Patents

Literature

71results about How to "Implement mobile control" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

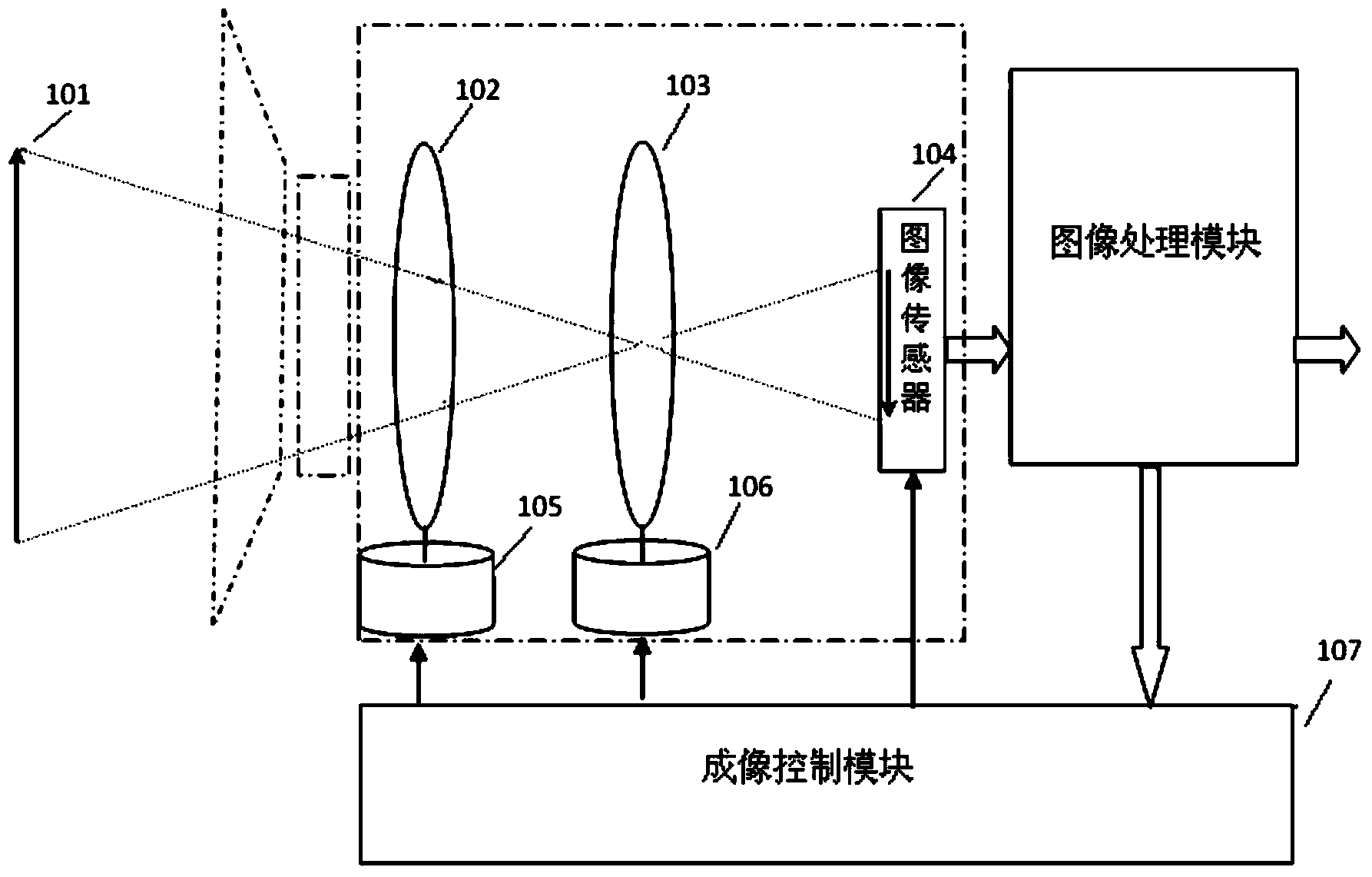

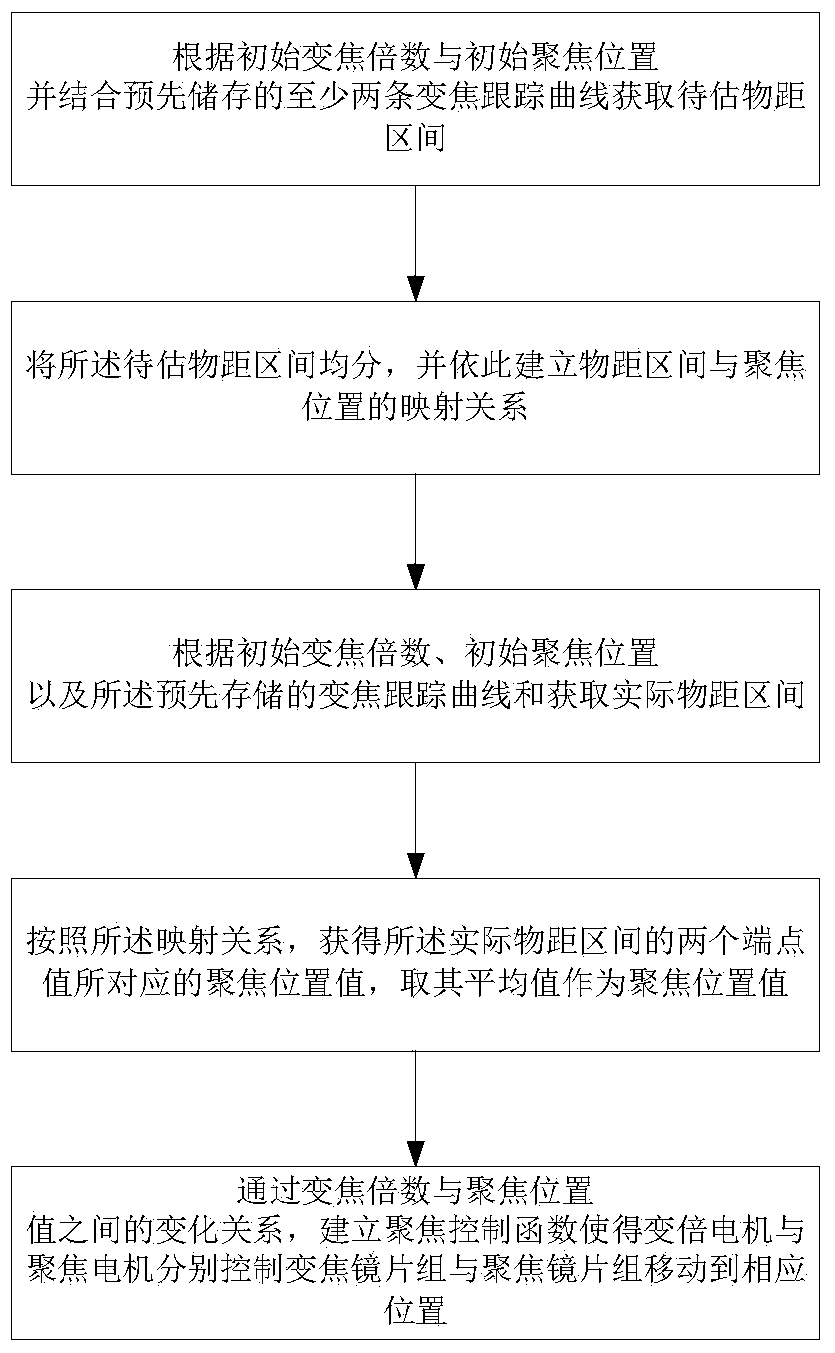

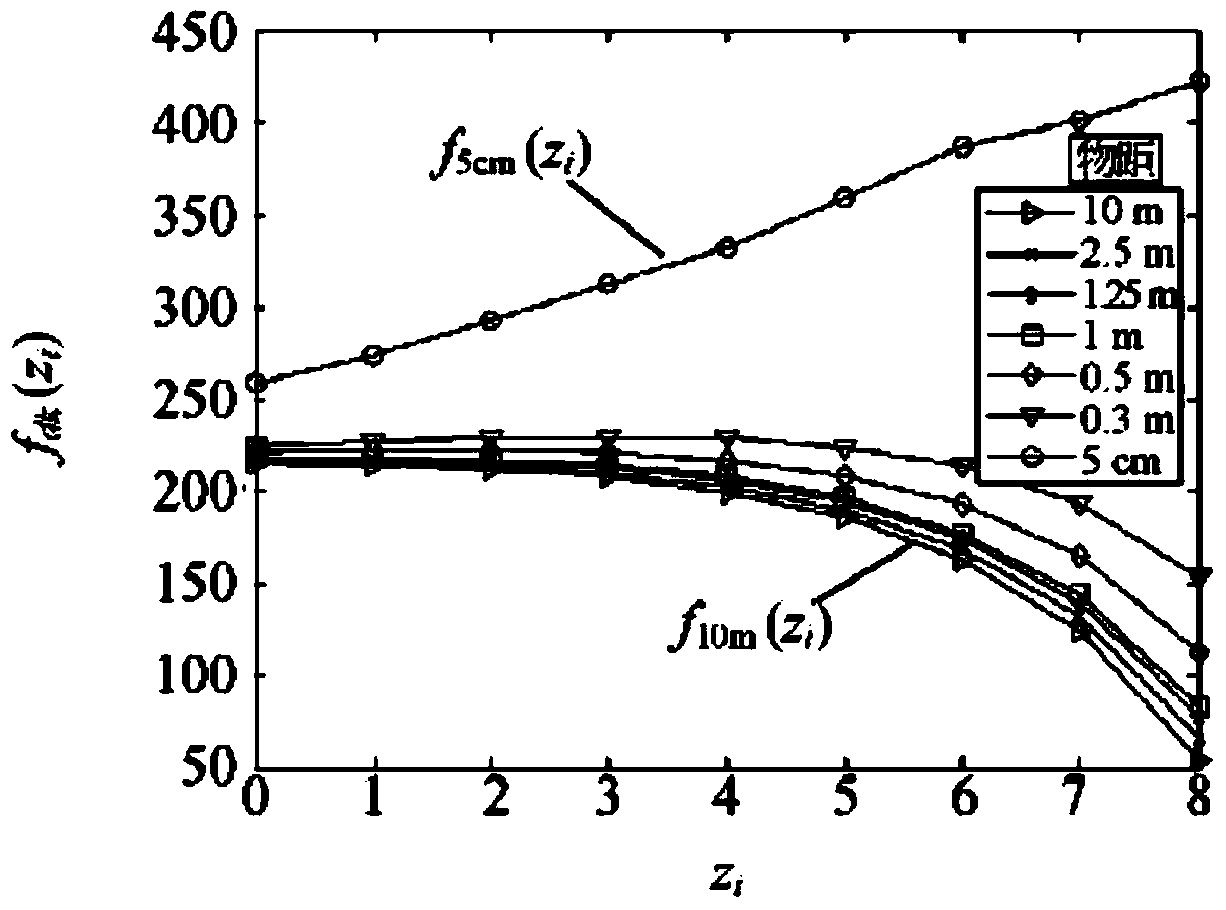

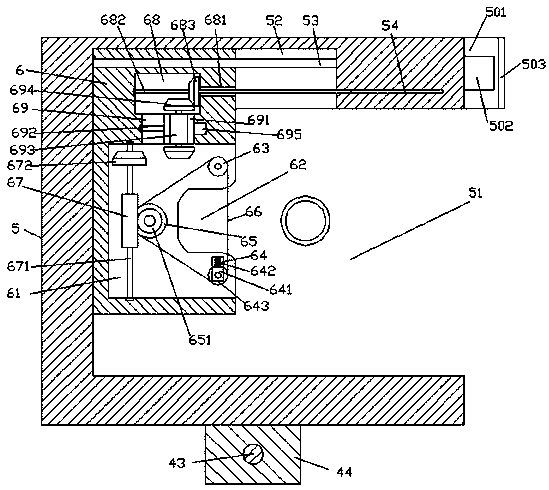

Method and system achieving integrated camera automatic focusing

InactiveCN103546692AImplement mobile controlMeet real-time requirementsTelevision system detailsColor television detailsComputer scienceMobility control

The invention provides a method and system for achieving integrated camera automatic focusing, and provides a zooming tracking method based on a relationship type, namely for a shot object at a fixed object distance, according to the initial zooming multiple, the value of an initial focusing position and a plurality of zooming tracking curves stored in advance, the mapping relation between the object distance interval and the focusing position is constructed, and the position to be focused is calculated in real time. Then, a gradient control function obtained by the combination of the statistical law of a lot of experimental data is utilized to achieve mobility control over a zooming motor and a focusing motor, the value of the position to be focused is improved and amended to a certain degree, the value of the position to be focused is closer to a real zooming tracking curve, and an automatic focusing effect is more accurate. Meanwhile, the zooming tracking curves are not needed to be stored in advance, all the zooming tracking curves corresponding to different object distances are not needed to be calculated point by point, an algorithm is simple, it is possible that the zooming speed meets a real-time property, and the focusing effect can meet the requirement for clearness in the whole process.

