An automatic lamination and transfer mechanism of a double-alignment flap laminating machine and its control method

A technology of laminating machine and conveying mechanism, which is applied in the direction of control lamination, chemical instruments and methods, lamination device, etc. Efficiency, reduce labor costs, and improve the effect of product qualification rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Embodiment 1: An automatic laminating transfer mechanism of a double-alignment flap laminating machine.

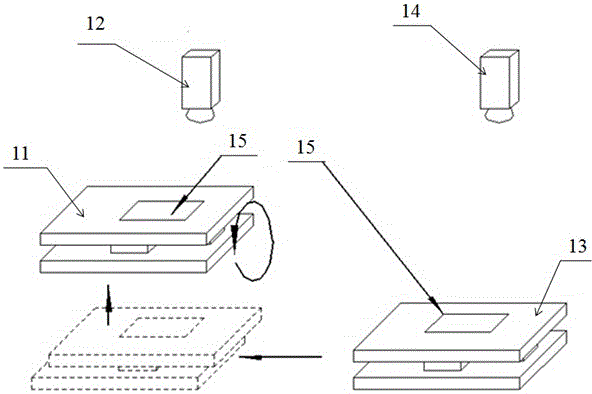

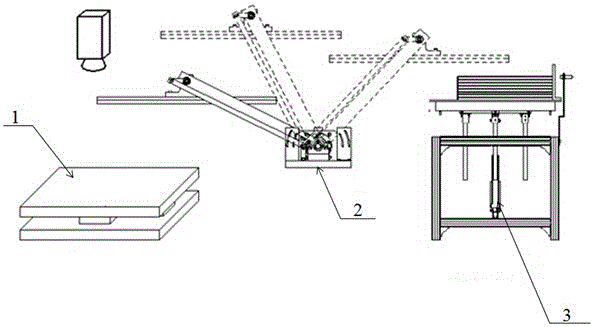

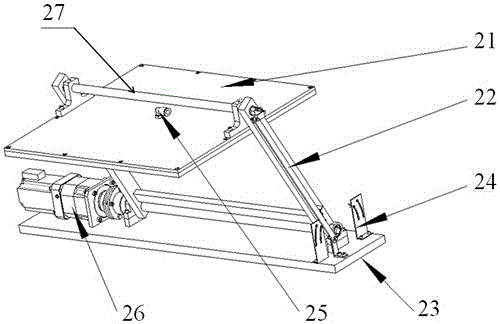

[0041] refer to Figure 1 to Figure 6 As shown, an automatic lamination and transfer mechanism of a double alignment flap laminating machine includes a UVW alignment platform mechanism 1, a transport mechanism 2 and a discharging platform mechanism 3, and the UVW alignment platform mechanism includes a first UVW alignment platform mechanism. Platform 11, the first positioning camera 12, the second UVW alignment platform 13 and the second positioning camera 14, the first positioning camera 12 is installed above the first UVW alignment platform 11, and the second positioning camera 14 is installed on Above the second UVW alignment platform 13, the first UVW alignment platform 11 is fixed, and the second UVW alignment platform 13 moves below the first UVW alignment platform 11; the transport mechanism 2 includes an adsorption platform 21. Double crank mechanism 22, ma...

Embodiment 2

[0044] Embodiment 2: A method for controlling the automatic laminating transfer mechanism of a double-alignment flap laminating machine.

[0045] refer to Figure 6 to Figure 9 As shown in the figure, a method for controlling the automatic lamination and transfer mechanism of a double-alignment flap laminating machine. This control method is based on using machine vision for alignment, and adding a detection method to improve the alignment accuracy and control accuracy of the laminating machine. Function, the specific operation method of this function is reflected in the control software. The calibration method needs to set two Mark points of different sizes on the alignment platform. The connection line of the two Mark points is parallel to the X axis of the alignment platform. The two Mark points The position of the center of the point in the coordinate method is fixed or known, and they are now recorded as M1(X M1 ,Y M1 ), M2(X M2 ,Y M2 ). The function is executed in f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com