Automatic test system and method of electric micromirror

An automatic test system, electrothermal micromirror technology, applied in machine/structural component testing, optical instrument testing, optical performance testing, etc., can solve the problem of electrothermal micromirror without automatic test control system, etc., to achieve data storage and call Convenience, simple realization and high accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

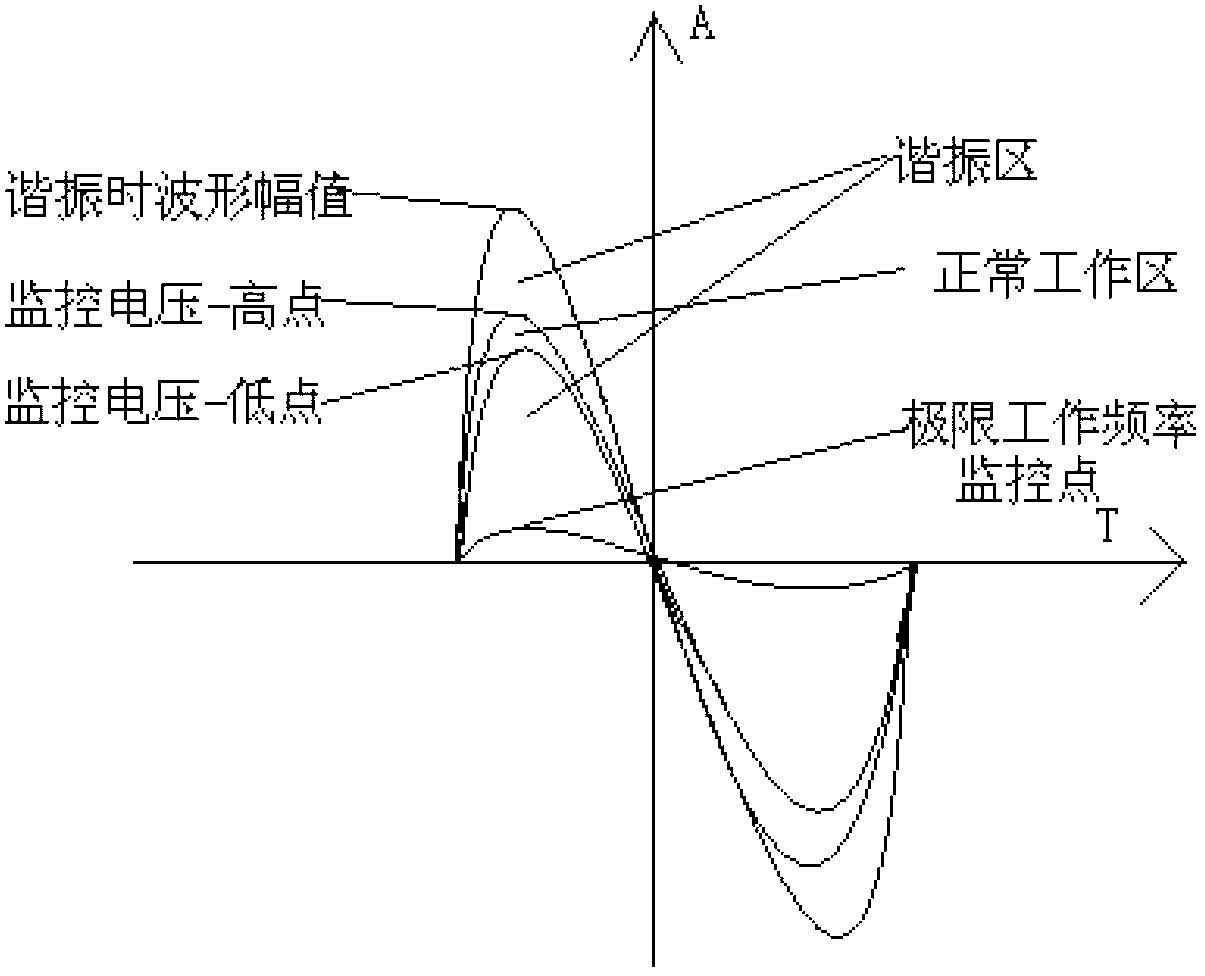

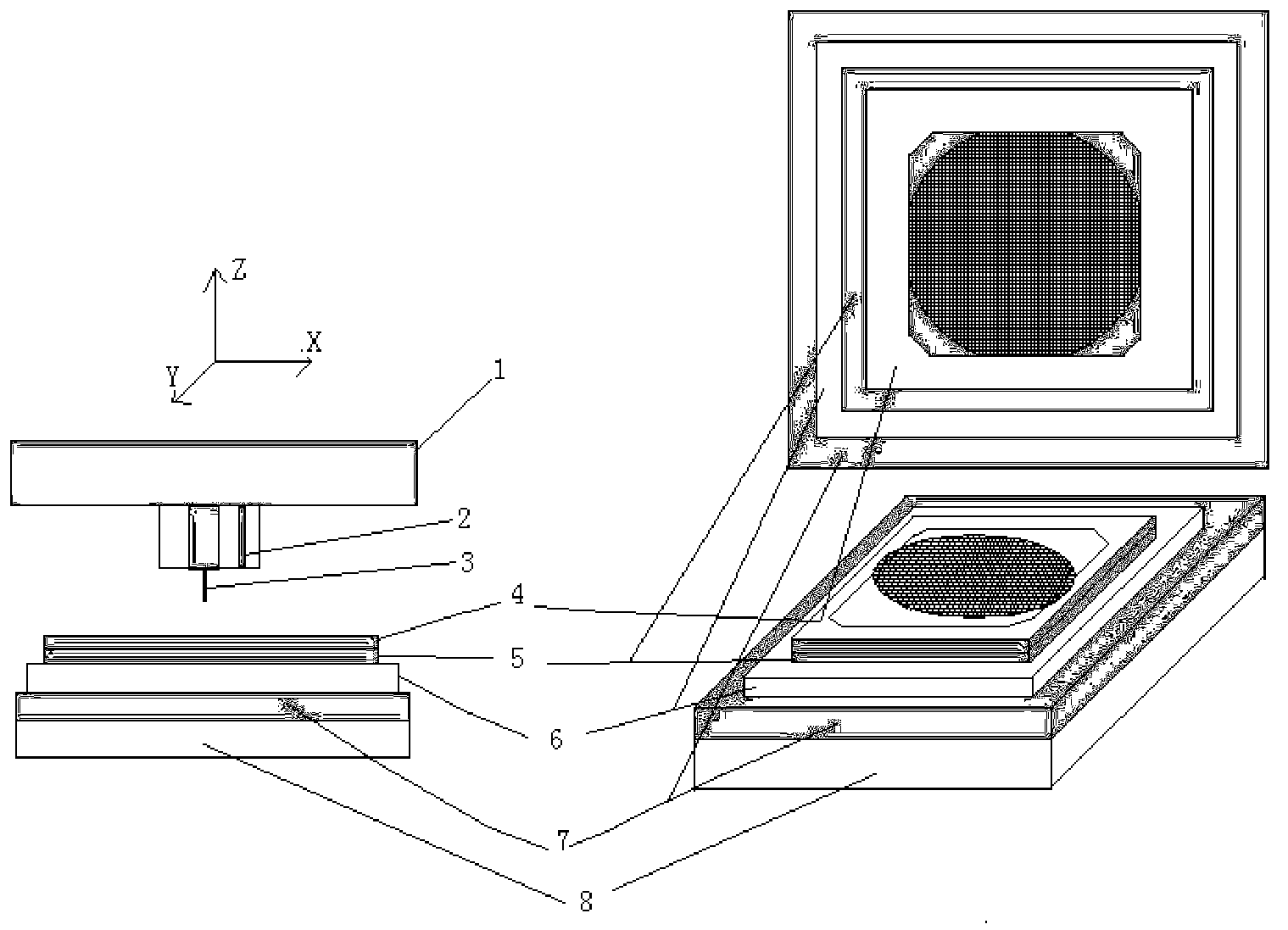

[0058] An automatic test system for an electrothermal micromirror, comprising an electric displacement platform, a needle for testing the electrothermal micromirror, a data acquisition system, and an optical path for an automatic test control system for the electrothermal micromirror.