Owner:SUZHOU KEDA TECH

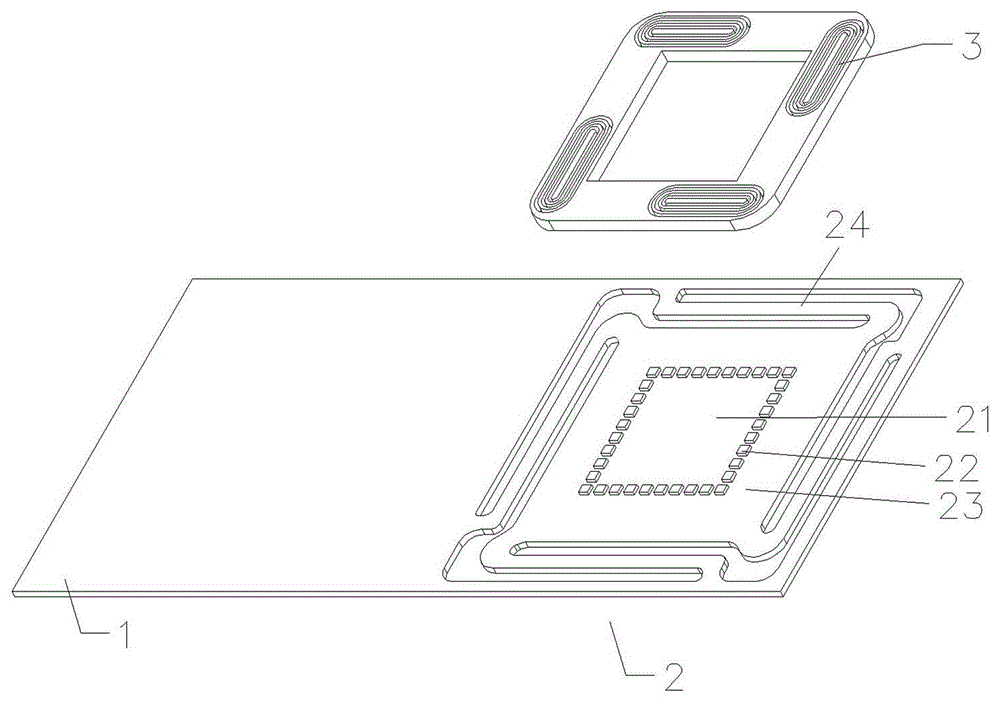

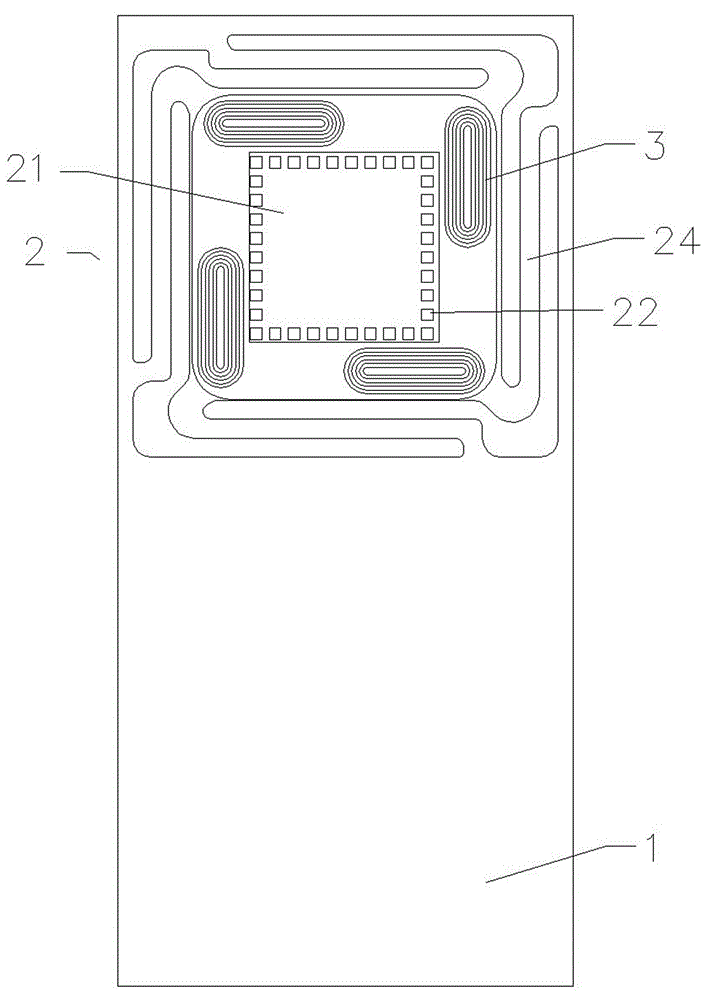

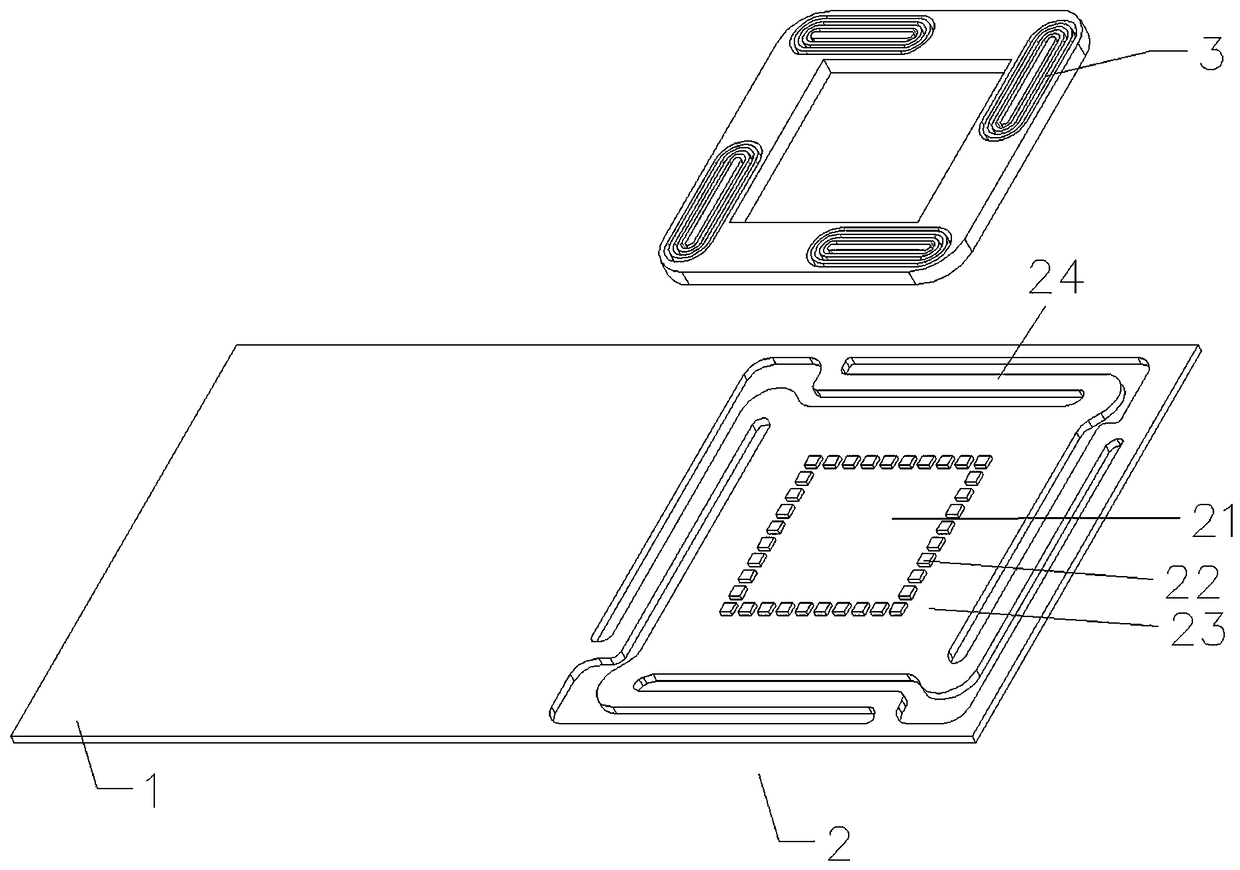

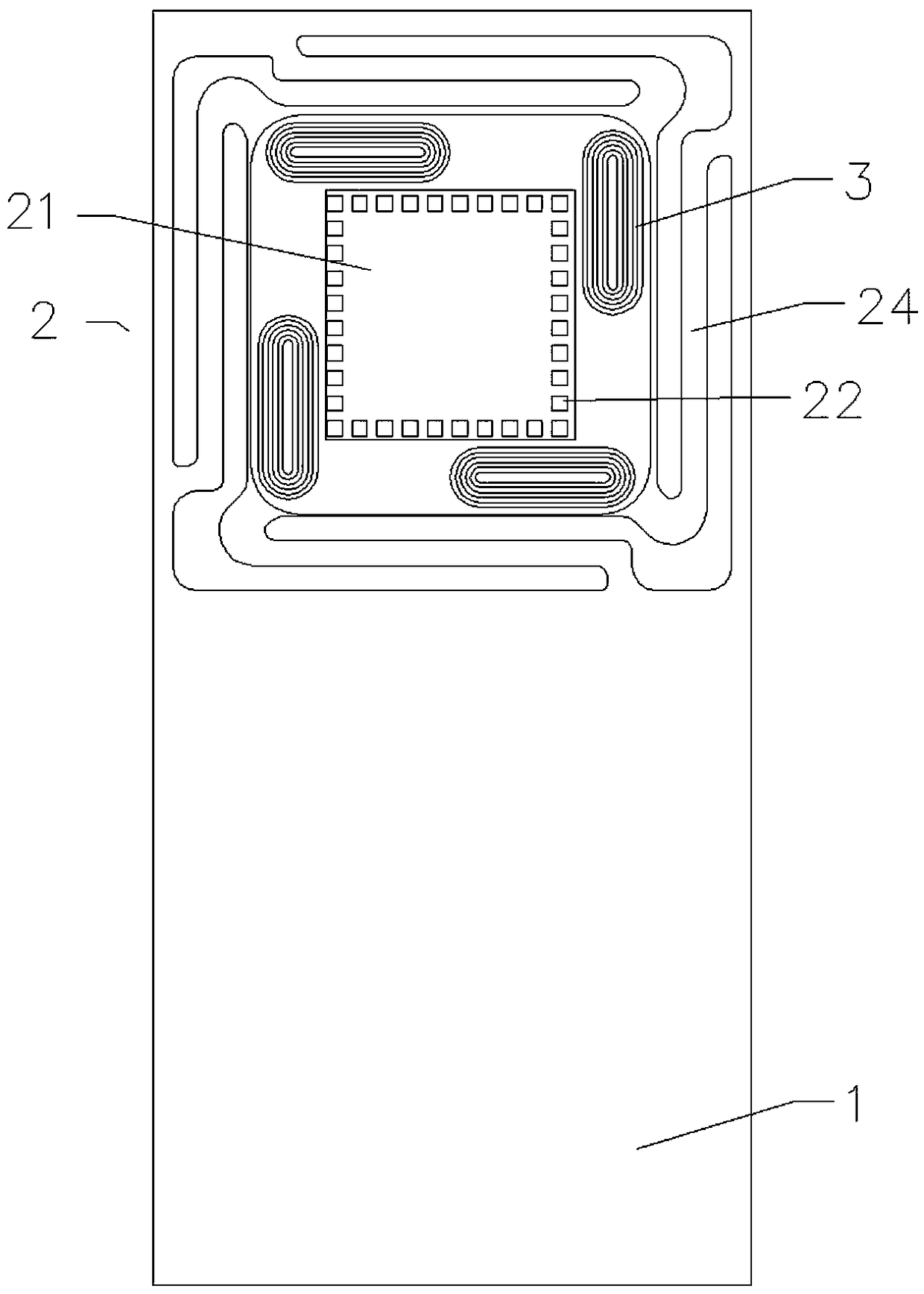

Flexible printed circuit board for welding imaging sensor

ActiveCN105025657AImplement mobile controlPrinted circuit aspectsPrinted circuit non-printed electric components associationFlexible circuitsCamera module

The invention discloses a flexible printed circuit board for welding an imaging sensor, comprising a first area and a second area which are arranged sequentially. The second area comprises a center part located in the center of the second area and welded with the imaging sensor and a frame part arranged at the periphery of the center part. The frame part is provided with coil groups uniformly distributed. The center part and the frame part are connected with the edge of the second area through elastic arms. The flexible printed circuit board can be used for installing the coil, provides elasticity for focusing and anti-shake motion of the imaging sensor, can simplify the structure of a camera module, and can greatly reduce the volume of the camera module.

Owner:SHENZHEN STR TECHNO

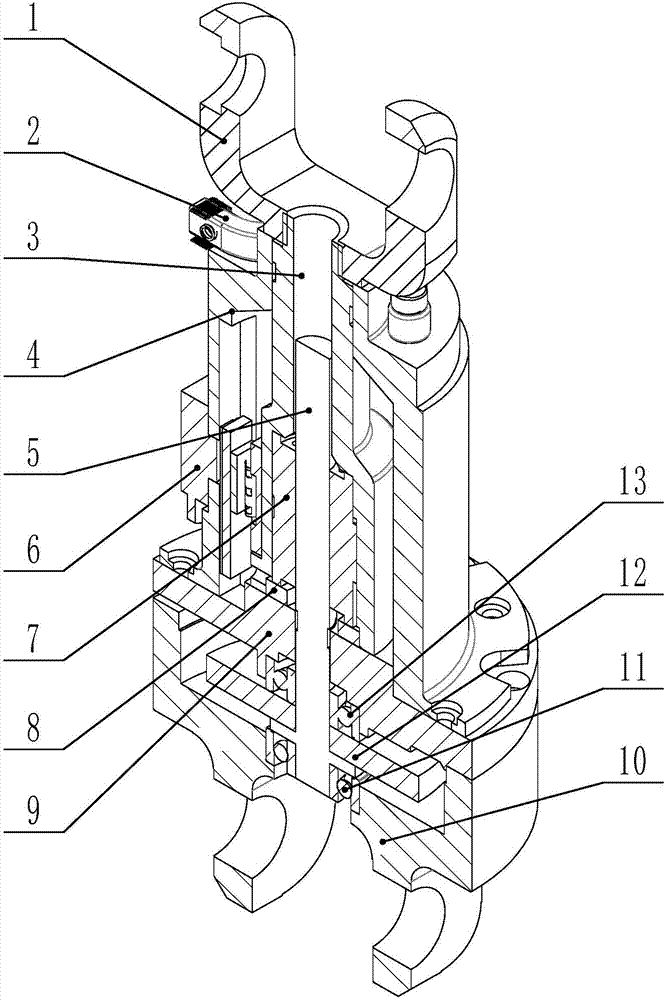

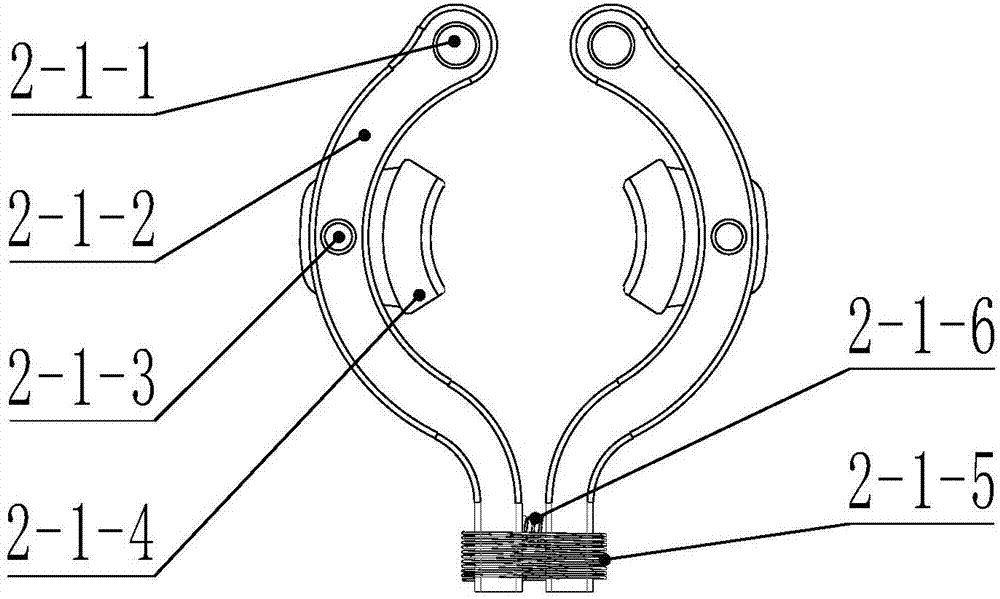

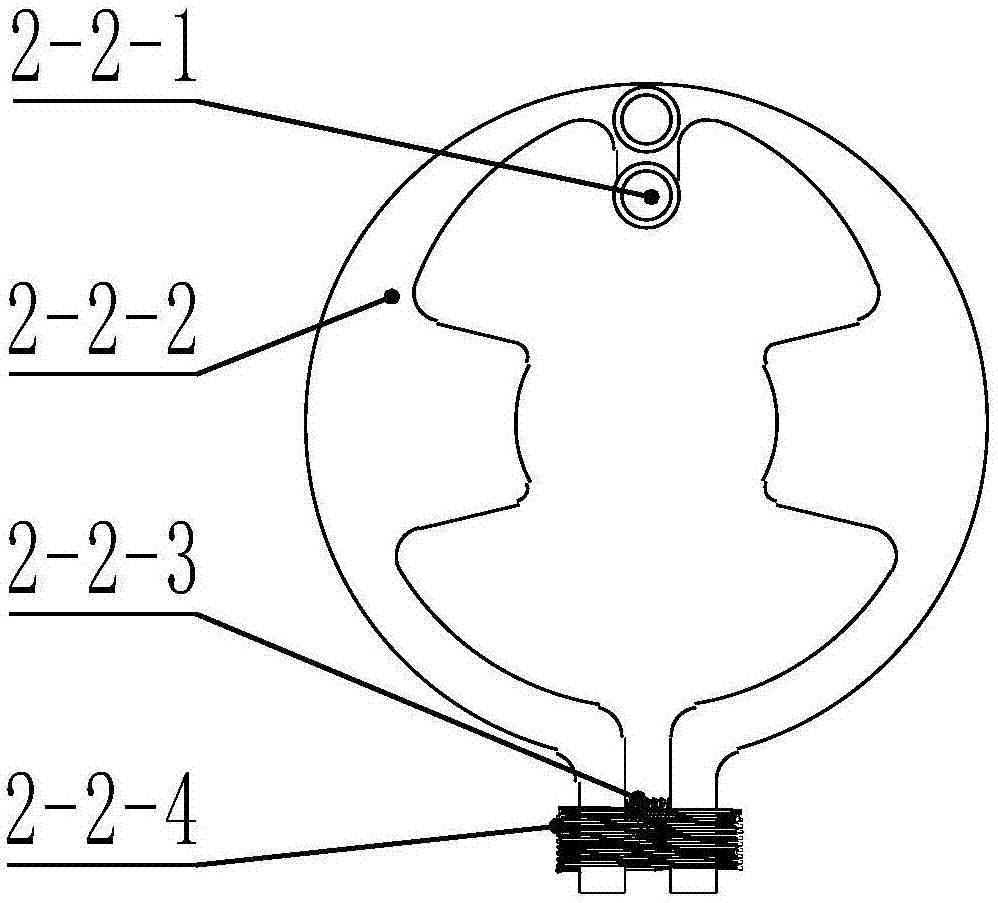

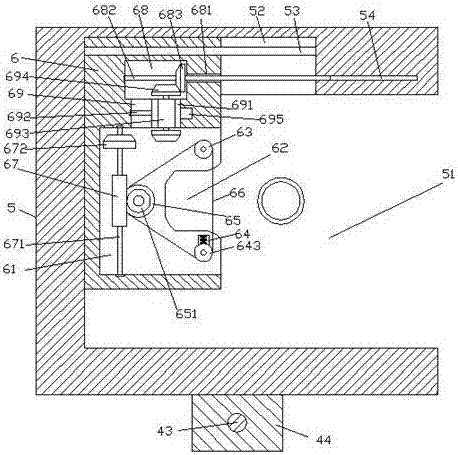

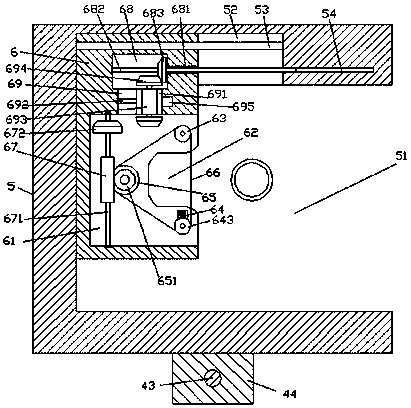

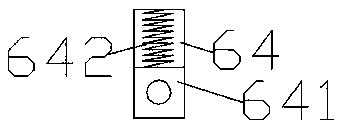

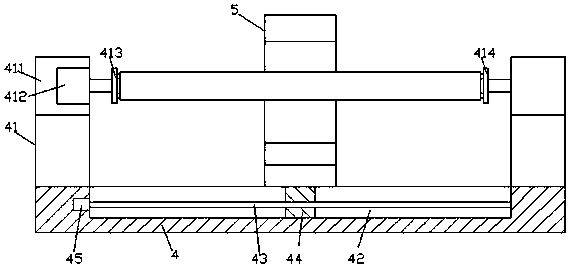

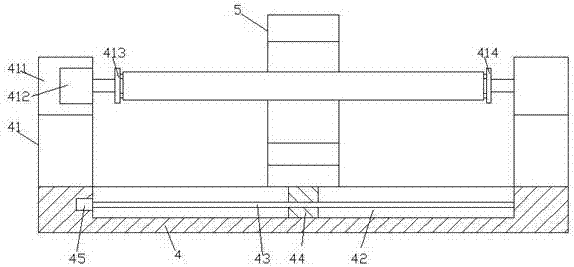

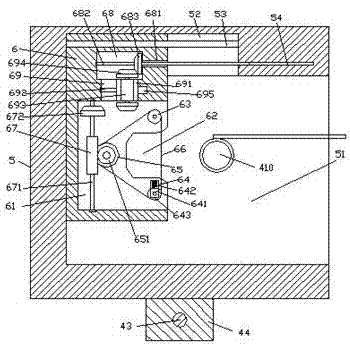

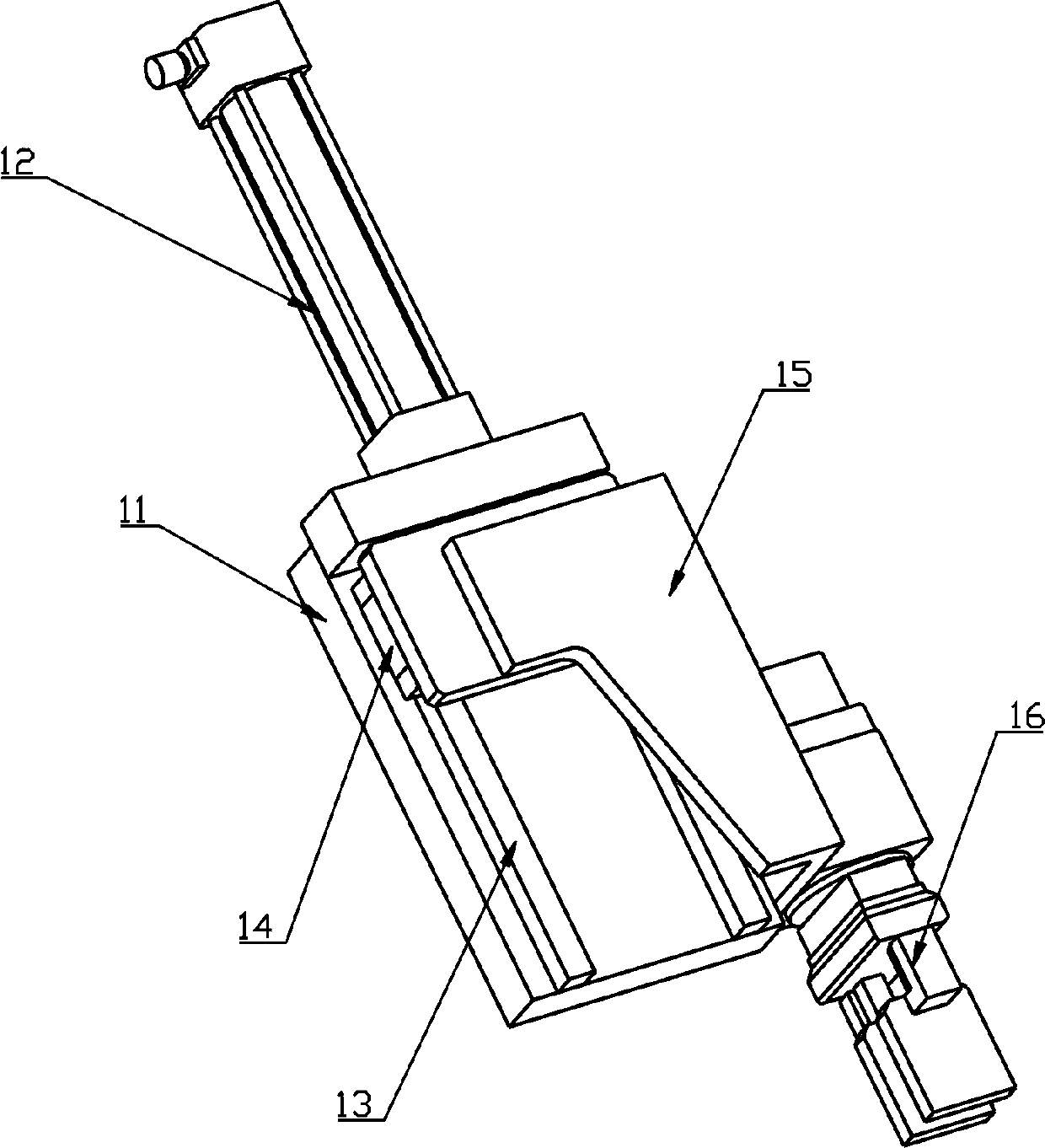

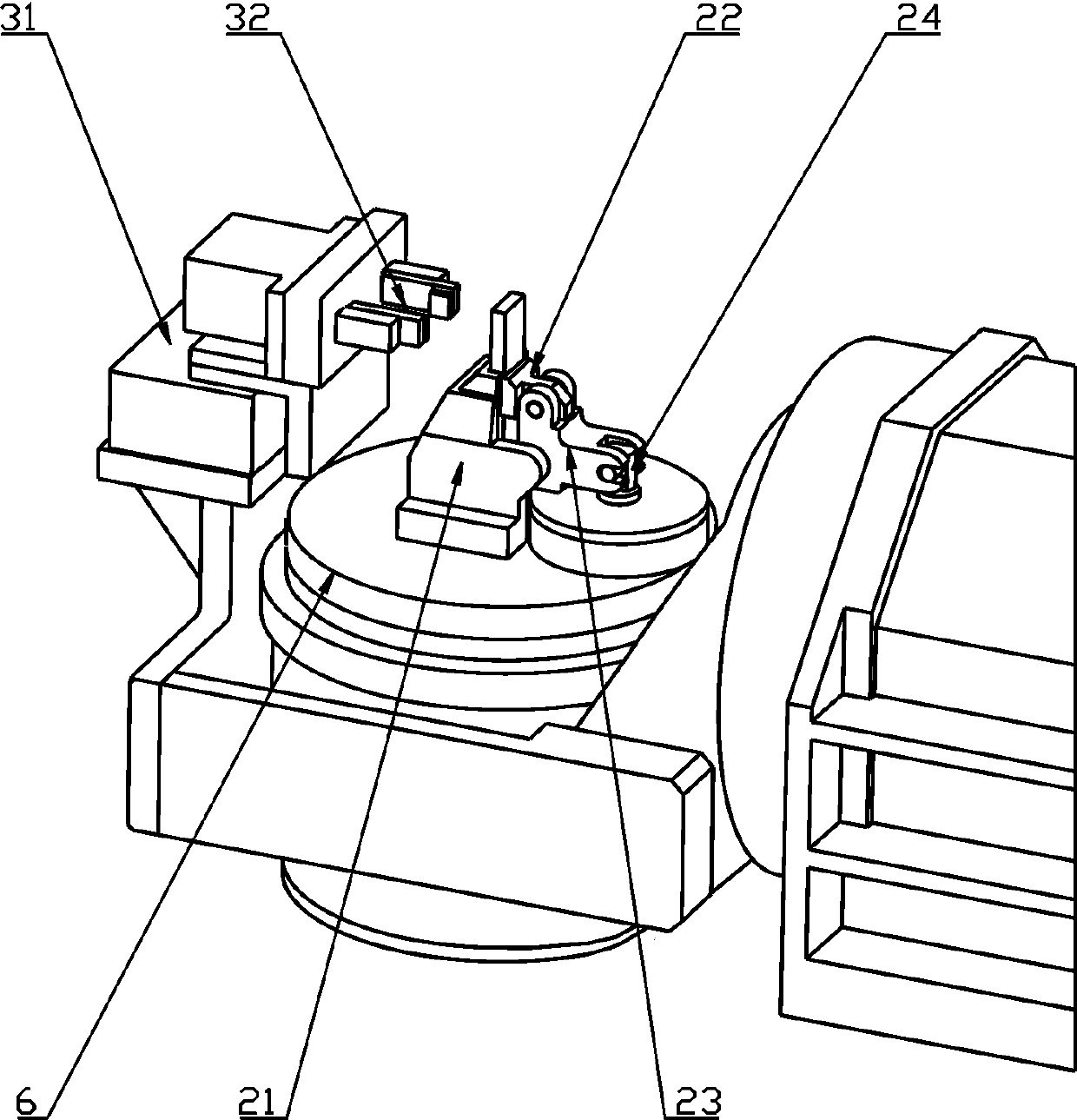

Precision actuator with impact-resistant locking device

ActiveCN107979222AAchieve shock-resistant lockingImplement mobile controlTelescopesStructural associationClosed loopMotor control

A precision actuator with an impact-resistant locking device comprises the impact-resistant locking device, a grating ruler swinging installation block, an extension rod installation head, an extension rod, a driving screw rod, a driving nut, a nut fastening piece, a first motor bearing, a main driving motor, a second motor bearing, a main shell, a motor upper shell and a base. The precision actuator has an impact-resistant locking function, a locking block and the extension rod are locked by a matched groove under a locking state, impact bearing employs a contact form, and the impact-resistant capability can be improved; by employing a fuse mechanism, extra motor control is reduced, and the control difficulty is reduced; and position feedback fully-closed loop is achieved, meanwhile, theextension rod can freely rotate at a small angle, the measurement accuracy cannot be affected, and the actuator is suitably applied to a multi-dimensional gesture adjustment platform.

