Patents

Literature

71results about How to "Set free" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

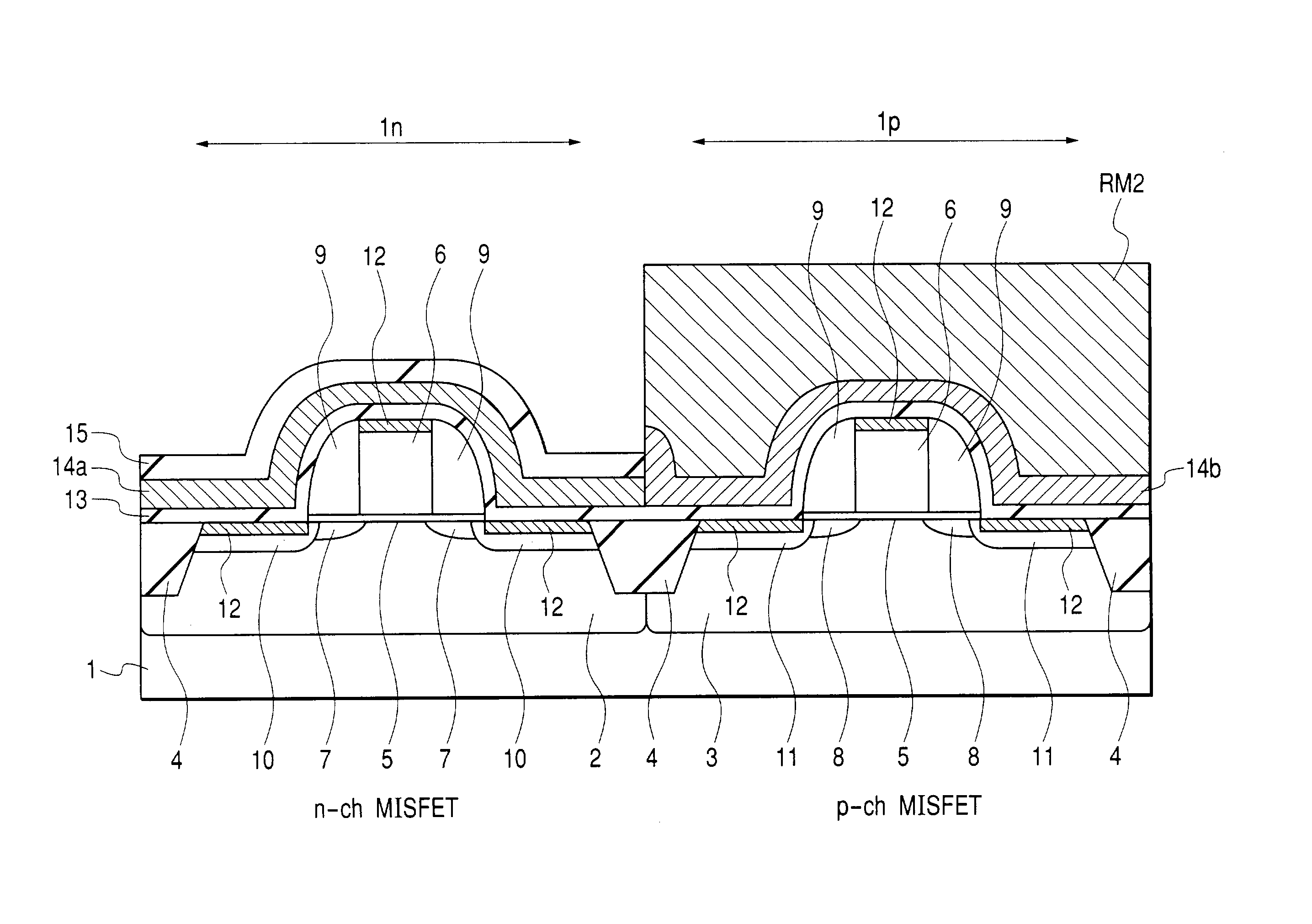

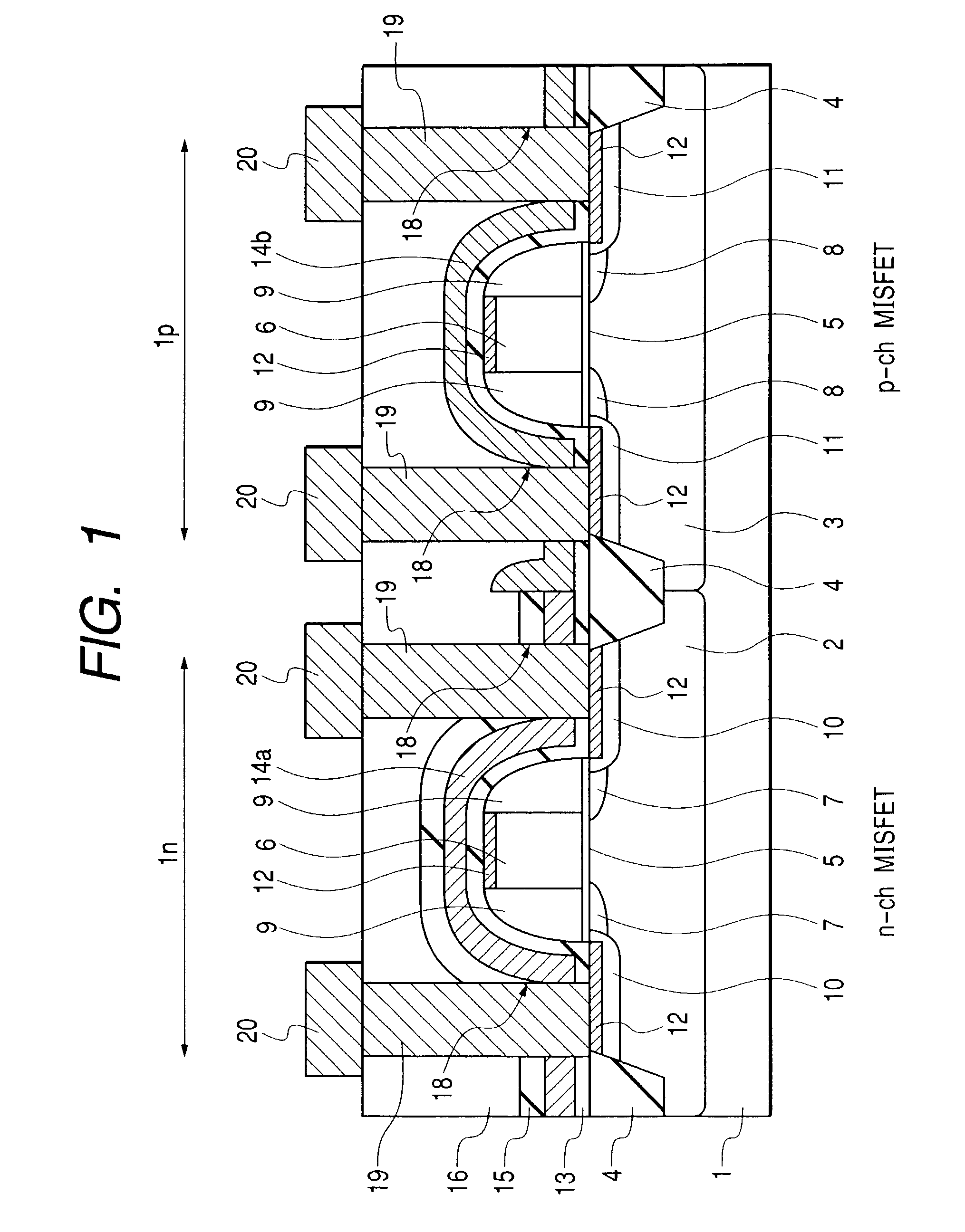

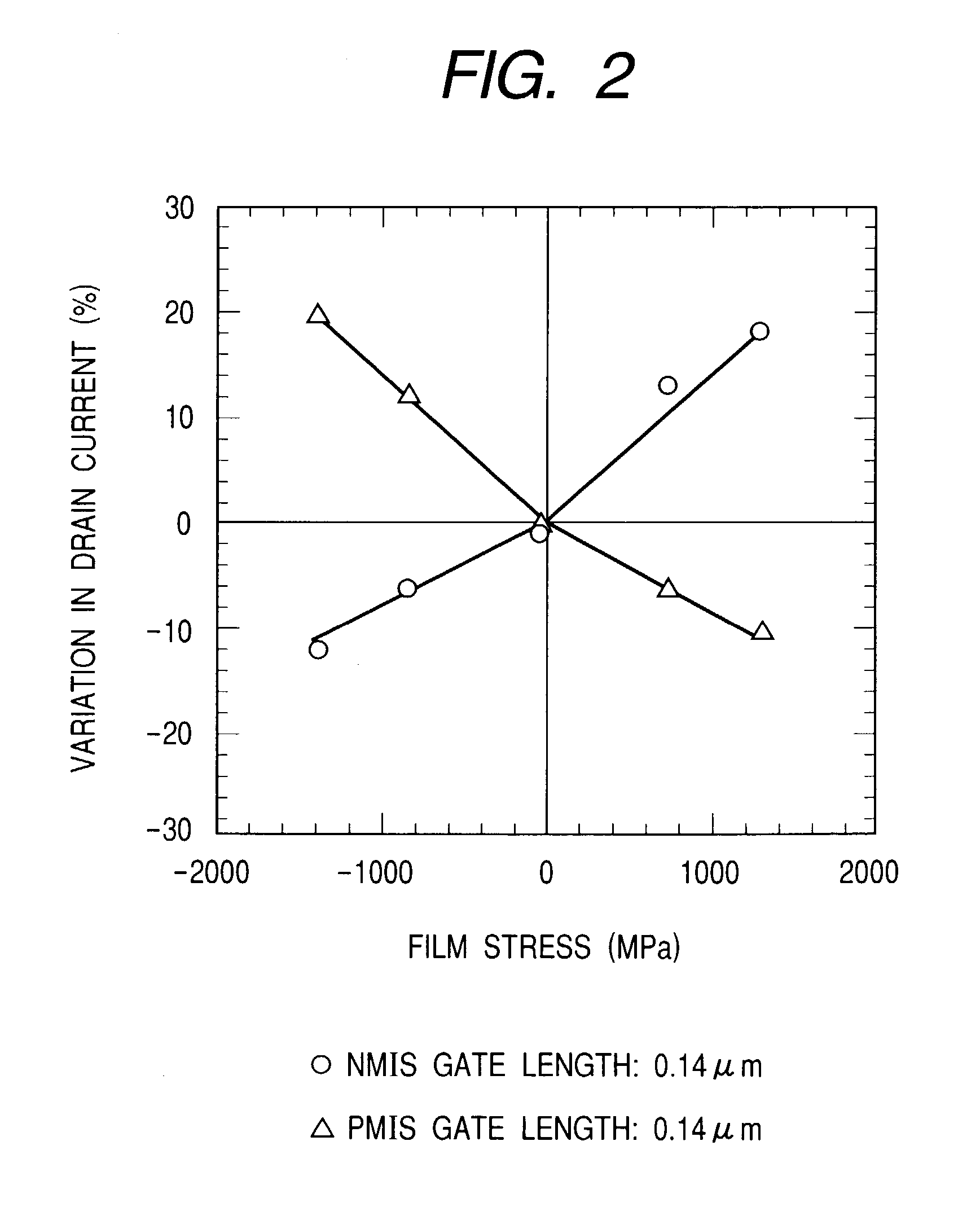

Semiconductor device and a method of manufacturing the same

InactiveUS7105394B2Relieve pressureIncrease currentTransistorSemiconductor/solid-state device manufacturingSemiconductorEtching selectivity

A method of manufacturing a semiconductor device having an n-type FET and p-type FET, each formed over a semiconductor substrate, calls for (a) forming, over the n-type FET and p-type FET, a first insulating film, for generating a tensile stress in the channel formation region of the n-type FET, to cover gate electrodes of the FETs, while covering, with an insulating film, a semiconductor region between the gate electrode of the p-type FET and an element isolation region of the semiconductor substrate; (b) selectively removing the first insulating film from the upper surface of the p-type FET by etching; (c) forming, over the n-type and p-type FETs, a second insulating film, for generating a compressive stress in the channel formation region of the p-type FET, to cover gate electrodes of the FETs; and (d) selectively removing the second insulating film from the upper surface of the n-type FET.

Owner:RENESAS ELECTRONICS CORP

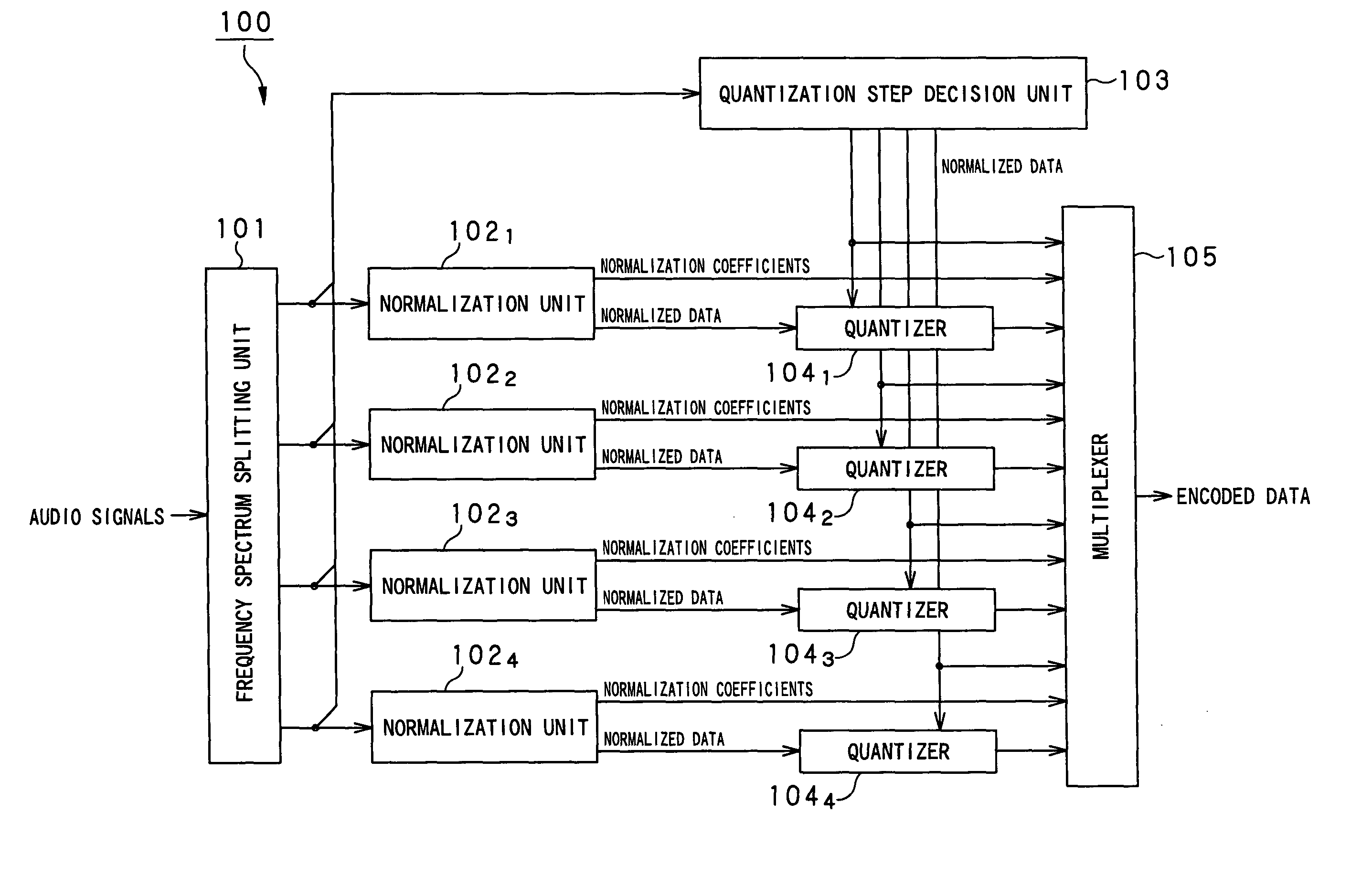

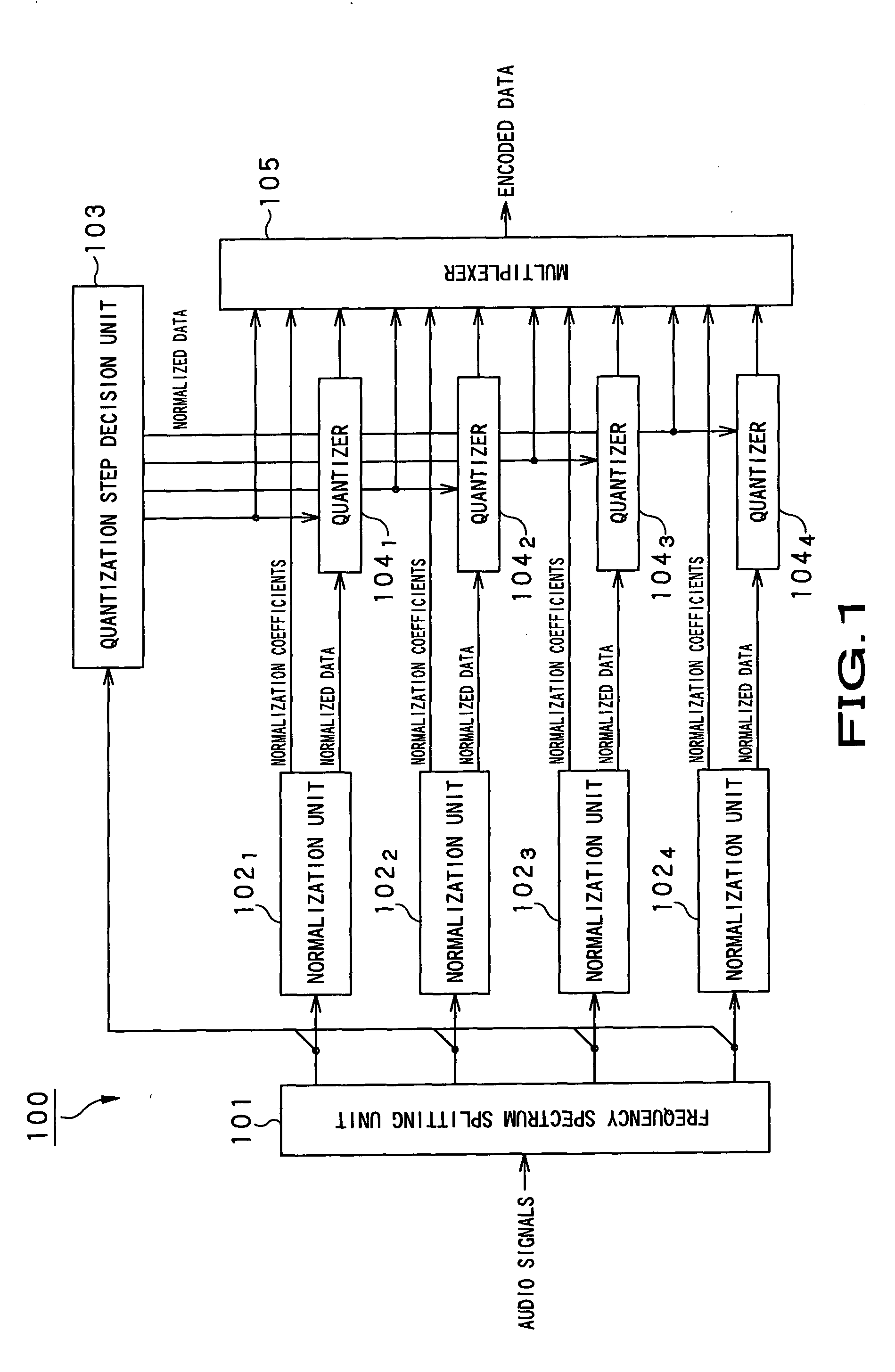

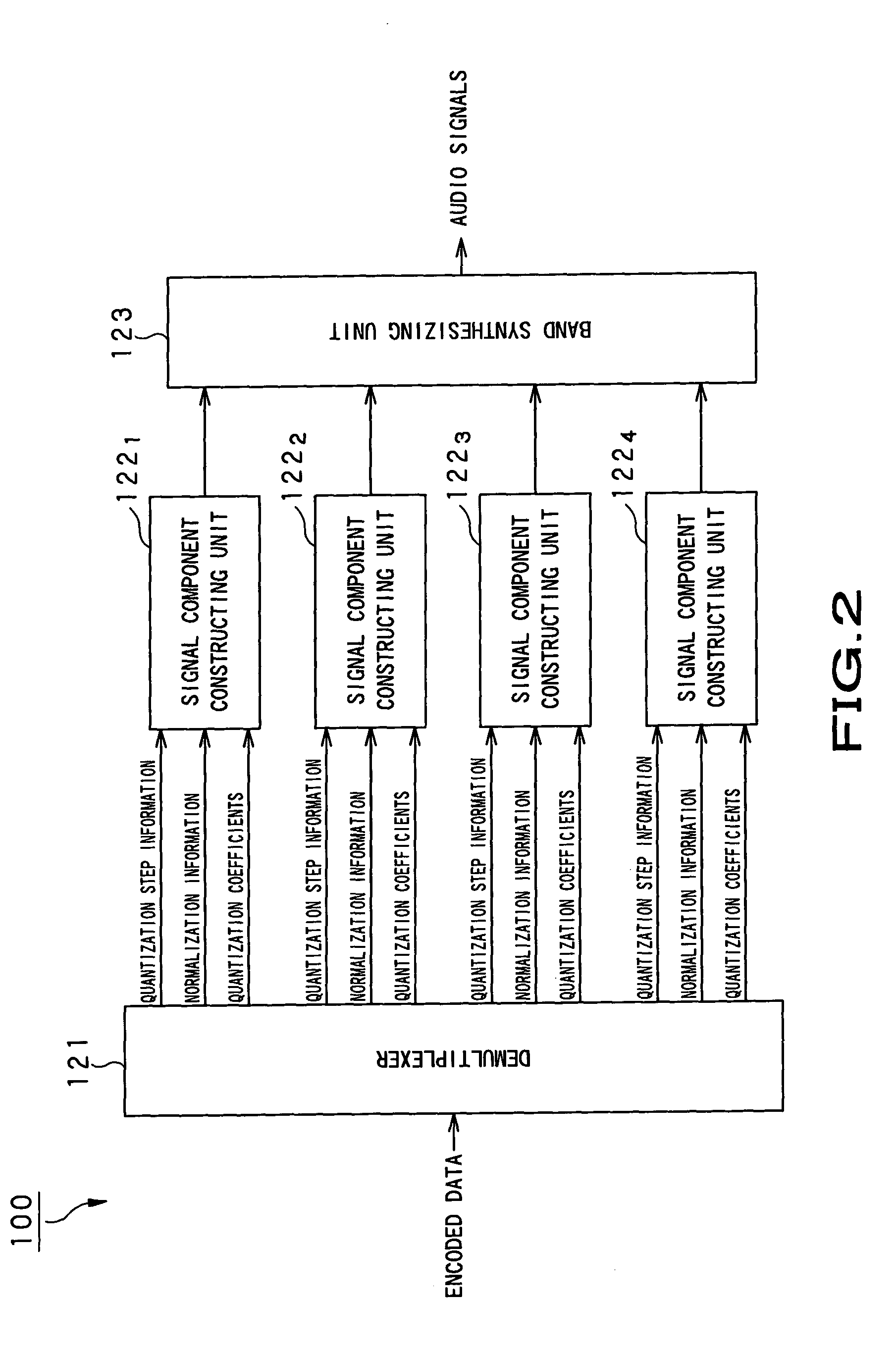

Encoding Method, Encoding Apparatus, Decoding Method, Decoding Apparatus and Program

ActiveUS20050261893A1Improve efficiencySet freeSpeech analysisCode conversionVariable lengthShape vector

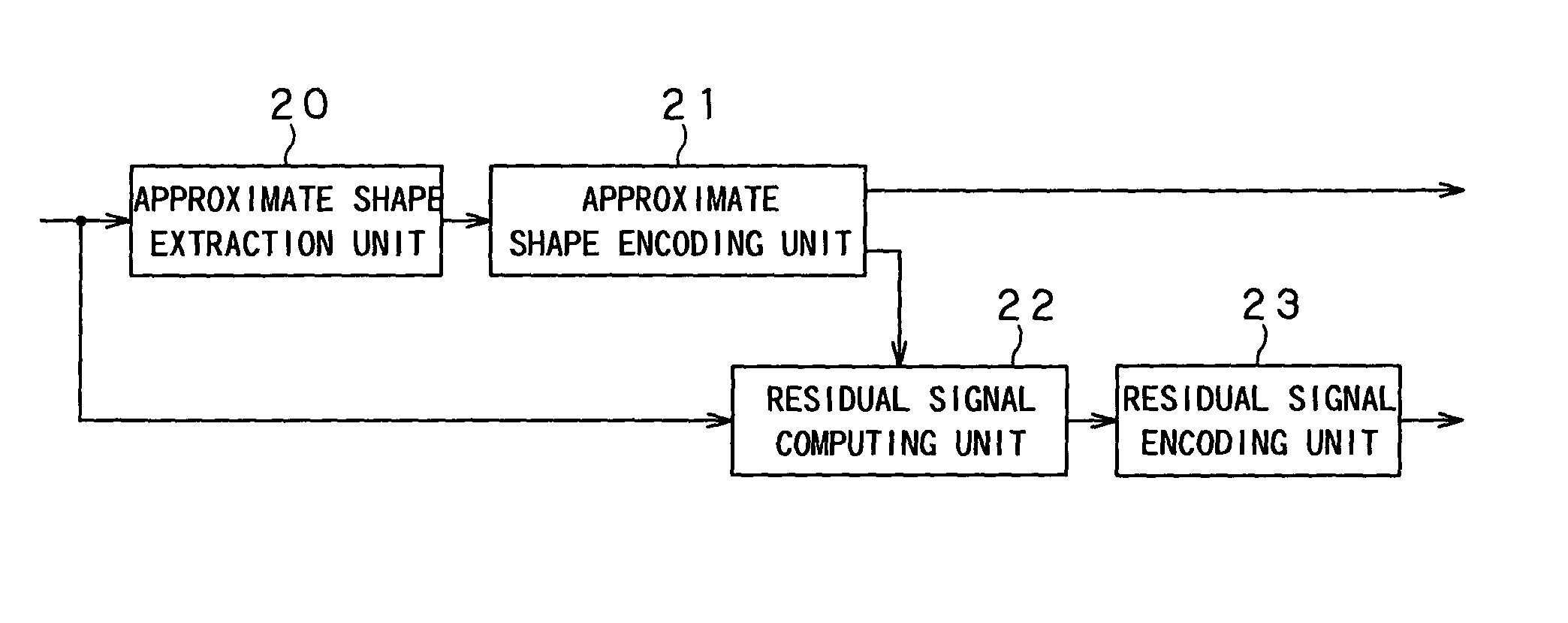

In a quantization step information encoding unit, an average value of the quantization step information is found in an approximate shape extraction unit (20), first of all, from one set of a given number of unitary quantization units to another. In an approximate shape encoding unit (21), the approximate shape information is vector-quantized. In a residual signal computing unit (22), the residual signals between the quantization step information and the quantized approximate shape vector are computed. In a residual signal encoding unit (23), the residual signals are variable length encoded, and the so encoded residual signals and the vector quantized approximate shape information are output.

Owner:SONY CORP

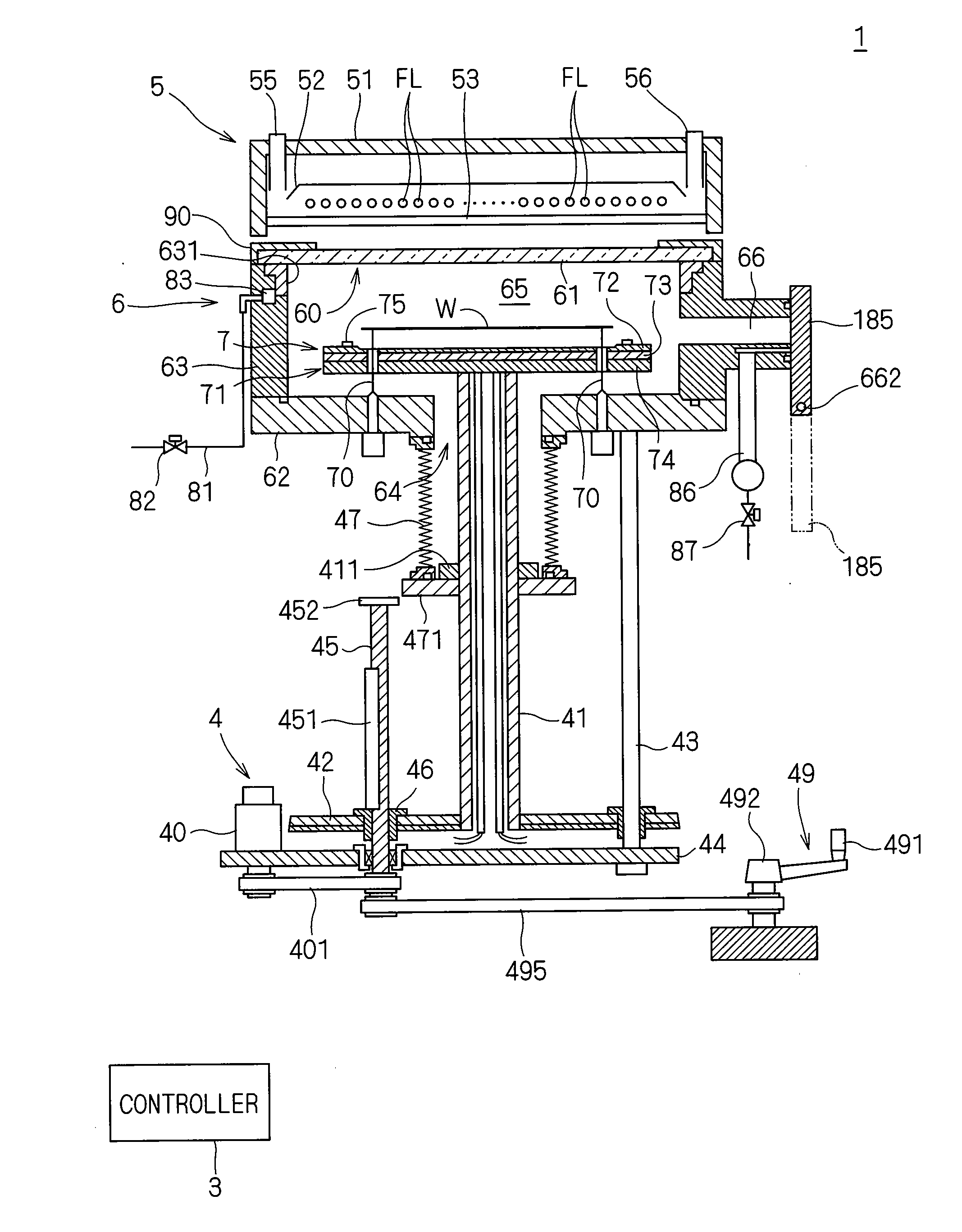

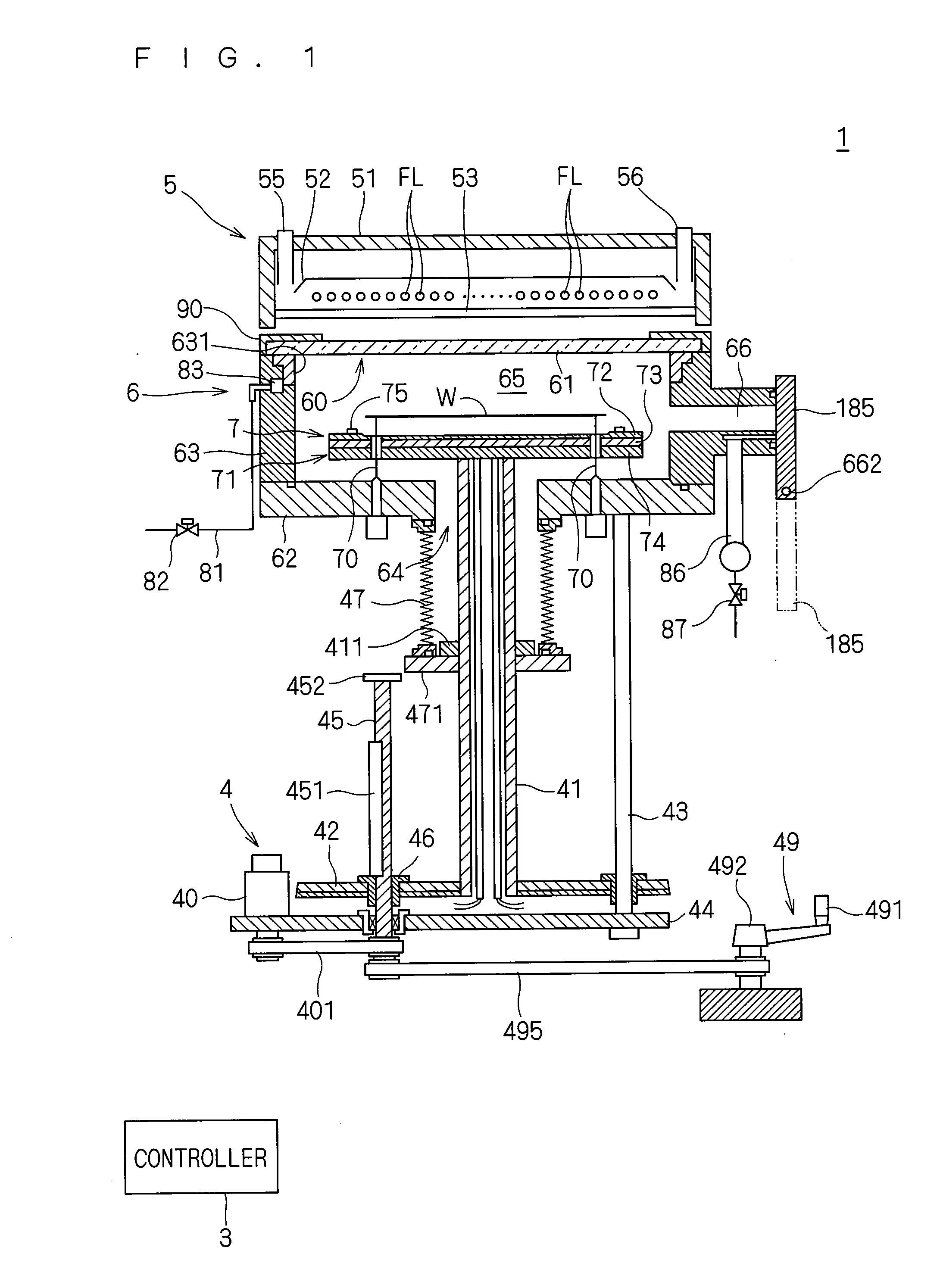

Heat treatment apparatus heating substrate by irradiation with light

ActiveUS20090067823A1Set freeDomestic stoves or rangesDrying solid materials with heatPower flowIrradiation

A capacitor, a coil, a flash lamp, and a switching element such as an IGBT are connected in series. A controller outputs a pulse signal to the gate of the switching element. A waveform setter sets the waveform of the pulse signal, based on the contents of input from an input unit. With electrical charge accumulated in the capacitor, a pulse signal is output to the gate of the switching element so that the flash lamp emits light intermittently. A change in the waveform of the pulse signal applied to the switching element will change the waveform of current flowing through the flash lamp and, accordingly, the form of light emission, thereby resulting in a change in the temperature profile for a semiconductor wafer.

