Device for achieving automatic welding of T-shaped stud on embedded part

A technology of automatic welding and pre-embedded parts, applied in auxiliary devices, welding equipment, auxiliary welding equipment, etc., can solve problems affecting the health of welding workers, bone hyperplasia of welding workers, and welding quality cannot be guaranteed, achieving significant progress and practical value, high degree of automation, and the effect of welding quality assurance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

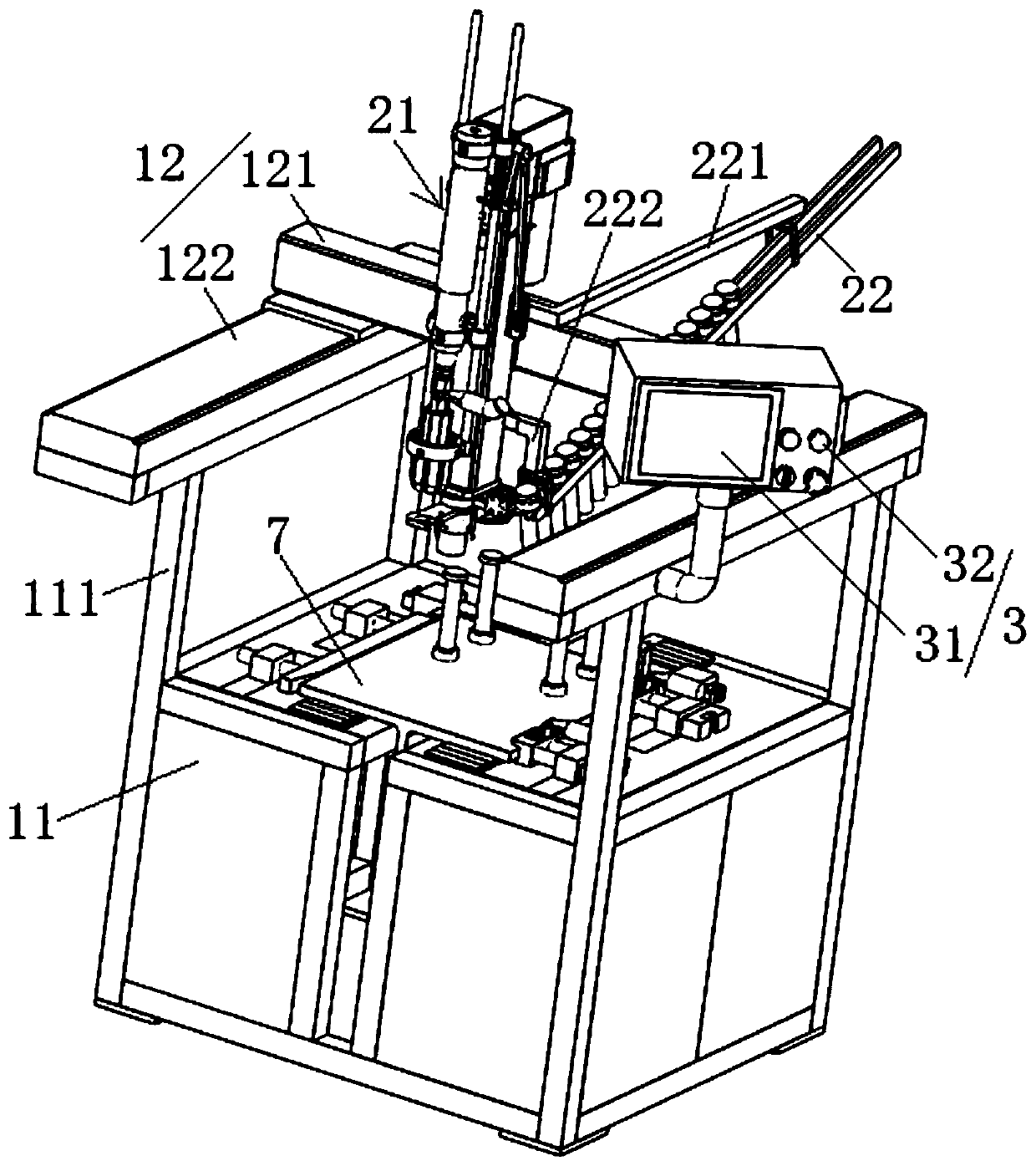

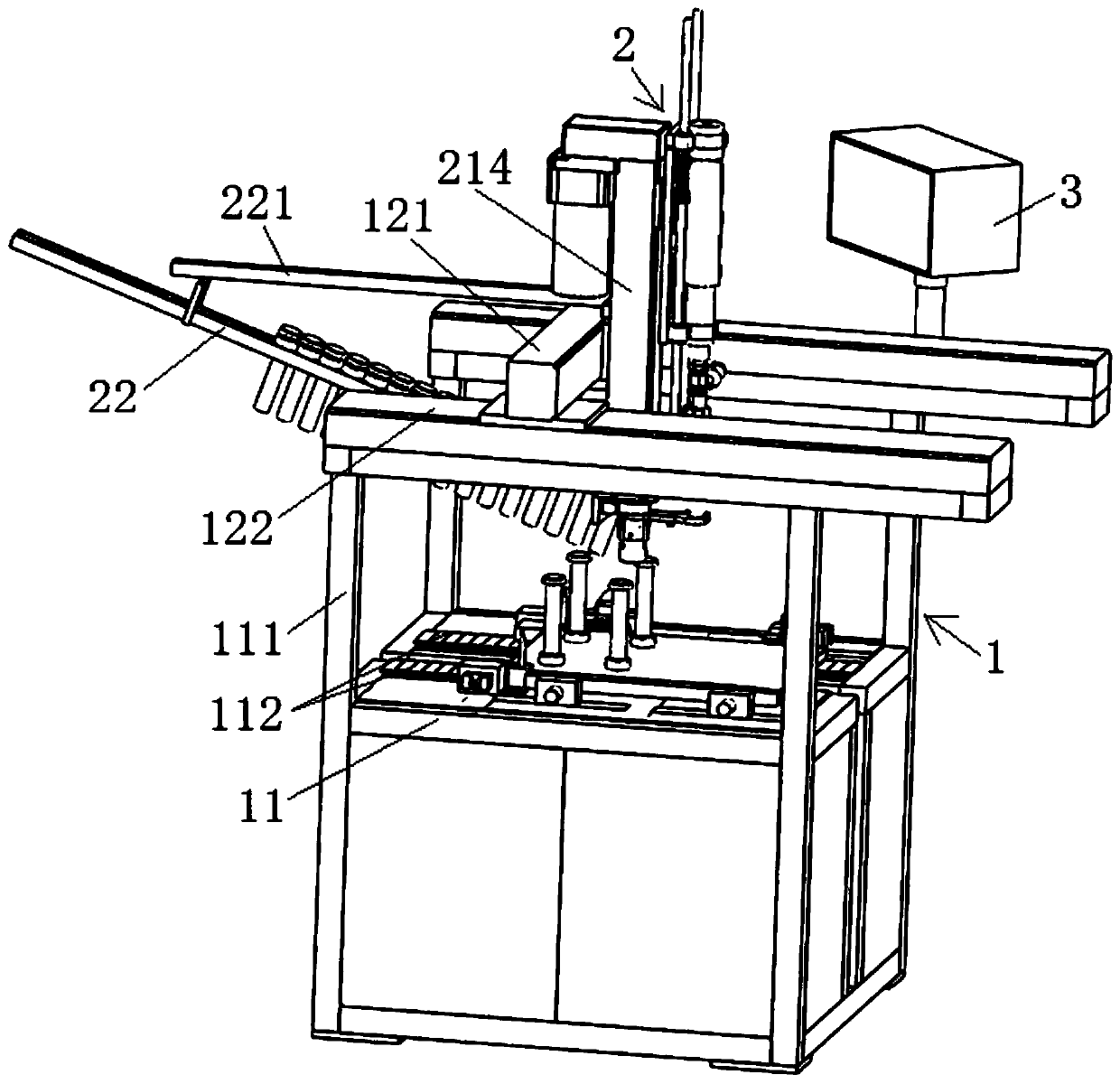

[0048] Please combine figure 1 and figure 2 As shown: a device for automatic welding of T-shaped studs on embedded parts provided by this embodiment, including a welding platform 1 and an automatic welding mechanism 2, and the welding platform 1 includes a cabinet-type workbench 11 and a biaxial movement support 12. The biaxial motion bracket 12 includes an X-direction slide rail 121 and two Y-direction slide rails 122, the X-direction slide rail 121 and the Y-direction slide rail 122 are slidingly connected, and the two Y-direction slide rails 122 are respectively It is fixed above the brackets 111 on both sides of the cabinet workbench 11 .

