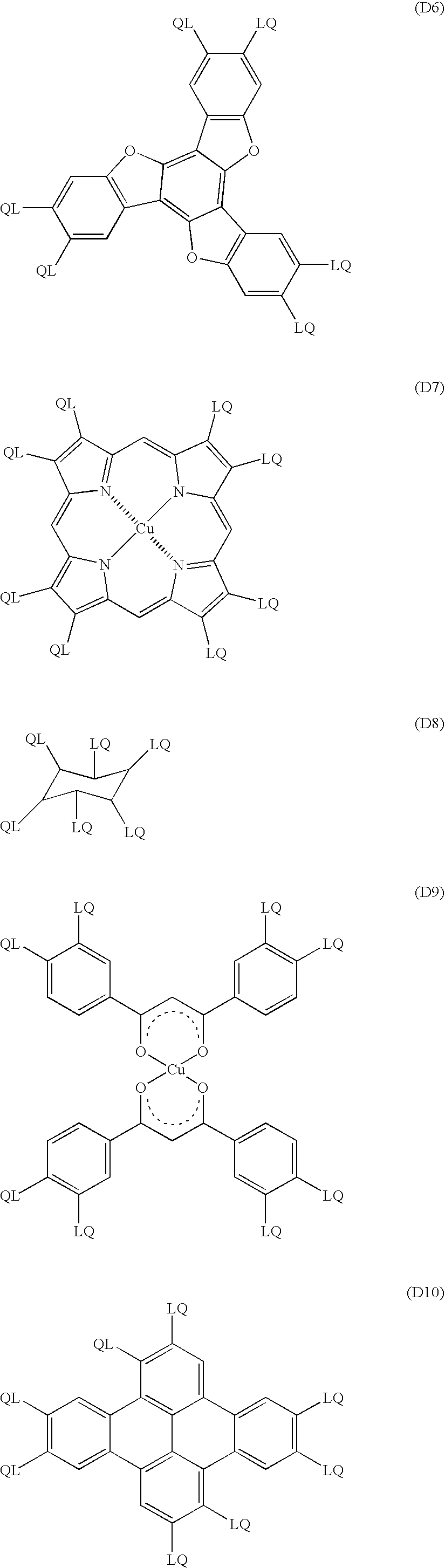

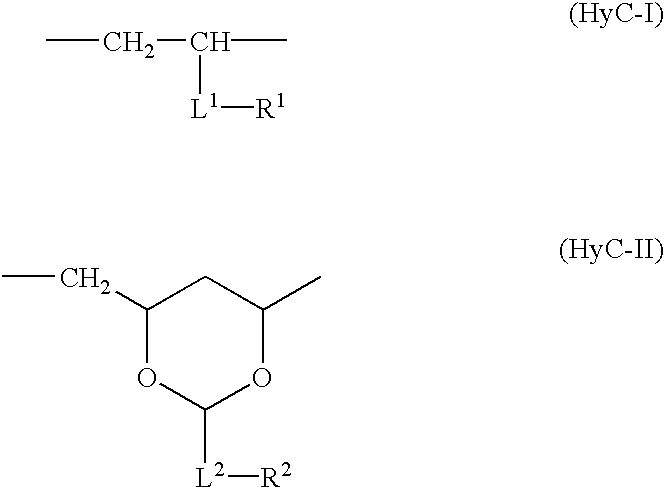

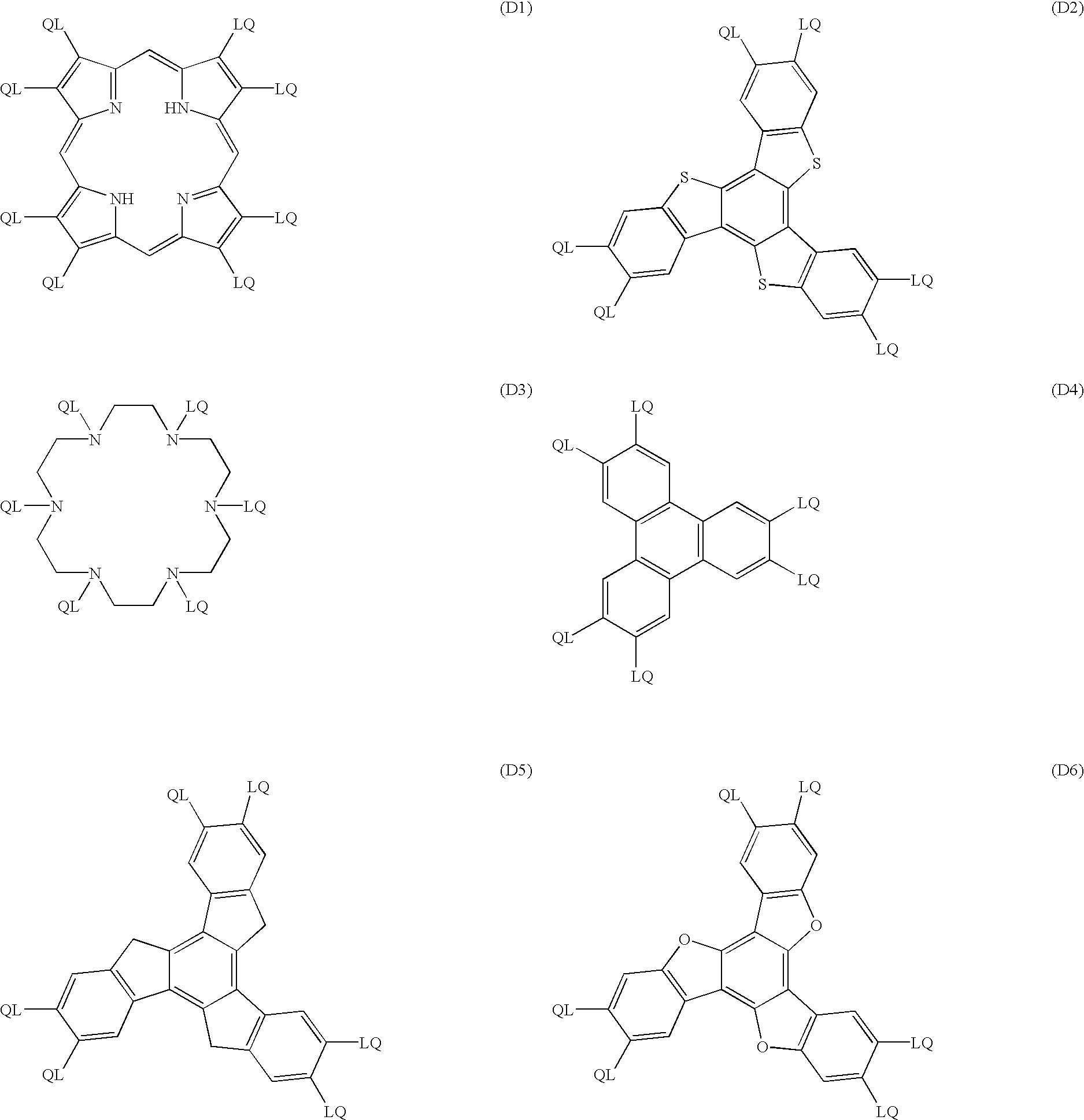

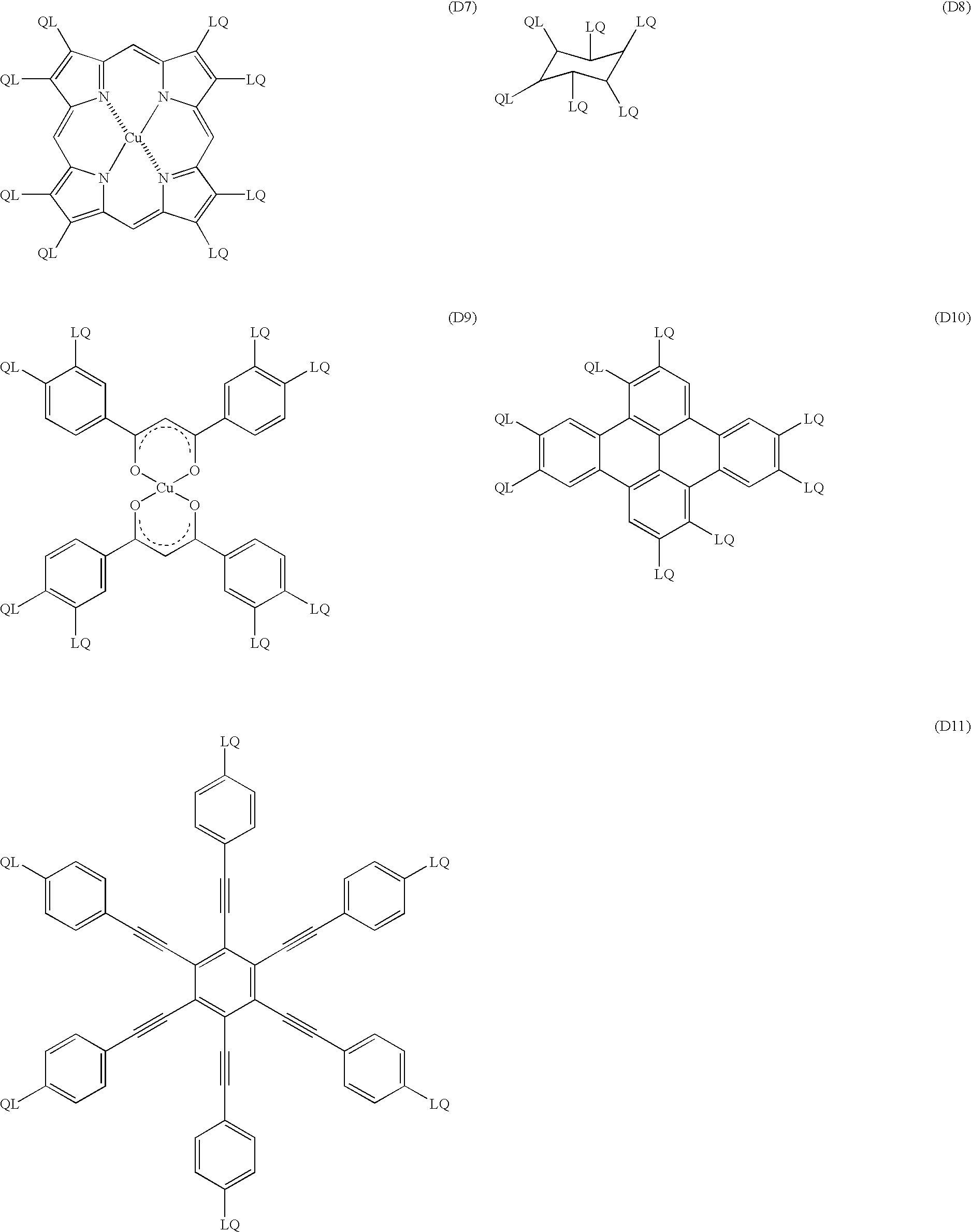

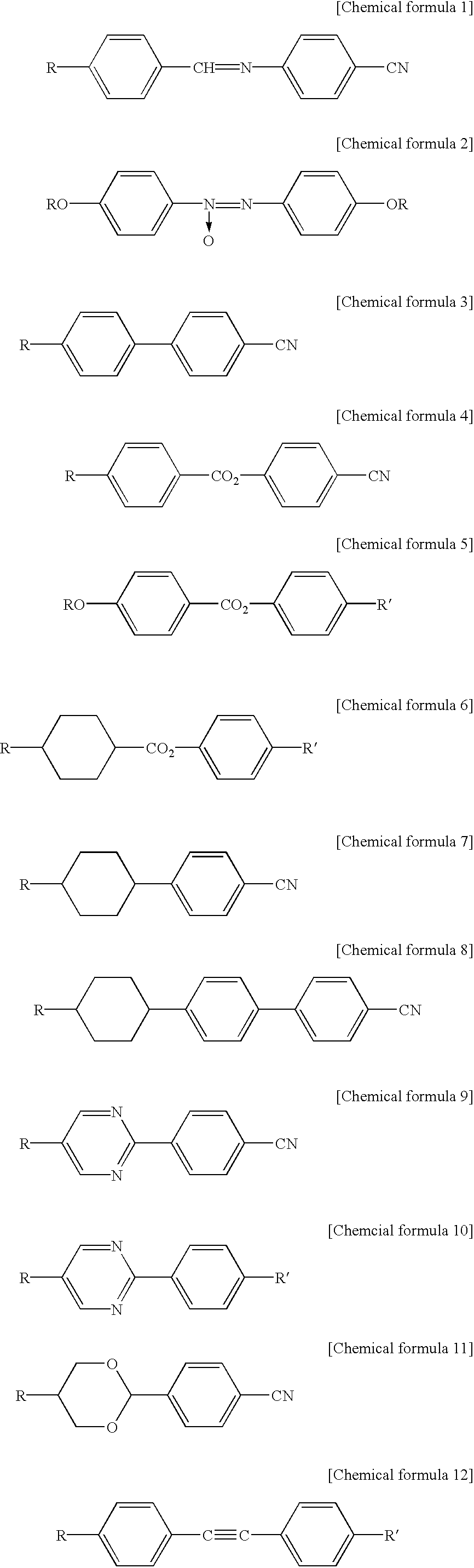

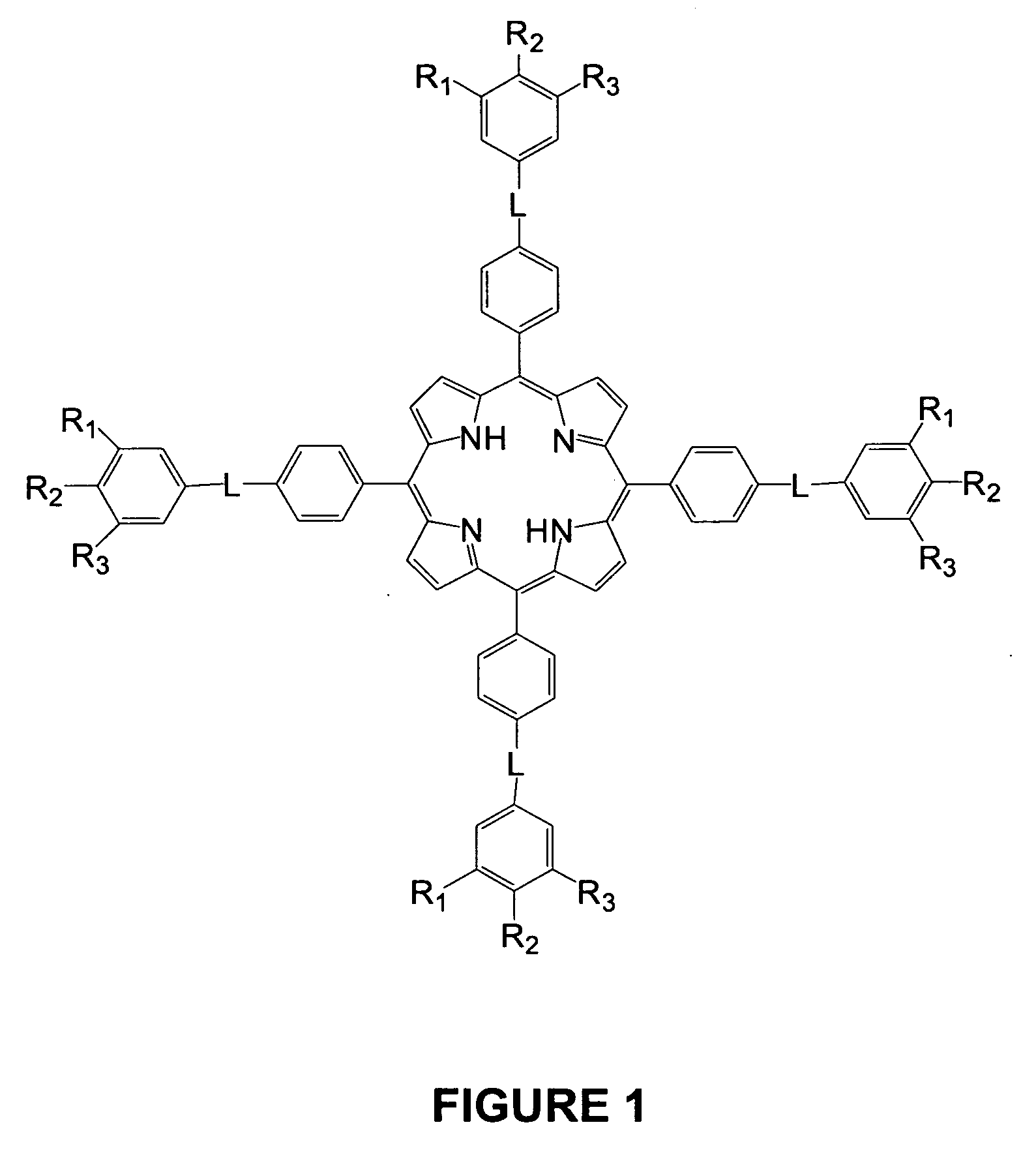