Owner:YANSHAN UNIV

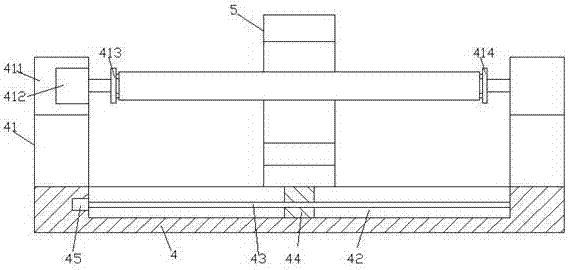

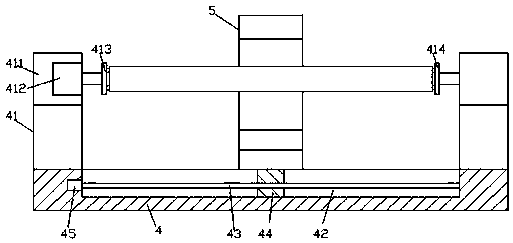

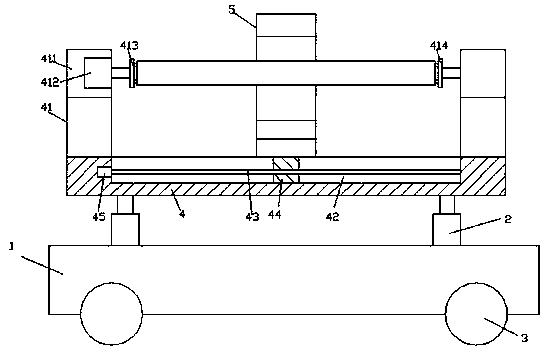

Welding seam polishing equipment of belt-type stainless steel pipe

InactiveCN106985039ARealize automatic controlAdjustable tension controlGrinding carriagesBelt grinding machinesAutomatic controlMotor drive

The invention discloses welding seam polishing equipment of a belt-type stainless steel pipe. The welding seam polishing equipment comprises a base frame and a polishing supporting frame arranged on the base frame; a containing groove is formed in the end face of the front side of the polishing supporting frame; a first sliding groove formed in a front-and-back extending manner is formed in the rear side of the top wall in the containing groove; a guide rod arranged in a front-and-back extending manner is arranged in the first sliding groove; a threaded hole extending to the front side is formed in the inner wall of the front side of the first sliding groove; the guide rod is slidingly matched with a polishing mechanism extending downwards; and a bottom extending section of the polishing mechanism stretches into the containing groove. The welding seam polishing equipment is simple in structure, reasonable in design, and low in manufacturing cost and maintenance cost; automatic control on switching of polishing transmission and movement control on the polishing mechanism can be realized, leftward and rightward movement work of the polishing supporting frame can be realized simultaneously, and the polishing requirements of different positions of a welding seam of the stainless steel pipe can be met; in addition, when a rotating motor drives the stainless steel pipe to rotate for achieving omnibearing welding seam polishing, the polishing efficiency is improved.

Owner:FOSHAN JINHAI HUIHUANG STAINLESS STEEL

Welding line polishing equipment of stainless steel pipes

ActiveCN107695835ARealize automatic controlAdjustable tension controlGrinding carriagesBelt grinding machinesMotor driveAutomatic control

The invention discloses welding line polishing equipment of stainless steel pipes. The equipment comprises a base frame, and a polishing support frame arranged on the base frame; an accommodating tankis formed in the front side end surface of the polishing support frame; a first slide groove extending front and back is formed in the back side of the top wall in the accommodating tank; a guide rodextending front and back is arranged in the first slide groove; a thread hole extending to the front side is formed in the inner wall of the front side of the first slide groove; the guide rod is slidingly matched and connected with a polishing mechanism downwards extending; and the bottom extension section of the polishing mechanism extends into the accommodating tank. The equipment is simple instructure, reasonable in design and low in manufacturing cost and maintenance cost, can realize automatic control of switching between polishing and transmission and mobile control of the polishing mechanism, meanwhile, can realize left-right moving work of the polishing support frame, and satisfies the polishing demands of different welding line positions of the stainless steel pipes; and in addition, when a rotating motor drives the stainless steel pipes to rotate to realize comprehensive welding line polishing, the polishing efficiency is improved.

Owner:NINGXIA DEXING & HENGTONG PIPE IND

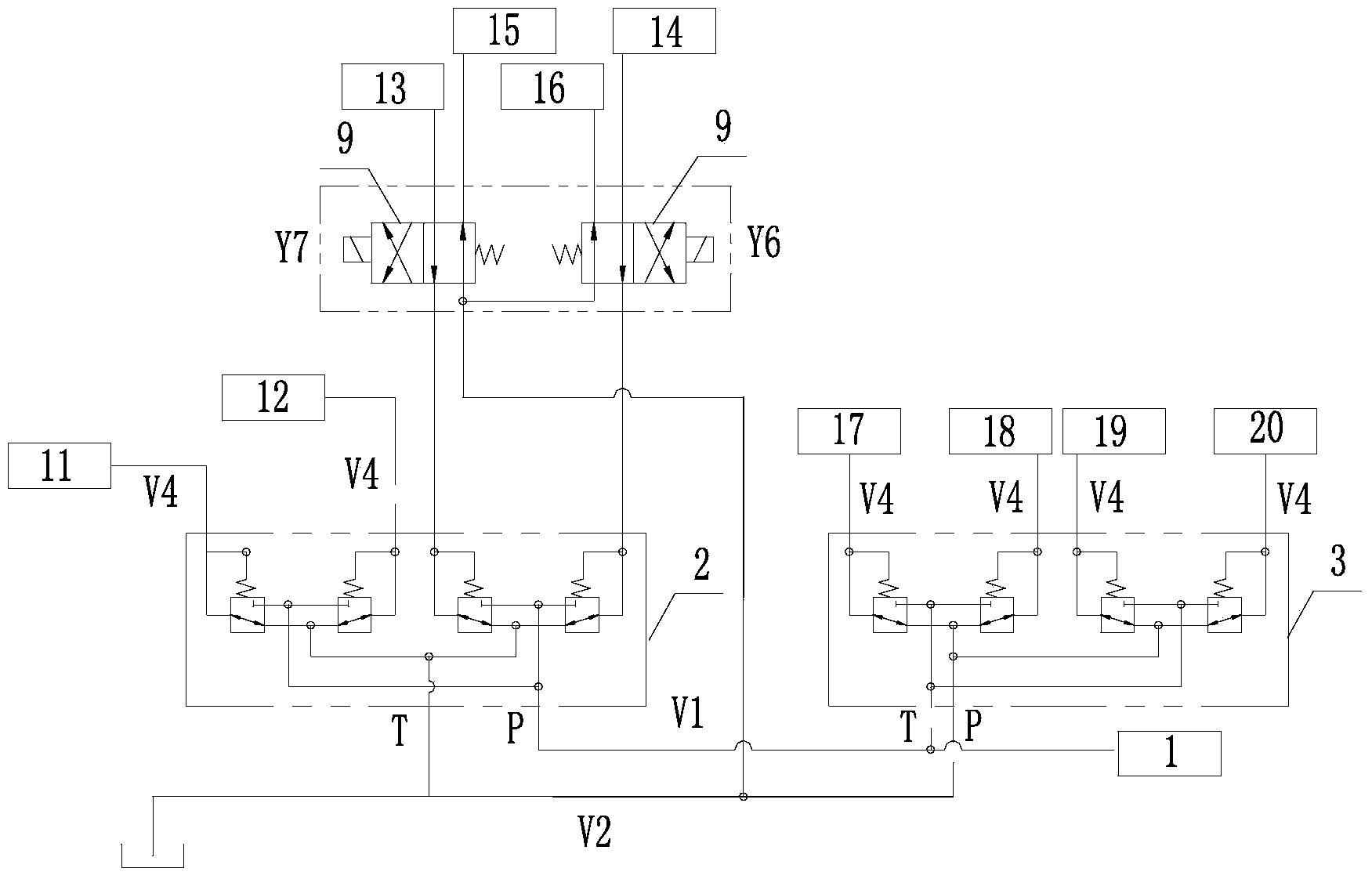

Hydraulic control handle system

ActiveCN103640975AImplement mobile controlLabor-free operationLoad-engaging elementsElectricityHuman–machine interface

The invention discloses a hydraulic control handle system. The hydraulic control handle system comprises a pressure oil source (1), a hydraulic control handle and an operating control loop, which are successively connected through an oil way, wherein the operating control loop realizes the operating control through the operation of the hydraulic control handle; the hydraulic control handle system also comprises a proportion pressure reducing valve (10) and a controller for controlling the proportion pressure reducing valve, the proportion pressure reducing valve is arranged on a handle oil inlet oil way (V1) arranged between the pressure oil source and an oil inlet (P) of the hydraulic control handle, and a controller is electrically connected with the proportion pressure reducing valve so as to control the pressure of the hydraulic oil which flows through the proportion pressure reducing valve. Therefore, the opening of the proportion pressure reducing valve is controlled and set through the controller such as computer software, a condition that a human-computer interface control manner can enhance control or replace a manual operation hydraulic control handle manner, the labor operation of the manual operation is avoided, the operation control is accurate, and in addition, the electronic control manner is combined with the proportion pressure reducing valve to realize the movable control and the like.

Owner:ZOOMLION HEAVY IND CO LTD

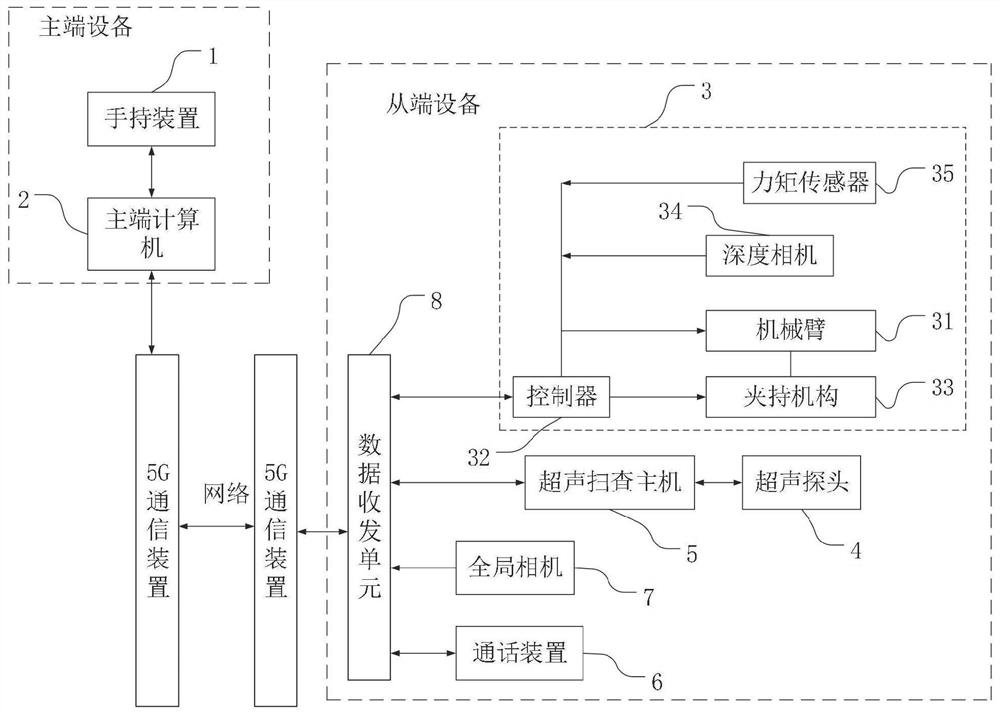

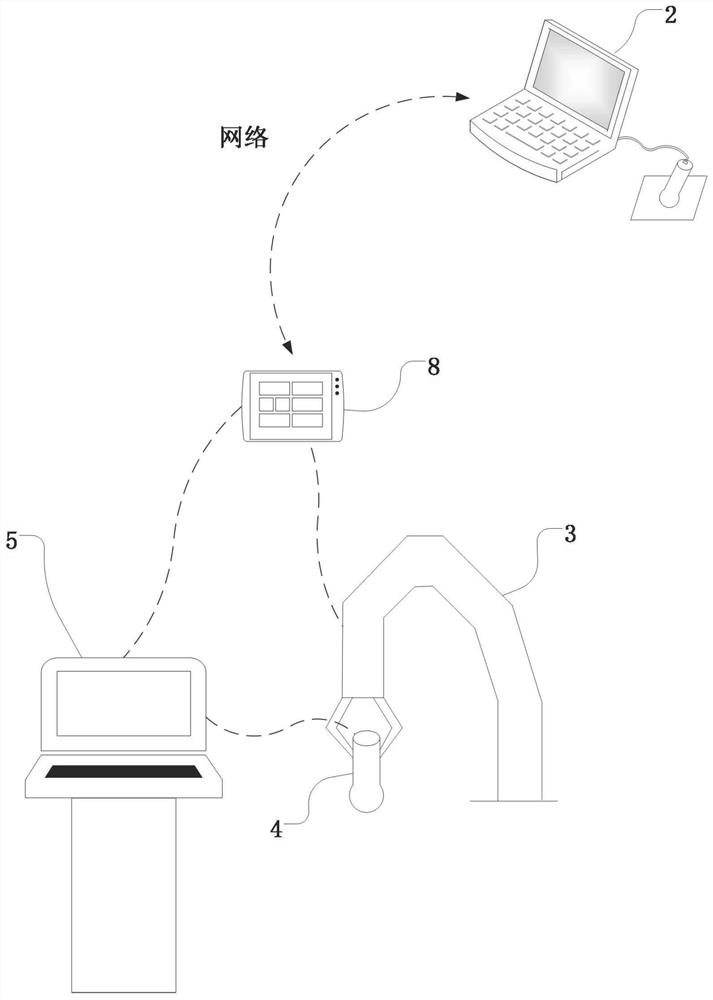

Portable remote ultrasonic scanning system and safe ultrasonic scanning compliance control method

ActiveCN113842165ASimple structureEasy to carryOrgan movement/changes detectionInfrasonic diagnosticsUltrasound probeElectrical and Electronics engineering

The invention discloses a portable remote ultrasonic scanning system. Master end equipment comprises a handheld device and a master end computer; slave end equipment comprises a slave end scanning robot, slave end ultrasonic equipment, a slave end environment sensing unit and a data receiving and transmitting unit; the handheld device sends the moving speed, the rotating angular speed and the pressing force of the handheld device to a controller of the slave end scanning robot through the master end computer and the data receiving and transmitting unit, and the controller controls a mechanical arm to move on the horizontal plane, move in the space and move in the normal direction of a scanning face; the master end computer displays an ultrasonic scanning image, so that a doctor can conveniently observe a scanning state; the whole movement process of the mechanical arm is controlled in a compliant mode, the mechanical arm can imitate the human arm, external acting force is compliant when the mechanical arm makes contact with the external environment, and the safety of a patient during ultrasonic scanning can be guaranteed; and in addition, continuity of the whole movement process of the slave end scanning robot can be ensured, and continuity of contact force between a ultrasonic probe and a human body can be ensured.

Owner:合肥合滨智能机器人有限公司

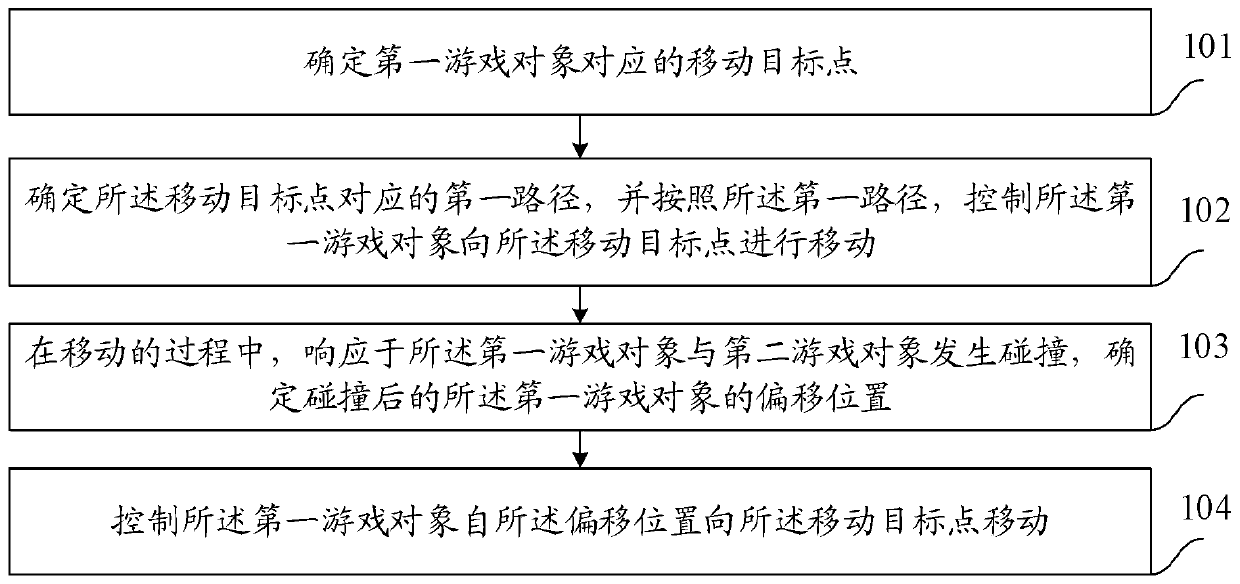

Mobile control method and device in games, electronic equipment and storage medium

ActiveCN110141862AImplement mobile controlIncrease authenticityVideo gamesElectric equipmentElectronic equipment

The embodiment of the invention provides a mobile control method and device in games, electronic equipment and a storage medium. The mobile control method comprises the steps that a moving target point corresponding to a first game object is determined; a first path corresponding to the moving target pointis determined, and the first game object is controlled to move to the moving target point according to the first path; in the process of moving, in response to the collision between the first game object and a second game object, and the offset position of the first game object after the collision is determined; and the first game object is controlled to move from the offset position to the moving target point. According to embodiments of the mobile control method and devicein the games,the electronic equipment and the storage medium, the mobile control of a game object is achieved, and the authenticity of the game effect is improved.