Owner:DAINIPPON SCREEN MTG CO LTD

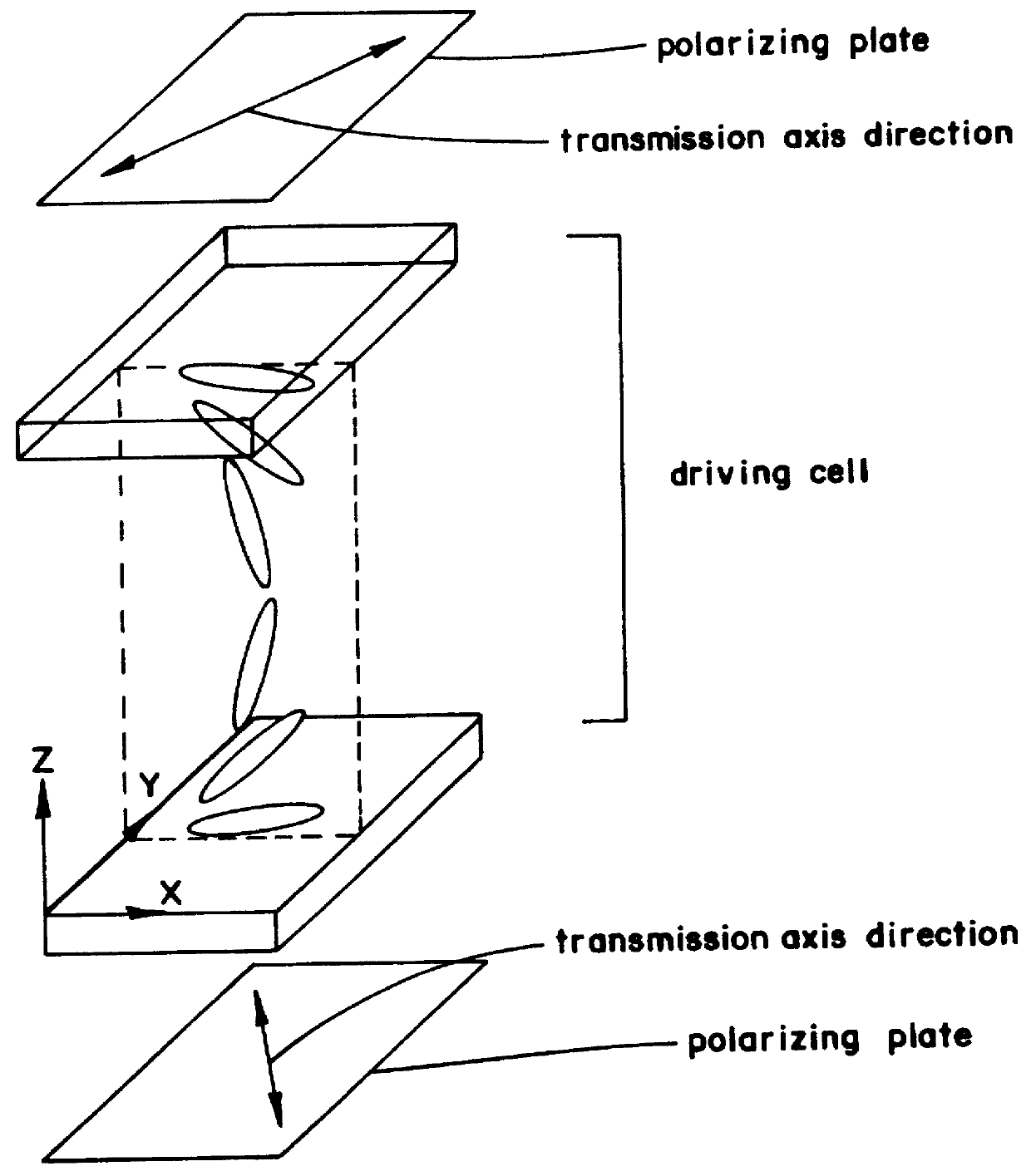

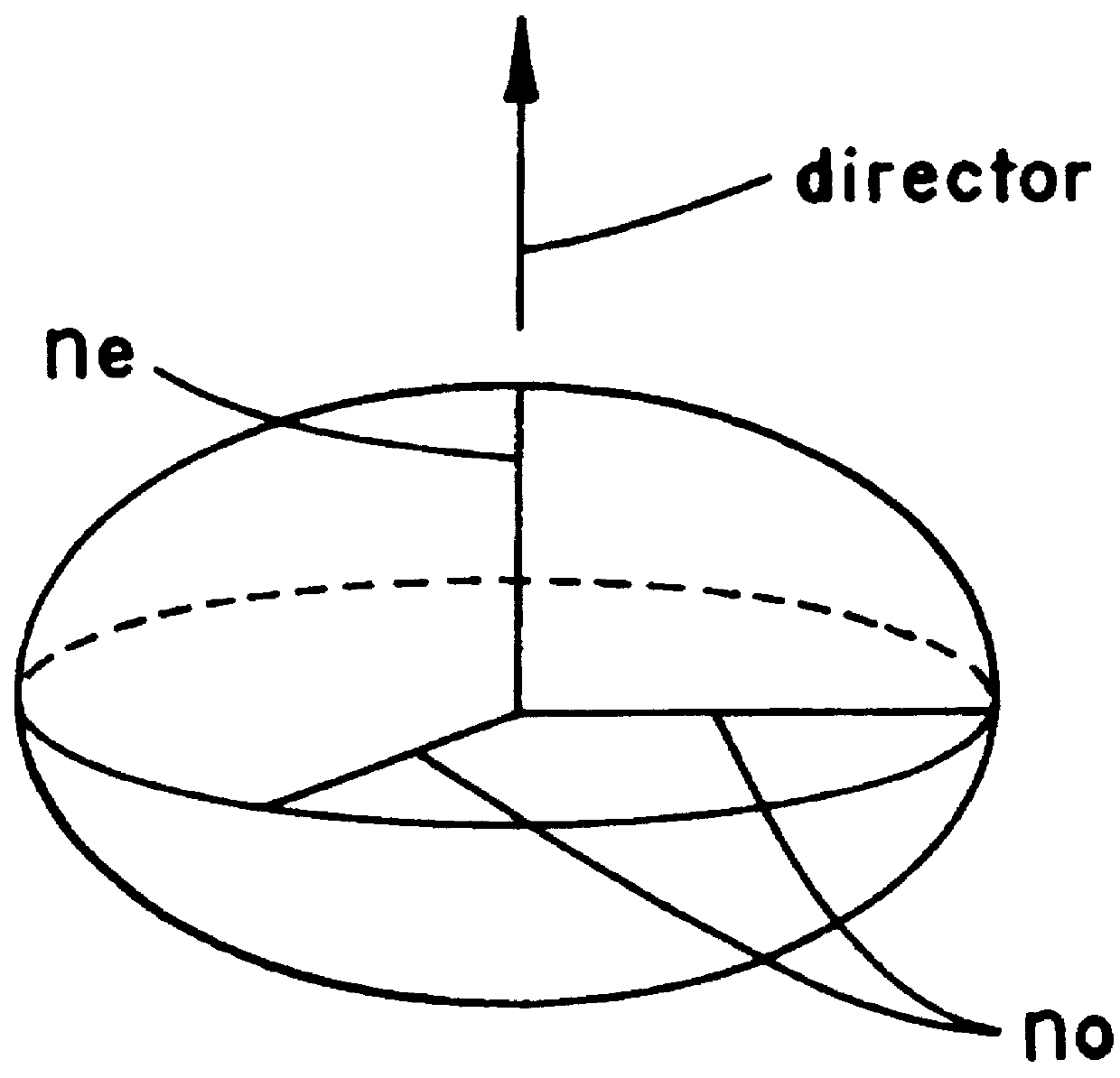

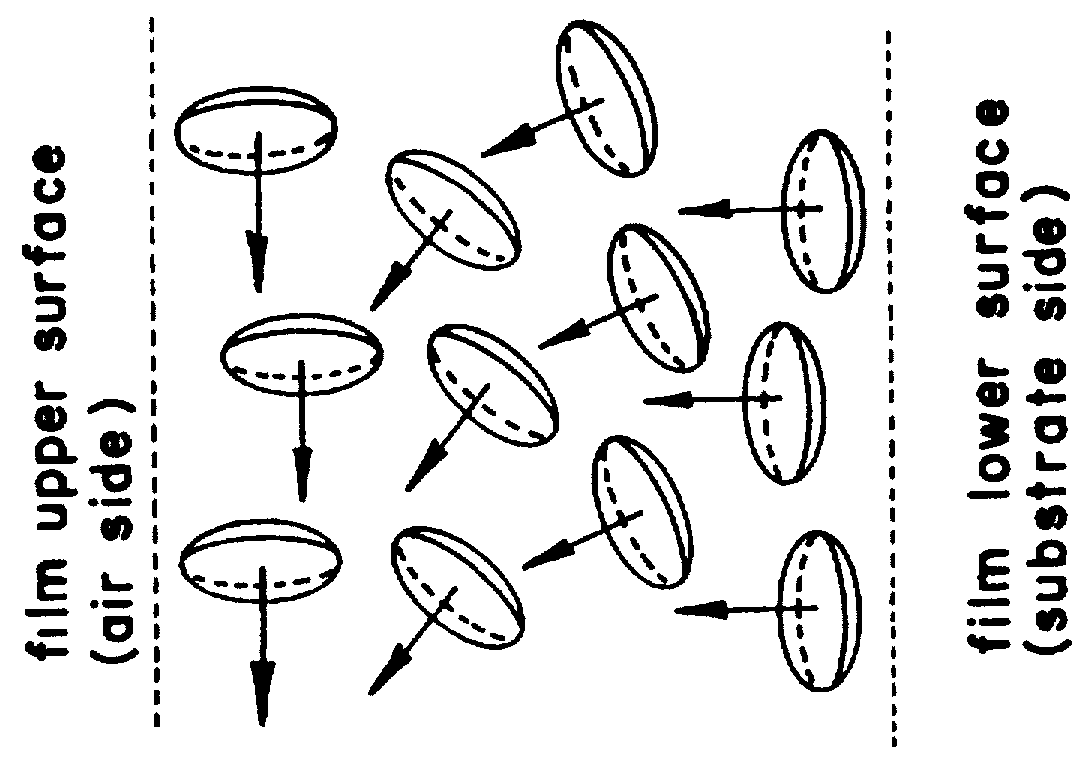

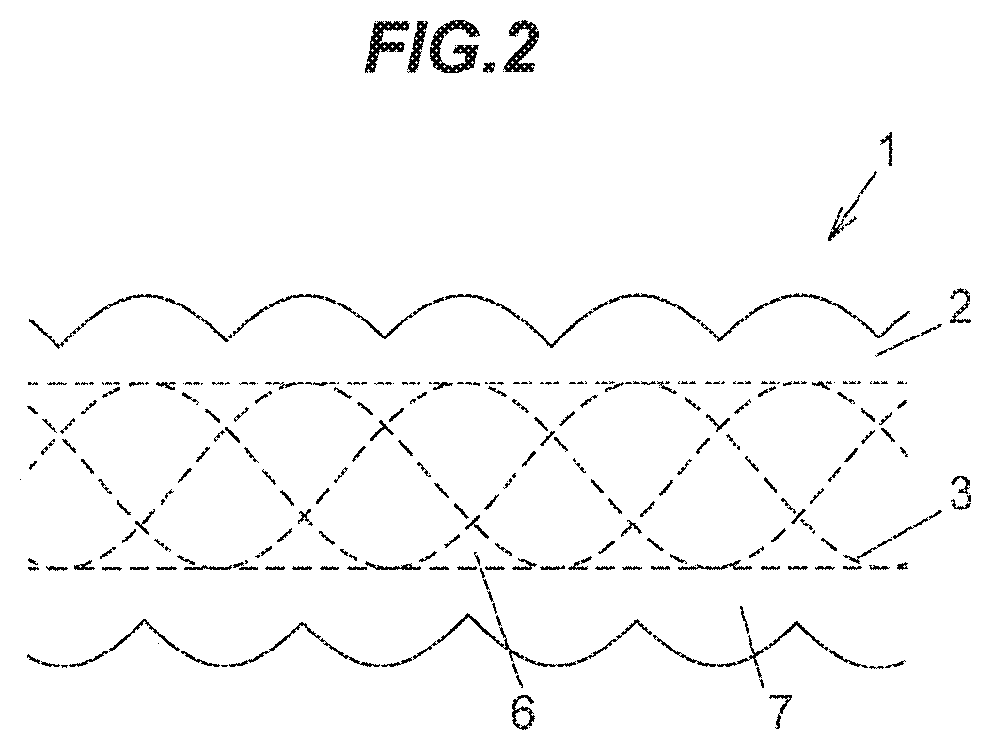

Compensating film for a liquid crystal display and an OCB mode liquid crystal display incorporating the compensating film

InactiveUS6124913AGood compensationSet freeLiquid crystal compositionsDiffusing elementsColor compensationFilm plane

As a compensator for use in an OCB mode liquid crystal display there is provided a compensating film capable of making color compensation and attaining such a viewing angle expansion as has not been attainable heretofore. A compensating film for a liquid crystal display, constituted by at least one layer of a compensating film to be used in an OCB mode liquid crystal display, the compensating film being formed by a discotic liquid crystalline material having a fixed orientation form of a discotic liquid crystal, the compensating film being disposed between a driving liquid crystal cell and a pair of upper and lower polarizing plates, and the orientation form being a hybrid orientation in which the angle between discotic liquid crystal directors near the upper interface of the film and the film plane and the angle between discotic liquid crystal directors near the lower interface of the film and film plane are different from each other.

Owner:NIPPON MITSUBISHI OIL CORP

Encoding method, encoding apparatus, decoding method, decoding apparatus and program

ActiveUS7212973B2Improve efficiencySet freePicture reproducers using cathode ray tubesCode conversionVariable lengthShape vector

In a quantization step information encoding unit, an average value of the quantization step information is found in an approximate shape extraction unit (20), first of all, from one set of a given number of unitary quantization units to another. In an approximate shape encoding unit (21), the approximate shape information is vector-quantized. In a residual signal computing unit (22), the residual signals between the quantization step information and the quantized approximate shape vector are computed. In a residual signal encoding unit (23), the residual signals are variable length encoded, and the so encoded residual signals and the vector quantized approximate shape information are output.

Owner:SONY CORP

Mobile terminal and icon processing method for function key of mobile terminal

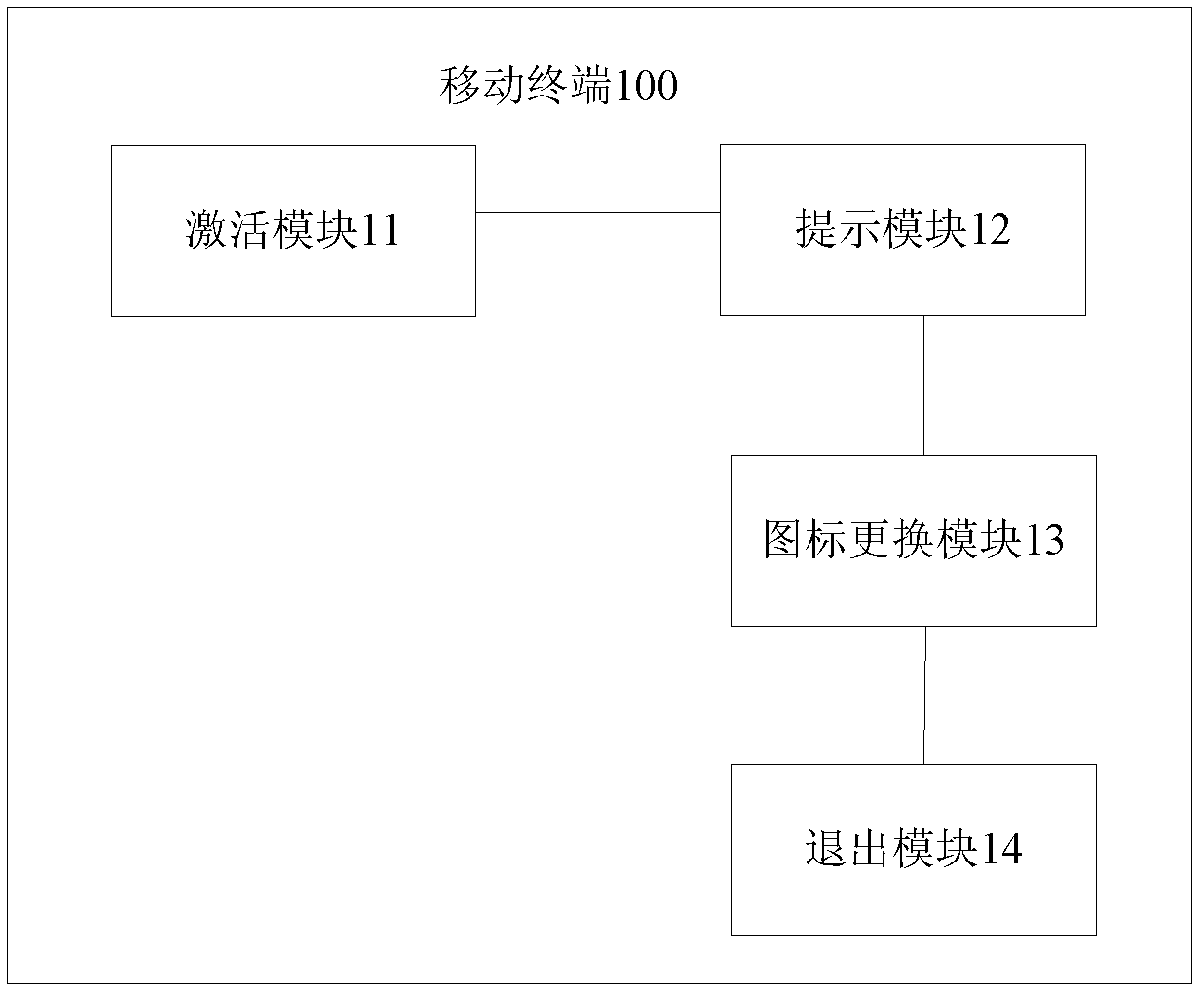

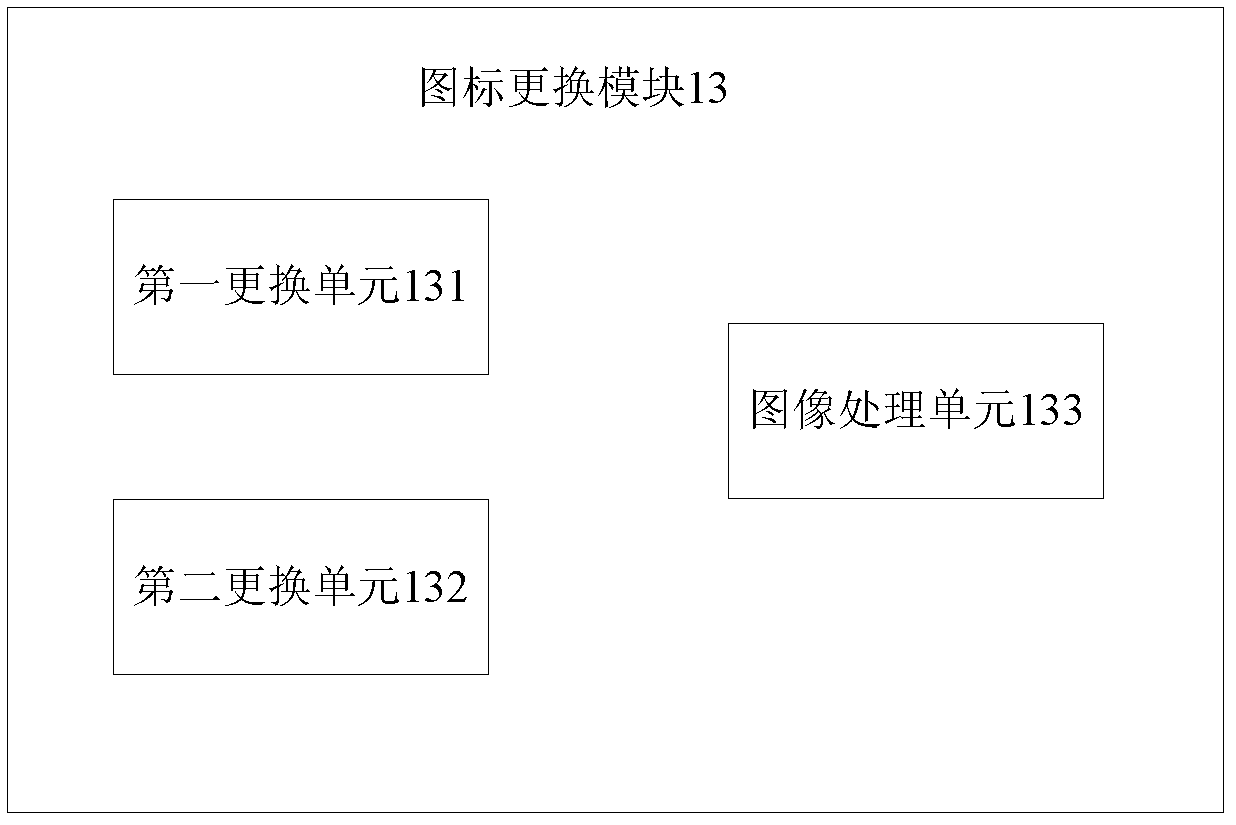

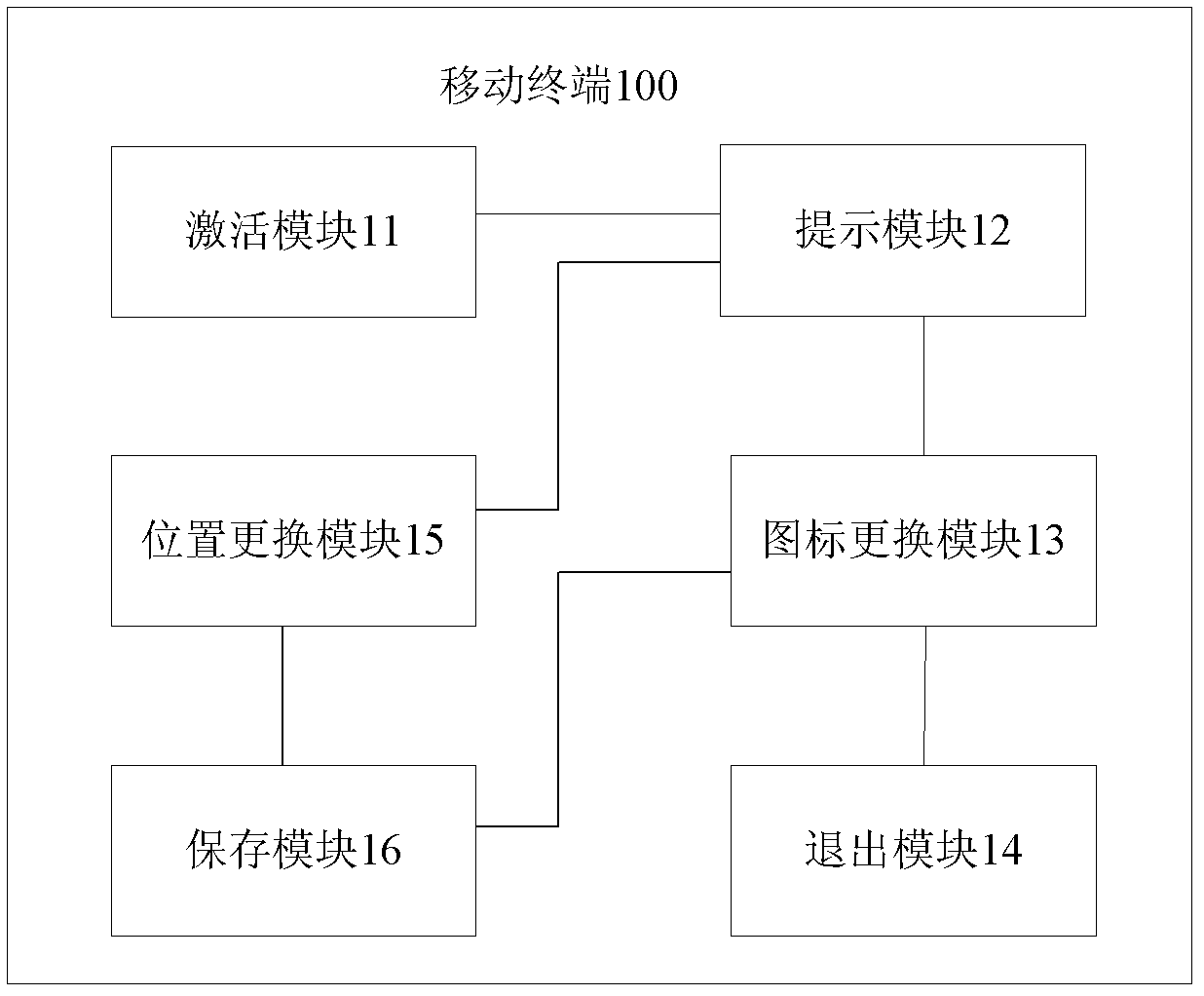

ActiveCN103019662AMeet individual needsSimple structureSpecific program execution arrangementsInput/output processes for data processingBiological activationComputer engineering

The invention provides a mobile terminal which comprises an activation module, a prompt module, an icon replacing module and an exit module, wherein the prompt module is used for sending icon replacing prompt after controls on the mobile terminal are activated by the activation module, the icon replacing prompt is used for prompting a user whether icons of the controls are replaced or not, and the controls include an icon replacing control and an icon exit control; the icon replacing module is used for activating the icon replacing control, selecting a picture as the icon of the control and establishing the relation between the icon and the corresponding function of the control when the user selects to replace the icon of the control; and the exit module is used for activating the icon exit control so as to exit the icon replacing operation when the user does not select to replace the icon of the control. The invention further provides an icon processing method for a function key of the mobile terminal. According to the mobile terminal and the icon processing method, the picture of the function key of the mobile terminal can be self-defined in accordance with the requirement of the user, the operation is simple, and the implementation is easy.

