Built-in automatic feeding and discharging device capable of realizing progressive feeding of bars

A technology of automatic loading and unloading, bar material, applied in positioning devices, clamping devices, metal processing machinery parts, etc., can solve the problems of high cost, complex structure, low efficiency, etc., to achieve less space occupation, high surface quality, structure simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

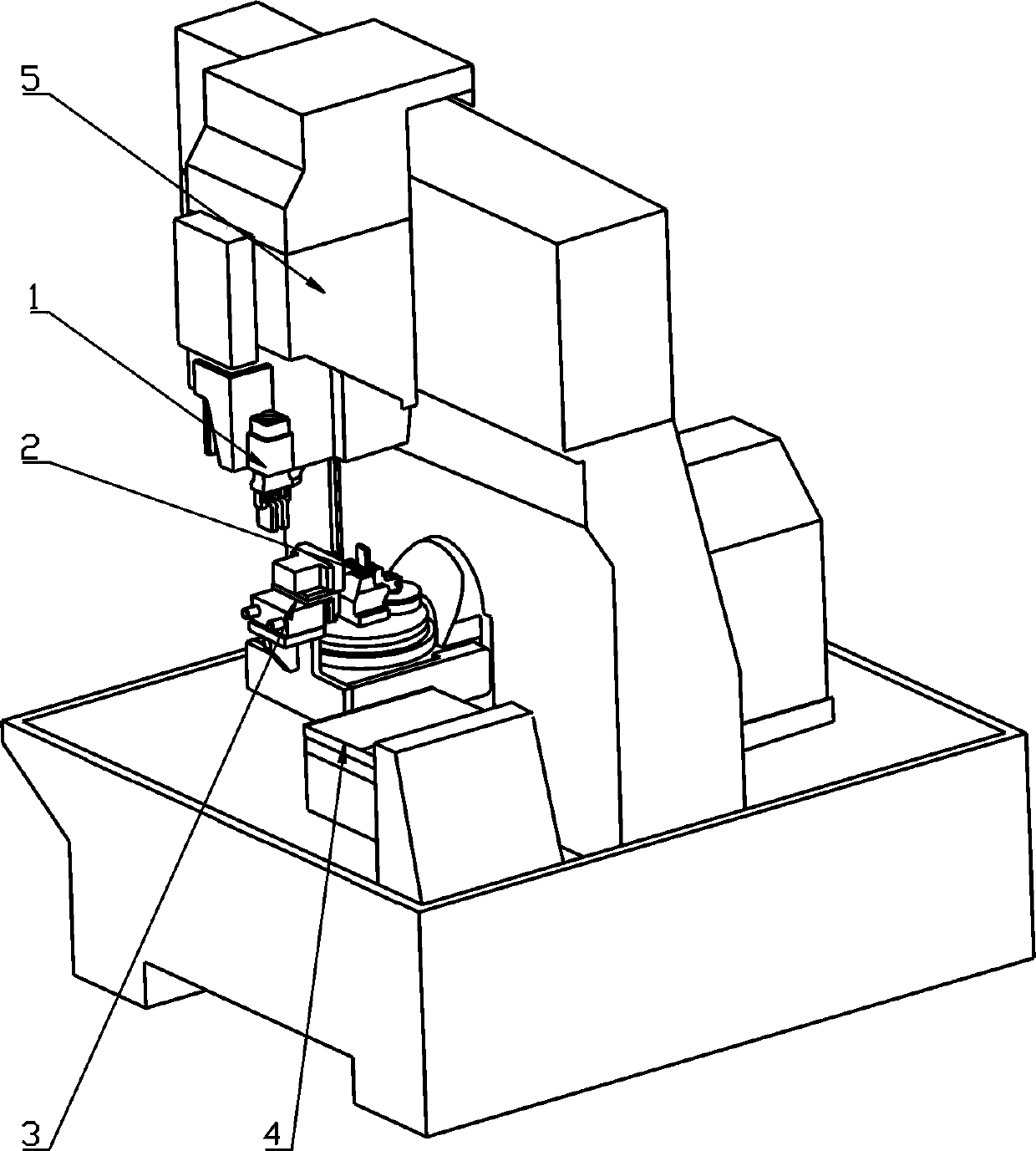

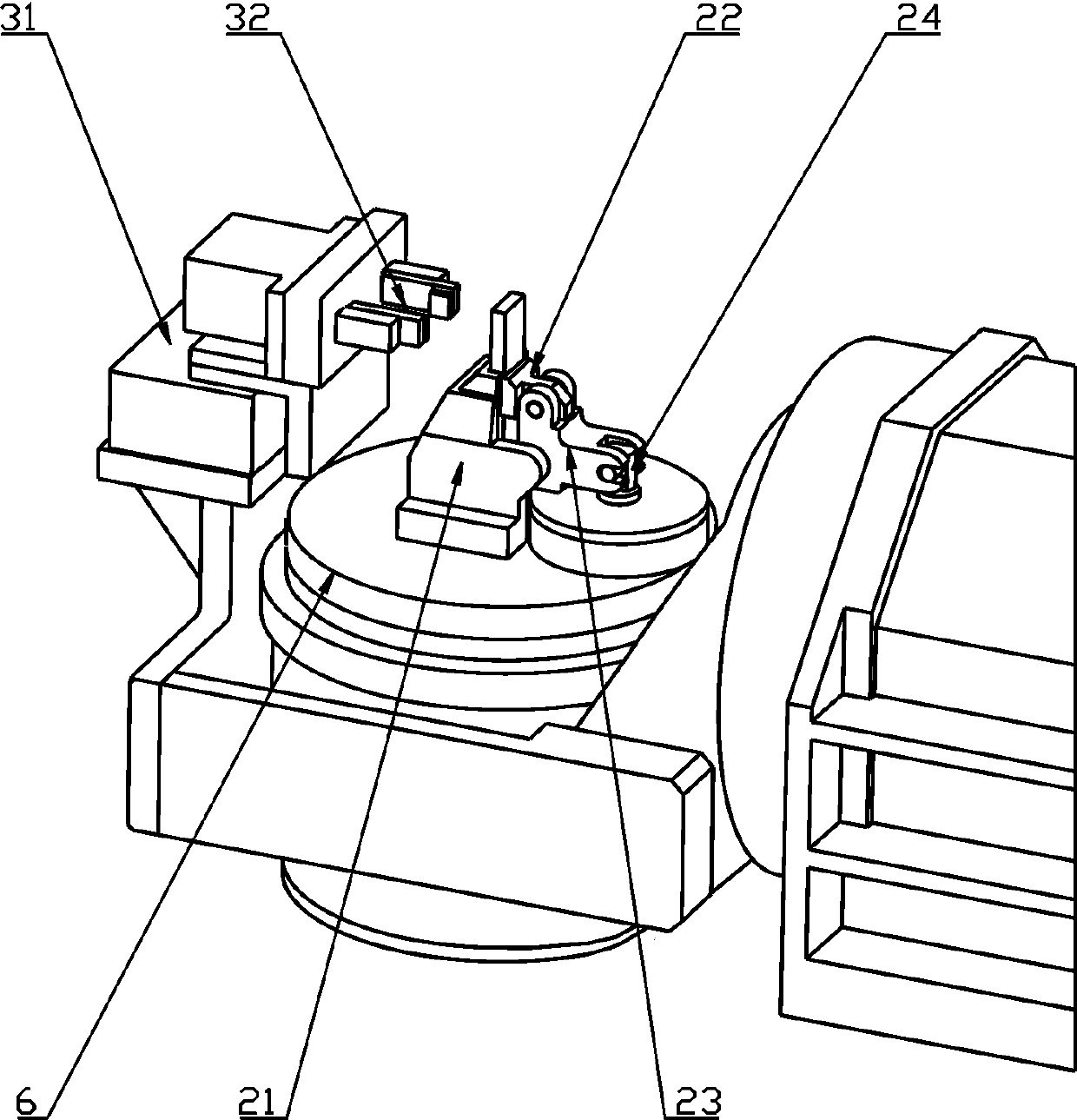

[0017] Such as figure 1 As shown, an automatic loading and unloading device in the machine that can realize the progressive feeding of bars in the present invention is composed of a grabbing manipulator 1, a clamping fixture 2, a supporting mechanism 3 and a material bin 4. The grasping manipulator 1 is fixedly installed on the front end of the machine head 5, and can move linearly and reciprocatingly along the X-axis direction and the Z-axis direction together with the head 5. The clamping jig 2 and the lifting mechanism 3 are respectively installed on the rotary table 6 of the machine tool, and together with the rotary table 6, they can perform a linear motion along the Y axis and a rotary motion around the B axis and the C axis. The feed bin 4 is arranged in the non-processing area inside the machine tool, and is used to hold the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com