Patents

Literature

37results about How to "Realize automatic loading and unloading function" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

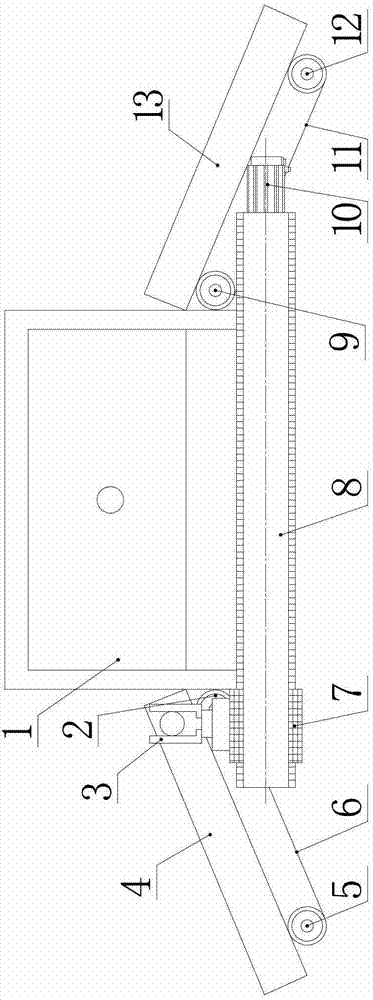

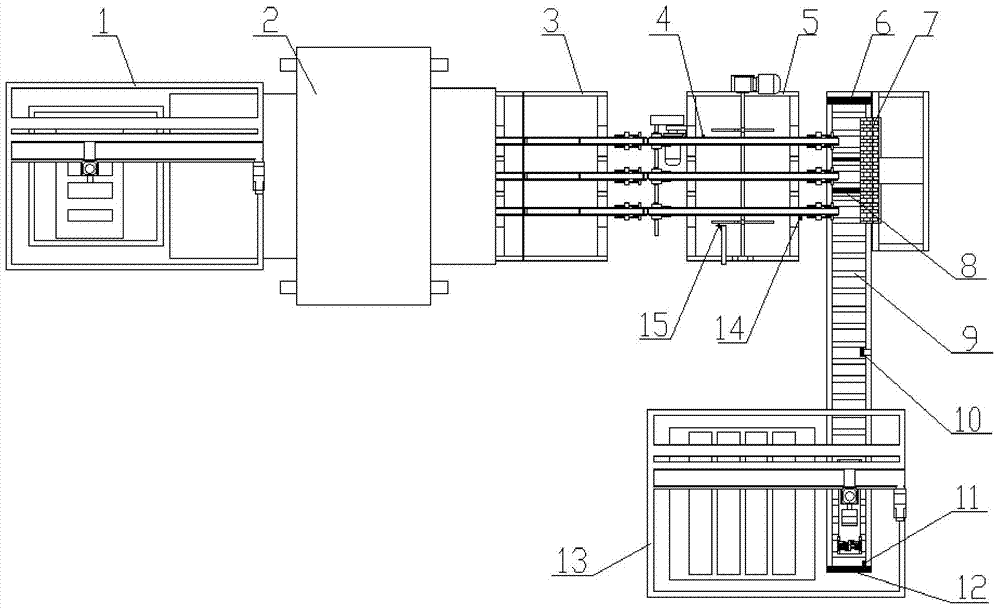

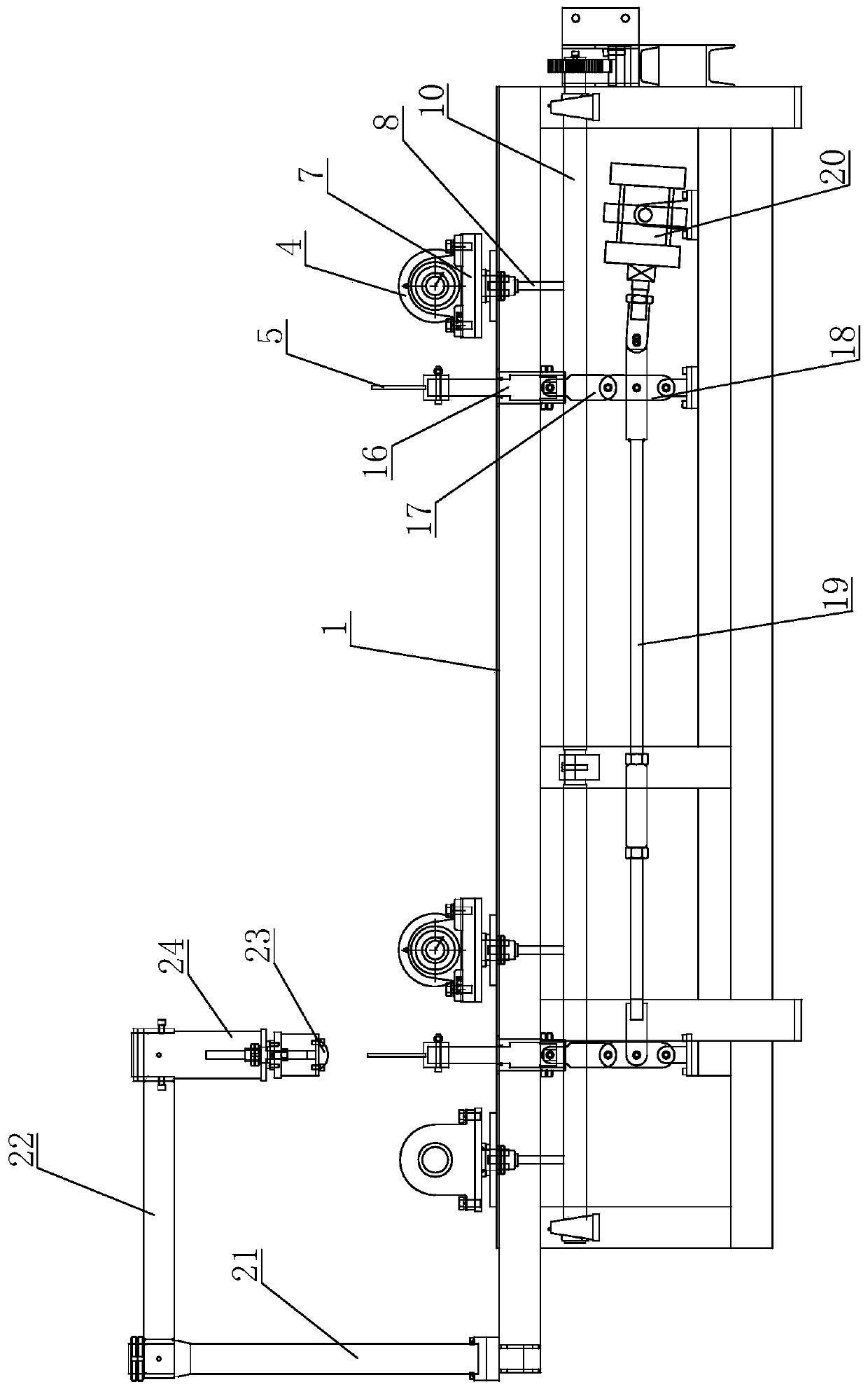

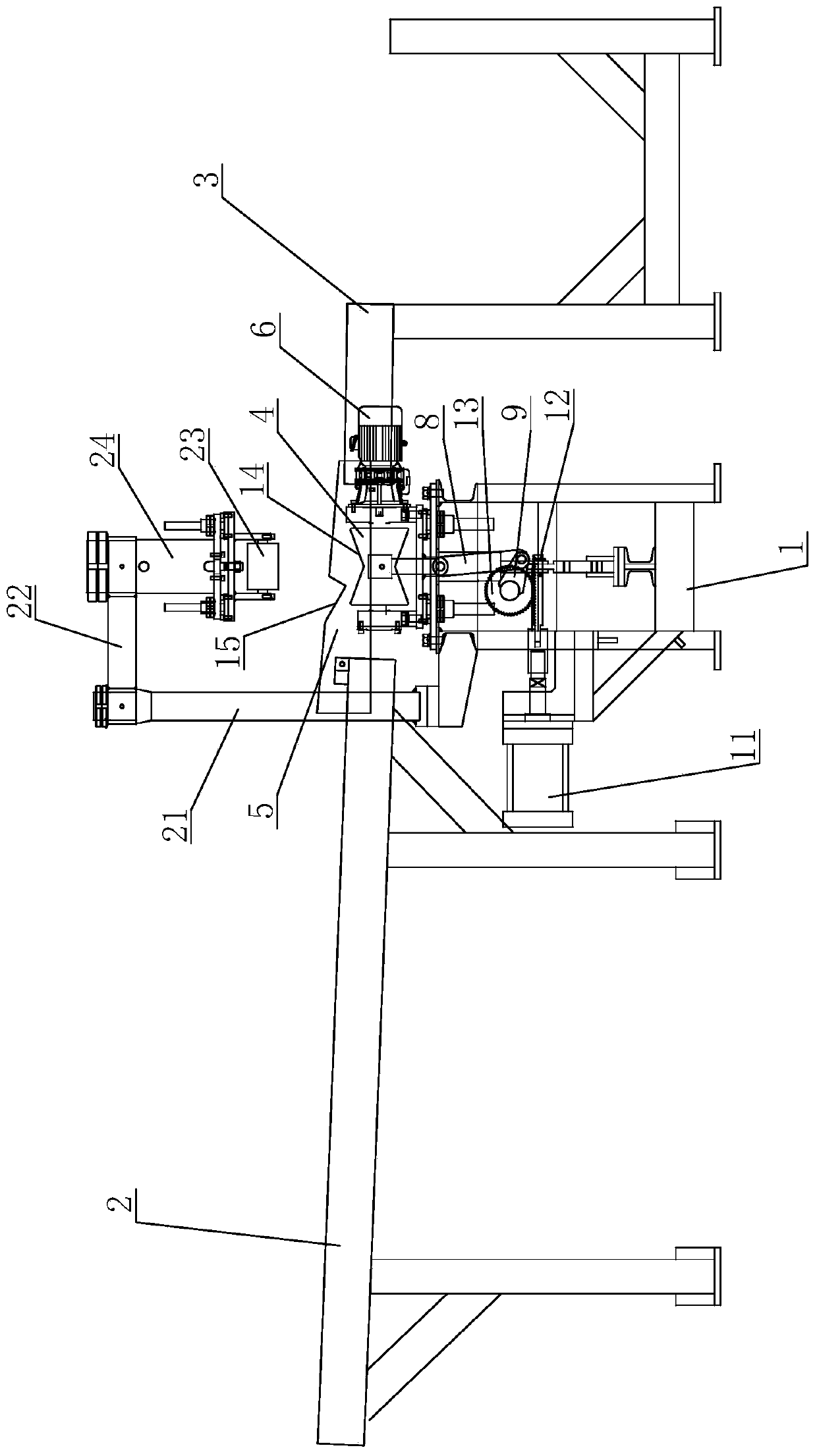

Automatic punching machine assembly line system for PVC floor

ActiveCN103625871AImprove work efficiencyLabor savingConveyor partsMechanical conveyorsPunch pressEngineering

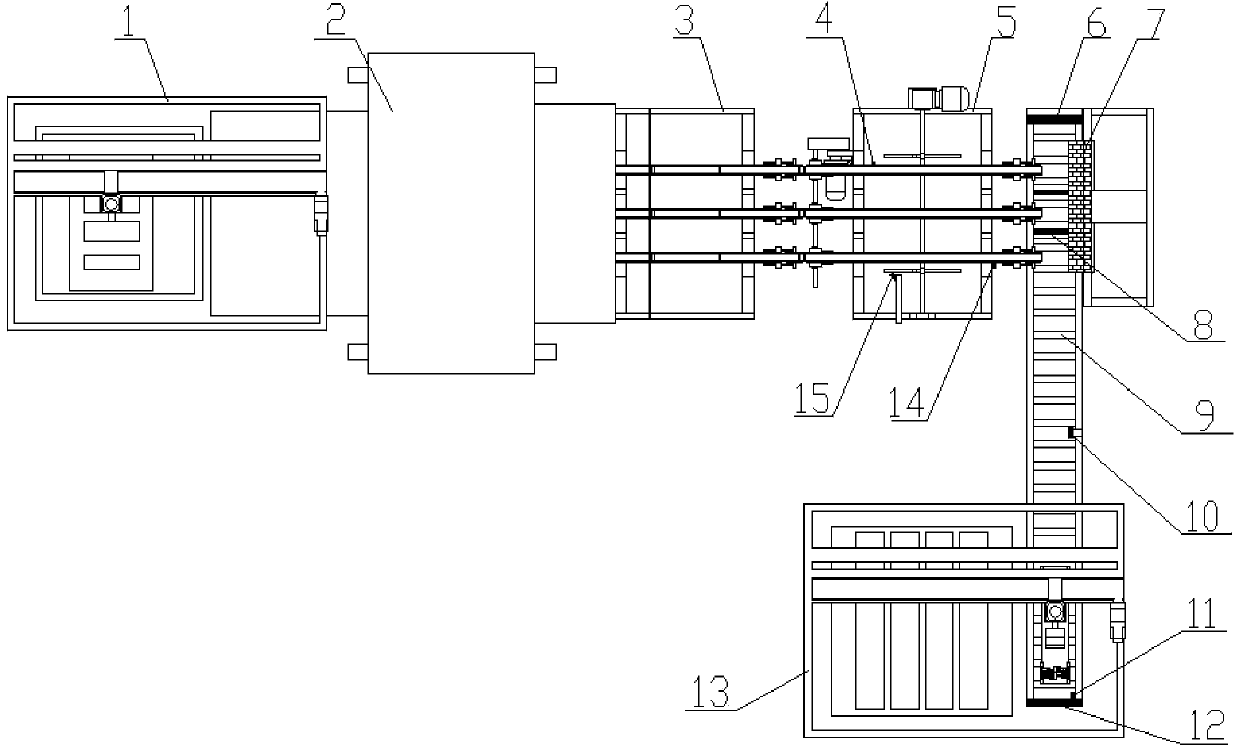

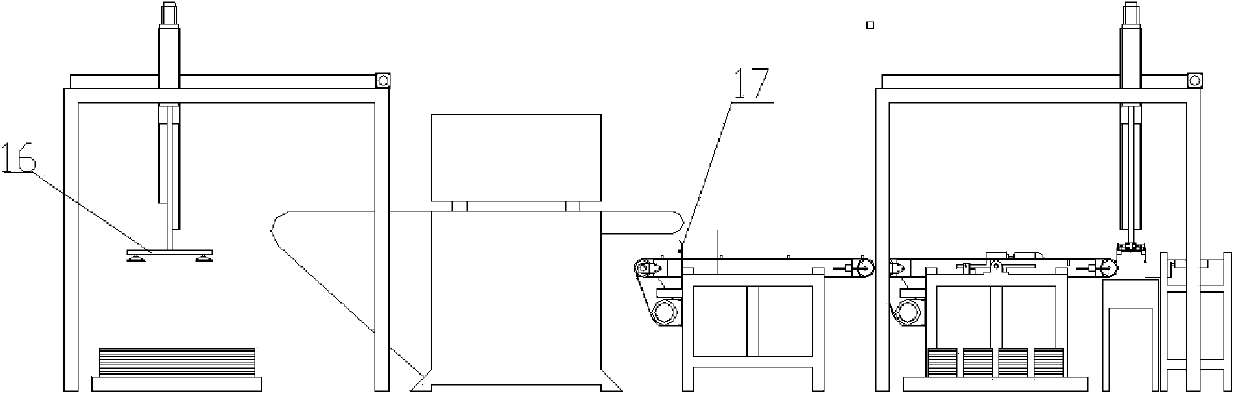

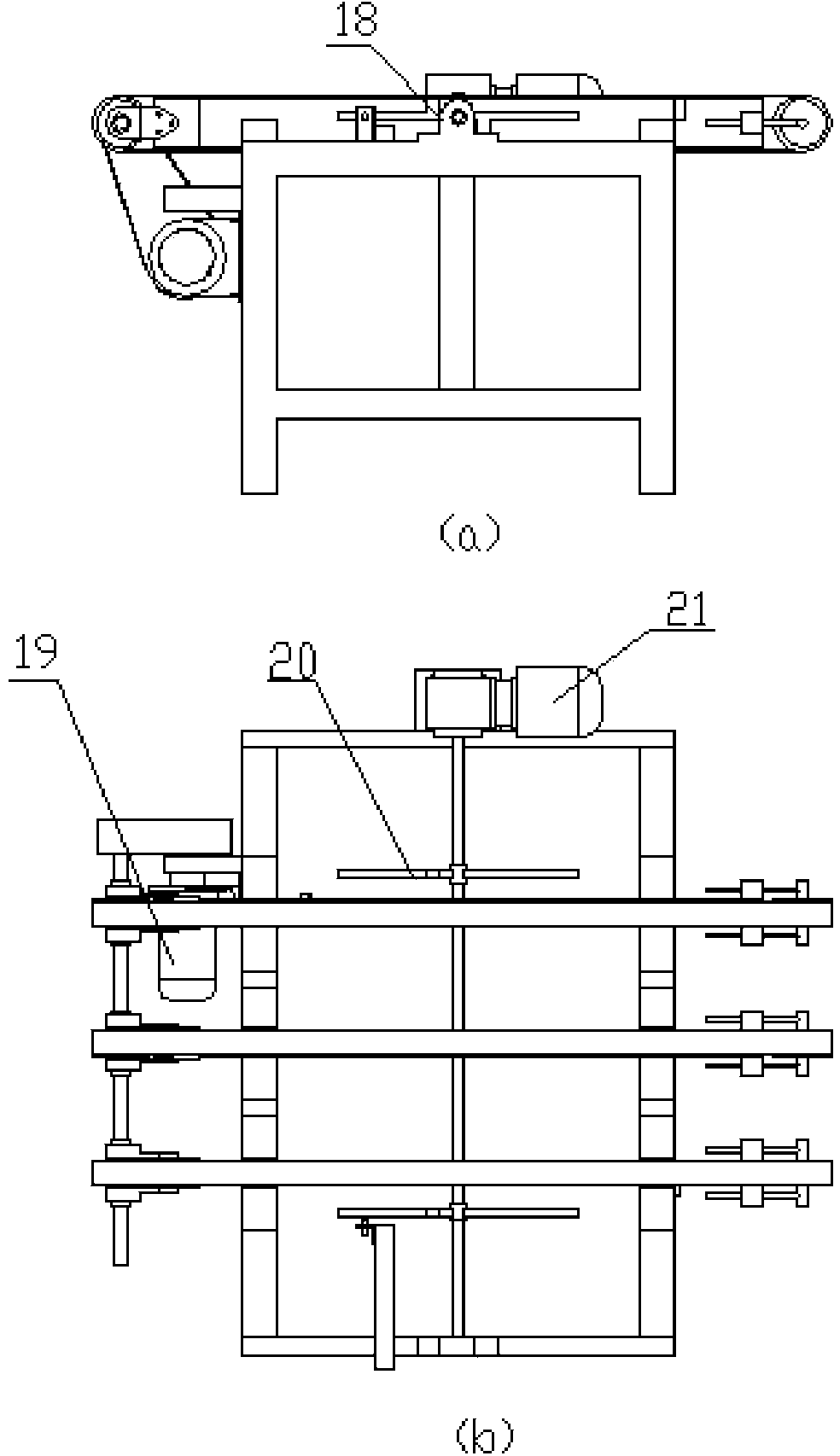

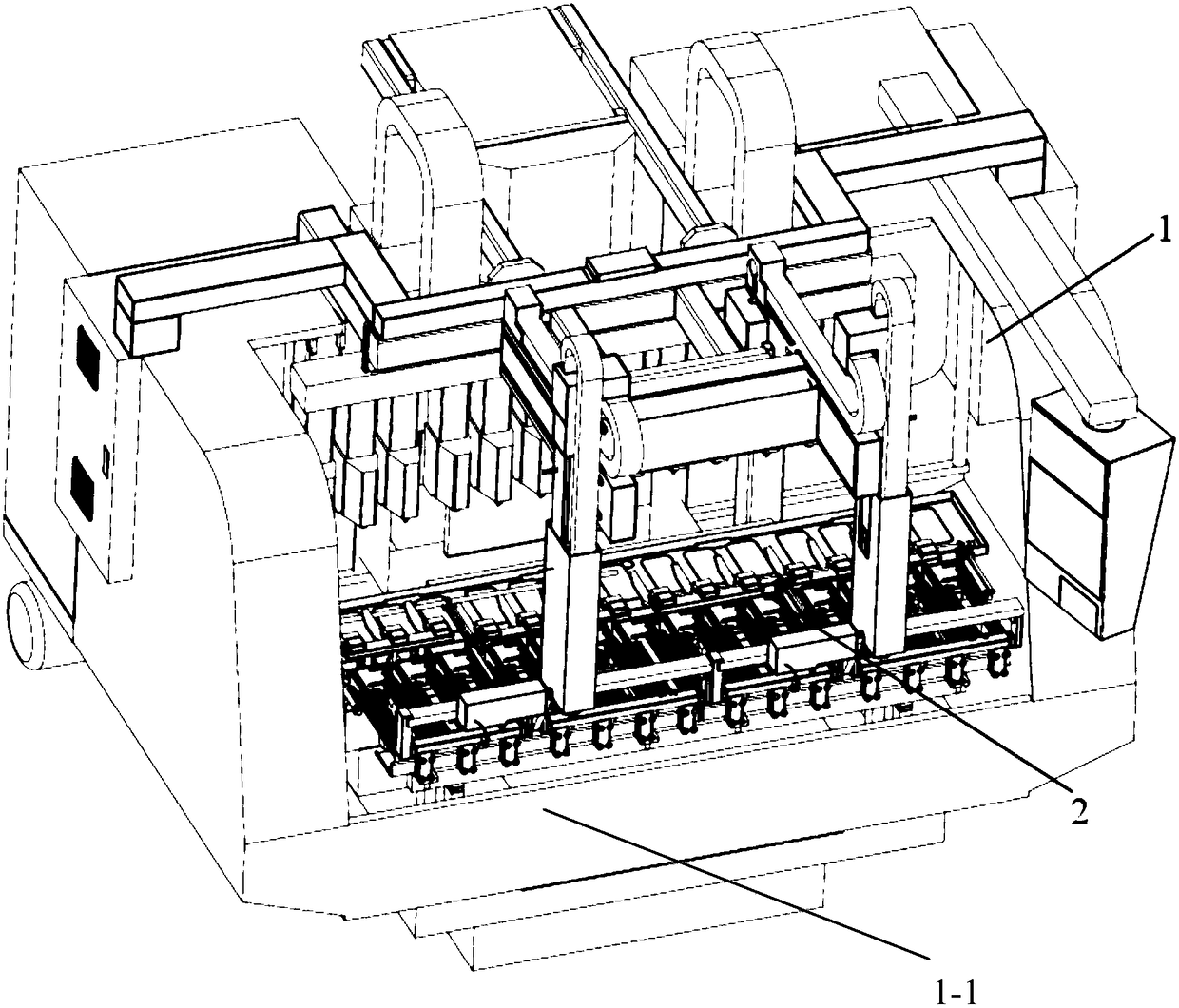

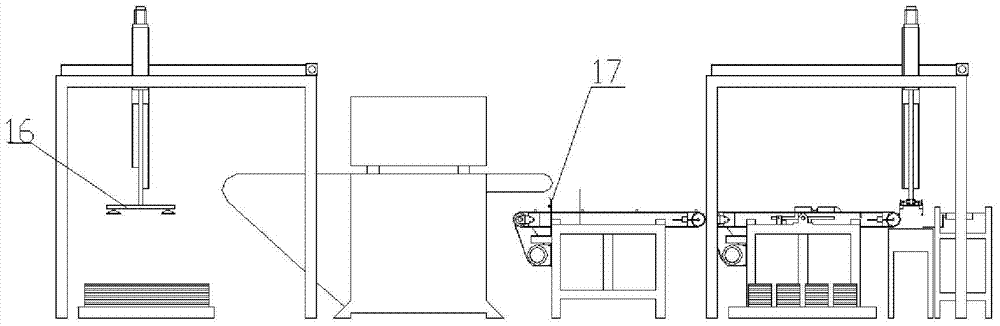

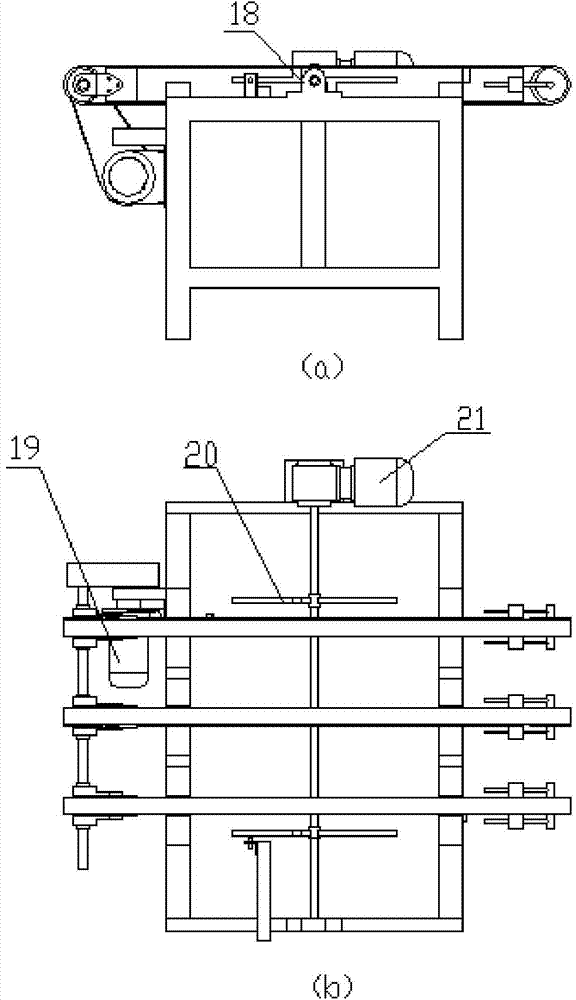

The invention discloses an automatic punching machine assembly line system for a PVC floor. The automatic punching machine assembly line system is formed by sequentially connecting feeding stacker crane system, an automatic punching system, a spacing wafer separator system, a 180-degree panel turnover machine system, a roller machine conveying system and a discharging stacker crane system, wherein the spacing wafer separator system is provided with a first light sensation system; the 180-degree panel turnover machine system is provided with a panel turnover photoelectric switch, a panel turnover proximity switch and a panel turnover counter system; the roller machine conveying system is provided with a pneumatic lifting plate system, a pneumatic splicing plate system and a second light sensation system. According to the automatic punching machine assembly line system, not only is labor force lowered, but also intellectualization of equipment transportation is achieved, and therefore the overall working process of an automatic punching machine assembly line for the PVC floor is orderly. Moreover, production efficiency is greatly improved, and a large amount of labor force is reduced.

