Automatic feeding and discharging mechanism of engraving and milling machine and feeding and discharging method

A technology of automatic loading and unloading, engraving machine, applied in the field of engraving machine, to achieve the effect of simple implementation method, high positioning accuracy, and favorable promotion and application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

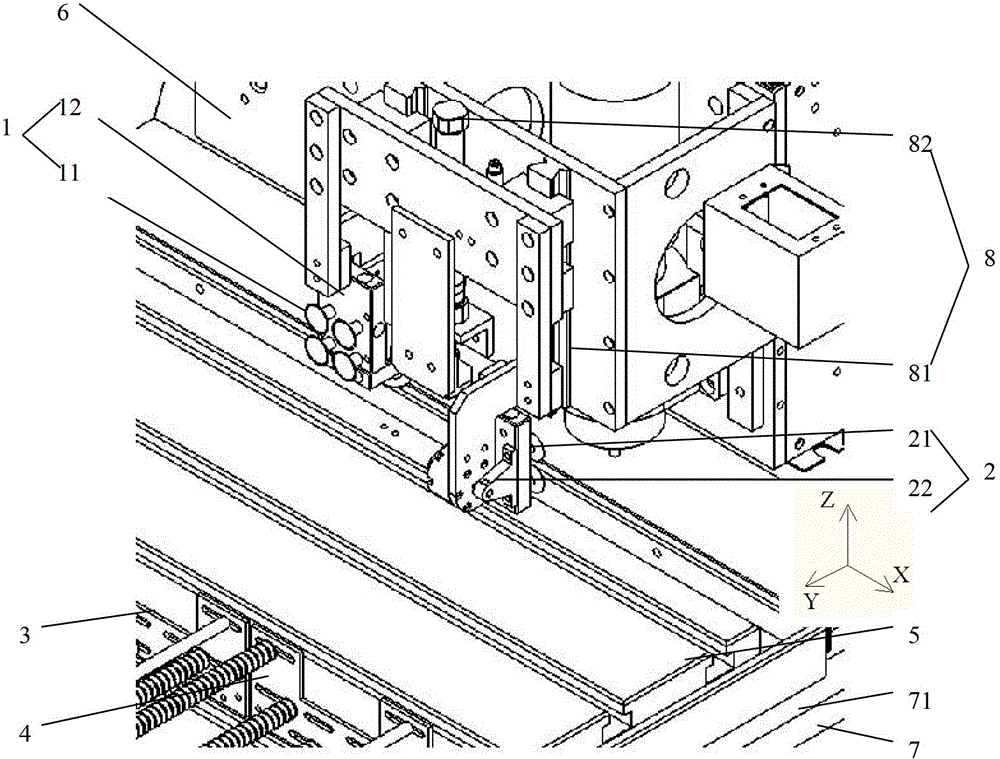

[0029] Such as figure 1 An automatic loading and unloading mechanism of the engraving machine shown in Embodiment 1, including a retrieving component 1, a discharging component 2, a loading frame 3, a unloading frame 4, a positioning fixture, a workbench 5, and an X-axis displacement structure 6 , Y-axis displacement structure 7 and Z-axis displacement structure 8. The loading frame 3 and the blanking frame 4 are placed side by side on the workbench 5, the positioning jig is placed on the workbench, and the positioning jig is located on one side of the loading frame and the unloading frame; the Z-axis displacement structure 8 is set on the X axis displacement structure 6, and the Z-axis displacement structure 8 is displaced along the X-axis direction; the reclaiming assembly 1 and the discharging assembly 2 are arranged on the Z-axis displacement structure 8, and the reclaiming assembly 1 and the discharging assembly 2 are arranged along the Z-axis Axial displacement; the wor...

Embodiment 2

[0038] Embodiment 2 discloses the loading and unloading method used in Embodiment 1, including:

[0039] a. Both the loading frame 3 and the blanking frame 4 are installed on the workbench 5, and the distance between the loading frame 3 and the blanking frame 4 is adjusted so that the distance is the same as the distance between the feeding assembly 1 and the discharging assembly 2 basically the same;

[0040] b. When starting processing, the glass to be processed is installed in the loading frame 3, the blanking frame 4 is an empty box, and the workbench 5 moves back and forth along the Y axis with the loading frame 3; the suction cup 11 moves along the X axis. The axial direction moves to the position matched with the loading frame 3; at the same time, the retrieving suction cup 11 turns over 90 degrees and faces the workbench 5, and the Z-axis driving device 82 starts to work at the position where the first piece of glass is expected to be taken, so that the retrieving suct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com