Automatic key pulling device for plate cylinder plugs

A plug-and-roll technology, which is applied to broaching device, accessories of broaching device, broaching machine, etc., can solve the problems of unsatisfactory production efficiency, manual installation of plugs, low automation level, etc., and achieve seamless The effect of docking, improving the level of automation, and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

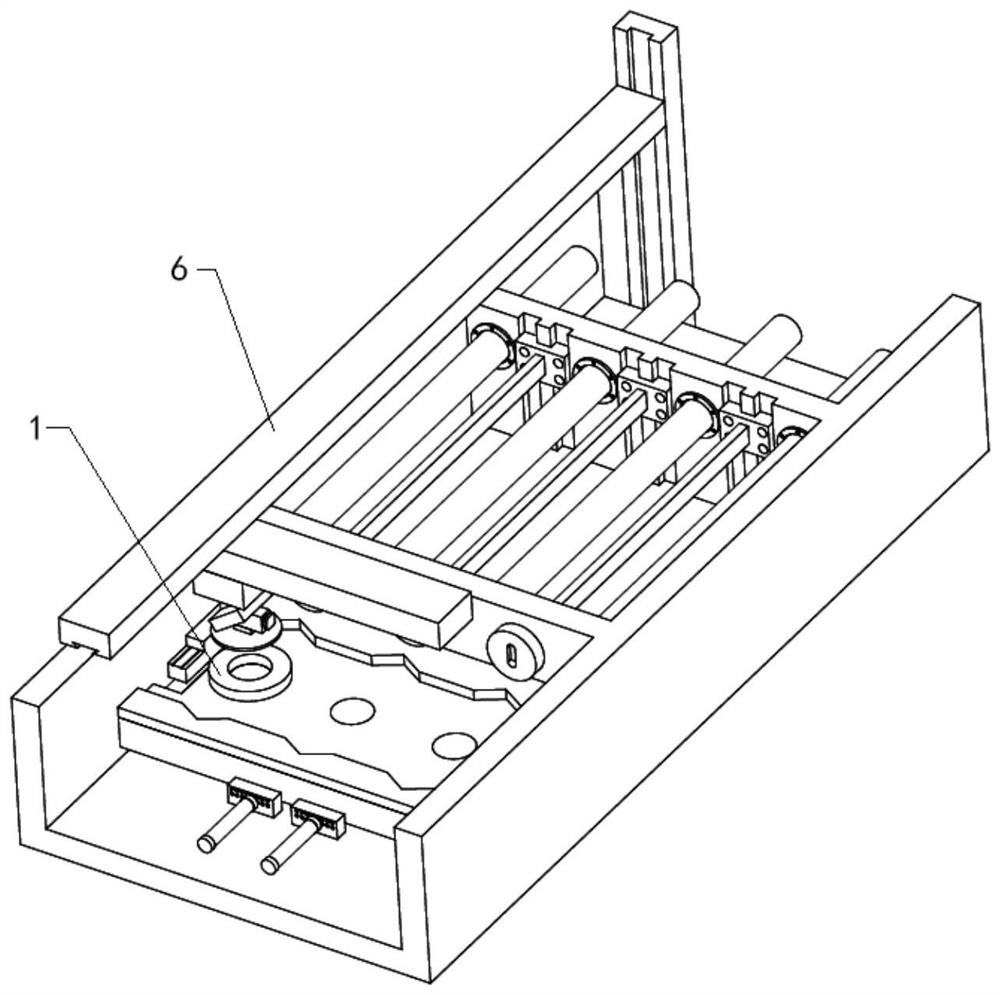

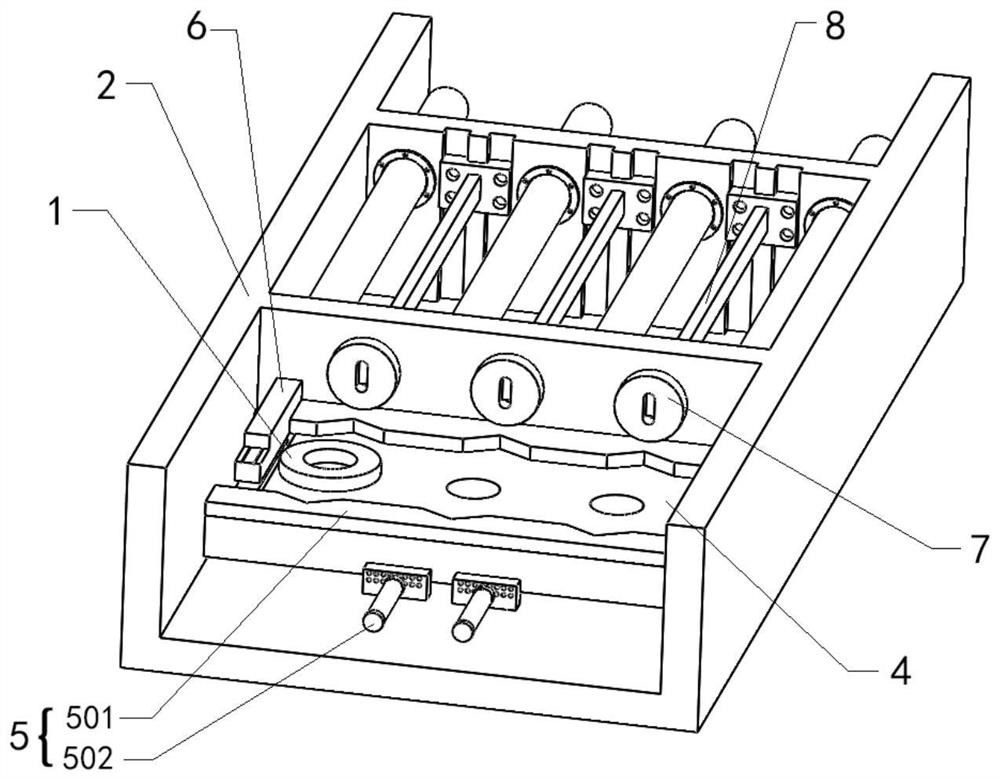

[0027] An automatic key pulling device for plate roller plugs, which is used to perform key pulling operations on plate roll plugs 1, and its structure is as follows figure 1 with figure 2 As shown, the automatic key pulling device includes a frame platform 2, a plug loading and unloading mechanism 3, a plug placing frame 4, a plug positioning mechanism 5, a rotary pressing mechanism 6, a grinding tool 7, a key pulling tool rail 8 and a key pulling mechanism. Tool rail drive mechanism. The plug loading and unloading mechanism 3 is installed on the top of the frame platform 2, the plug placement frame 4, the plug positioning mechanism 5, the rotating and pressing mechanism 6, the grinding tool 7, the pull key knife rail 8 and the key pull knife rail driving mechanism respectively Installed on the frame platform 2, the plug positioning mechanism 5 is installed on the plug placement frame 4, the output shaft of the rotary pressing mechanism 6 is connected with the plug placemen...

Embodiment 2

[0044] An automatic key pulling device for plate roller plugs, which is used to perform key pulling operations on plate roll plugs 1, and its structure is as follows figure 1 with figure 2 As shown, the automatic key pulling device includes a frame platform 2, a plug loading and unloading mechanism 3, a plug placing frame 4, a plug positioning mechanism 5, a rotary pressing mechanism 6, a grinding tool 7, a key pulling tool rail 8 and a key pulling mechanism. Tool rail drive mechanism. The plug loading and unloading mechanism 3 is installed on the top of the frame platform 2, the plug placement frame 4, the plug positioning mechanism 5, the rotating and pressing mechanism 6, the grinding tool 7, the pull key knife rail 8 and the key pull knife rail driving mechanism respectively Installed on the frame platform 2, the plug positioning mechanism 5 is installed on the plug placement frame 4, the output shaft of the rotary pressing mechanism 6 is connected with the plug placemen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com