Owner:JIANGSU UNIV OF SCI & TECH

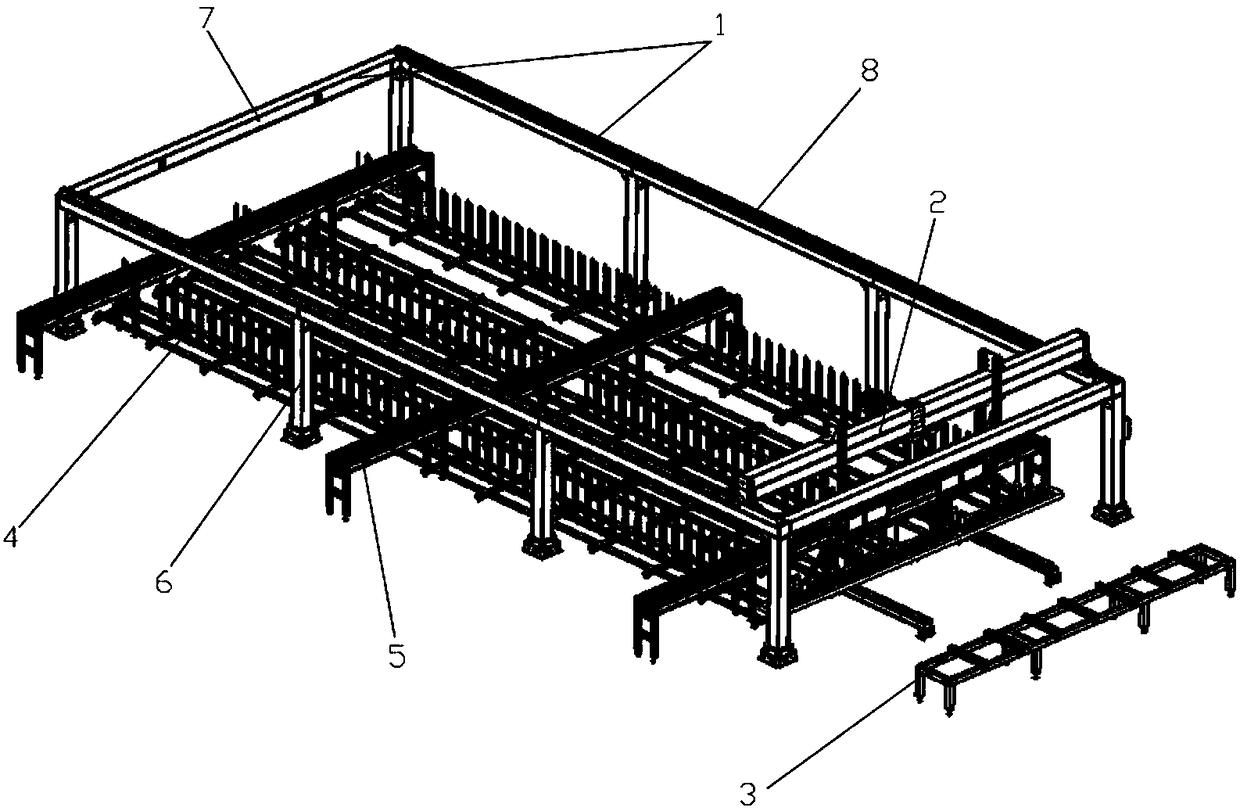

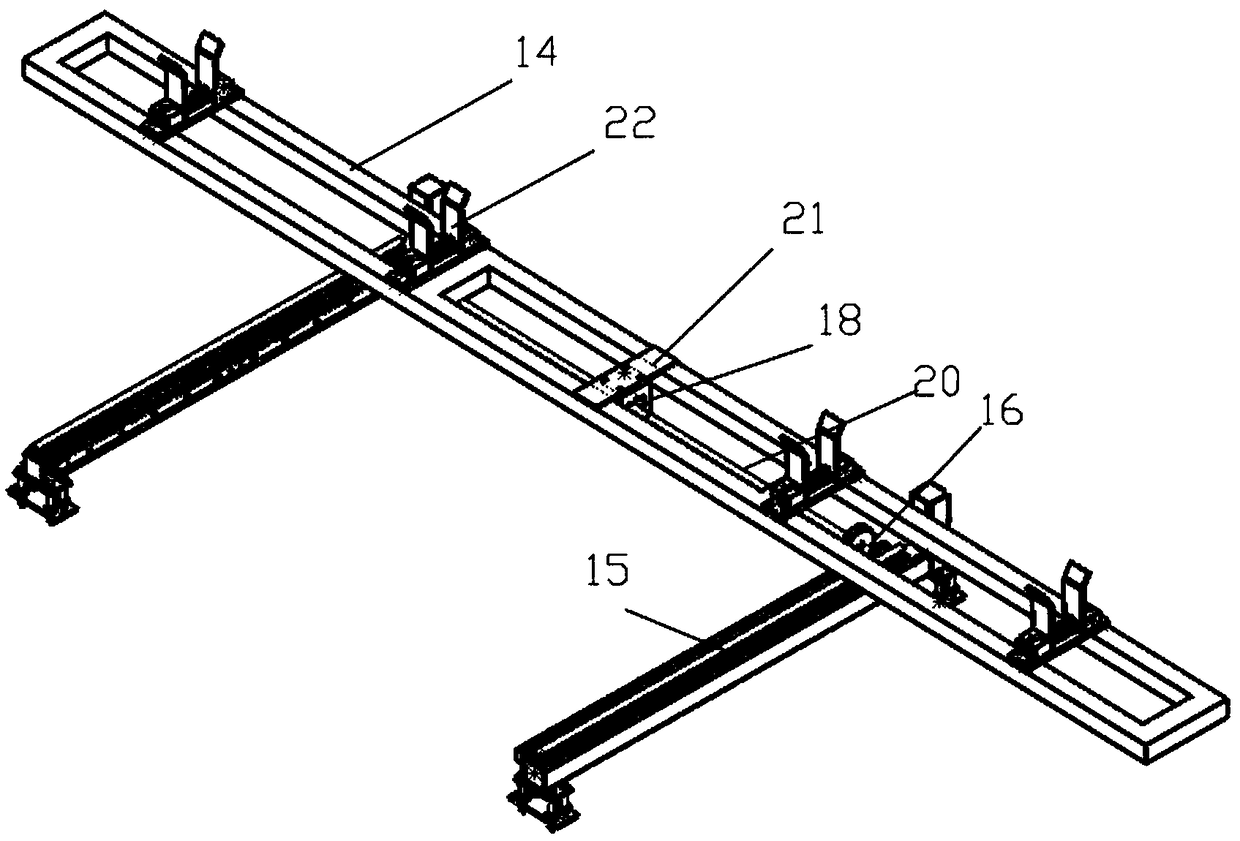

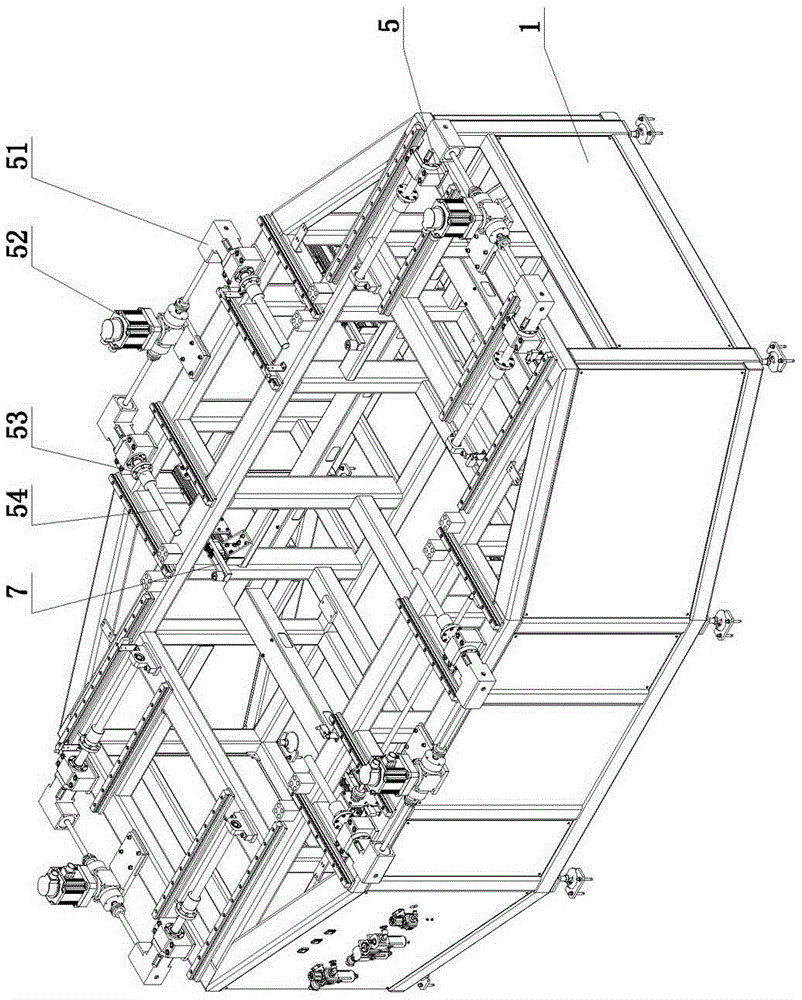

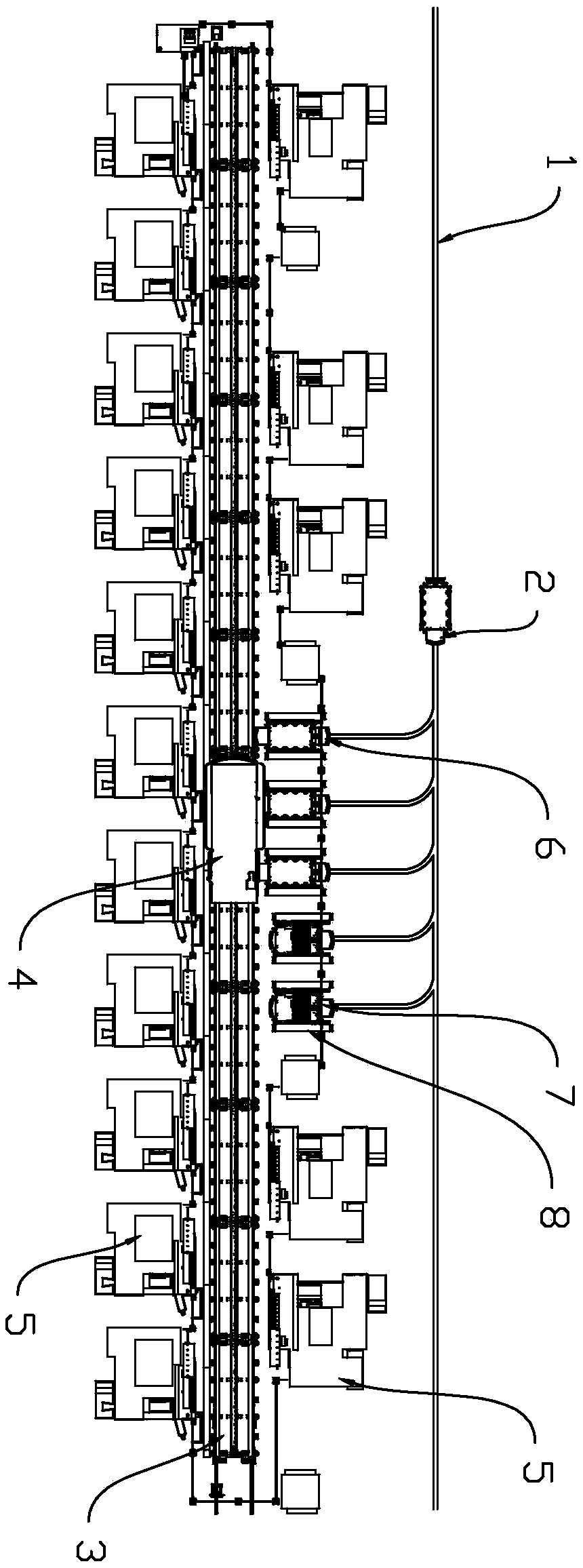

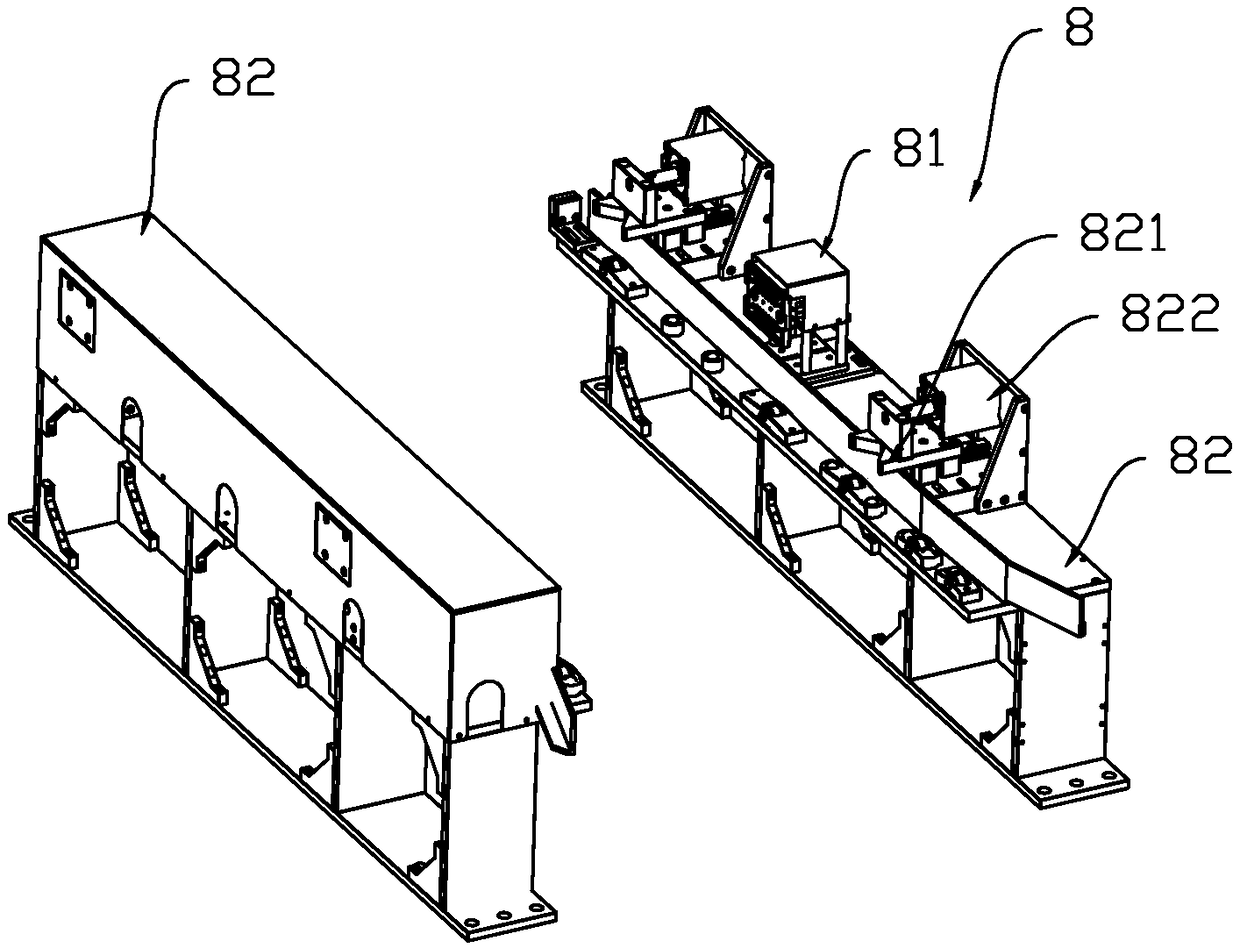

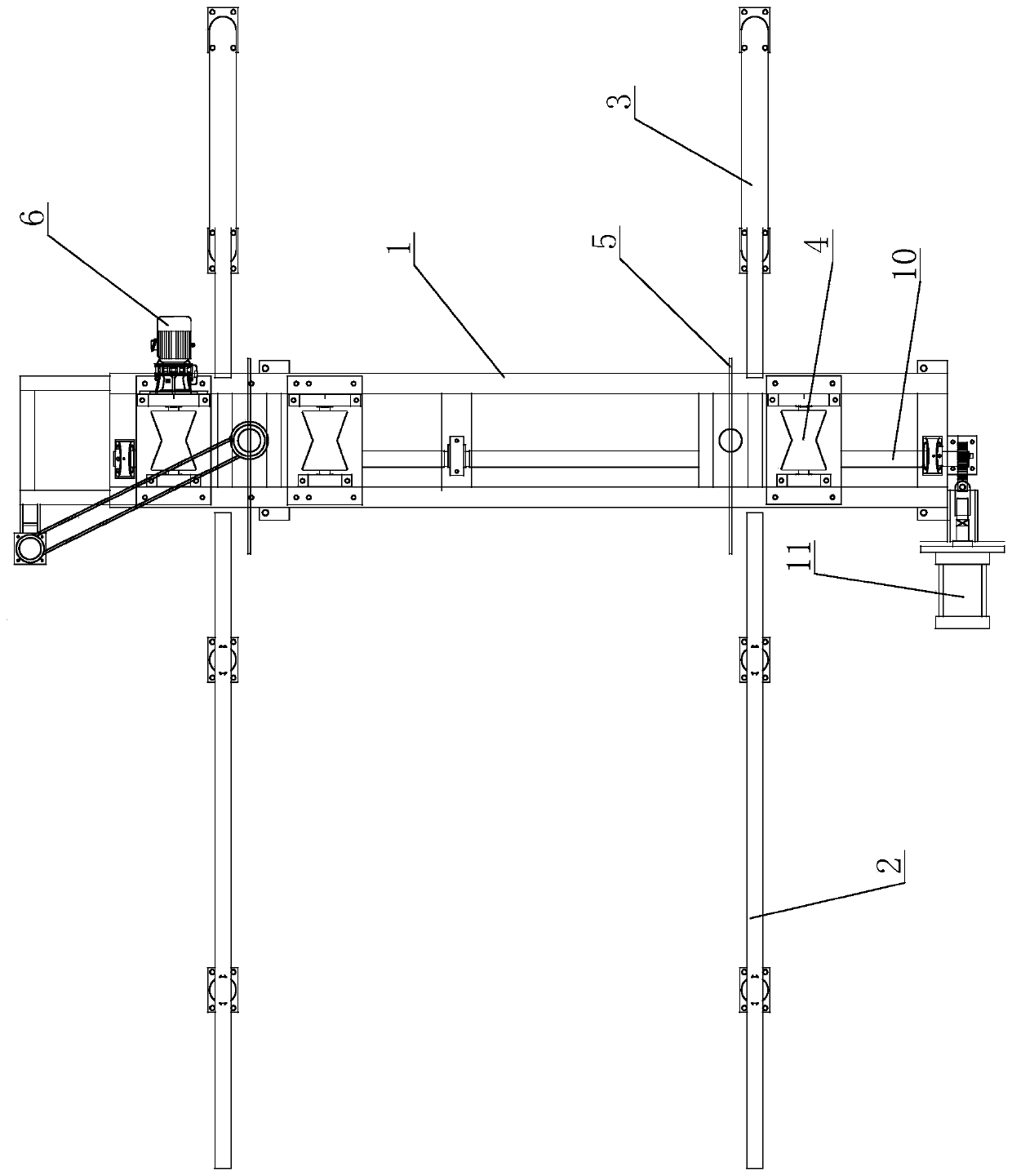

Copper bar automatic plane warehouse and copper bar integrated production line

PendingCN108249119ASmooth transferRealize automatic loading and unloading functionOther manufacturing equipments/toolsMechanical conveyorsProduction lineEngineering

