Patents

Literature

232results about How to "Does not affect measurement accuracy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

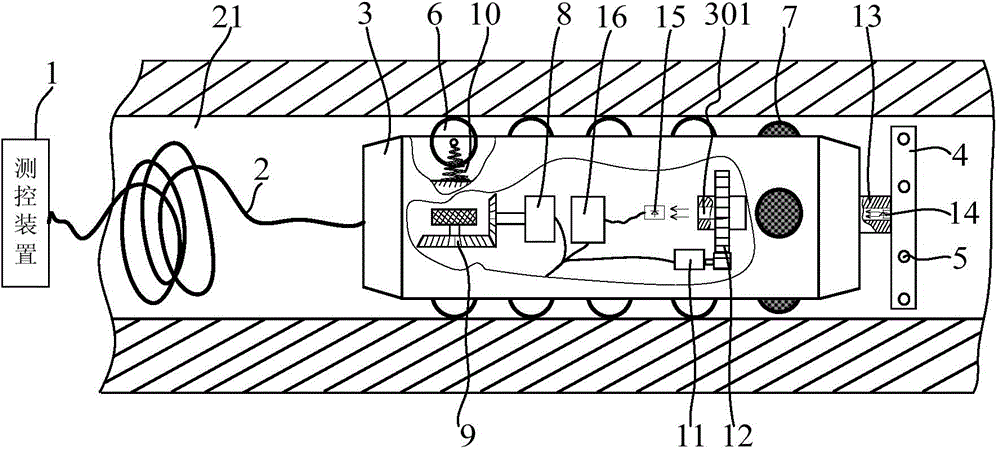

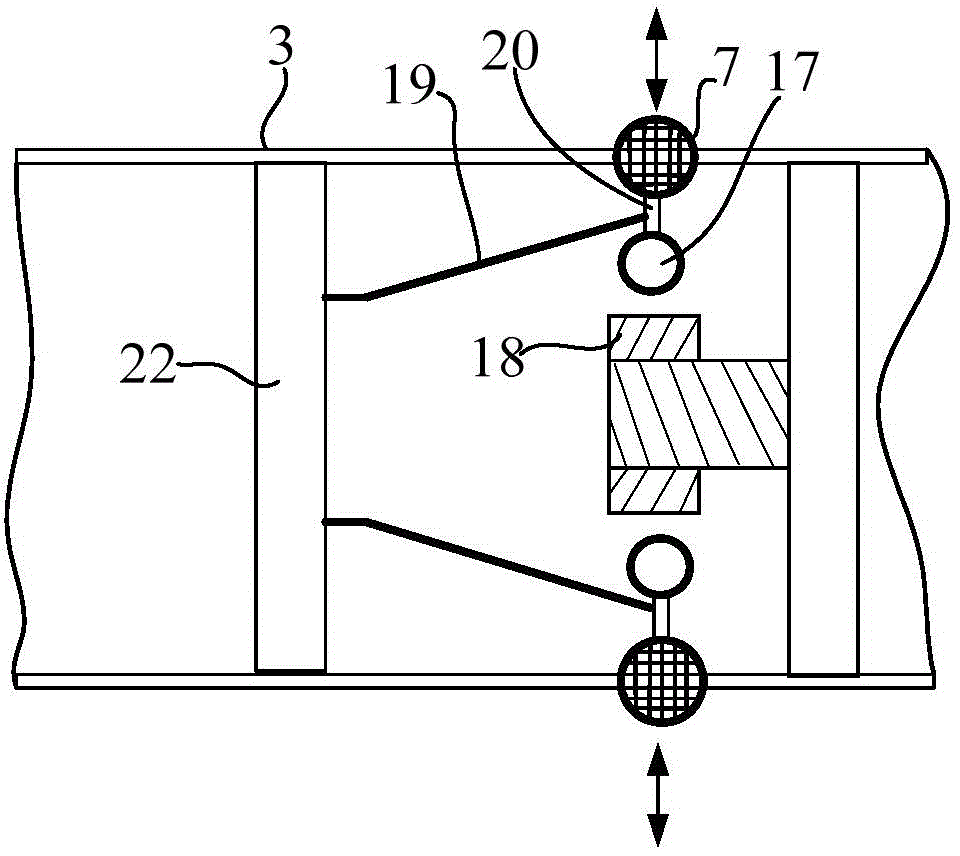

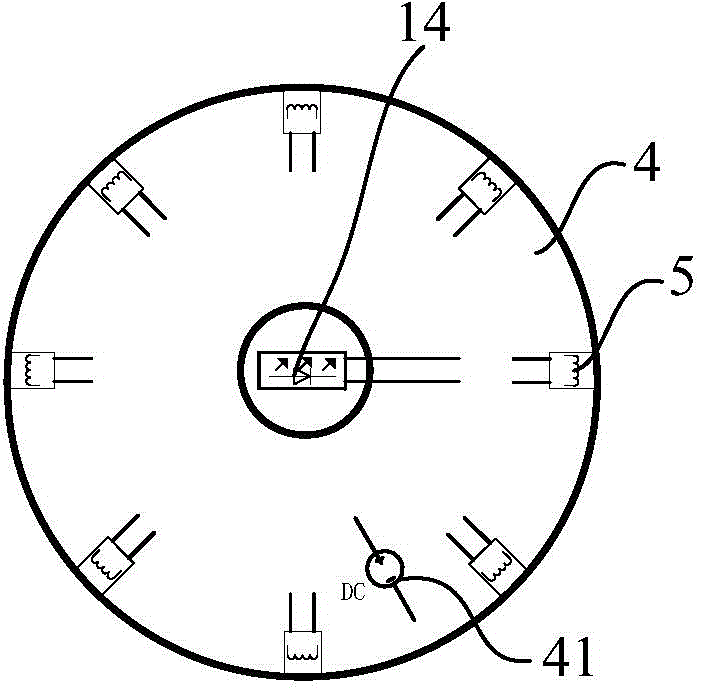