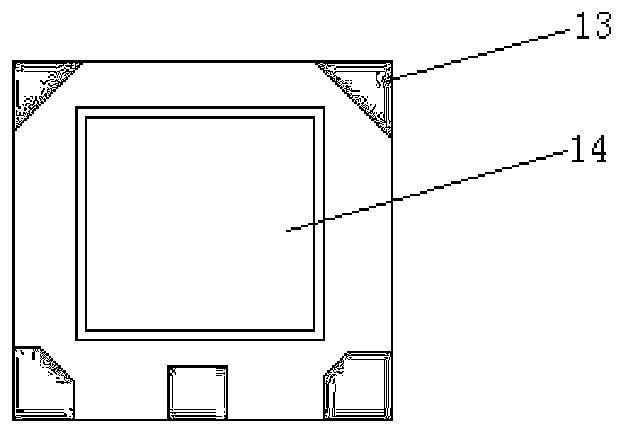

[0059] like figure 1 The electric displacement platform is used for placing the bare core wafer of the electrothermal micromirror, and can drive the wafer to move in the directions of X, Y, and Z axes. The platform includes a base 8 , an X-axis displacement platform 6 , a Y-axis displacement platform 7 , and a Z-axis displacement platform 1 , and a micro camera 2 and a needle 3 are arranged on the Z-axis displacement platform 1 . Placed on the transparent bottom plate 5 on the X-axis displacement platform 6 of the electrothermal micromirror bare chip wafer, covered with a hollow cover plate 4. The electric displacement platform is arranged on the base 8 .

[0060] The needle of the electrothe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com