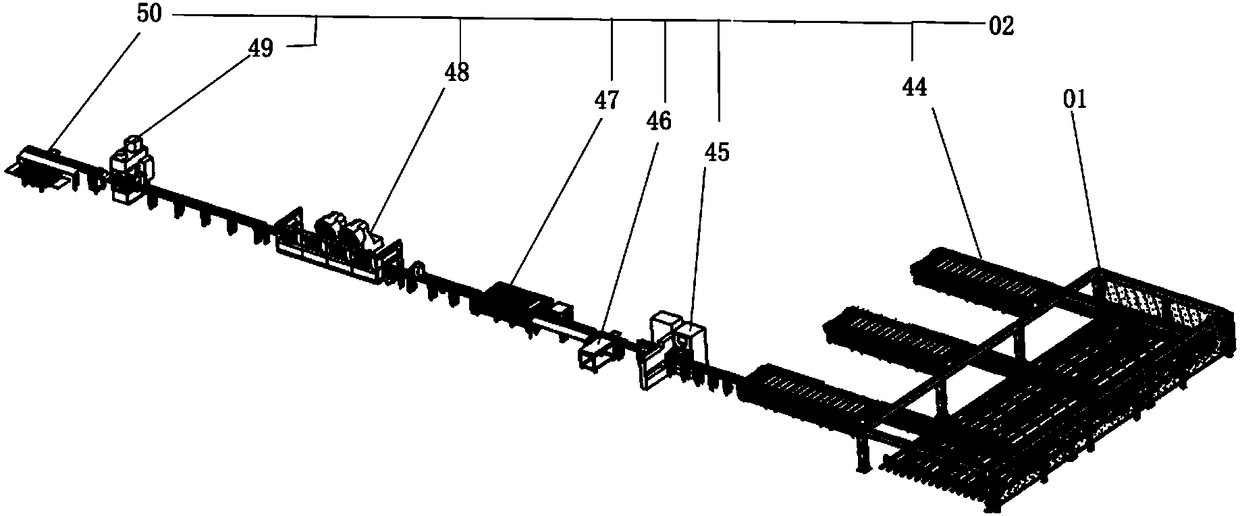

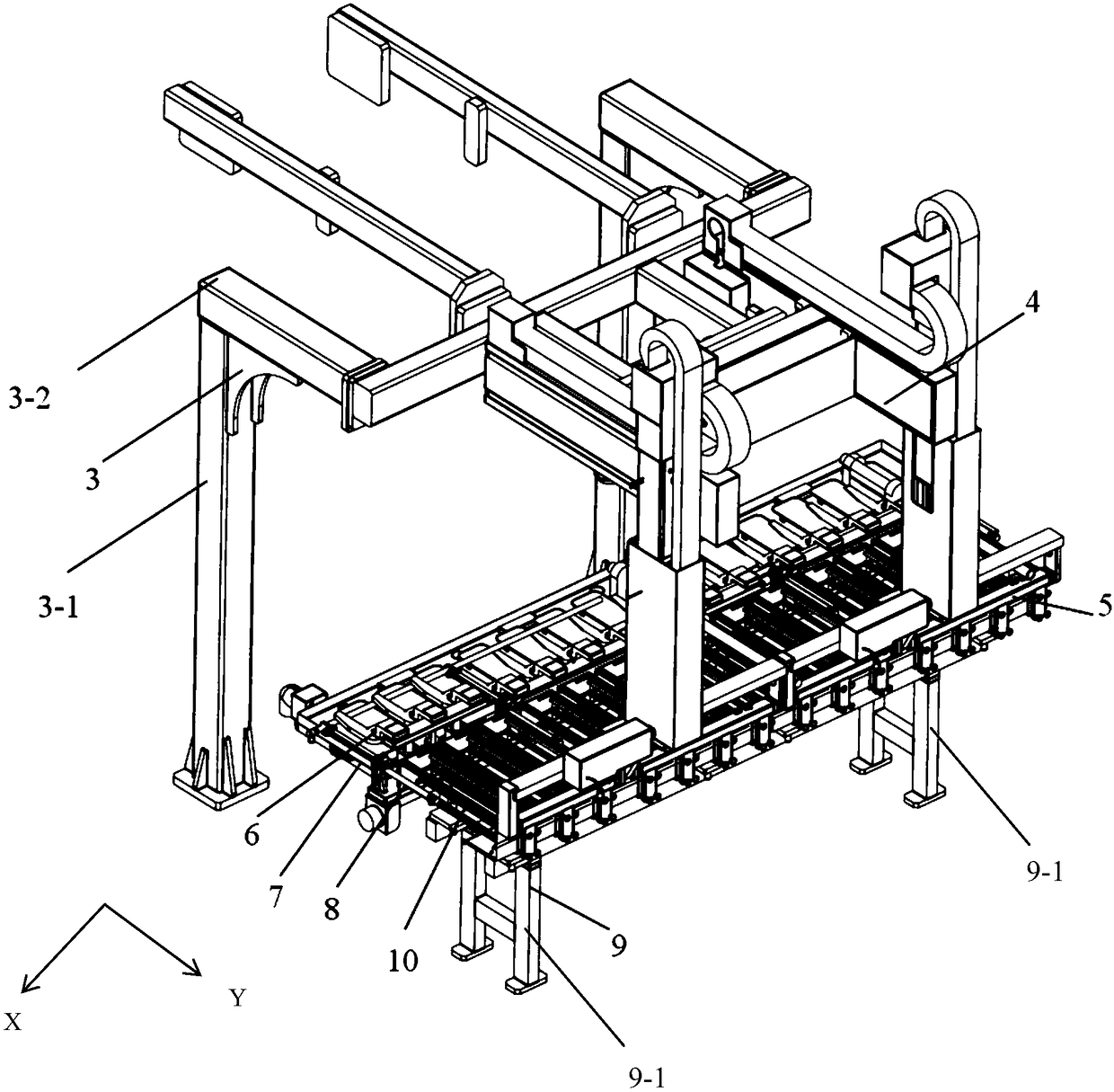

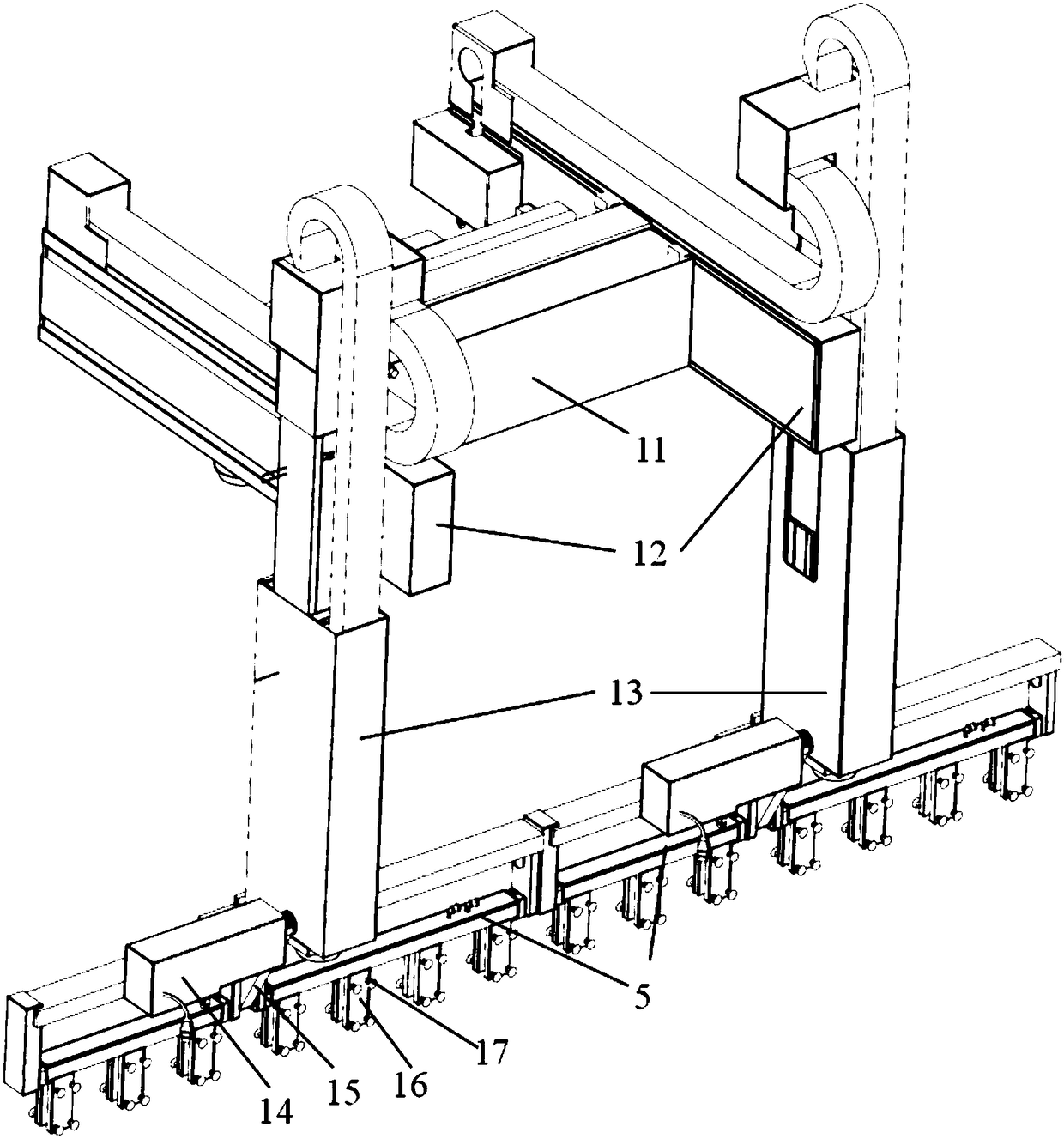

The invention relates to a copper bar production technology, in particular to copper bar automatic plane warehouse and copper bar integrated production line which achieves automatic storage, automaticfeeding, automatic production and automatic discharge for copper bars. The production line comprises a copper bar automatic plane warehouse and a copper bar automatic production line. A copper bar warehouse outer frame comprises stand columns, a beam and a linear guide rail, the stand columns are installed on the ground, the beam is connected with the stand columns on the two sides, the linear guide rail is installed on the stand column, each copper bar warehouse location comprises a copper bar warehouse location frame and multiple limiting columns, the copper bar warehouse location is arranged inside the copper bar warehouse outer frame, the multiple limiting columns are installed on the copper bar warehouse location frame, a copper bar discharge conveying line is also arranged in the copper bar warehouse outer frame and penetrates through multiple copper bar warehouse locations, the copper bar discharge conveying line comprises a copper bar discharge conveying frame, a copper bar discharge motor and a conveying belt wheel, and the copper bar discharge motor is installed on the copper bar discharge conveying frame and is in linkage with the conveying belt wheel.

Owner:JIANGSU SENLAN INTELLIGENCE SYST CO LTD

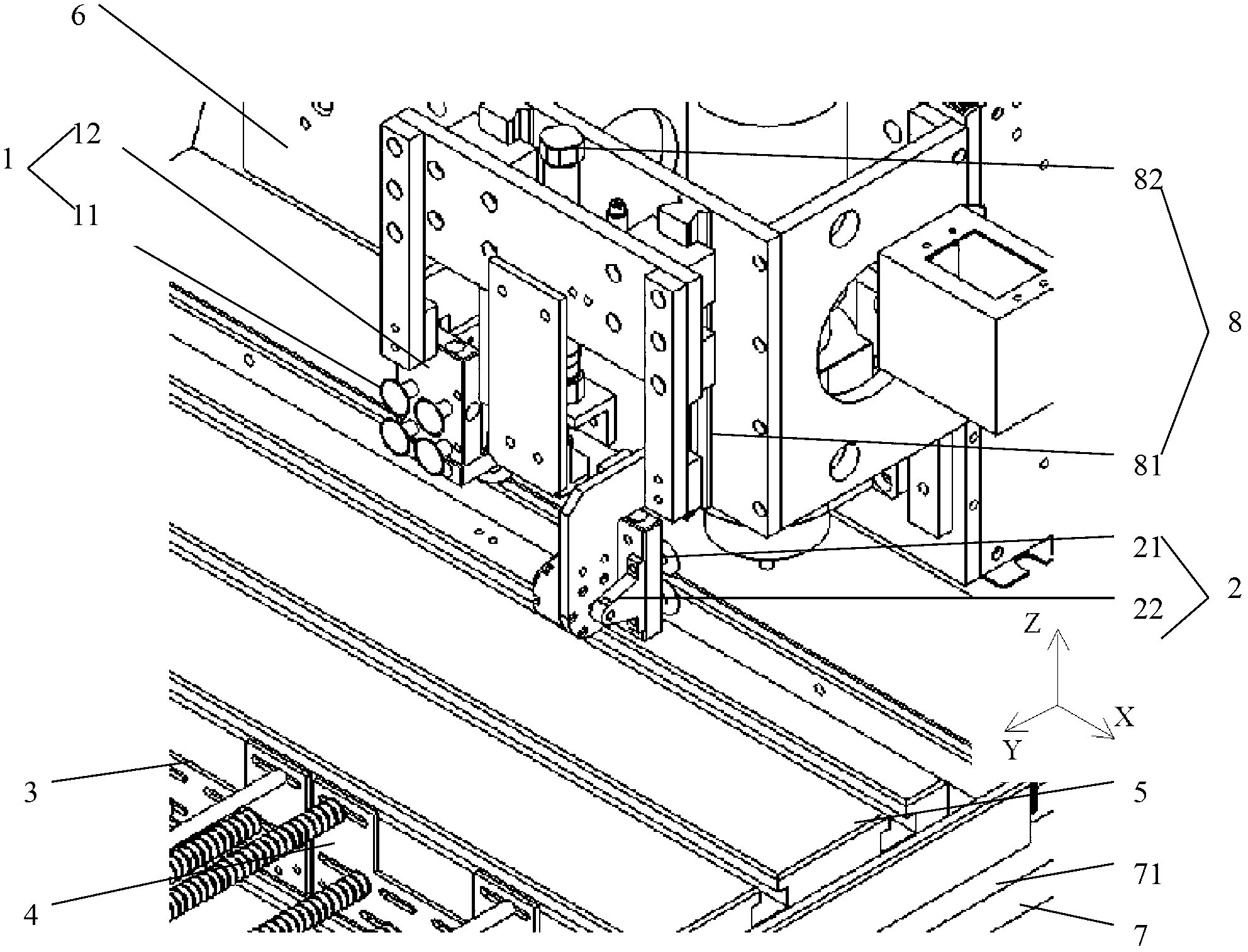

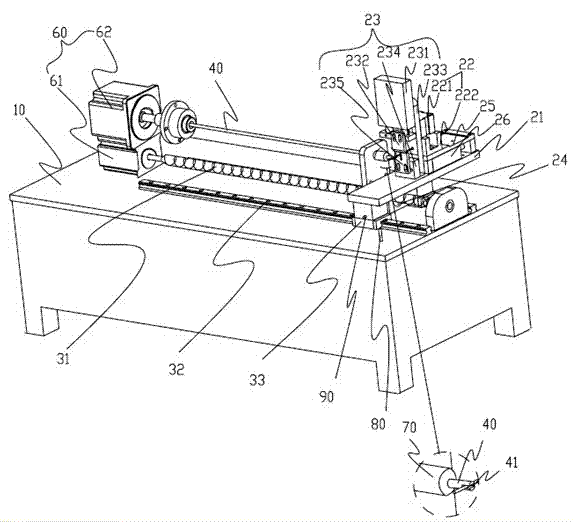

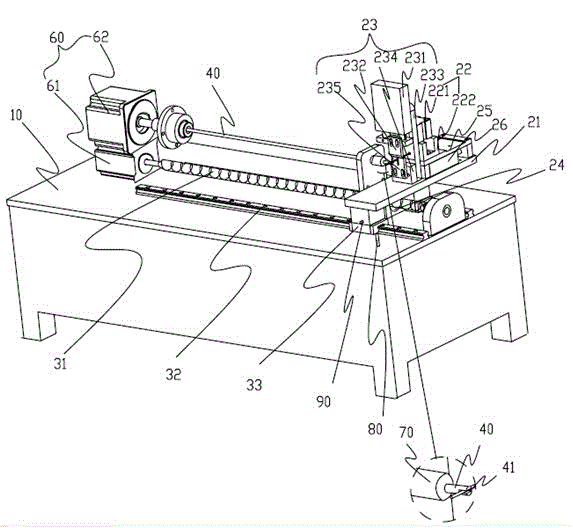

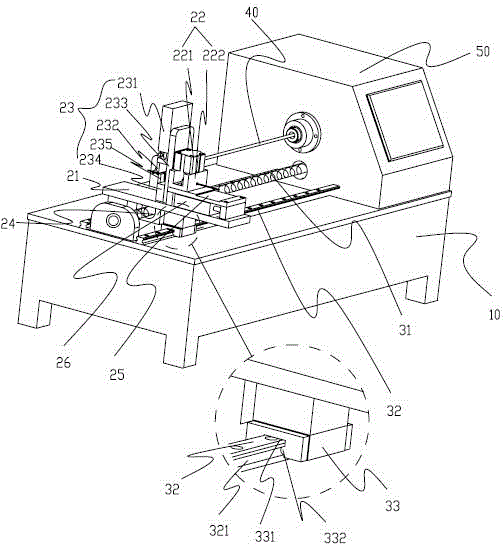

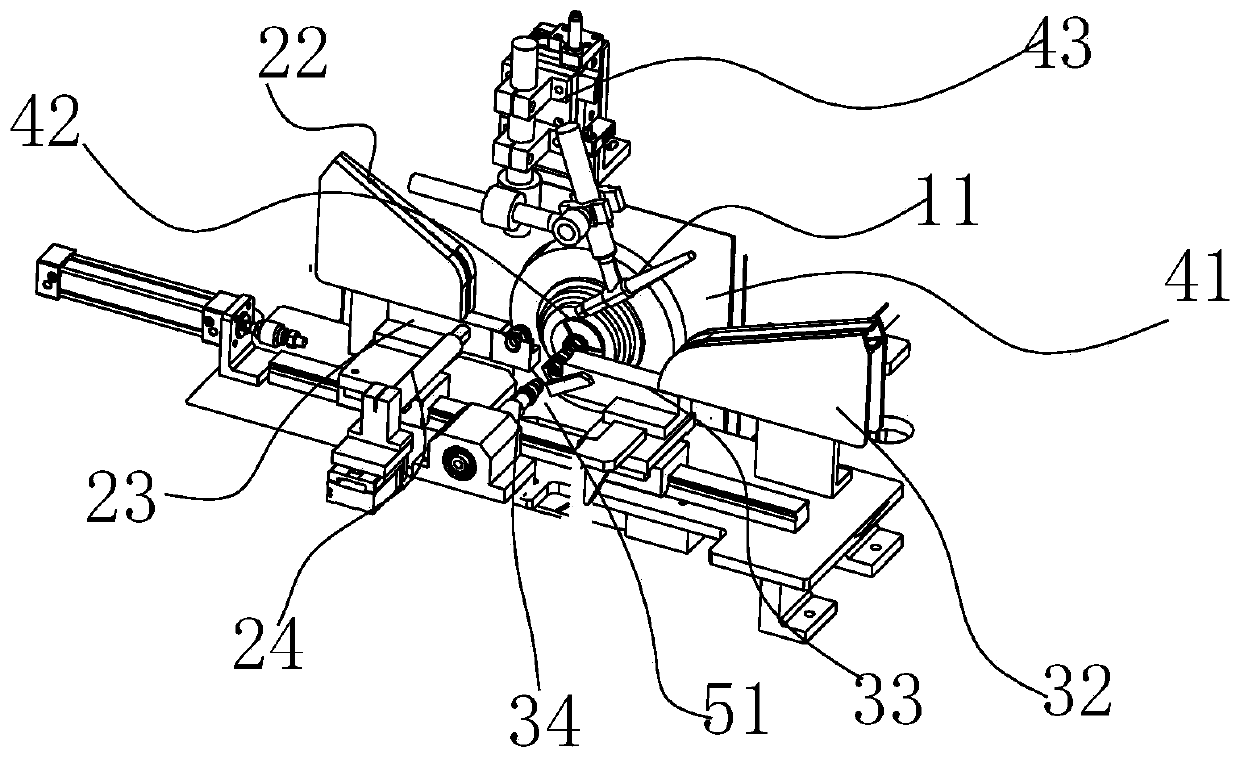

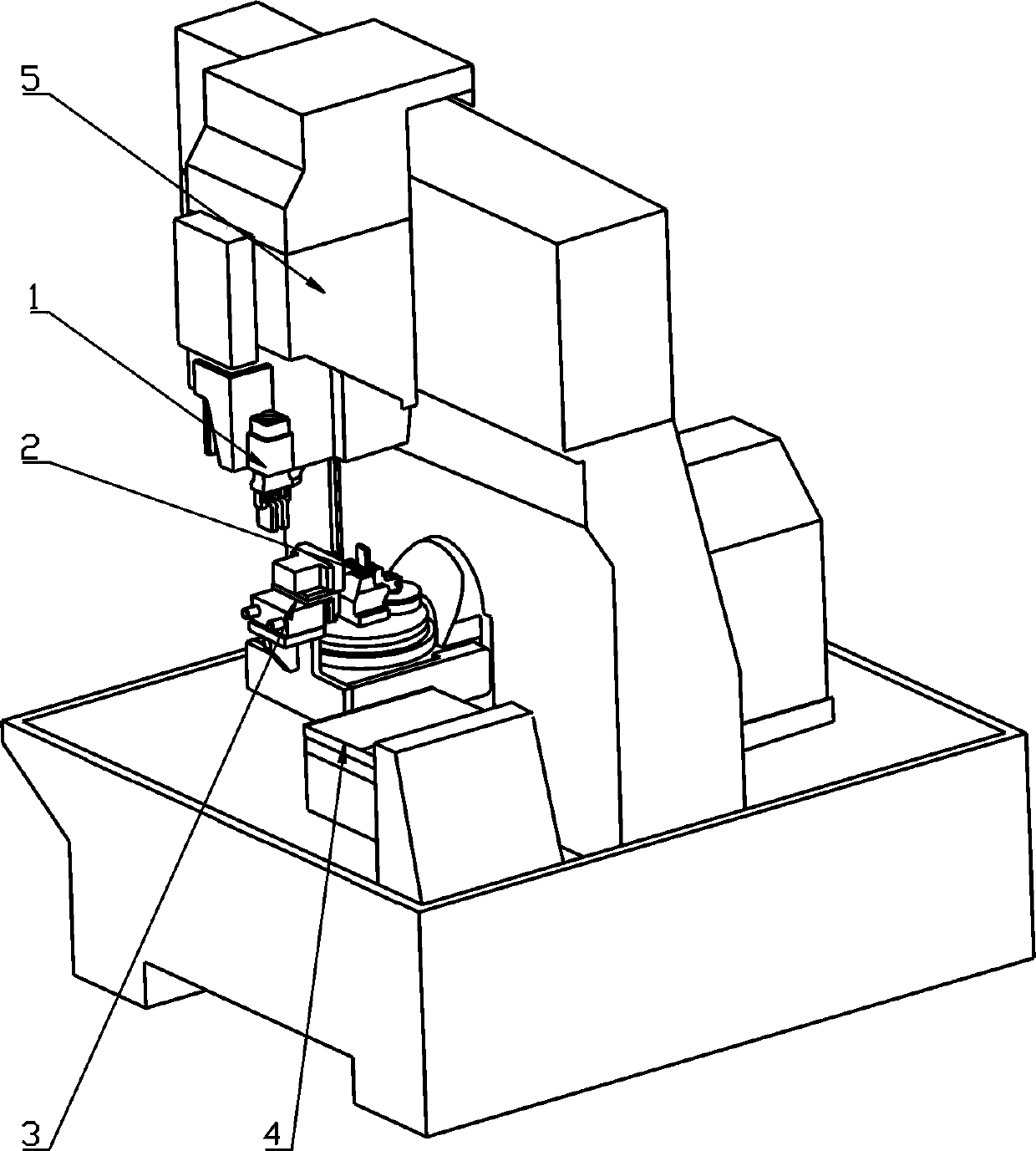

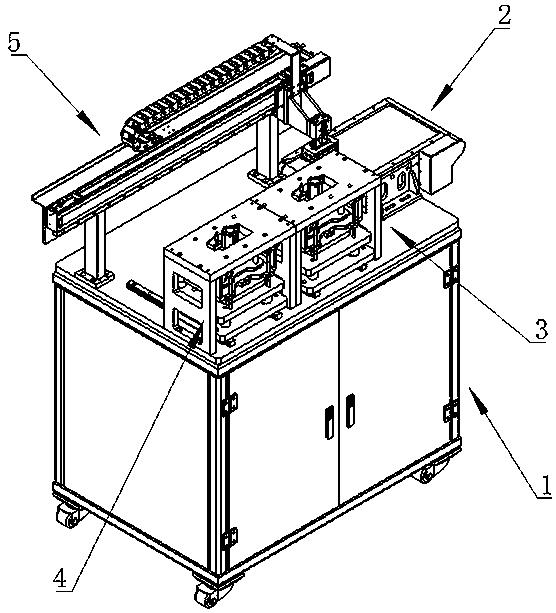

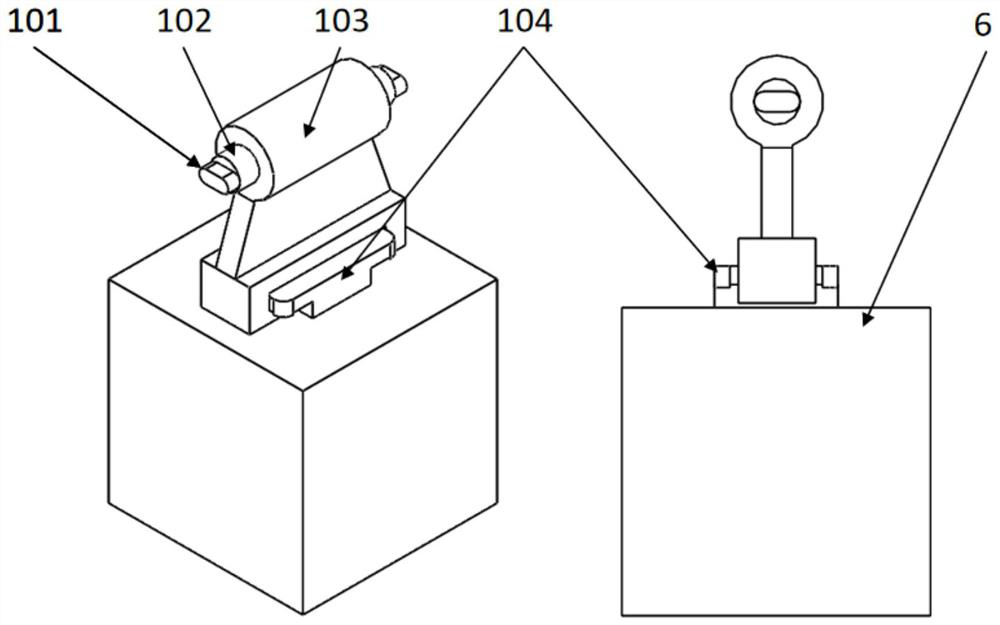

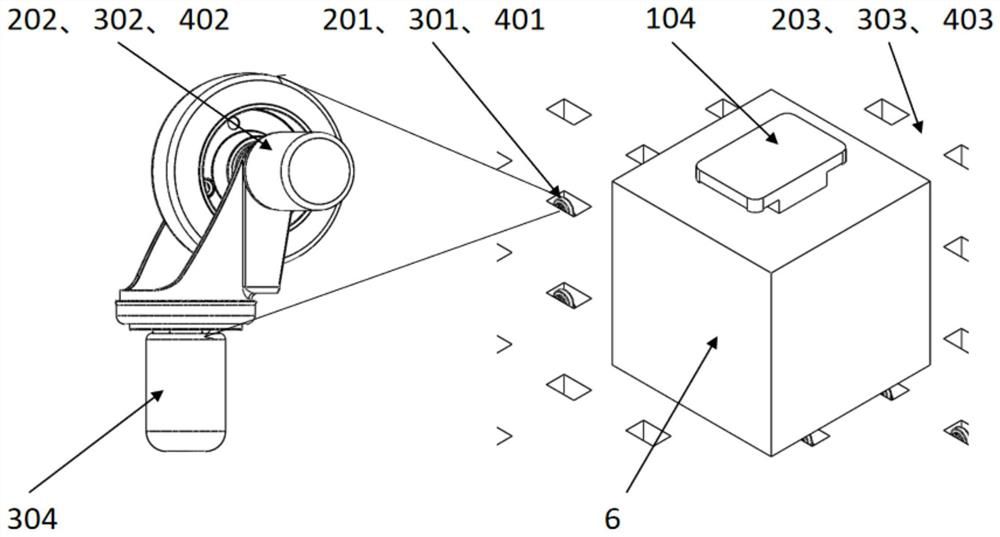

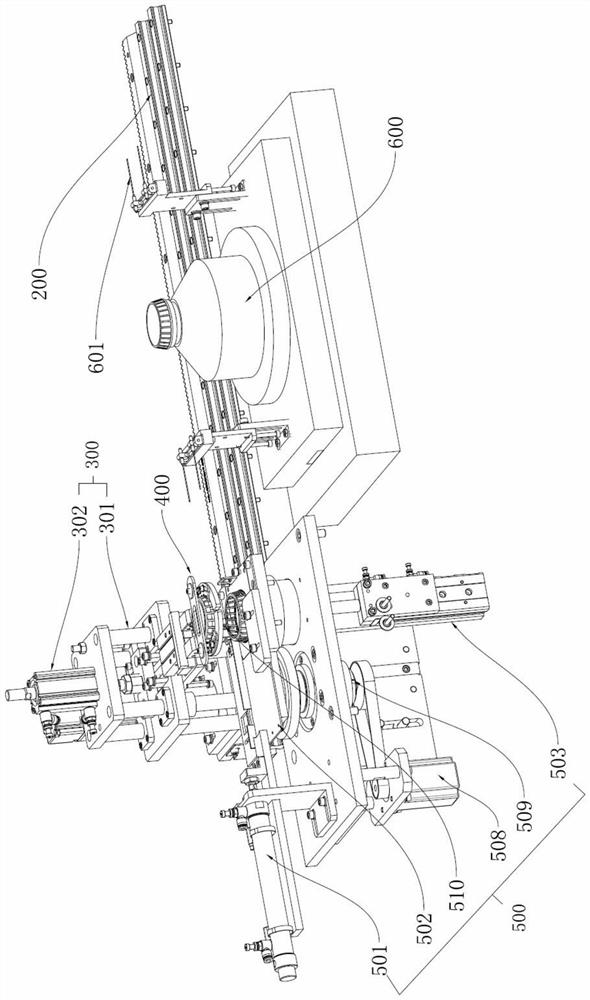

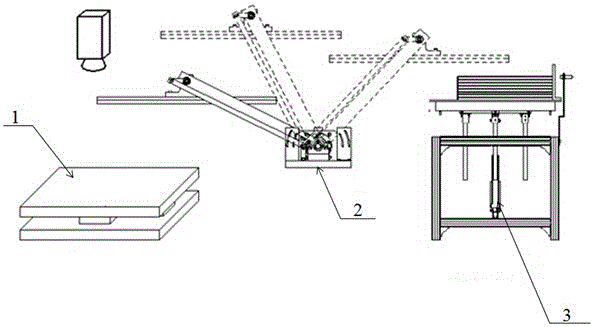

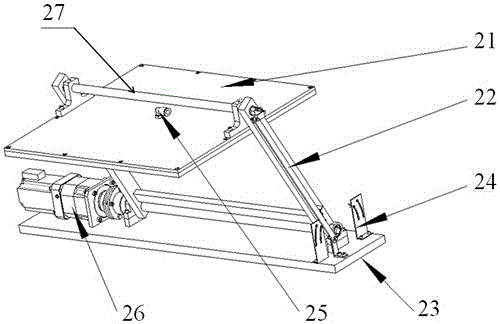

Automatic feeding and discharging mechanism of engraving and milling machine and feeding and discharging method

ActiveCN103213440ARealize automatic loading and unloading functionSolve the problem of automatic loading and unloadingModel makingEngineeringMechanical engineering

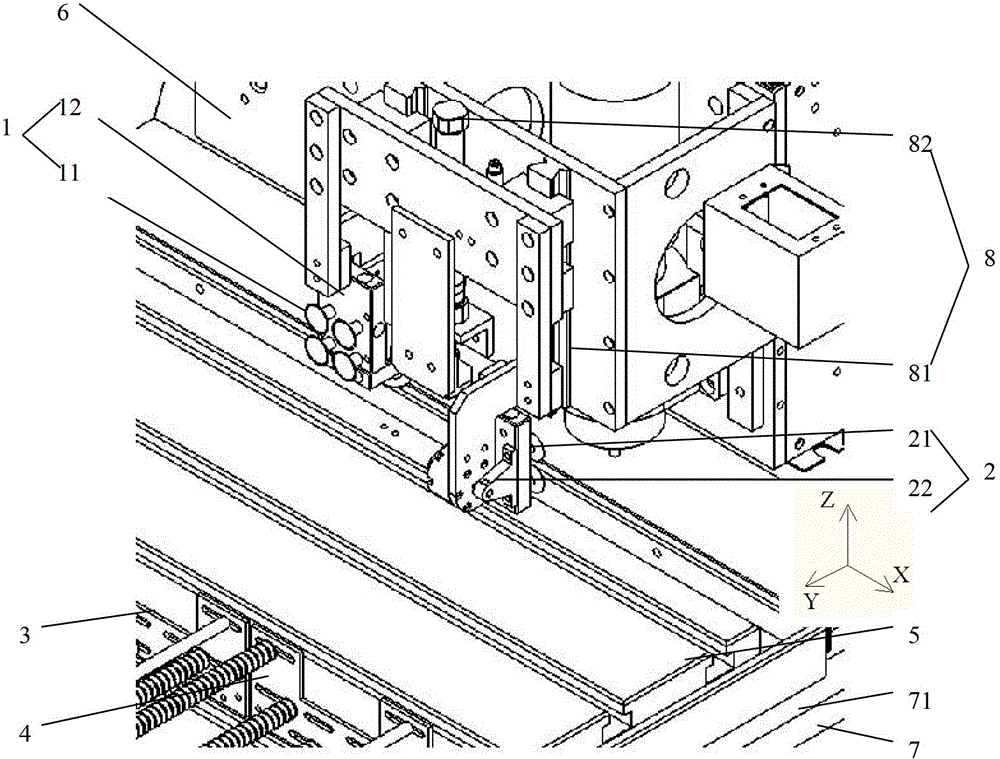

The invention discloses an automatic feeding and discharging mechanism of an engraving and milling machine and a feeding and discharging method. The automatic feeding and discharging mechanism of the engraving and milling machine comprises a taking assembly, a placing assembly, a feeding frame, a discharging frame, a positioning jig, a worktable, an X-axis displacement structure, a Y-axis displacement structure and a Z-axis displacement structure, wherein the feeding frame and the discharging frame are arranged on the worktable in parallel, the positioning jig is arranged on the worktable and is positioned at one sides of the feeding frame and the discharging frame, the Z-axis displacement structure is arranged on the X-axis displacement structure and moves in the X-axis direction, the taking assembly and the placing assembly are arranged on the Z-axis displacement structure and move in the Z-axis direction, and the worktable is arranged on the Y-axis displacement structure and moves in the Y-axis direction. By adopting the structure, the automatic feeding and discharging function of the engraving and milling machine is realized, the problem of automatic feeding and discharging during the glass processing is solved, and the automatic feeding and discharging mechanism has the advantages that the implementation method is simple, the efficiency is higher, and the positioning precision is high.