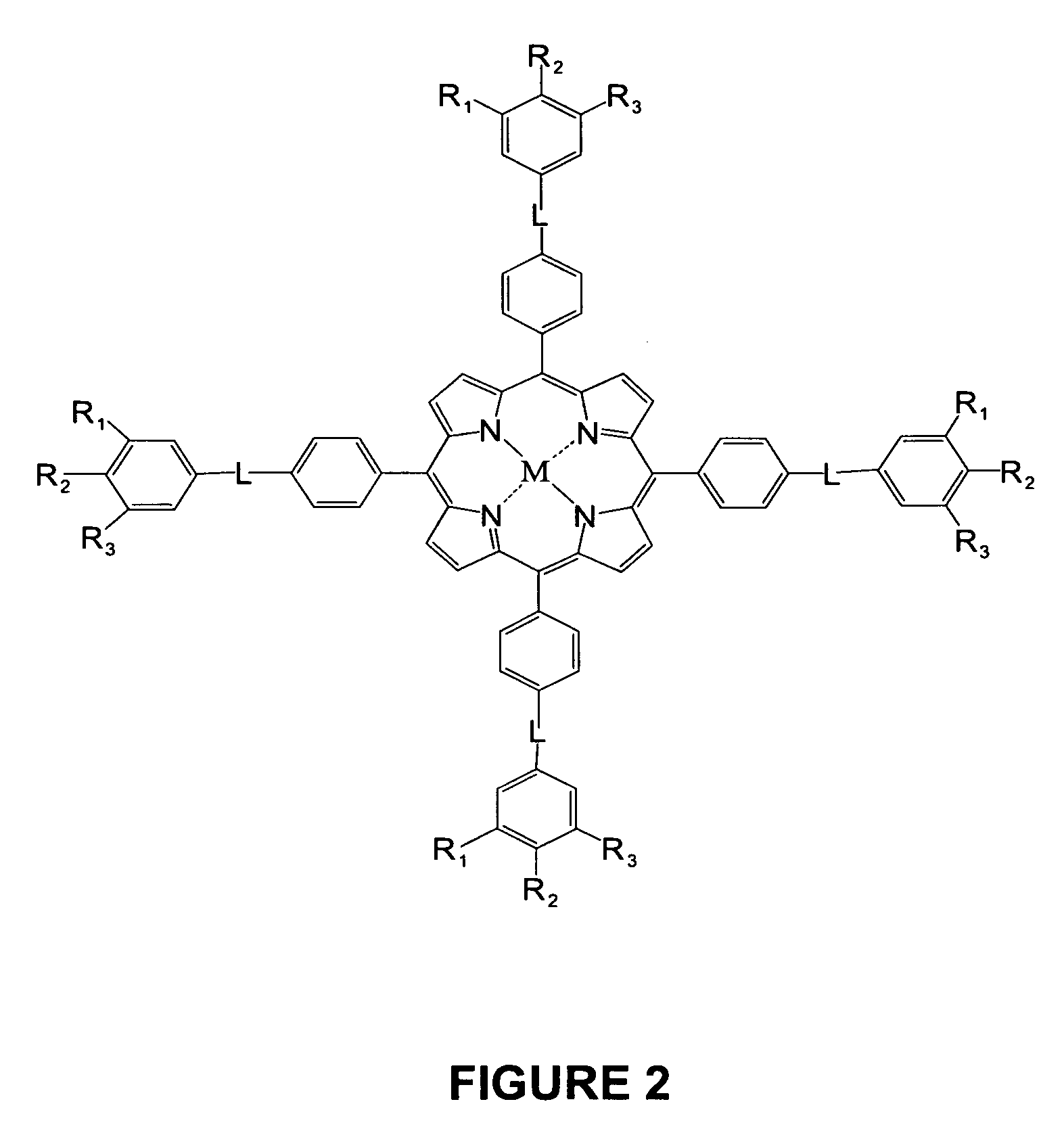

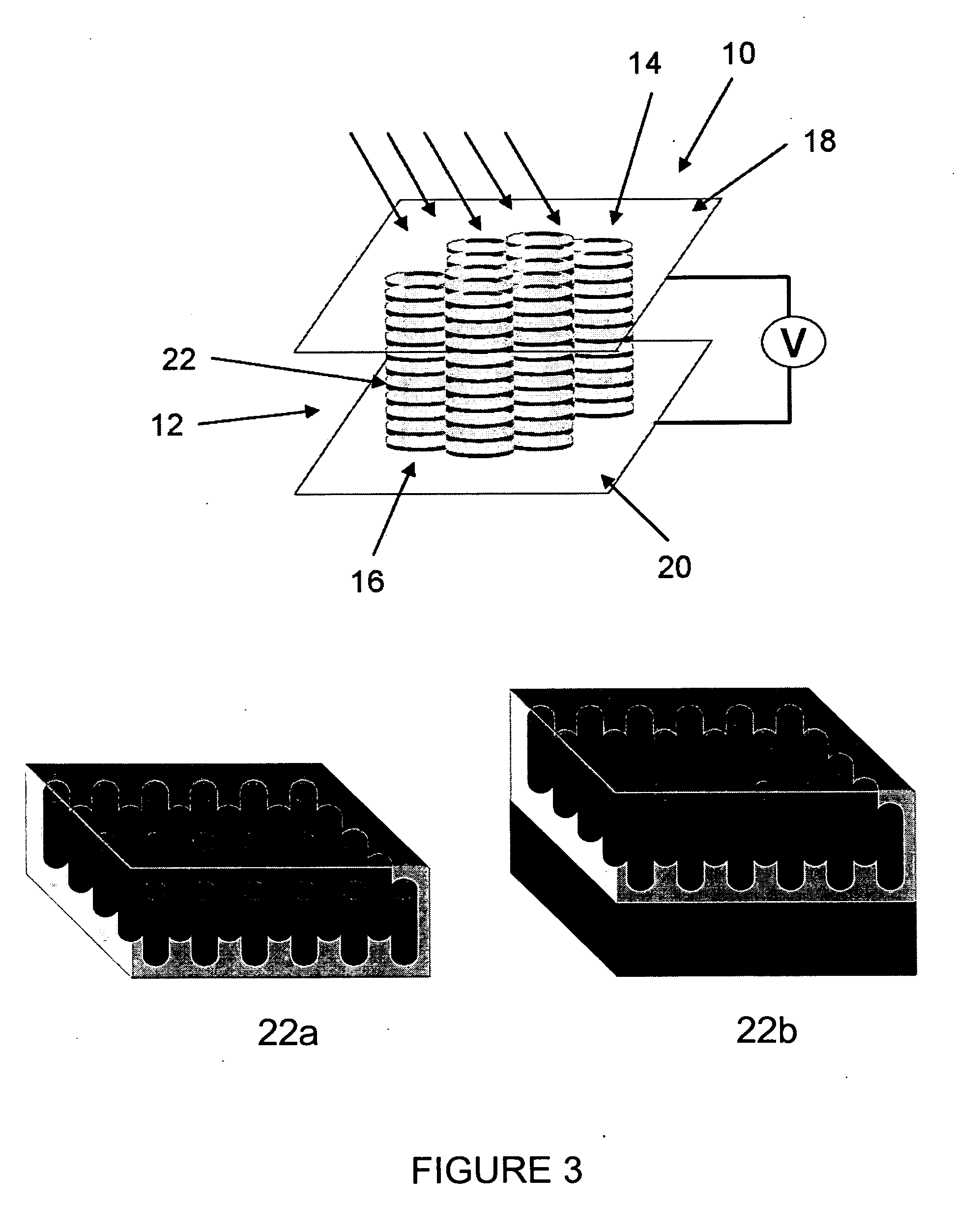

Light-harvesting discotic liquid crystalline porphyrins and metal complexes

InactiveUS20070152189A1Liquid crystal compositionsFinal product manufactureLiquid crystallinePorphyrin

Novel discotic liquid crystalline porphyrins and discotic liquid crystalline metal complexes, methods for their preparation, and device fabrication are disclosed. Materials with partially perfluorinated alkyl group in the peripheral chains show a strong tendency towards the formation of homeotropic alignment. These compounds are capable of being used as high-efficiency photovoltaic materials, organic semiconducting materials, and organic light emitting materials.