Owner:NETEASE (HANGZHOU) NETWORK CO LTD

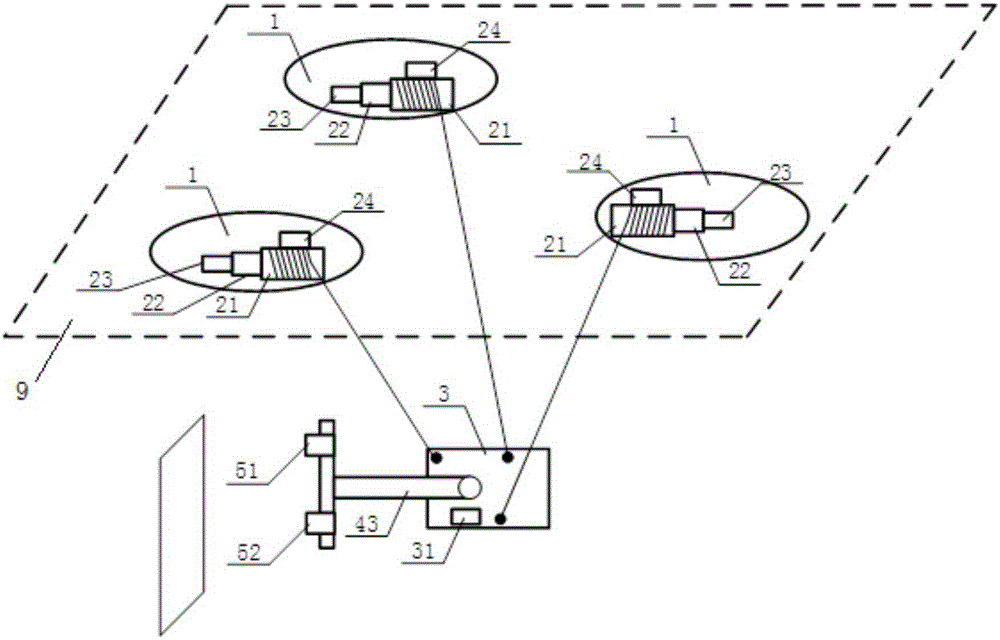

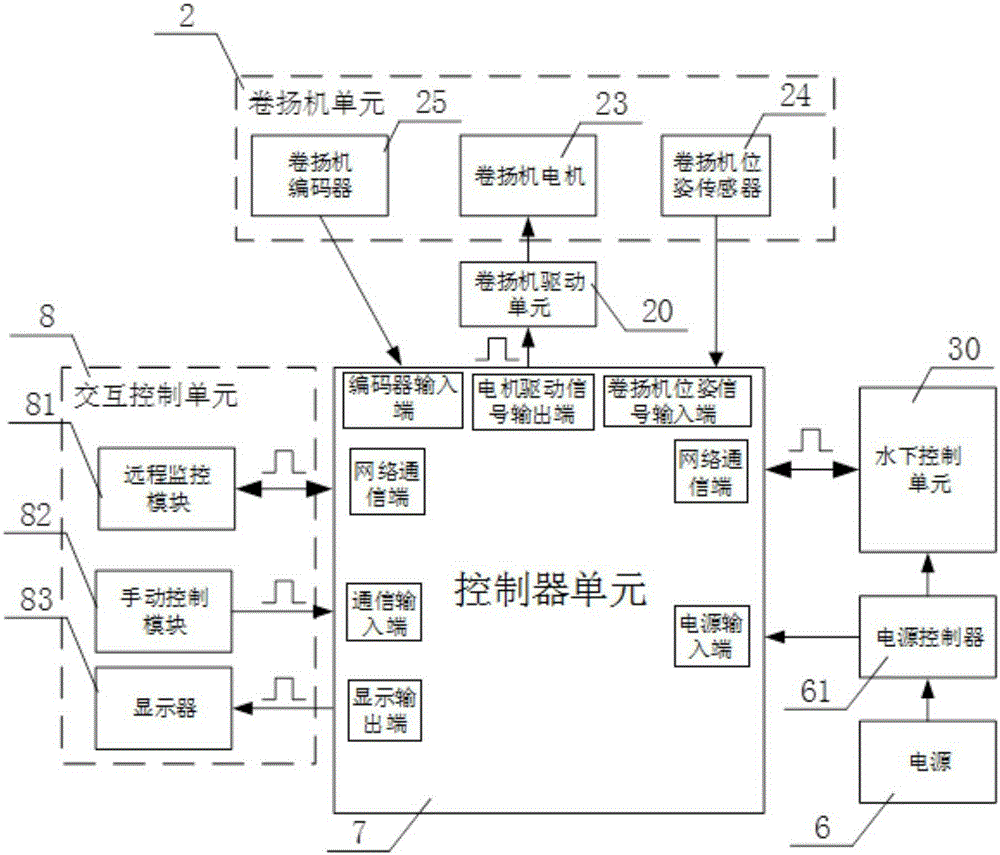

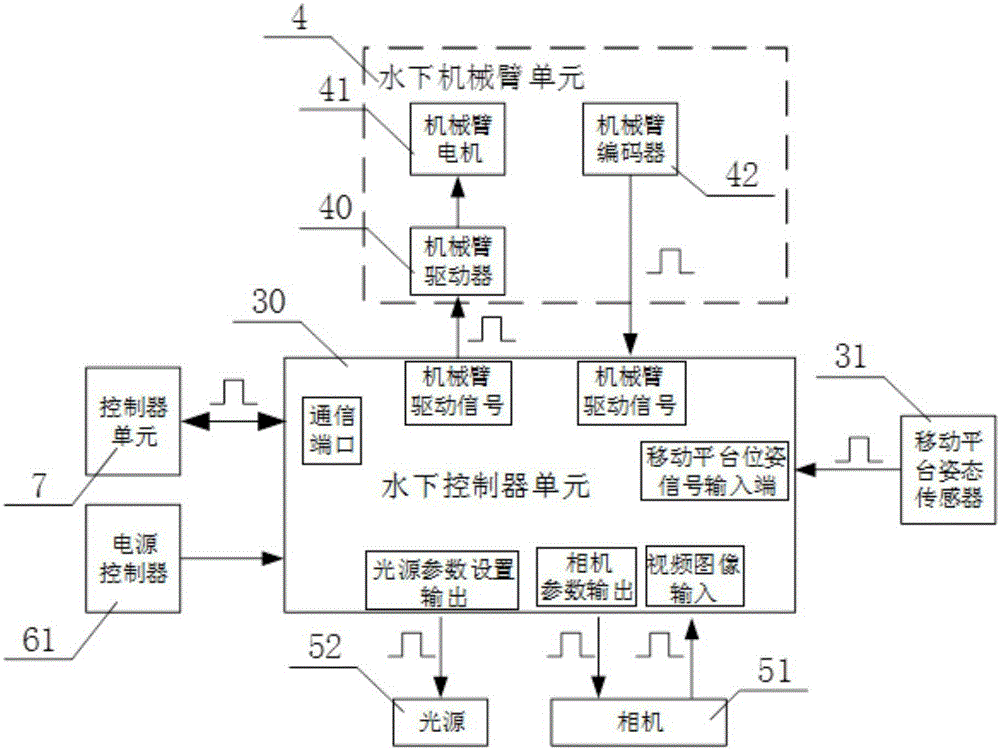

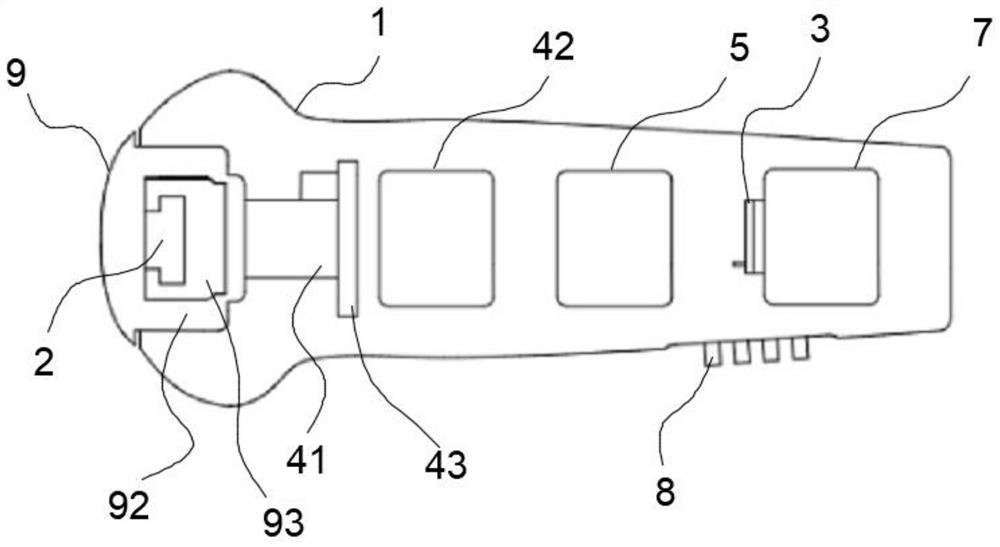

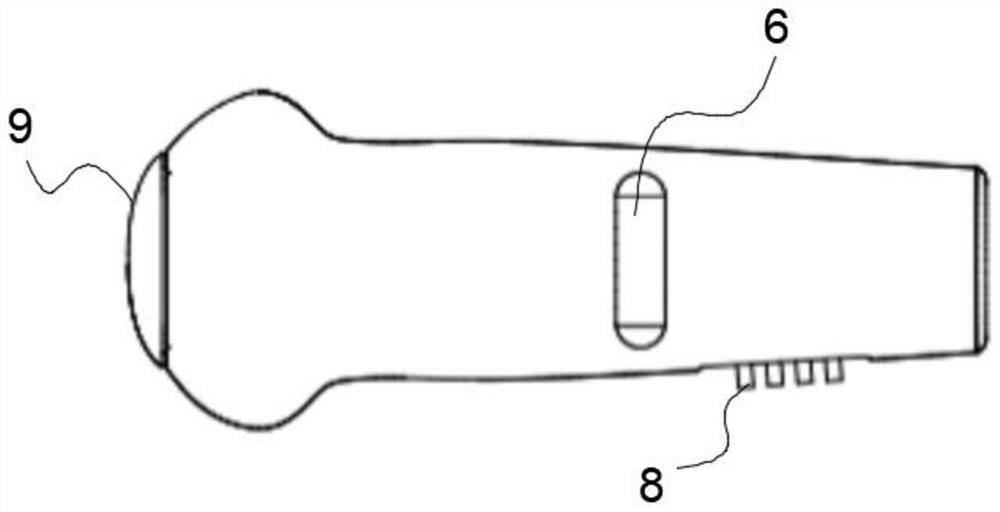

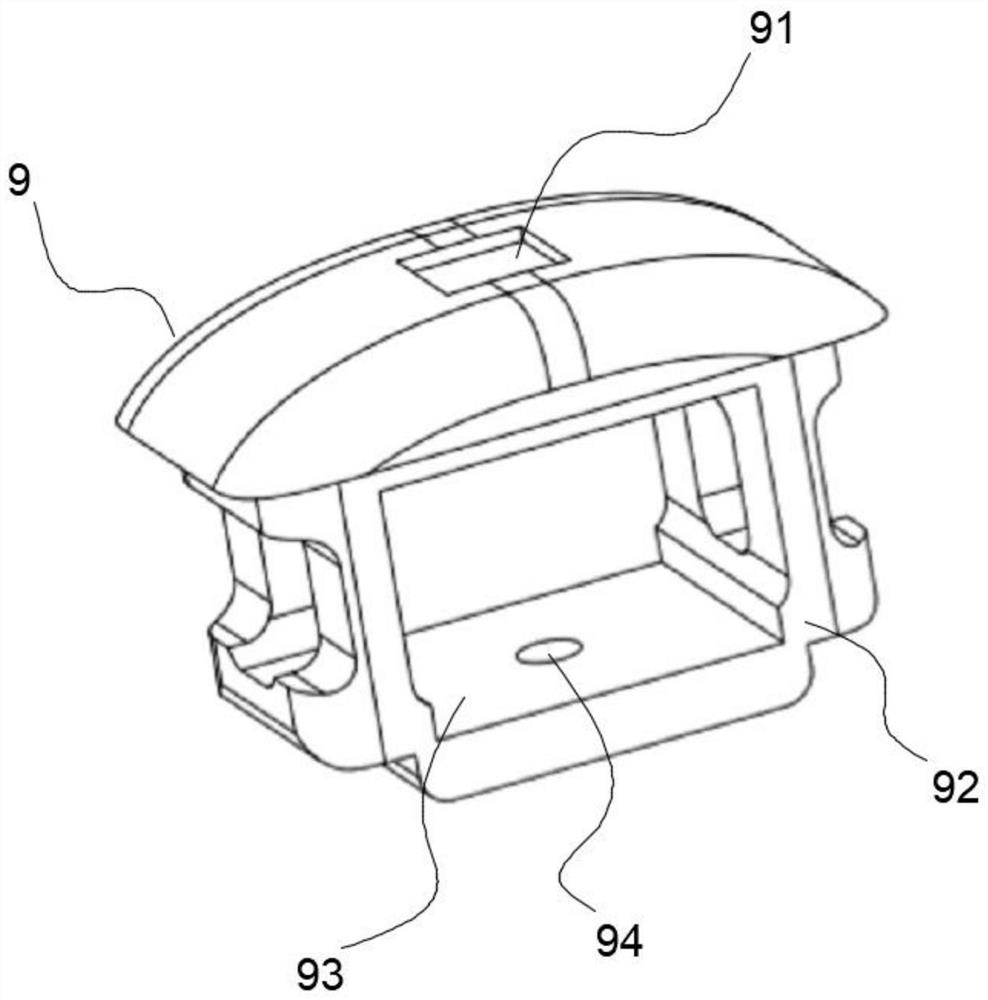

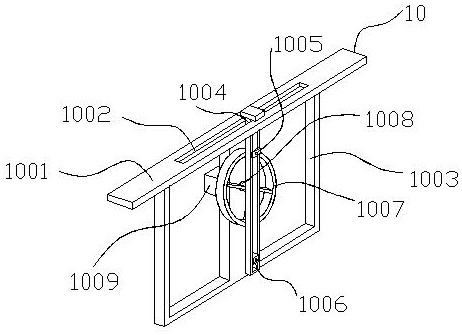

Rope-driven underwater detection robot

ActiveCN105197206AImplement mobile controlRealize visual inspectionUnderwater equipmentPropellerWinch

The invention relates to a rope-driven underwater detection robot, which can be used for visual detection on an underwater structure and comprises an above water platform, a winch unit, an underwater mobile platform, an underwater mechanical arm unit, a camera, a light source, a power supply, a controller unit and an interactive control unit, wherein a winch is connected with the mobile platform by a rope, and the rope is wound on the winch; the camera and the light source respectively sleeve one end of the underwater mechanical arm unit; an underwater control unit is fixed on the underwater mobile platform, and the underwater mechanical arm unit, the camera, the light source, a mobile platform attitude sensor and the controller unit are respectively connected with the underwater control unit. By means of rope driving, the mobile platform is controlled to do the actions of ascending and horizontal movement, and a mechanical arm adjusts the camera in a small scope; the condition that a propeller is adopted, so that a water body is more turbid and imaging detecting quality is reduced can be avoided, and thus a final detection effect can be improved, and the underwater imaging detecting sensitivity is improved.

Owner:苏州蛟视智能科技有限公司

Portable teleoperation handheld device for remote ultrasonic examination

ActiveCN113907788AConvenient Ultrasound ScanningSimple structureInfrasonic diagnosticsSonic diagnosticsHuman bodyHuman skin

The invention discloses a portable teleoperation handheld device for remote ultrasonic examination. A speed acquisition module acquires speed information of the handheld device moving on a working surface; an angular velocity acquisition module acquires angular velocity information of rotation of the handheld device in the space; and a force acquisition module is connected with a pressing module and is used for acquiring the pressing force of the handheld device. The portable teleoperation handheld device adopts an integrated design, is simple in structure and convenient to carry, can be connected with a computer, and is convenient for ultrasonic scanning of a patient in a home environment; force sense feedback is formed by using a display screen and a vibration module; operation can be carried out on any working face such as a desktop, a human body skin model surface or a human body surface, other auxiliary equipment such as a touch table is not needed, and more visual force feedback can be provided when the device works on the human body skin model surface; and by means of speed mapping and force mapping, continuity of the whole movement process of the slave end scanning robot is ensured, and continuity of contact force between an ultrasonic probe and a human body is ensured.

Owner:HEFEI HEBIN INTELLIGENT ROBOTS CO LTD

Stainless steel pipe grinding device

ActiveCN107695836ARealize automatic controlAdjustable tension controlBelt grinding machinesGrinding work supportsTransmission switchingMotor drive

The invention discloses a stainless steel pipe grinding device. The stainless steel pipe grinding device comprises a base frame and a grinding supporting frame arranged on the base frame; a containinggroove is formed in the front side end face of the grinding supporting frame, a first sliding groove extending front and back is formed in the rear side of the inner top wall of the containing groove, a guide rod which extends front and back is arranged in the first sliding groove, a thread hole extending towards the front side is arranged on the inner wall of the front side of the first slidinggroove, a grinding mechanism which extends downwards is in sliding fit connection to the guide rod, and the bottom extension segment of the grinding mechanism extends into the containing groove. The stainless steel pipe grinding device is simple in structure, reasonable in design, low in manufacturing cost and maintaining cost and capable of automatically controlling grinding transmission switching and grinding mechanism moving control, the grinding supporting frame can move left and right for work, the grinding needs of a stainless steel pipe at the different welding line positions can be met, in addition, a rotating motor drives a stainless steel pipe to achieve comprehensive welding line grinding, and meanwhile, grinding efficiency is improved.

Owner:昆山赫斯顿精密五金机械有限公司

Smart home robot control method

InactiveCN106292318AImplement mobile controlComputer controlProgramme total factory controlRobot controlHome robot

The invention relates to the field of robots and more particularly to a smart home robot control method. A smart home robot is provided with a temperature sensor, a humidity sensor, an infrared sensor. The method comprises steps of: acquiring information on whether or not a person is present in a room by means of the infrared sensor; performing determination after obtaining the information on whether or not a person is present in the room, and jf yes, acquiring the temperature information of the room by means of the humidity sensor; acquiring the humidity information by means of the humidity sensor; after the temperature information in the room is obtained, determining whether cooling or heating of an air conditioner is required by comparing the temperature information with a temperature threshold, switching on the air conditioner to cool or heat; after the humidity information is obtained, determining whether the humidification of a humidifier is required by comparing the humidity information with a humidity threshold and switching on or off the humidifier. Compared with a prior art, the smart home robot control method has beneficial effects of moving things, adjusting temperature and controlling humidity, functioning in the presence of people, and being controlled by a mobile phone APP.

Owner:KUNSHAN YIBANGTAI AUTO PART MFG CO LTD

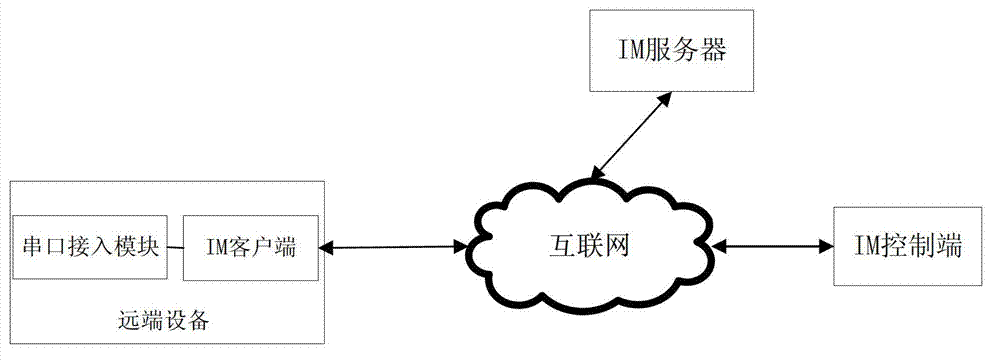

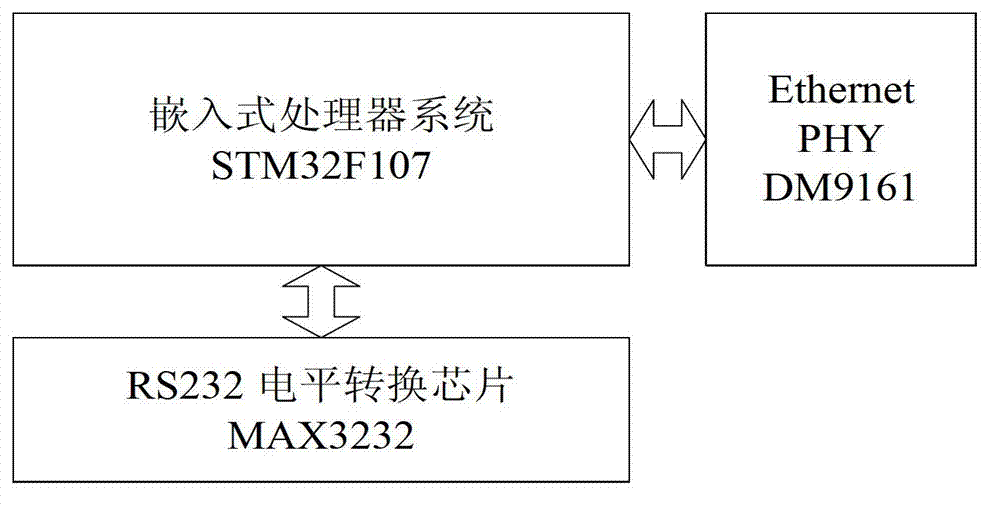

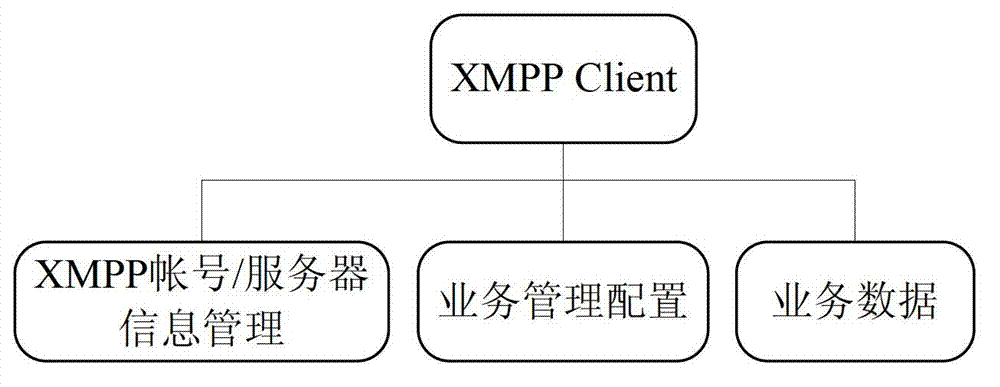

Serial server system based on the Internet

InactiveCN103118085ALow costRealize global remote controlData switching networksRemote controlControl system

The invention discloses a serial server system based on the Internet. The system comprises instant messaging (IM) servers, IM control ends and far-end devices, wherein IM is the English abbreviation of instant messaging, the IM servers are arranged on nodes of the public Internet and used for coordinately organizing the far-end devices to be communicated with the IM control ends and supporting an instant messaging protocol, the IM control ends are used for remote monitoring of the far-end devices, each far-end device comprises an IM client end and a serial port access module, the serial port access module is connected with industrial on-site devices through serial ports, the IM client end is accessed into the public Internet and supports the instant messaging protocol, and therefore communication between the IM client ends and the IM servers on the Internet nodes is achieved. Public Internet infrastructure construction is sufficiently utilized to achieve global remote control, moving control and the like, remote control efficiency is improved, and building comprehensive cost of a large-scale remote control system is lowered.