Owner:SHENZHEN YUANYANG XIANGRUI MACHINERY

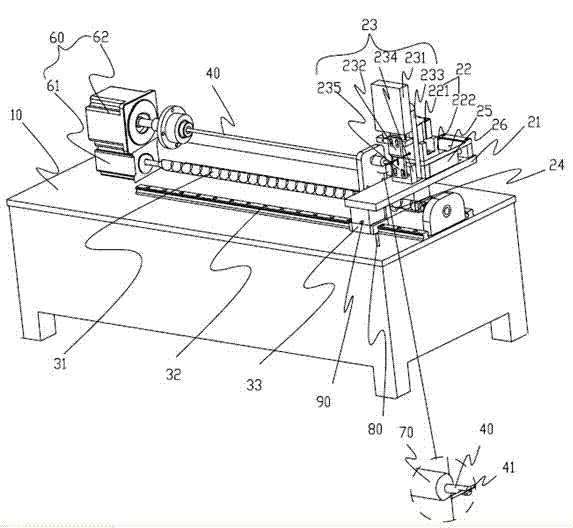

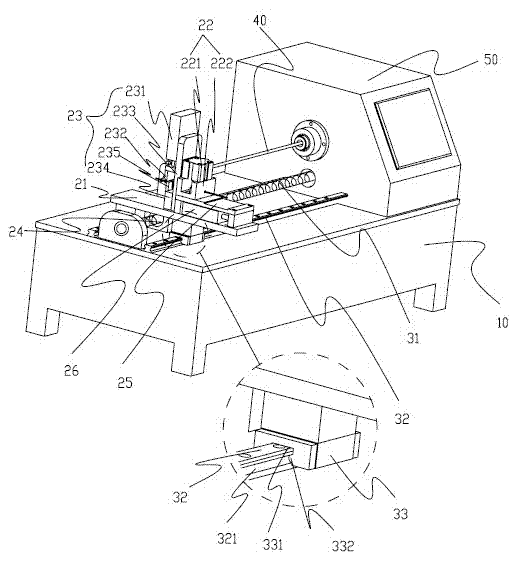

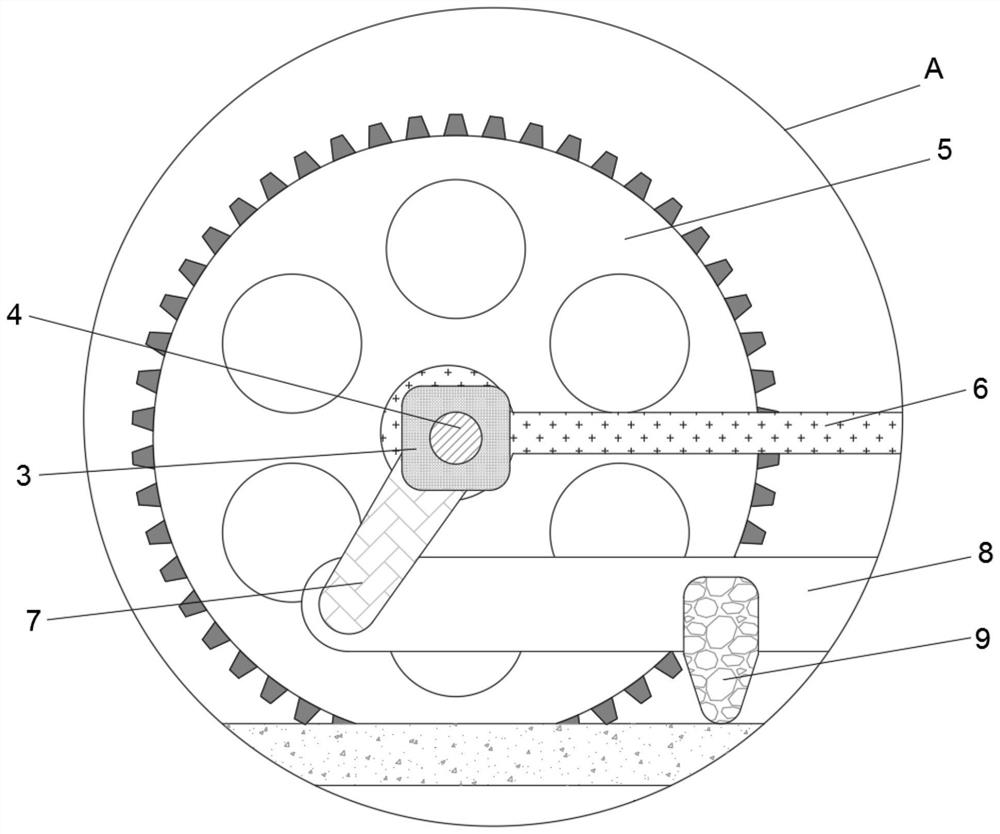

Full-automatic spring shaped coil winder

InactiveCN102403121AHigh precisionImprove qualityFilament handlingCoils manufactureWinding machineCopper wire

The invention discloses a full-automatic spring shaped coil winder, which comprises a box body. The box body is provided with a control system, a mobile mechanism, a winding mechanism and a guide rail mechanism. The mobile mechanism includes a bearing seat, a wire pressing device and a wire cutting device. The winding mechanism comprises a rotating shaft. The wire pressing device comprises a pushing cylinder and a pushing cylinder fixing seat. The pushing cylinder fixing seat is arranged on a plate. The plate is fixedly connected with a transverse cylinder below the plate. The cylinder rod of the transverse cylinder is fixed on the end part of the bearing seat. The wire cutting device comprises a wire cutting cylinder and a cutting tool. A wire cutting cylinder plate is arranged between the wire cutting cylinder and the pushing cylinder. The wire cutting cylinder is fixed onto the wire cutting cylinder plate. The cutting tool is fixedly connected with the end part of the cylinder rod of the wire cutting cylinder. A fixed block is arranged below the wire cutting cylinder. The fixed block is fixedly connected with the wire cutting cylinder plate. A cutter holder is arranged on the fixed block. The invention is automatically loaded and unloaded, which has the advantages of high degree of automation, stable and reliable performance, correct winding turns, the same standard of manufactured coils and high production efficiency.

Owner:康展电子(东莞)有限公司

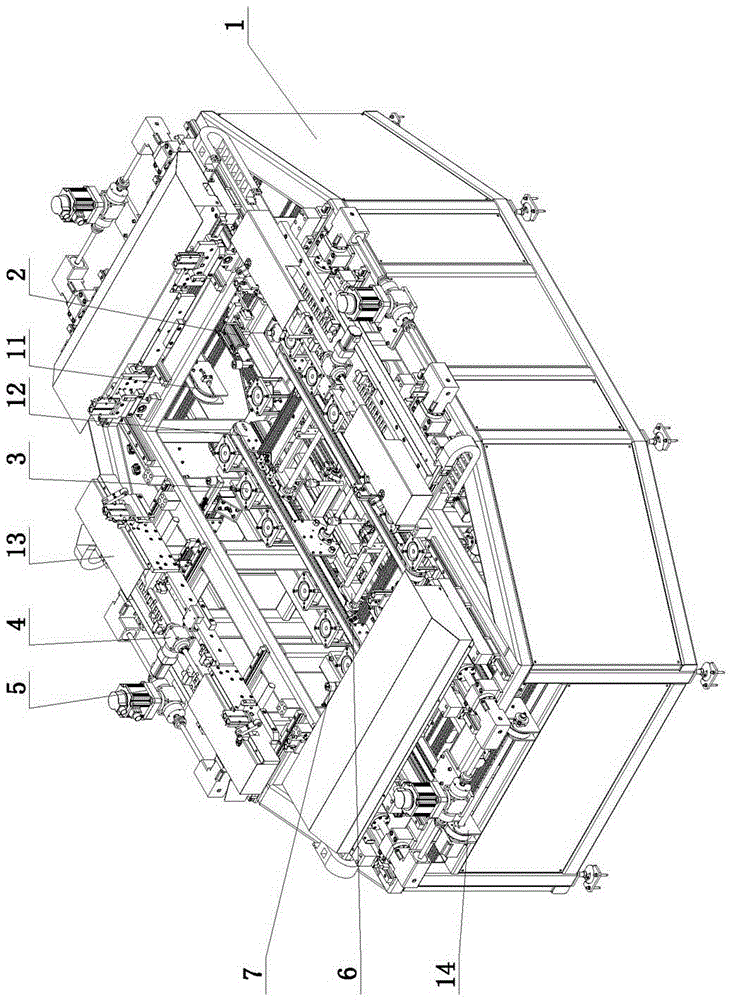

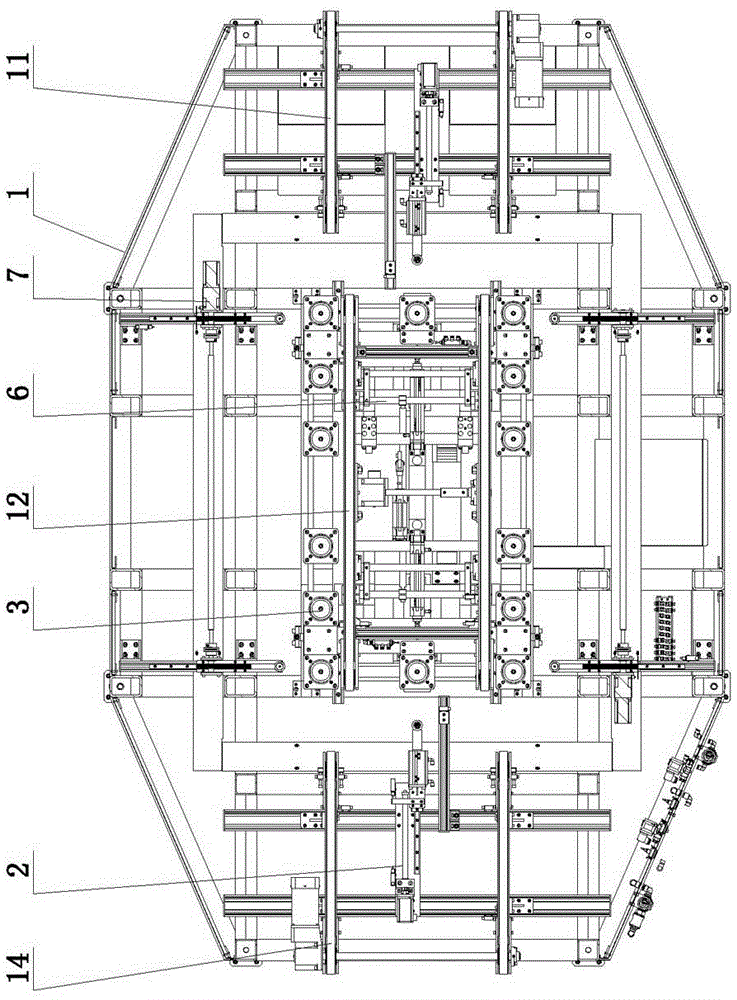

High efficiency full-automatic framing machine for solar cell module

ActiveCN106298608AEasy to adjustAvoid visual differencesFinal product manufactureSemiconductor/solid-state device manufacturingSolar cellAutomation

The invention provides a high efficiency full-automatic framing machine for a solar cell module, which belongs to the technical field of automatic production devices. The invention particularly relates to the high efficiency full-automatic framing machine in a solar cell module packaging device. The high efficiency full-automatic framing machine for the solar cell module has the advantages of high automation degree, good product uniformity and high production efficiency. The high efficiency full-automatic framing machine is characterized in that a feeding conveying device and a discharging conveying device are respectively arranged on two ends of the machine body; an intermediate conveying device is arranged at the middle part of the machine body through a lifting device; a component positioning device is arranged at a position corresponding to the intermediate conveying device in the machine body; and frame bonding devices are arranged on four sides of the component positioning device.

