Ring welding equipment

A kind of equipment, the technology of girth welding, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of scalding, human body easy to cause injury, low welding efficiency and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

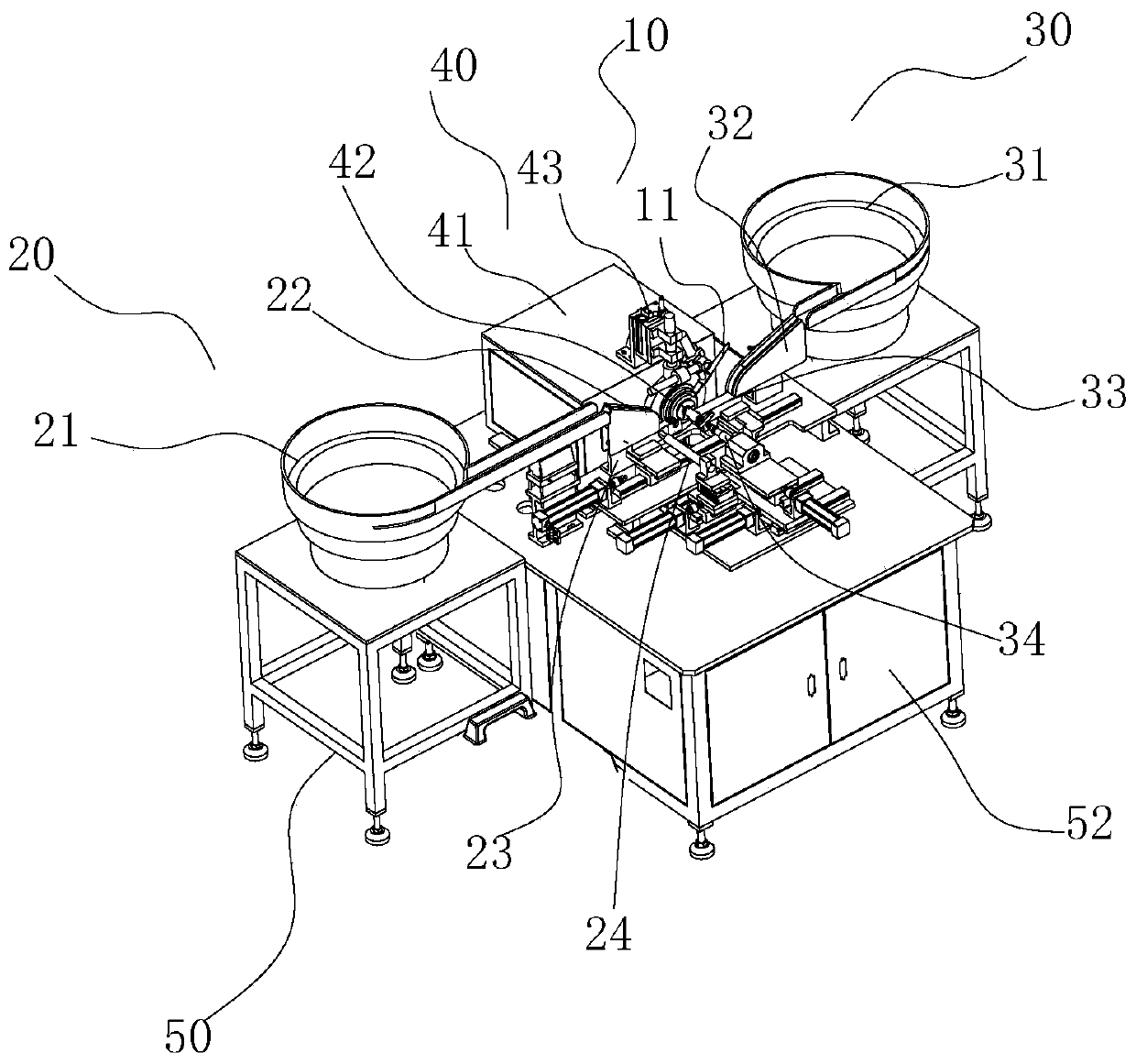

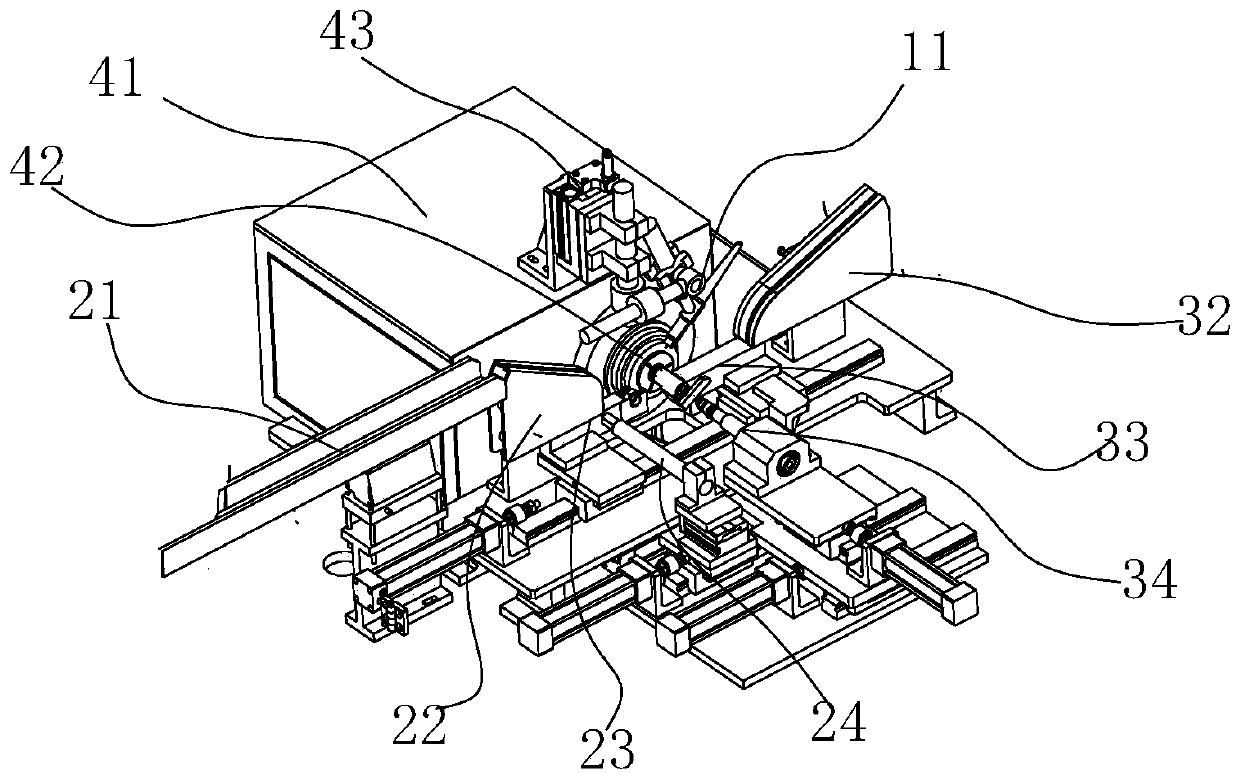

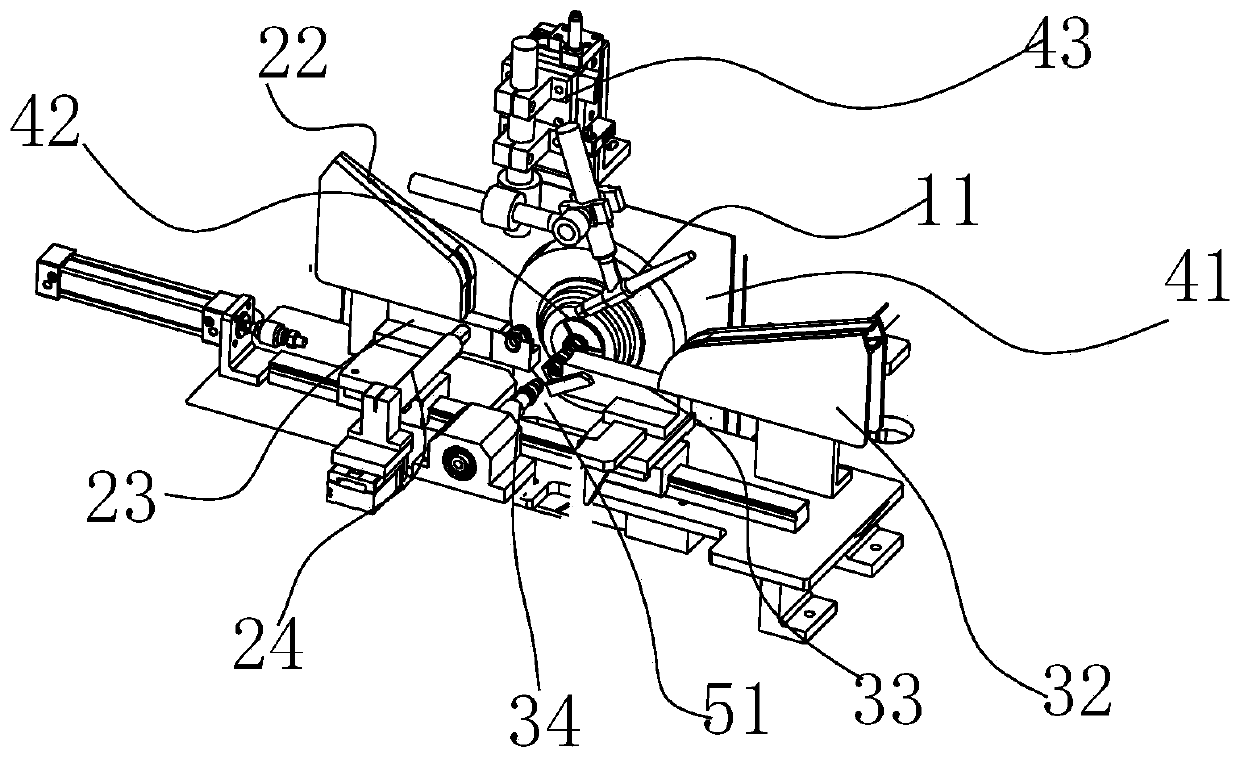

[0022] Such as Figure 1-3 As shown, a girth welding equipment of this embodiment includes a welding gun 10, a first workpiece feeding device 20, a second workpiece feeding device 30, and a pneumatic chuck 40. The first workpiece feeding device includes a first vibration feeding device. The disc 21, the first feeding trough 22, the first feeding rod 23 and the first pushing mechanism 24. The first feeding rod 23 is provided with a first clamping port. One end of the first feeding trough 22 is connected to the first feeding rod 