Owner:KENT STATE UNIV

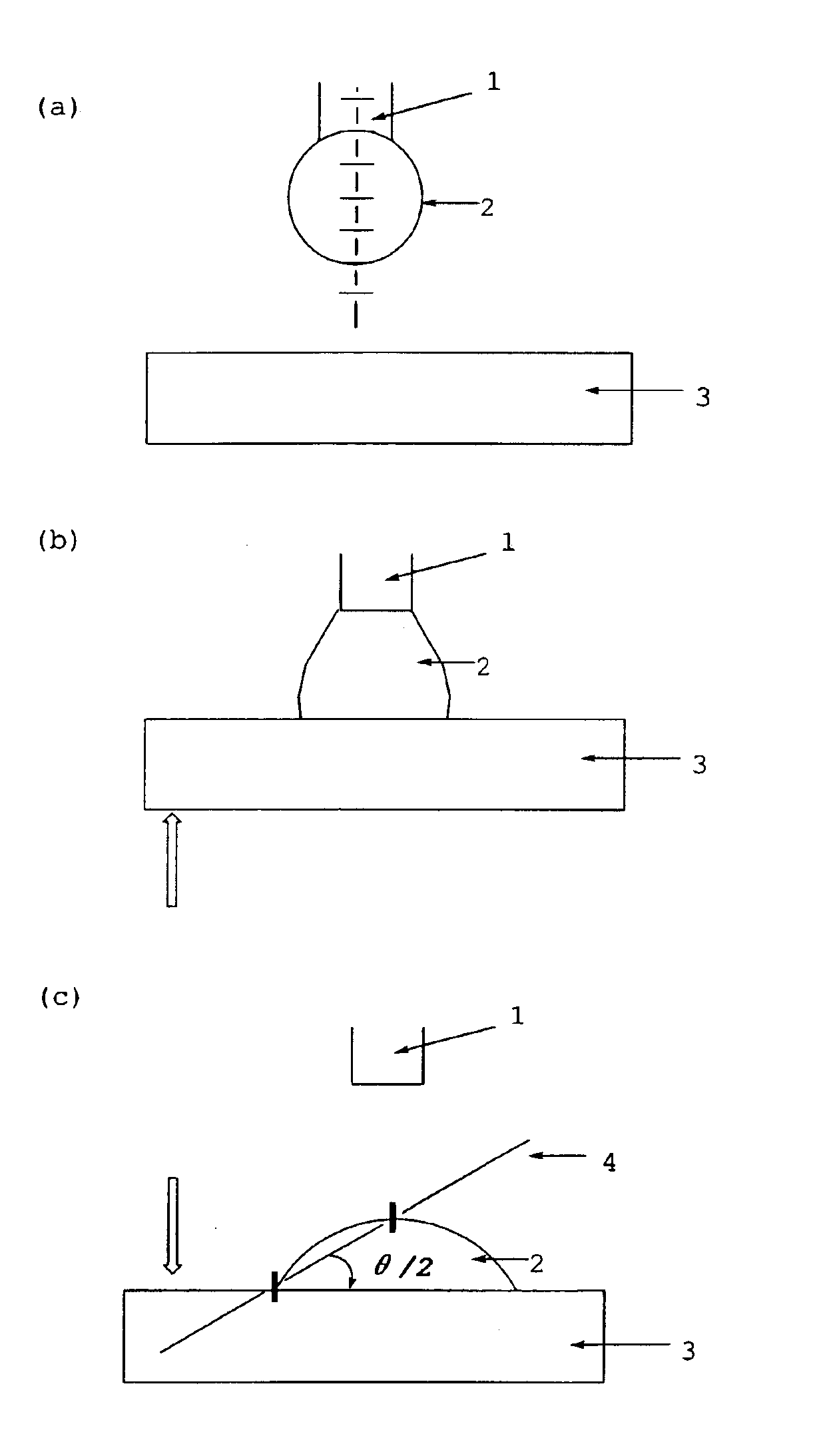

Discotic liquid crystal device and alignment method therefor

InactiveUS6159562ALiquid crystal compositionsNon-aqueous electrolyte accumulatorsCrystallographyDiscotic liquid crystal

A layer of discotic liquid crystal having a molecular structure including a disk-shaped core and plural side chains connected to the core is disposed in contact with a substrate boundary provided with a homeotropic alignment power for aligning the side chains of the discotic liquid crystal molecules vertically to the boundary, whereby a uniform columnar structure vertical to the substrate of the discotic liquid crystal is formed. As a result, a discotic liquid crystal device having a stable homeotropic monodomain alignment can be formed from a wide scope of discotic liquid crystal materials.

Owner:CANON KK

Pressure-sensitive adhesive optical film and image display

InactiveUS20080278672A1Suppress display unevennessInhomogeneous suppressionLiquid crystal compositionsSynthetic resin layered productsMeth-Antioxidant

A pressure-sensitive adhesive optical film of the present invention comprises: an optical film comprising a transparent base film and a discotic liquid crystal layer provided on one side of the transparent base film; an undercoat layer; and a pressure-sensitive adhesive layer provided on the discotic liquid crystal layer with the undercoat layer interposed therebetween, the undercoat layer comprises a polymer and an antioxidant; and the pressure-sensitive adhesive layer comprises a (meth)acrylic polymer (A) comprising 80 to 99.5% by weight of an alkyl (meth)acrylate monomer unit and 0.05 to 3% by weight of a hydroxyl group-containing monomer unit and having a weight average molecular weight of 1,000,000 to 2,500,000; a (meth)acrylic oligomer (B) comprising 80 to 99.9% by weight of an alkyl (meth)acrylate monomer unit and 0.1 to 3% by weight of a carboxyl group-containing monomer unit and having a weight average molecular weight of 3,000 to 8,000; a crosslinking agent (C); and a silane coupling agent (D), and the pressure-sensitive adhesive layer comprises 10 to 40 parts by weight of the (meth)acrylic oligomer (B) based on 100 parts by weight of the (meth)acrylic polymer (A). The pressure-sensitive adhesive optical film has durability and can suppress display unevenness in a peripheral portion of a display screen and window frame unevenness in a state that a backlight is on.