Owner:SHANGHAI NORMAL UNIVERSITY

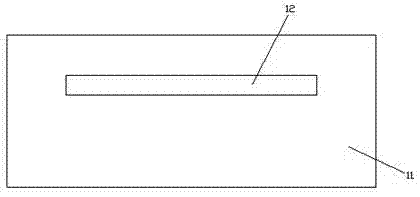

Intelligent letter box

InactiveCN106974536AAdjustable tension controlExtended service lifeKitchen equipmentDomestic articlesAutomatic controlEngineering

The invention discloses an intelligent letter box which comprises a framework and a reading vertical frame. The reading vertical frame is arranged on the framework, a letter groove is formed inside the front side surface of the reading vertical frame, a first slide groove is formed in the rear side of the inner top wall of the letter groove in a front-back extension manner, a movement guide rod is arranged inside the first slide groove in a front-back extension manner, a spiral hole is formed in the front side of the first slide groove in a front-back extension manner, a reading assembly which is arranged in a downward extension manner is slidably fittingly connected onto the movement guide rod, and an extension section at the bottom of the reading assembly extends into the letter groove. The intelligent letter box has the advantages that the intelligent letter box is simple in structure, reasonable in design and low in manufacturing cost and maintenance cost, reading transmission can be switched over under the automatic control, the reading assembly can move under the control, the reading vertical frame can move and work in the left-right directions, and letter identification and reading requirements can be met; the letters can be driven by a first motor to rotate and can be comprehensively read, and the reading efficiency can be improved.

Owner:浙江特意电气有限公司

Belt type stainless steel pipe welding line grinding device

ActiveCN107695838AExtended service lifeRealize automatic controlBelt grinding machinesAutomatic grinding controlPipe weldingMotor drive

The invention discloses a belt type stainless steel pipe welding line grinding device. The belt type stainless steel pipe welding line grinding device comprises a base frame and a grinding supportingframe arranged on the base frame; a containing groove is formed in the front side end face of the grinding supporting frame, a first sliding groove extending front and back is formed in the rear sideof the inner top wall of the containing groove, a guide rod which extends front and back is arranged in the first sliding groove, a thread hole extending towards the front side is arranged on the inner wall of the front side of the first sliding groove, a grinding mechanism which extends downwards is in sliding fit connection to the guide rod, and the bottom extension segment of the grinding mechanism extends into the containing groove. The belt type stainless steel pipe welding line grinding device is simple in structure, reasonable in design, low in manufacturing cost and maintaining cost and capable of automatically controlling grinding transmission switching and grinding mechanism moving control, the grinding supporting frame can move left and right for work, the grinding needs of a stainless steel pipe at the different welding line positions can be met, in addition, a rotating motor drives a stainless steel pipe to achieve comprehensive welding line grinding, and meanwhile, grinding efficiency is improved.

Owner:JIANGSU HUAHAI STEEL STRUCTURE CO LTD

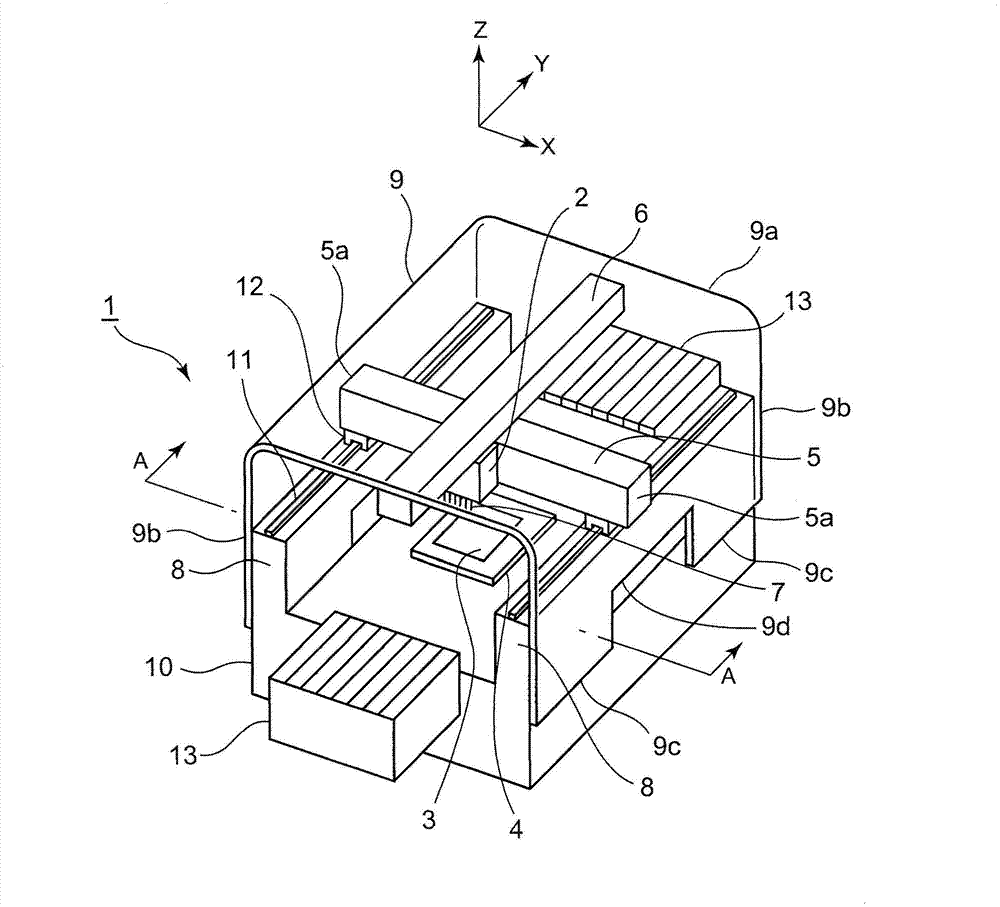

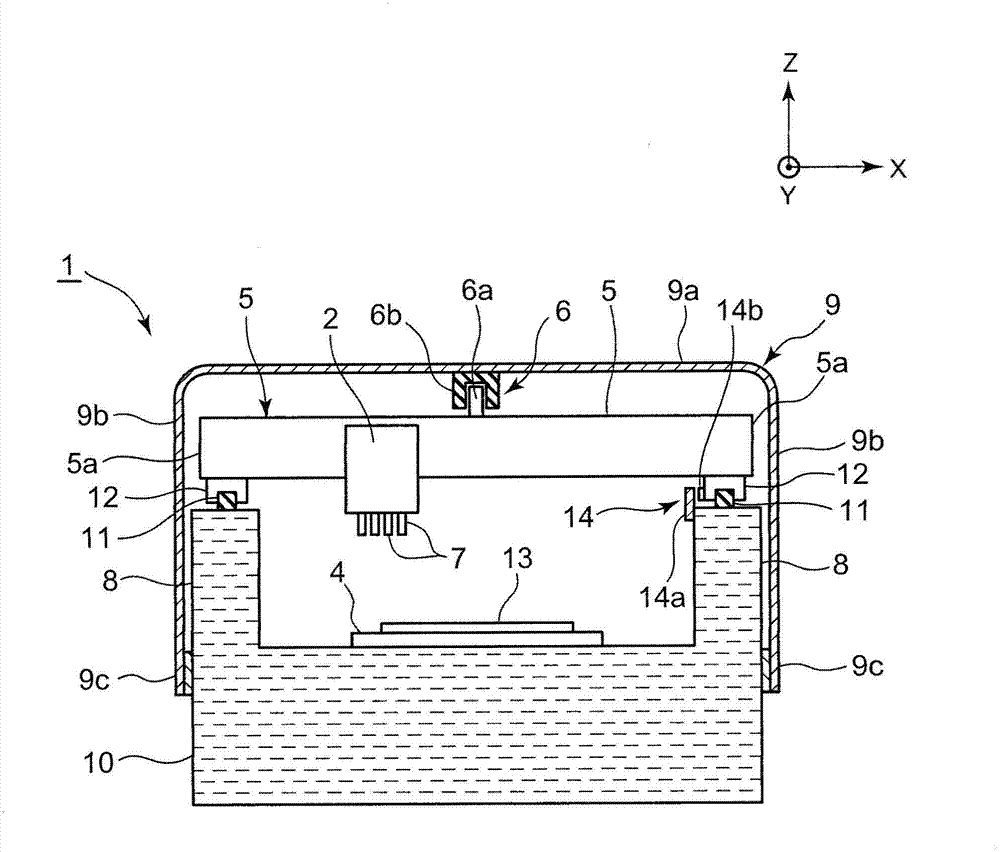

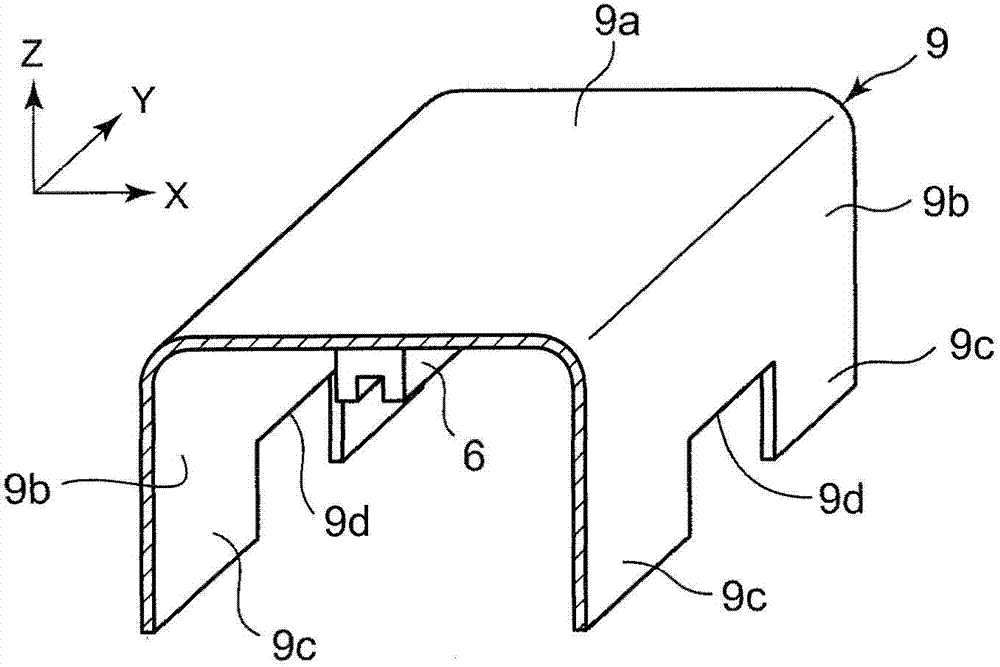

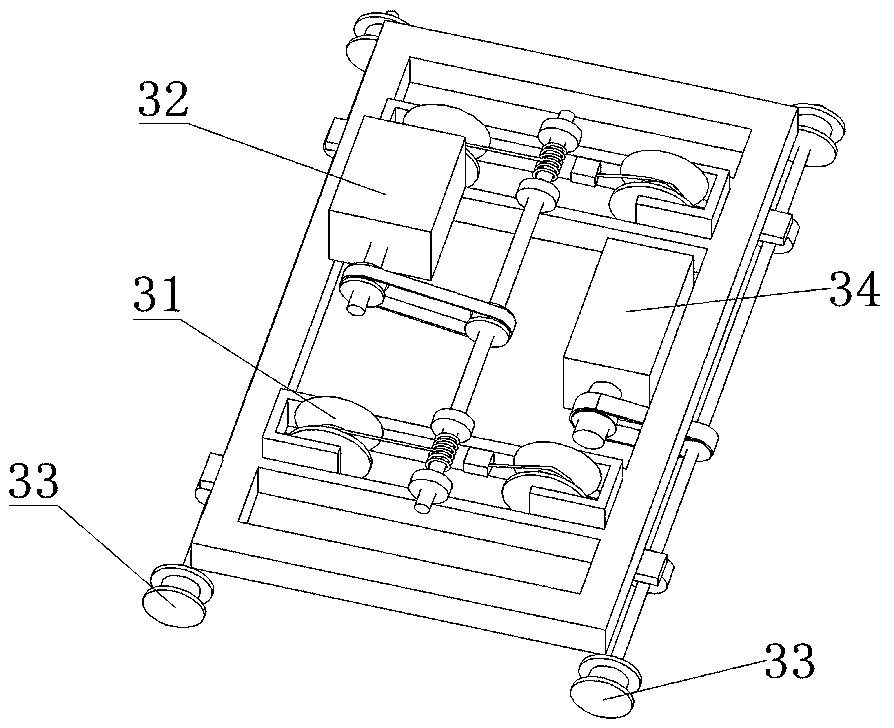

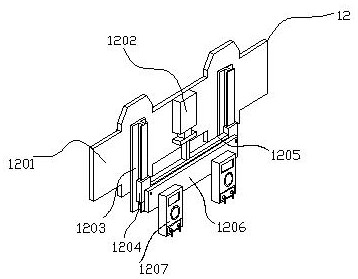

Part mounting device and method

InactiveCN103369945AImplement mobile controlReduce delivery volumeElectrical componentsEngineeringMobile control

Owner:PANASONIC CORP

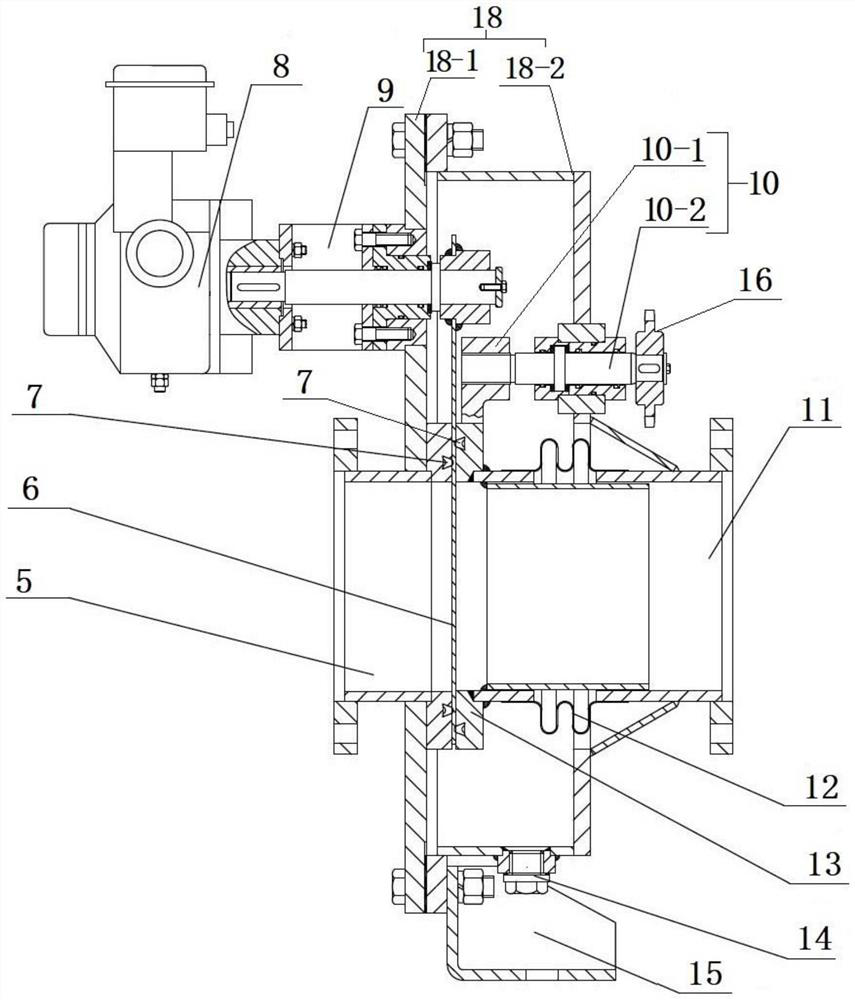

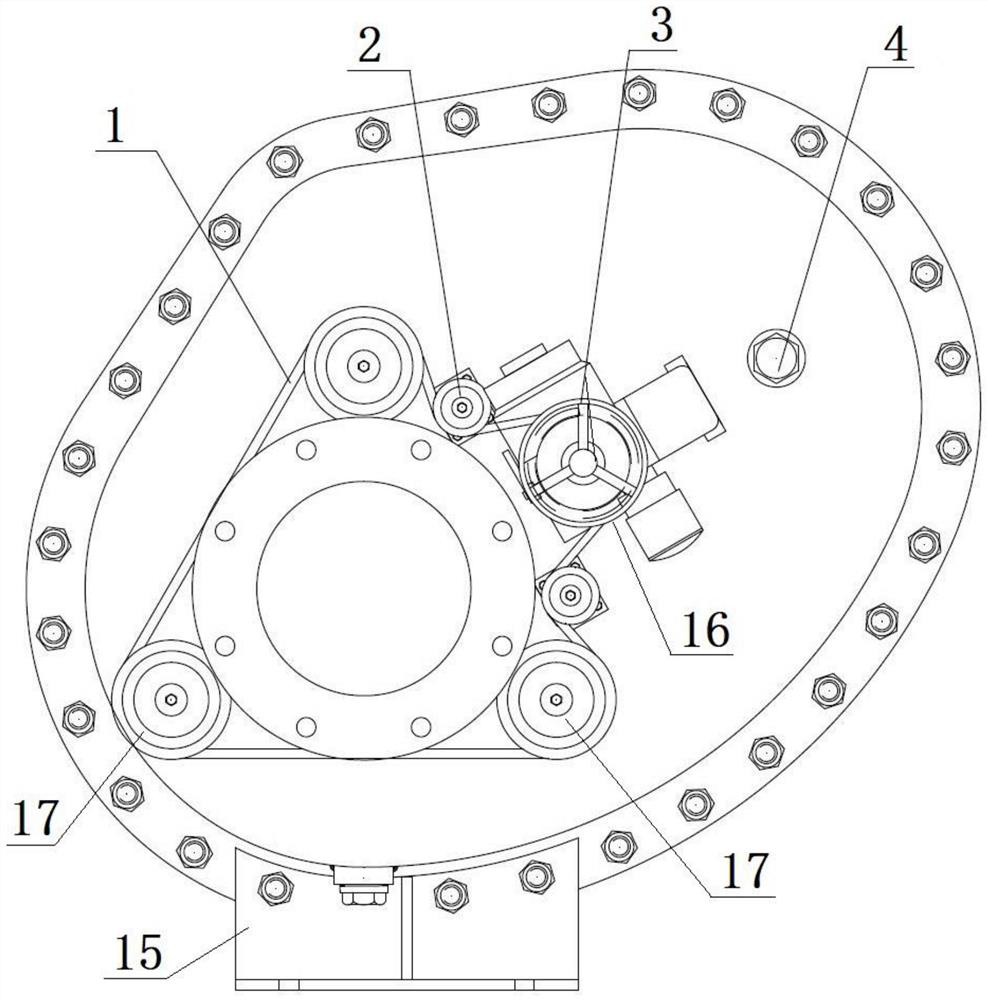

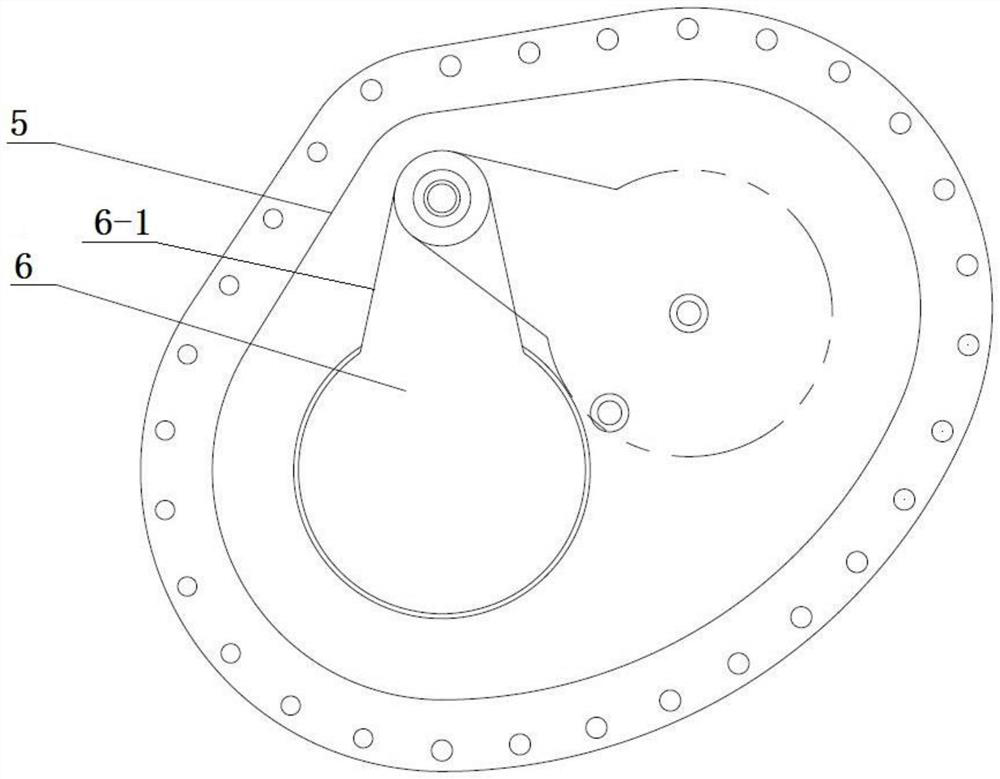

Fully-sealing flap valve

PendingCN113339535AAchieve leak-freeImprove securityOperating means/releasing devices for valvesSlide valveEngineeringFlap valve

The invention relates to a full-sealing flap valve, and belongs to the technical field of flap valves. The full-sealing flap valve comprises a fixed valve body, a movable valve body and a valve plate located between the fixed valve body and the movable valve body. The valve plate is driven by a plate turning device to swing so as to switch the opening state and the closing state. A corrugated pipe for achieving compression and stretching is arranged in the middle of the movable valve body and divides the movable valve body into a fixed section and a movable section, and the movable section is driven by a loosening and pressing device to move. The butt joint position of the fixed valve body and the movable valve body is located in a valve body box playing a sealing role. Sealing rings are arranged between the fixed valve body and the valve plate and between the movable valve body and the valve plate. According to the full-sealing flap valve, a closed space is formed in the valve body box, the valve plate is located in the valve body box in the valve opening and closing process, no leakage of media in the valve opening and closing process is achieved, the valve body box is in an irregular sector shape, the requirement for the moving track of the valve plate is met, and the occupied space is saved; and no medium leaks in the valve opening and closing process, and the safety is good.

