Optical grating, display device and manufacturing method of optical grating

一种制造方法、光栅的技术,应用在显示装置及光栅的制造,光栅领域,能够解决液晶选择有限、可视角度小、液晶成本高等问题,达到成本低、提高可视角度、温度适应性好的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

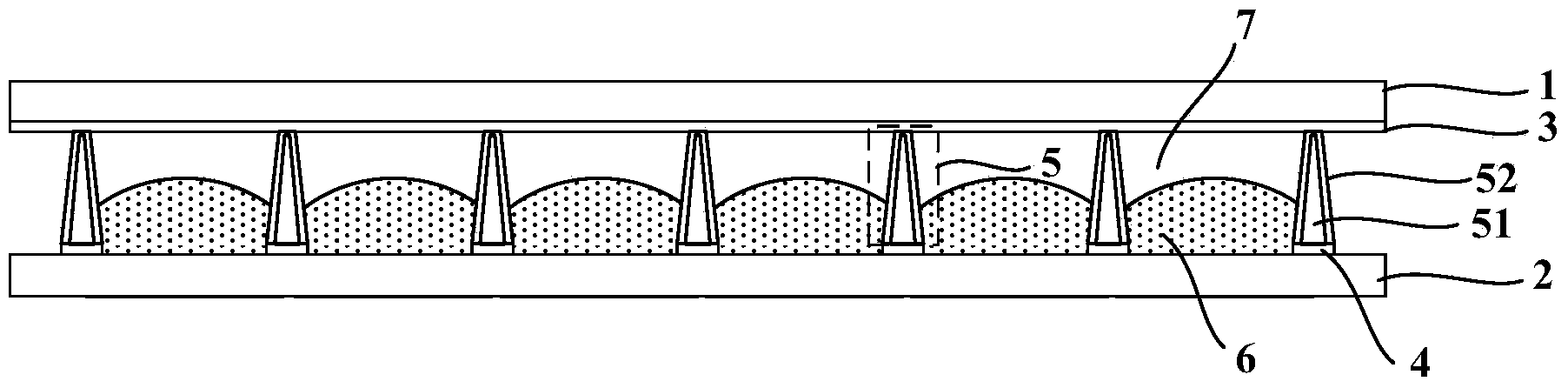

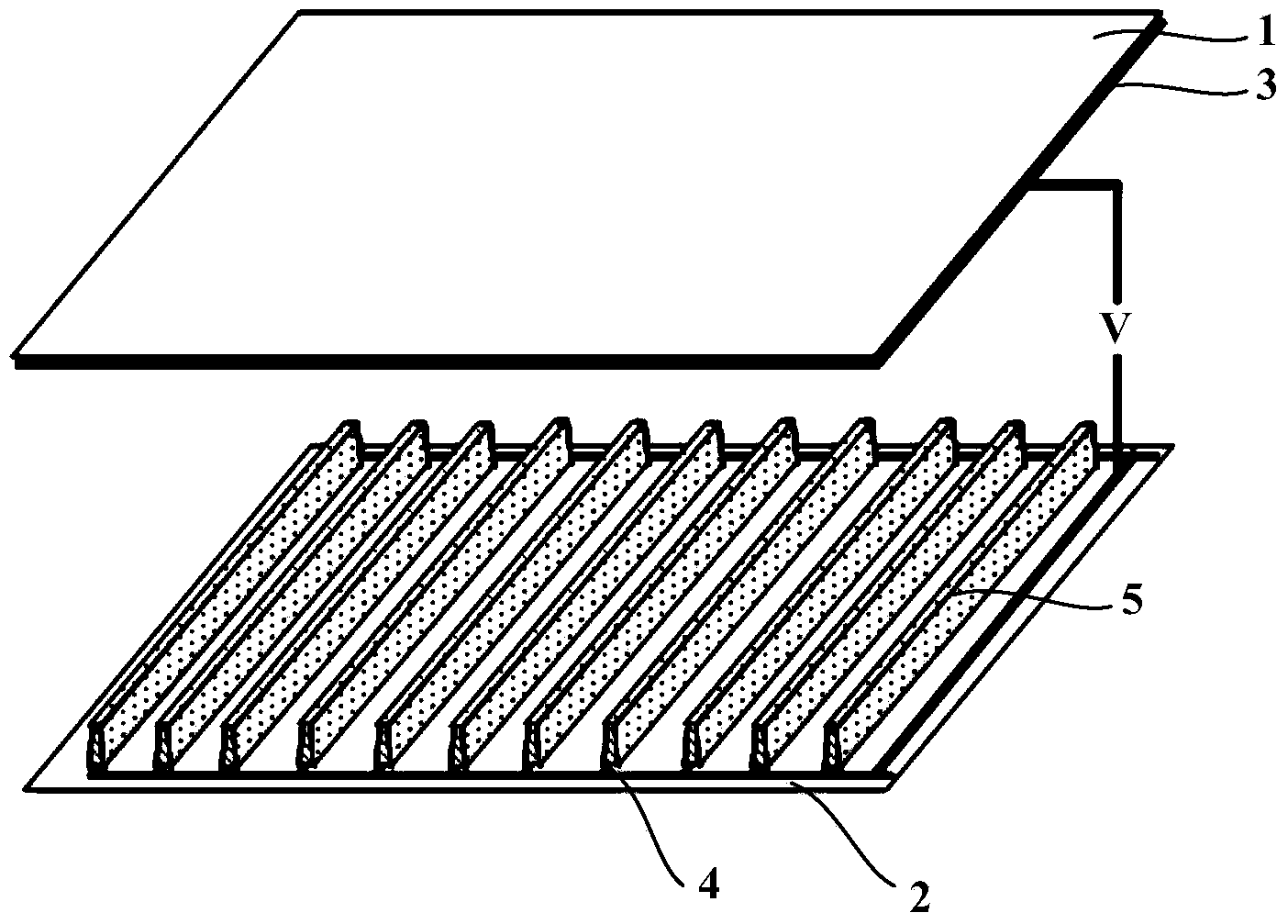

[0051]In order to improve the viewing angle of the grating and reduce the cost of the grating, the invention provides a grating, a display device and a manufacturing method of the grating. In this technical solution, since there are multiple options for polar liquids and non-polar liquids, the refractive index difference between the two liquids is relatively large, and the curved surface formed