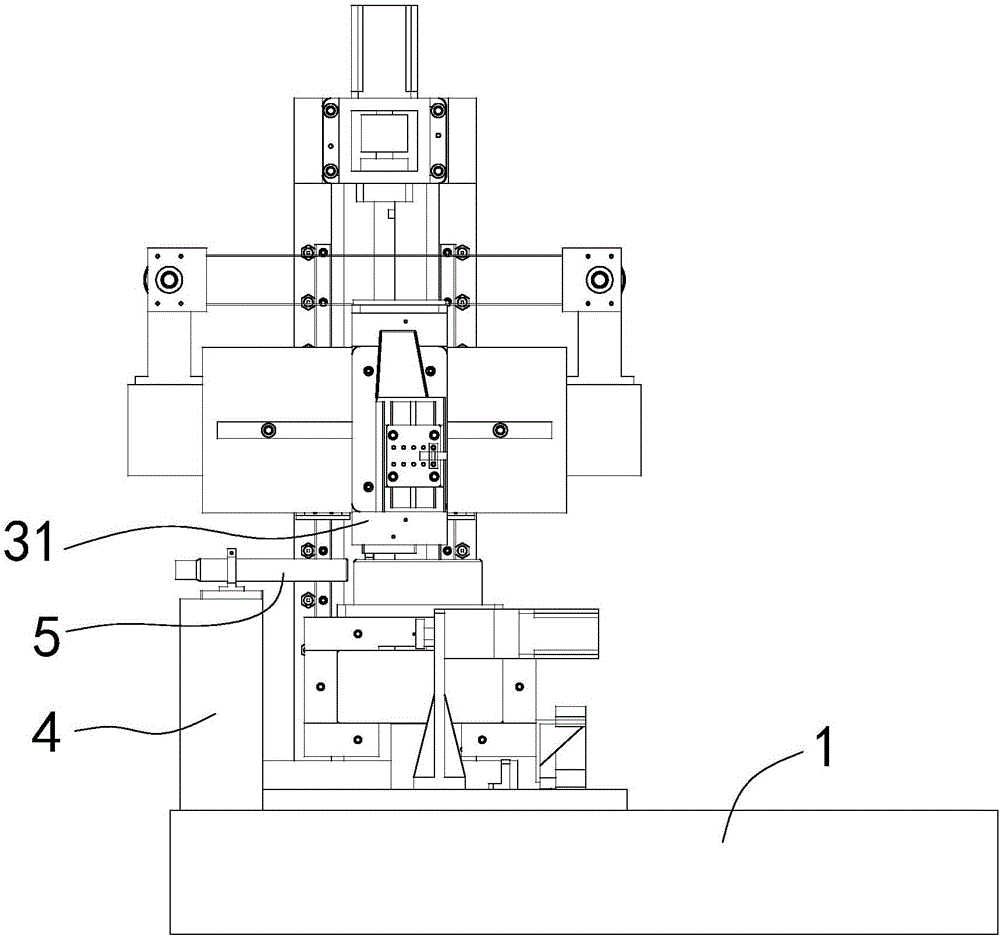

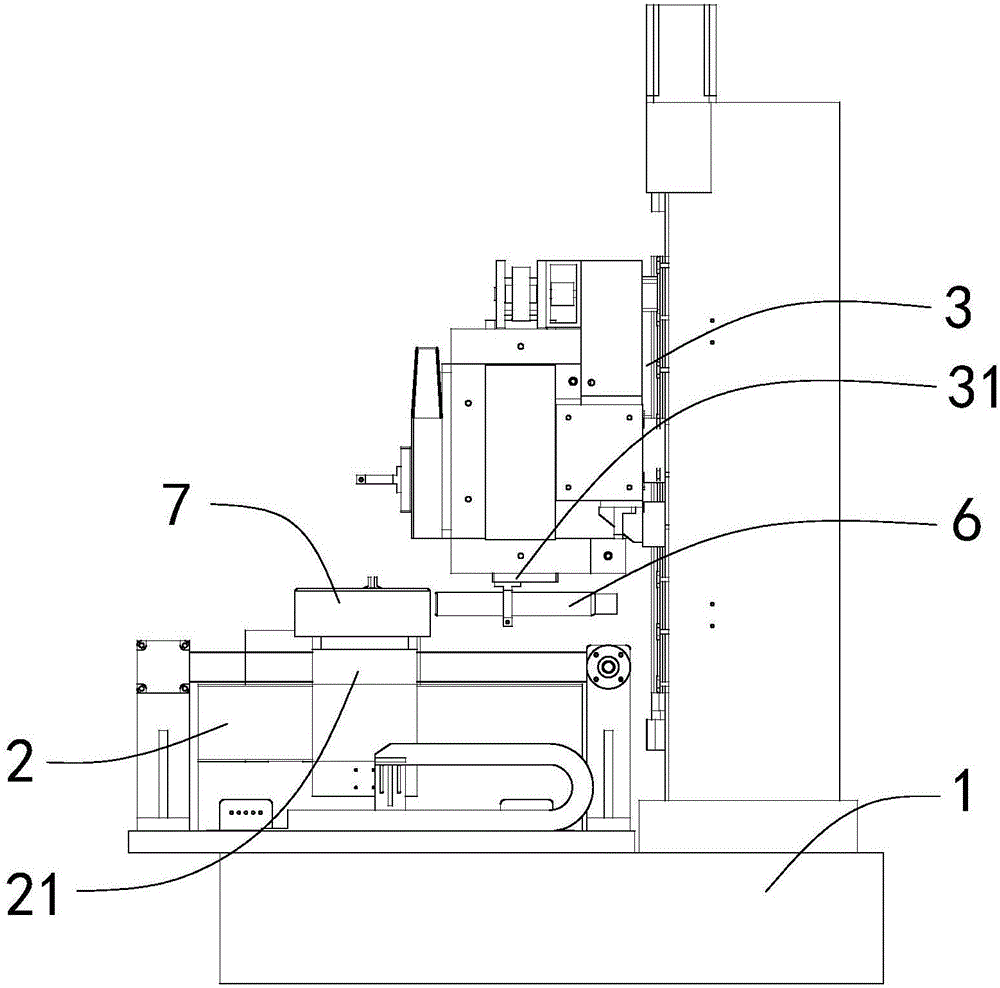

Deep hole inner diameter measuring system

ActiveCN104089561ASimple structureImprove stabilityMechanical diameter measurementsPhysicsMicrometer