Owner:SHIJIAZHUANG SHITE VALVE

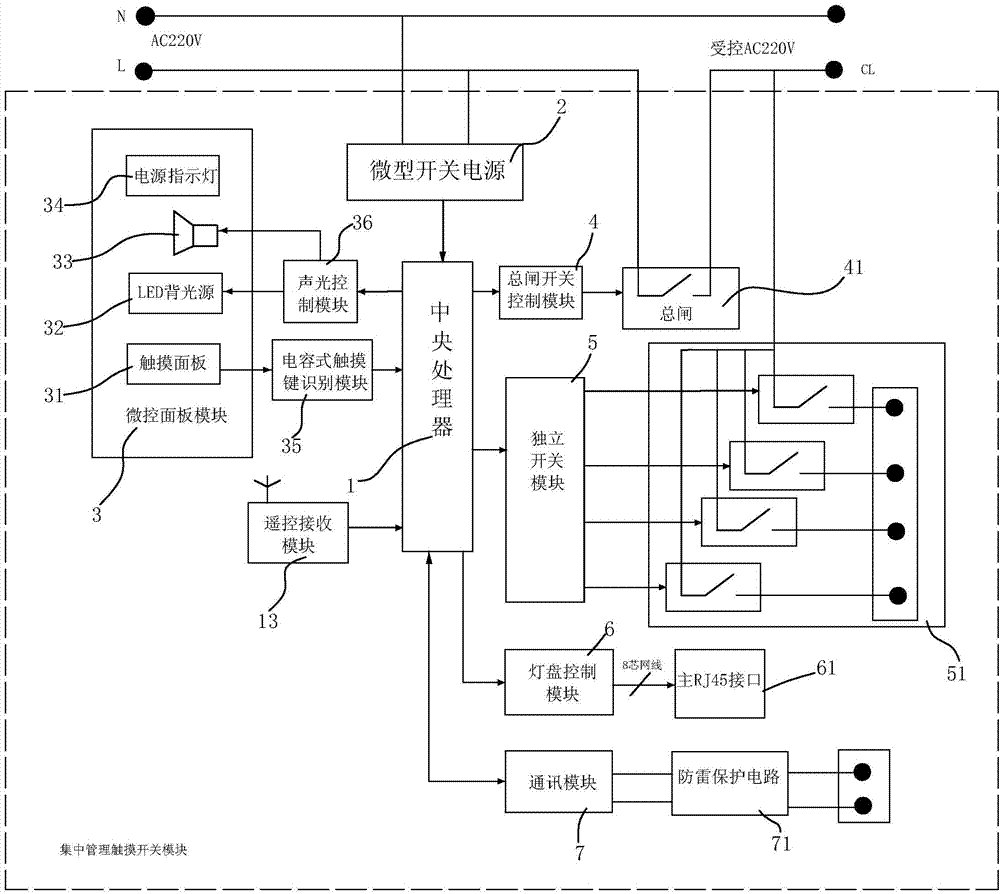

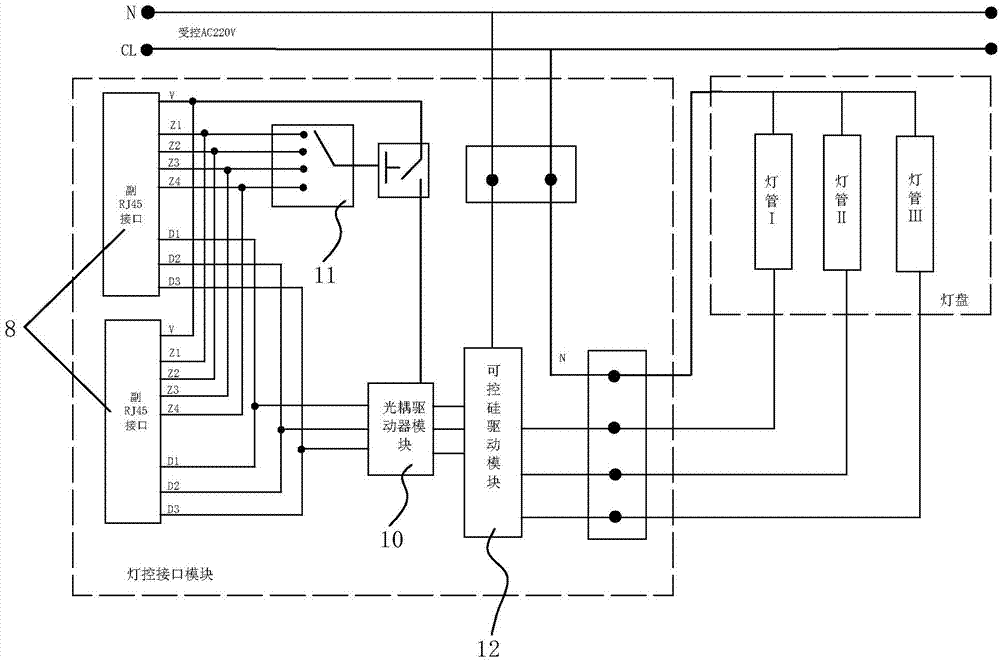

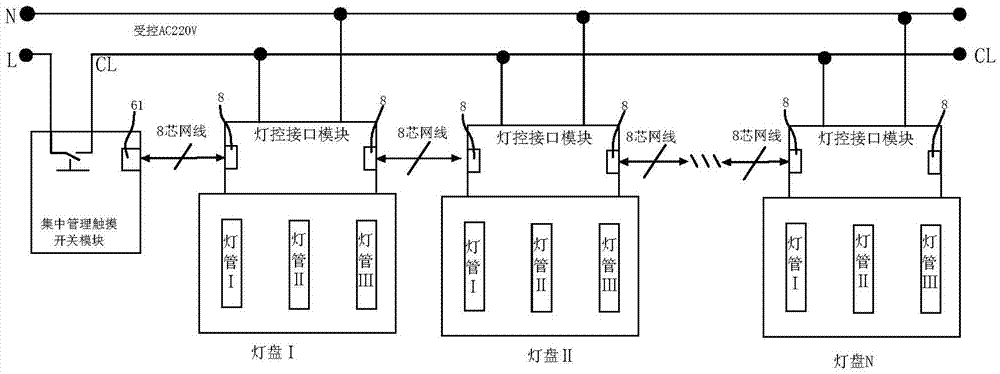

Centrally-managed touch electricity-saving switch controlling system

InactiveCN103699034ASimple wiringSave resourcesProgramme controlTransmission systemsTouch panelLighting system

The invention discloses a centrally-managed touch electricity-saving switch controlling system. A centrally-managed touch electricity-saving switch mainly comprises two parts, i.e. a centrally-managed touch-switch module and a lamp-controlling interface module, wherein the lamp-controlling interface module is installed on a lamp panel. A microcomputer controlling technology is adopted by the touch electricity-saving switch, the central management for many kinds of switches can be realized through a touch panel, the touch electricity-saving switch is integrated with an independent switch module for controlling electricity-using equipment, such as televisions, sounders, computers and table lamps, a zone-bit-dividing and brightness-dividing flexible control mode is implemented for an illuminating system, and the touch electricity-saving switch has one-key turn-off and electricity-saving functions. According to the centrally-managed touch electricity-saving switch controlling system, the purposes of simplifying wiring, saving resources and clearing away a blind control area are achieved by means of controlling strong current by weak current, controlling an interface in a standardized way and the like, and finally the purpose of electricity saving is achieved. The centrally-managed touch electricity-saving switch controlling system is also provided with a remote-control receiving module and a communication module, so that mobile control and mobile-phone or network remote monitoring can be realized, and the centrally-managed touch electricity-saving switch controlling system is especially suitable for controlling lamplight, sockets and the like at places, such as families and workplaces.

Owner:JIANGMEN LIANCHUANG DEV

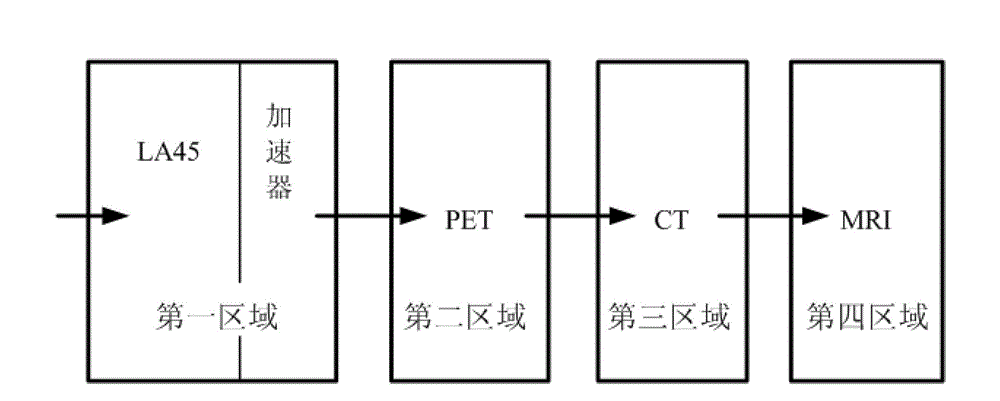

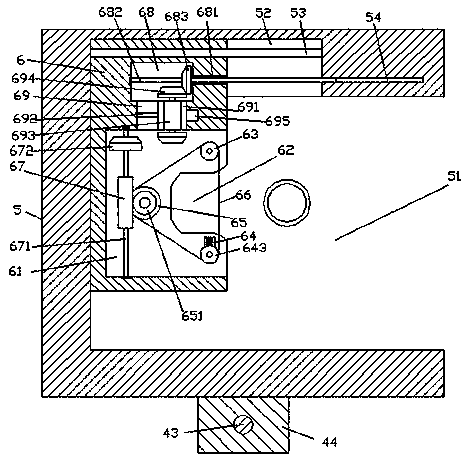

Radiotherapy and imaging-diagnosis combined combination operation system

InactiveCN104146725AImplement mobile controlReduce on-site operationsComputerised tomographsDiagnostic recording/measuringOperational systemImage diagnosis

The invention provides a radiotherapy and imaging-diagnosis combined combination operation system, and relates to the technical field of medical imaging diagnosis devices. The combination operation system comprises a high-energy photon accelerator, a rotary accelerator, a PET device, a CT device, an MRI device, a flat plate and a shifter, wherein the high-energy photon accelerator and the rotary accelerator are arranged in a first area, the PET device is arranged in a second area, the CT device is arranged in a third area, the MRI device is arranged in a fourth area, the flat plate is used for bearing a detected body, the detected body is limited to the fixed position of the flat plate, and the shifter is used for controlling the flat plate to move among the areas. By means of the combination operation system, injuries of rays to operators can be reduced, and the therapy and diagnosis accuracy is improved.

Owner:BEIJING TOP GRADE HEALTHCARE MEDICAL EQUIP CO LTD

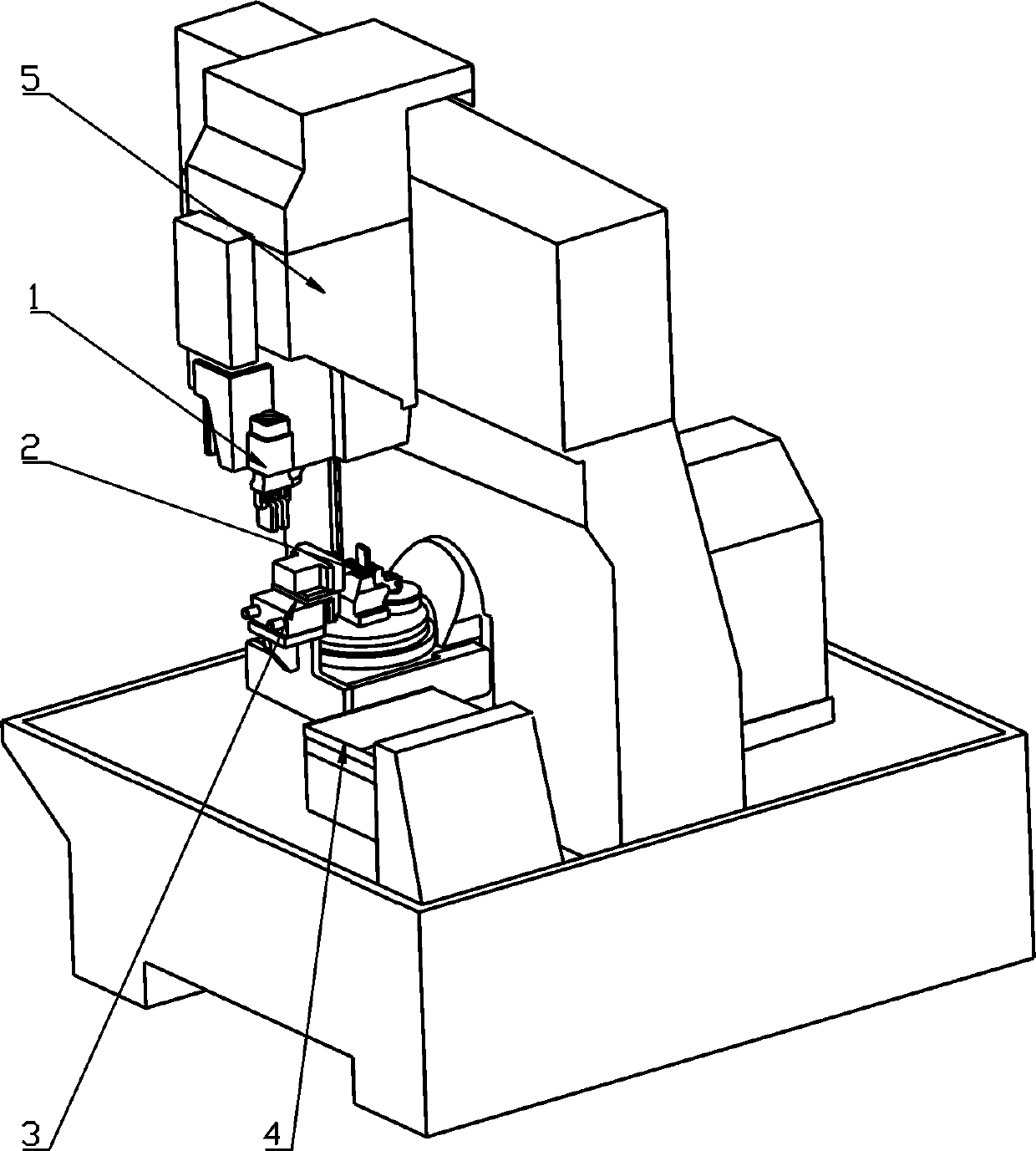

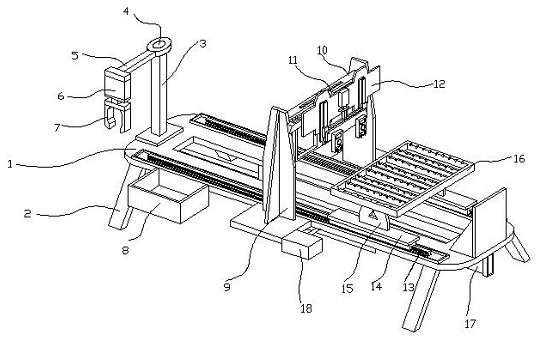

Built-in automatic feeding and discharging device capable of realizing progressive feeding of bars

PendingCN111590376ARealize automatic loading and unloading functionImprove surface qualityWork clamping meansPositioning apparatusInterior spaceRobot hand

The invention relates to a built-in automatic feeding and discharging device capable of realizing progressive feeding of bars. The device is composed of a stock bin, a grabbing manipulator and a clamping jig, wherein the stock bin is arranged inside a machine tool, the grabbing manipulator is installed on a machine head of the machine tool and can linearly reciprocate along with the machine head along an X-axis direction and a Z-axis direction, the clamping jig is installed on a workbench of the machine tool and can move along with the workbench of the machine tool, and different parts of thesame bar can be sequentially positioned and clamped in cooperation with the lifting action of the grabbing manipulator on the bar. According to the built-in automatic feeding and discharging device, the internal space of the machine tool is fully utilized, the structure is simple, the occupied space is small, the manufacturing cost is low, and automatic progressive feeding machining of bar blankscan be achieved.

Owner:BEIJING JINGDIAO GRP CO LTD

A belt type stainless steel pipe weld seam grinding equipment

ActiveCN107695838BRealize automatic controlAdjustable tension controlBelt grinding machinesAutomatic grinding controlTransmission switchingArchitectural engineering