by the hydrophilic-hydrophobic conversion material layer has a large radian. Therefore, the range of refractive index distribution Larger for better viewing angles and lower cost for liquid compared to liquid crystal. In order to make the purpose, technical solution and advantages of the present invention clearer, the following specific examples are given to further describe the present invention in detail.

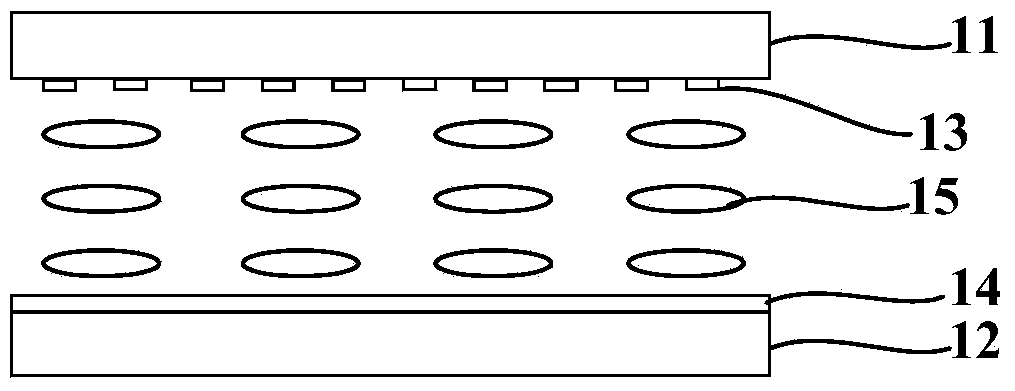

[0052] like figure 2 As shown, the structure diagram of the first embodiment of the grating of the present invention, the grating includes a first substrate 1 and a second substr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com