A system and method for automatic loading and unloading of heavy objects for reloading and palletizing and heavy object storage

A technology of automatic loading and unloading, storage system, applied in loading/unloading, transportation and packaging, conveyors, etc., can solve the problems of reduced efficiency, impact on the bearing surface, loss of kinetic energy of heavy objects, etc., to reduce coupling and reduce kinetic energy loss , the effect of improving flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described in detail below in conjunction with the accompanying drawings.

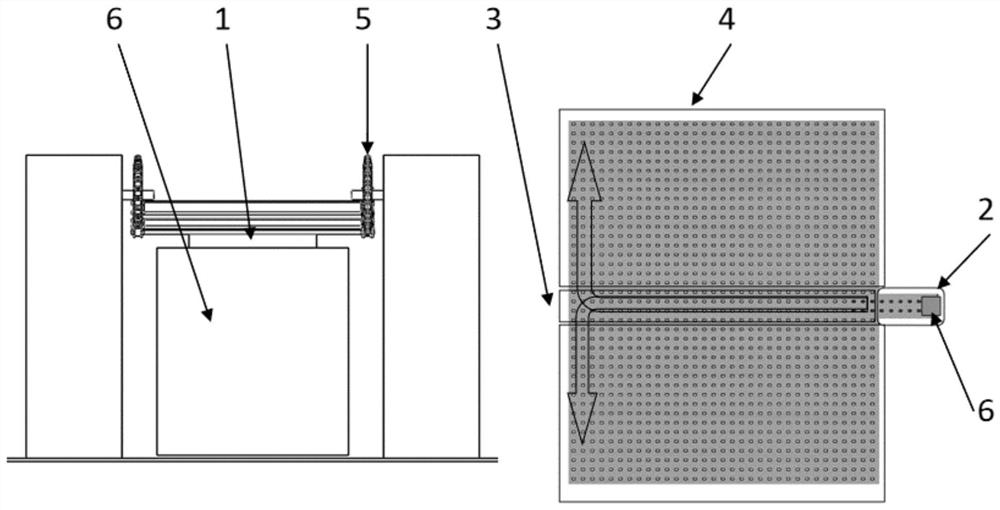

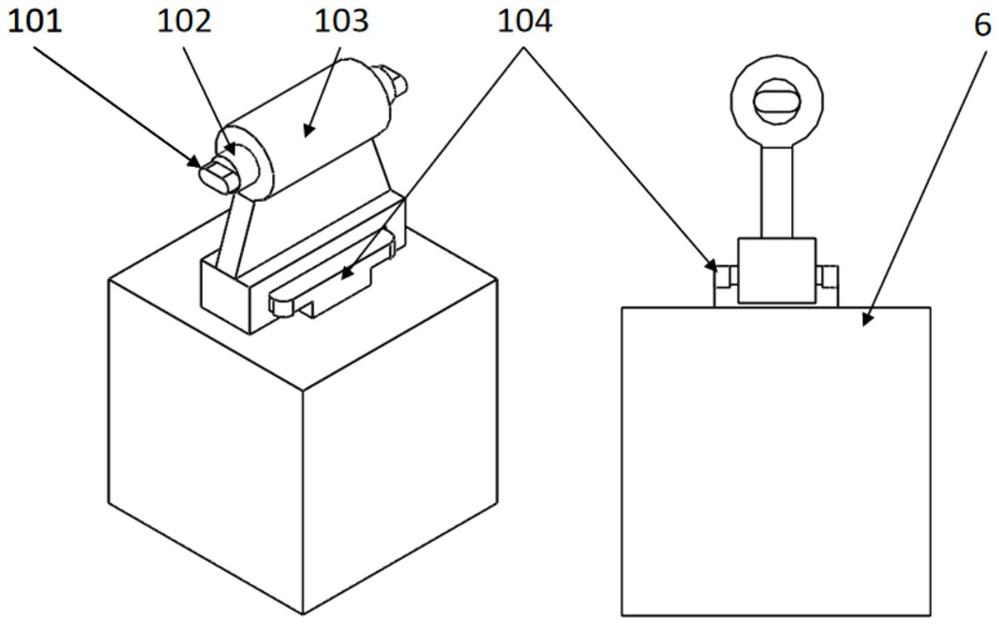

[0027] like figure 1 As shown in the figure, the present invention provides a reloading, stacking and heavy object storage system for automatically loading and unloading heavy objects, including an automatic loading and unloading head 1, a heavy object transfer area 2, a turning area 3 and a heavy object storage area 4;

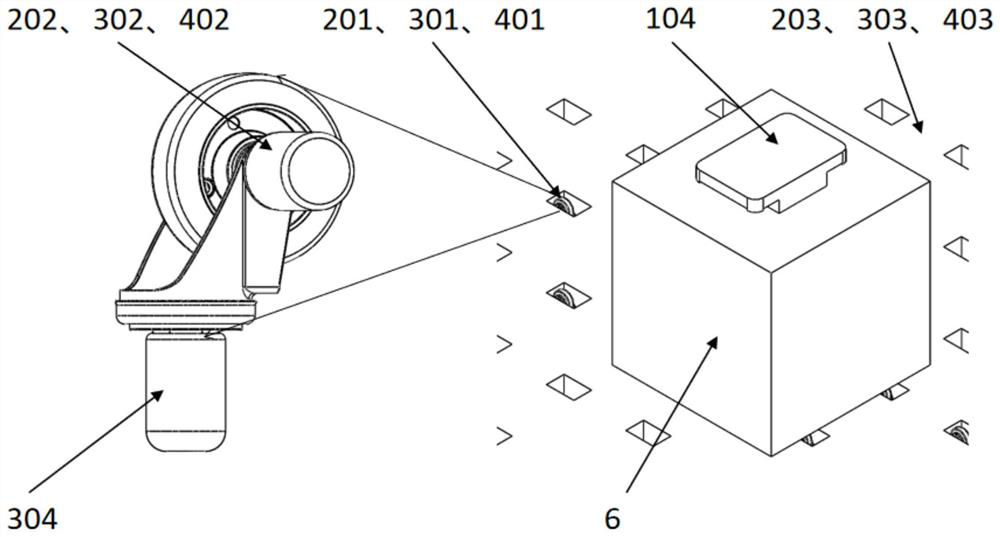

[0028] The heavy object transfer area 2 includes a directional wheel 1 201, a speed regulating motor 1 202, and a bearing surface 1 203. The heavy object transfer area 1 is located at the bottom of the heavy object lifting equipment 5 loading and unloading heavy object block area, and its one side is connected with the turning area 3;

[0029] The steering area 3 includes a universal wheel 301, a second speed regulating motor 302, a second bearing surface 303, and a second stepping motor 304, one side of which is connected to the heavy objec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com