Owner:JIANGSU HUAHAI STEEL STRUCTURE CO LTD

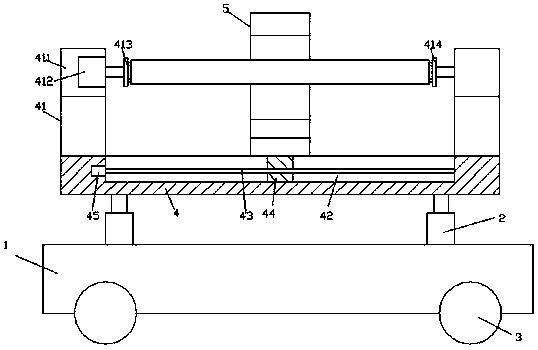

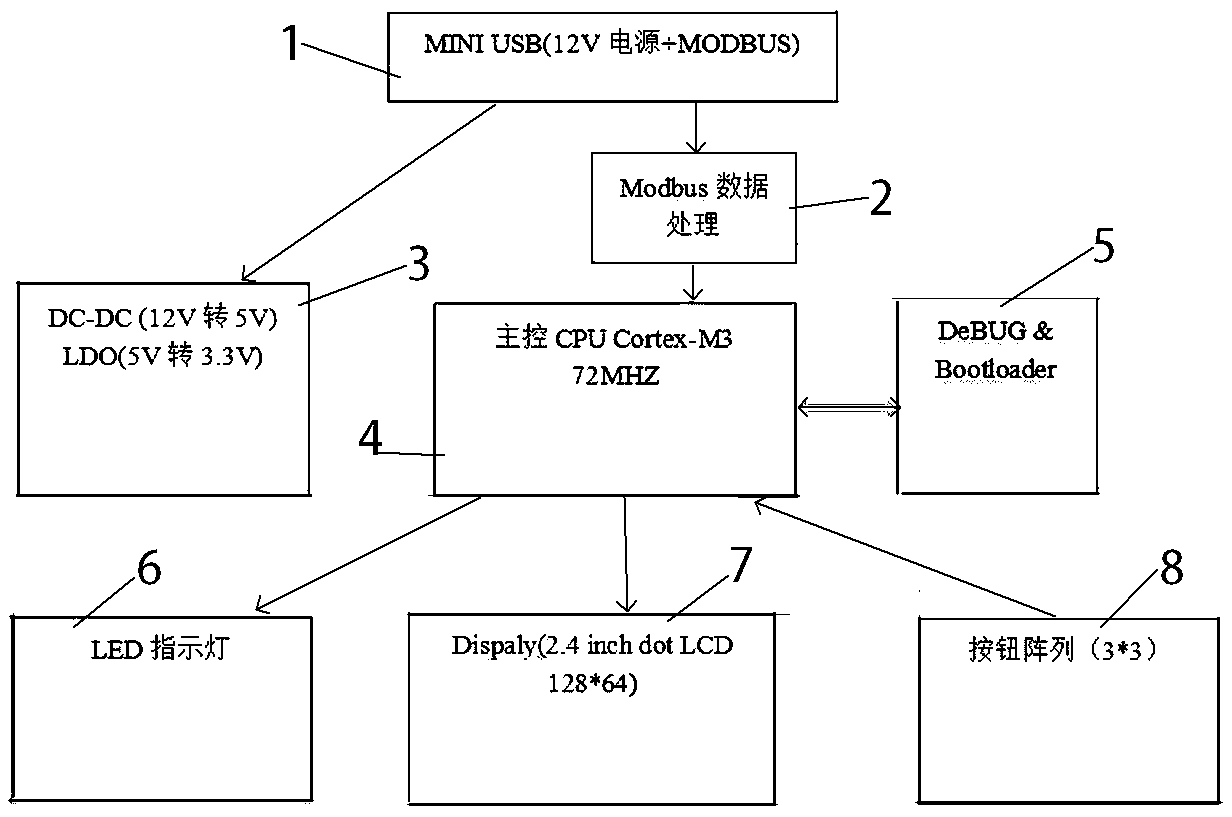

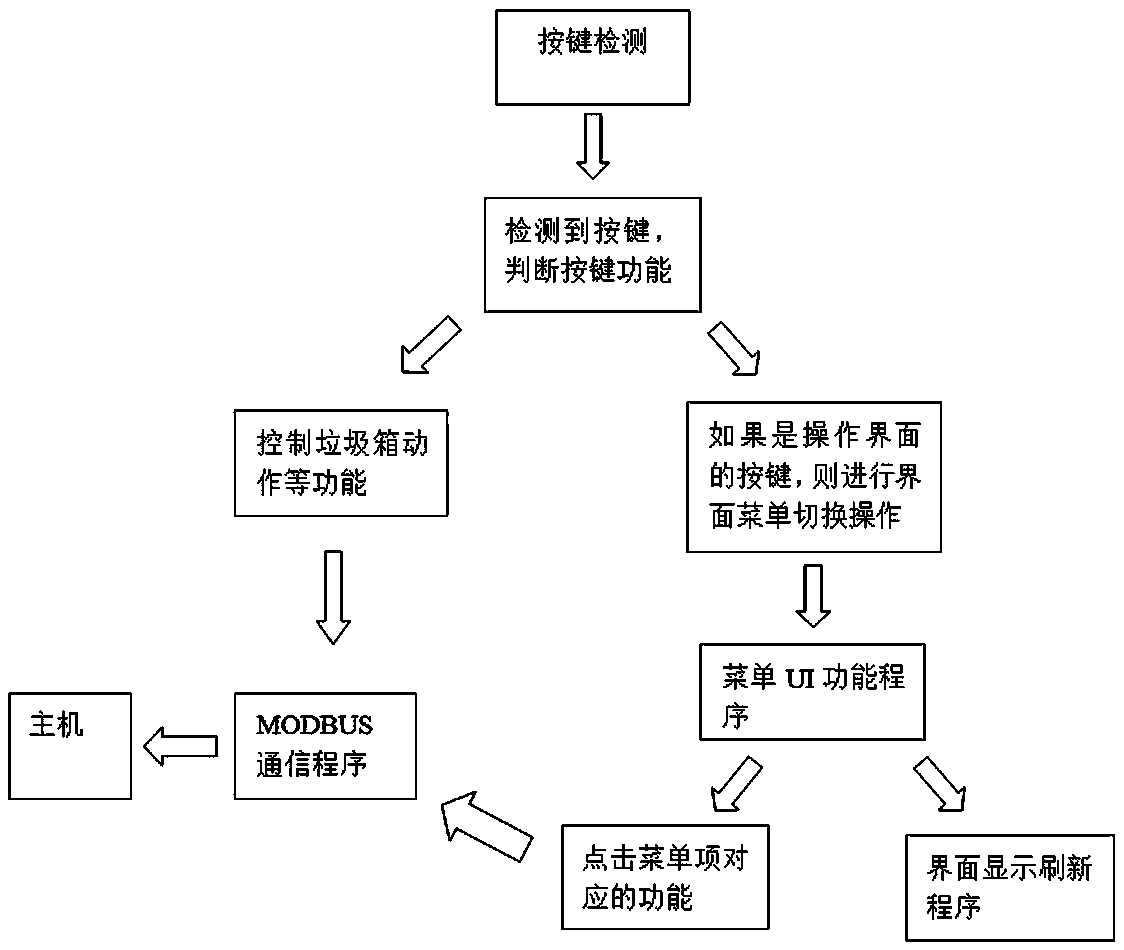

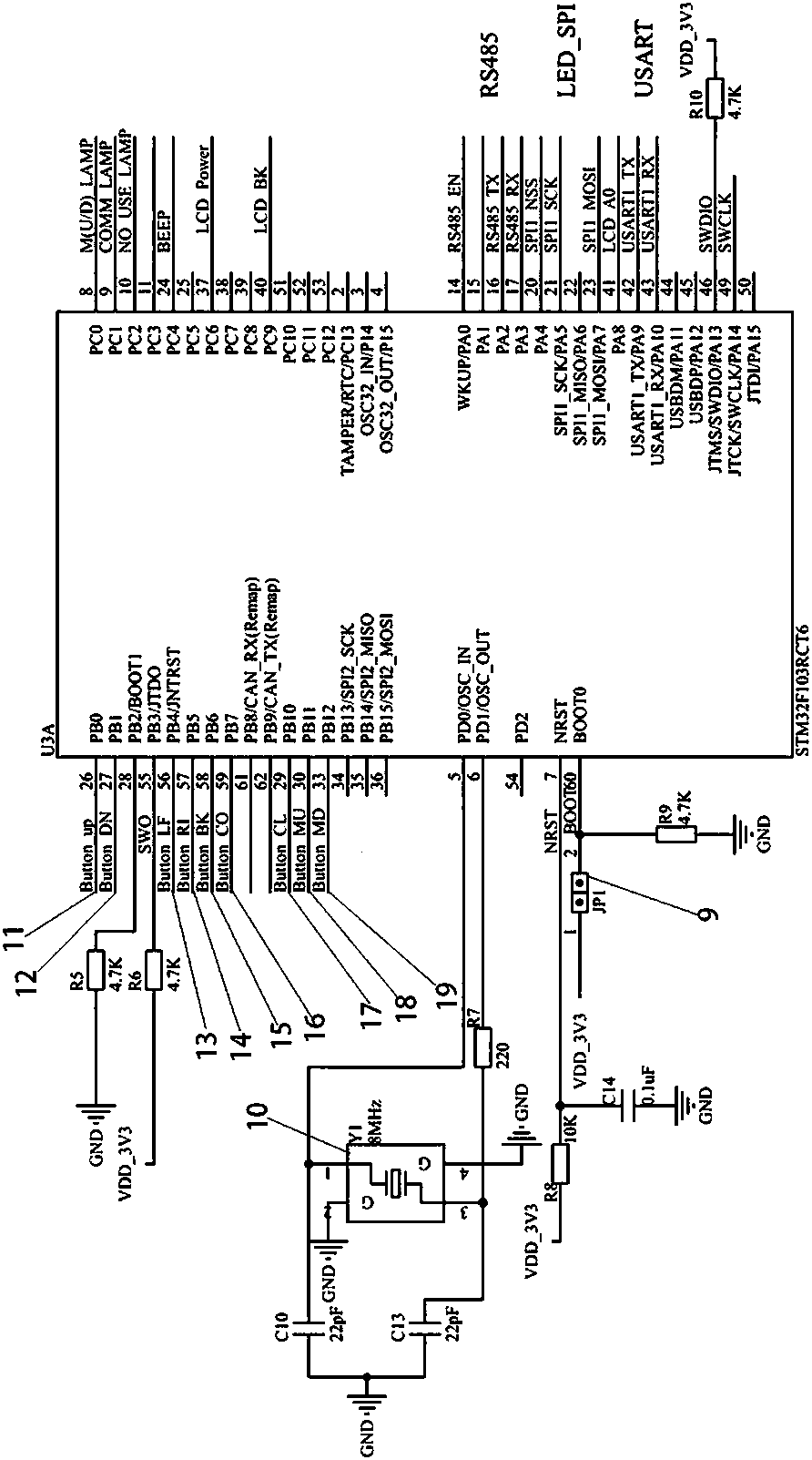

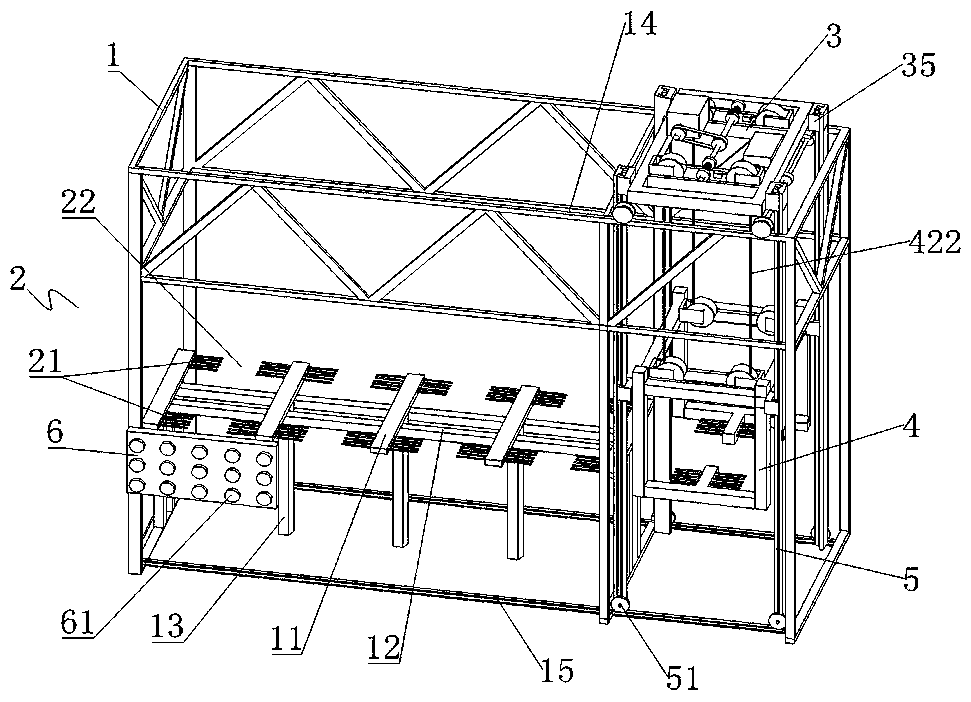

Sweeper intelligent manual operator

PendingCN108170066ASimplify the wiring harnessStable transmissionProgramme controlComputer controlMobility controlEngineering

The invention relates to a sweeper intelligent manual operator, which comprises a power supply 1 and a master control module 4. The sweeper intelligent manual operator also comprises a data processingmodule 2, a power supply processing module 3, a data update module 5, an indicating lamp 6, a display screen 7 and a button matrix 8. The indicating lamp 6, the display screen 7 and the button matrix8 are connected with the master control module 4. The beneficial effects are that the manual operator realizes mobility control by means of a modbus communication protocol; the manual operator has the advantages of being simple in wiring harness, stable in transmission, portable and having multiple nodes; and equipped with the 2.4 inch dot LCD 128*64 display screen, the manual operator allows anoperator to monitor current state of the equipment and set parameters in real time outside a driving cab.

Owner:JIANGSU MORAL ENVIRONMENTAL PROTECTION TECH CO LTD

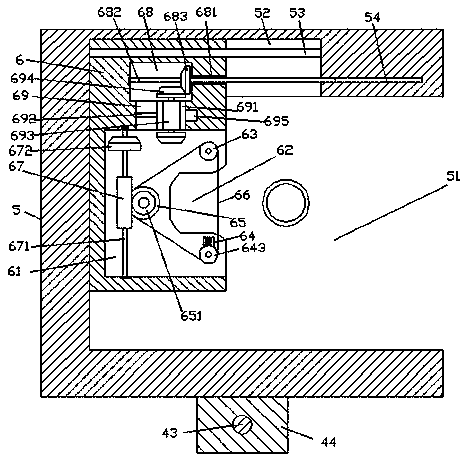

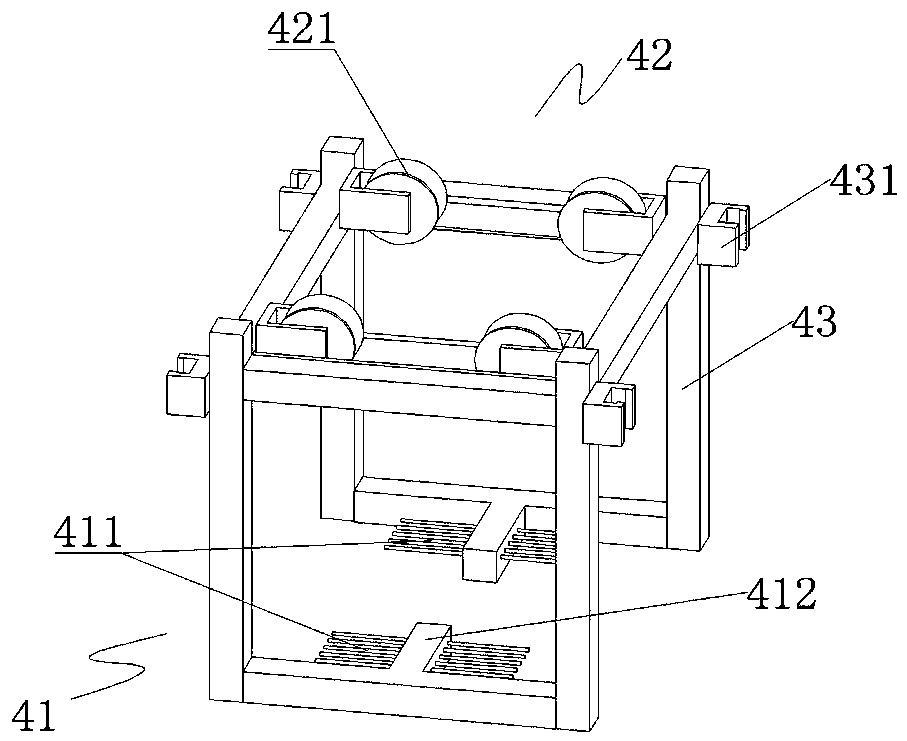

Miniature mechanical parking apparatus

PendingCN108979259AEasy to controlImprove securityParkingsVehicular energy storageOptical axisElectric machine

The invention discloses a miniature mechanical parking apparatus. The miniature mechanical parking apparatus comprises a main body framework, a parking vehicle support, an upper device and a vehicle carrying board. The main body framework is provided with the parking vehicle support which is in the structure of comb teeth. A vehicle-carrying platform in the lower layer of the vehicle carrying board is in the structure of comb teeth. Forward and backward positions of the vehicle-carrying platform are staggered from comb teeth of the parking vehicle support. A lifting mechanism for combining theupper device with the upper layer of the vehicle carrying board forms an elevating mechanism. fixed pulleys and steel wire ropes are utilized to elevate. Meanwhile, the upper device and a lifting mechanism are slidbaly installed on optical axis linear elevating guide rails. The staggering of the comb teeth is utilized to transfer vehicles. The optical axis linear elevating guide rails are adoptedto ensure stability of elevation. Therefore, the parking process is more stable and safer. Meanwhile, the apparatus is combined with a motor to achieve movable control of vehicles. The motor is combined with a PLC and a photoelectric switch so that precise control over parking positions is achieved. A parking garage is advantaged by being high in safety coefficient, long in service lifetime and green and eco-friendly and can adjust the number of parking lots according to the actual place.

Owner:LONGYAN UNIV

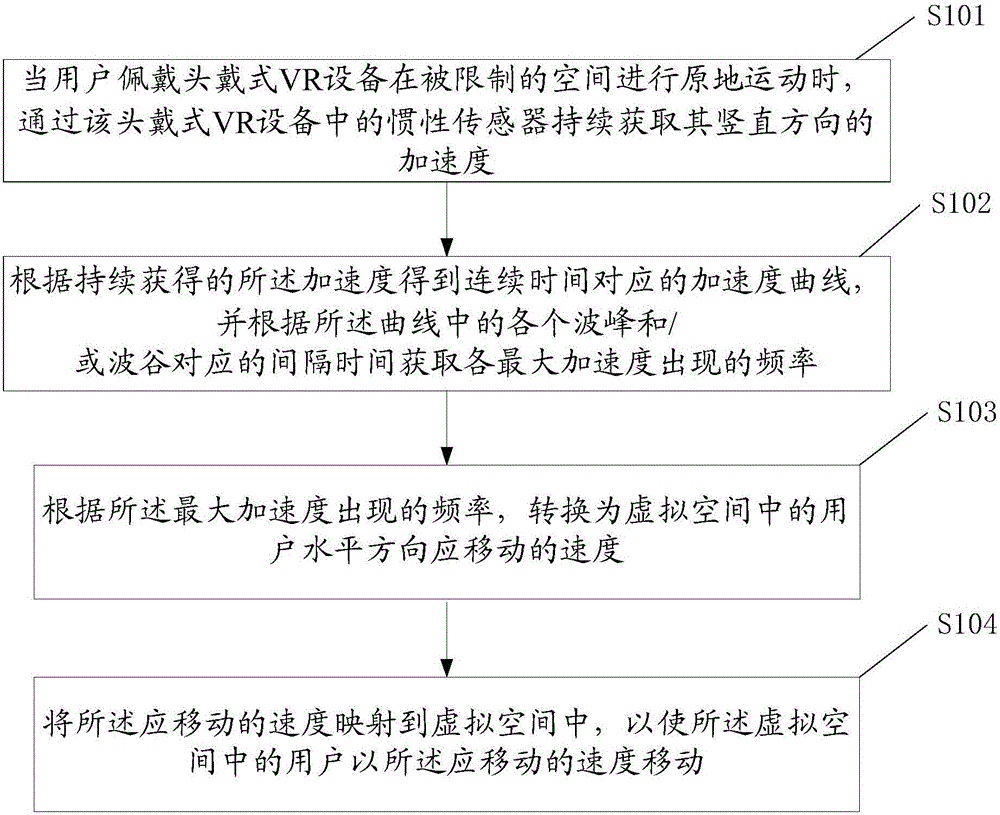

Virtual space moving control method and device based on inertia sensor

InactiveCN106774892AMovement Speed ControlEasy to moveInput/output for user-computer interactionGraph readingVirtual spaceHuman–computer interaction

The invention discloses a virtual space moving control method and device based on an inertia sensor. The method applicable to head-mounted VR equipment includes: when a user wears the head-mounted VR equipment and moves at one spot in a limited space, and the vertical acceleration of the user is continuously acquired through the inertia sensor in the head-mounted VR equipment; acquiring a corresponding acceleration curve in continuous time according to the continuously acquired vertical acceleration, and acquiring the frequency of maximum acceleration according to interval time corresponding to each peak and / or valley in the curve; converting into the speed of the horizontal moving of the user in a virtual space according to the frequency of the maximum acceleration; mapping the speed of the horizontal moving into the virtual space to allow the user in the virtual space to move at the speed. By the virtual space moving control method, virtual space moving control when the space is limited or an external device is unavailable is achieved.