Owner:BYD CO LTD

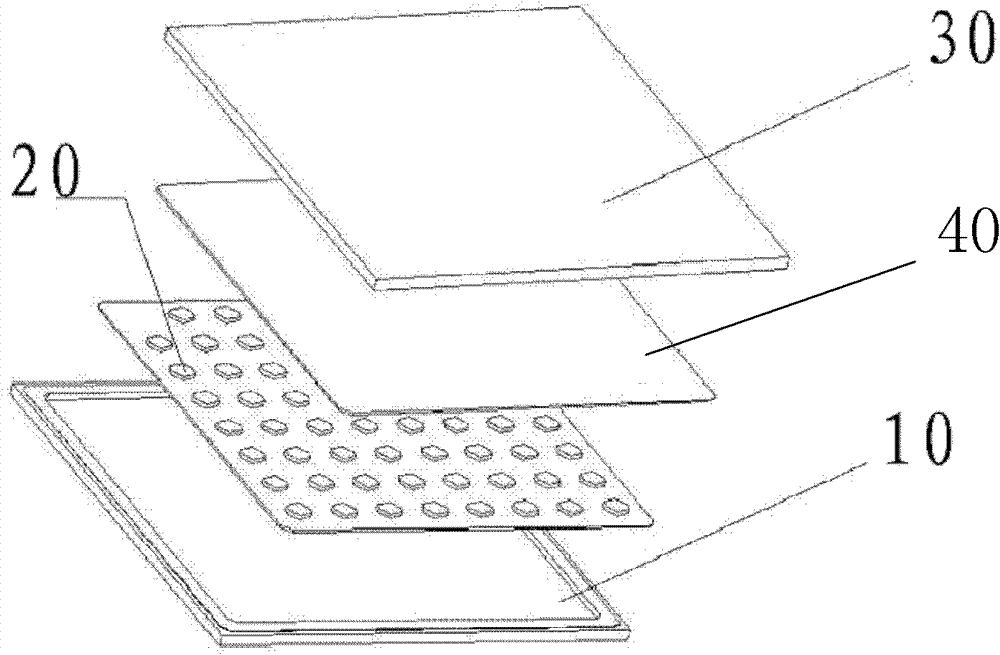

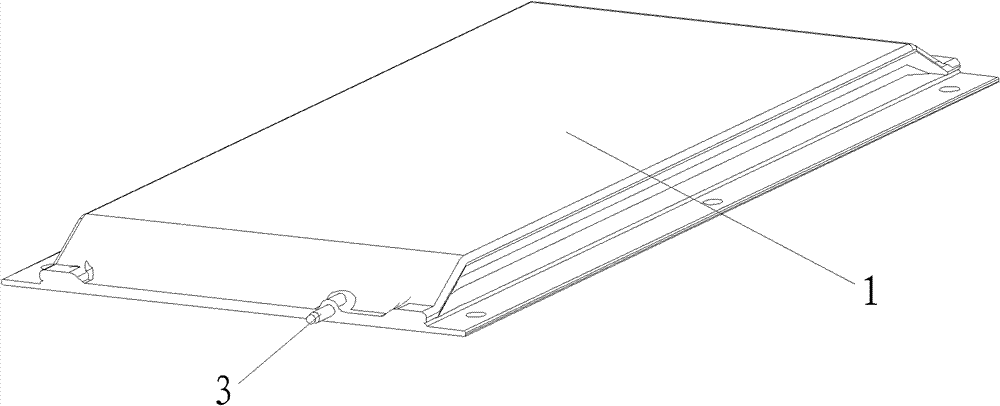

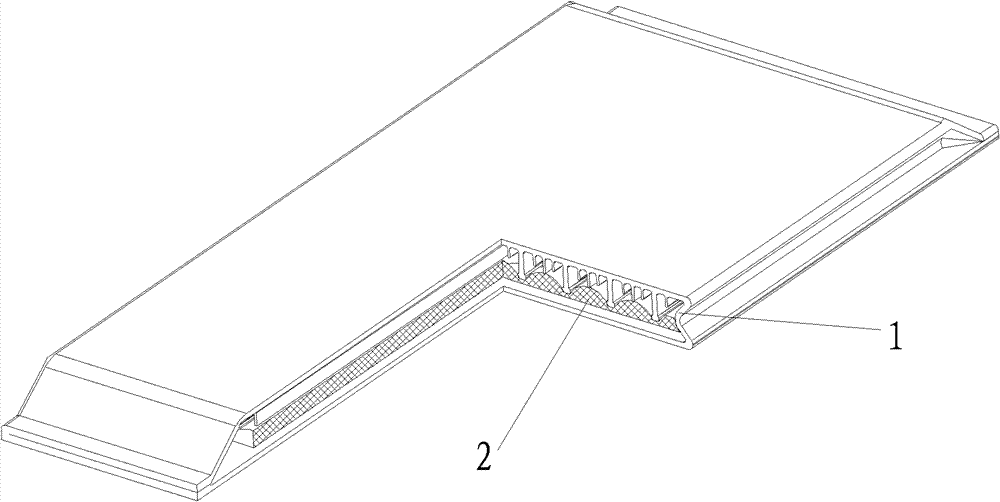

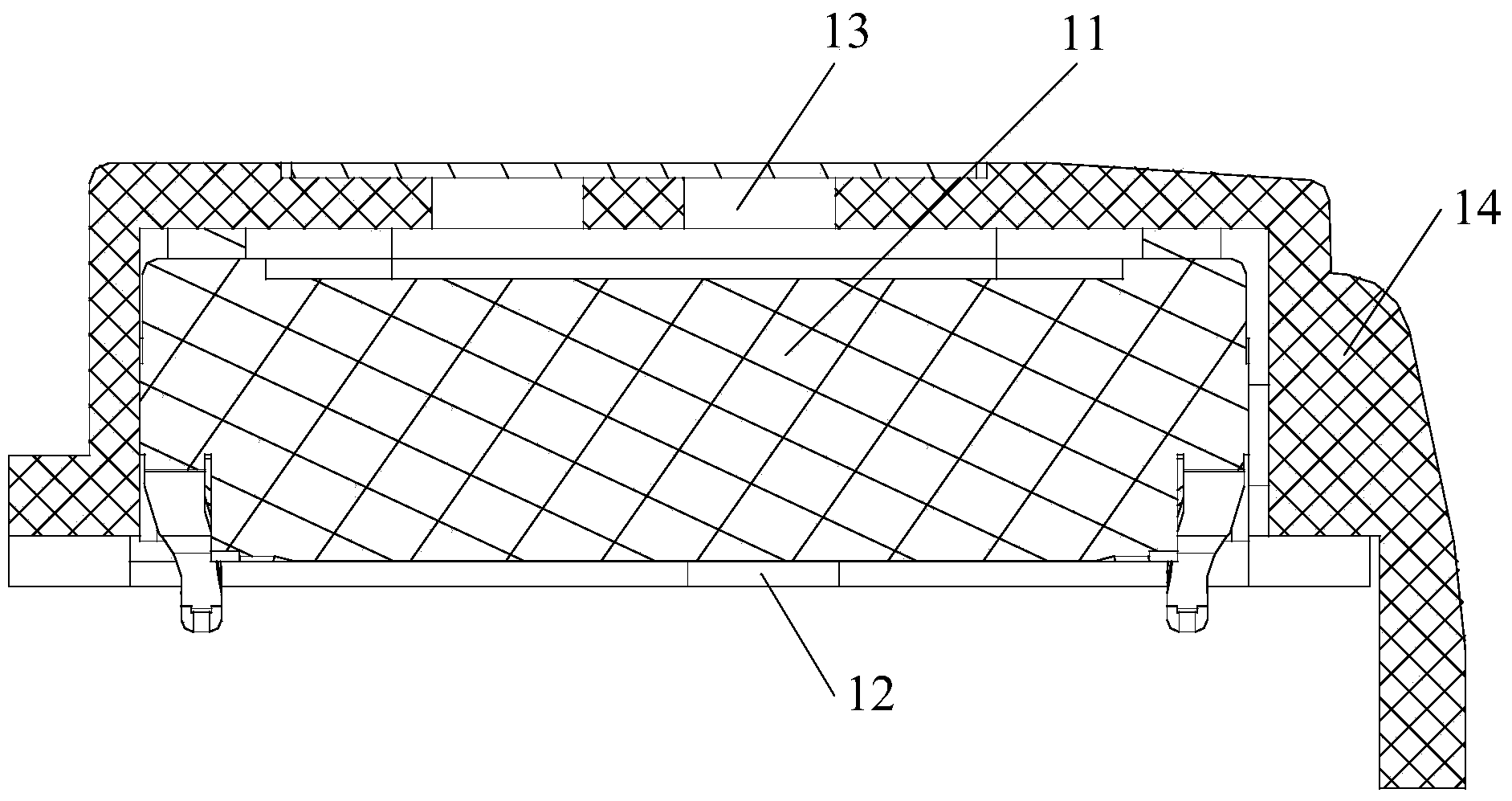

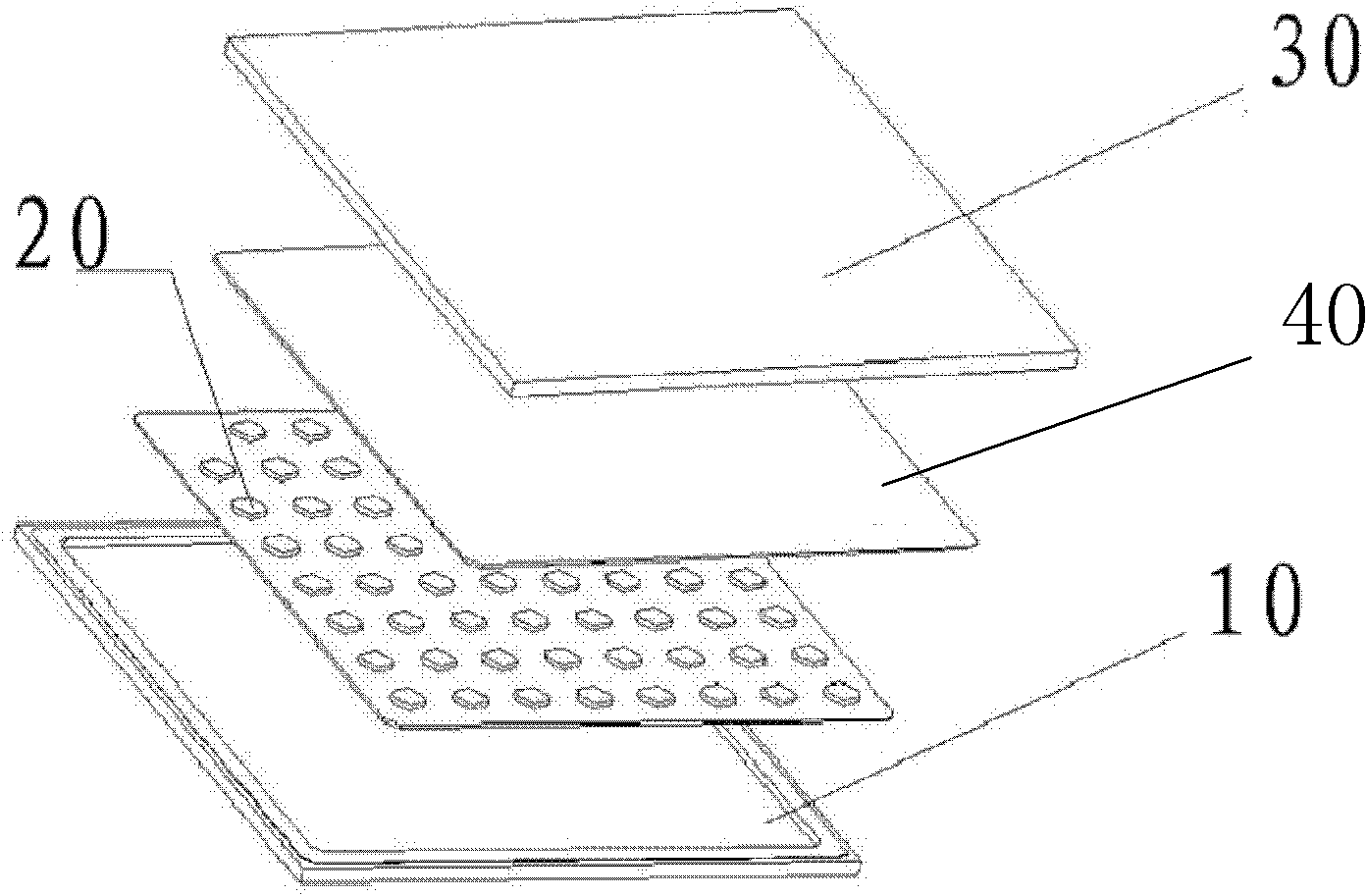

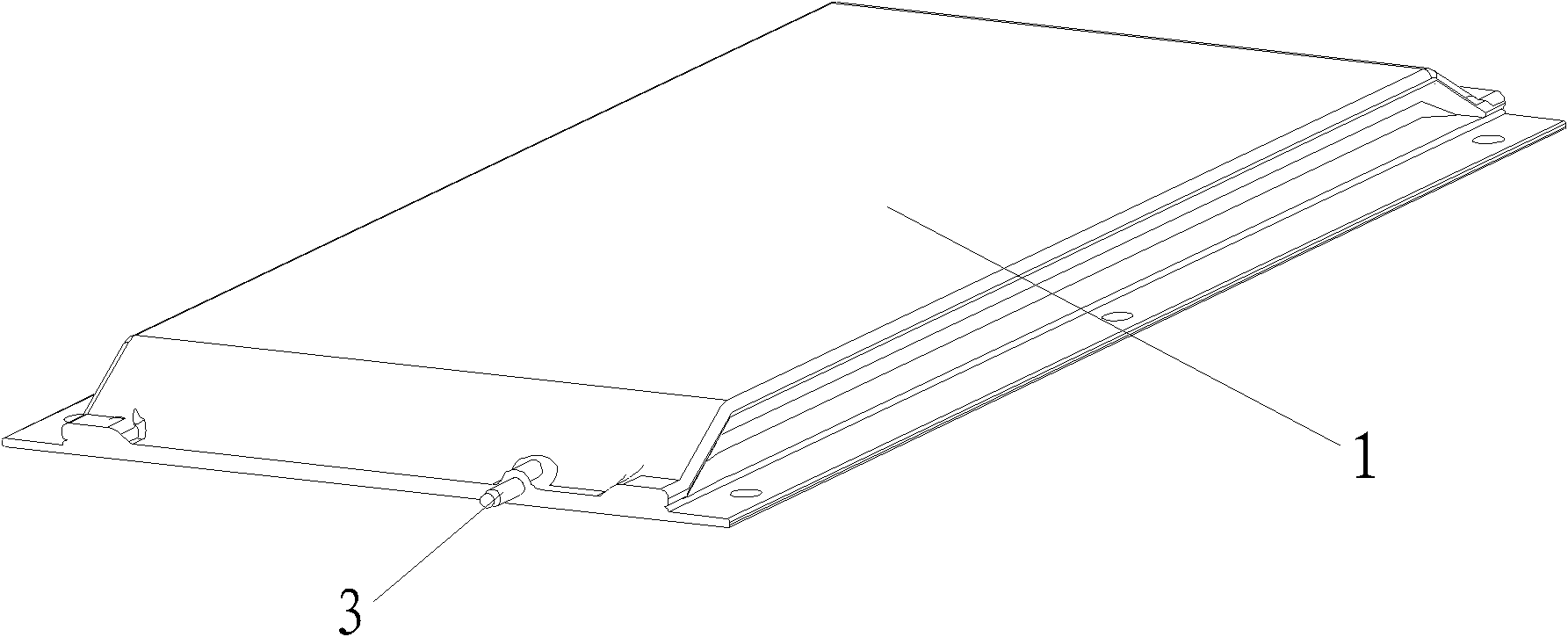

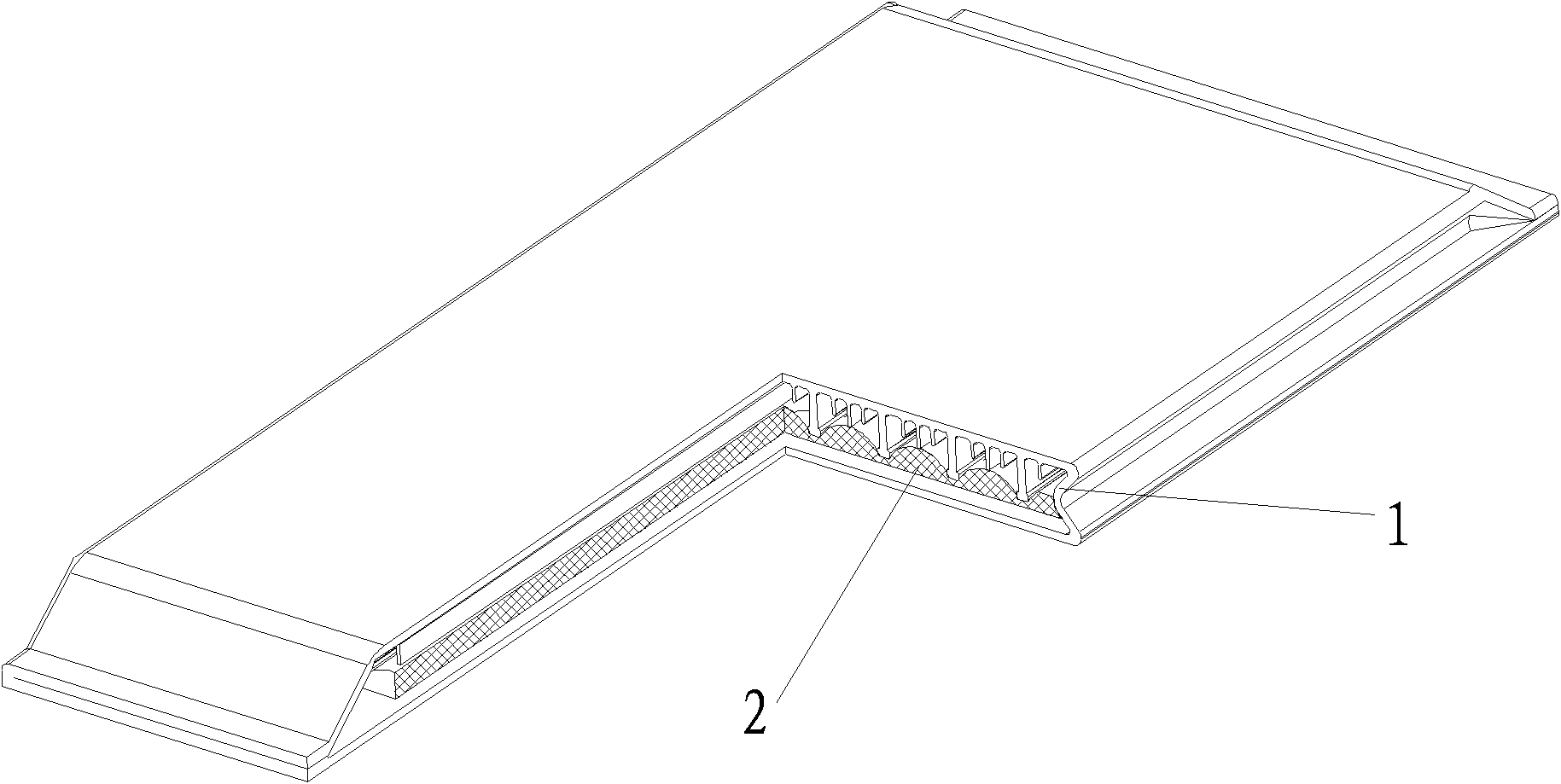

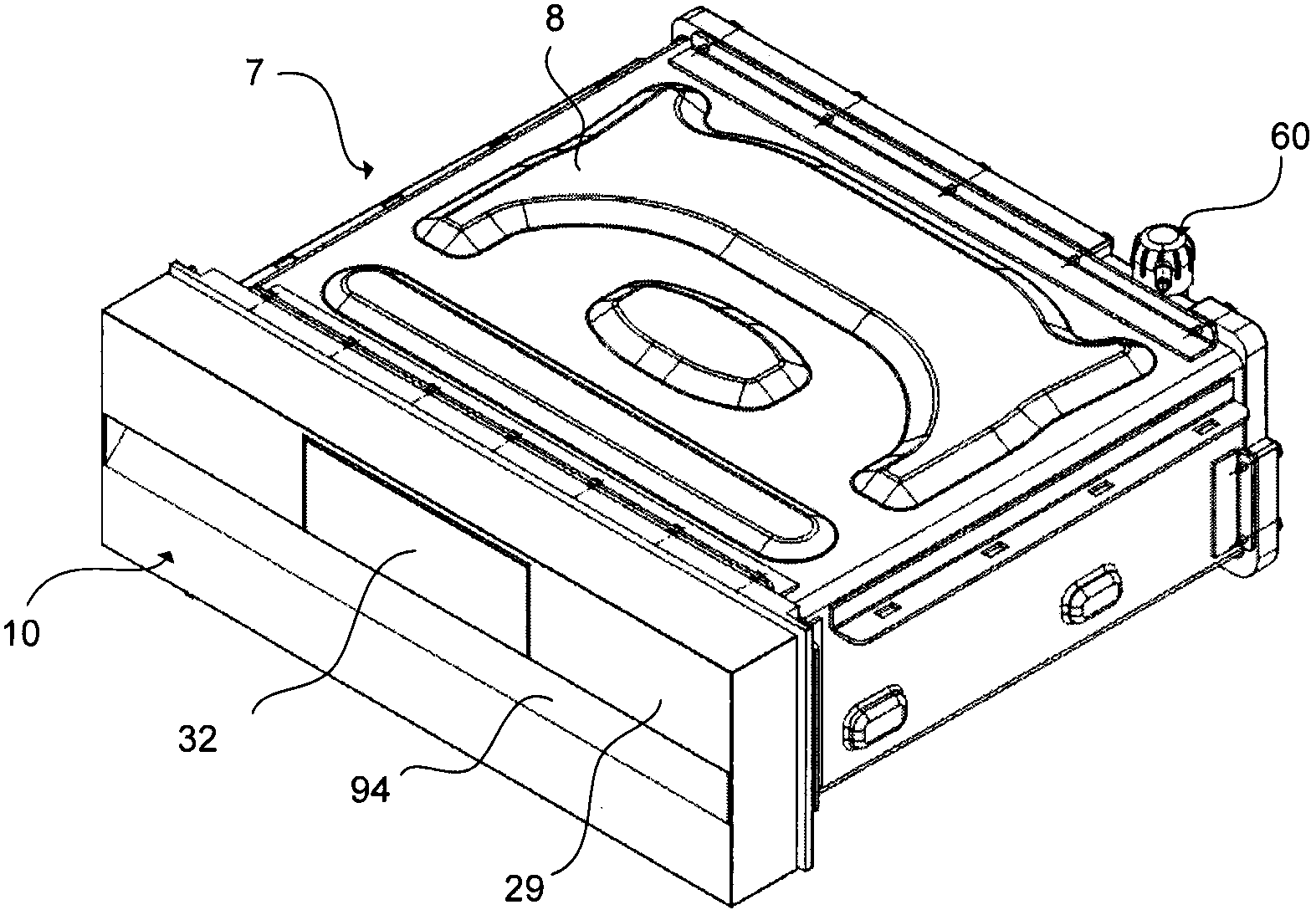

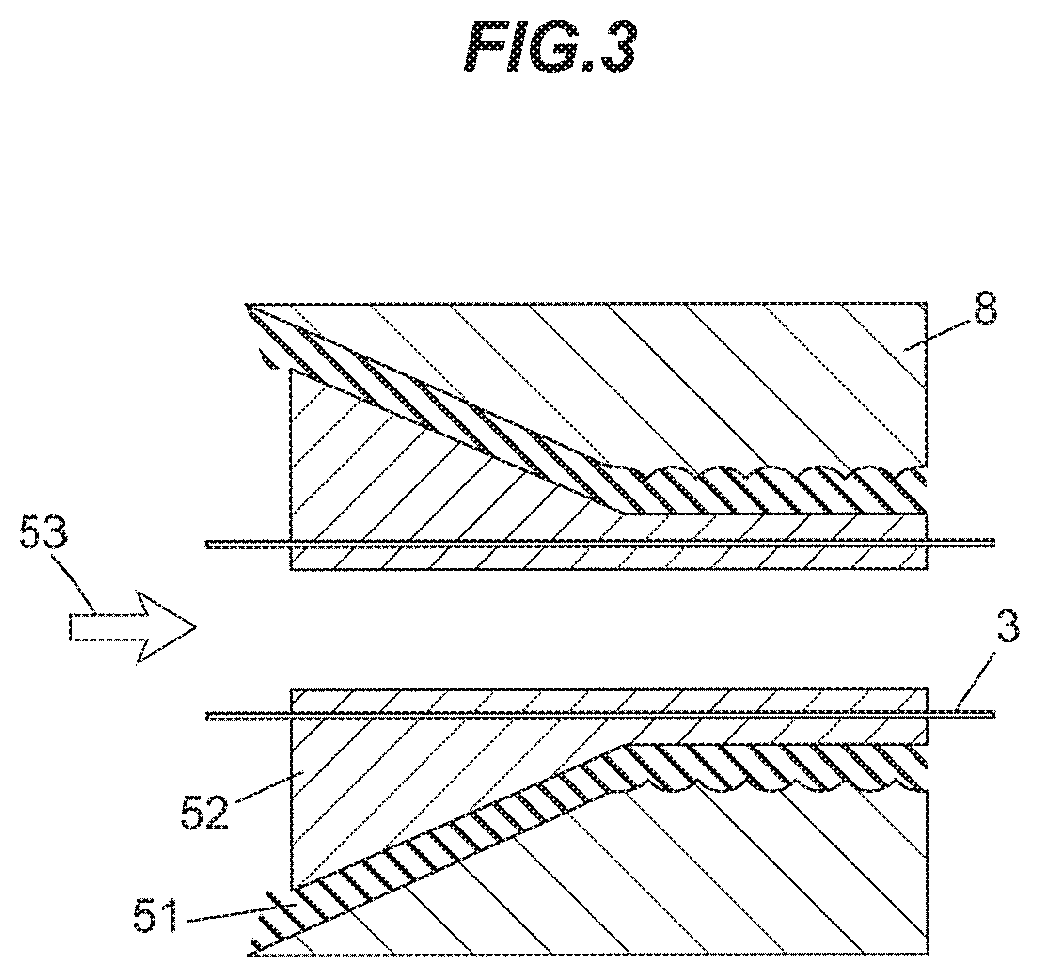

Flat plate vapor chamber and manufacturing method thereof

InactiveCN102778157AArbitrary increase in structure sizeEasy to set upSemiconductor/solid-state device detailsSolid-state devicesEngineeringLimited structures

The invention relates to a flat plate vapor chamber and a manufacturing method thereof. The flat plate vapor chamber comprises a packaging chamber, a porous capillary wick, a working medium and a vacuumizing and work medium filling interface, wherein the porous capillary wire and the working medium are positioned inside the packaging chamber; one end of the vacuumizing and work medium filling interface is communicated with the inside of the packaging chamber; and the other end of the vacuumizing and work medium filling interface is positioned outside the packaging chamber and is sealed. The manufacturing method of the flat plate vapor chamber comprises the following steps of: forming the packaging chamber by extruding or casing; forming the porous capillary wick by sintering or knitting; inserting the porous capillary wick into the packaging chamber; placing one end of the vacuumizing and work medium filling interface in the packaging chamber; extruding the packaging chamber by using a cold press die; moving away the cold press die; welding and sealing a front-rear end closing surface of the packaging chamber; vacuumizing the packaging chamber and filling a working medium; and pinching off the vacuumizing and work medium filling interface and welding and sealing the vacuumizing and work medium filling interface. According to the flat plate vapor chamber disclosed by the invention, the defects of limited structure, high manufacturing cost, low reliability, limited heat-radiating capability and the like in a traditional vapor chamber are fully overcome.

Owner:北京芯铠电子散热技术有限责任公司

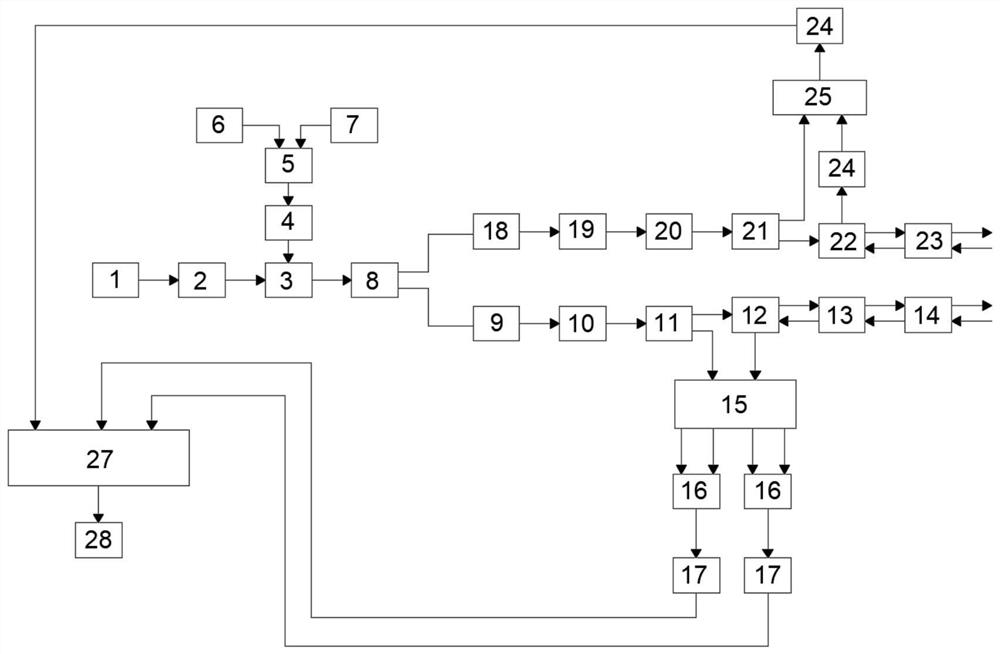

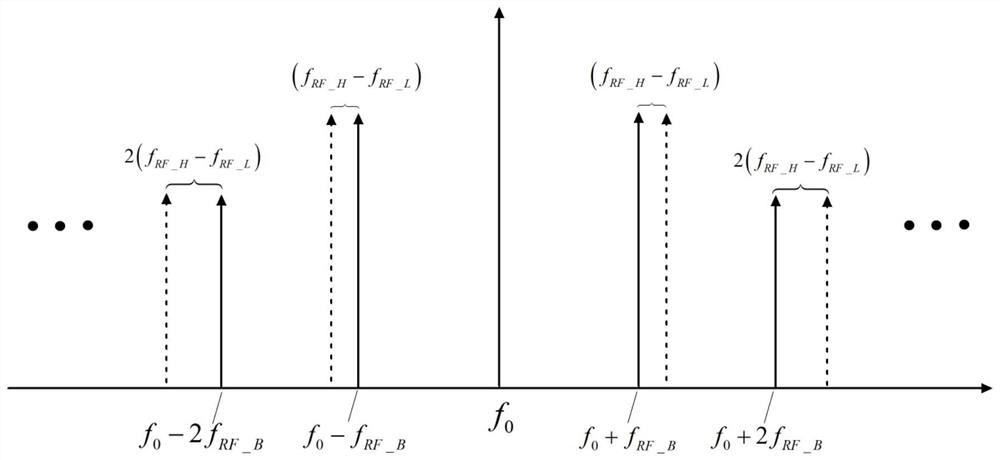

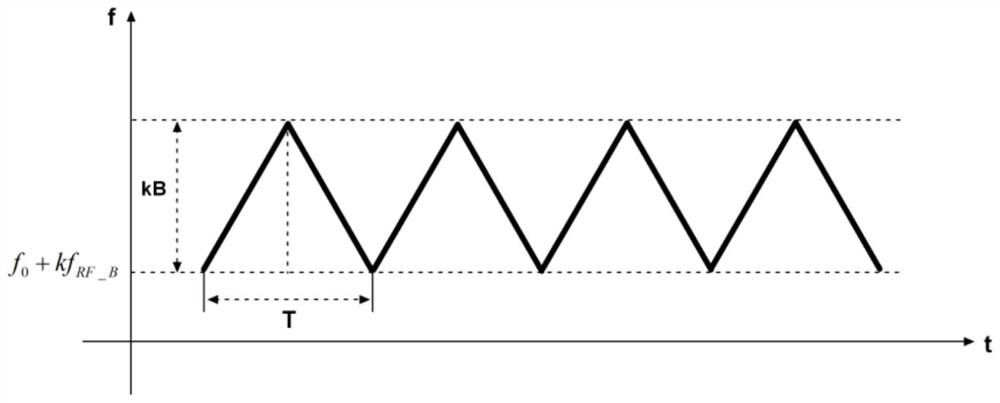

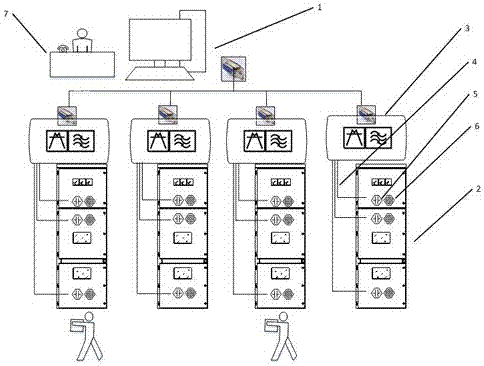

Laser millimeter wave integrated ranging and speed measuring radar method and device

InactiveCN111693988AImprove performanceImprove compatibilityElectromagnetic wave reradiationRadio wave reradiation/reflectionLocal oscillator signalEngineering

The invention discloses a laser millimeter wave integrated ranging and speed measuring radar method. Modulated optical signals are filtered to generate broadband linear frequency modulation laser signals and broadband linear frequency modulation millimeter wave signals in two channels respectively. The laser signals are divided into laser local oscillation signals and laser emission signals, the laser emission signals are emitted, laser echo signals are received, coherent light mixing is carried out on the laser echo signals and the laser local oscillation signals, and laser channel ranging and speed measuring data are obtained through filtering, analog-to-digital conversion and Fourier transform; the millimeter wave signals are divided into millimeter wave local oscillation signals and millimeter wave emission signals, the millimeter wave emission signals are emitted, millimeter wave echo signal are received, frequency mixing coherent reception is performed on the millimeter wave echosignals and the millimeter wave local oscillator signals, and Fourier transform is used to obtain millimeter wave channel ranging and speed measuring data. Finally, the data of the two channels are fused. According to the invention, the structure is compact, the compatibility is higher, more complex environment can be adapted to, the sweep frequency bandwidth and the repetition frequency can be greatly improved, and bandwidth setting is freer.

Owner:孙建锋

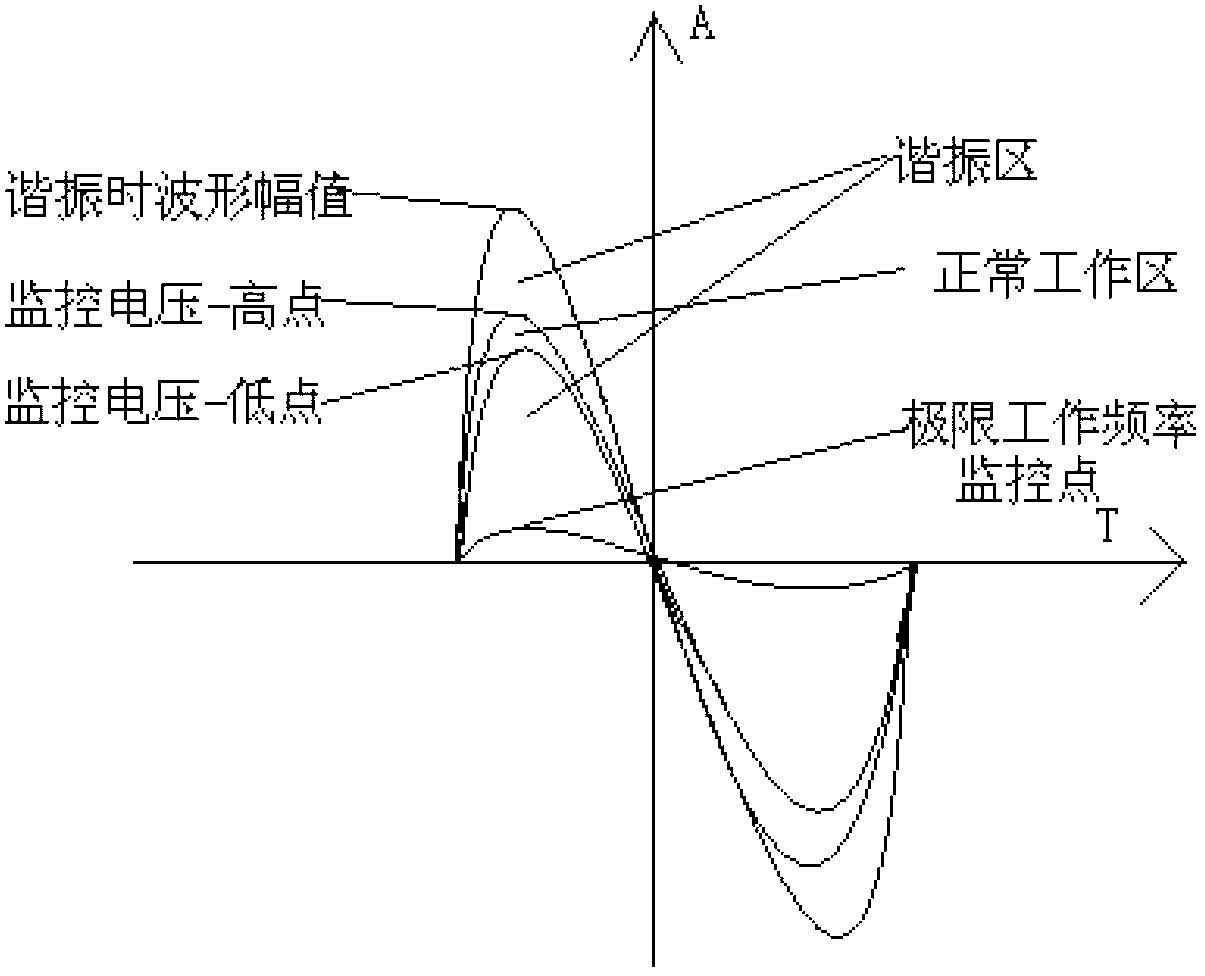

Horn seal structure and processing method thereof

ActiveCN103458326AReduce the thickness of the whole machineSet freeTransducer casings/cabinets/supportsUltrasonic weldingResonance

The invention provides a horn seal structure and a processing method thereof. The horn seal structure comprises a horn, a first shell, a second shell and a third shell. The first shell and the second shell are fixedly connected, the back face of the horn, the first shell and the second shell form a rear sound cavity, the second shell and the third shell are fixedly connected, and the front face of the horn, the second shell and the third shell form a front sound cavity. In the processing method of the horn seal structure, the first shell and the second shell are fixedly connected in an ultrasonic welding mode, the horn is fixed, and the rear sound cavity is sealed. The horn seal structure reduces the entire thickness of mobile terminal equipment, the horn and a sound-out opening can be arranged more freely, and the influence of salt mist, sand dust and the like can be more effectively resisted. The processing method of the horn seal structure can effectively avoid resonance between the horn and the shells.