Owner:YINGKOU JINCHEN MACHINERY

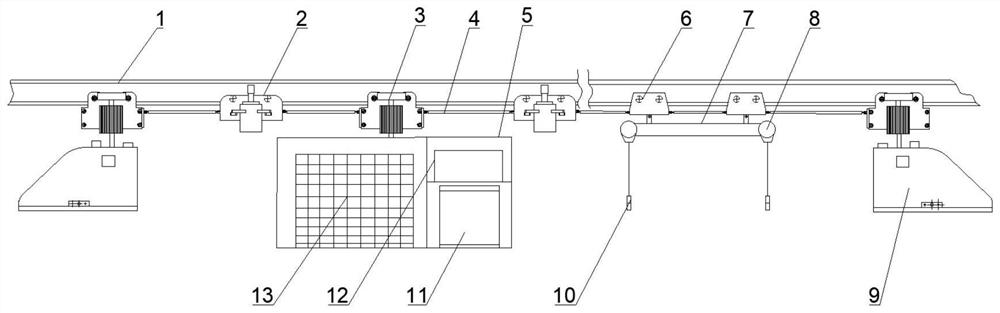

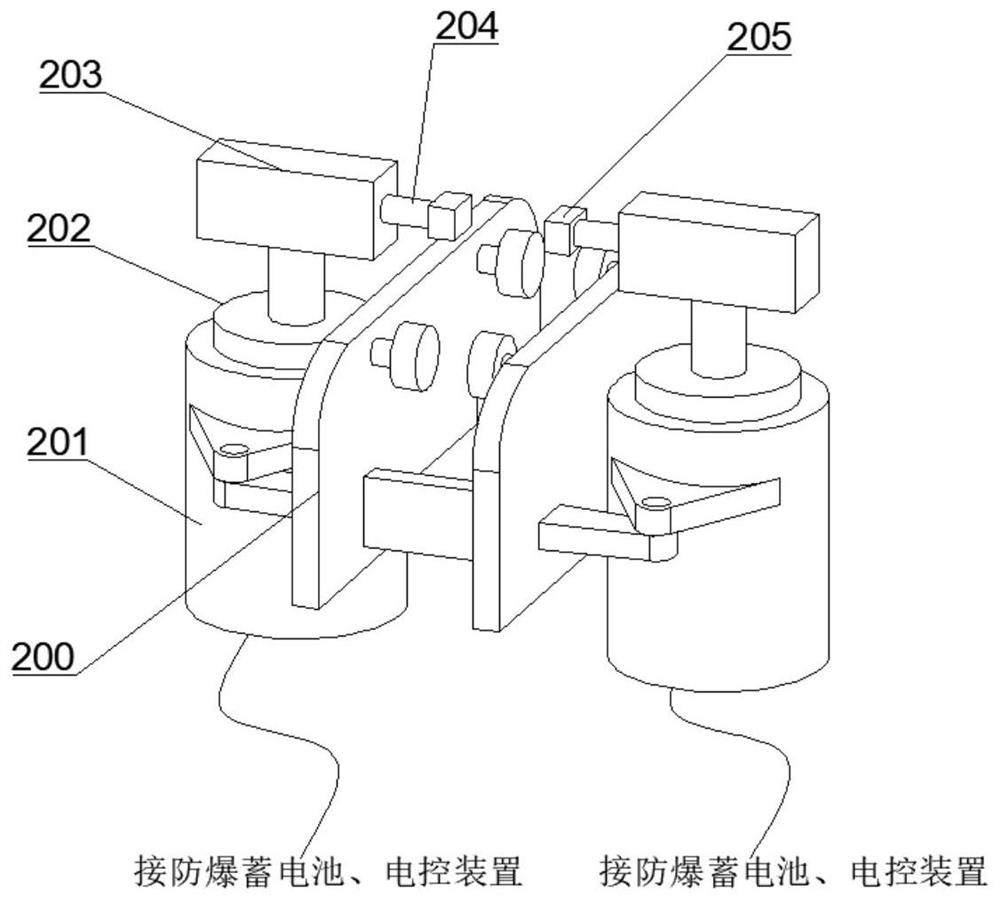

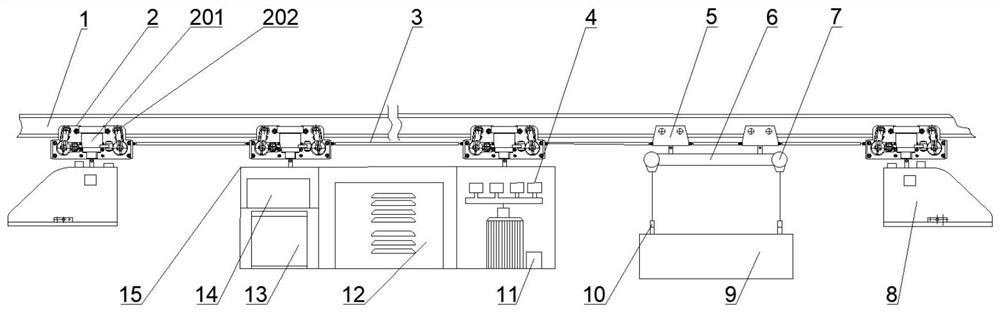

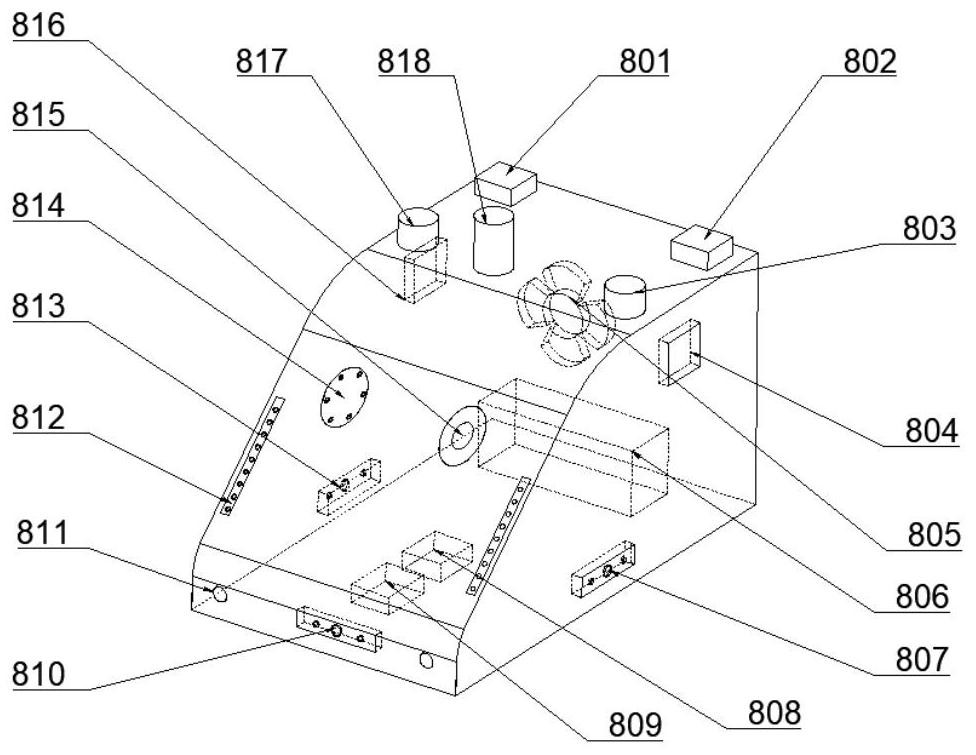

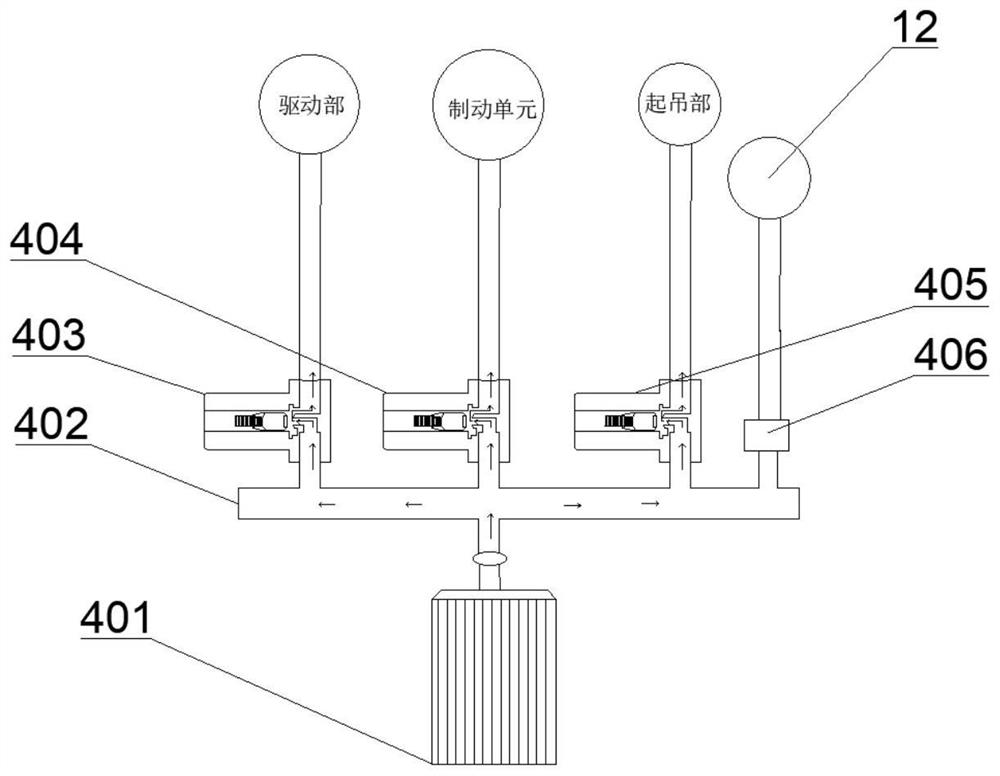

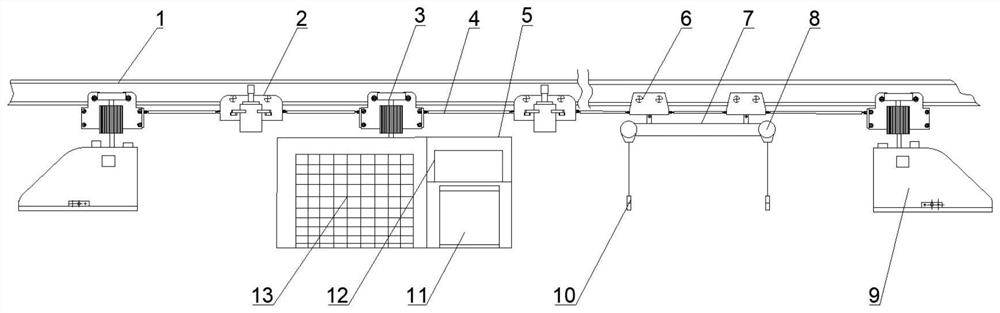

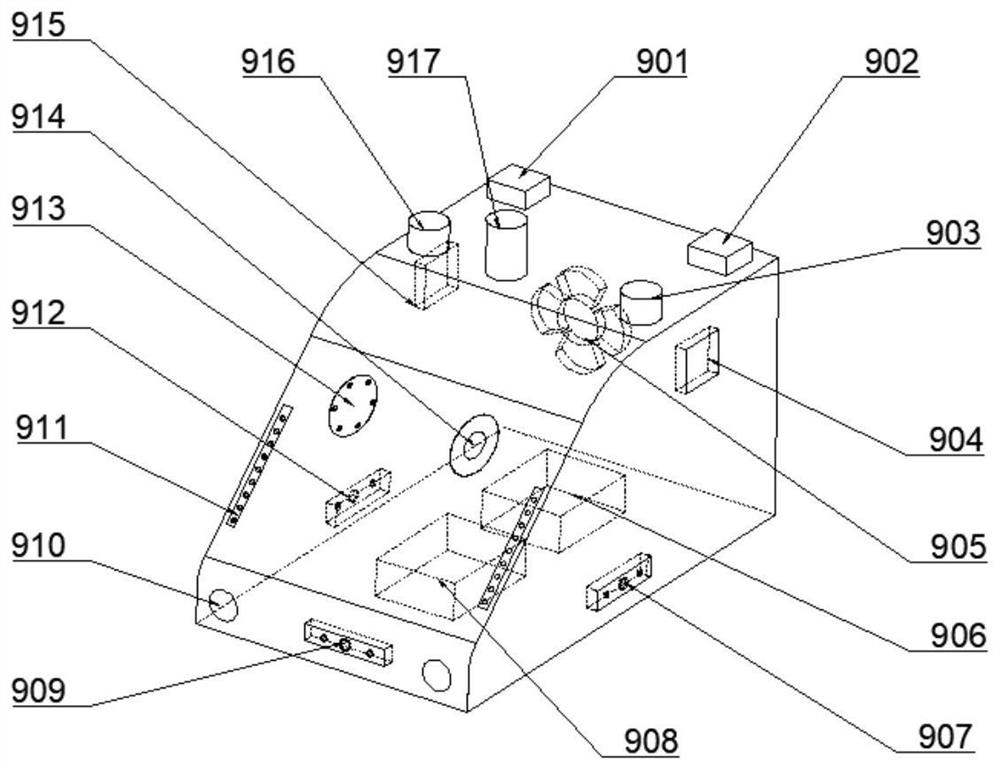

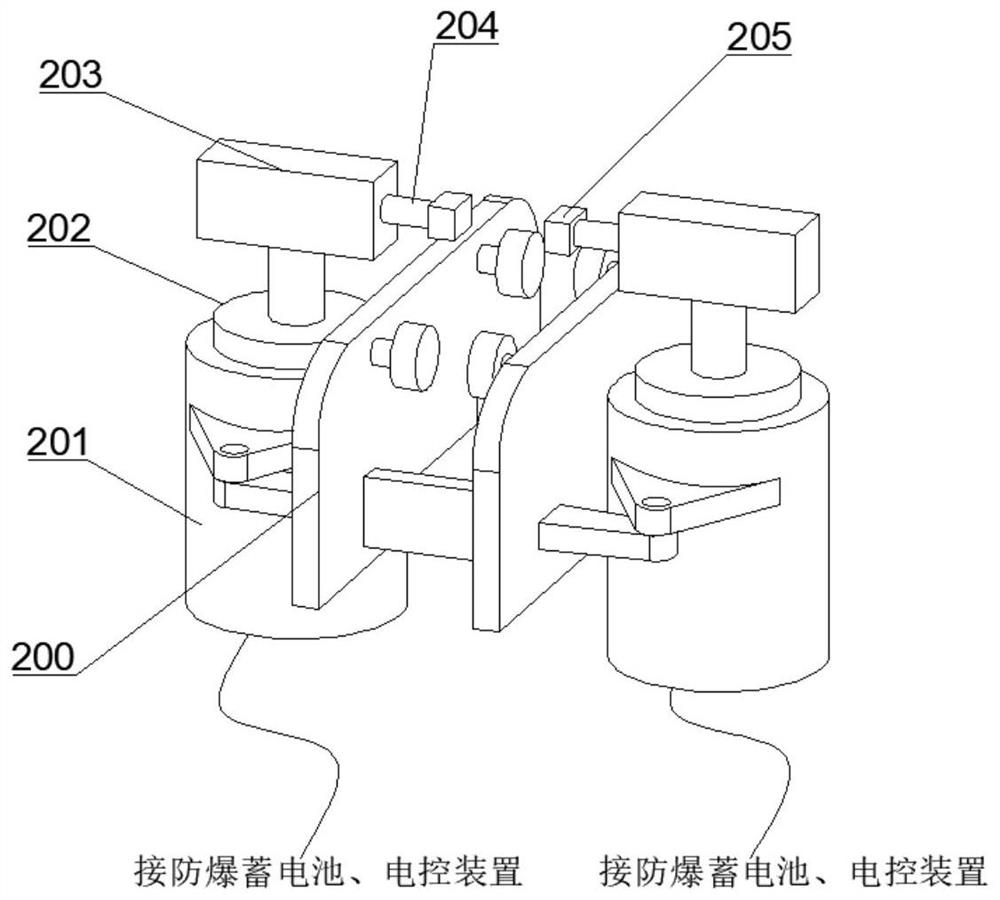

Storage battery type unmanned monorail crane and control method thereof

ActiveCN112850481AIncrease loading capacityCompact structureTravelling gearSafety gearSUSPENDING VEHICLEHydraulic pump

The invention discloses a storage battery type unmanned monorail crane and a control method thereof. The storage battery type unmanned monorail crane comprises a suspended rail, a braking device, a driving device, an intelligent cab, a lifting device and a power device. The intelligent cab, the lifting device and the power device are suspended on the suspended rail through the driving device and a bearing car respectively; and the intelligent cab is internally provided with a laser radar sensor, a depth camera sensor, a millimeter wave radar sensor and other sensors to sense the surrounding information of the monorail crane in real time, and positioning and mapping of the monorail crane are achieved. By using the electrically controlled braking device, pure-electric braking of the monorail crane is achieved. The lifting part uses a tight-connecting hook to achieve the process that the monorail crane automatically grabs and releases devices, and unmanned device loading and unloading are achieved. A cockpit and a hydraulic pump station are omitted structurally; the structure is more compact; autonomous unmanned driving can be achieved; and a basis is provided for underground unmanned and continuous auxiliary transportation.

Owner:CHINA UNIV OF MINING & TECH

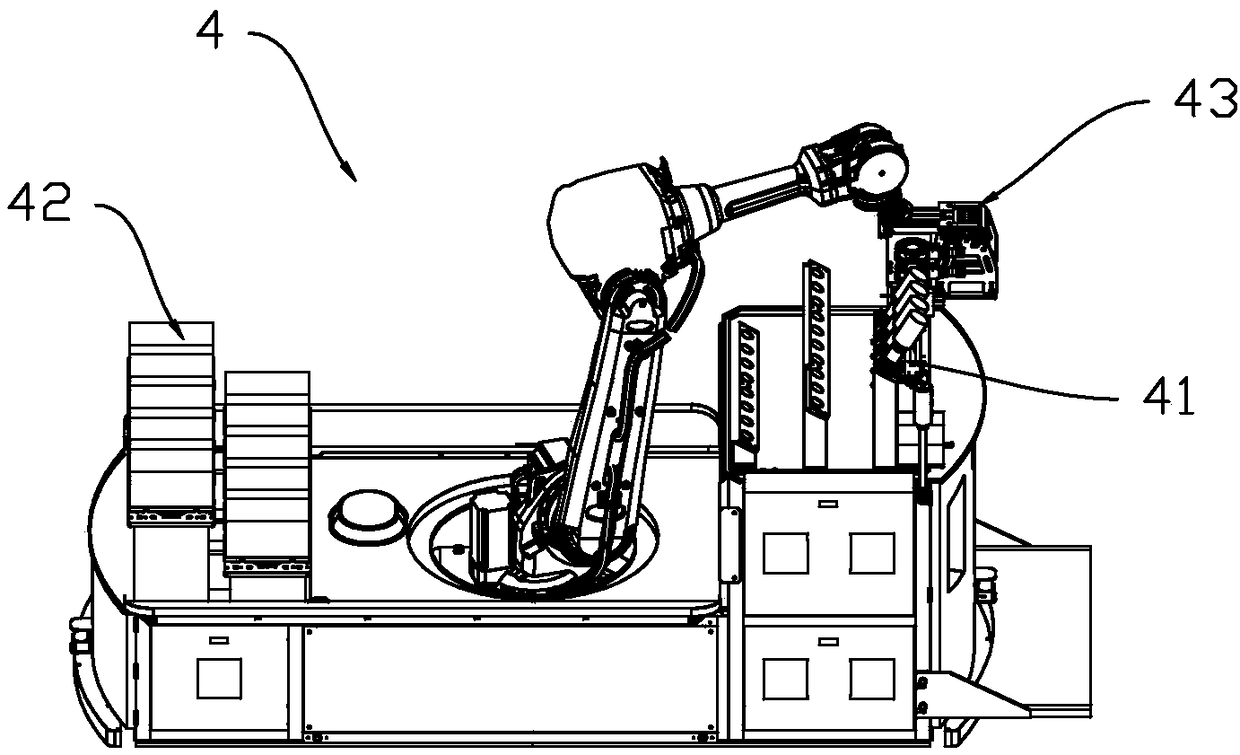

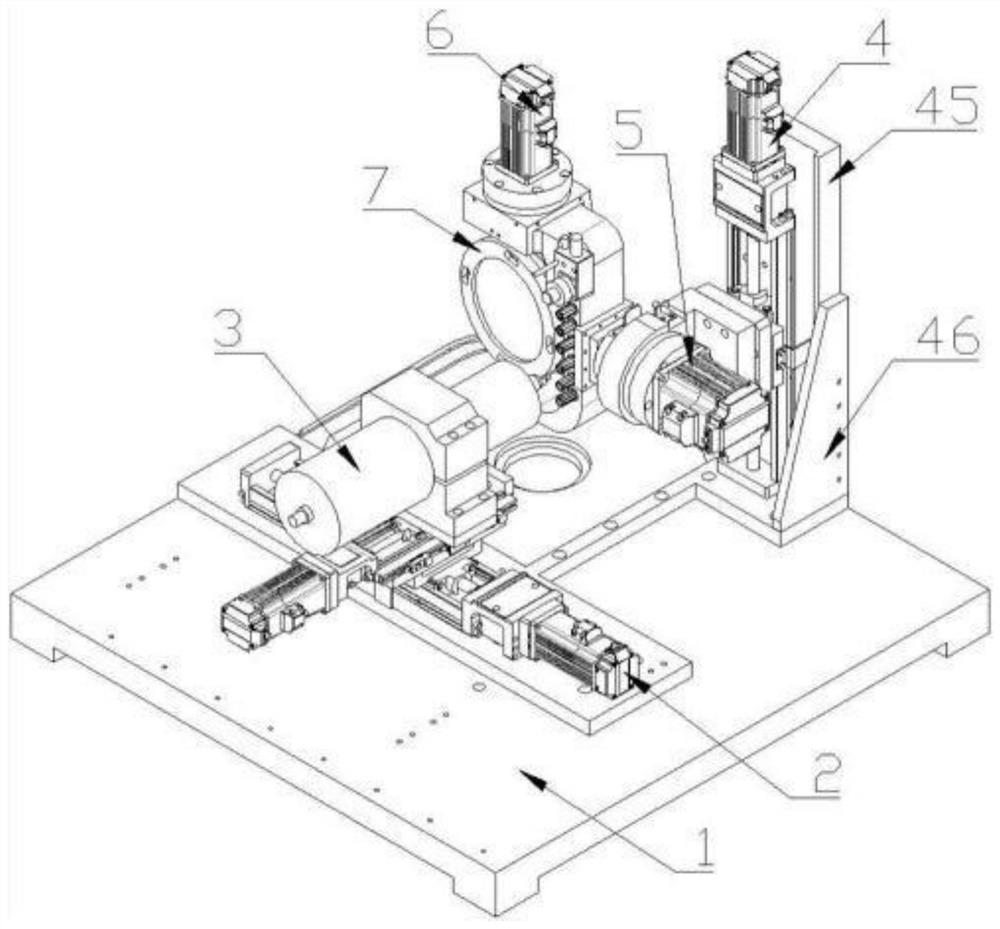

Automatic loading and unloading production line

PendingCN109128963ARealize automatic loading and unloading functionImprove work efficiencyMetal working apparatusProduction lineNumerical control

The invention discloses an automatic loading and unloading production line. The production line comprises an AGV rail, an AGV car arranged on the AGV rail, a RGV rail and a RGV car arranged on the RGVrail, and further comprises multiple numerical control machine tools and a material vehicle for carrying materials; multiple parking wharfs are arranged on the side surface of the RGV rail; and the parking wharfs and the material vehicle are provided with first butt joint pieces and second butt joint pieces matched with each other. The automatic loading and unloading production line uses an automatic tracking function of the AGV car for conveying materials to the parking wharfs; then, the RGV car uses an intelligent manipulator for taking the materials on the parking wharfs; finally, the RGVcar conveys the materials into the corresponding numerical control machine tools according to the demands of all the numerical control machine tools; clinkers machined in the numerical control machinetools are taken out and conveyed into the AGV car to realize automatic loading and unloading functions, so that the working efficiency is high, and a lot of labor costs are saved; and the productionline is applied to the field of automation equipment.

Owner:KEYIZHAN INTELLIGENT EQUIP CO LTD +1

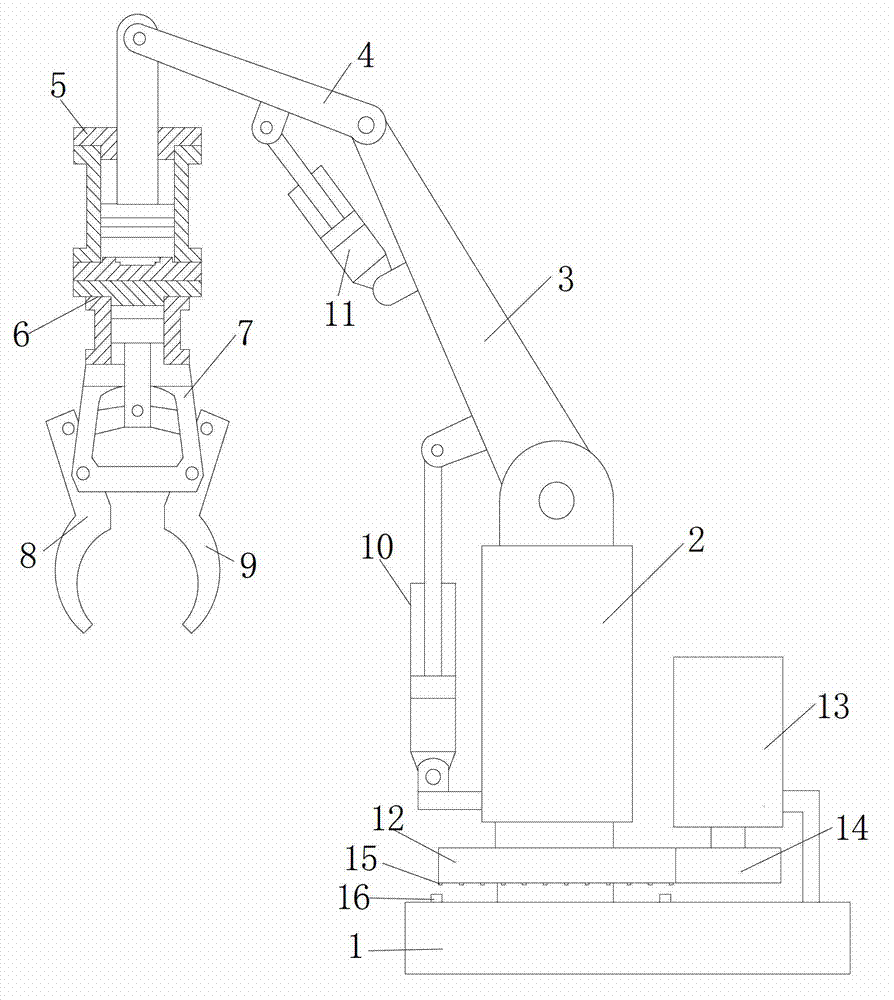

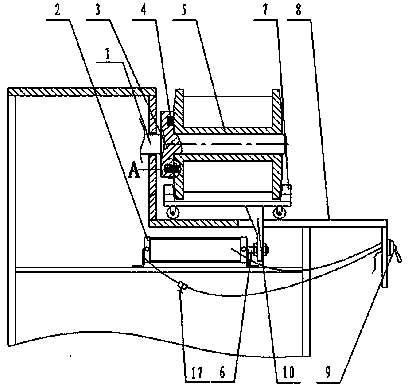

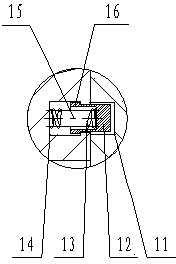

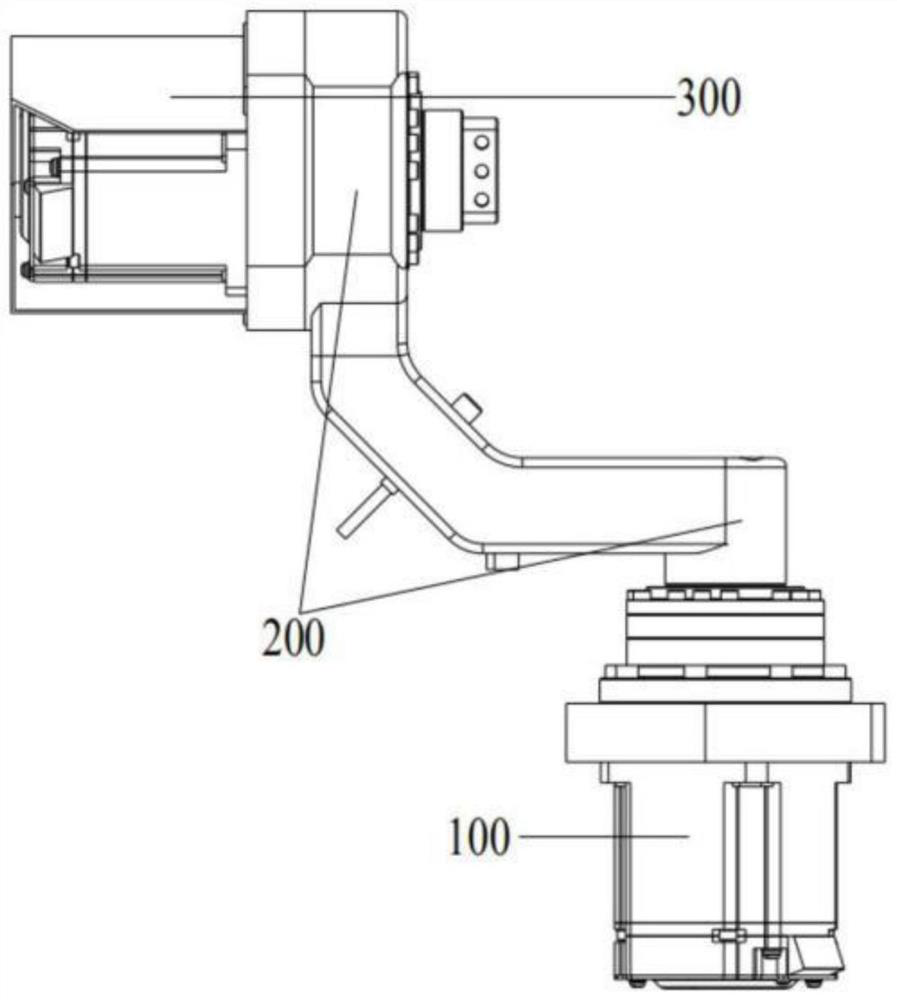

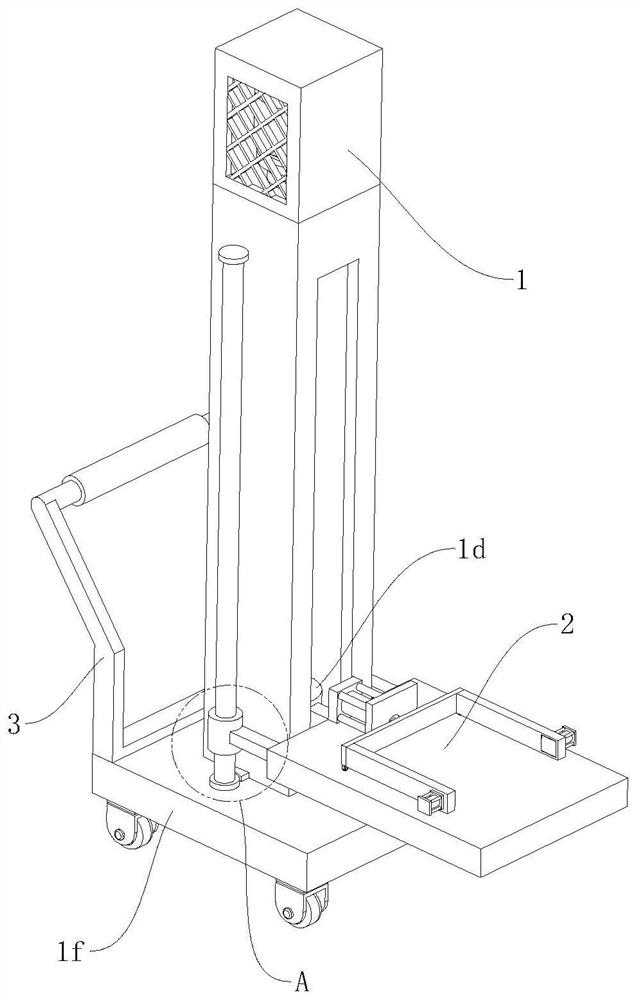

Loading and unloading device capable of automatic clamping

InactiveCN102862813ARealize automatic loading and unloading functionImprove work efficiencyConveyor partsEngineeringMechanical engineering

The invention relates to a loading and unloading device capable of automatic clamping. The loading and unloading device comprises a base, a stand column arranged on the base and a driving mechanism driving the stand column to rotate on the base, wherein a first swing arm and a second swing arm are arranged above the stand column; one end of the first swing arm is movably connected onto the stand column; the other end of the first swing arm is movably connected one end of the second swing arm; a lifting cylinder is arranged at the other end of the second swing arm; a piston rod of the second swing arm is connected with the second swing arm; a clamping cylinder is fixedly arranged below a cylinder body of the lifting cylinder; a finger support, a left clamping finger and a right clamping finger are fixedly arranged on the clamping cylinder, wherein the middle portions of the left clamping finger and the right clamping finger are movably connected onto the finger support; the piston rod of the clamping cylinder is movably connected with an upper end portion of the left clamping finger and an upper end portion of the right clamping finger; a first piston cylinder is arranged between the stand column and the first swing arm; and a second piston cylinder is arranged between first swing arm and the second swing arm. With the adoption of the loading and unloading device capable of automatic clamping, objects can be automatically clamped and loosened, and the objects can be placed at a specified position, so that the work efficiency is improved, manpower labor is lightened and a large quantity of manpower is saved.

Owner:CHANGZHOU LIWEI KNIFE

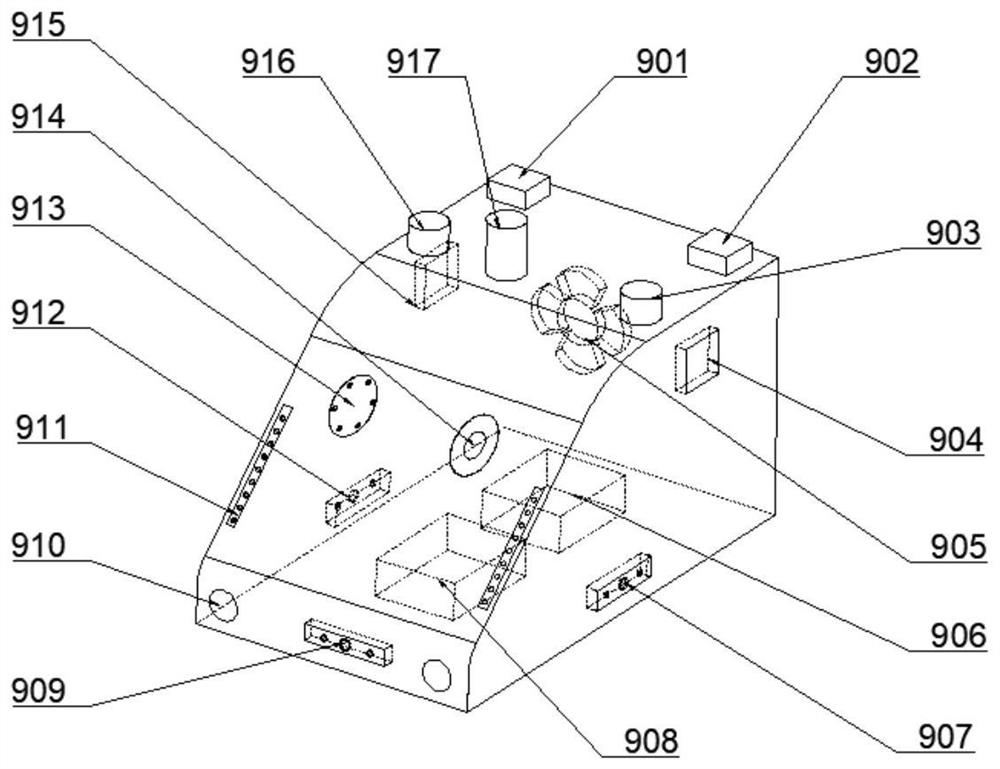

Diesel type unmanned monorail crane and control method thereof

ActiveCN112850482AIncrease loading capacityCompact structureTravelling gearSafety gearSolenoid valveHydraulic circuit

The invention discloses a diesel type unmanned monorail crane and a control method thereof. The diesel type unmanned monorail crane comprises a suspended rail, a driving part, an intelligent cab, a lifting device and a power device. The intelligent cab, the lifting device and the power device are suspended on the suspended rail; and the intelligent cab is internally provided with a laser radar sensor, a depth camera sensor, a millimeter wave radar sensor and other sensors to sense the surrounding information of the monorail crane in real time, and positioning and mapping of the monorail crane are achieved. By using a tight-connecting hook to achieve the process that the monorail crane automatically grabs and releases devices, and unmanned device loading and unloading are achieved. By using a driving proportional solenoid valve, a braking proportional solenoid valve, a lifting proportional solenoid valve and other proportional solenoid valves to control a hydraulic loop, and the magnitudes of current flowing into different proportional solenoid valves are autonomously controlled by the controller to achieve switch-on or switch-off of different hydraulic loop. The intelligent cab is more compact in structure; autonomous unmanned driving is achieved; the bearing capacity of the whole crane is improved; and a basis is provided for underground unmanned and continuous auxiliary transportation.

