Full-automatic spring shaped coil winder

A fully automatic, winding machine technology, applied in the direction of coil manufacturing, electrical components, conveying filamentous materials, etc., can solve the problems of increased processing costs, inaccurate results, low processing efficiency, etc., to achieve convenient maintenance, operation and Easy adjustment and accurate number of coils

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to further understand the features, technical means, specific objectives and functions achieved by the present invention, and to analyze the advantages and spirit of the present invention, a further understanding of the present invention can be obtained through the following detailed description of the present invention in conjunction with the accompanying drawings and specific embodiments.

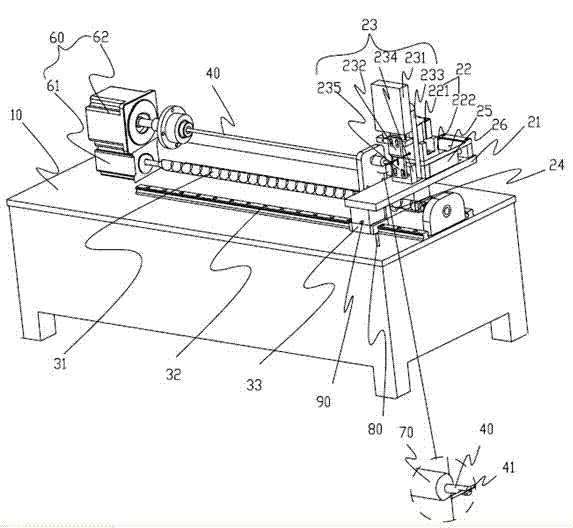

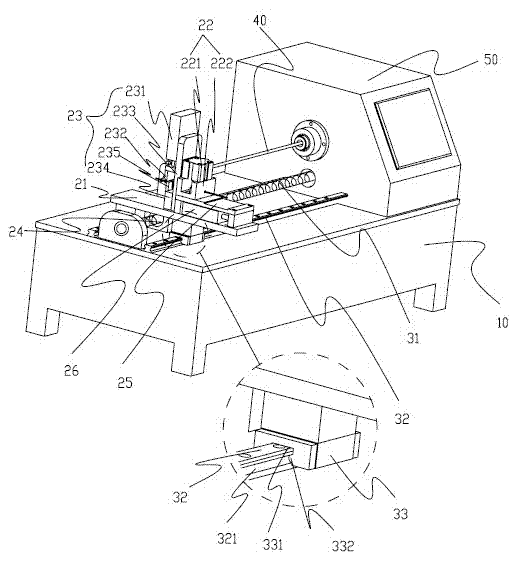

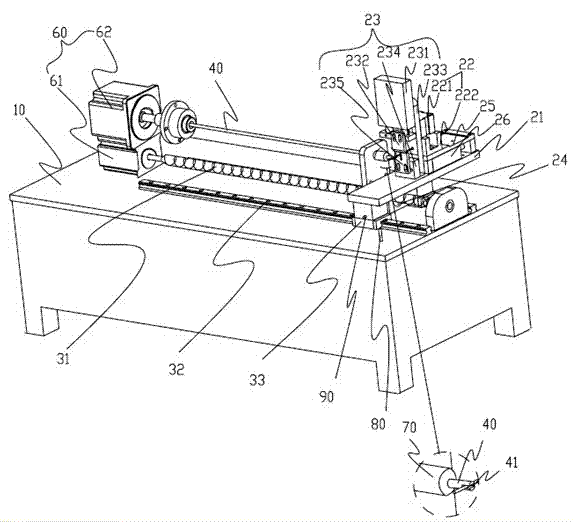

[0018] As shown in the accompanying drawings, the present invention includes a box body 10, and a control system is arranged inside the box body 10, and the control system is used to control the movement of the winding machine. The box body 10 is provided with a moving mechanism, a winding mechanism and a rail mechanism. The moving mechanism includes a support base 21 and a thread crimping device 22 and a thread cutting device 23 arranged on the support base 21 . The wire crimping device 22 includes a downward pressure cylinder 221 and a downward pressure cylinder fixing s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com