Owner:SHANGHAI CHUANGGONG COMM TECH

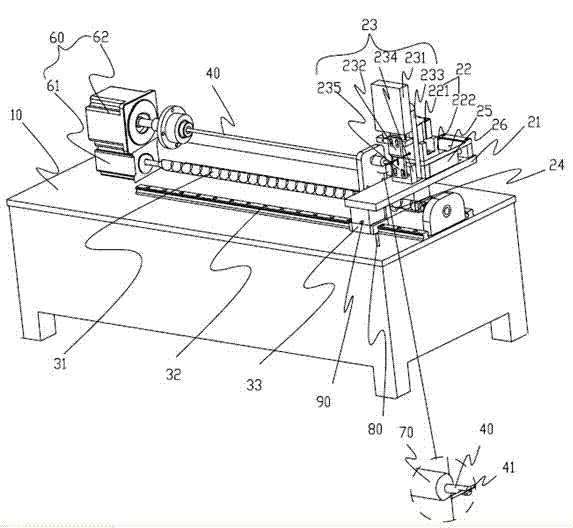

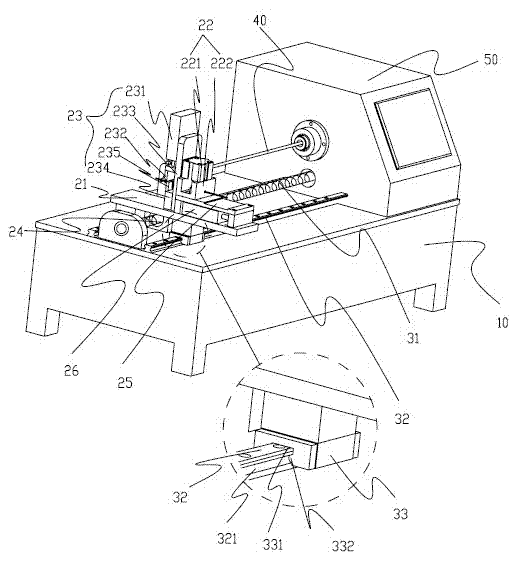

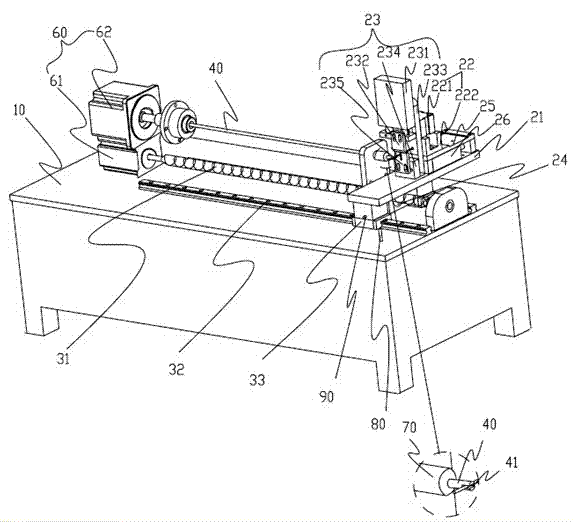

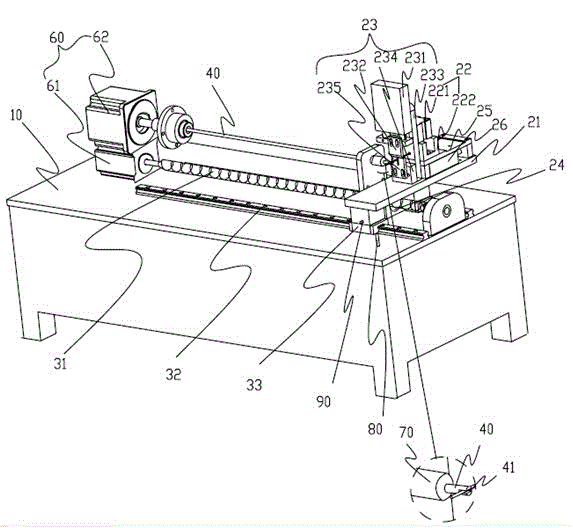

Full-automatic spring shaped coil winder

InactiveCN102403121AHigh precisionImprove qualityFilament handlingCoils manufactureWinding machineCopper wire

The invention discloses a full-automatic spring shaped coil winder, which comprises a box body. The box body is provided with a control system, a mobile mechanism, a winding mechanism and a guide rail mechanism. The mobile mechanism includes a bearing seat, a wire pressing device and a wire cutting device. The winding mechanism comprises a rotating shaft. The wire pressing device comprises a pushing cylinder and a pushing cylinder fixing seat. The pushing cylinder fixing seat is arranged on a plate. The plate is fixedly connected with a transverse cylinder below the plate. The cylinder rod of the transverse cylinder is fixed on the end part of the bearing seat. The wire cutting device comprises a wire cutting cylinder and a cutting tool. A wire cutting cylinder plate is arranged between the wire cutting cylinder and the pushing cylinder. The wire cutting cylinder is fixed onto the wire cutting cylinder plate. The cutting tool is fixedly connected with the end part of the cylinder rod of the wire cutting cylinder. A fixed block is arranged below the wire cutting cylinder. The fixed block is fixedly connected with the wire cutting cylinder plate. A cutter holder is arranged on the fixed block. The invention is automatically loaded and unloaded, which has the advantages of high degree of automation, stable and reliable performance, correct winding turns, the same standard of manufactured coils and high production efficiency.

Owner:康展电子(东莞)有限公司

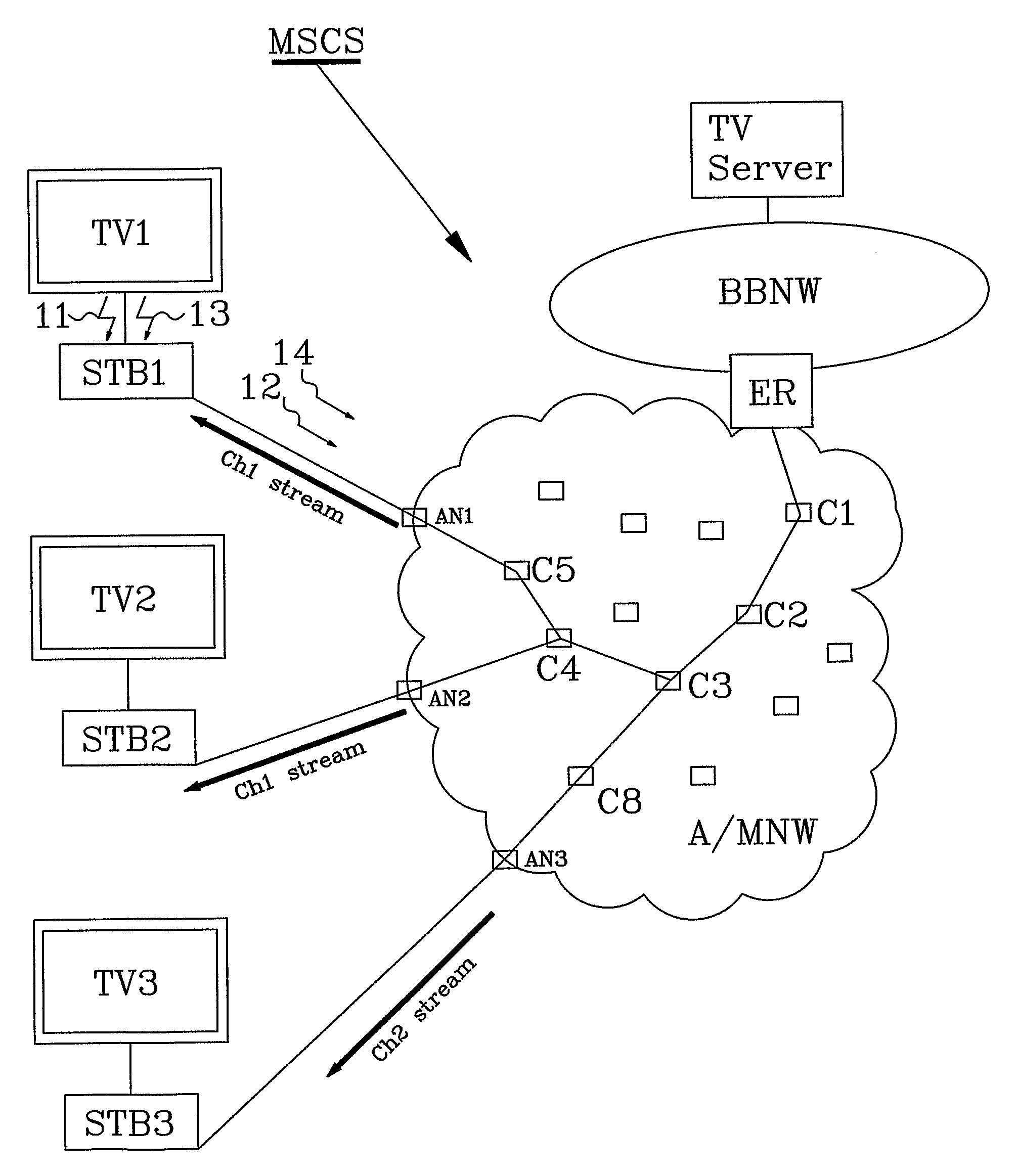

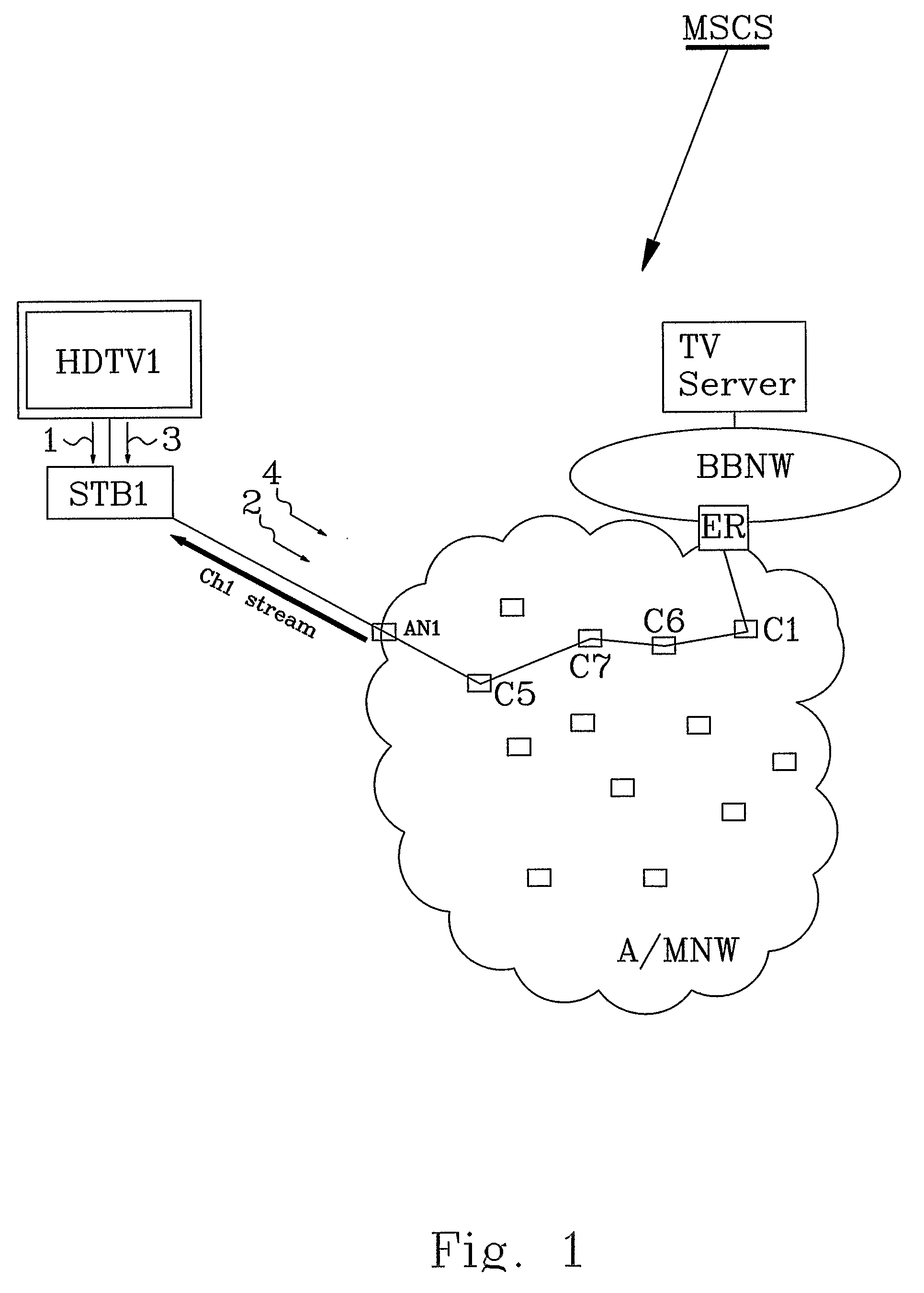

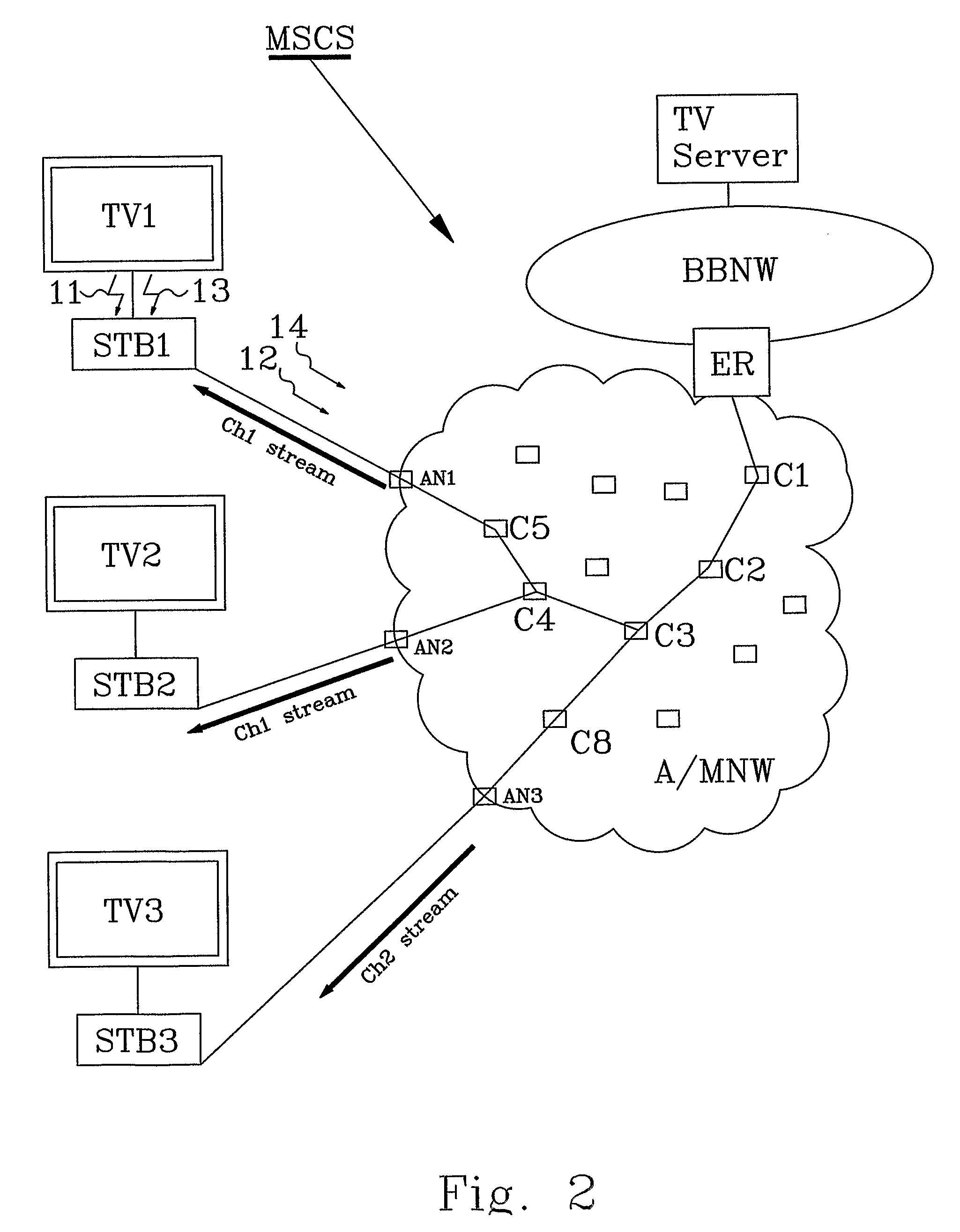

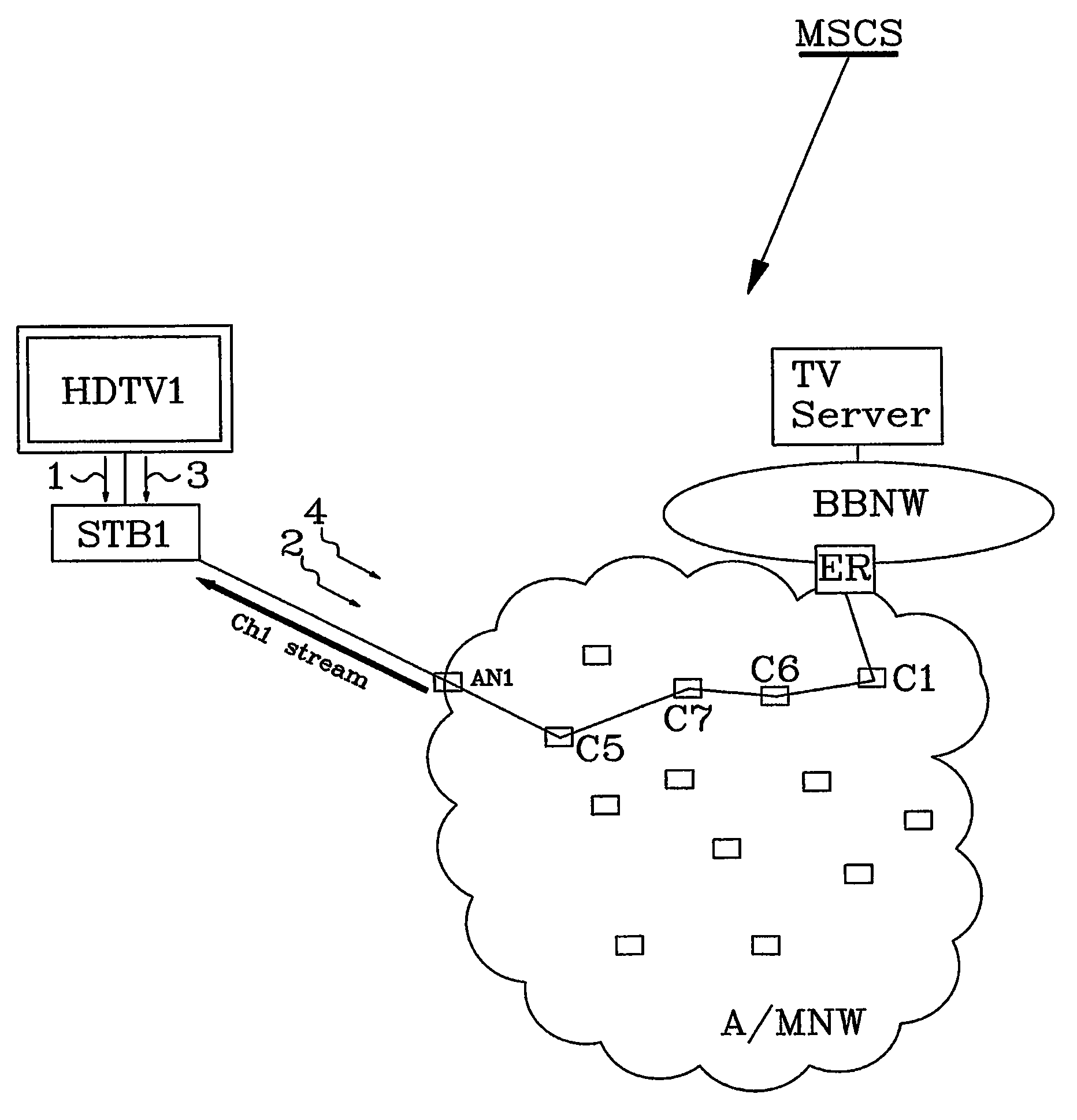

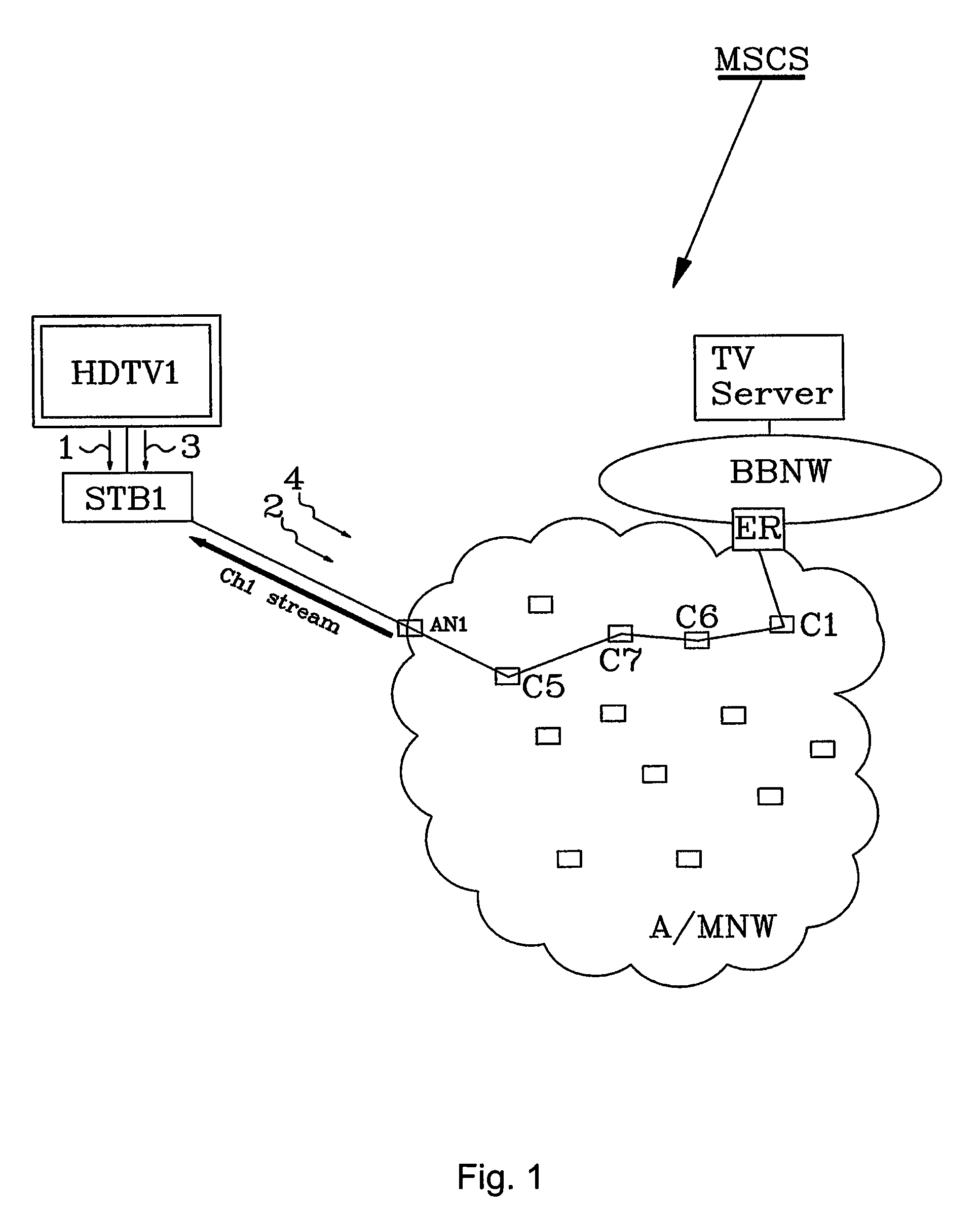

Multicast Control

ActiveUS20090141735A1Bandwidth of networkSet freeTime-division multiplexTwo-way working systemsControl systemService control

A method and arrangement for optimizing bandwidth usage in a Multicast Services Control System (MSCS), which transports digital information in a multicast stream from a broadband network to a Set Top Box (STB) connected to a terminal TV. When the terminal TV is disabled, and can no longer utilize the multicast stream, the terminal TV sends a terminal status signal to the STB indicating deactivation of the terminal TV. In response, the STB sends an IGMP leave report signal to the broadband network, which then ceases its transmission of the multicast stream to the STB.

Owner:TELEFON AB LM ERICSSON (PUBL)

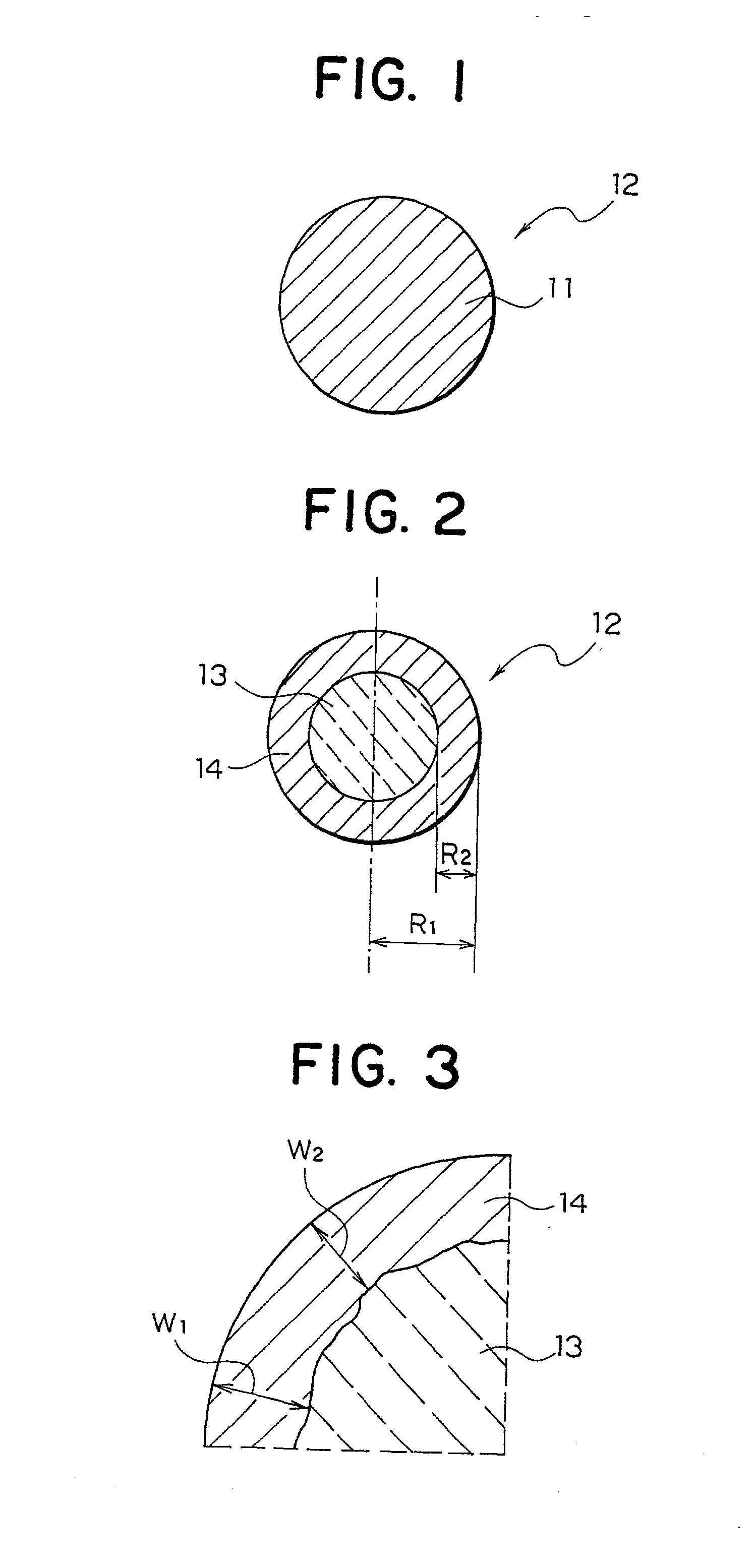

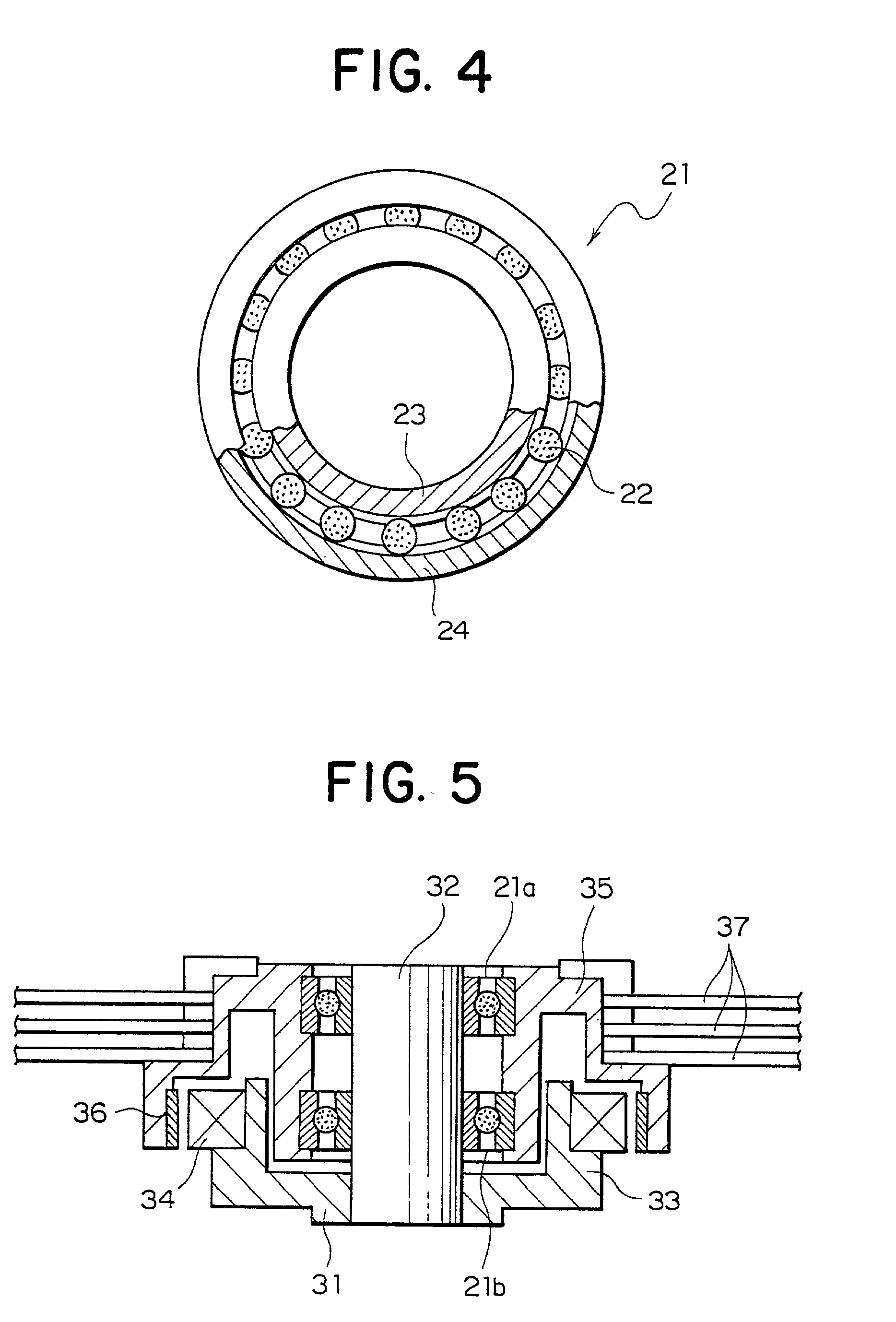

Wear resistant member for electronic equipment and bearing and spindle motor therewith

InactiveUS20020013211A1High densityClose in thermal expansionShaftsRecord information storageElectrical resistance and conductanceWear resistant

Wear resistant member for electronic equipment comprises a zirconium oxide sintered body of which specific resistance is in the range from 1 to 105 OMEGA.m. A conductivity enhancer of which specific resistance is 10-5 OMEGA.m or less is compounded to a zirconium oxide sintered body to materialize specific resistance from 1 to 105 OMEGA.m. For a conductivity enhancer, carbides and nitrides of various kinds of metals can be used. Wear resistant member can be used as a bearing ball, being applied in a rotational driver of electronic equipment such as a magnetic recording device and an optical disk device. Deficiency due to static electricity of electronic equipment is cancelled due to specific resistance that a zirconium oxide sintered body has.

