Liquid crystal display

A liquid crystal display device, liquid crystal technology, applied in optics, instruments, nonlinear optics, etc., can solve the problems of uneven display surface, increased current consumption, residual liquid or smudges on the alignment film, etc., to expand the viewing angle, improve the The effect of speed of response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

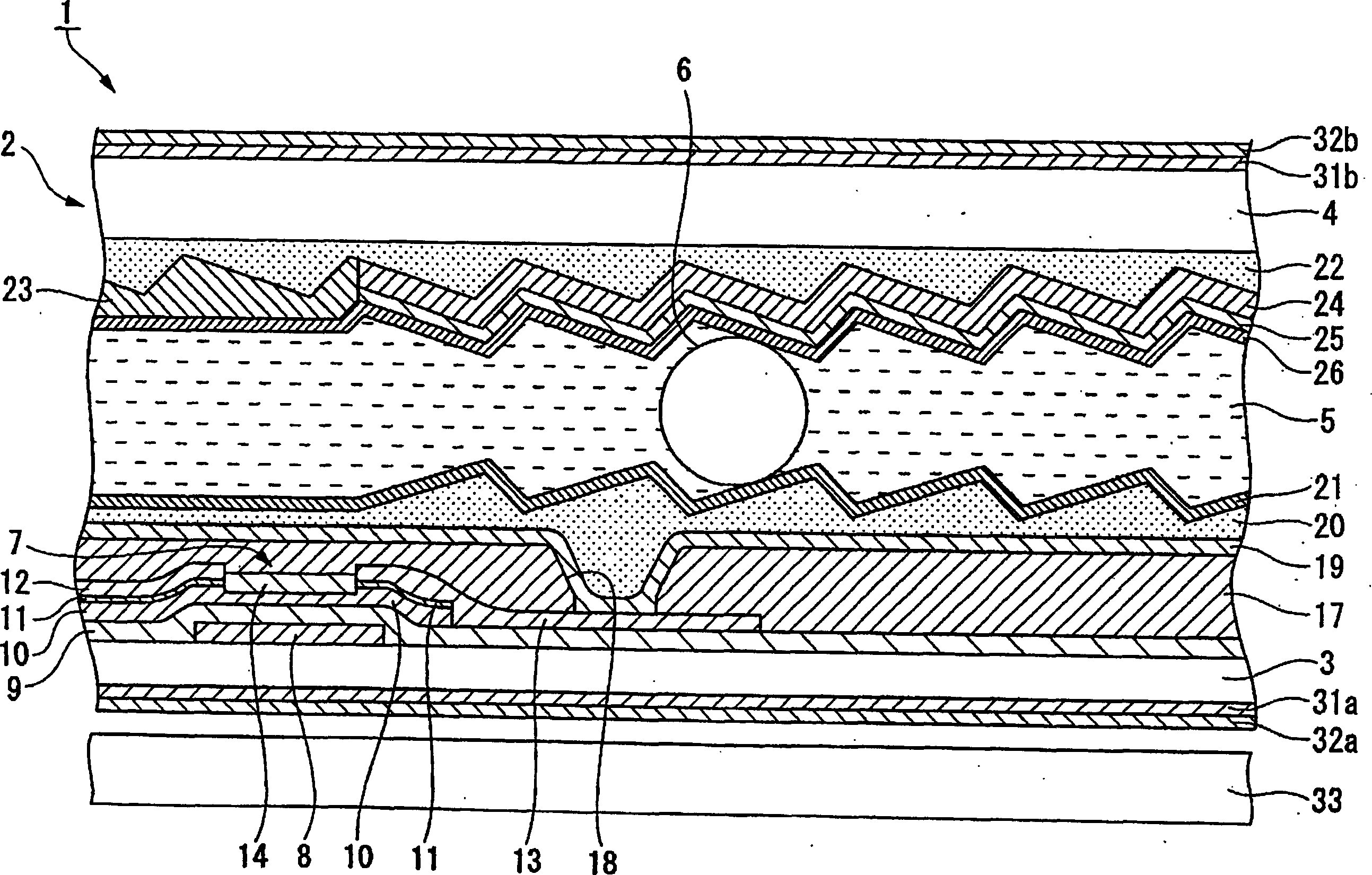

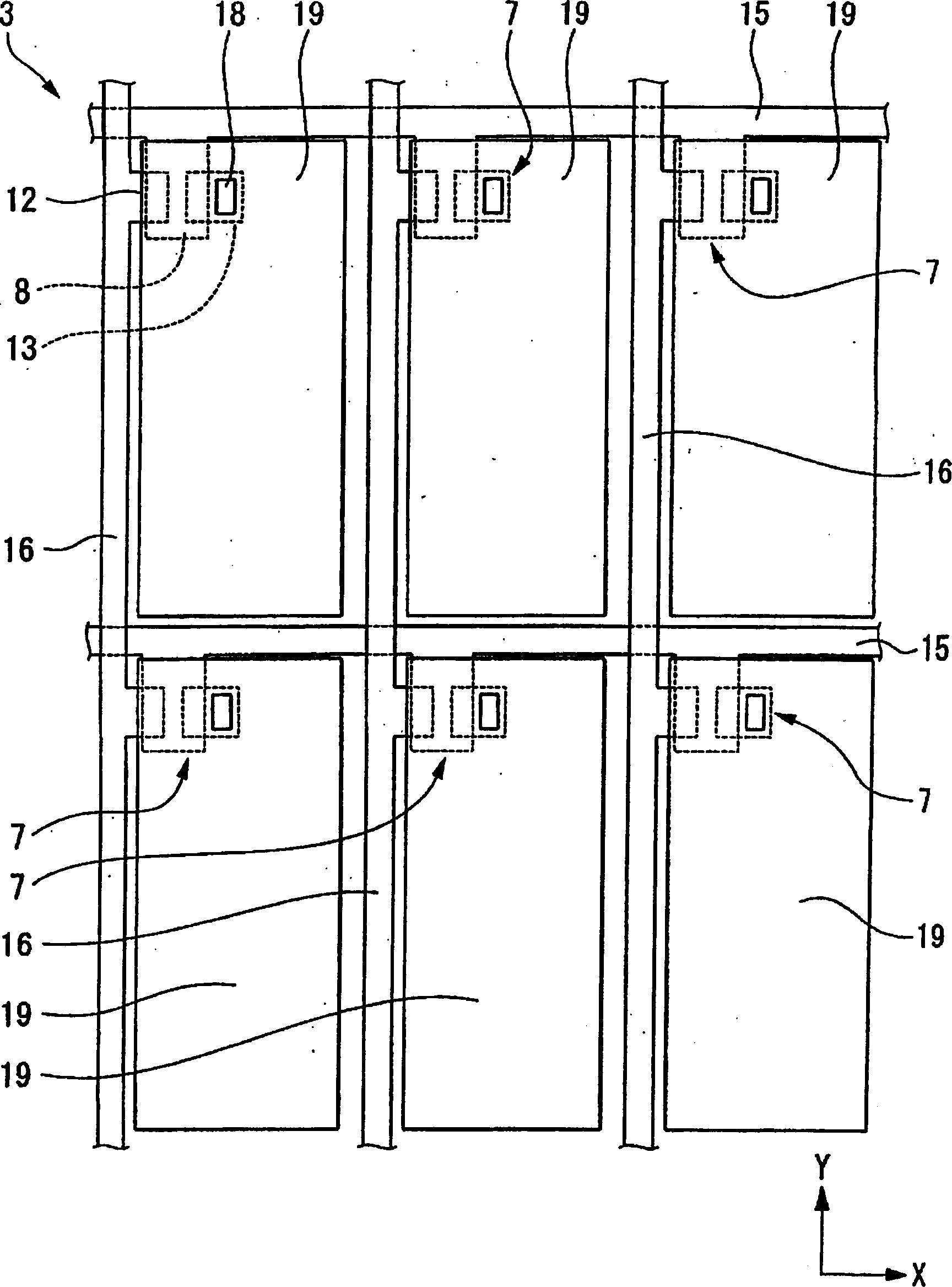

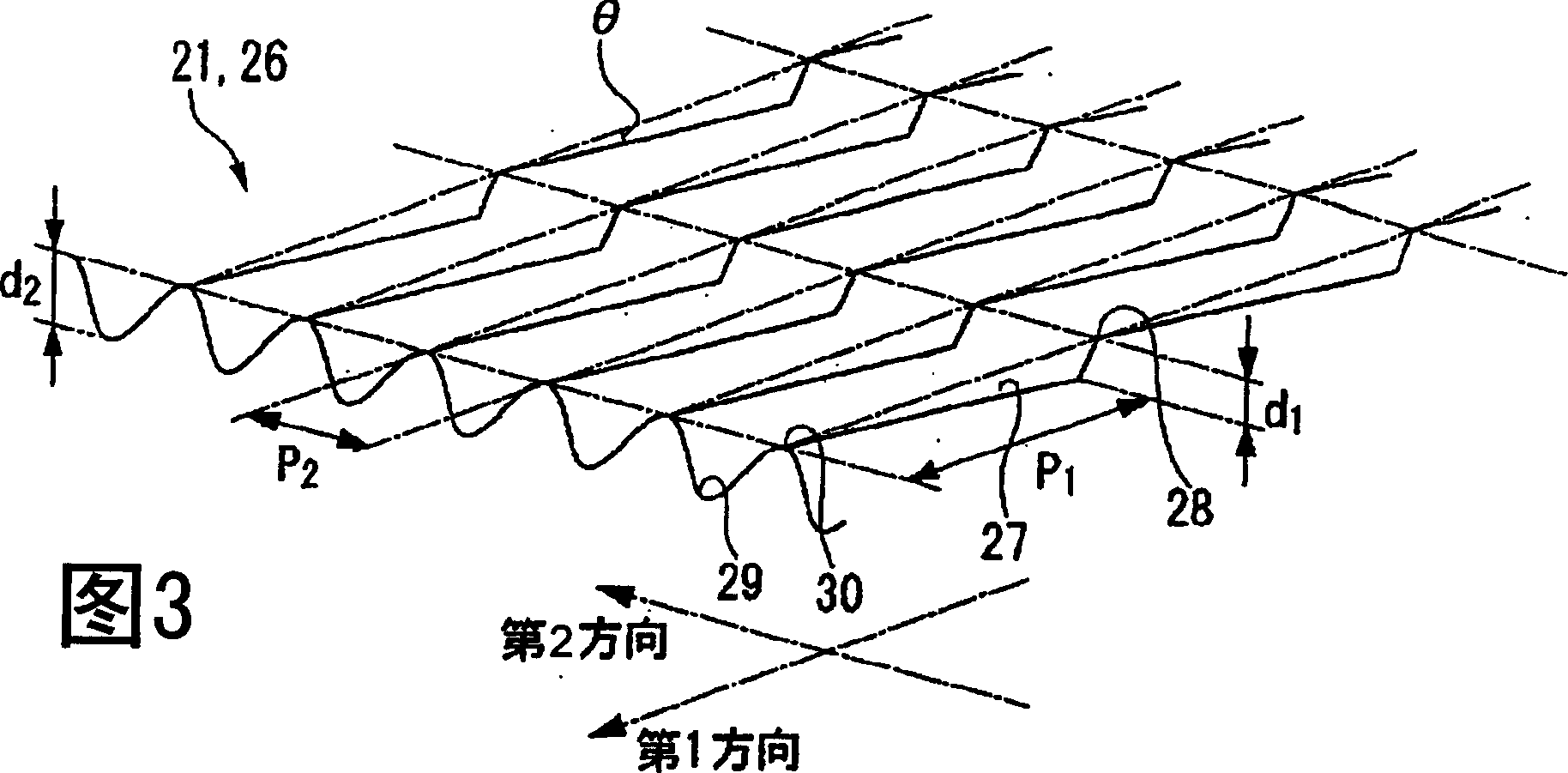

Embodiment 1

[0051] Example 1 A liquid crystal panel with a diagonal size of about 55 mm (2.2 inches) and a pixel size of 176×128 (XRGB) was fabricated. Specifically, when making the liquid crystal panel, first prepare TFTs, active matrix substrates with scanning lines and signal lines on one main surface side, and form a transparent substrate made of ITO on the active matrix substrates with an insulating film sandwiched between them. the pixel electrode. Next, a photosensitive acrylic resin film is formed on the active matrix substrate, and a replication mold with fine concave-convex shapes to be replicated is formed on the surface and pressed against the film-forming resin layer, and the fine concave-convex shapes are replicated on the active matrix substrate. on the resin layer. In addition, the concavo-convex shape is the same as the shape of the above-mentioned liquid crystal panel 2 shown in FIG. d1 is 0.1 μm. On the other hand, the pitch P2 of the concave-convex shapes repeated i...

Embodiment 2

[0056] Example 2 A liquid crystal panel was produced in the same manner as in Example 1, except that the concentration of γ-methacryloxypropyltrimethoxysilane used for the surface treatment of spacers was 0.1 wt % and 0.3 wt %.

Embodiment 3

[0058] Example 3 A liquid crystal panel was fabricated in the same manner as in Example 1, except that an aqueous solution of γ-glycidoxypropyltrimethoxysilane with a concentration of 0.03 wt% was used for the surface treatment of the spacer material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com