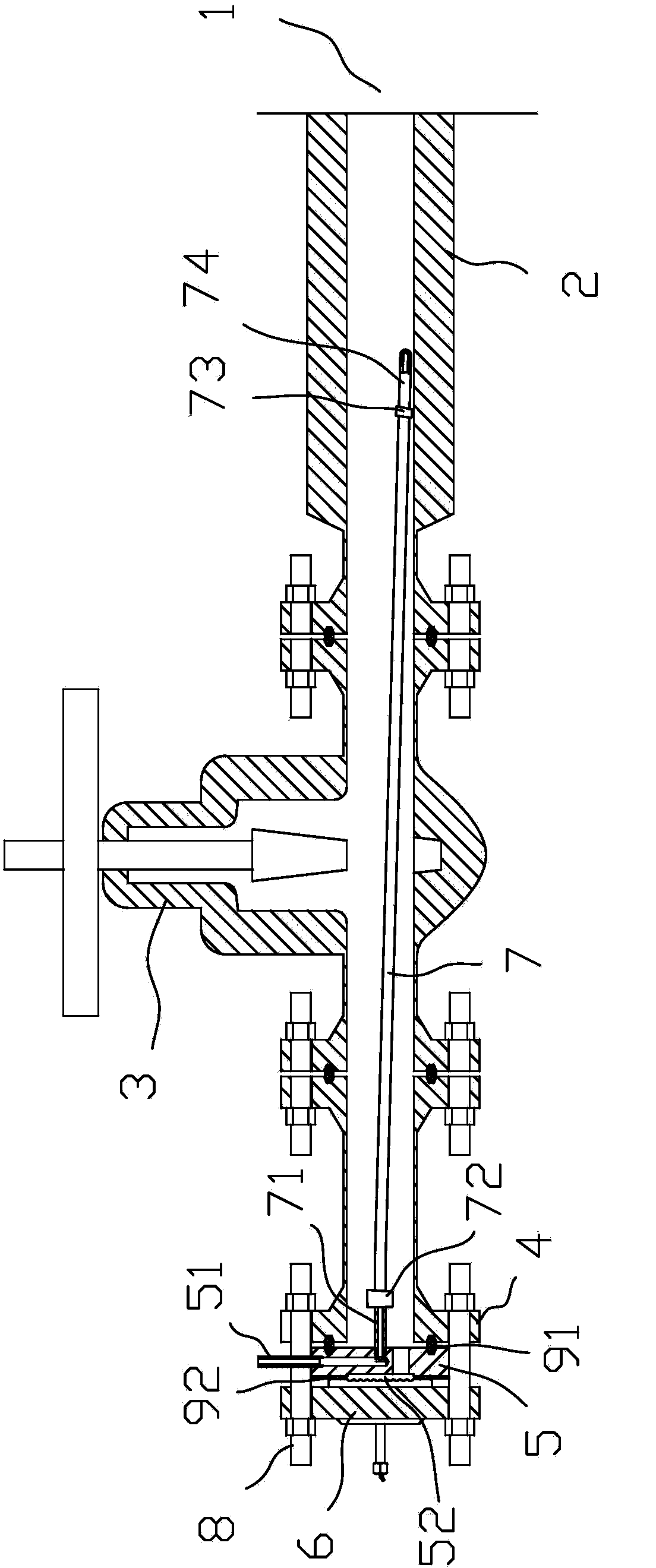

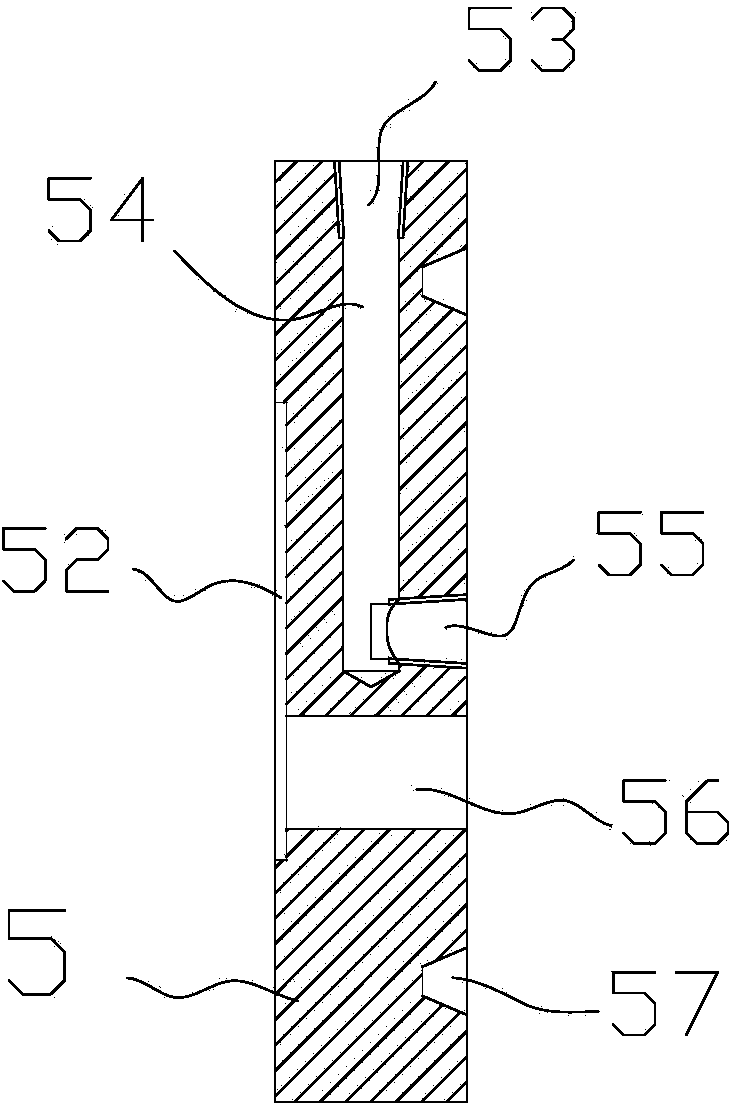

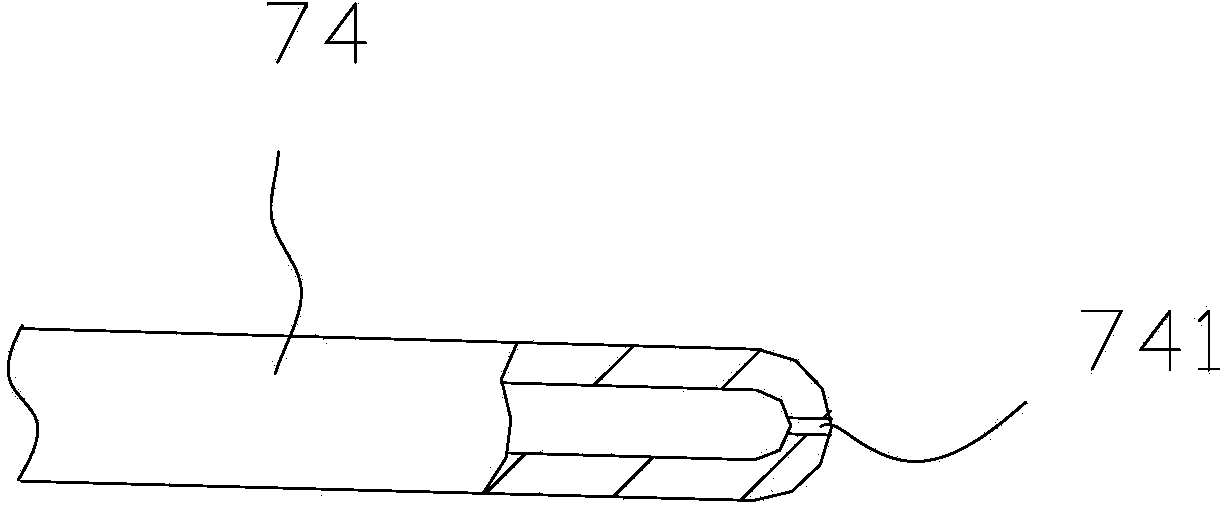

The invention discloses a deep hole inner diameter measuring system which comprises a measuring main body moving in the axial direction of a deep hole and a measuring control device connected with the measuring main body. The measuring main body comprises a cavity, at least three rows of supporting rolling wheels, at least two stopping balls and a rotating measuring disc, wherein the supporting rolling wheels are evenly distributed outside the cavity, one supporting rolling wheel is provided with a driving wheel for driving, the stopping balls are evenly distributed outside the cavity, the rotating measuring disc is arranged at one end of the cavity, a plurality of eddy current displacement sensors for measuring the inner diameter of the deep hole are arranged in the radial direction of the rotating measuring disc, and the eddy current displacement sensors are designed to achieve high sensitivity of 20 mv / micrometer within the 1mm measuring range on the basis of the simple series resonance principle. The stopping balls, the driving wheel and the rotating measuring disc are driven by corresponding driving devices respectively. The measuring control device comprises a first control module, a second control module, a third control module and a measuring calculation module for processing voltage signals output by the eddy current displacement sensors and calculating the inner diameter of the deep hole. According to the system, the inner diameter of the deep hole can be measured, and the measuring precision of the inner diameter of the deep hole can be improved.