Owner:NITTO DENKO CORP

Composition, light reflecting film, luminance-improving film, backlight unit, and liquid crystal display device

ActiveUS20170010398A1Increased durabilityFew alignment defectLiquid crystal compositionsPolarising elementsLiquid crystallineLiquid-crystal display

There is provided a composition containing a discotic liquid crystal compound, a chiral agent, and a surfactant which can form a light reflecting layer formed by fixing a cholesteric liquid crystalline phase, which exhibits excellent durability under a hot and humid environment and excellent heat resistance, and has few alignment defects; a light reflecting film; a luminance-improving film; a backlight unit; and a liquid crystal display device.

Owner:FUJIFILM CORP

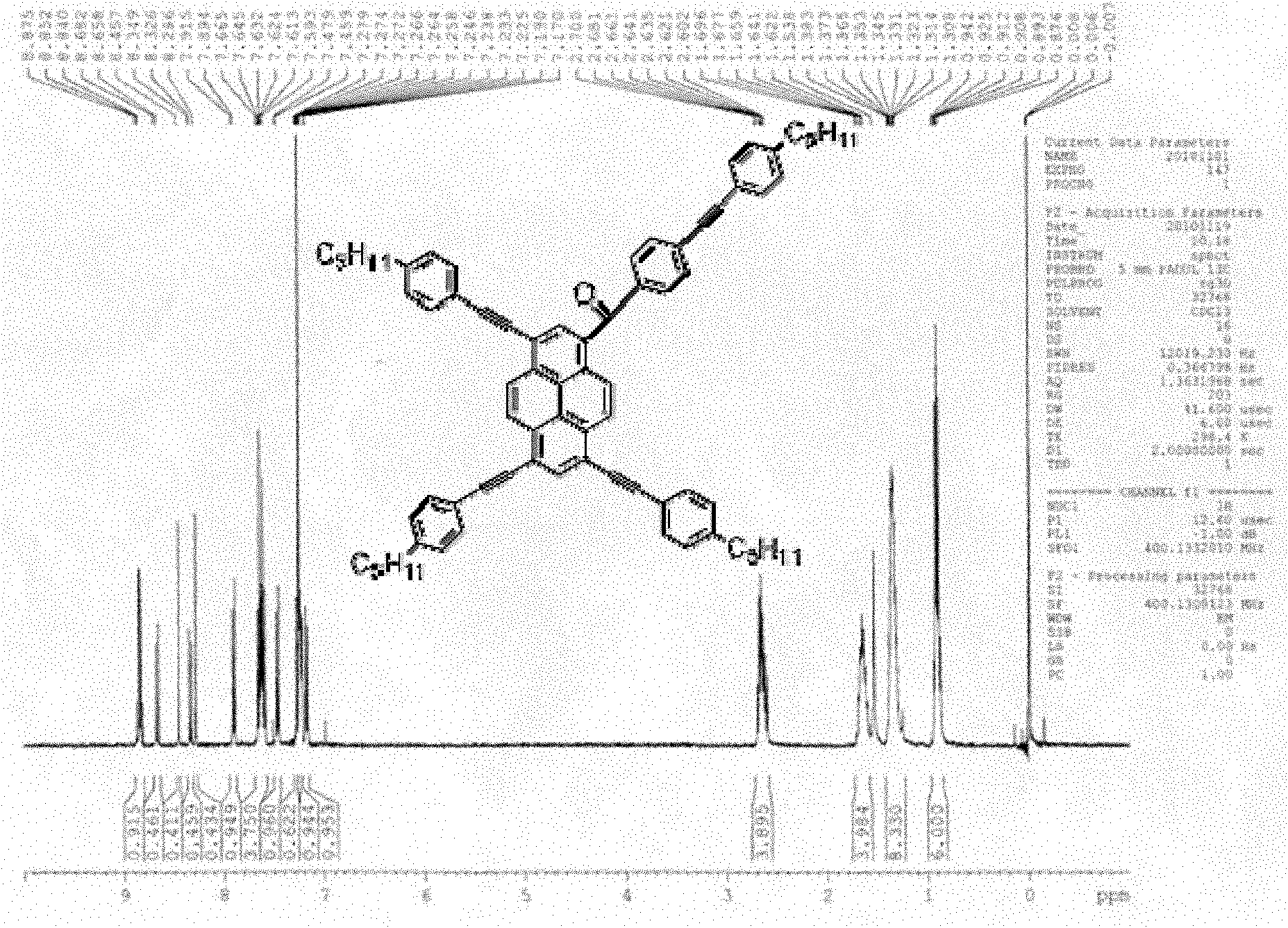

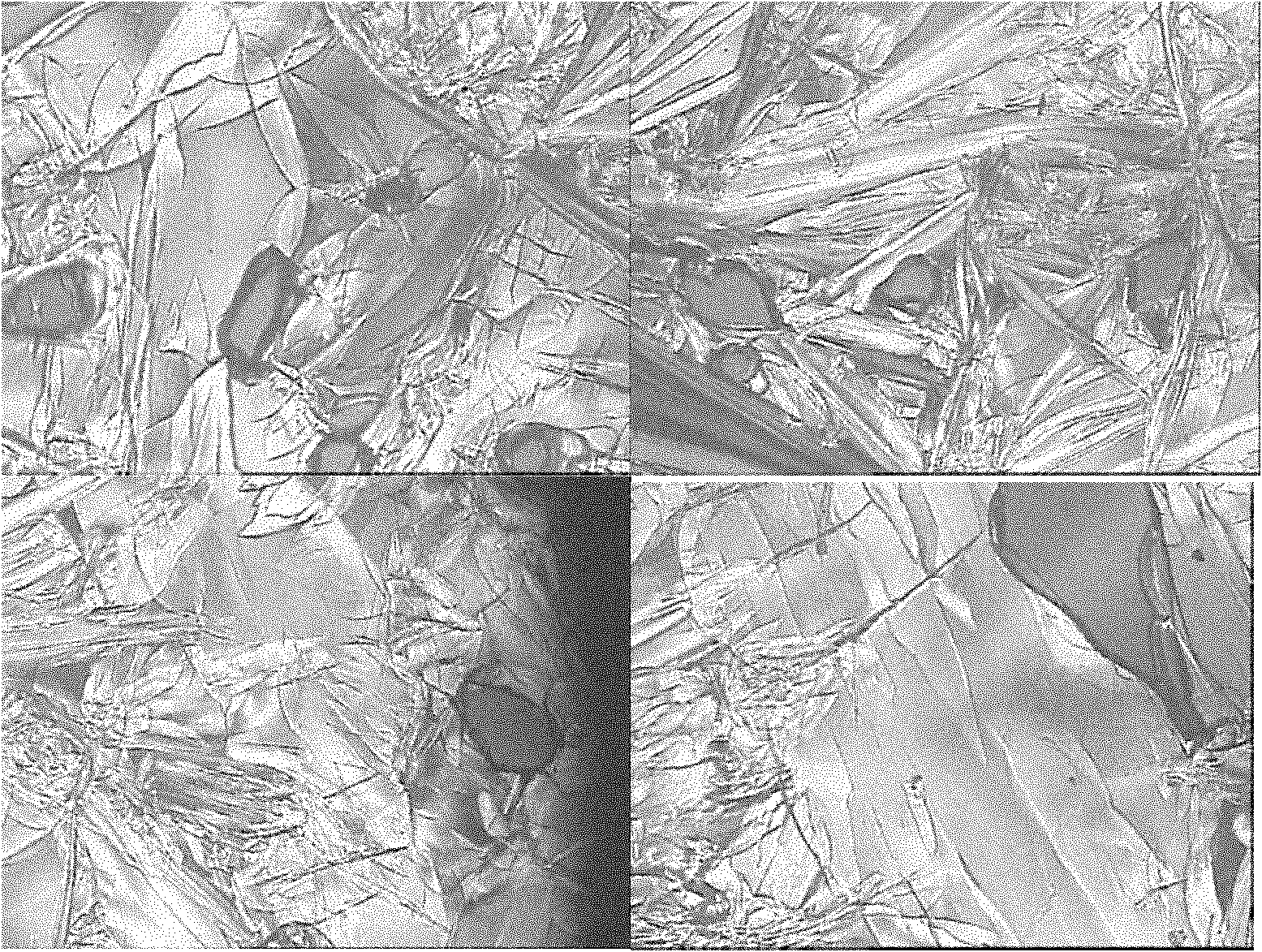

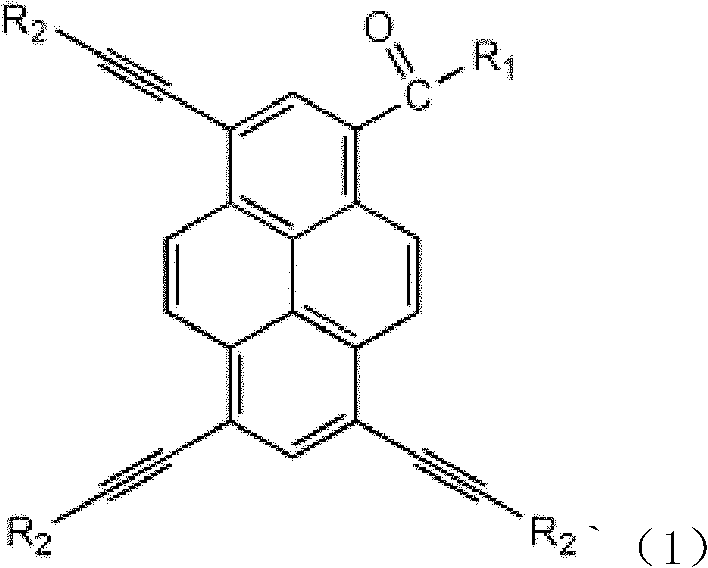

Pyrene asymmetrical double-shaft discotic liquid crystal compound and preparation method thereof

InactiveCN102061179AStrong fluorescenceFast refresh rateLiquid crystal compositionsOrganic compound preparationOrganic synthesisFluorescence

The invention belongs to the technical field of organic synthesis and relates to a pyrene asymmetrical double-shaft discotic liquid crystal compound and a preparation method thereof. The compound has a typical columnar hexagonal-phase discotic liquid crystal structure. The preparation method of the compound comprises the following steps of: carrying out a friedel-crafts acylation reaction on pyrene; carrying out a bromination reaction on an intermediate product; carrying out a Sonogashira coupling reaction; carrying out reaction for removing trimethyl silicon; and carrying out reaction for connecting bromination chains. The pyrene asymmetrical double-shaft discotic liquid crystal compound has biaxial orientation, i.e. a disk is used as a shaft, and an asymmetrical rod molecular chain is used as a shaft. Compared with the prior art, the invention has the advantages that the discotic liquid crystal compound with an asymmetrical structure is easier to form biaxial nematic discotic liquid crystal which has quicker refresh rate and low energy consumption, and has strong fluorescence and wide application prospect.