Owner:KK TOSHIBA

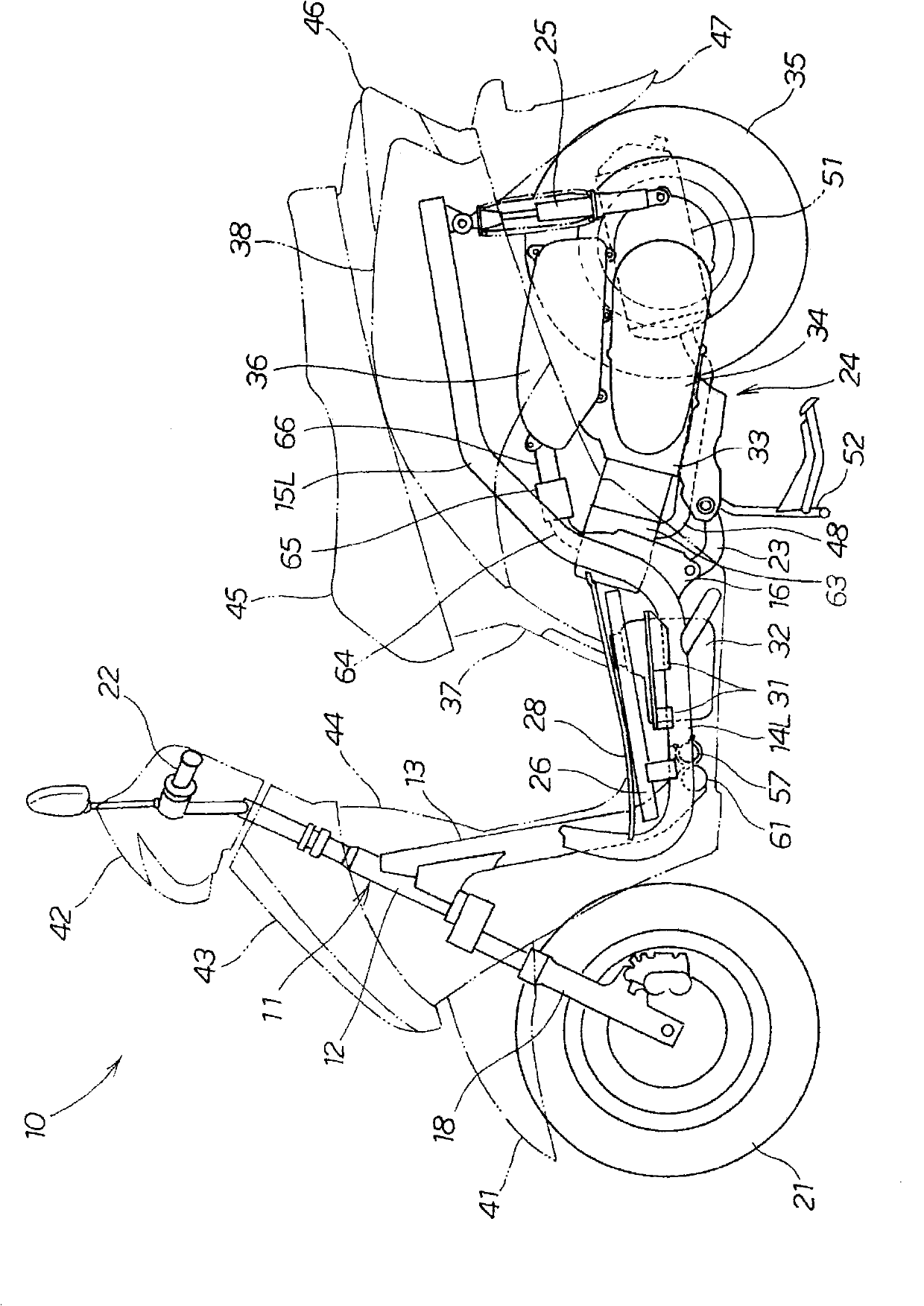

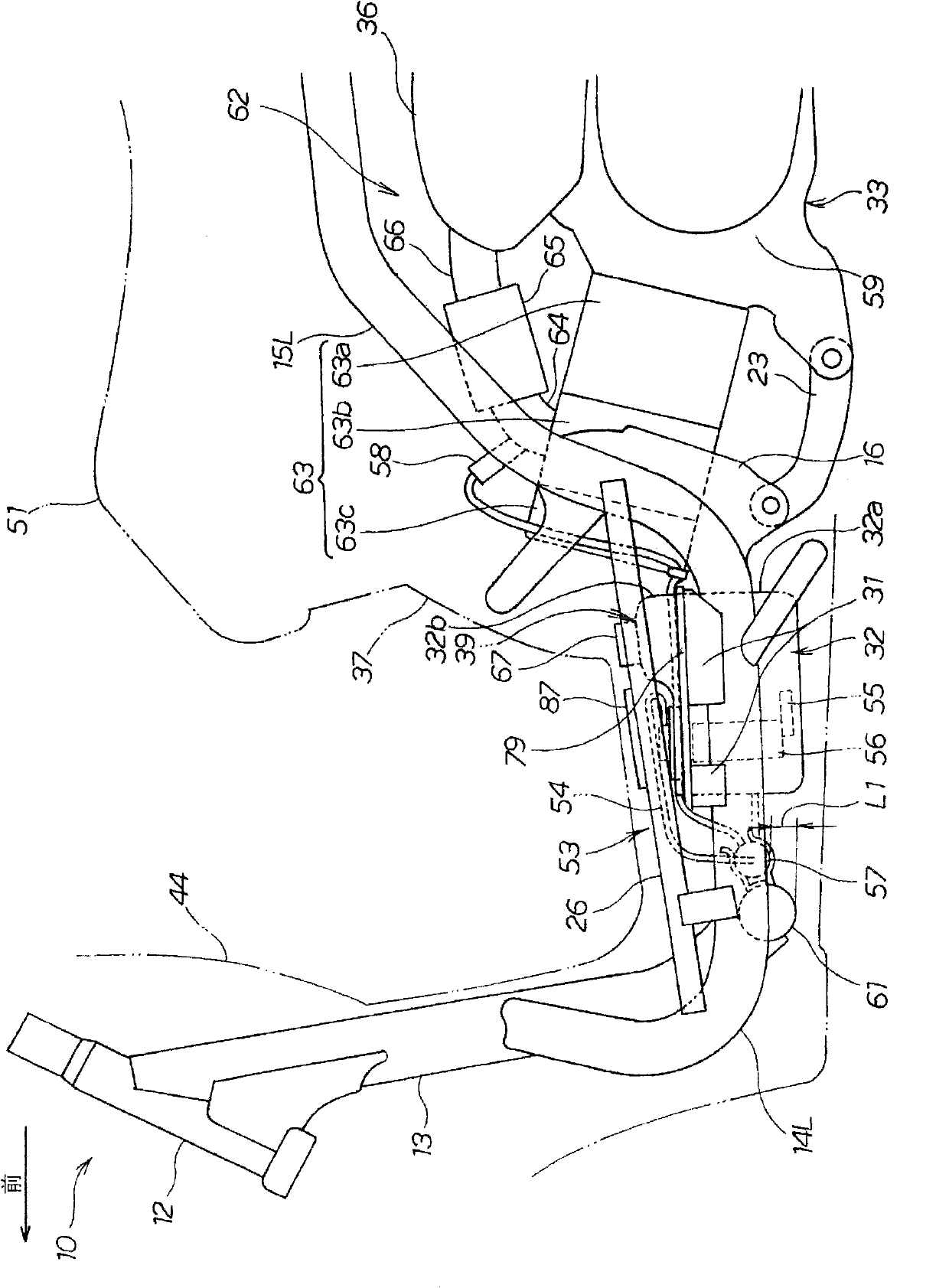

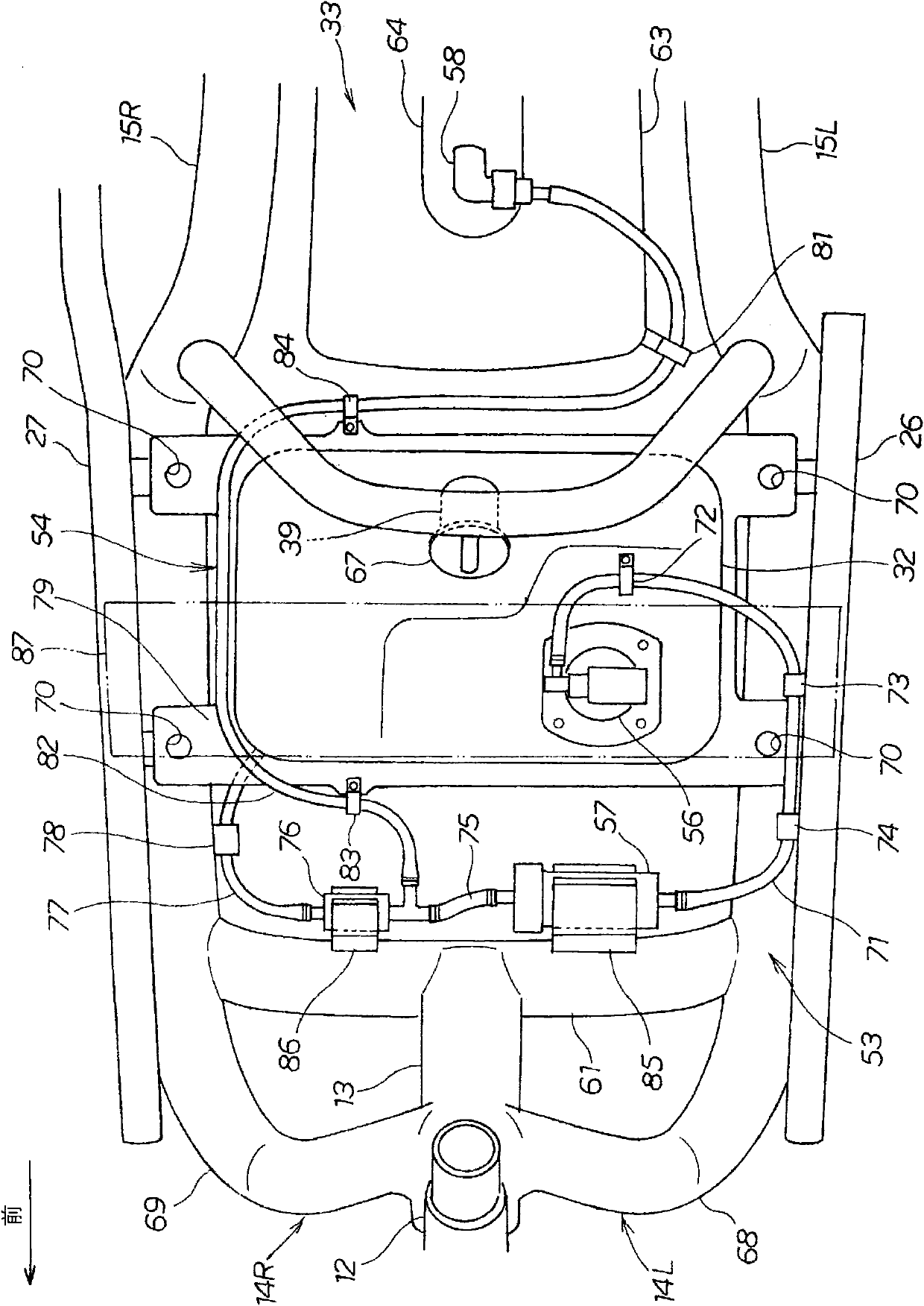

Scooter-type vehicle

A scooter-type vehicle comprising a cross pipe (61) spanned between a pair of left and right lower frames (14L) and a lower end of a down frame (13) is connected to a central portion of the cross pipe (61). A fuel filter (57) is disposed so that its lower end is higher by distance (L1) than the lower end of cross pipe (61). The fuel filter (57) is disposed between the down frame (13) and the fuel tank (32). Because the fuel filter is arranged in front of the fuel tank, it is not restricted by the swinging of the engine behind the fuel tank, consequently, the capacity of the fuel filter can be set freely.

Owner:HONDA MOTOR CO LTD

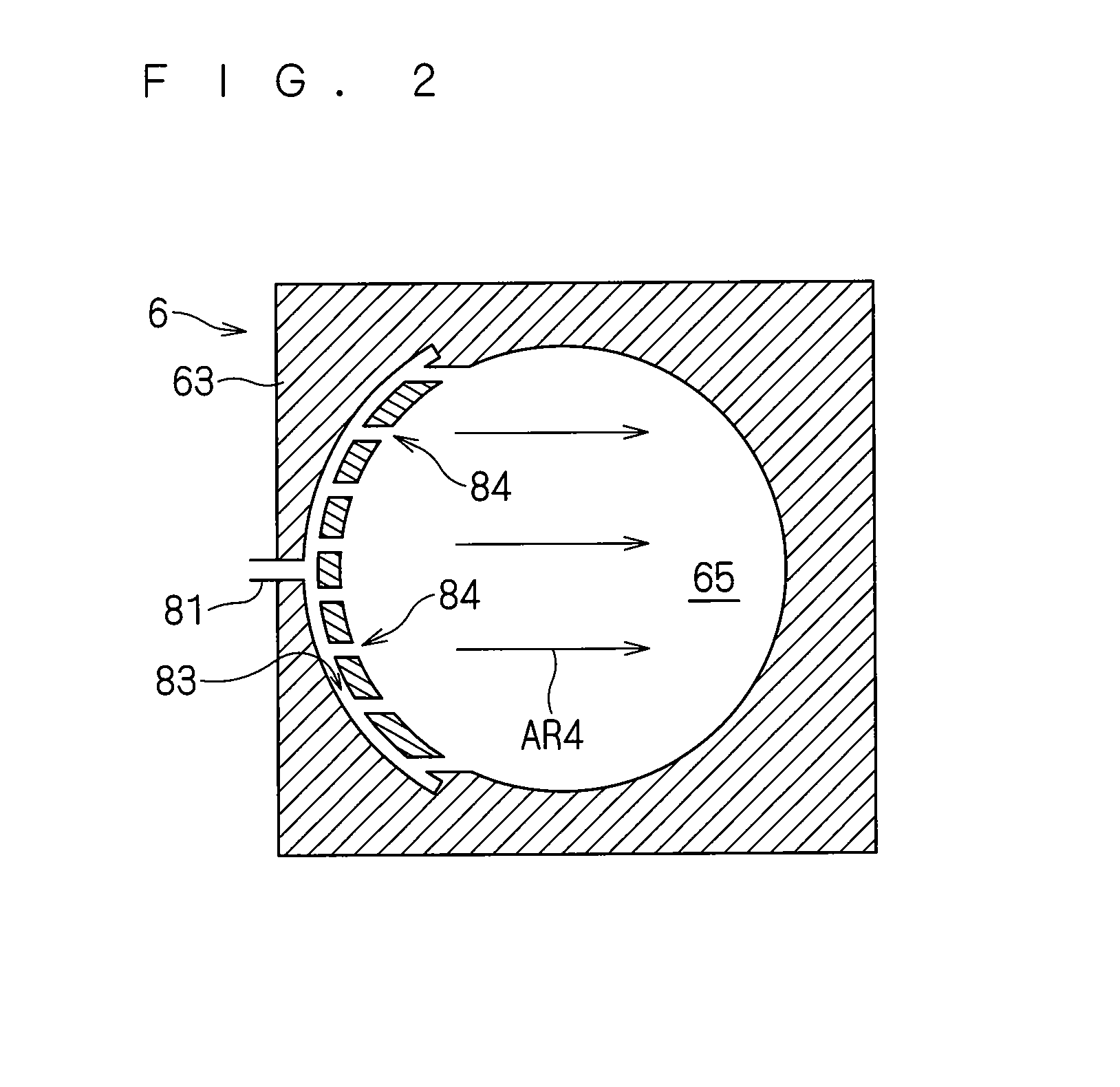

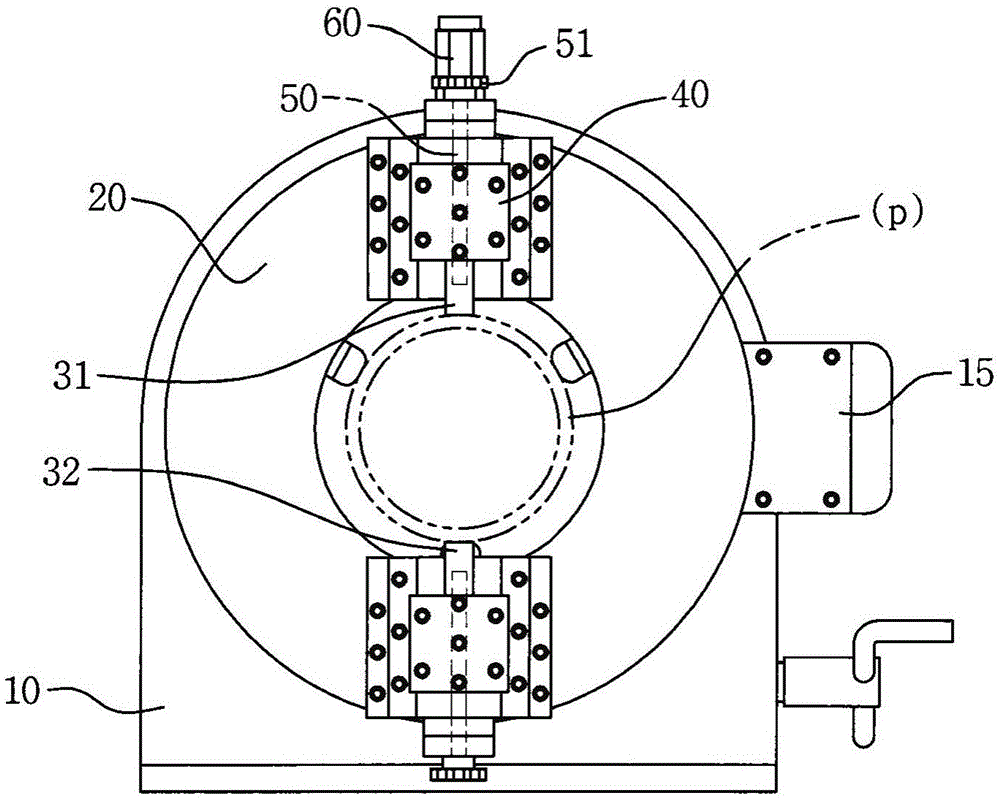

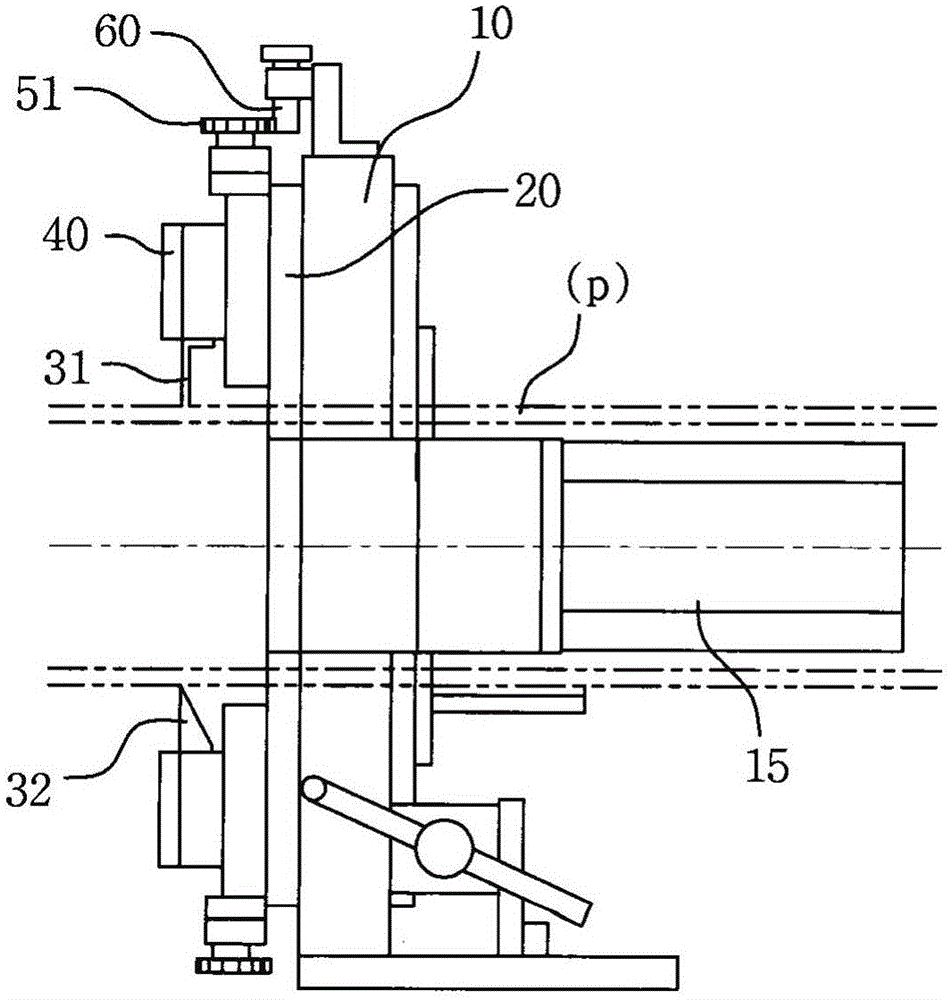

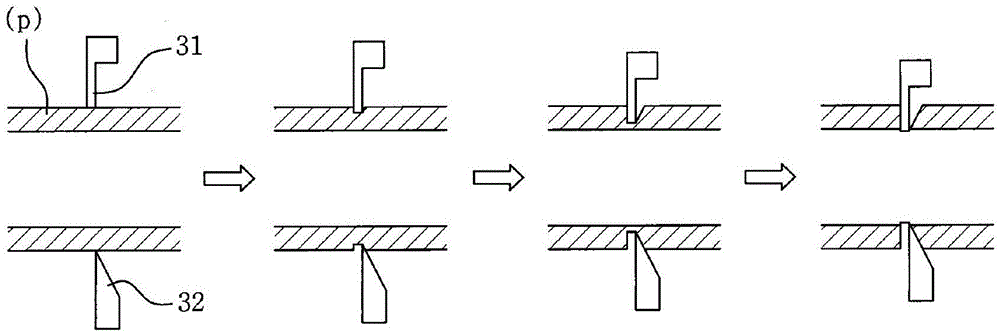

Power transmitting device for transmitting external force into rotating body, and orbital pipe cutting device and hydraulic chucking device able to freely control cutting tool movement inside rotating body by using the power transmitting device

ActiveCN105121075AGuaranteed durabilityImprove economyGearingTelemotorsHydraulic cylinderEngineering

Owner:DCSENG CO LTD

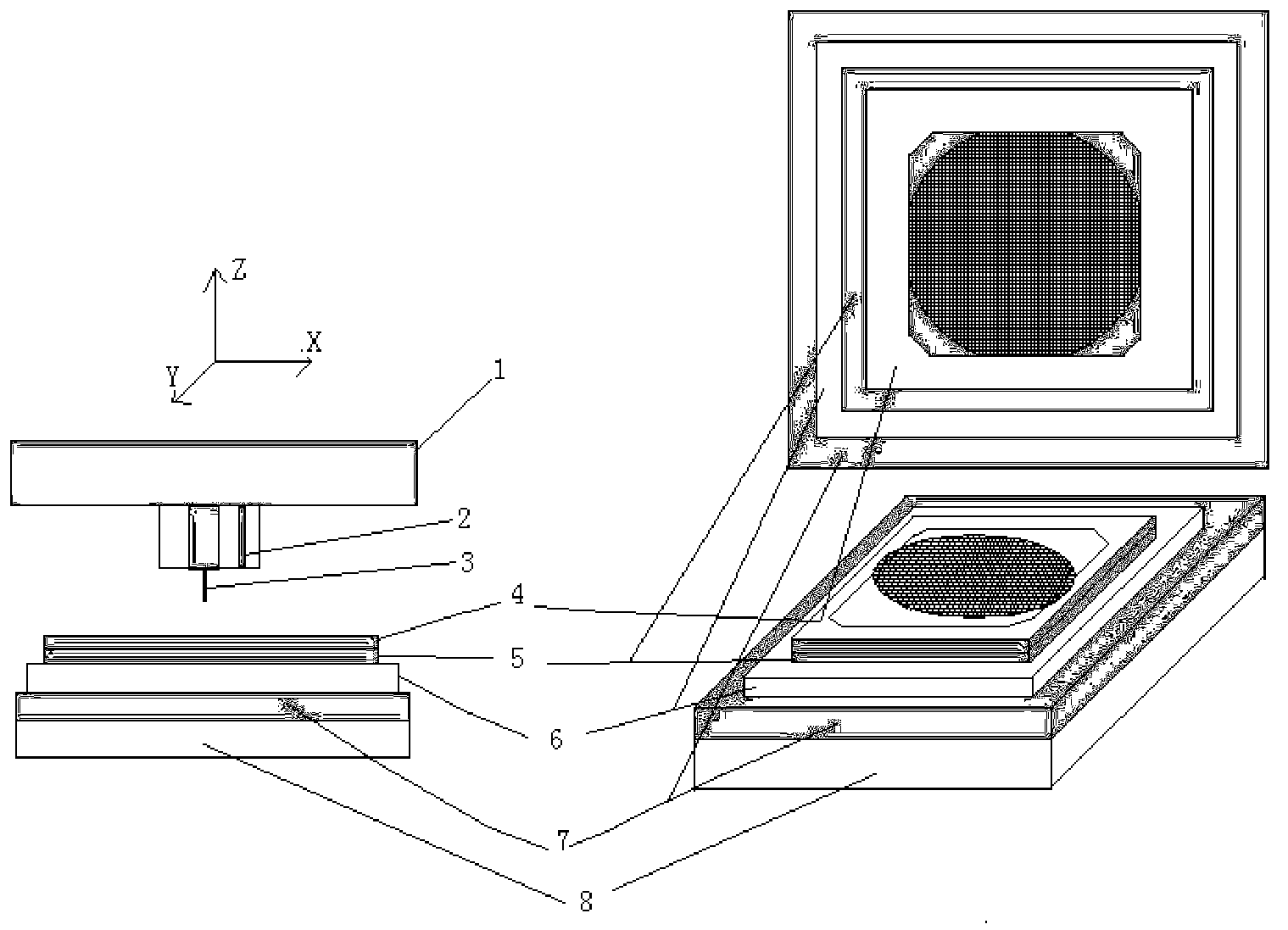

Automatic test system and method of electric micromirror

InactiveCN102914417AImprove efficiencyImprove accuracyResistance/reactance/impedenceElectrical testingControl systemData acquisition

The invention discloses an automatic test system of an electric micromirror, which comprises an electric displacement platform, a pinhead for an electric micromirror test, a data acquisition system, and an electric micromirror automatic test control system optical path. The automatic test method of the electric micromirror comprises the steps of test of the electric micromirror yield, aging test and optical scanning test of the electric micromirror, test of the electric micromirror attribute. With the test system and method, the yield and the attribute of the micromirror can be automatically tested.