Owner:NAT INST OF METROLOGY CHINA

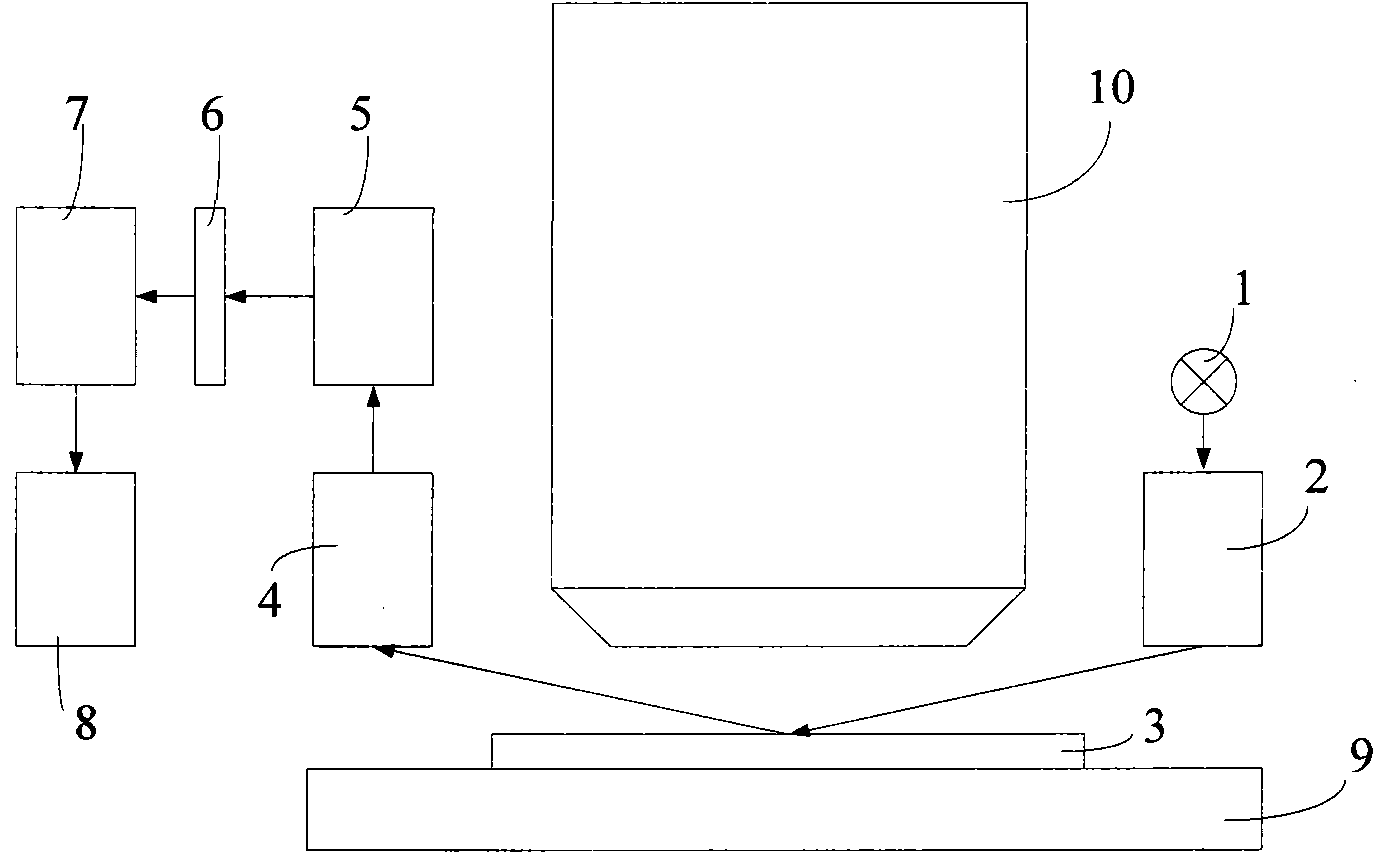

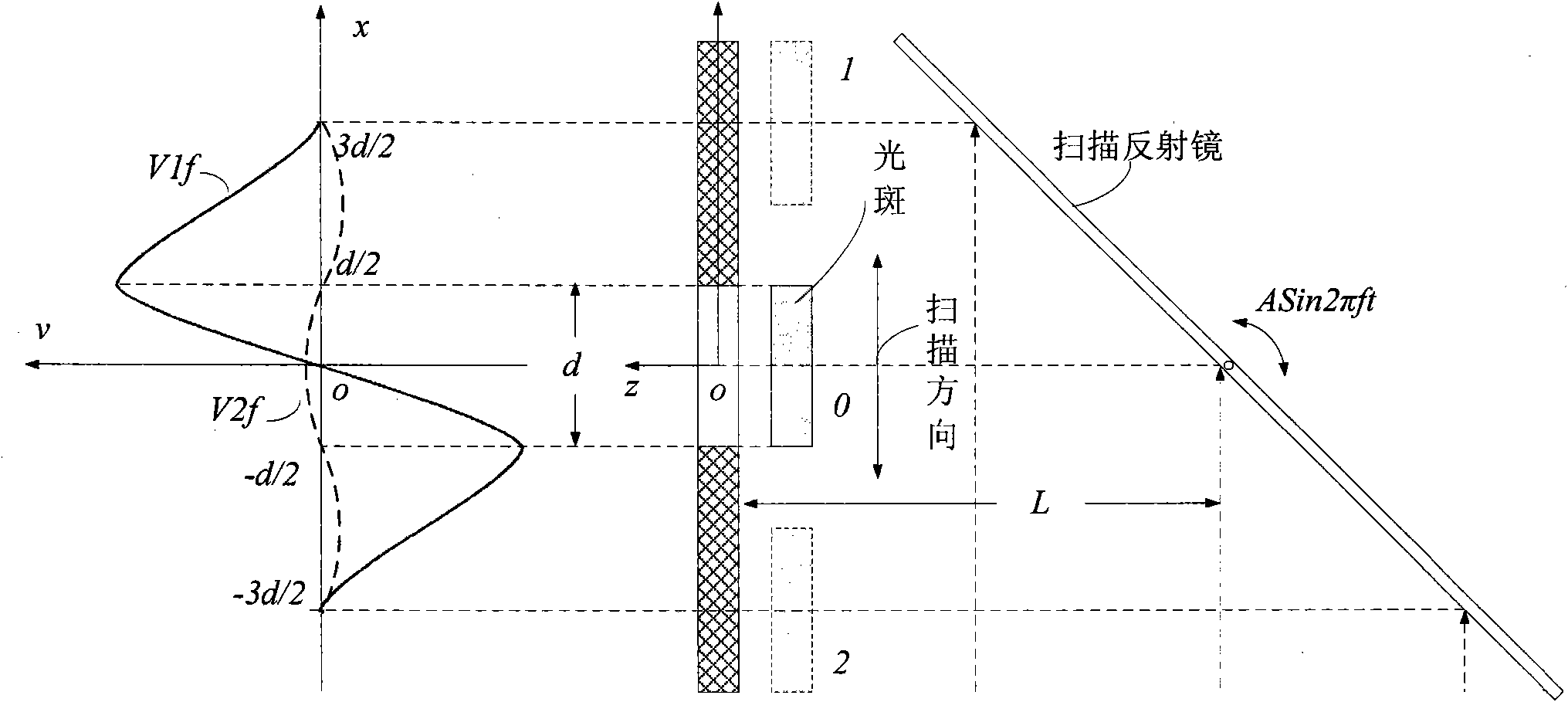

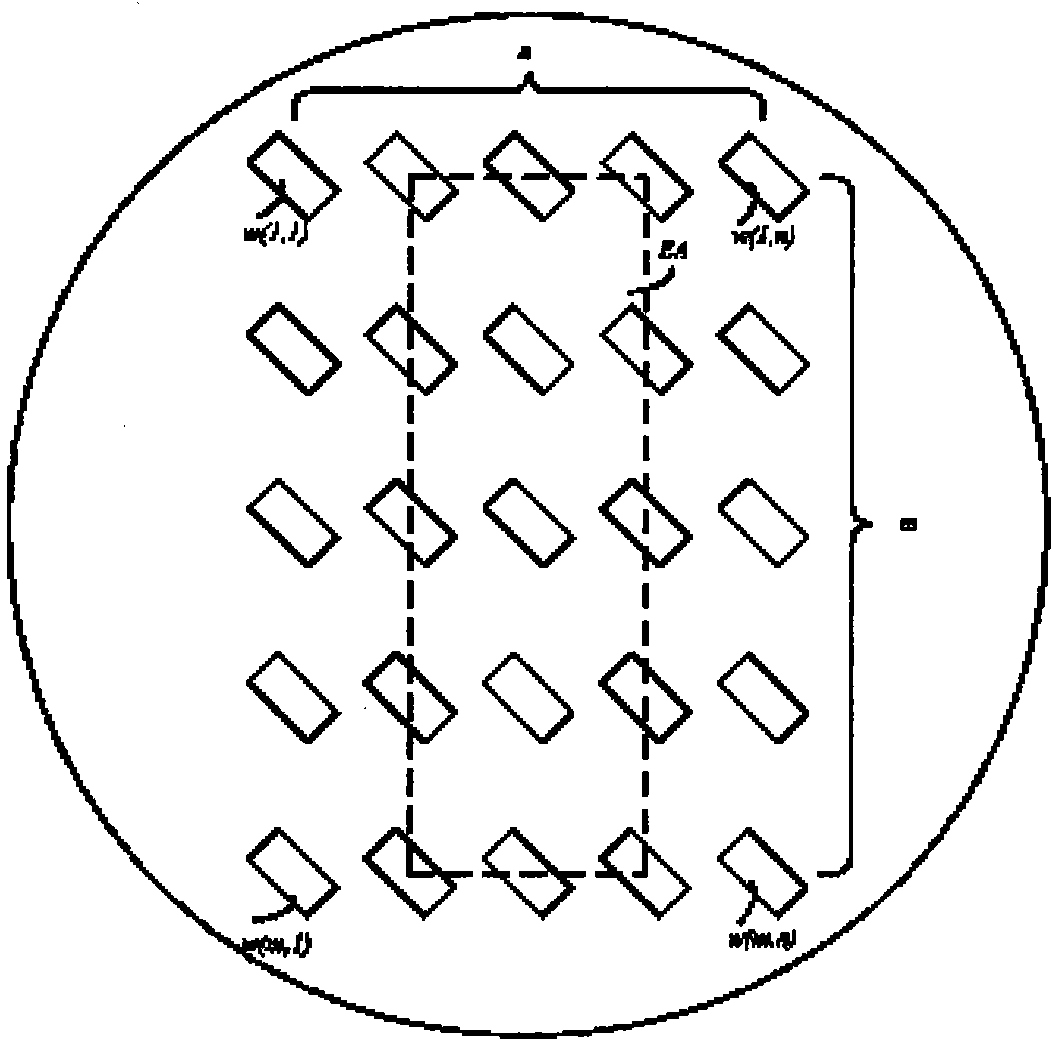

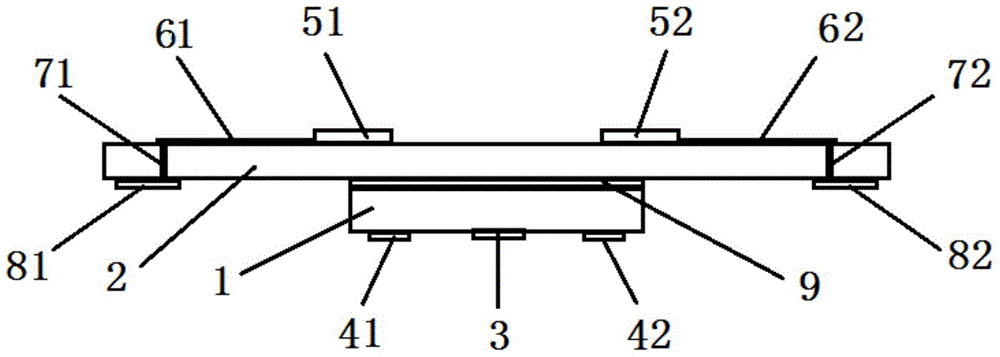

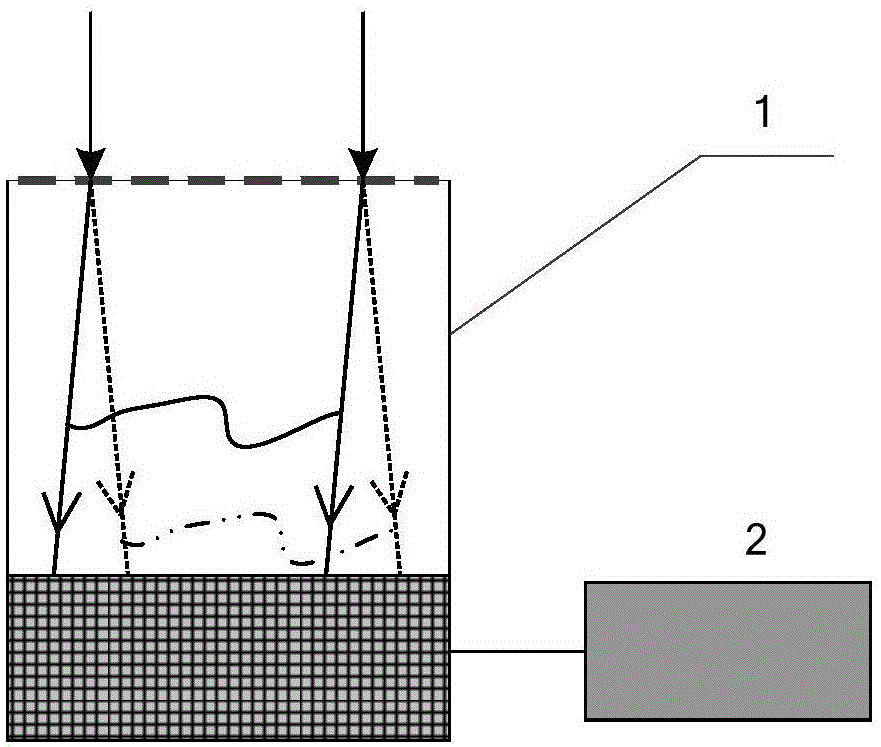

Focusing and levelling device with expandable measuring range and focusing and levelling method

ActiveCN102033438AExpand the measurable rangeReduce complexityPhotomechanical exposure apparatusMicrolithography exposure apparatusPhotovoltaic detectorsLight energy

The invention relates to a focusing and levelling device with an expandable measuring range, which comprises a light source, an optical projection unit, an optical receiving unit, an optical modulation unit, a receiving silt surface, a photoelectric detector and a control unit, wherein the optical projection unit receives light emitted by the light source and irradiates the light to the surface of a measured silicon wafer to form a measuring light spot matrix W; the optical receiving unit receives the light reflected by the measured silicon wafer; the optical modulation unit is provided with a scanning reflector which makes sinusoidal vibration during levelling measurement; a silt matrix S of silts corresponding to each light spot on the silicon wafer is formed on the receiving silt surface, and the light spots reflected by the scanning reflector are imaged on the receiving silt surface; the photoelectric detector converts a light energy signal passing through the silts into an electrical signal; the control unit analyzes the electrical signal outputted by the photoelectric detector; and an expanding silt positioned on the edge of the silt matrix is also formed on the receiving silt surface and is used for expanding the measuring range of the focusing and levelling device. The invention also discloses a focusing and levelling method using the device.