23. The vibrating feeding tray 21 is connected, and the other end is set directly above the first feeding rod 23, and the first feeding rod 23 can move relative to the first unloading trough 22, and the first workpiece is dropped from the first unloading trough 22 in an orderly manner And it just falls to the first clamping port, and each time there is one and only one falling on the first clamping port, the first feeding rod 23 pushes the first workpiece...

Embodiment 2

[0028] Such as Figure 1-3 As shown in the circular welding equipment of this embodiment, the welding gun 10 includes a gun head 11, the gun head 11 is installed on the work box 41 by a lift 43, and the gun head 11 can move up and down relative to the locking mechanism 42. The main purpose of the design of this structure is to facilitate the movement of the first feeding rod 33 and the second pushing mechanism 34. After the welding is completed, the gun head 11 of the welding gun 10 moves upward through the elevator 43 to wait for welding. When the feeding is completed, the gun head 11 Lowering for welding, so that each component will not hinder each other.

Embodiment 3

[0030] Such as image 3 As shown, the girth welding equipment of this embodiment further includes a workbench 50. The first workpiece feeding device 20, the second workpiece feeding device 30, and the pneumatic chuck 40 are all installed on the workbench 50. The table 50 is located directly below the locking mechanism 43 and is provided with a discharge port 51. The welded workpiece is automatically discharged from the discharge port 51. The main purpose of this structural design is to allow the workpiece to fall freely after the welding is completed. Object space is convenient for the collection of workpieces.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com