Owner:WUXI WIO TECH

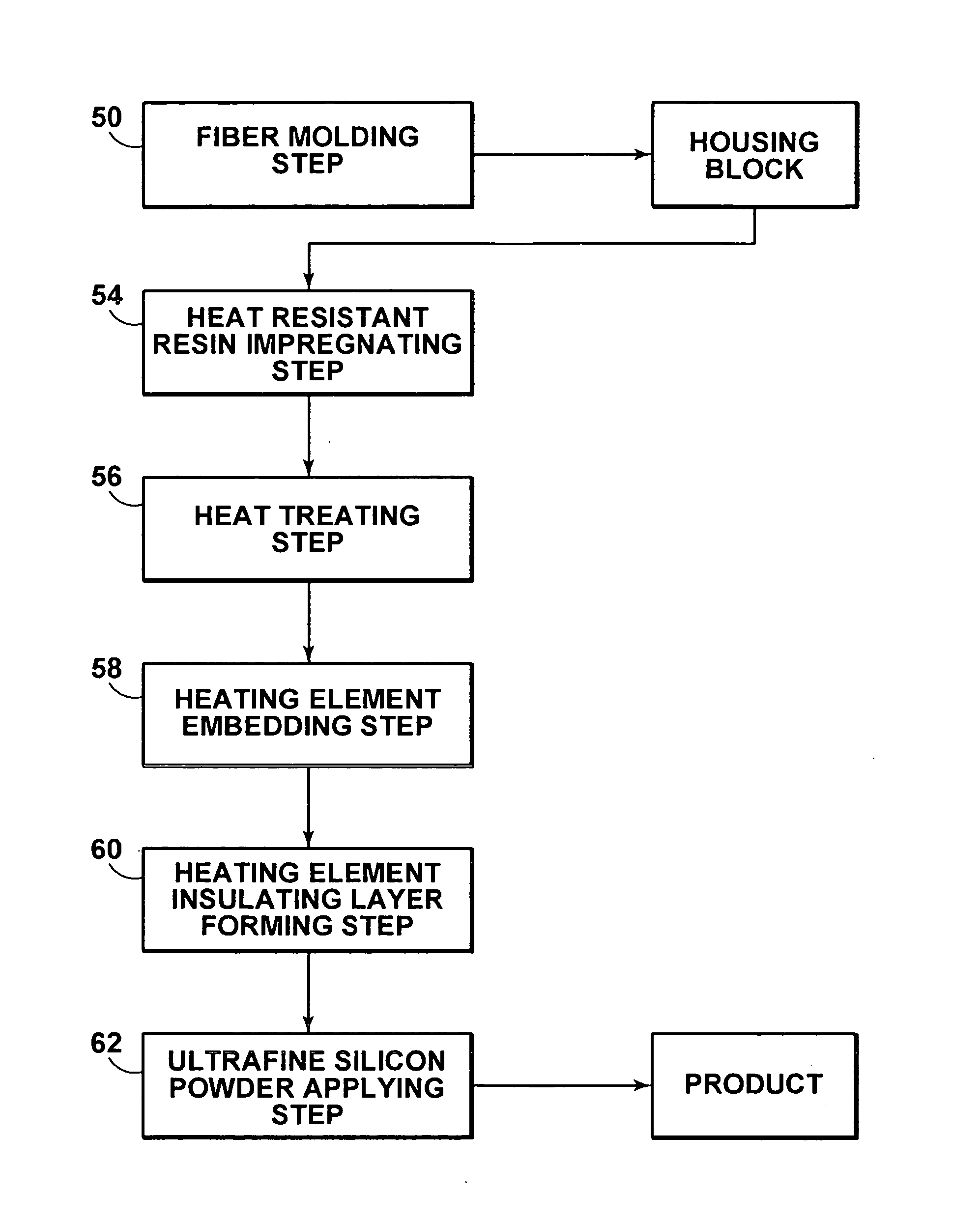

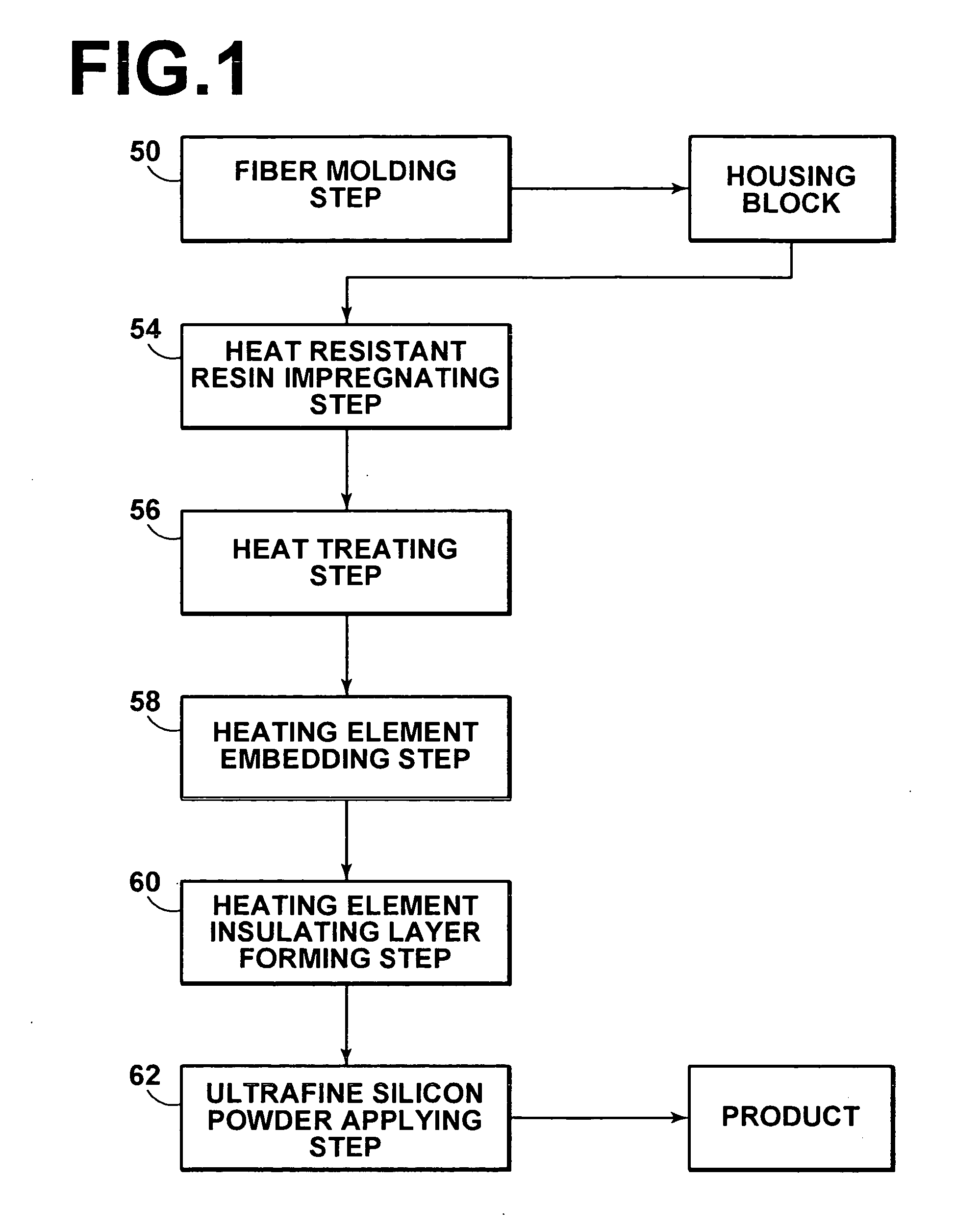

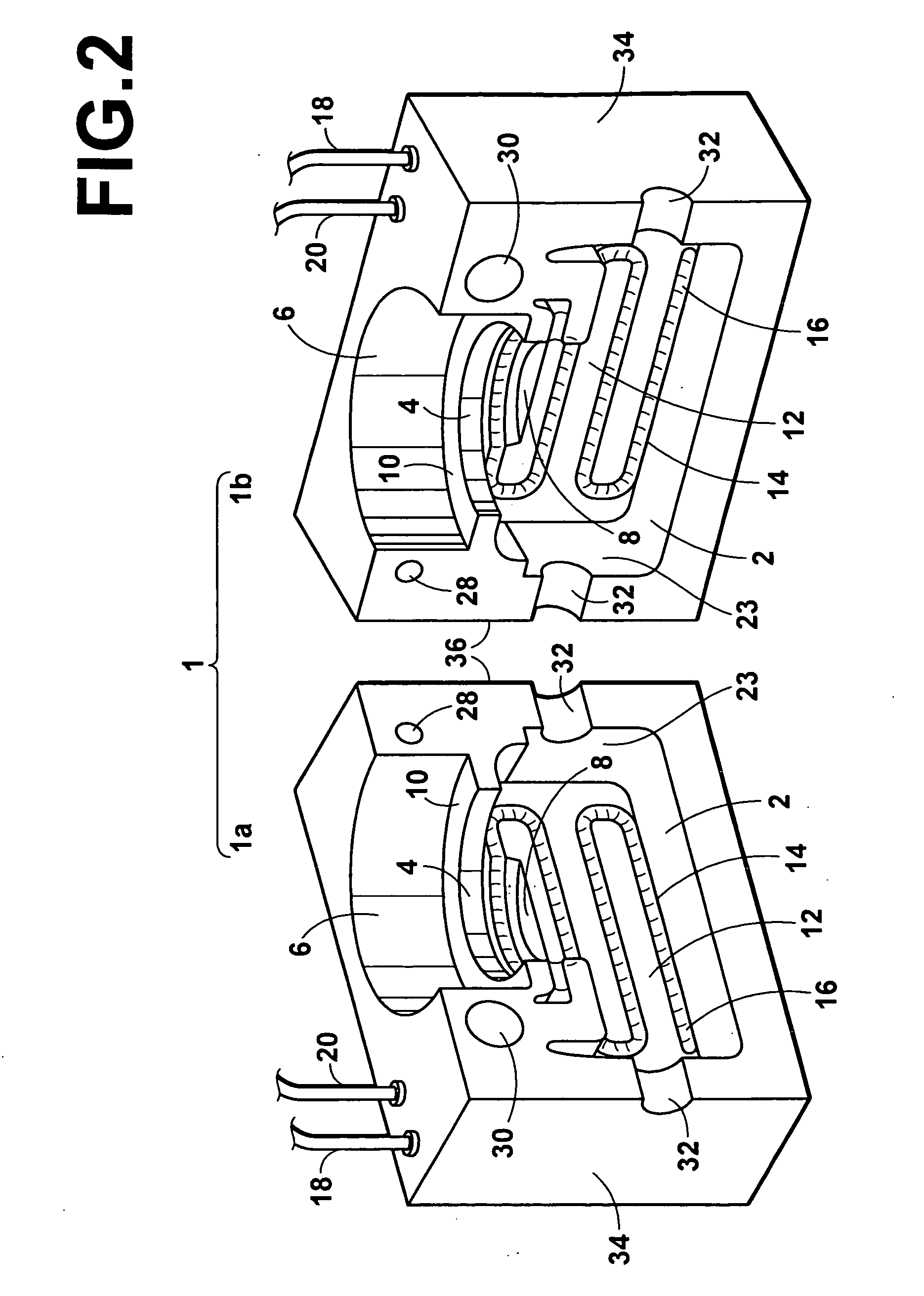

Heater unit manufacturing method

InactiveUS20070098992A1Low costReduce the number of partsLayered productsPedestrian/occupant safety arrangementFiberEngineering

A heater unit manufacturing method constituted by the steps of: forming multitudes of inorganic fibers into a heat insulating housing block through molding; heat treating the heat insulating housing block after impregnating the block with heat resistant resin; and mounting a heating element inside of the heat treated heat insulating housing block.

Owner:TOKYO TECHNOLOGICAL LABO

Flat plate soaking plate and manufacturing method thereof

InactiveCN102778157BArbitrary increase in structure sizeEasy to set upSemiconductor/solid-state device detailsSolid-state devicesEngineeringLimited structures

The invention relates to a flat plate vapor chamber and a manufacturing method thereof. The flat plate vapor chamber comprises a packaging chamber, a porous capillary wick, a working medium and a vacuumizing and work medium filling interface, wherein the porous capillary wire and the working medium are positioned inside the packaging chamber; one end of the vacuumizing and work medium filling interface is communicated with the inside of the packaging chamber; and the other end of the vacuumizing and work medium filling interface is positioned outside the packaging chamber and is sealed. The manufacturing method of the flat plate vapor chamber comprises the following steps of: forming the packaging chamber by extruding or casing; forming the porous capillary wick by sintering or knitting; inserting the porous capillary wick into the packaging chamber; placing one end of the vacuumizing and work medium filling interface in the packaging chamber; extruding the packaging chamber by using a cold press die; moving away the cold press die; welding and sealing a front-rear end closing surface of the packaging chamber; vacuumizing the packaging chamber and filling a working medium; and pinching off the vacuumizing and work medium filling interface and welding and sealing the vacuumizing and work medium filling interface. According to the flat plate vapor chamber disclosed by the invention, the defects of limited structure, high manufacturing cost, low reliability, limited heat-radiating capability and the like in a traditional vapor chamber are fully overcome.

Owner:北京芯铠电子散热技术有限责任公司

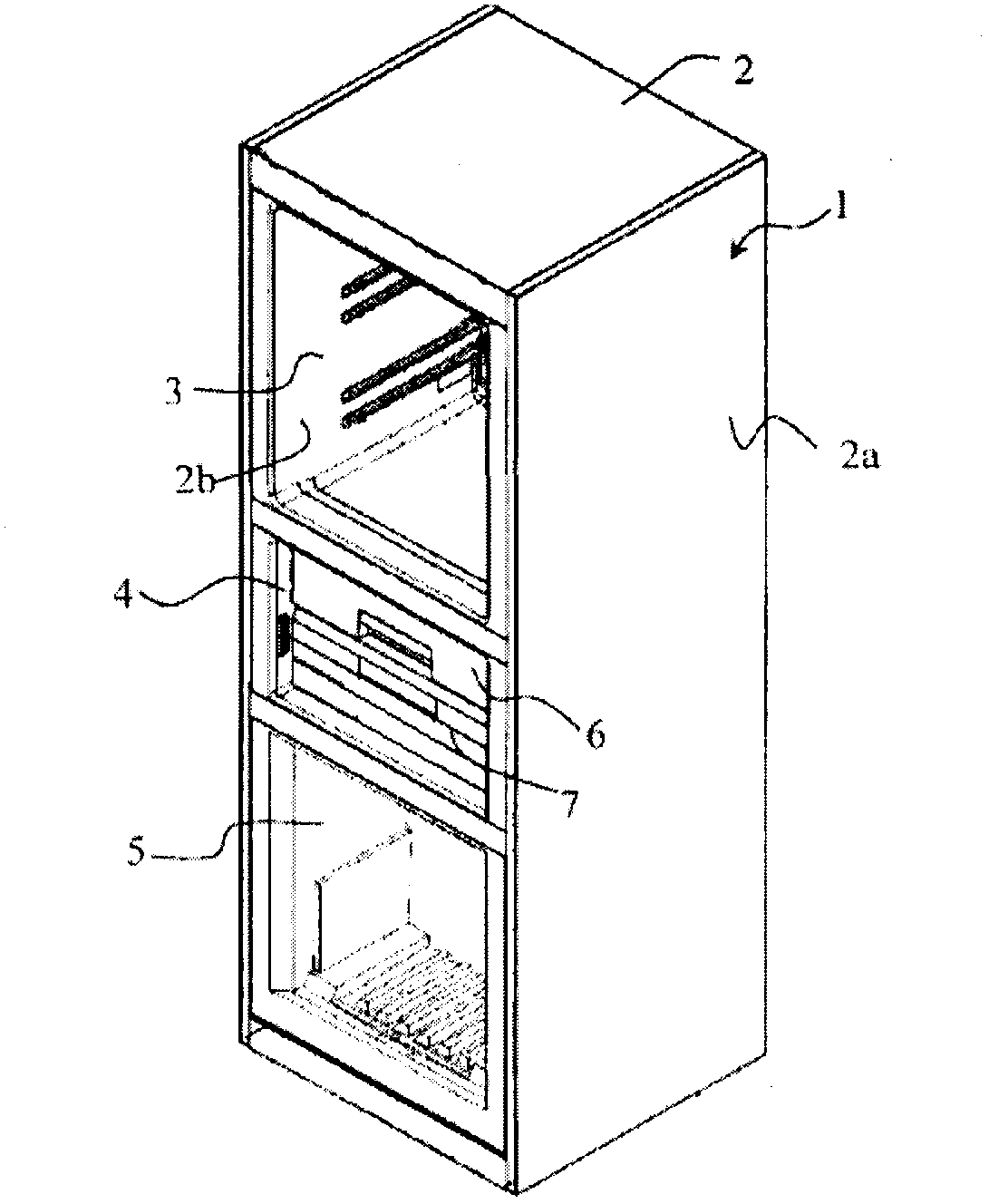

Low-pressure container and refrigerator with same

ActiveCN103423952AOvercomes the problem of position being limited by the position of the locking mechanismGood lookingLighting and heating apparatusBuilding locksRotational axisLocking mechanism

The present invention relates to a low-pressure container (7) for a refrigerator and a refrigerator having such low-pressure container. The low-pressure container (7) comprises: a main body (8); a door (10); a locking mechanism (34, 44) for locking the door (10) with the main body (8) when the door (10) is in a closed position, wherein the locking mechanism (34, 44) comprises at least a first mating part (34) located on the door (10) and a second mating part (44) located on the main body (8) and engaged and locked with the first mating part (34); and a handle (32) which is rotatable around a first rotational axis (X) and drives the first mating part (34) to rotate. According to the present invention, the low-pressure container further comprises a transmission mechanism (901, 902) by which the handle (32) drives the first mating part (34) to rotate around a second rotational axis (Y), and wherein the second rotational axis (Y) is not aligned with the first rotational axis (X).

Owner:BSH ELECTRICAL APPLIANCES JIANGSU

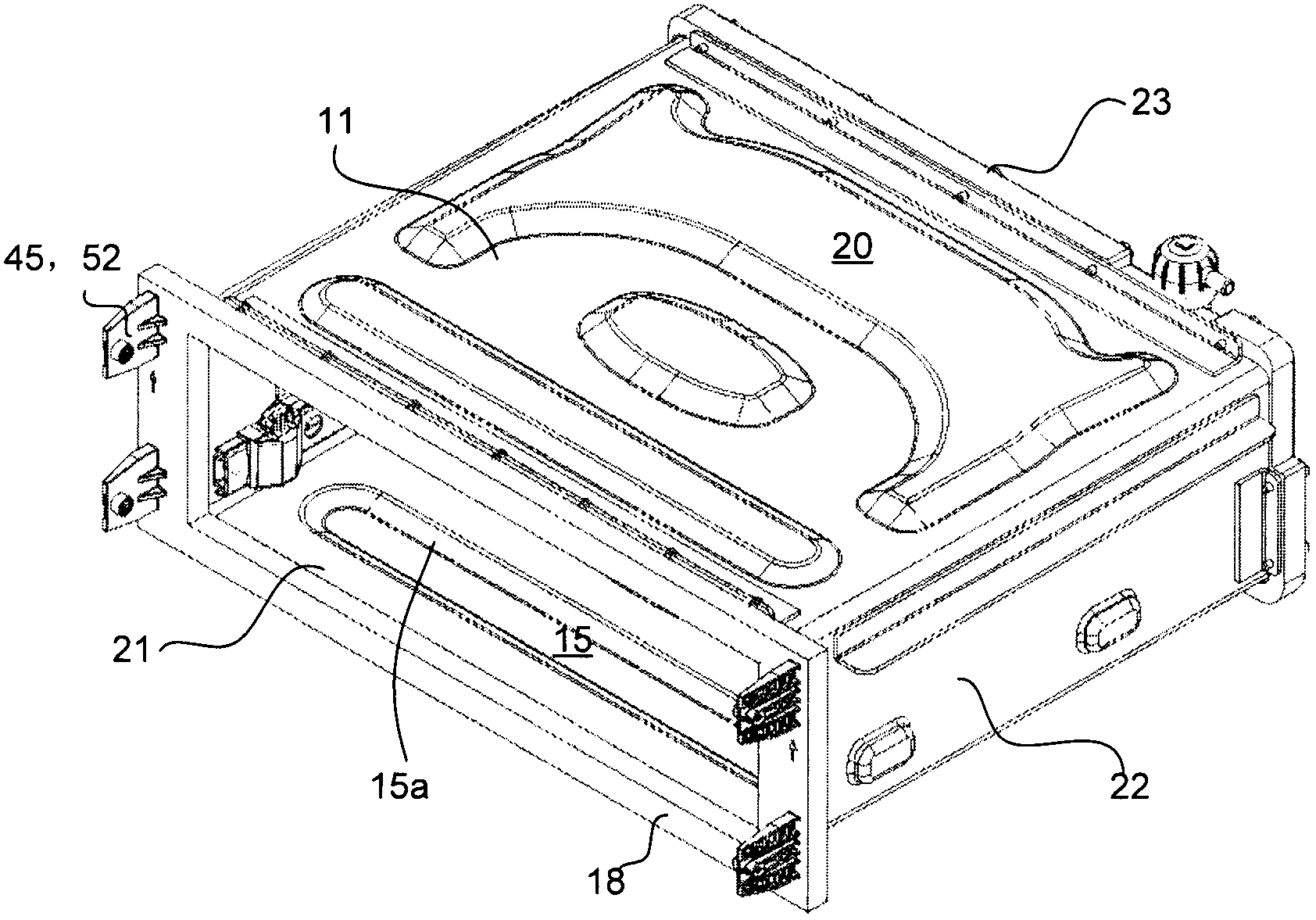

Partial discharge detection simulation training system

ActiveCN107067859AStable environmentThe result is stableCosmonautic condition simulationsEducational modelsControl signalHigh pressure

The invention relates to a partial discharge detection simulation training system, which comprises multiple groups of distribution network equipment, a simulation control unit and simulation terminals, and is characterized in that multiple groups of simulation terminals are distributed and installed in each group of distribution equipment; the simulation control unit sends control signals and on-off signals with specified intensity to one or more groups of simulation terminals of the distribution equipment; and the simulation terminals realize startup or shutdown according to the on-off signals sent by the simulation main control unit, and output high voltage loading free partial discharge signals with predetermined amplitude according to the control signals sent by the simulation main control unit. The partial discharge detection simulation training system overcomes problems and defects of lack of real scenes, lack of assessment links, existence of potential safety hazards and inability of performing united training for various partial discharge states of existing partial discharge training equipment.

Owner:吴笃贵 +1

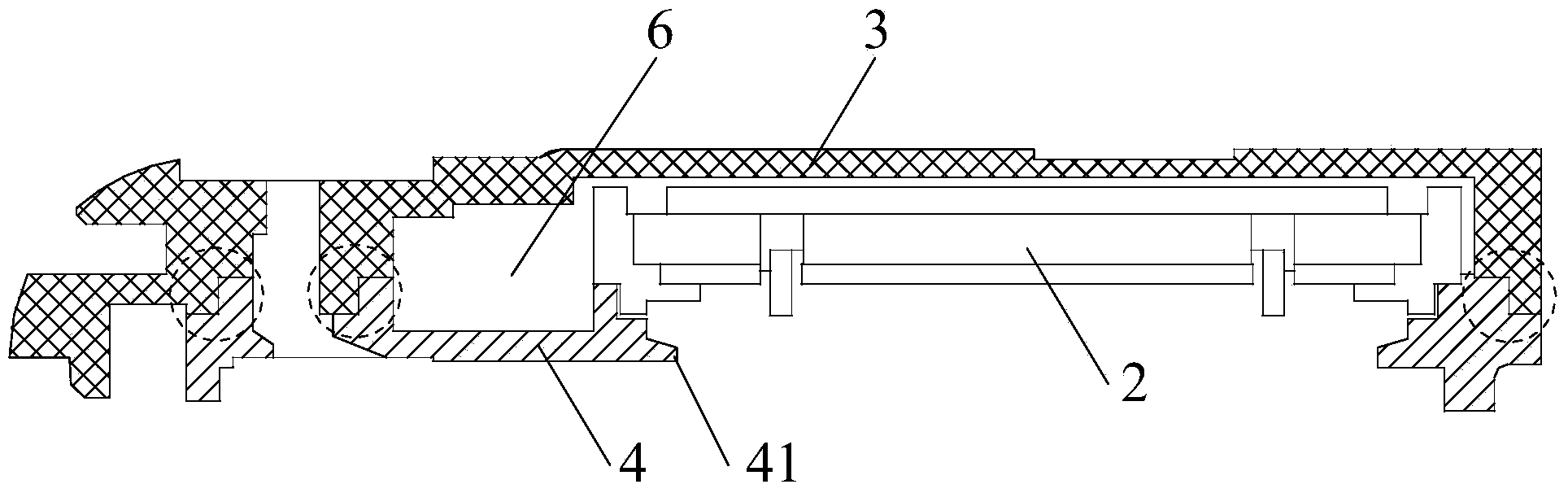

Pressure-sensitive sensor and method for manufacturing the same

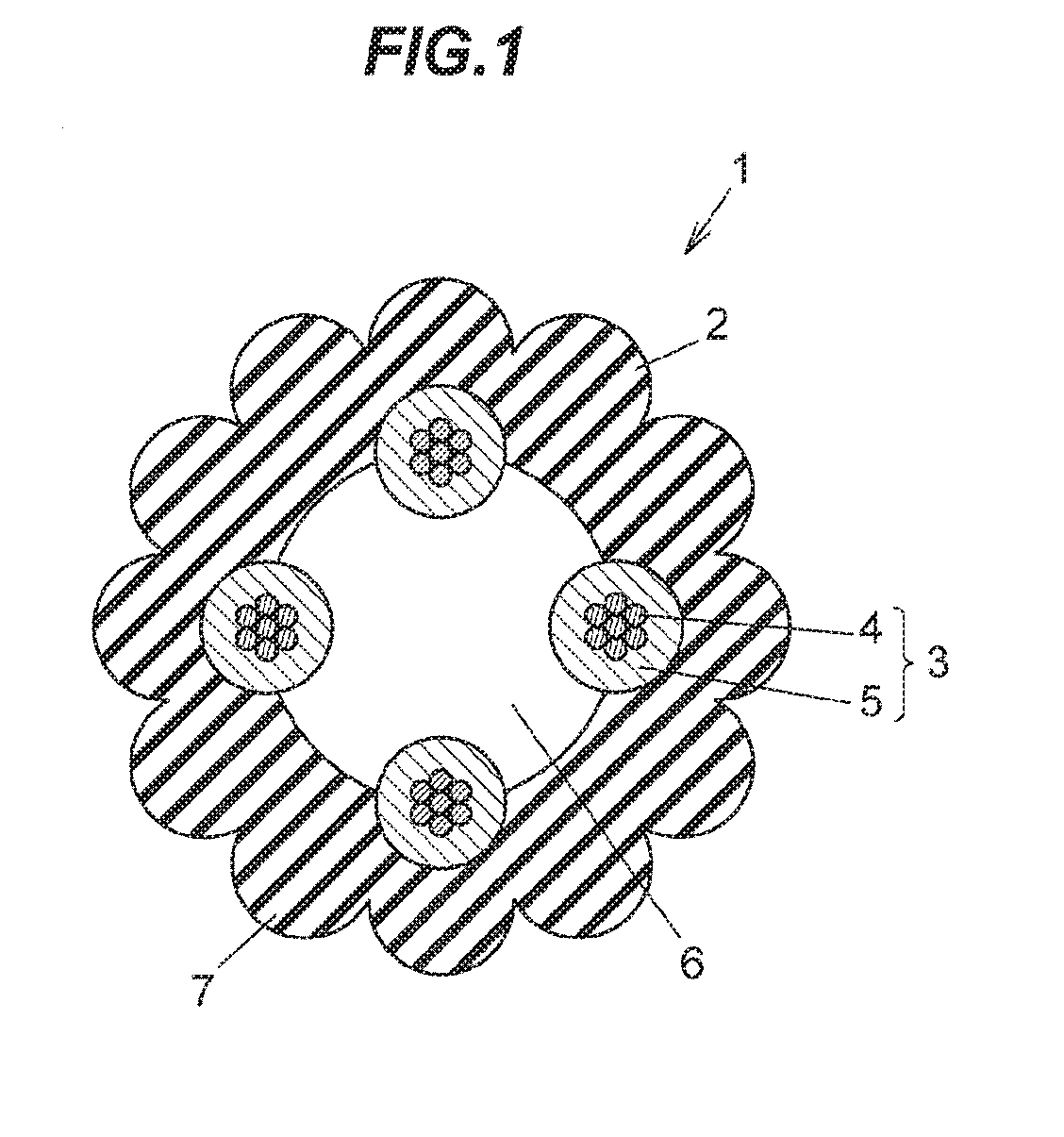

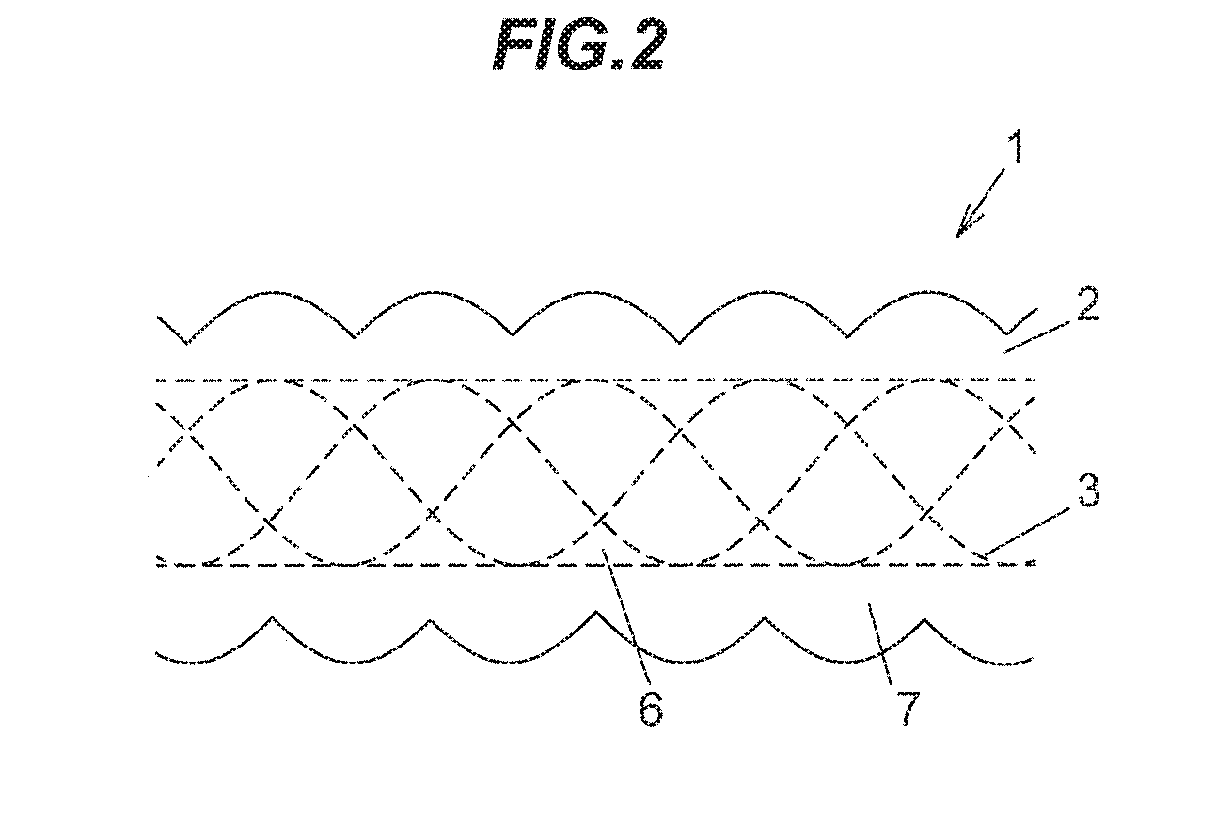

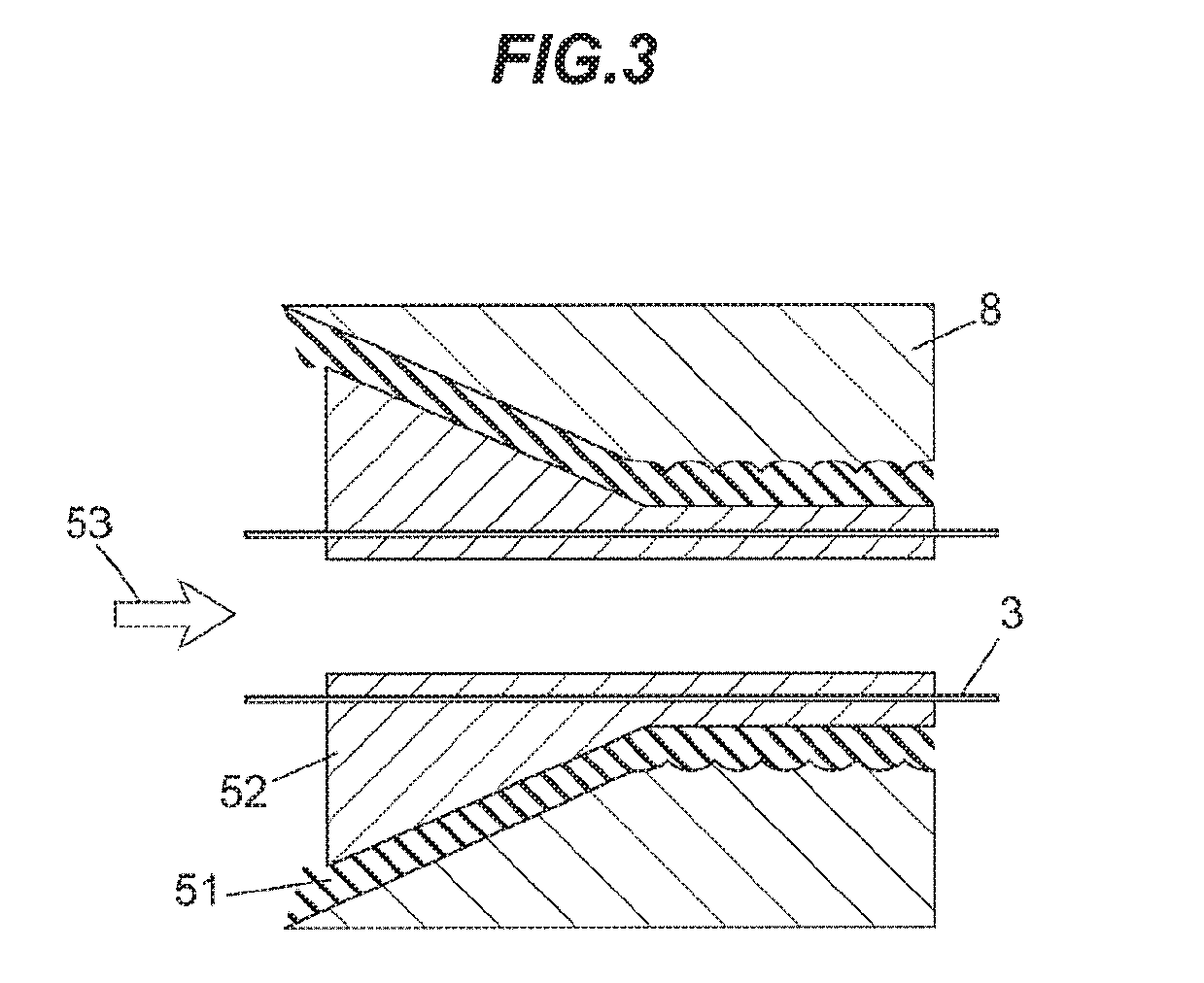

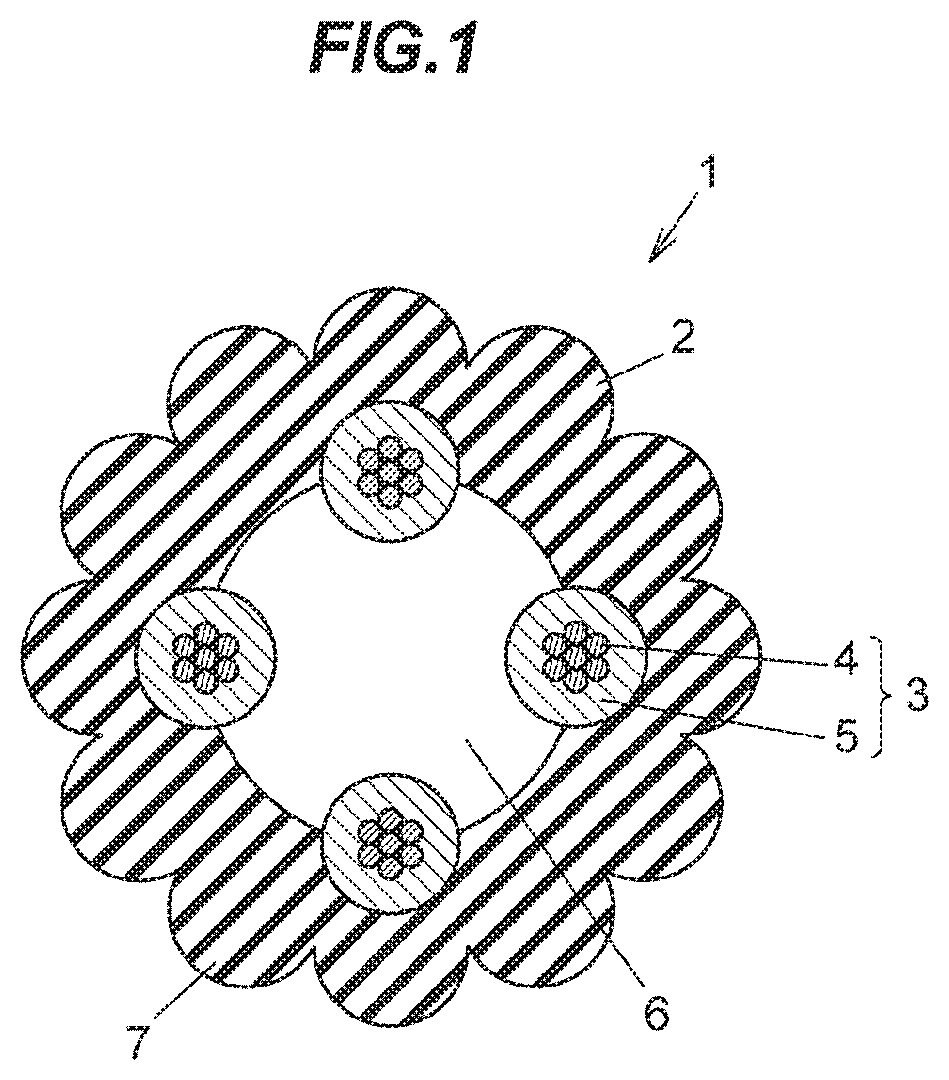

ActiveUS20190178729A1Set freeLow cost manufacturingWires contactsNon-conductive material with dispersed conductive materialBiomedical engineeringHelix

A pressure-sensitive sensor includes a hollow tubular member including an elastic insulation, plural electrode wires spaced from one another and held on an inner circumferential surface of the tubular member, and helical ribs formed on at least one of inner and outer circumferential surfaces of the tubular member along a longitudinal direction thereof. The electrode wires are helically arranged along the longitudinal direction. A helical direction of the helical ribs of the tubular member is a same as a helical direction of the helically-arranged electrode wires.

