Horn seal structure and processing method thereof

A sealing structure and processing method technology, applied in the direction of transducer housing/cabinet/bracket, sensor, electrical components, etc., can solve the problems of thick horn sealing structure, easy resonance, limited installation position, etc., and achieve reduction The thickness of the whole machine, the effect of avoiding resonance and resisting salt spray and sand dust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

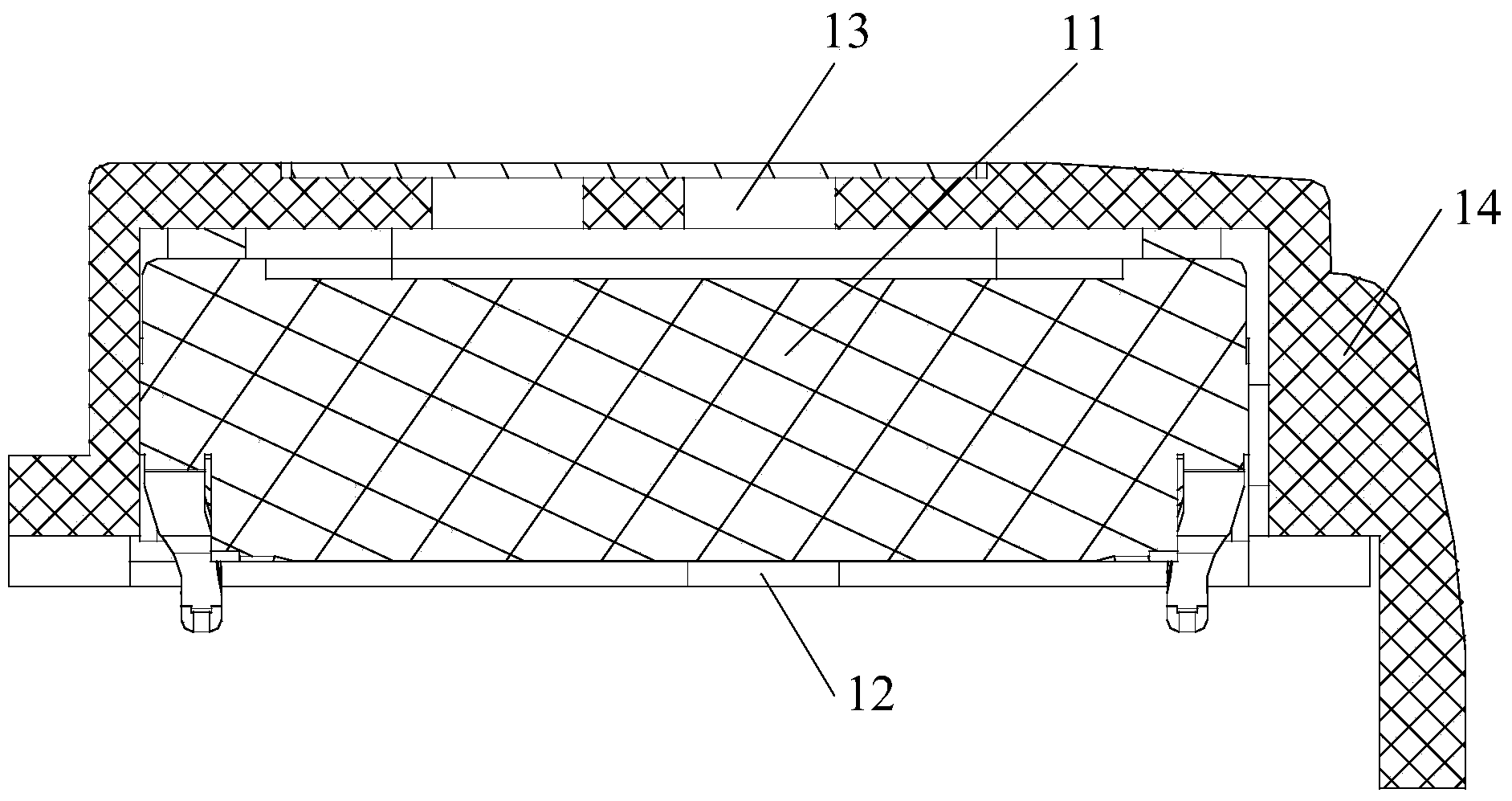

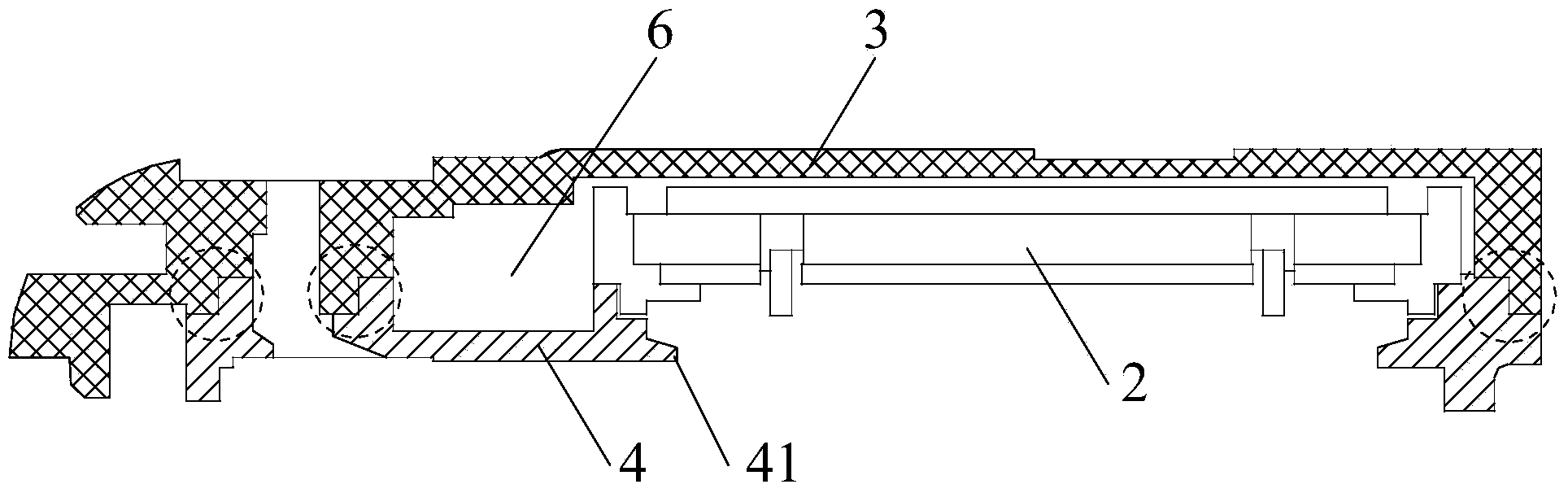

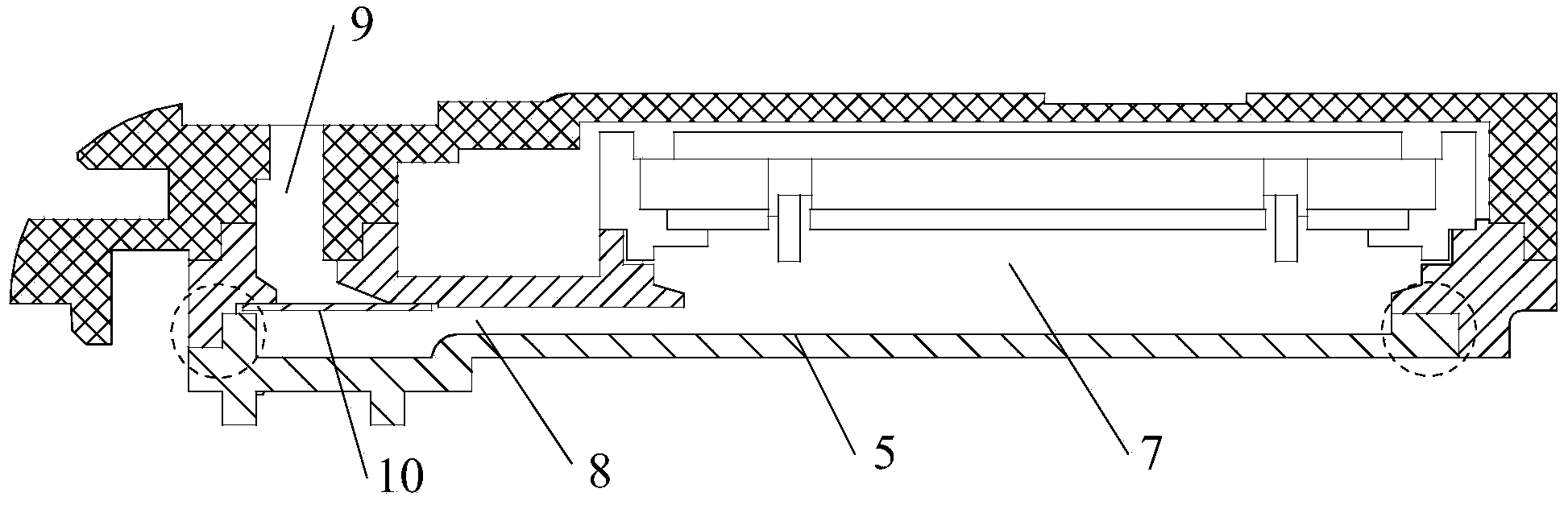

[0019] A preferred embodiment will be given below, and the present invention will be described more clearly and completely in conjunction with the accompanying drawings.

[0020] Such as figure 2 As shown, the horn sealing structure of the present invention includes a horn 2 , a first shell 3 , and a second shell 4 . The upward direction in the figure indicates the outer direction of the mobile terminal device, and the downward direction indicates the inner direction of the mobile terminal device. The front of the speaker 2 in the figure faces downward, that is, it faces the inside of the mobile terminal device, which is different from the front of the speaker in the general mobile terminal device facing the outside.

[0021] It can be seen from the figure that the first casing 3 and the second casing 4 are affixed, specifically, the two are affixed together by means of ultrasonic welding. Ultrasonic welding can connect the two shells into a whole piece to achieve the effec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com