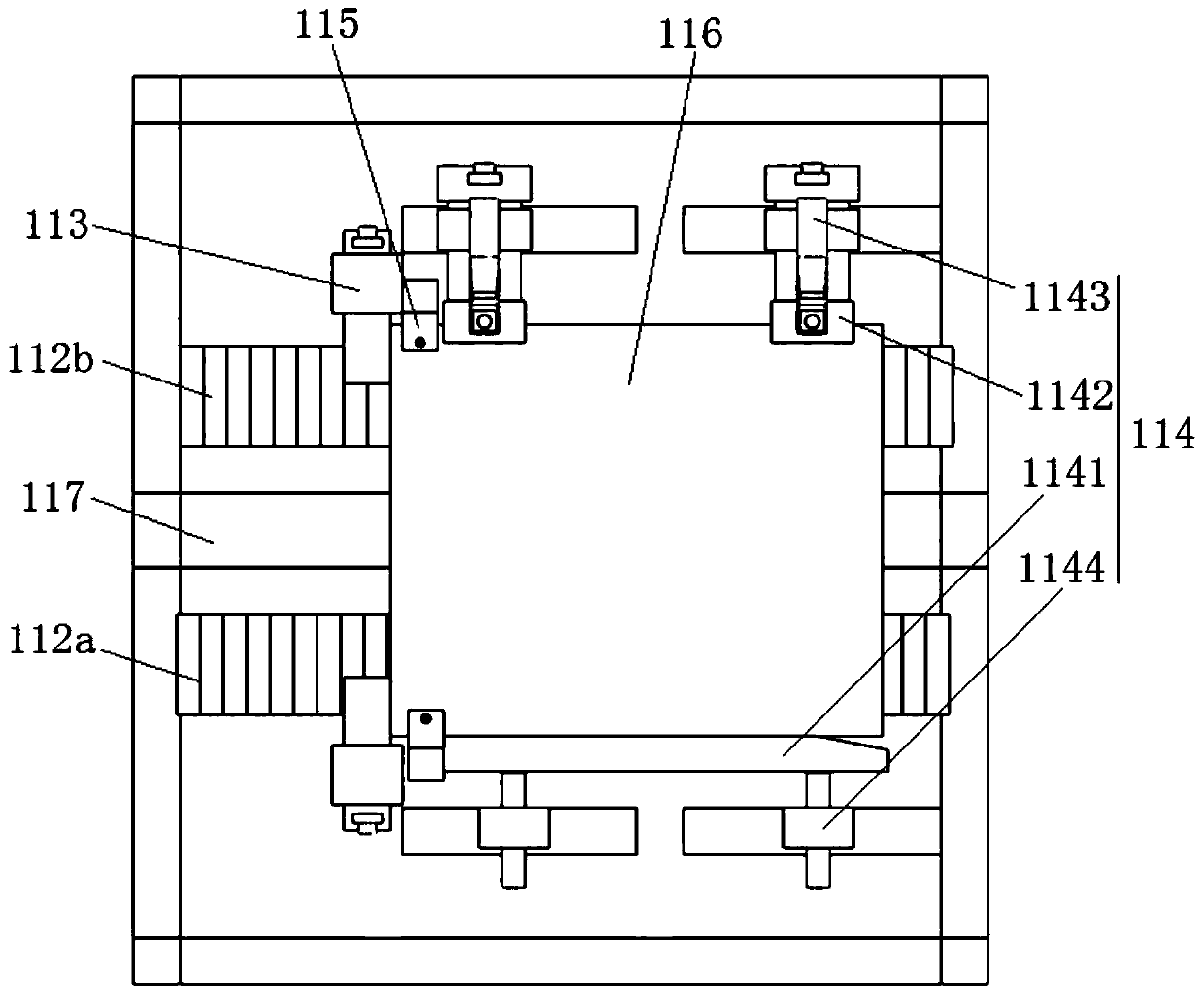

[0049] Please reunite image 3 and Figure 4 As shown: the cabinet-type workbench 11 is provided with a conveyor belt 112, a blocking piece 113 and a clamping positioning piece 114, and the blocking piece 113 is arranged A proximity sensor 115 is fixed between the parts 114 . In this embodiment, the stopper 113 is two telescopic m...

Embodiment 2

[0069] See Figure 14As shown, the device provided in this embodiment for automatic welding of T-shaped studs on embedded parts differs from the device described in Embodiment 1 only in that the device also includes an embedded part input unit 4, an embedded part part delivery unit 5 and finished product output unit 6, the end of the embedded part input unit 4 is spliced with the input end of the embedded part delivery unit 5, and the output end of the embedded part delivery unit 5 is connected to the cabinet workbench 11, the front end of the finished product output unit 6 is spliced with the rear end of the cabinet workbench 11; the embedded part input unit 4 includes a mounting seat 41 and a sliding slope 42 with a high head end and a low end , the embedded part conveying unit 5 includes a mounting bracket 51, a conveyor belt 52 and a conveying motor 53, and the finished product output unit 6 includes a mounting seat 61 and a sliding slope 62 with a high head end and a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com