Owner:UNIV OF SCI & TECH BEIJING

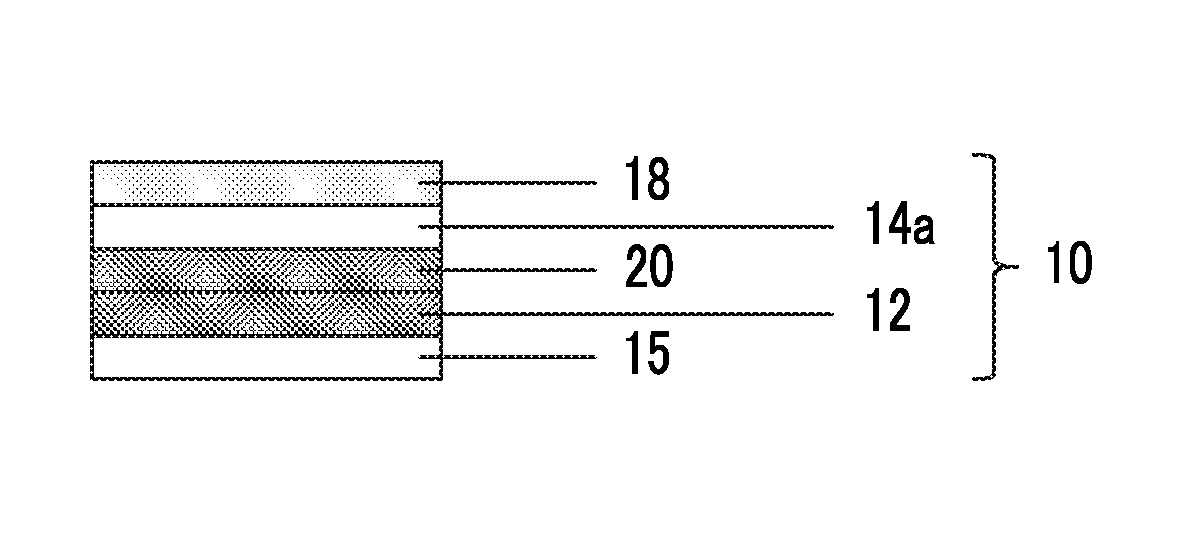

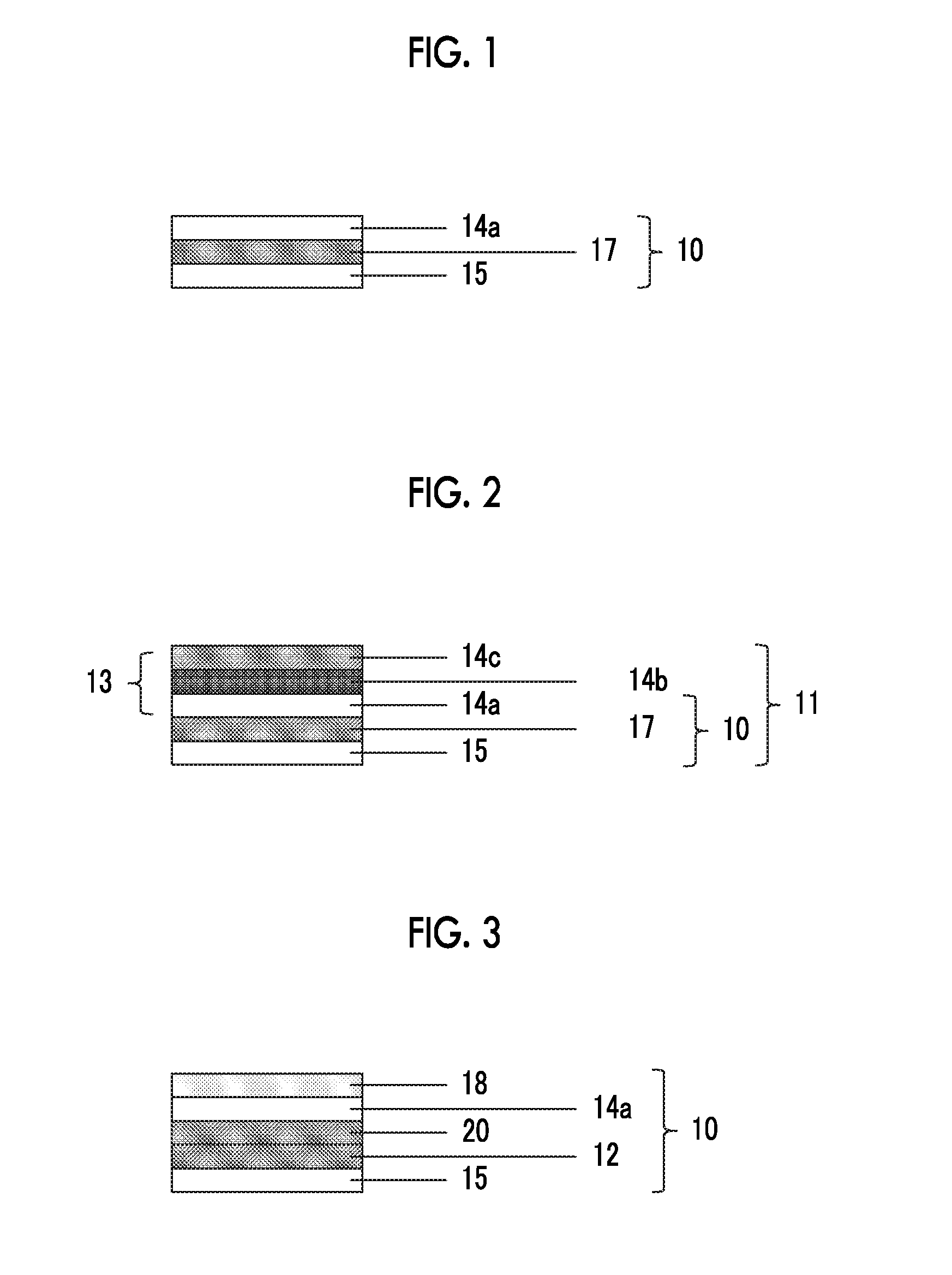

Laminated retardation optical element, process of producing the same, and liquid crystal display

The present invention provides a laminated retardation optical element that never lowers contrast and thus never degrades display performance even when placed between a liquid crystal cell and a λ / 4 retardation film. In a liquid crystal display 90, a laminated retardation optical element 10 is placed between a polarizer 102A on the incident side and a liquid crystal cell 104, and a λ / 4 retardation film 102C is placed between a polarizer 102B on the emergent side and the liquid crystal cell 104. The laminated retardation optical element 10 comprises: a λ / 4 retardation layer 14 having the function of bringing, to light that passes through this retardation layer, a phase difference corresponding to a quarter of the wavelength of the light; and a C plate-type retardation layer 16 that acts as a negative C plate. The λ / 4 retardation layer 14 and the C plate-type retardation layer 16 are laminated to a transparent substrate 12 in the order mentioned, and are optically bonded to each other. The λ / 4 retardation layer 14 comprises as its main component a horizontally-aligned, cross-linked nematic liquid crystal, while the C plate-type retardation layer 16 comprises as its main component a cross-linked chiral nematic liquid crystal (a cross-linked nematic liquid crystal and a cross-linked chiral agent) or cross-linked discotic liquid crystal.

Owner:DAI NIPPON PRINTING CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com