Owner:HITACHI METALS LTD

Pressure-sensitive sensor including a hollow tubular member of an elastic insulation

ActiveUS10890495B2Set freeLow cost manufacturingWires contactsNon-conductive material with dispersed conductive materialStructural engineeringMechanical engineering

A pressure-sensitive sensor includes a hollow tubular member including an elastic insulation, plural electrode wires spaced from one another and held on an inner circumferential surface of the tubular member, and helical ribs formed on at least one of inner and outer circumferential surfaces of the tubular member along a longitudinal direction thereof. The electrode wires are helically arranged along the longitudinal direction. A helical direction of the helical ribs of the tubular member is a same as a helical direction of the helically-arranged electrode wires.

Owner:HITACHI METALS LTD

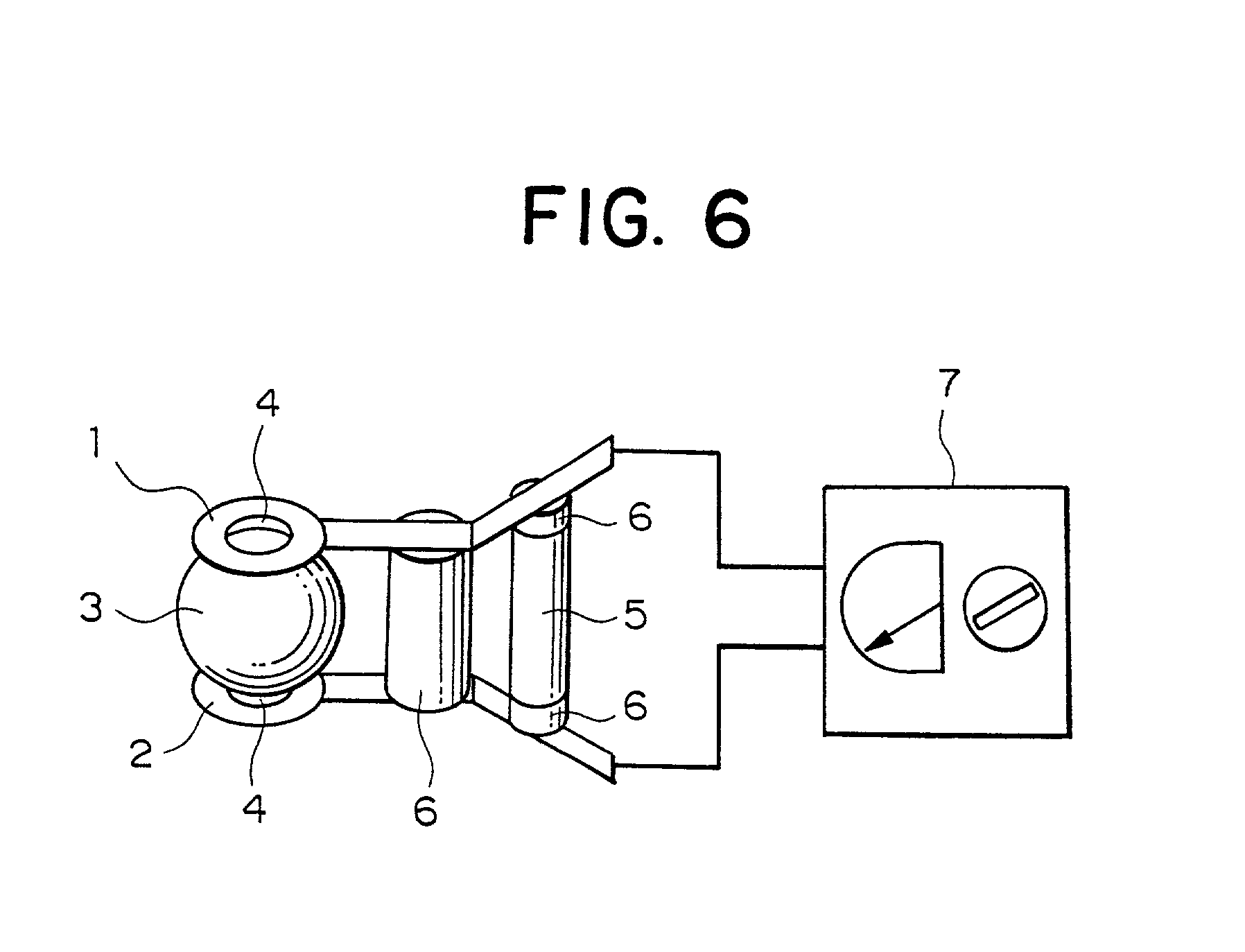

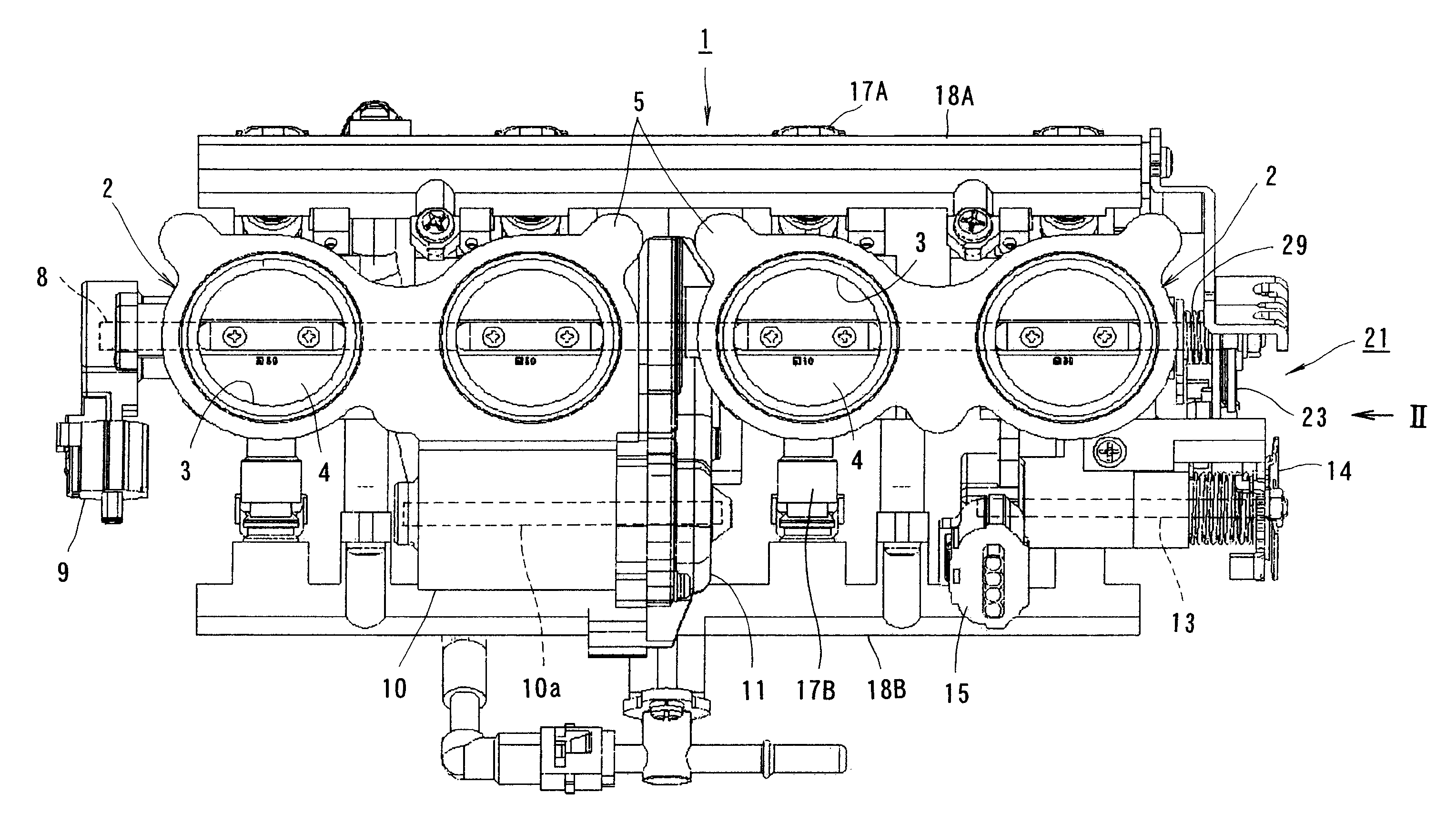

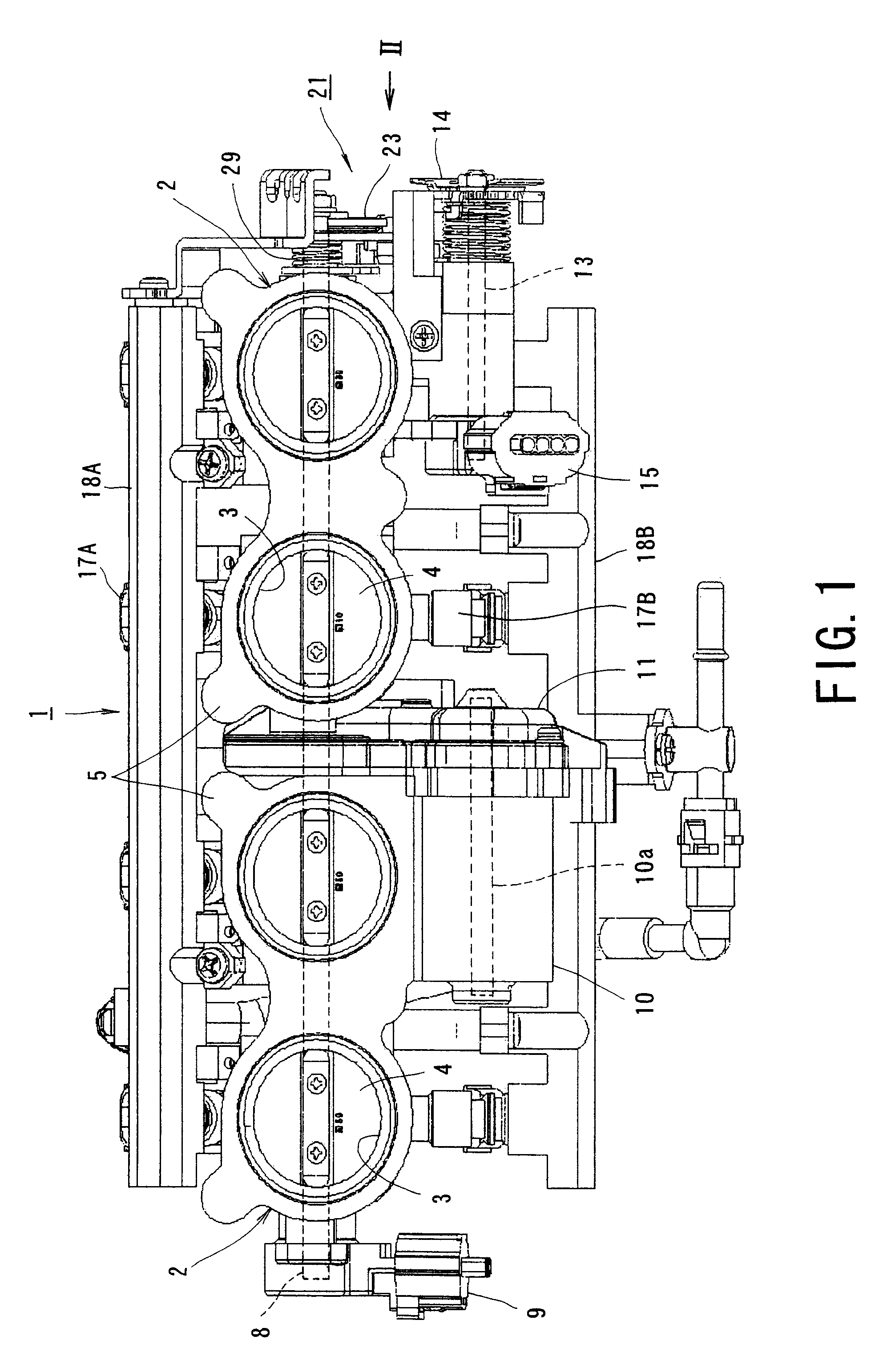

Electronically controlled throttle valve unit

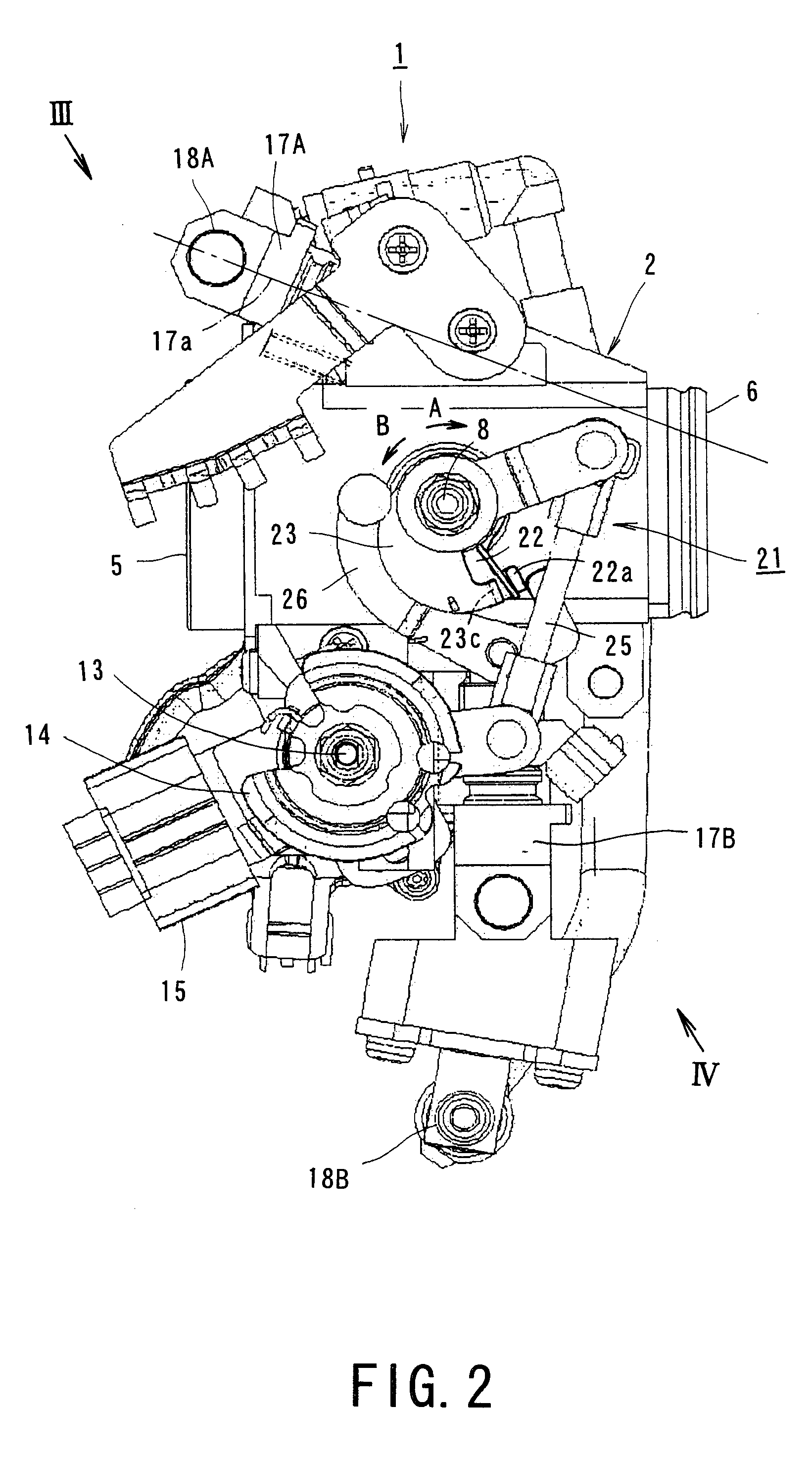

InactiveUS7490589B2Increased durabilityHigh setting freedomEngine controllersMachines/enginesCamActuator

An electronically controlled throttle valve unit includes a valve shaft supported by a throttle body, a throttle valve provided on the valve shaft rotatably therewith, an actuator for controlling the valve shaft, and a mechanical valve opening / closing mechanism. The mechanical valve opening / closing mechanism comprises: a valve lever provided on the valve shaft rotatably therewith; a cam lever supported rotatably with respect to the valve shaft so as to be directly operated through a throttle operation; and a link lever supported rotatably by the throttle body and transmitting a rotation of the cam lever in a direction of opening the throttle valve to the valve lever so as to rotate the valve lever and the valve shaft in a throttle valve opening direction with a predetermined rotation angle characteristics.

Owner:SUZUKI MOTOR CORP

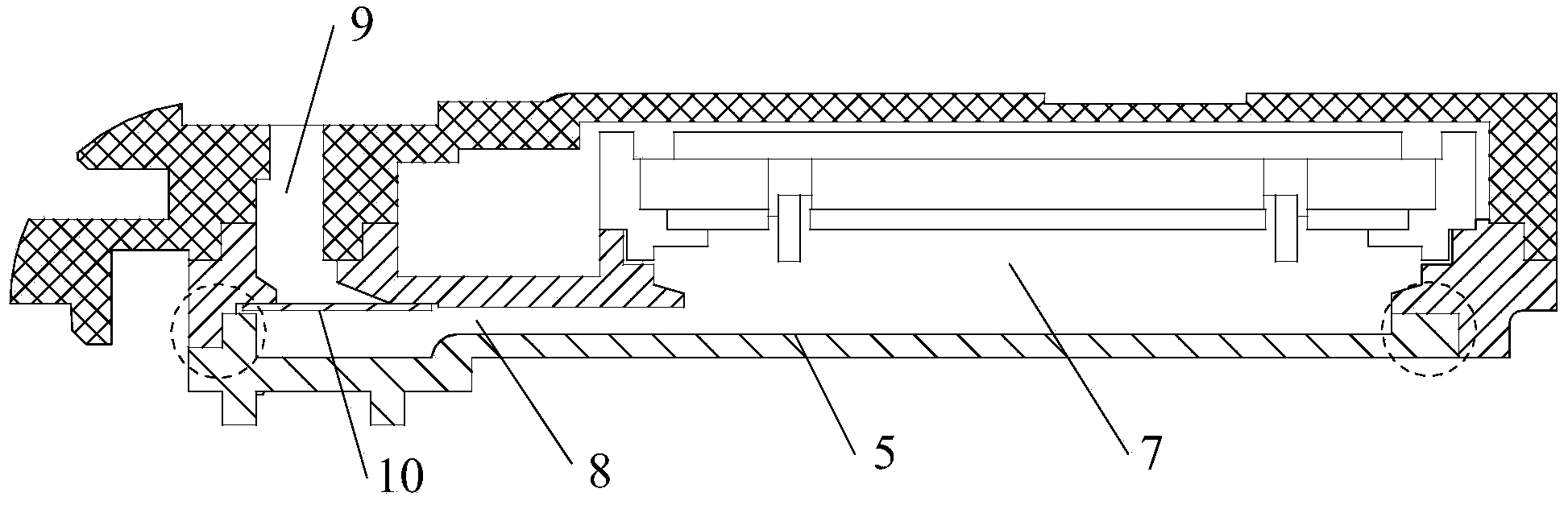

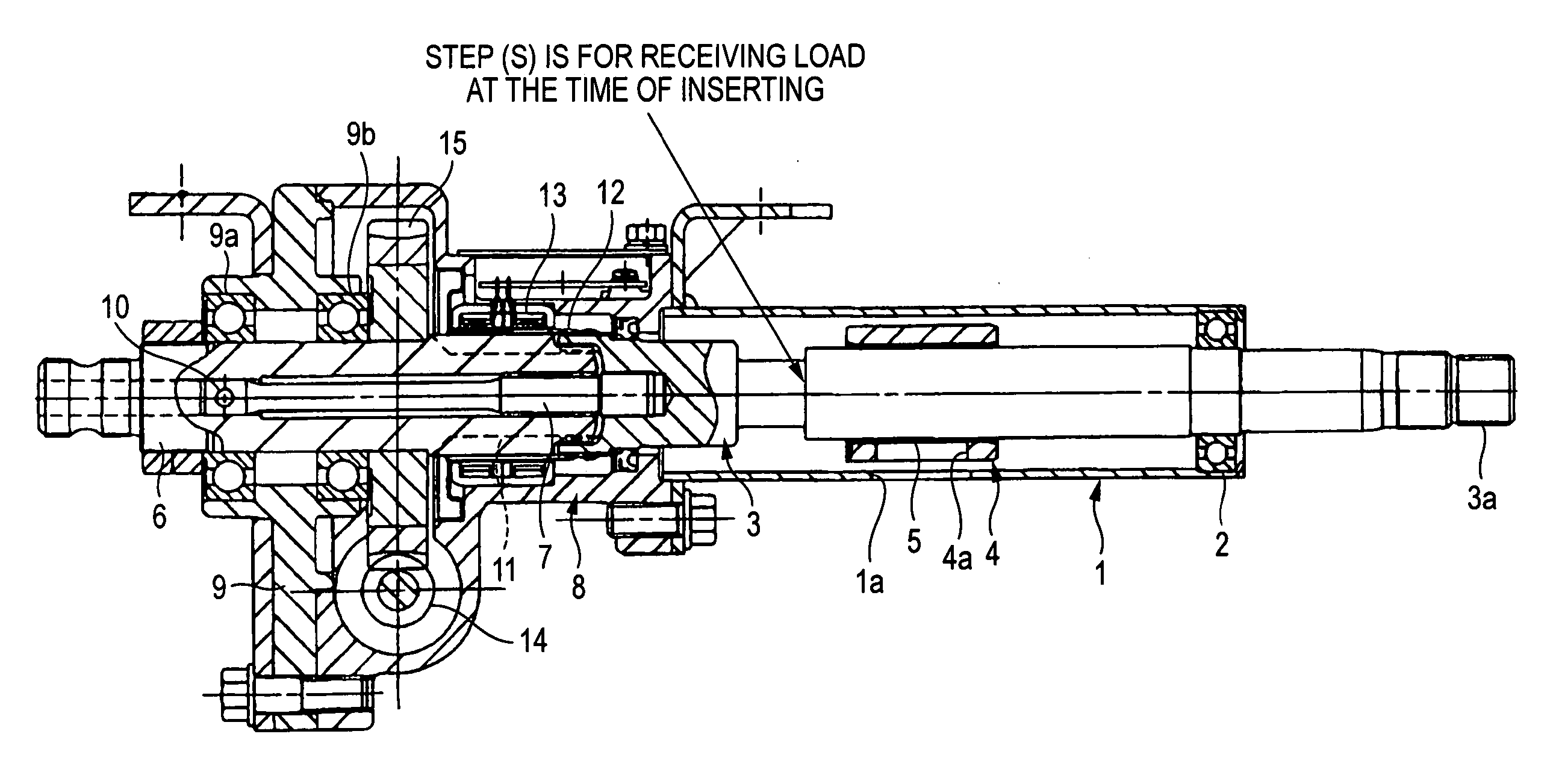

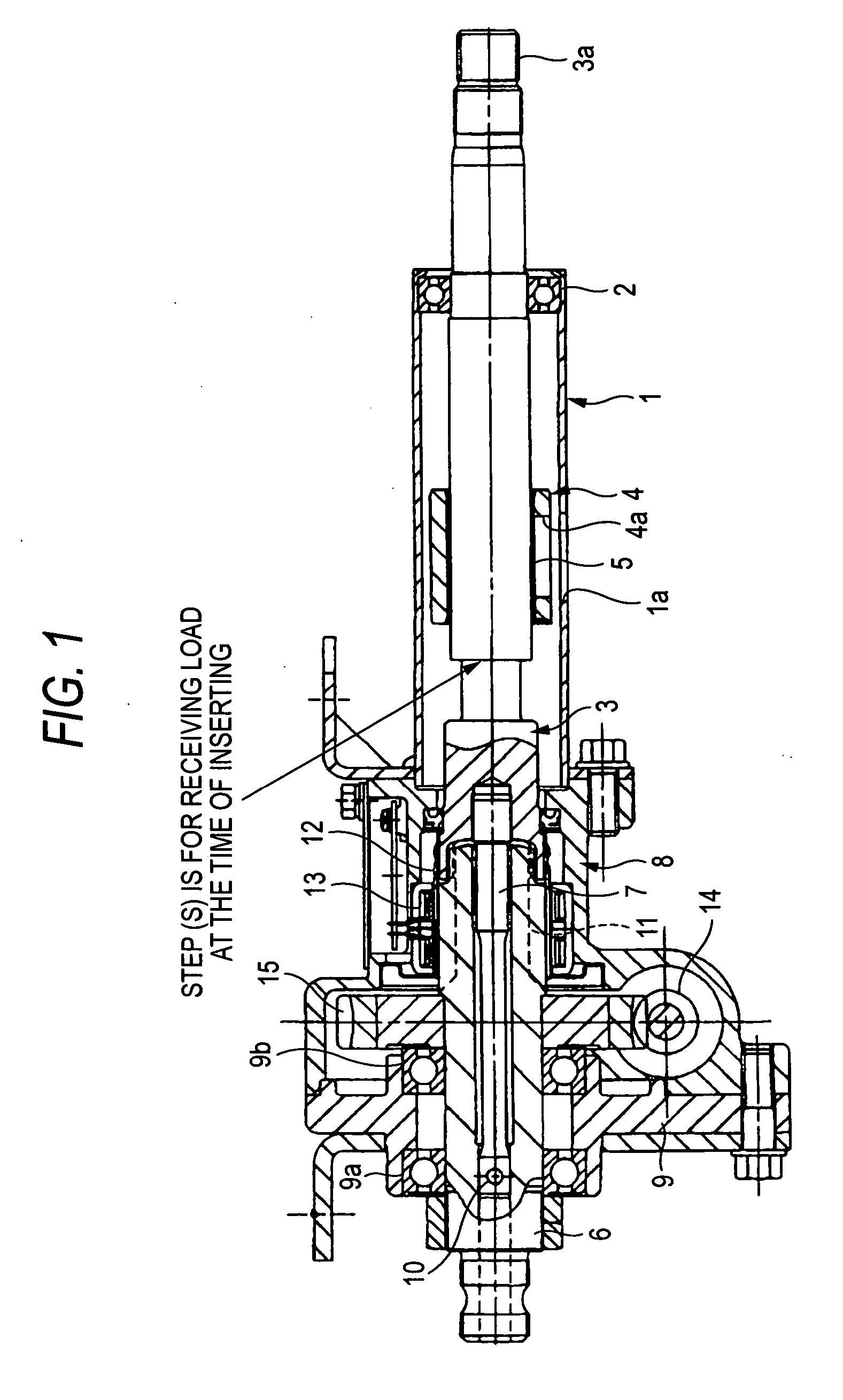

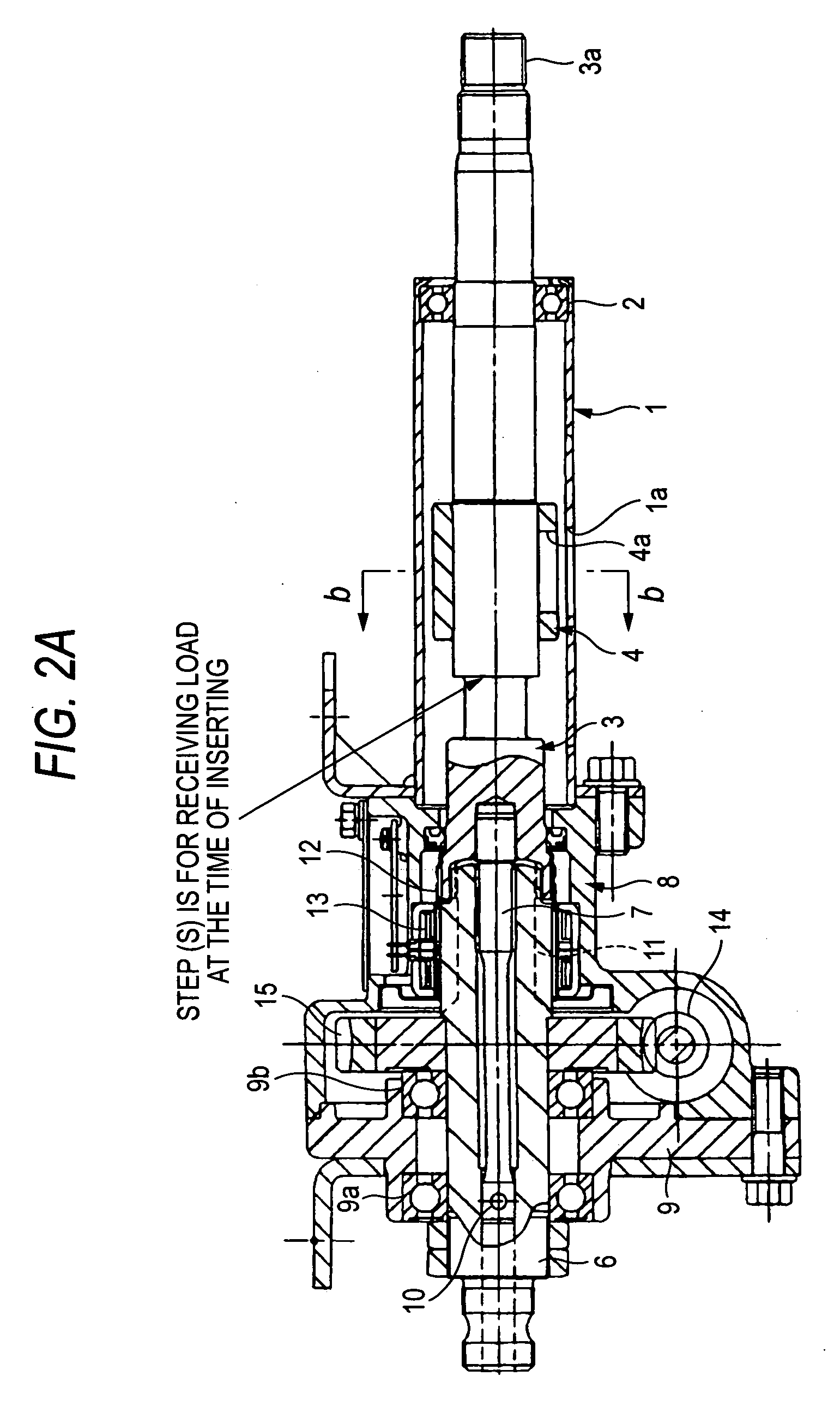

Vehicle Steering System And Assembling Method Thereof

A vehicle steering system includes: a sensor mechanism having a sensor coil 13; an antitheft device which has a key lock collar 4 and is disposed on the rear side of the sensor mechanism, in which the outer diameter of the key lock collar 4 of the antitheft device is larger than the inner diameter of the sensor coil 13 of the sensor mechanism; and a member 15 which has a diameter larger than the inner diameter of the sensor coil 13 and which is disposed on the front side of the sensor mechanism, wherein a steering shaft 3 or 6 to which the member 15 having the large diameter is fixed is inserted to the sensor coil 13 and then the key lock collar 4 is fitted to the steering shaft 3 or 6.

Owner:NSK LTD

Full-automatic spring shaped coil winder

InactiveCN102403121BHigh precisionImprove qualityFilament handlingCoils manufactureWinding machineControl system

The invention discloses a full-automatic spring shaped coil winder which has simple structure and convenient operation, comprising a tank body, wherein the inside of the tank body is provided with a control system. A mobile mechanism, a winding mechanism and a guide rail mechanism are installed on the tank body. The mobile mechanism includes a bearing seat, a wire pressing device and a wire cutting device on the bearing seat; the winding mechanism comprises a rotary shaft for winding the copper wire into a coil. The guide rail mechanism includes a screw rod, two guide rails and two guide sliding blocks matched with two guide rails. The invention is automatically loaded and unloaded, which has the advantages of high degree of automation, controllable range, automatic winding and cutting process, ordered wire distribution, convenient operation and adjustment, stable and reliable performance, correct winding turns and the same standard of manufactured coils and high production efficiency.