Owner:北京奇幻科技有限公司

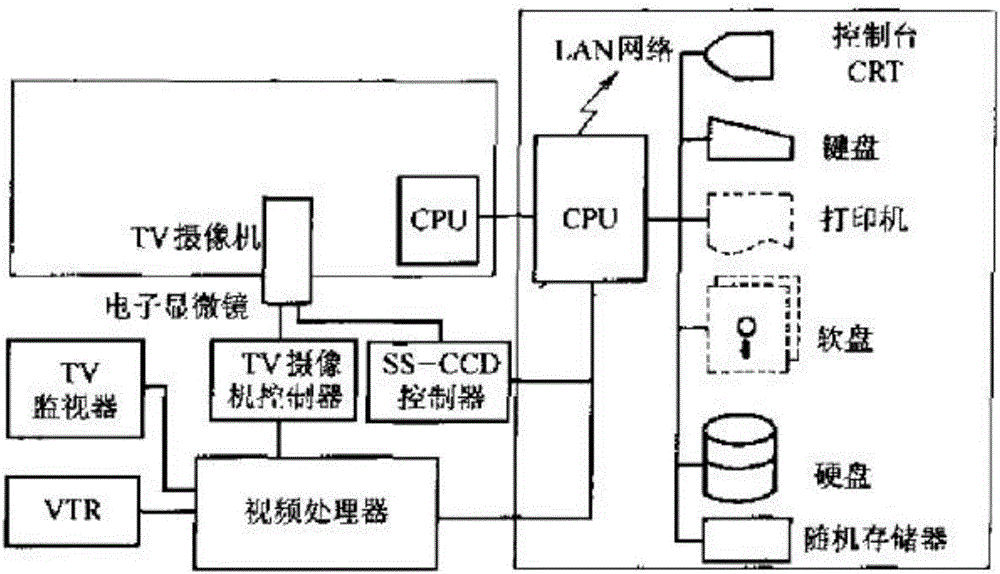

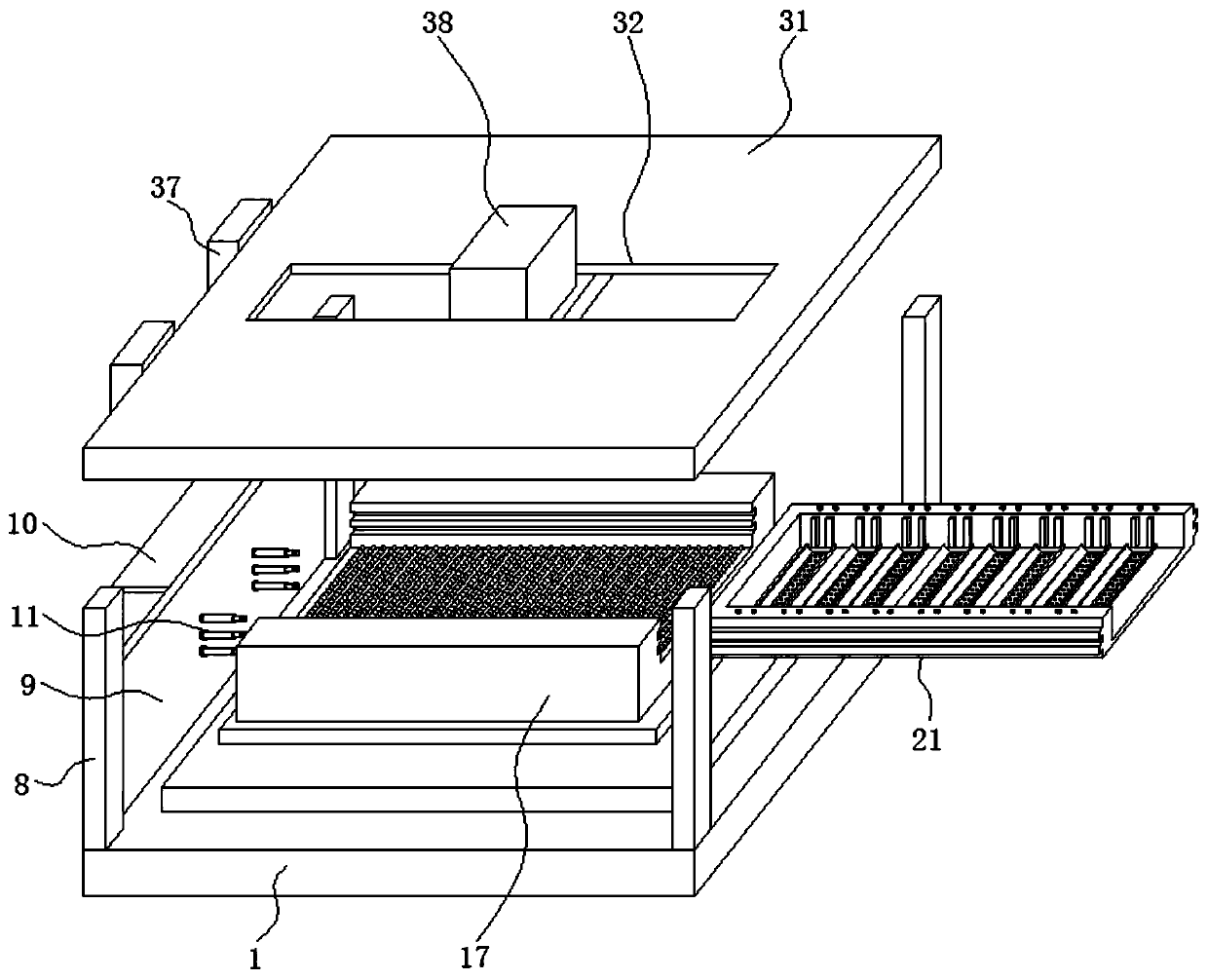

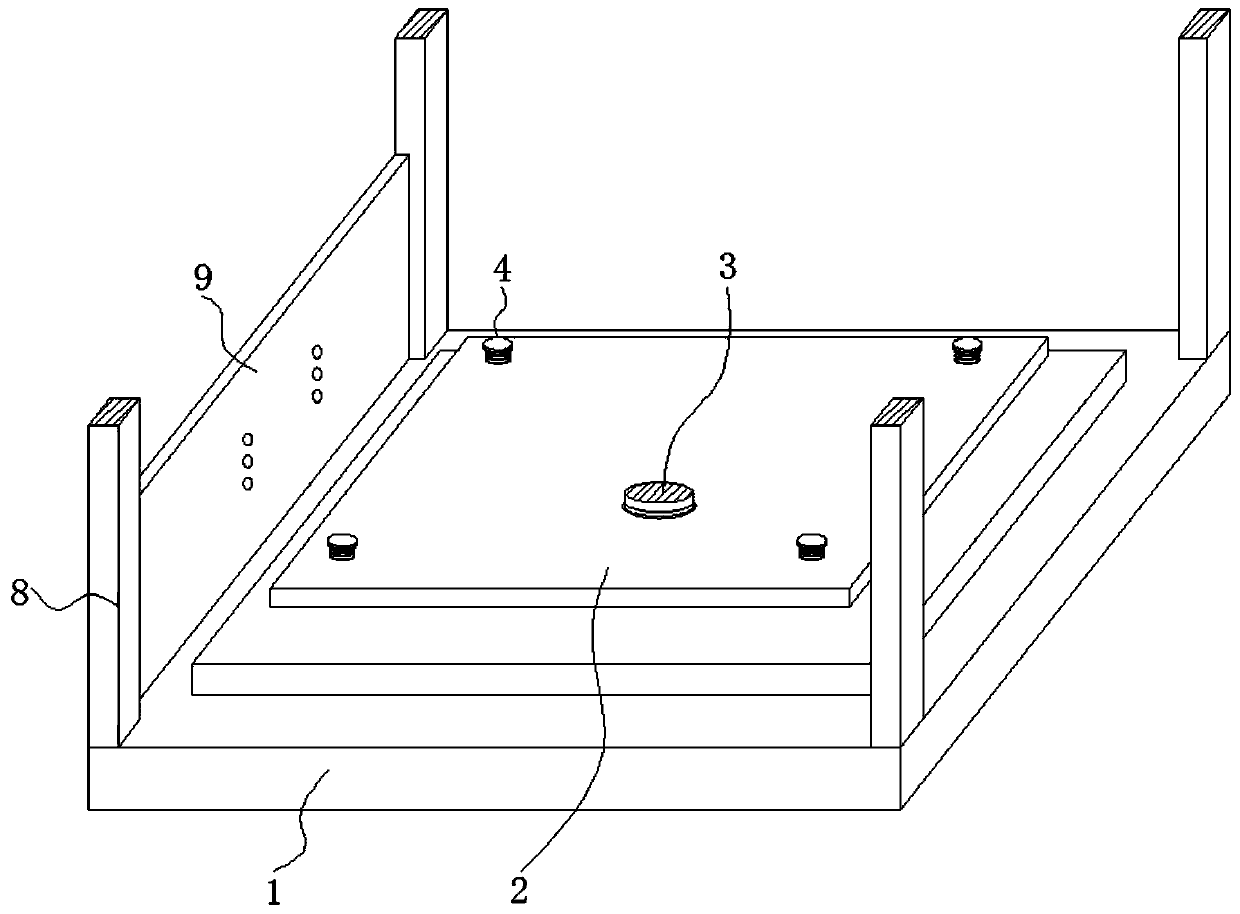

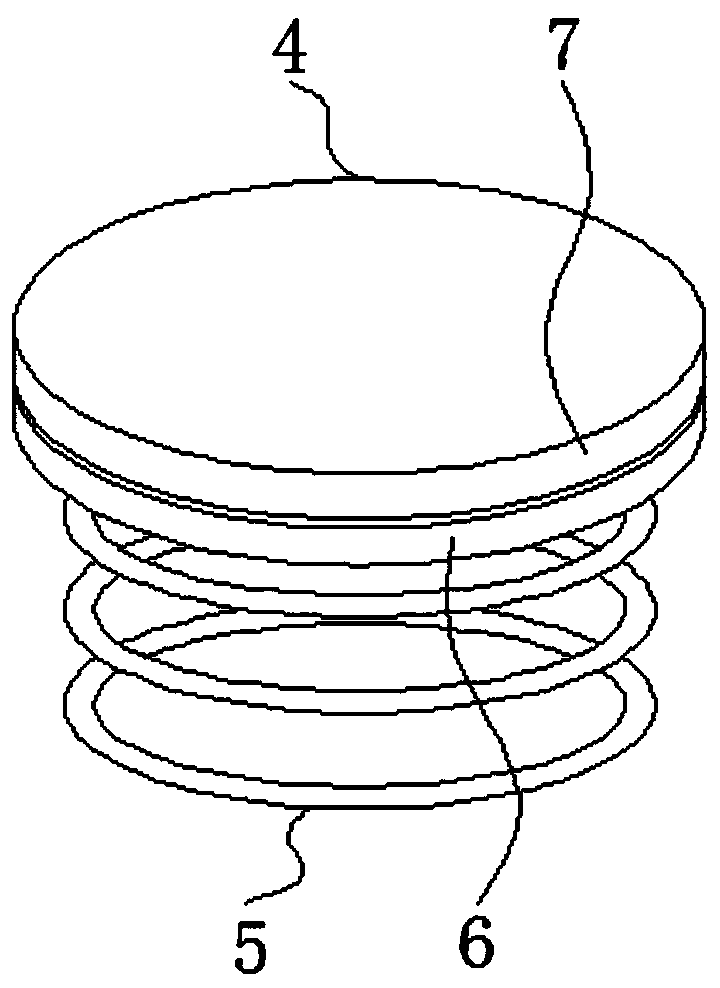

Multifunctional microscope for physical teaching experiments

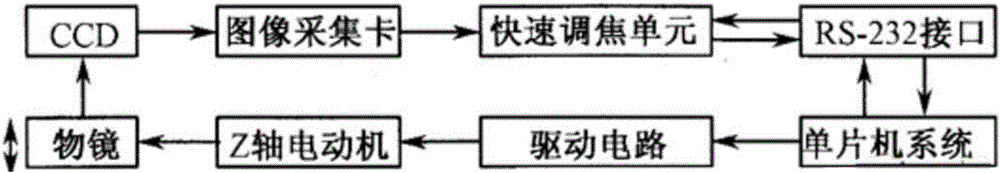

InactiveCN106646846AImplement mobile controlRealize remote controlMicroscopesMicrocontrollerCamera control

The invention relates to the technical field of microscopes, and specifically relates to a multifunctional microscope for physical teaching experiments. The multifunctional microscope comprises an electron microscope system, a CPU, a TV camera control system, an external computer control system and a remote mobile control system. The multifunctional microscope provided by the invention is provided with a Bluetooth identification unit that can be connected with a smart phone, the mobile control can be monitored, the Bluetooth identification unit can be wirelessly connected with a CRT through a LAN network to realize remote control, a TV camera is provided to display a video below the microscope on a computer through a video processor, a quick automatic focusing unit of a miniature computer calculates the definition of an image, analyzes the defocus state of the image, and then sends a command and data to a singlechip through an RS-232 interface to control the step pitch and the steering of a z-axis step motor for focusing, automatic focusing can be realized, the multifunctional microscope disclosed by the invention can realize automatic focusing, the video of the microscope can be displayed on the computer to realize remote mobile control, and the creativity is very high.

Owner:陈忠信

Chill grid line processing equipment and processing technology thereof

PendingCN111545729AEnables motorized press molding operationsReduce adhesionFoundry mouldsFoundry coresMaterial resourcesMolten steel

The invention discloses chill grid line processing equipment and a processing technology thereof and relates to the technical field of casting production. The chill grid line processing equipment specifically comprises a base, pressing easing mechanisms, a bracket, a film forming seat and a top plate; a lifting plate is fixed above the base; the pressing easing mechanisms are arranged at four corners of the upper surface of the lifting plate; an air cylinder case is mounted on the outer wall surface of a support plate; the bracket is arranged above the pressing easing mechanisms; the film forming seat is mounted in the middle above the bracket in a sliding manner; and the top plate is fixed at the top end of a support rod. The chill grid line processing equipment and the processing technology thereof can process grid line chill, can realize mechanization compression moulding operation of the grid line chill and save manpower and material resources; the grid line chill is prepared by adopting a grid line chill manufacturing die, that is, on the basis of smooth-surface chill, the grid line is cast on the surface of the chill, and through adding the grid line, the coating adhesive force is increased, and the surface tension of molten steel is reduced to reduce the risk of forming an air vent.

Owner:无锡市蠡湖铸业有限公司

A flexible circuit board for soldering image sensors

ActiveCN105025657BImplement mobile controlPrinted circuit aspectsPrinted circuit non-printed electric components associationFlexible circuitsEngineering

The invention discloses a flexible circuit board for welding an image sensor, which includes a first area and a second area arranged in sequence, and the second area includes a central part at its center and welded with the image sensor, and a central part around the central part. The frame portion is provided with evenly distributed coil groups, and the central portion and the frame portion are connected to the edge of the second area through elastic arms. The flexible circuit board of the present invention can be used to install coils, and at the same time provide flexibility for the focus and anti-shake movement of the image sensor, can simplify the structure of the camera module, and greatly reduce its volume.

Owner:SHENZHEN STR TECHNO

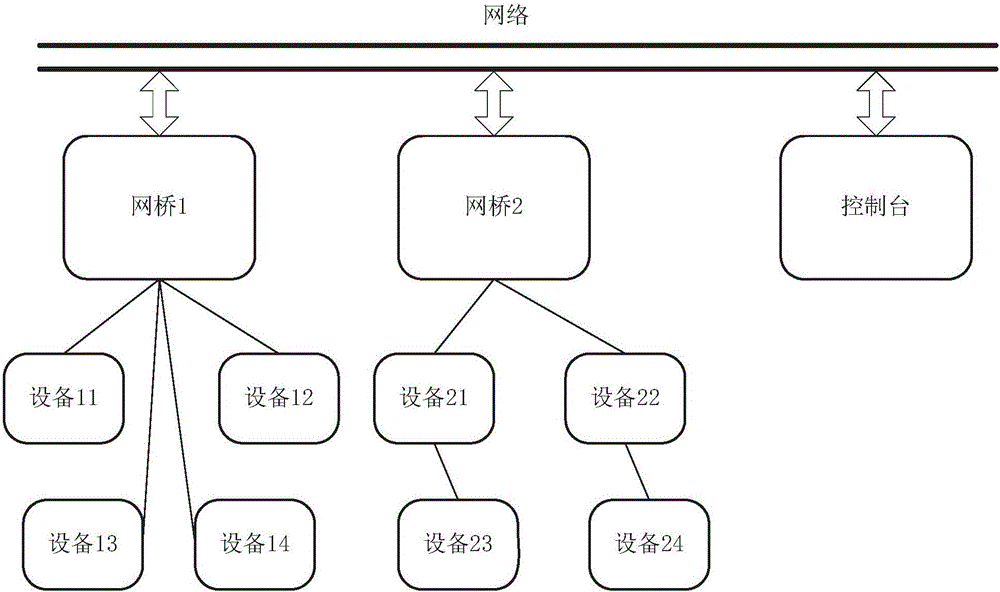

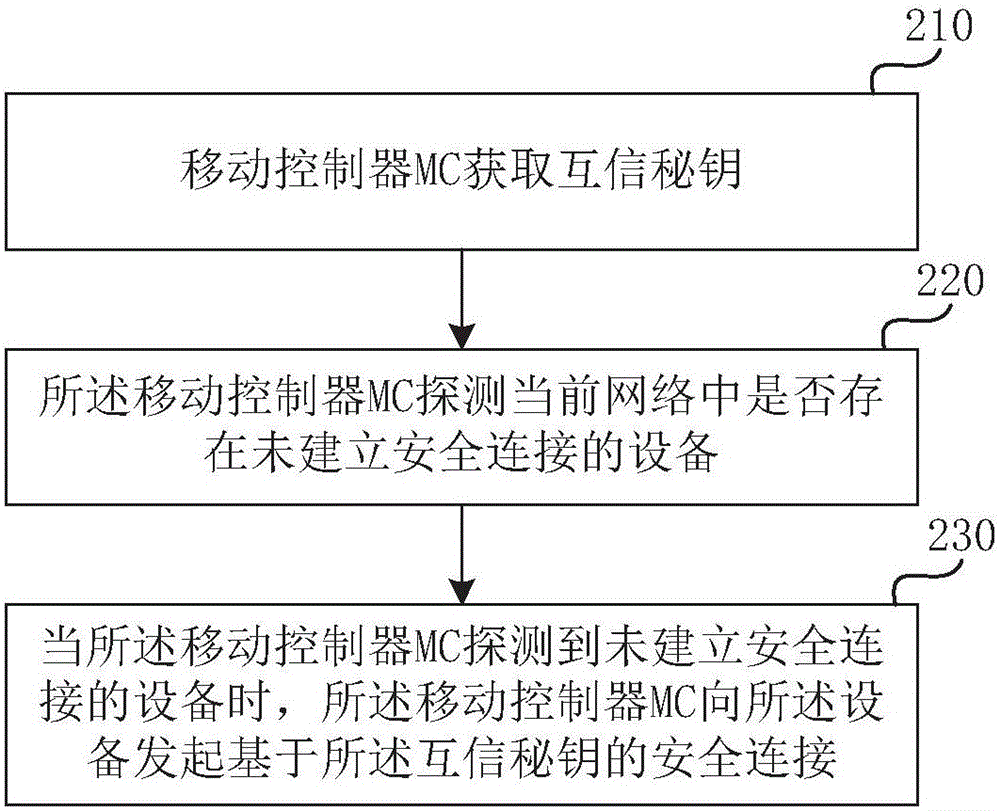

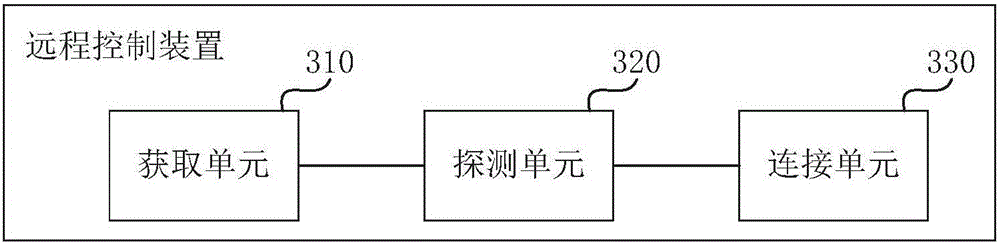

Remote control method, apparatus and system

ActiveCN105743919AAccurate controlImplement mobile controlWireless commuication servicesTransmissionComputer securitySafety Connect

The invention relates to a remote control method, apparatus and system. The method comprises the steps that a mobile controller (MC) obtains a trust key; the mobile controller MC detects whether a device that has not established a secure connection exists in a current network; and when the mobile controller MC detects the device that has not established the secure connection, the mobile controller MC initiates the secure connection based on the trust key. When the number of the devices is large, the process of establishing the trust key between the mobile controller MC and the devices can be omitted, and the secure connection is directly initiated to quickly and accurately control the devices.

Owner:TANGRAM MICROELECTRONICS TECH SHANGHAI CO LTD

Packaging detection equipment with classified clamping function for diode processing

The invention discloses packaging detection equipment with a classified clamping function for diode processing. The packaging detection equipment comprises a device body and a first containing cavity,side plates are arranged on the left side and the right side of the outer portion of the device body, rotating shafts are installed on the outer walls of the side plates, and a cover plate is arranged on the inner side of the first containing cavity; and the first containing cavity is located in the device body, second containing cavities are formed in the left side and the right side of the inner part of the device body, and lifting plates are arranged on the inner sides of the second containing cavities. According to an external heat dissipation device for a power bank, through the arrangement of the side plates, the device body forms a complete closed structure, by using the structural arrangement of the rotating shafts the cover plate can rotate on the side plates, the ventilation andheat dissipation environment in the device body is guaranteed through the arrangement of ventilation net plates on the side plates, the closed structure of the device body is adjusted through turnover control over the cover plate, and when the ventilation net plates are exposed, the device body has good heat dissipation capacity.

Owner:东莞市固德智能科技有限公司

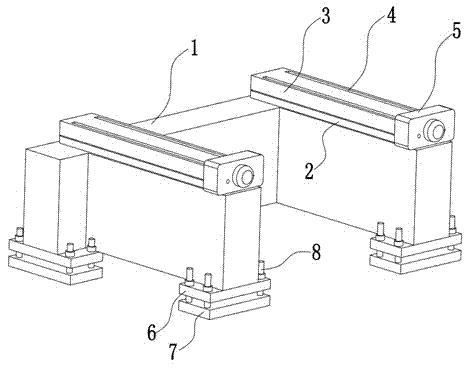

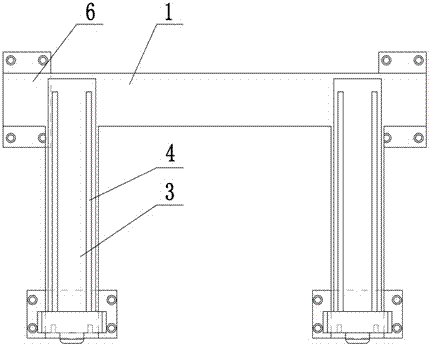

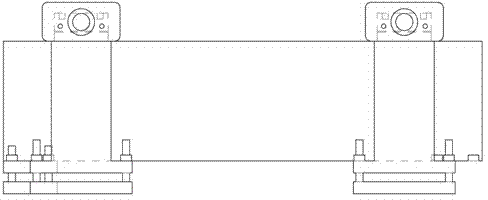

Large-size numerically-controlled machine tool supporting device

InactiveCN104493502AImplement mobile controlHeight adjustableLarge fixed membersNumerical controlLarge size

The invention discloses a large-size numerically-controlled machine tool supporting device. The large-size numerically-controlled machine tool supporting device comprises a support, guide rail seats, guide rails and base assemblies, wherein the support comprises a transverse supporting part and longitudinal supporting parts; the two longitudinal supporting parts are arranged on one side of the transverse supporting part at interval; the guide rail seats are fixedly arranged on the longitudinal supporting parts and extend along the longitudinal supporting parts; the guide rails are detachably fixed on the guide rail seats; guide grooves are formed in the guide rails, are concave inwards into the guide rails and extend along the guide rails; slide blocks of a numerically-controlled machine tool are embedded into the guide grooves and freely move along the guide grooves, so as to drive the numerically-controlled machine tool to move longitudinally; the base assemblies are arranged at the two ends of the transverse supporting part and on the outer sides of the two longitudinal supporting parts respectively so as to support the support. The large-size numerically-controlled machine tool supporting device has a simple structure and a large bearing capability; the height of the machine tool can be conveniently adjusted and the position of the machine tool can be moved.

Owner:哈尔滨理工大学科技园发展有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com