Owner:CHINA UNIV OF MINING & TECH

Automatic feeding and discharging device for machine tool

InactiveCN103707110ARealize automatic loading and unloading functionReduce the incidence of personal accidentsAutomatic workpiece supply/removalMetal working apparatusBall screwEconomic benefits

The invention provides an automatic feeding and discharging device for a machine tool. The automatic feeding and discharging device for the machine tool comprises a working platform, a manipulator and a pushing device, wherein the working platform comprises a servo motor, a ball screw and a linear guide track; the ball screw is provided with a nut in a matched manner; the linear guide track is provided with a sliding block in a matched manner; the nut and the sliding block are fixedly connected with each other together; the manipulator comprises a gas claw and a gas claw seat; the gas claw is fixedly connected to the gas claw seat; the gas claw seat is fixedly connected with the nut or the sliding block; the pushing device comprises a shifting plate; and the shifting plate is connected with a pneumatic device or a hydraulic device. An automatic feeding and discharging function of a workpiece can be fulfilled, direct manual operation is not required, so that the labor is saved, potential safety hazards in a working procedure are eliminated, and production efficiency is greatly improved. At present, the automatic feeding and discharging device is used; an expectant effect is achieved; and the automatic feeding and discharging device brings great economic benefit for a company.

Owner:天津天海同步科技有限公司

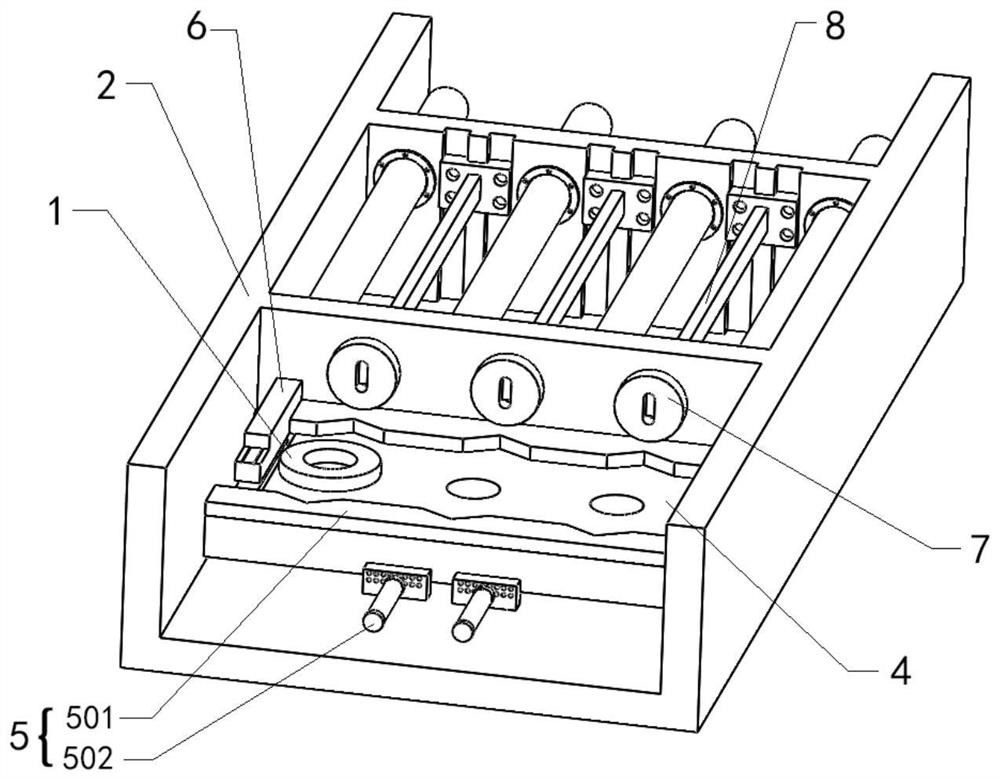

Automatical disassembling device for spool

The invention discloses an automatical disassembling device for a spool. The automatical disassembling device comprises a winding shaft, the spool, a permanent magnet, a magnet seat and a driven shaft. A driven hole is formed on the spool. The magnet seat and a stirring pin are arranged on the winding shaft. The permanent magnet is fixed in the magnet seat. The automatical disassembling device further comprises a rail trolley for carrying the spool and a workbench for loading the rail trolley for performing reciprocating motion. The rail trolley is connected with a control device of reciprocating motion through a connecting steel. The spool on the rail trolley is driven by the control device of the reciprocating motion to perform reciprocating motion on the rail, the spool is assembled through strong magnetic adsorption of the permanent magnet and is disassembled by connecting steel pushing the rail trolley to allow the spool to escape from the strong magnetic adsorption of the permanent magnet, functions of assembling and disassembling the spool automatically are realized by operating a control switch directly, labor intensity of operators can be reduced effectively, effect is more significate while the spool is disassembled especially, and producing efficiency of a machine tool is improved effectively.

Owner:JIANGSU XINGDA STEEL TYPE CORD

Full-automatic spring shaped coil winder

InactiveCN102403121BHigh precisionImprove qualityFilament handlingCoils manufactureWinding machineControl system

The invention discloses a full-automatic spring shaped coil winder which has simple structure and convenient operation, comprising a tank body, wherein the inside of the tank body is provided with a control system. A mobile mechanism, a winding mechanism and a guide rail mechanism are installed on the tank body. The mobile mechanism includes a bearing seat, a wire pressing device and a wire cutting device on the bearing seat; the winding mechanism comprises a rotary shaft for winding the copper wire into a coil. The guide rail mechanism includes a screw rod, two guide rails and two guide sliding blocks matched with two guide rails. The invention is automatically loaded and unloaded, which has the advantages of high degree of automation, controllable range, automatic winding and cutting process, ordered wire distribution, convenient operation and adjustment, stable and reliable performance, correct winding turns and the same standard of manufactured coils and high production efficiency.

Owner:康展电子(东莞)有限公司

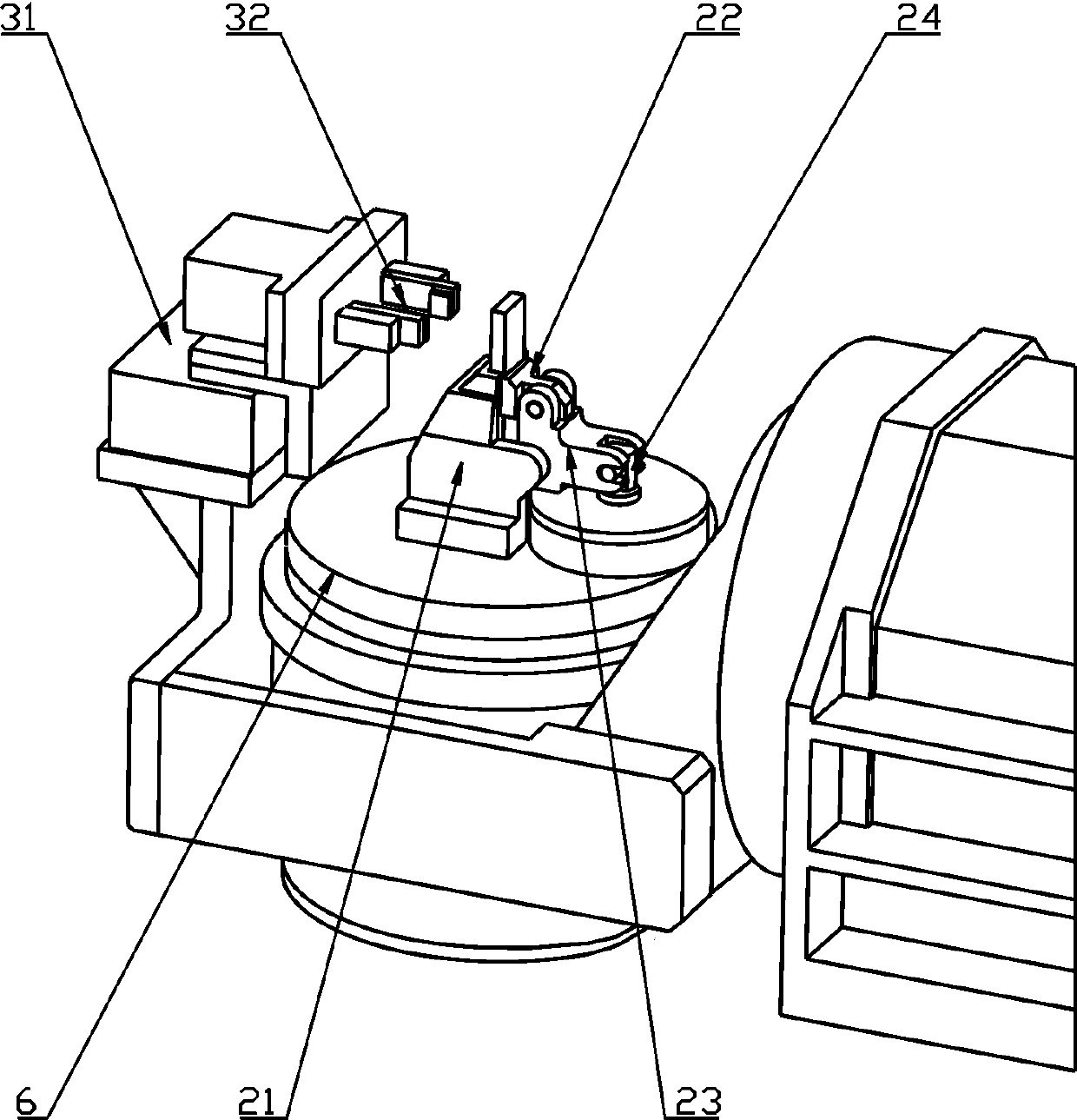

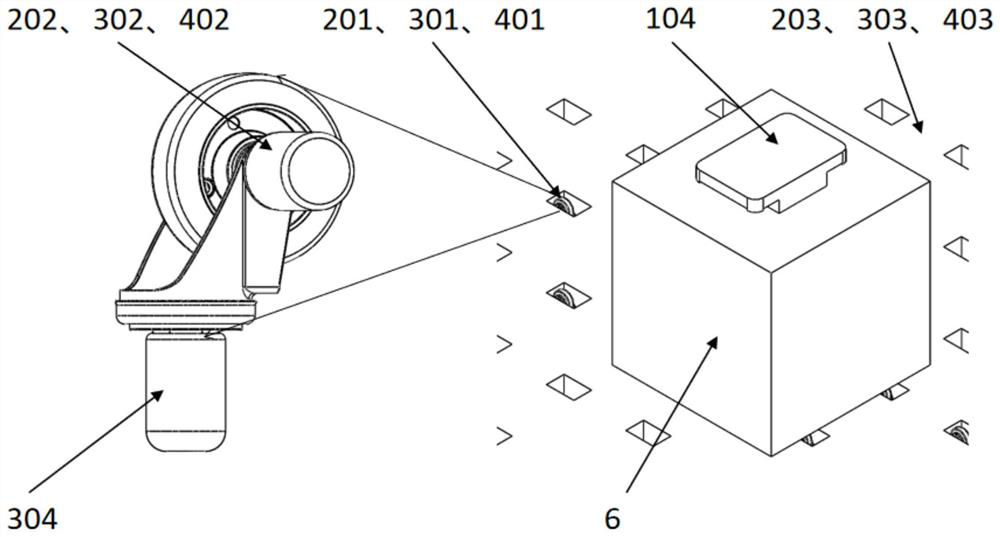

Automatic loading and unloading equipment of multi-shaft finish carving machine

ActiveCN108058523ASave loading and unloading timeIncrease productivityModel makingVertical motionEngineering

The invention discloses automatic loading and unloading equipment of a multi-axis finish carving machine. The equipment comprises a fixed bracket structure, a material frame, a three-axis linear motion mechanism, a glass piece grabbing and overturning mechanism, a positioning mechanism and a vacuum worktable; the fixed bracket structure is connected with the finish carving machine; the material frame is connected with the finish carving machine; the material frame is provided with a material basket; the three-axis linear motion mechanism is connected with the fixed bracket structure; the three-axis linear motion mechanism is provided with a transverse motion mechanism, a longitudinal motion mechanism and a vertical motion mechanism; the glass piece grabbing and overturning mechanism is connected with the three-axis linear motion mechanism; the positioning mechanism is connected above the material frame; and the vacuum worktable is positioned above the material frame, and is positionedbelow the positioning mechanism. The equipment realizes full-automatic multi-station loading and unloading, greatly shortens the loading and unloading time, greatly improves the production efficiency,is delicate and compact in structure, forms a whole with the finish carving machine without increasing the floor area of the finish carving machine to increase the factory building utilization rate,and is precise and reliable in positioning to reduce scratch by glass pieces.

Owner:上海神添实业有限公司

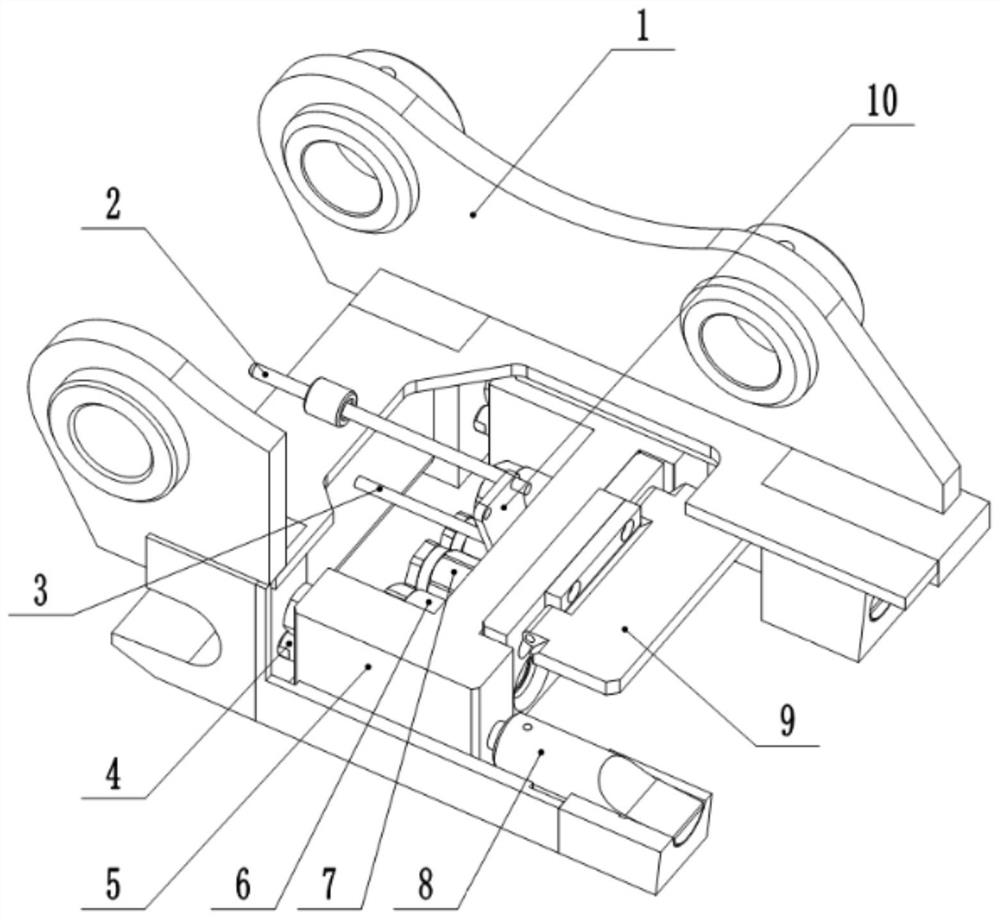

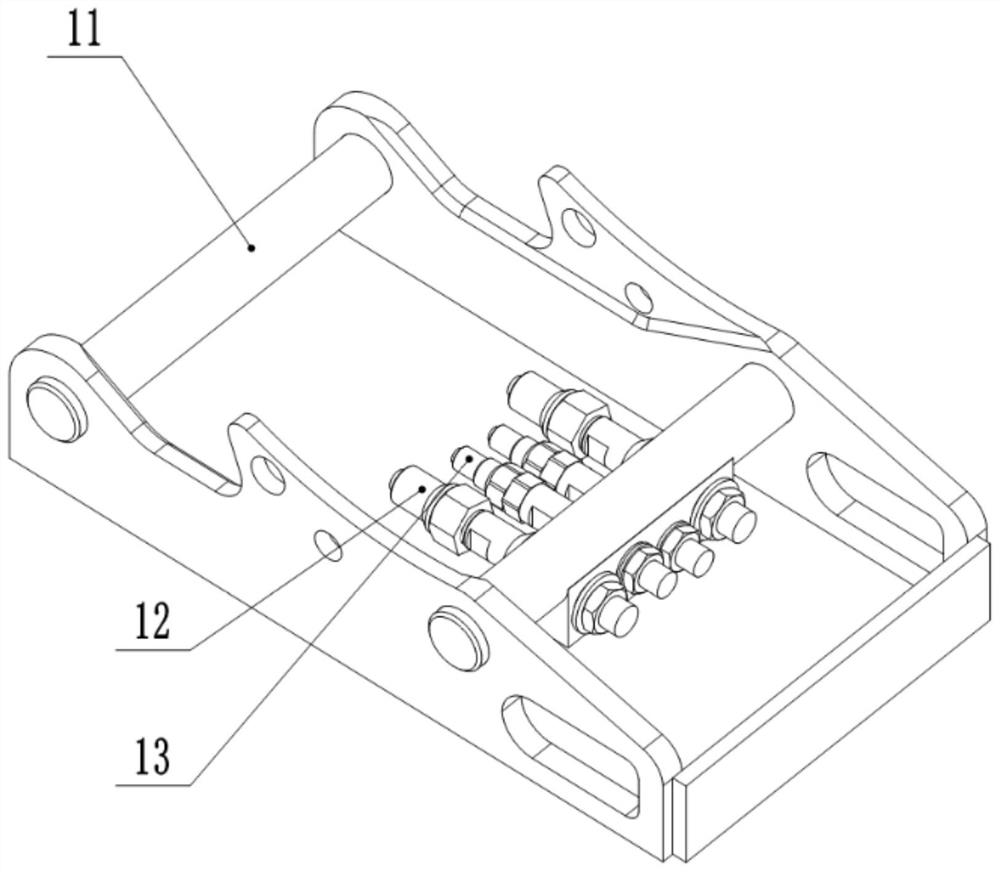

Quick-change device capable of automatically conducting hydraulic and electrical channels

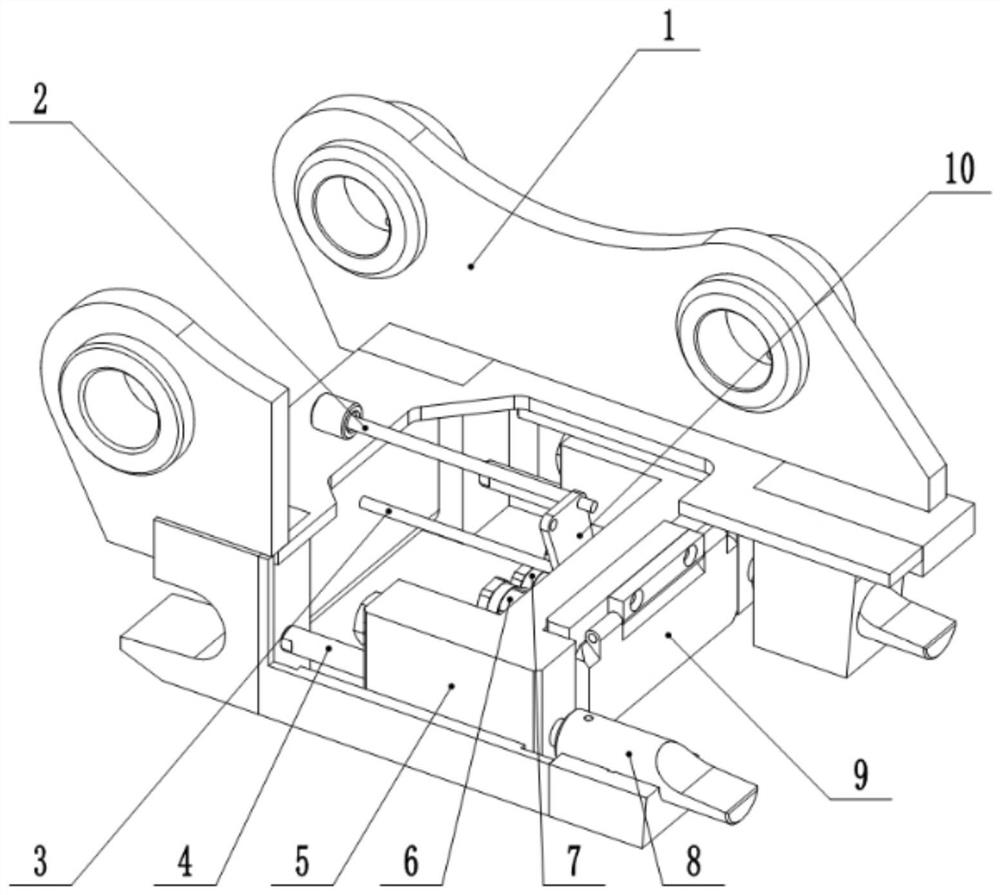

InactiveCN112252386ARealize automatic loading and unloading functionSimple structureServomotor componentsMechanical machines/dredgersStructural engineeringMachine

The invention discloses a quick-change device capable of automatically conducting hydraulic and electrical channels. The quick-change device comprises an upper connecting frame and a lower connectingframe. The upper connecting frame comprises a machine frame, a signal rod, a supporting rod, hydraulic push rods, a valve body, hydraulic quick-plug female ends, electrical quick-plug female ends, spring bolts, a fender and a bracket. The lower connecting frame comprises a lower machine frame, hydraulic quick-plug male ends and electrical quick-plug male ends, the hydraulic push rods are installedin the valve body, and the telescopic ends of the hydraulic push rods are fixed to the machine frame; and the hydraulic quick-plug female ends, the electrical quick-plug female ends and the spring bolts are fixed to the valve body. By operating the quick-change device, the purpose of easily and quickly replacing different working accessories can be achieved; and meanwhile, automatic conducting ofa hydraulic oil way and a control circuit between a main machine and the lower connecting working accessory is achieved, and the quick-change device is particularly important to be applied to some high-risk environments and special working conditions.

