Display panel, manufacturing method, and display device

A technology for display panels and manufacturing methods, which is applied in semiconductor/solid-state device manufacturing, diodes, semiconductor devices, etc., and can solve problems that do not conform to the development trend of light and thin mobile display devices, limit the thinnest size, and are difficult to satisfy users, etc. Achieve the effect of being conducive to the development of light and thin, reducing the thickness of the whole machine, and improving the utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

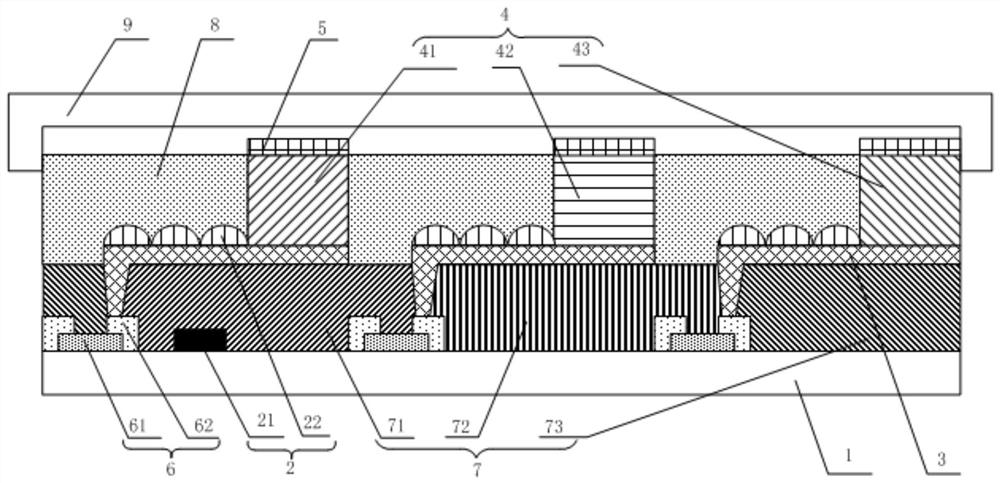

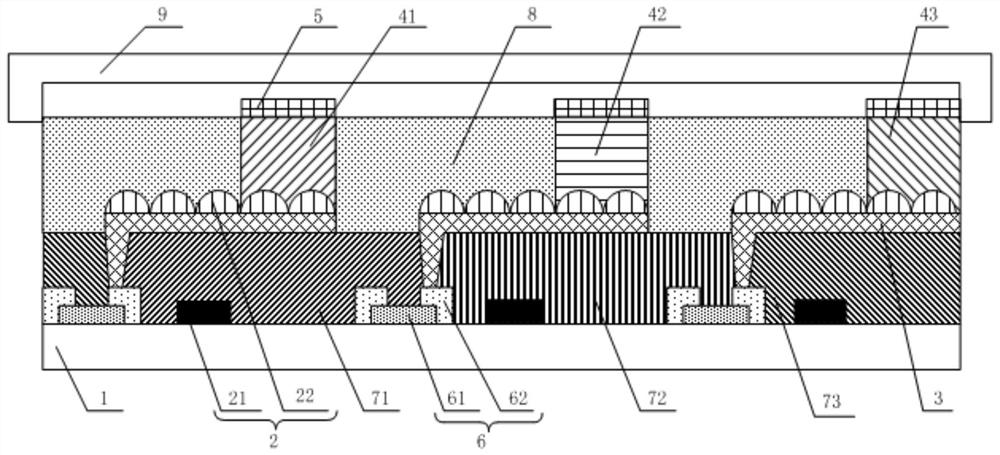

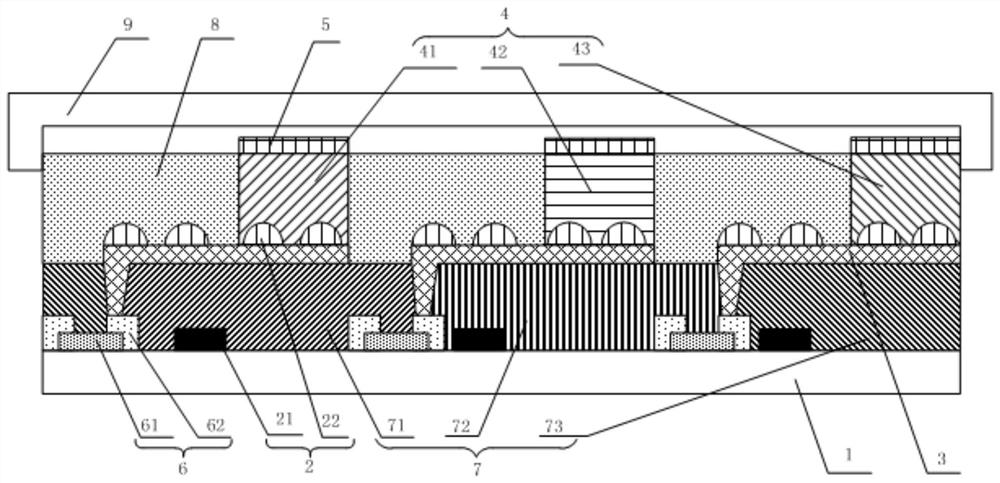

[0090] In addition, in the above-mentioned embodiment, refer to Figure 12 If the OLED light-emitting functional layer is formed of white light organic light-emitting materials, there is another implementation mode for forming the first electrode layer 3 on the surface of the photodiode 21 away from the base substrate 1, for example: when the photodiode 21 is away from the base substrate 1 A planarization layer 12 is formed on the surface of the planarization layer 12 with a light-transmitting material, and a first electrode layer 3 is formed on the surface of the planarization layer 12 away from the photodiode 21;

[0091] Then the manufacturing method of the display panel also includes:

[0092] Form the third color filter 13 on the surface of the second electrode layer 5 away from the OLED light-emitting functional layer, so that the orthographic projection of the third color filter 13 on the base substrate 1 covers the corresponding white OLED light-emitting functional lay...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com