Owner:康展电子(东莞)有限公司

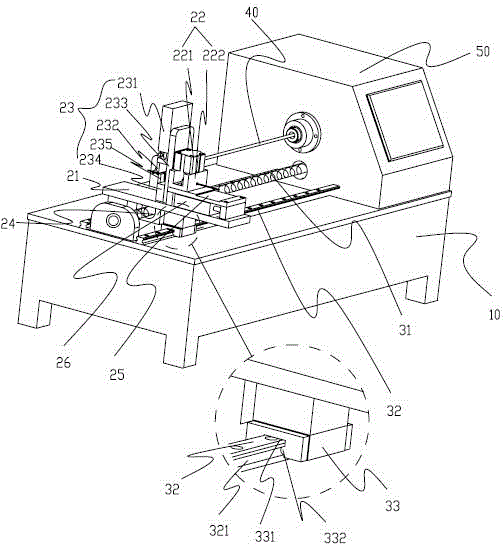

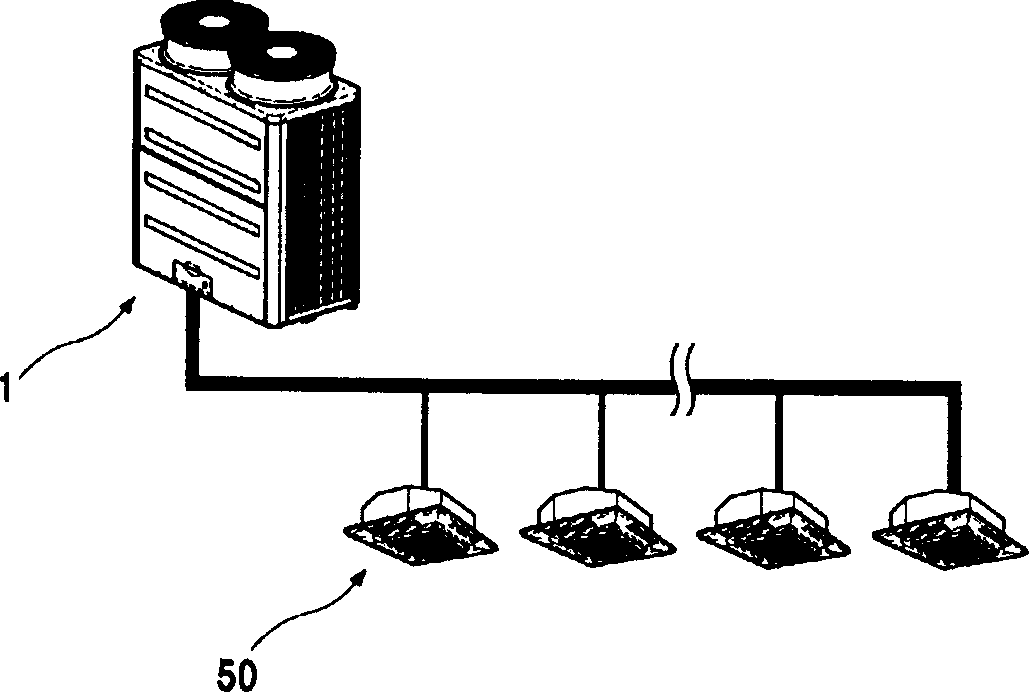

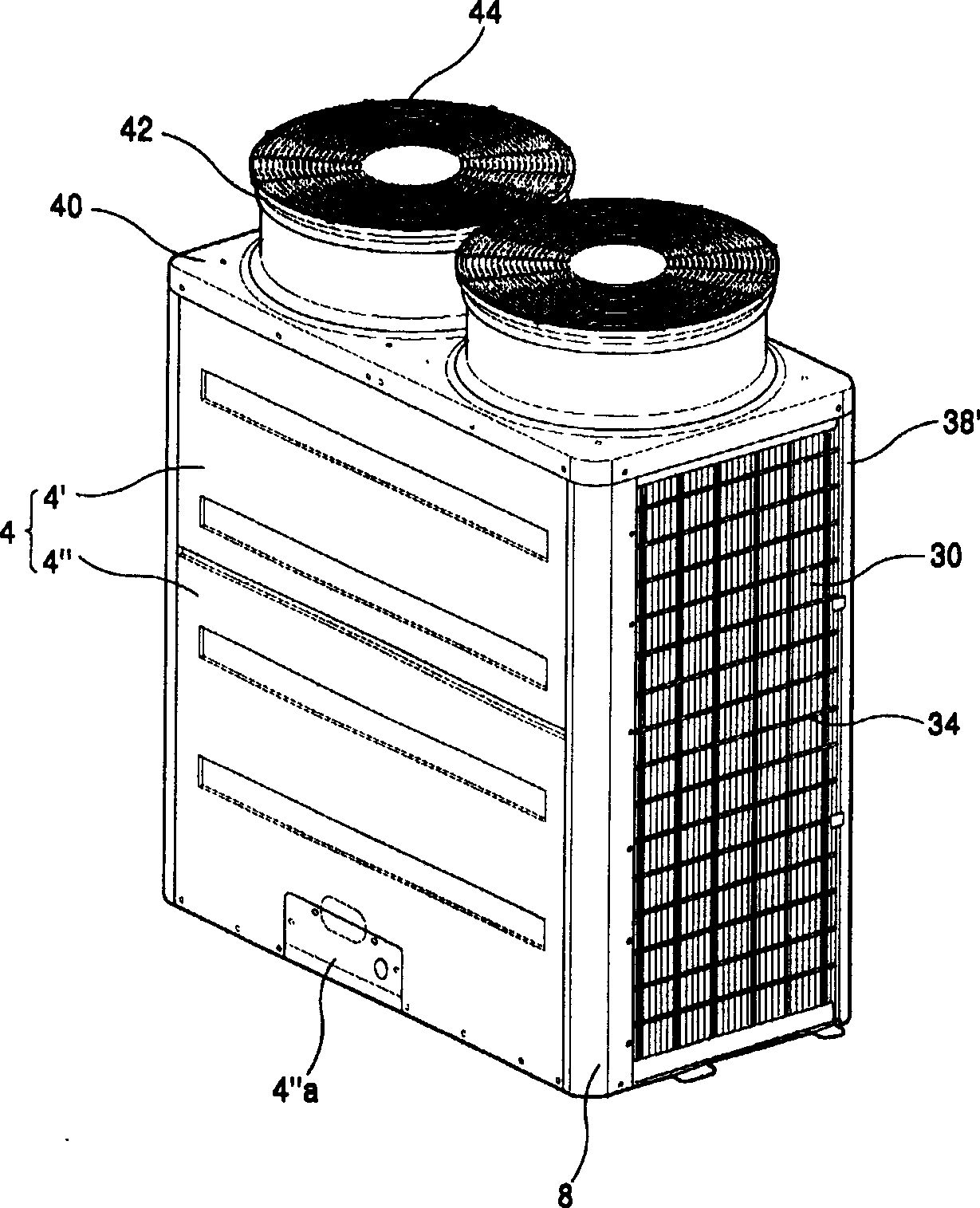

One dragging more air conditioner

InactiveCN1782547AEasy to set upLarge capacityCompression machines with several condensersCompression machines with several evaporatorsProcess engineeringHeat exchanger

The present invention discloses multi-split air conditioner with compressor with several evaporation loops. The multi-split air conditioner includes one or more outdoor unit with compressor, liquid storage, outdoor heat exchanger and outdoor solenoid valve; several indoor units with indoor heat exchanger, expansion valve, branched gas pipe and branched liquid pipe; single common liquid pipe set between the outdoor unit and indoor units for liquid refrigerant to flow through; single common gas pipe set between the outdoor unit and indoor units for gas refrigerant to flow through; and high and low pressure common pipe set between compressors of different outdoor units for homogenizing refrigerant. The present invention has less pipes, simple operation, facilitated installation of the system, high overall heat exchange efficiency and other advantages.

Owner:LG ELECTRONICS (TIANJIN) APPLIANCES CO LTD

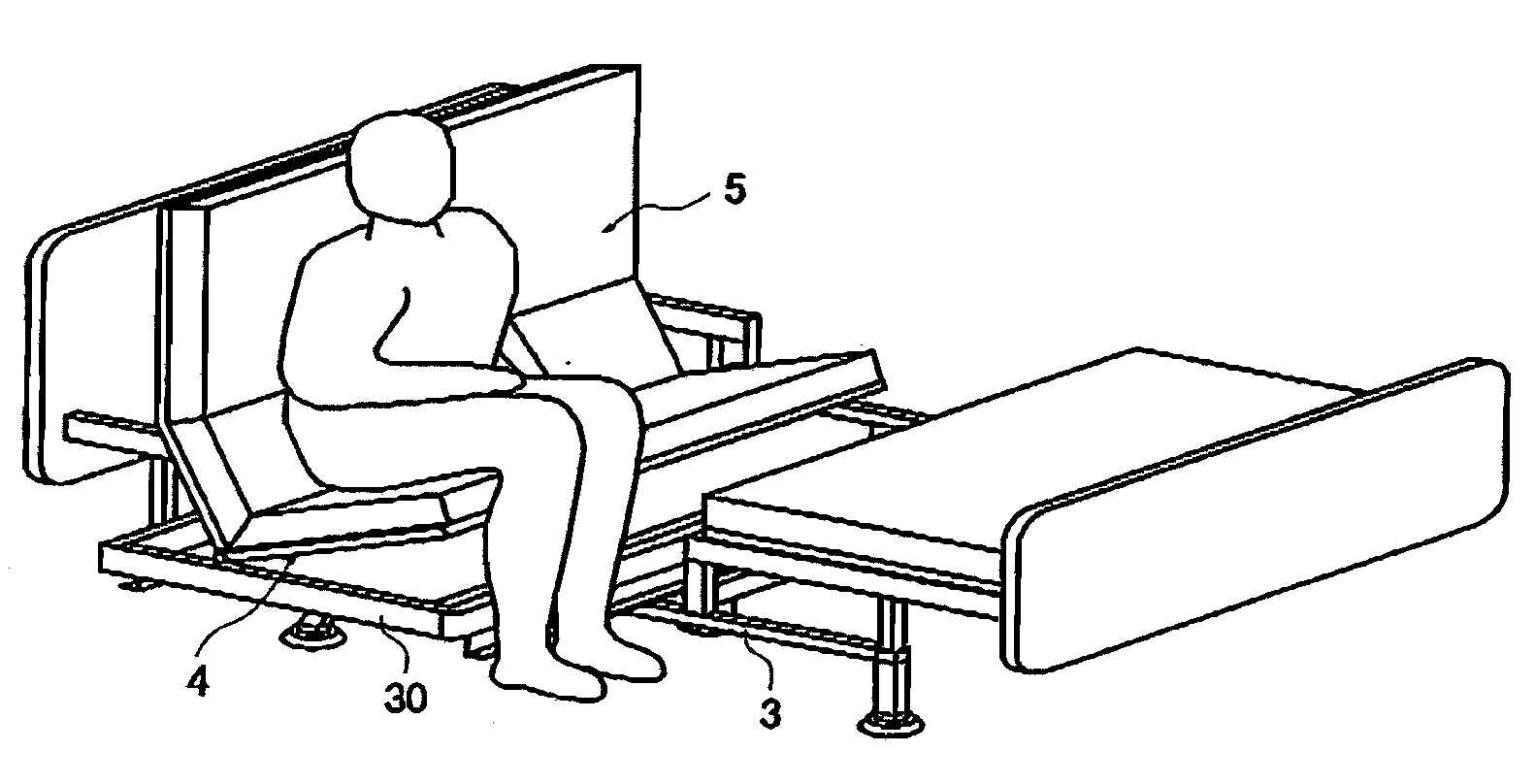

Bed for allowing posture for sitting on chair to be taken

The invention provides a bed on which a patient and so forth can take a posture for sitting on a chair, in particular, a bed for allowing the posture for sitting on a chair to be taken, effectively usable even by those having the back in the shape of the round back, Kyphosis or the like.

Owner:NOMURA KYOZO

Multicast control

ActiveUS7961750B2Set freeTime-division multiplexTwo-way working systemsService controlControl system

A method and arrangement for optimizing bandwidth usage in a Multicast Services Control System (MSCS), which transports digital information in a multicast stream from a broadband network to a Set Top Box (STB) connected to a terminal TV. When the terminal TV is disabled, and can no longer utilize the multicast stream, the terminal TV sends a terminal status signal to the STB indicating deactivation of the terminal TV. In response, the STB sends an IGMP leave report signal to the broadband network, which then ceases its transmission of the multicast stream to the STB.

Owner:TELEFON AB LM ERICSSON (PUBL)

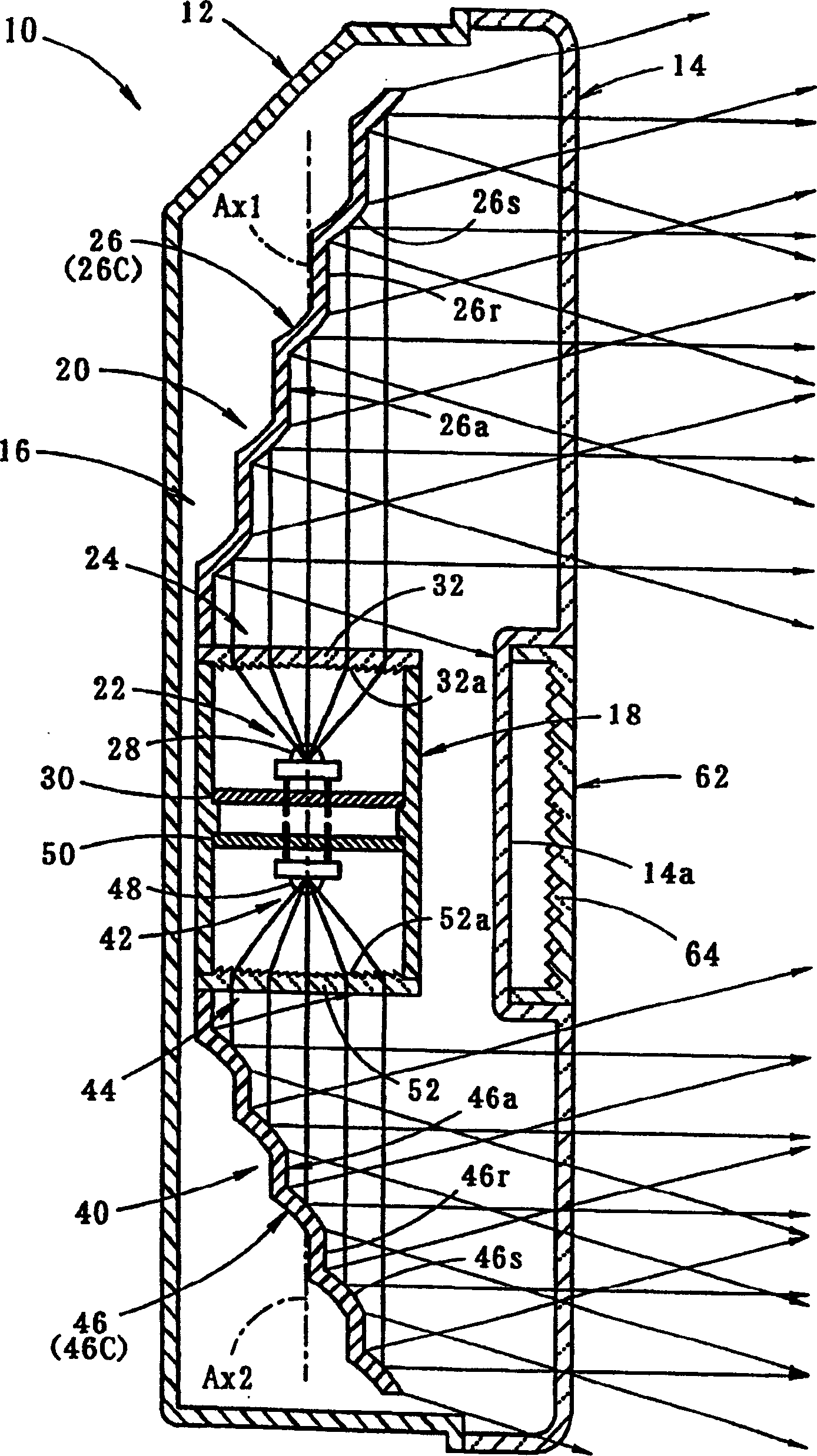

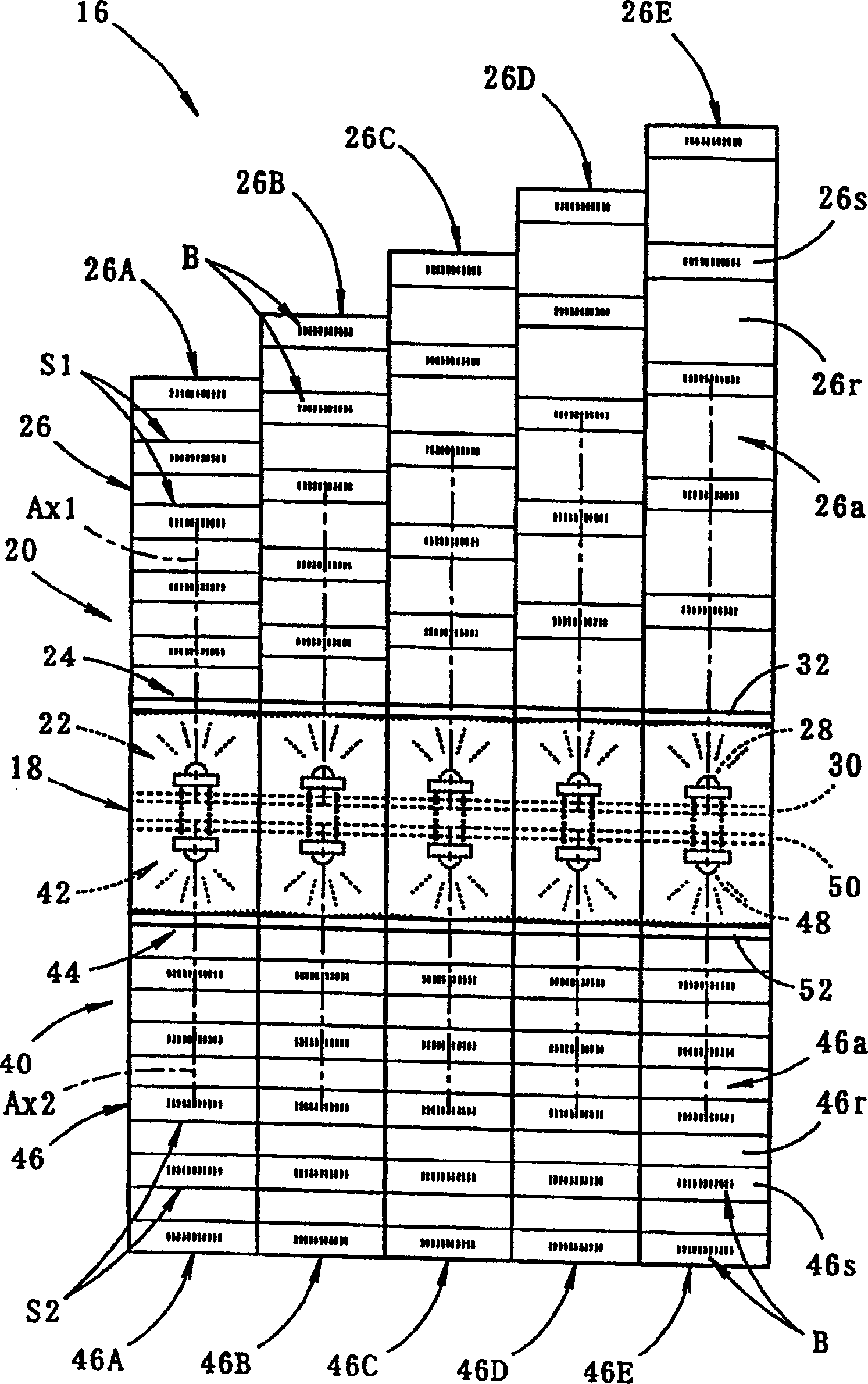

Vehicle lamp

InactiveCN1209570CBright reflective surfaceSet freePoint-like light sourceDisplay meansLight reflexFresnel lens

A lamp for a vehicle uses a plurality of LED light sources to irradiate light through indirect lighting, so that not only the entire reflecting surface of a reflector looks roughly the same brightness, but also the degree of freedom of the shape of the lamp is increased. In the vehicle lamp, a plurality of LED light sources (28, 48) are arranged back to back in a row to form first and second LED light source groups (22, 24). A plurality of Fresnel lenses (32, 52) that change the light from each LED light source (28, 48) into parallel light are arranged in a row for each LED light source group (22, 24) to converge into parallel light direction to form the first and second lens groups (24, 44). Also provided are first and second reflection mirrors (26, 46) for reflecting parallel light from each lens group (24, 44). In this way, not only the whole reflective surface of the reflector looks roughly the same brightness, but also the end shapes of the first and second reflectors (26, 46) can be relatively freely set.

Owner:KOITO MFG CO LTD

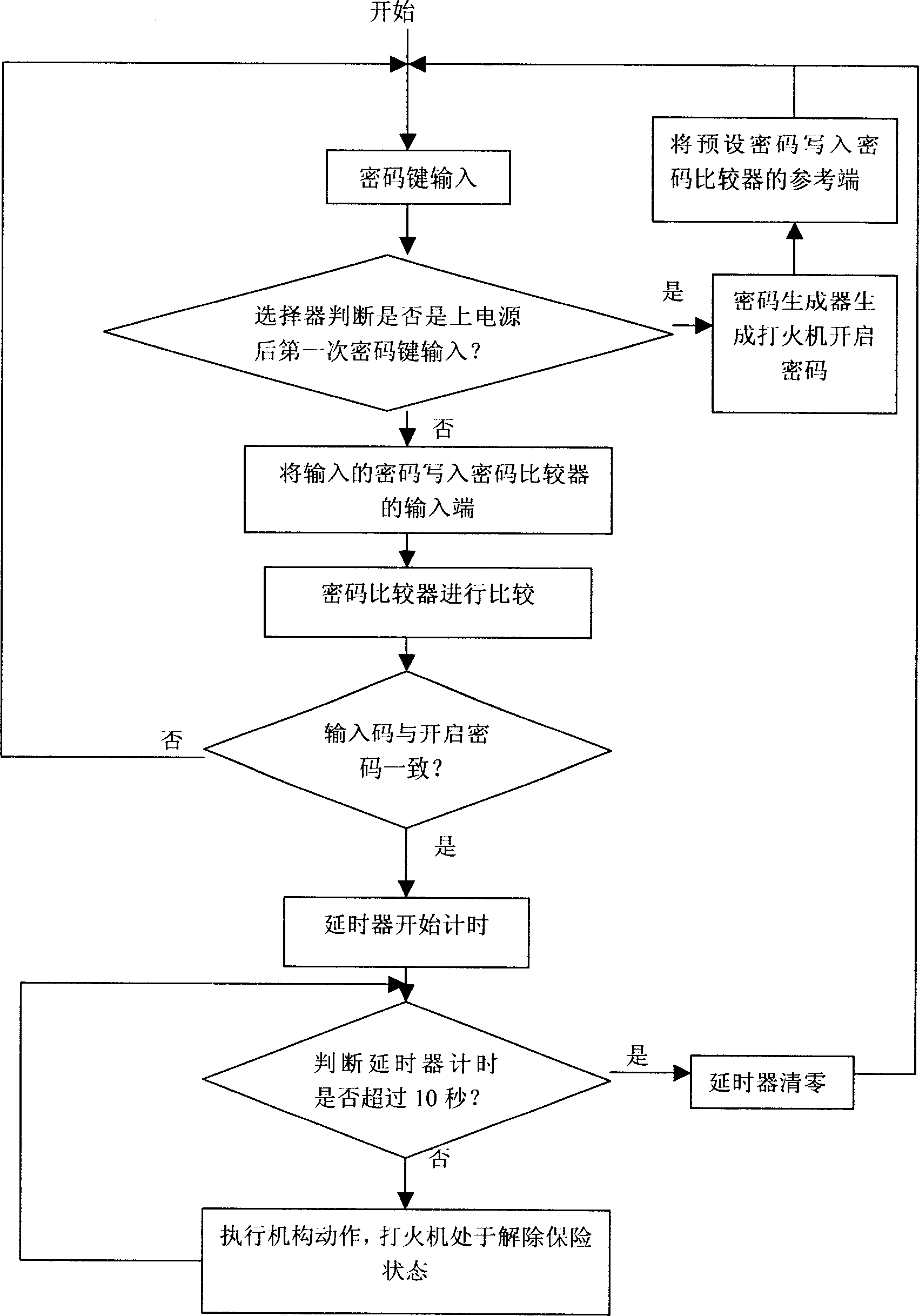

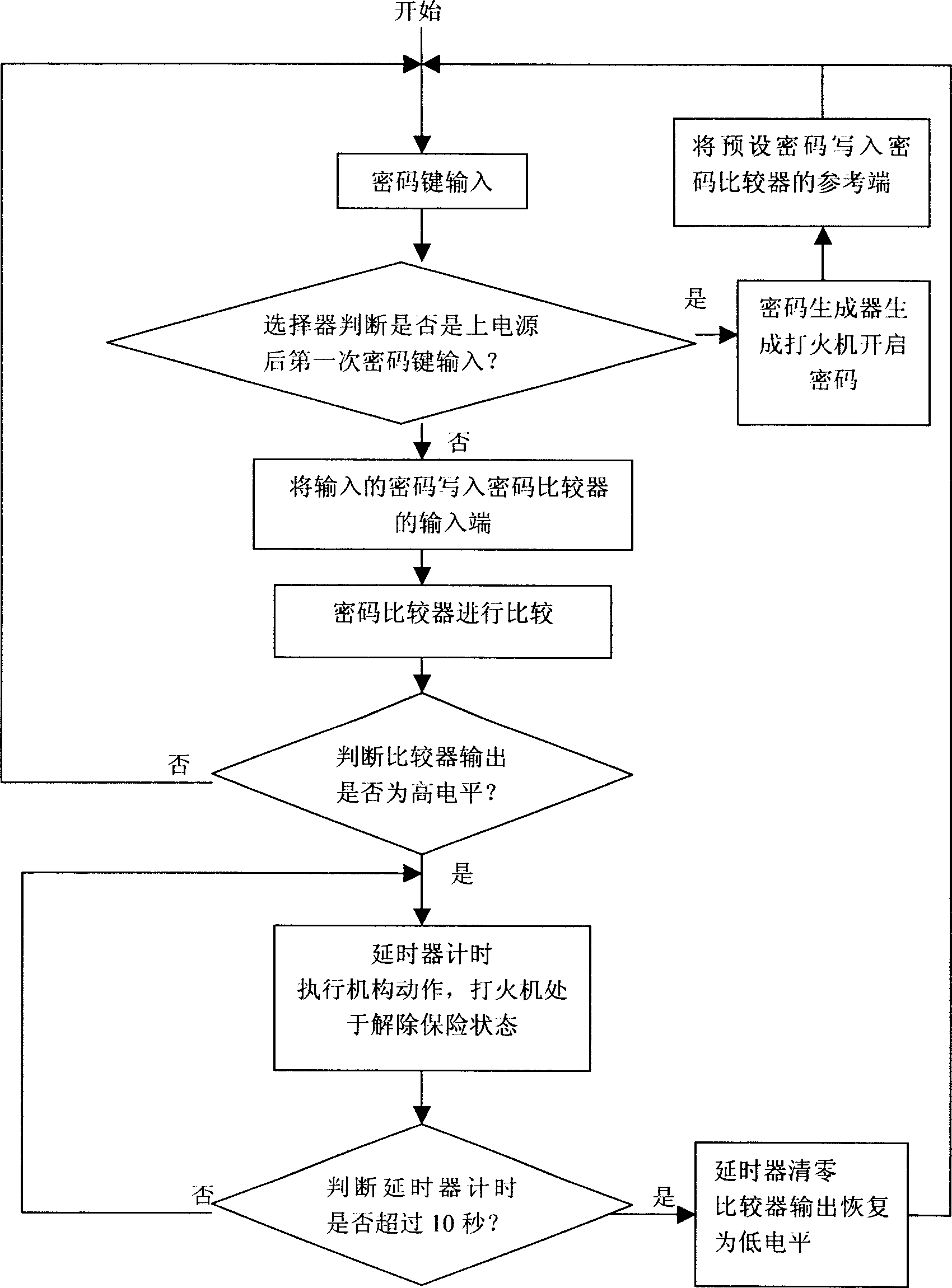

Lighter controlled by intelligent cipher

This invention relates to an igniter controlled by intellectual code, which comprises casing and sparking assembly, wherein the sparking assembly comprises epicranium, igniting button, electron high-voltage generator, liquid box with air drain, micro processor and safety actuator controlled by the micro processor; the micro processor comprises a selecting unit, a code creating unit, a code comparing unit, a time-delay unit setting the active time of releasing the safety mode; the consulting end of the code comparing unit is connected with the output of the code creating unit, and the output of the code comparing unit is connected with the actuator which is adapted to the igniting assembly. Said igniter can set code and recover safety condition automatically.

Owner:林勇

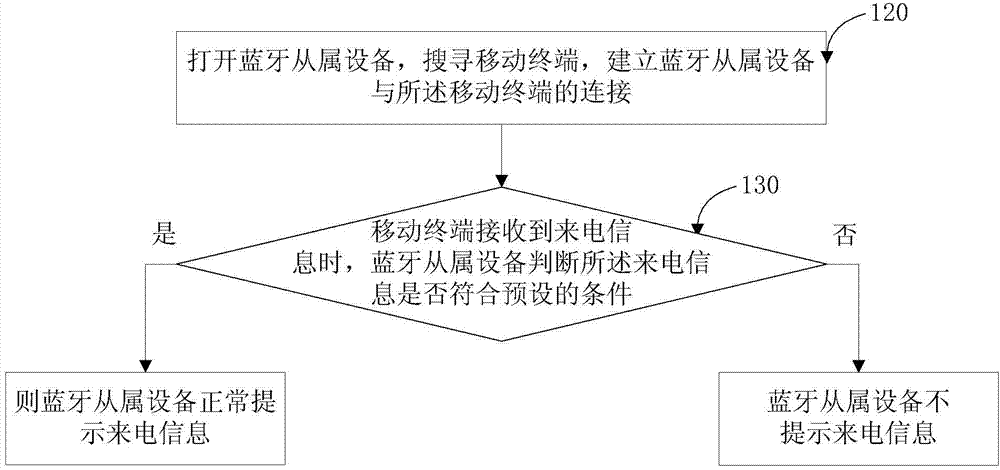

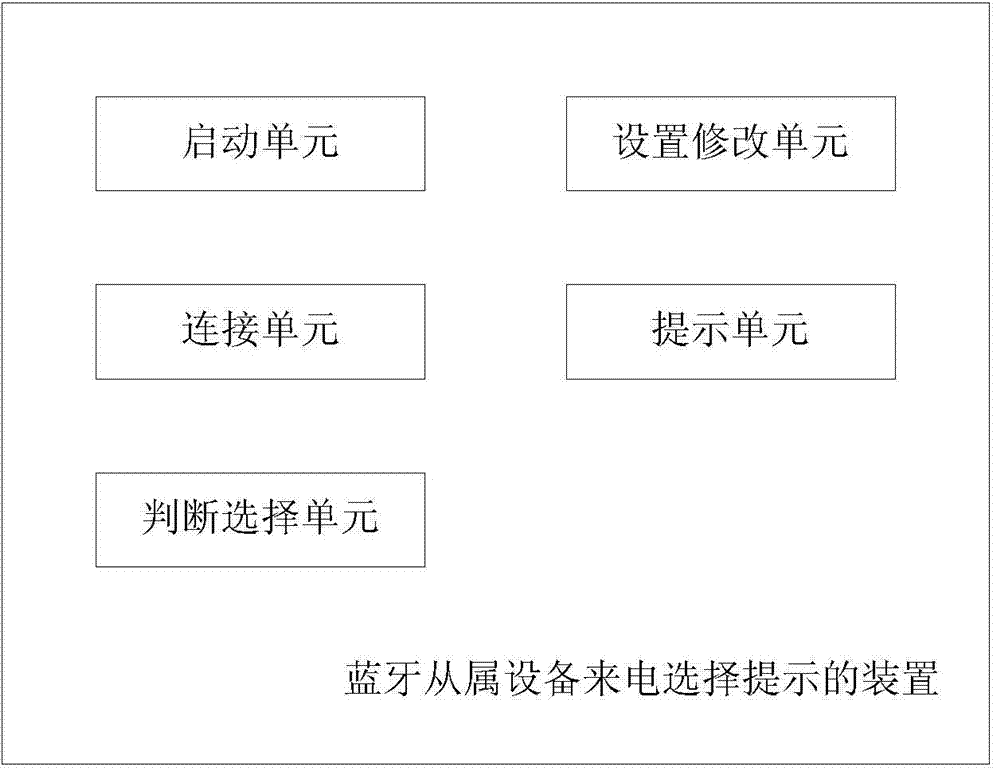

Bluetooth slave unit call selection prompting method and device

The invention relates to the field of Bluetooth technologies, and in particular relates to a Bluetooth slave unit call selection prompting method and a Bluetooth slave unit call selection prompting device. The method comprises the steps of: opening a Bluetooth slave unit, searching for a mobile terminal, and building connection between the Bluetooth slave unit and the mobile terminal; when the mobile terminal receives a call, the Bluetooth slave unit judges whether the call meets preset call selection prompting conditions, if yes, the Bluetooth slave unit prompts the call normally, otherwise, no prompt is given; According to the Bluetooth slave unit call selection prompting method and device, the call selection prompting conditions are set on the Bluetooth slave unit to intelligently filter unnecessary crank calls without setting through the mobile terminal, and can be freely set and modified on the Bluetooth slave unit at any time, thus being convenient to operate.

Owner:SHANGHAI DROI TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com