Owner:安徽恒创智能装备有限公司

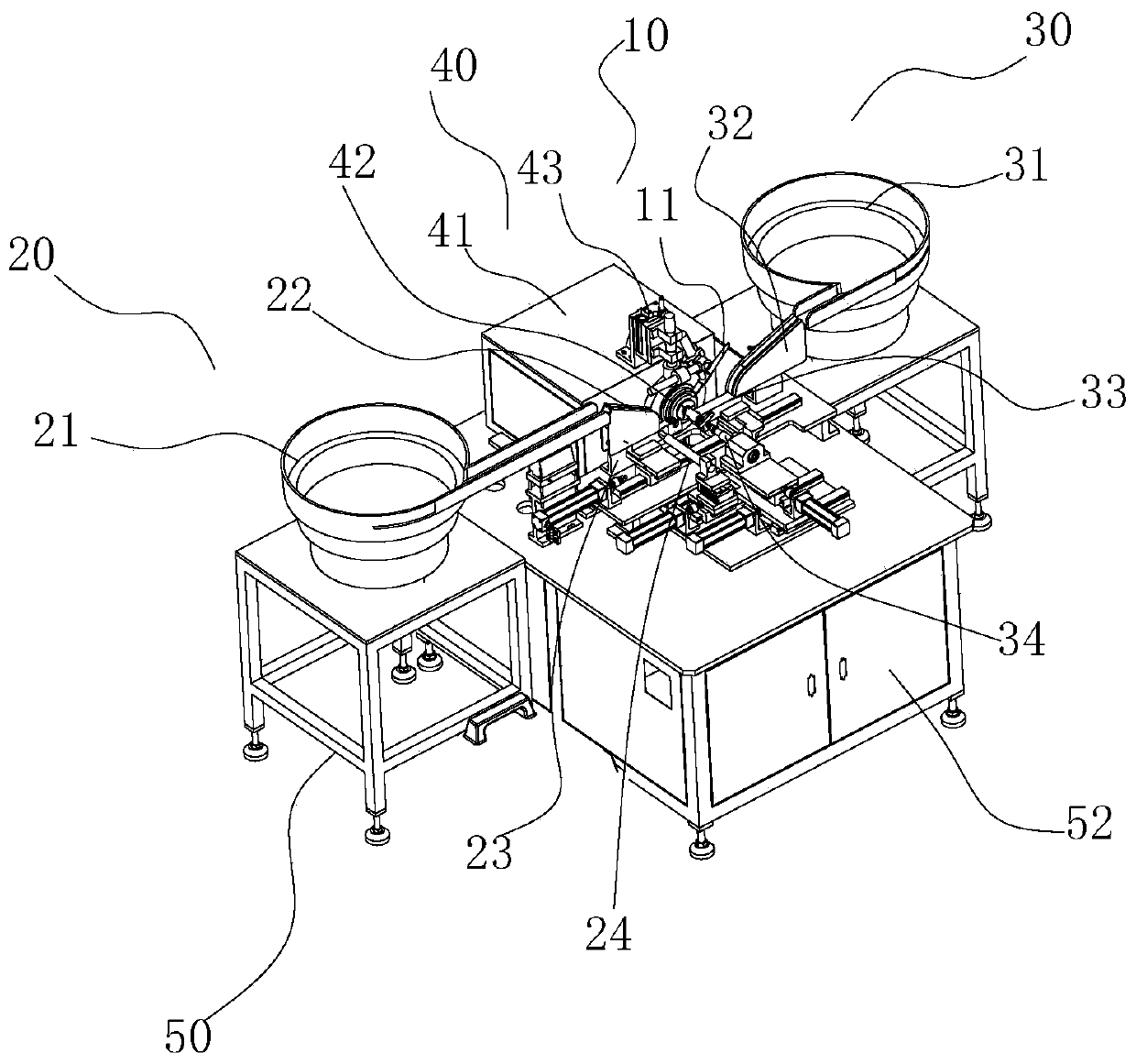

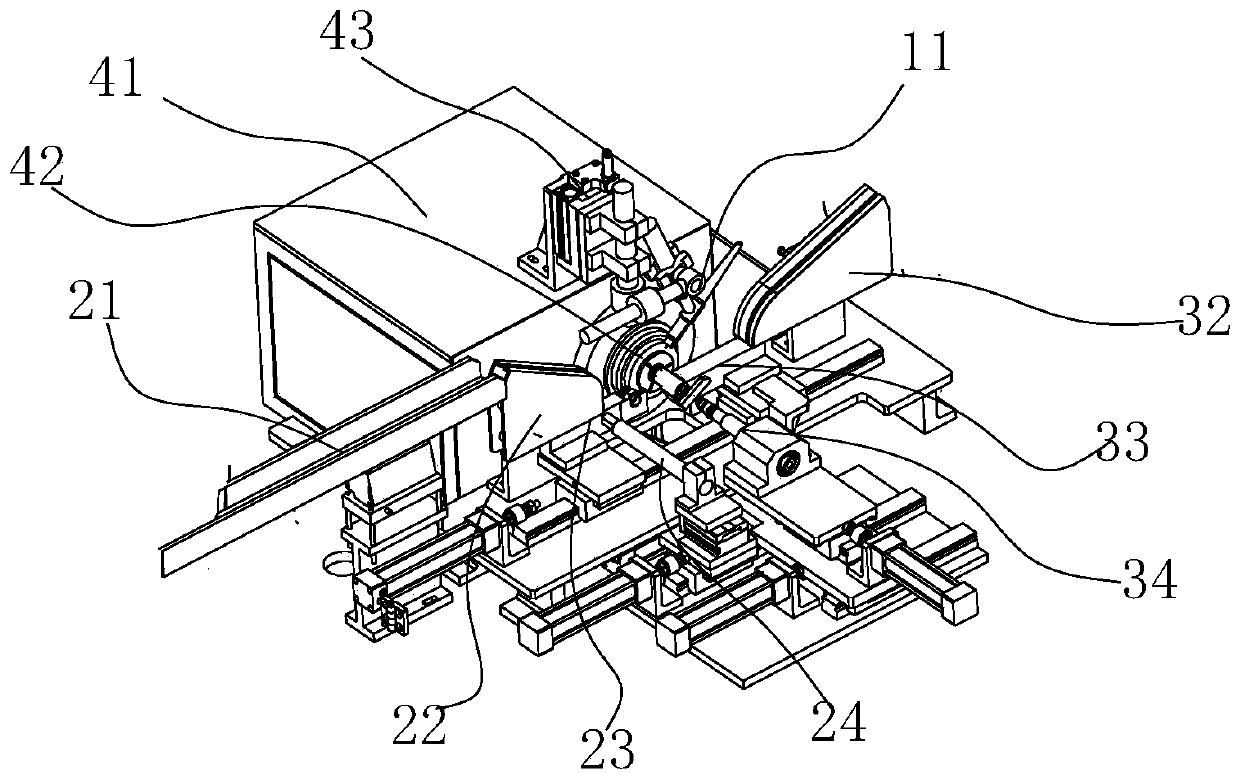

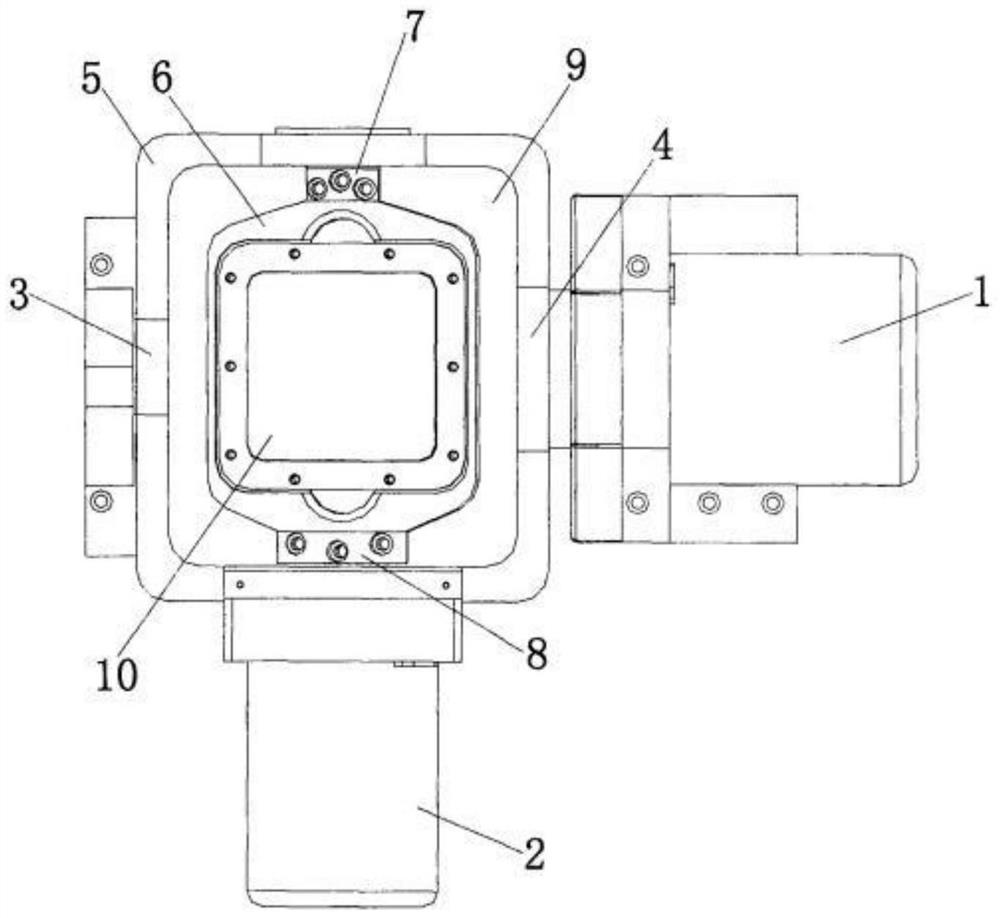

Ring welding equipment

PendingCN109955009ARealize automatic weldingHarm reductionWelding/cutting auxillary devicesAuxillary welding devicesLocking mechanismPipe fitting

The invention mainly relates to pipe fitting welding equipment, in particular to ring welding equipment. The ring welding equipment comprises a welding gun, a first workpiece feeding device, a secondworkpiece feeding device and a pneumatic chuck. According to the ring welding equipment, through the first workpiece feeding device and the second workpiece feeding device, a first workpiece is fed toa locking mechanism through the joint cooperation of a first feeding rod and a first pushing mechanism, a second workpiece is moved to be aligned and spliced with the first workpiece through a secondfeeding rod and a second pushing structure, a welding gun welds a gap between the first workpiece and the second workpiece, and a second pushing mechanism and the pneumatic chuck simultaneously drivethe first workpiece and the second workpiece to rotate, so that the welding is completed. Compared with traditional manual feeding and discharging welding equipment, automatic feeding and dischargingfunctions are realized, and the automatic welding can be realized after the feeding and discharging are completed, so that the production efficiency is greatly improved, the labor cost is reduced, the harm to a human body facing the welding equipment for a long time is reduced, and the automatic welding of pipe fittings is realized.

Owner:佛山市欧朗智能装备有限公司

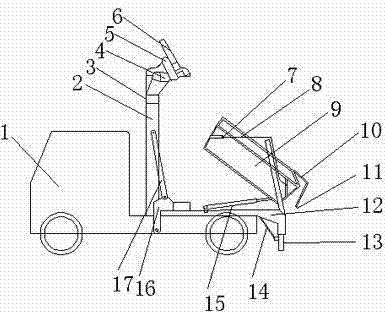

Stable self-loading and unloading garbage truck

InactiveCN104760794ARealize automatic loading and unloading functionSave cleaning laborRefuse vehiclesFixed frameEngineering

The invention discloses a stable self-loading and unloading garbage truck. The stable self-loading and unloading garbage truck comprises a truck body, an overturn arm, a telescopic arm, a connecting rod, a quick-changing connecting base, a bucket turning mechanism, chain buckles, chains, a garbage can, a back cover, a locking buckle, a truck hopper, a support foot, a support foot oil cylinder, a rocking arm oil cylinder, a fixing frame and an overturn oil cylinder, wherein the truck hopper is located on the truck body, the rocking arm oil cylinder is located at the middle end of the truck hopper, the support foot and the support foot oil cylinder are located at the rear end of the truck hopper, the chain buckles are located on the two sides of the garbage can, the chains are located on the chain buckles, the back cover is located on the garbage can, the locking buckle is located on the back cover, the fixing frame is located on the truck hopper, the overturn oil cylinder is located on the overturn arm, the overturn arm is located on the fixing frame, the telescopic arm is located on the overturn arm, the overturn arm is located on the fixing frame, the telescopic arm is located on the overturn arm, the quick-changing connecting base is located on the connecting rod, and the bucket turning mechanism is located on the connecting rod. The stable self-loading and unloading garbage truck has the advantages that an automatic loading and unloading function can be achieved, the garbage collection labor and cost are saved, the cleanness and sanitation of environment are kept, and meanwhile the stability of the garbage truck in garbage dumping is improved.

Owner:姬爱书

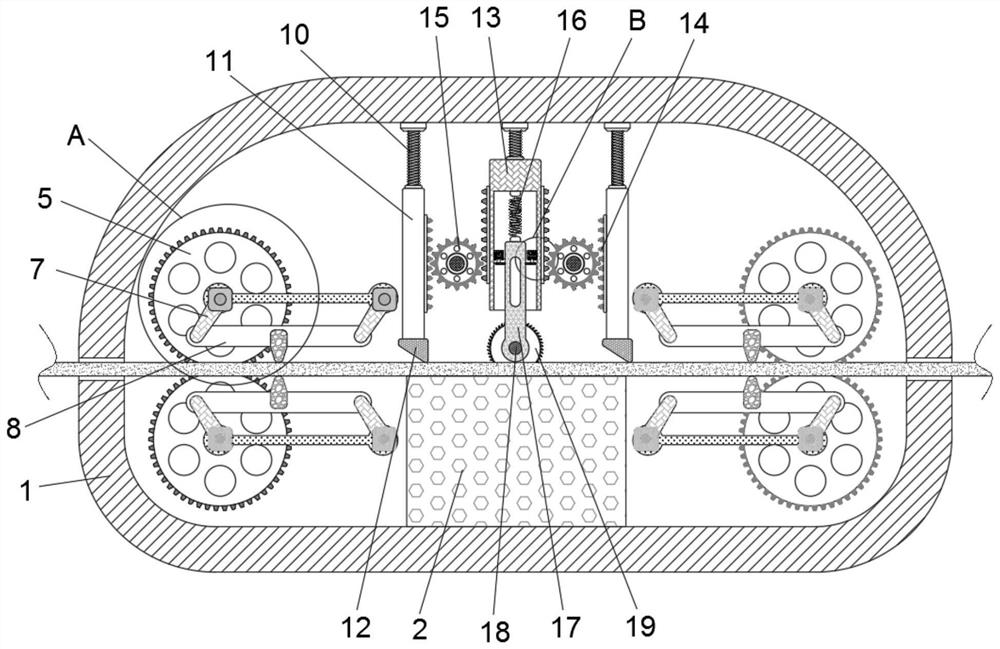

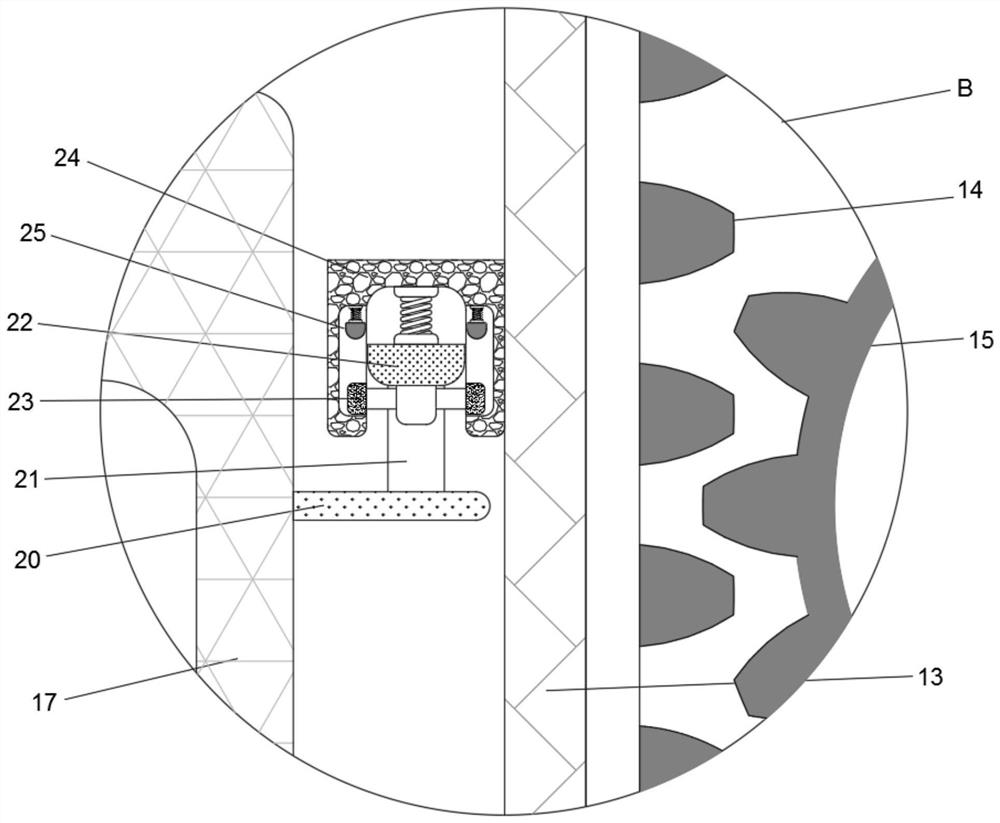

Cutting machine with automatic cutting pressure adjusting function for shipbuilding

PendingCN113369576AWith the function of automatic adjustment of cutting pressureRealize automatic loading and unloading functionMetal sawing devicesGear driveGear wheel

The invention relates to the technical field of shipbuilding, and discloses a cutting machine with an automatic cutting pressure adjusting function for shipbuilding. The cutting machine comprises a box body, a fixed seat is fixedly connected in the box body, the middle part of the fixed seat is movably connected with a rotating shaft, and the rear end of the rotating shaft is fixedly connected with a first gear; a connecting rod is movably connected with the middle of the rotating shaft and the front part of the first gear, a rotating rod is fixedly connected with the middle of the rotating shaft and the front part of the connecting rod, the end, away from the rotating shaft, of the rotating rod is movably connected with a push rod, and the middle of the push rod is fixedly connected with a push block. According to the cutting machine with the automatic cutting pressure adjusting function for shipbuilding, the first gear drives the rotating shaft to rotate, the rotating shaft drives the rotating rod to rotate, the rotating rod drives the push rod to rotate, the push rod drives the push block to rotate, the push block extrudes a steel plate to the middle in the rotating process, the push block moves rightwards while rotating, and the push block drives the steel plate to move rightwards, so that the automatic feeding and discharging function is achieved, the equipment cutting efficiency is improved, and the production cost is reduced.

Owner:龚兴

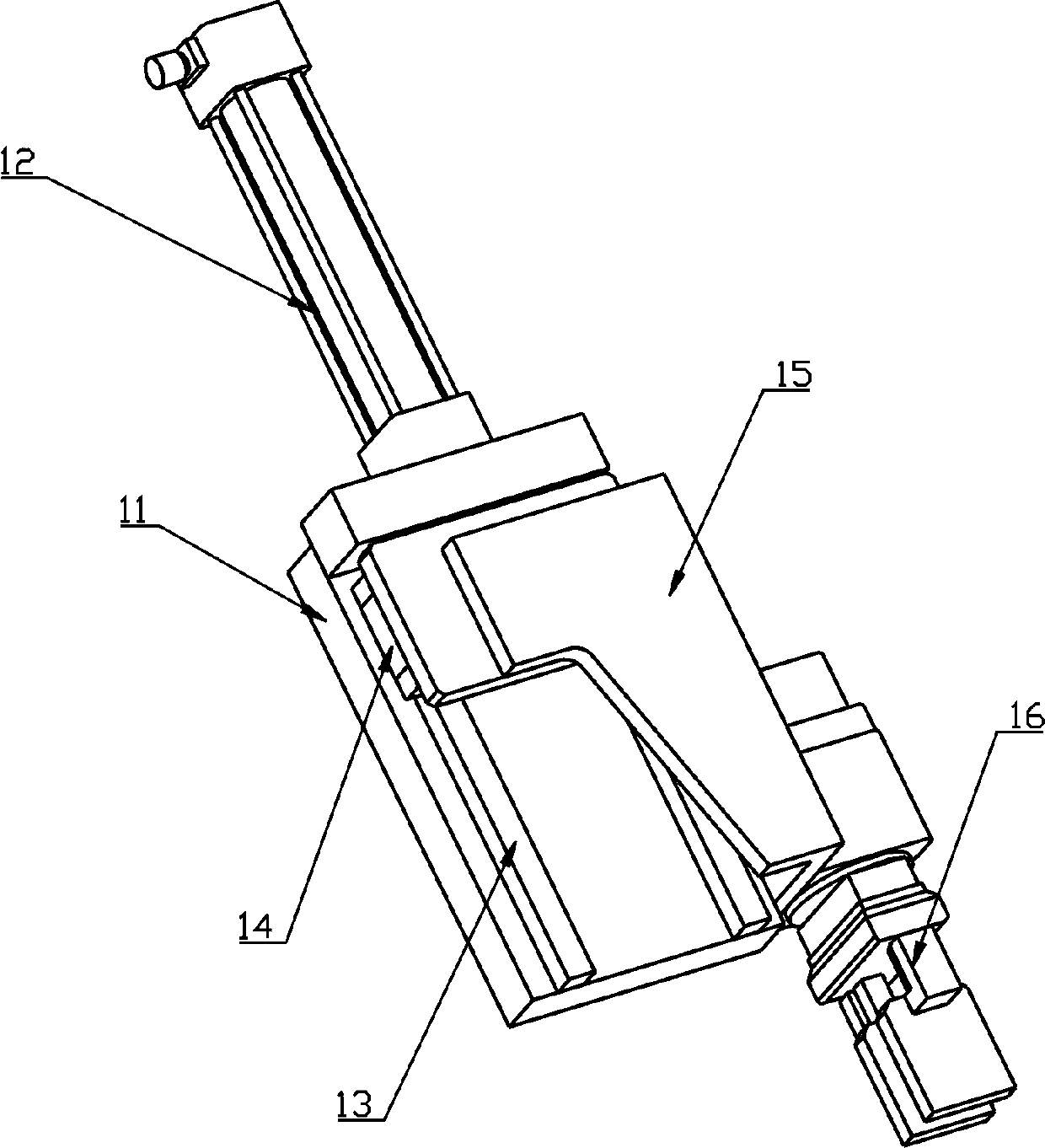

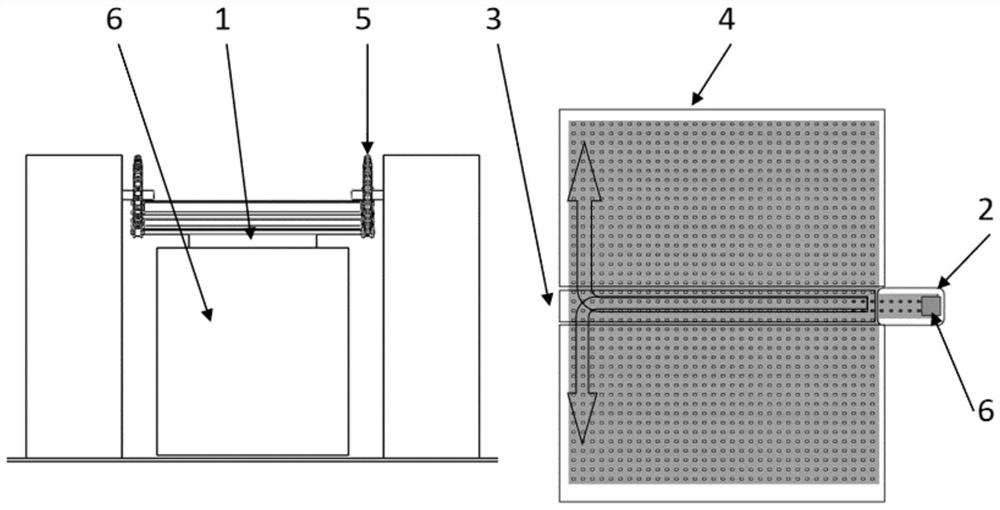

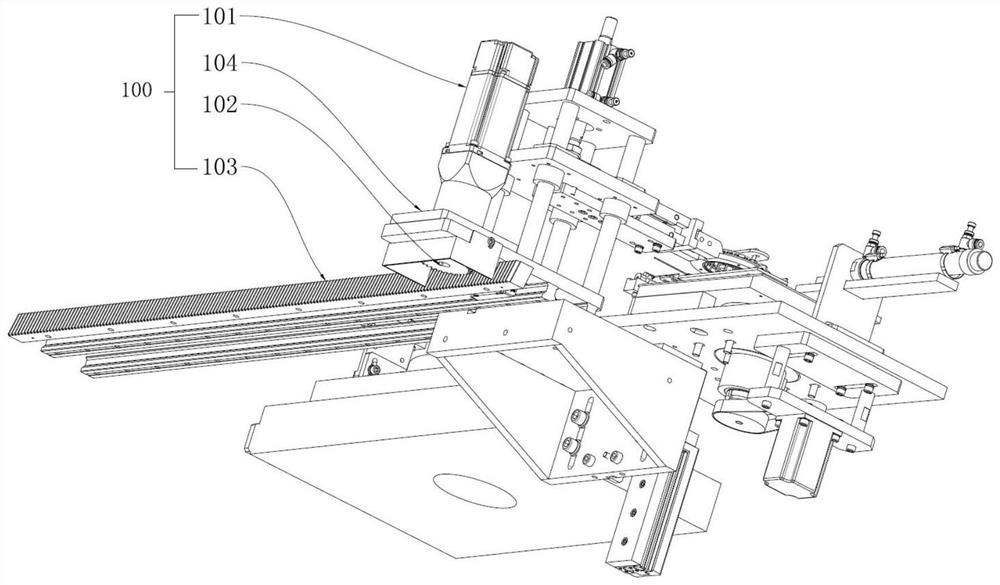

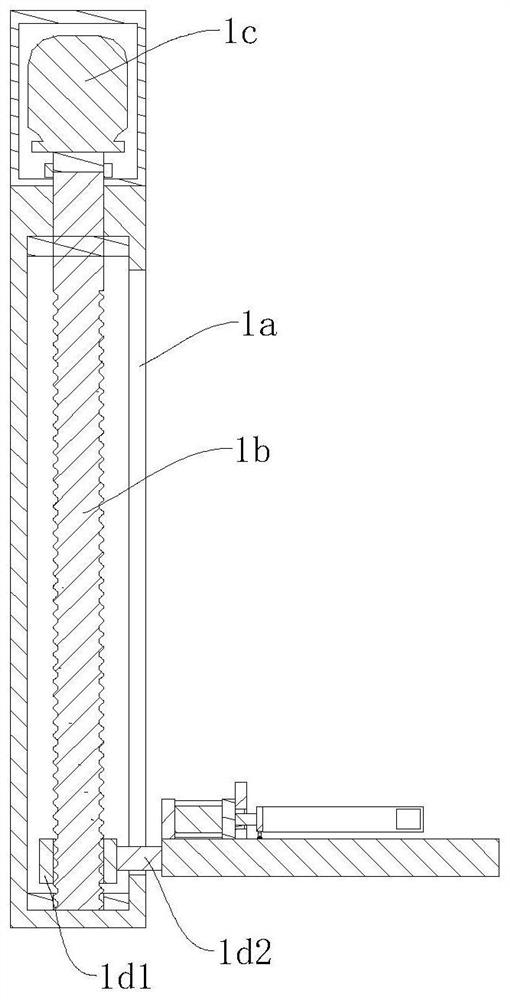

Built-in automatic feeding and discharging device capable of realizing progressive feeding of bars

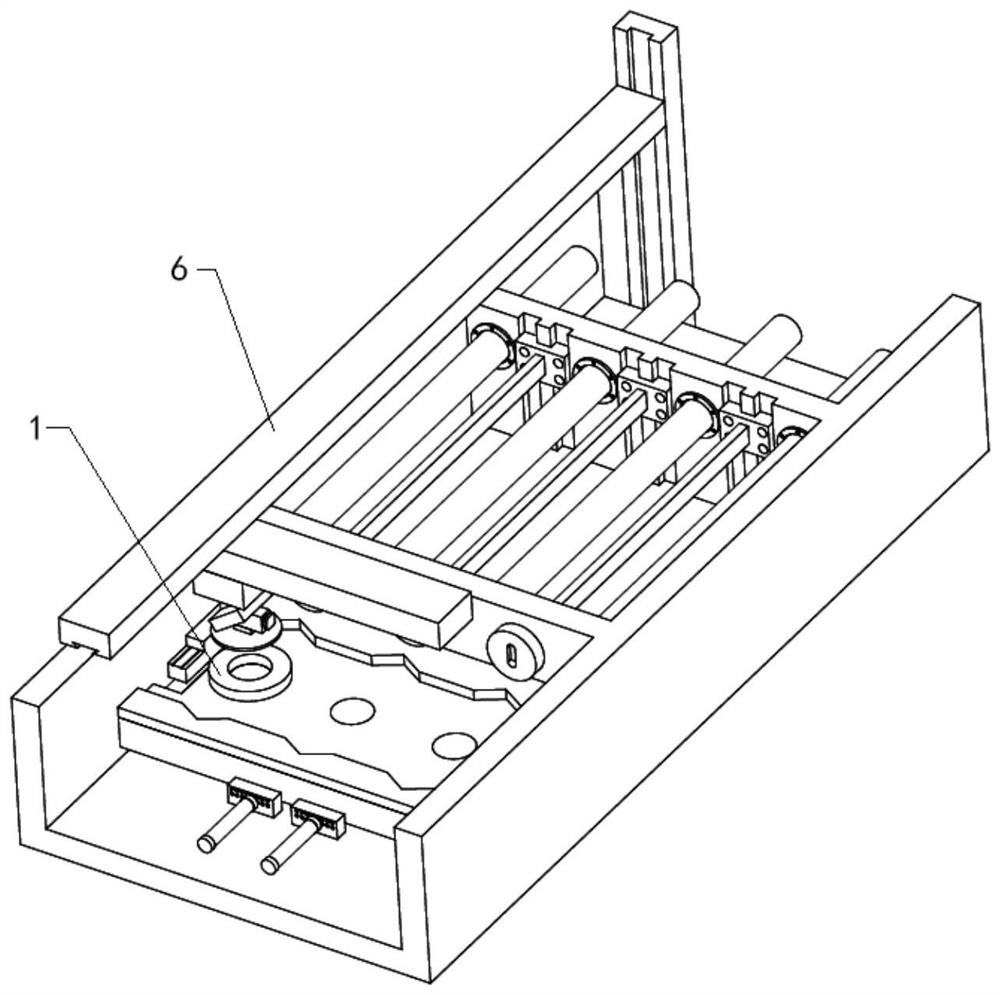

PendingCN111590376ARealize automatic loading and unloading functionImprove surface qualityWork clamping meansPositioning apparatusInterior spaceRobot hand

The invention relates to a built-in automatic feeding and discharging device capable of realizing progressive feeding of bars. The device is composed of a stock bin, a grabbing manipulator and a clamping jig, wherein the stock bin is arranged inside a machine tool, the grabbing manipulator is installed on a machine head of the machine tool and can linearly reciprocate along with the machine head along an X-axis direction and a Z-axis direction, the clamping jig is installed on a workbench of the machine tool and can move along with the workbench of the machine tool, and different parts of thesame bar can be sequentially positioned and clamped in cooperation with the lifting action of the grabbing manipulator on the bar. According to the built-in automatic feeding and discharging device, the internal space of the machine tool is fully utilized, the structure is simple, the occupied space is small, the manufacturing cost is low, and automatic progressive feeding machining of bar blankscan be achieved.

Owner:BEIJING JINGDIAO GRP CO LTD

A battery-type unmanned monorail crane and its control method

ActiveCN112850481BIncrease loading capacityCompact structureTravelling gearSafety gearSUSPENDING VEHICLEHydraulic pump

The invention discloses a battery-type unmanned monorail crane and a control method thereof, comprising a suspension rail, a braking device, a driving device, an intelligent cockpit, a lifting device and a power device, and the intelligent cockpit, the lifting device and the power device pass through the The driving device and the carrying trolley are hung on the suspension rail; sensors such as laser radar, depth camera, and millimeter-wave radar are installed in the intelligent cockpit to sense the surrounding environment information of the monorail crane in real time and realize the positioning and mapping of the monorail crane; electronic control is adopted The braking device realizes the pure electric braking of the monorail crane; the hoisting part adopts a close-connected hook to realize the automation in the process of grabbing and releasing the equipment by the monorail crane, and completes the unmanned loading and unloading equipment; the cockpit and hydraulic pump station are eliminated from the structure, and the structure It is more compact and can realize autonomous unmanned driving, providing the basis for unmanned and continuous auxiliary transportation in underground mines.

Owner:CHINA UNIV OF MINING & TECH

A pvc floor automatic punch assembly line system

ActiveCN103625871BImprove work efficiencyLabor savingConveyor partsMechanical conveyorsPunch pressAssembly line

The invention discloses an automatic punching machine assembly line system for a PVC floor. The automatic punching machine assembly line system is formed by sequentially connecting feeding stacker crane system, an automatic punching system, a spacing wafer separator system, a 180-degree panel turnover machine system, a roller machine conveying system and a discharging stacker crane system, wherein the spacing wafer separator system is provided with a first light sensation system; the 180-degree panel turnover machine system is provided with a panel turnover photoelectric switch, a panel turnover proximity switch and a panel turnover counter system; the roller machine conveying system is provided with a pneumatic lifting plate system, a pneumatic splicing plate system and a second light sensation system. According to the automatic punching machine assembly line system, not only is labor force lowered, but also intellectualization of equipment transportation is achieved, and therefore the overall working process of an automatic punching machine assembly line for the PVC floor is orderly. Moreover, production efficiency is greatly improved, and a large amount of labor force is reduced.

Owner:JIANGSU UNIV OF SCI & TECH

Automatic feeding and discharging mechanism of engraving and milling machine and feeding and discharging method

ActiveCN103213440BRealize automatic loading and unloading functionSolve the problem of automatic loading and unloadingModel makingMechanical engineeringEngineering

The invention discloses an automatic feeding and discharging mechanism of an engraving and milling machine and a feeding and discharging method. The automatic feeding and discharging mechanism of the engraving and milling machine comprises a taking assembly, a placing assembly, a feeding frame, a discharging frame, a positioning jig, a worktable, an X-axis displacement structure, a Y-axis displacement structure and a Z-axis displacement structure, wherein the feeding frame and the discharging frame are arranged on the worktable in parallel, the positioning jig is arranged on the worktable and is positioned at one sides of the feeding frame and the discharging frame, the Z-axis displacement structure is arranged on the X-axis displacement structure and moves in the X-axis direction, the taking assembly and the placing assembly are arranged on the Z-axis displacement structure and move in the Z-axis direction, and the worktable is arranged on the Y-axis displacement structure and moves in the Y-axis direction. By adopting the structure, the automatic feeding and discharging function of the engraving and milling machine is realized, the problem of automatic feeding and discharging during the glass processing is solved, and the automatic feeding and discharging mechanism has the advantages that the implementation method is simple, the efficiency is higher, and the positioning precision is high.

Owner:SHENZHEN YUANYANG XIANGRUI MACHINERY

Automatic key pulling device for plate cylinder plugs

PendingCN113042812ARealize automatic loading and unloading functionHigh degree of automationBroaching accessoriesBroaching machinesAutomationPhysics

The invention relates to an automatic key pulling device for plate cylinder plugs. The automatic key pulling device is used for carrying out key pulling operation on the plate cylinder plugs and comprises a rack platform, a plug feeding and discharging mechanism, a plug placing frame, a plug positioning mechanism, a rotary pressing mechanism, a grinding tool, a key pulling tool path and a key pulling tool path driving mechanism, wherein the plug feeding and discharging mechanism is installed at the top of the rack platform, the plug placing frame, the plug positioning mechanism, the rotary pressing mechanism, the grinding tool, the key pulling tool path and the key pulling tool path driving mechanism are installed on the rack platform, the plug positioning mechanism is installed on the plug placing frame, an output shaft of the rotary pressing mechanism is connected with the plug placing frame, the grinding tool is fixed on the rack platform, the grinding tool is provided with an inserting hole for the key pulling tool path to penetrate through, one end of the key pulling tool path penetrates through the inserting hole in the grinding tool, and the other end of the key pulling tool path is connected with the key pulling tool path driving mechanism. Compared with the prior art, and the automatic key pulling device has the advantages of high automation degree, wide application range, high key pulling precision and the like.

Owner:SHANGHAI YUNCHENG PLATE MAKING

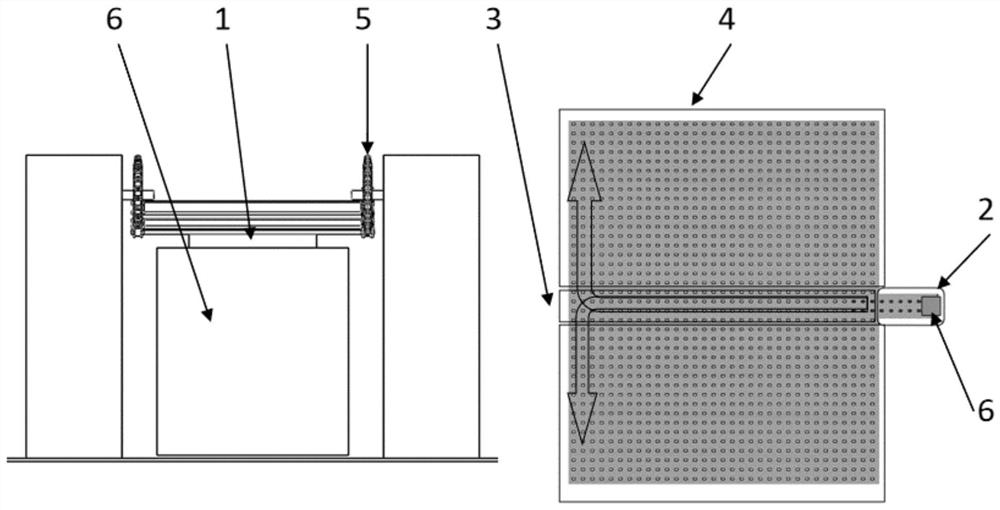

A flatness detection device

ActiveCN107843183BRealize automatic loading and unloading functionRealize continuous detectionMechanical roughness/irregularity measurementsConveyor beltComputer science

The invention discloses a flatness detection device. The device comprises a rack; a feeding module set is arranged at the right part of the upper surface of the rack; a first detection module set is arranged at the left side of the feeding module set; a second detection module set which is of the same structure as the first detection module set is arranged at the left side of the first detection module set; and a material shifting module set is arranged behind the first detection module set and the second detection module set. According to the feeding module, a conveyor belt is driven to perform feeding through a motor; the first detection module set is used for performing first flatness detection; the second detection module set is used for performing second detection so as to ensure theaccuracy of the detection; and the material shifting module set is used for shifting products between the feeding module set, the first detection module set, and the second detection module set. The flatness detection device of the invention has the advantages of simple structure, high work efficiency, and accurate detection results.

Owner:浙江省磐安县磐锋刀片有限公司

Five-axis false tooth carving machine

PendingCN114311317ASmall footprintReduce volumeArtificial teethWorking accessoriesEngineeringDentistry

The invention discloses a five-axis false tooth carving machine, which comprises an X-axis transfer device, a Y-axis transfer device, a Z-axis transfer device, an A-axis rotation driving device, a B-axis rotation driving device, a main shaft and a material loading disc, and is characterized in that the five-axis false tooth carving machine further comprises a closed working cavity, and the material loading disc is positioned in the closed working cavity; the A-axis rotation driving device is connected with the material carrying disc and used for driving the material carrying disc to rotate. The X-axis transferring device, the Y-axis transferring device, the Z-axis transferring device and the B-axis rotation driving device are all located outside the closed working cavity and used for driving the main shaft to move along the X axis, the Y axis, the Z axis and the B axis respectively. According to the five-axis denture engraving machine, the B-axis rotation driving device is arranged outside the closed working cavity, so that the B-axis rotation driving device is prevented from being influenced by dust generated in the machining process and / or used cooling liquid, and the service life of the five-axis denture engraving machine is prolonged to a great extent.

Owner:美立得科技(深圳)有限公司

Transferring stacking and heavy object storage system and method for automatically loading and unloading heavy objects

ActiveCN113104602ARealize automatic loading and unloading functionReduce kinetic energy lossConveyorsLoading/unloadingEngineeringLifting equipment

The invention discloses a transferring stacking and heavy object storage system and method for automatically loading and unloading heavy objects. The transferring stacking and heavy object storage system comprises an automatic loading and unloading head, a heavy object transferring area, a steering area and a heavy object storage area; the automatic loading and unloading head comprises a bearing rod and a sleeve located on the bearing rod, a locking head is arranged on the outer side of the sleeve, the two ends of the automatic loading and unloading head are connected with heavy object lifting equipment, the automatic loading and unloading head is matched with the heavy object lifting equipment to be used for loading and unloading heavy object blocks, the bottom area of the heavy object lifting equipment is the heavy object transferring area, the heavy object transferring area is used for unloading heavy objects from heavy object lifting equipment or loading the heavy objects into the heavy object lifting equipment, the steering area is used for transferring the heavy objects to different area inlets of the heavy object storage area, and the heavy object storage area is an area where the heavy objects are finally stored. According to the transferring stacking and heavy object storage system, a heavy object lifting system can load and unload the heavy object from a fixed place, so that the coupling of all the gravity energy storage systems is reduced, and the flexibility is improved.

Owner:XIAN THERMAL POWER RES INST CO LTD

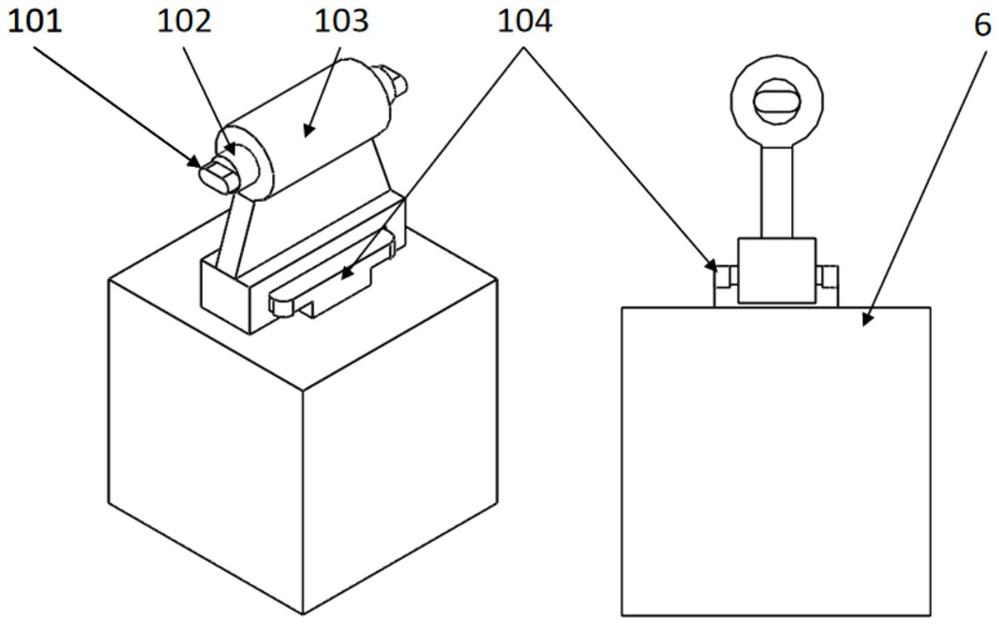

Machining loading and unloading mechanism for rod parts

ActiveCN106607709BRealize automatic loading and unloading functionNo manualMetal working apparatusEngineeringSurface structure

The invention discloses a rod part machining loading and unloading mechanism. The mechanism comprises a frame, and a loading frame and an unloading frame arranged on two sides of the frame; the frame is provided with multiple sets of feeding rollers capable of synchronously lifting and multiple ejecting plates capable of synchronously lifting in a part conveying direction at intervals; the feeding rollers are provided with grooves for limiting parts; the top surfaces of the ejecting plates are inclined surface structures, and one ends near the loading frame are higher than the other ends; clamping grooves are formed in the ejecting plates, and are eccentric to the grooves; the clamping grooves are arranged corresponding to one sides, near the loading frame, of the grooves; and a pressing roller is arranged above a discharge end of the frame in a lifting manner. The rod part machining loading and unloading mechanism is high in automation degree, saves labors, is delicate in design, improves the production efficiency, and reduces the production cost.

Owner:WUXI DOUBLE HORSE DRILLING TOOLS

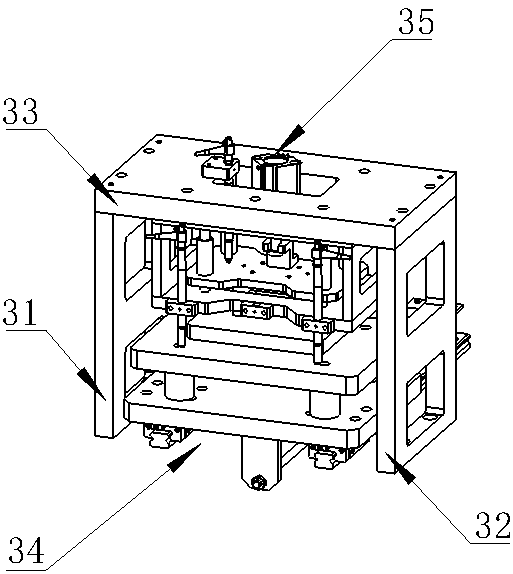

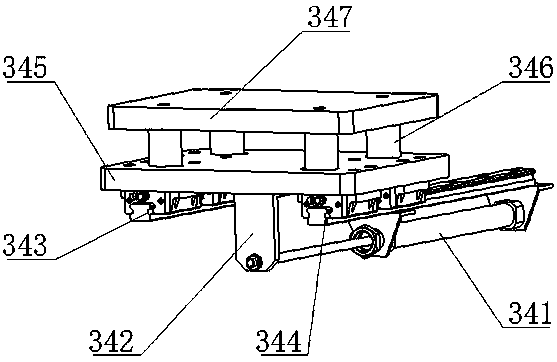

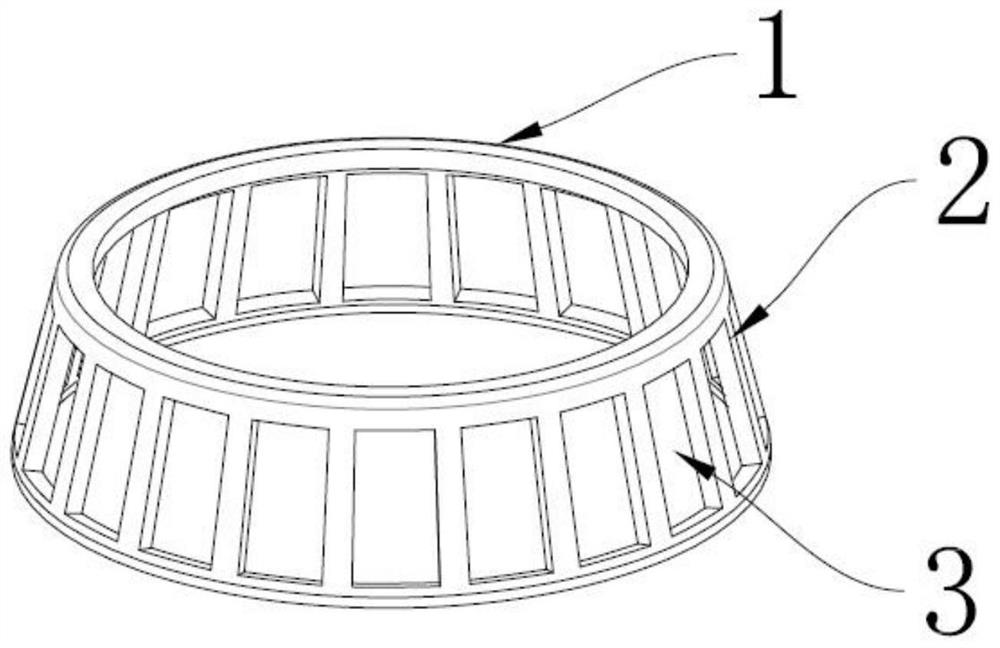

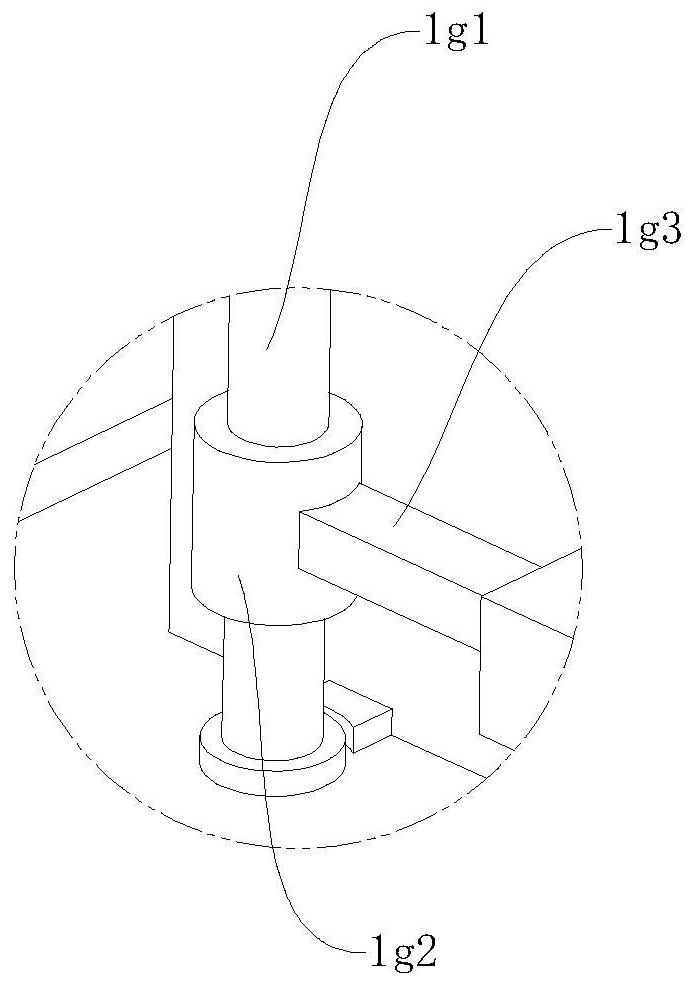

Tapered roller bearing retainer automatic positioning mechanism and control method thereof

InactiveCN112792248AGuaranteed stabilityGuaranteed continuityMetal-working feeding devicesBearing componentsTransfer mechanismServo

The invention discloses a tapered roller bearing retainer automatic positioning mechanism and a control method thereof. The tapered roller bearing retainer automatic positioning mechanism comprises a servo transfer mechanism, a sliding rail, a lifting mechanism, a gripper mechanism, a product positioning mechanism and a lower die, wherein the lifting mechanism is fixedly connected with the servo transfer mechanism, and the servo transfer mechanism drives the lifting mechanism to linearly move through the sliding rail; the gripper mechanism comprises a Z-shaped pneumatic gripper, the tail end of the Z-shaped pneumatic gripper is connected with a lifting mechanism, and the front end of the Z-shaped pneumatic gripper is connected with a profiling gripper. According to the technical scheme, the tapered roller bearing retainer automatic positioning mechanism has the following advantages that 1, an automatic feeding and discharging function is achieved when a precision mold is used in a slope pressing procedure of the tapered roller bearing retainer; and 2, the tapered roller bearing retainer automatic positioning mechanism can automatically identify defective products, the product quality is improved, the positioning precision is up to 100%, the problems that a mold is damaged and a retainer is scrapped after a slope is pressed due to positioning deviation of 0.01 mm are solved, and stability and continuity of automatic production are kept.

Owner:宁波致泰自动化装备有限公司

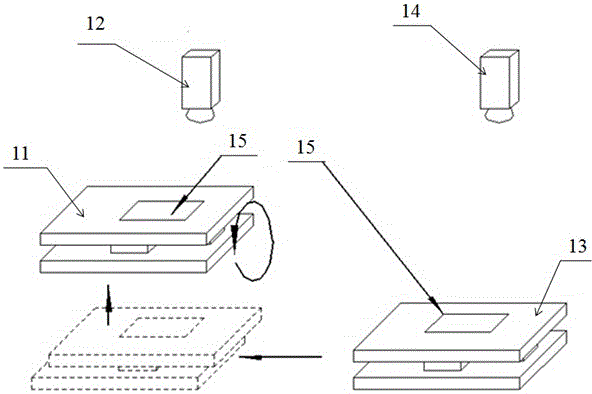

An automatic lamination and transfer mechanism of a double-alignment flap laminating machine and its control method

ActiveCN105150658BRealize automatic loading and unloading functionRealize automatic controlControlling laminationLaminationElectric machineryTransfer mechanism

The invention provides an automatic laminating and transferring mechanism for a dual-alignment turnover plate type laminating machine and a method for controlling the automatic laminating and transferring mechanism. The automatic laminating and transferring mechanism comprises UVW alignment platform mechanisms, a transport mechanism and a placement platform mechanism. The transport mechanism is a double-crank mechanism, an attraction platform is fixedly connected with a connection rod, and cranks rotate to drive the attraction platform to move so as to complete placement. The placement platform mechanism which serves as an assistance of the transport mechanism is convenient for stacking and supplying of lamination materials. The invention further provides a method for controlling the automatic laminating and transferring mechanism of the dual-alignment turnover plate type laminating machine. The method includes: calculating a motor control quantity, calculating a motor compensation value, calculating an error between the alignment platform mechanisms, laminating, transferring products and the like. The automatic laminating and transferring mechanism for the dual-alignment turnover plate type laminating machine has the advantages that automatic feeding and discharging of the laminating machine can be realized, laminating precision in operation of the laminating machine is improved, manpower cost is saved while laminating precision is improved greatly, and laminating quality of touch screens is guaranteed.

Owner:FOSHAN NANHAI GUANGDONG TECH UNIV CNC EQUIP COOP INNOVATION INST +1

Loading and unloading device for storage shelf

InactiveCN111924390ARealize automatic loading and unloading functionImprove work efficiencyStorage devicesMechanical conveyorsScrew threadThreaded rod

The invention relates to the technical field of loading and unloading for shelves, in particular to a loading and unloading device for a storage shelf. The loading and unloading device for the storageshelf comprises a lifting component and an executive component, wherein the lifting component includes a base, a fixing frame, a threaded rod, a first driving part, a threaded sleeve and a lifting platform; the executive component includes a second driving part, a fixing rack, a third driving part and a clamping plate. An output shaft of the first driving part drives the threaded rod to rotate torealize an automatic lifting function of the lifting platform, the third driving part drives the clamping plate to complete the clamping and fixing operation of a material from both sides, and finally the second driving part drives the fixing rack to move to push the material to the shelf or take the material out of the shelf. The device realizes the automatic loading and unloading functions. Anoperator only needs to put the material on the lifting platform when loading, and take the material from the lifting platform when unloading, so that the work efficiency is improved and labor force is saved.

Owner:徐巧芳

A system and method for automatic loading and unloading of heavy objects for reloading and palletizing and heavy object storage

ActiveCN113104602BRealize automatic loading and unloading functionReduce kinetic energy lossConveyorsLoading/unloadingClassical mechanicsEngineering

The invention discloses a reloading palletizing and heavy object storage system and method for automatic loading and unloading of heavy objects, including an automatic loading and unloading head, a heavy object reloading area, a steering area and a heavy object storage area; The sleeve on the load-bearing rod, the outside of the sleeve is provided with a locking head, the two ends of the automatic loading and unloading head are connected with the heavy object lifting equipment, and the automatic loading and unloading head cooperates with the heavy object lifting equipment to load and unload heavy objects. The bottom area of the heavy object lifting device is a heavy object transfer area, which is used for unloading heavy objects from the heavy object lifting device or loading heavy object blocks into the heavy object lifting device. The blocks are transferred to different area entrances of the heavy object storage area, which is the area where the heavy object blocks are finally stored. The invention enables the heavy object lifting system to load and unload heavy objects from a fixed location, thereby reducing the coupling of various gravity energy storage systems and improving their flexibility.

Owner:XIAN THERMAL POWER RES INST CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com