Owner:SHANGHAI MICRO ELECTRONICS EQUIP (GRP) CO LTD

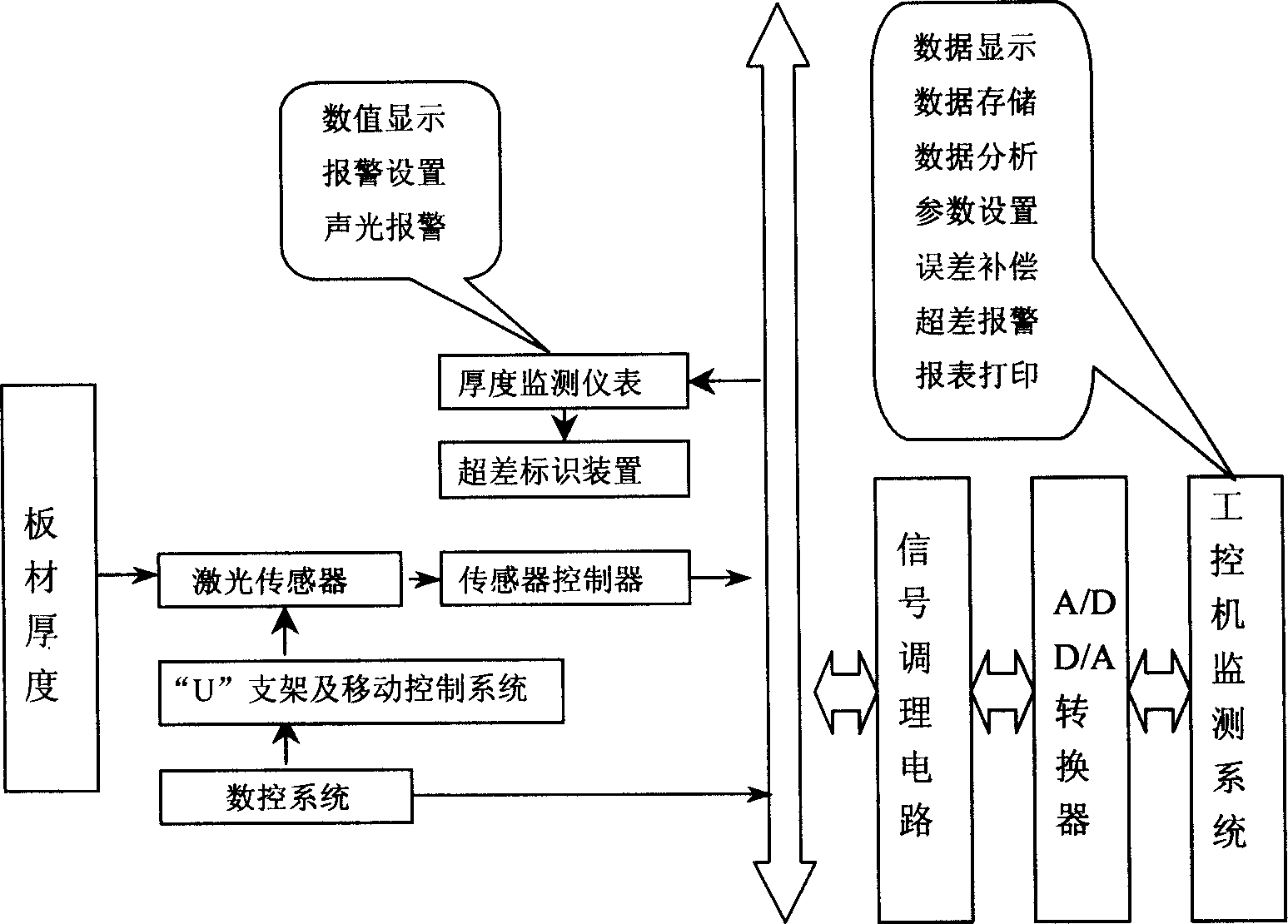

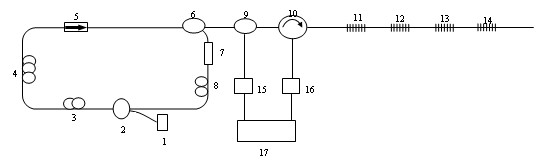

Online monitoring system for measuring thickness of clean-surface panel

InactiveCN1670472ADoes not affect measurement accuracyRealize measurementUsing optical meansSignal conditioning circuitsMonitoring system

This invention relates to smooth surface board materials thickness on-line measurement and especially to the ones influenced by temperature, which comprises the following steps: eliminating the impact on the structure deformation from temperature through extra set mark block in each journey. The measured board thickness signals from laser sensor, temperature compensation thickness signals and rack journey position signals are sent to the working control machine to accomplish the signal process to realize the monitoring.

Owner:JIAXING UNIV

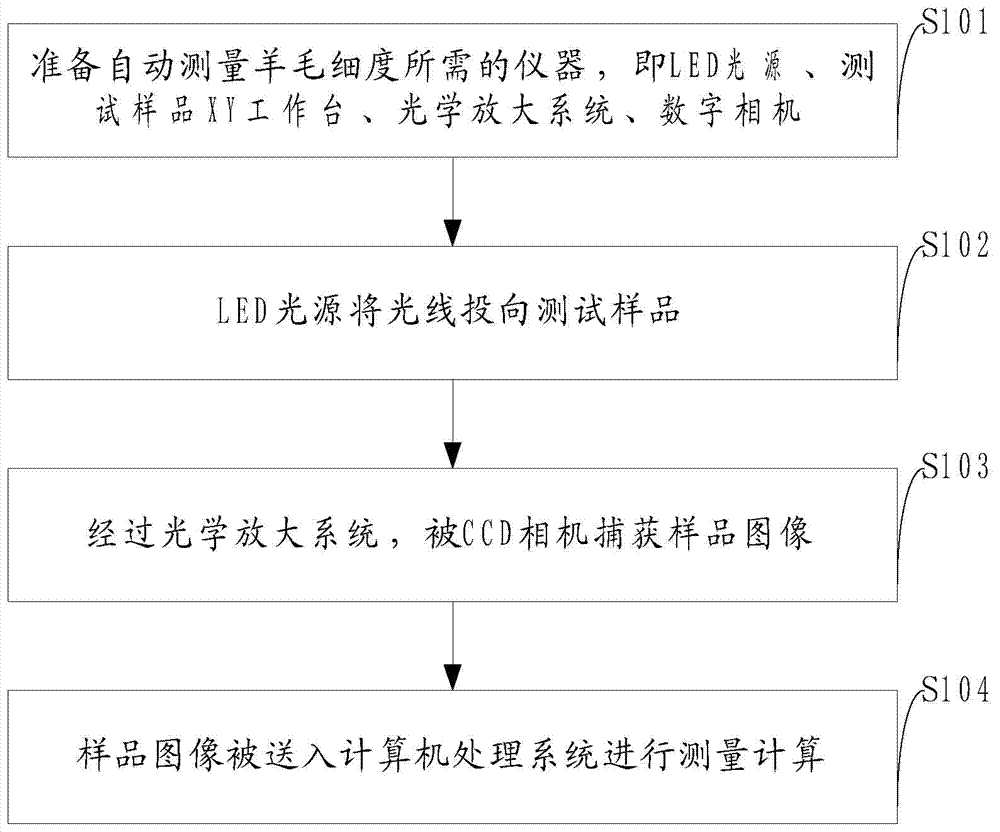

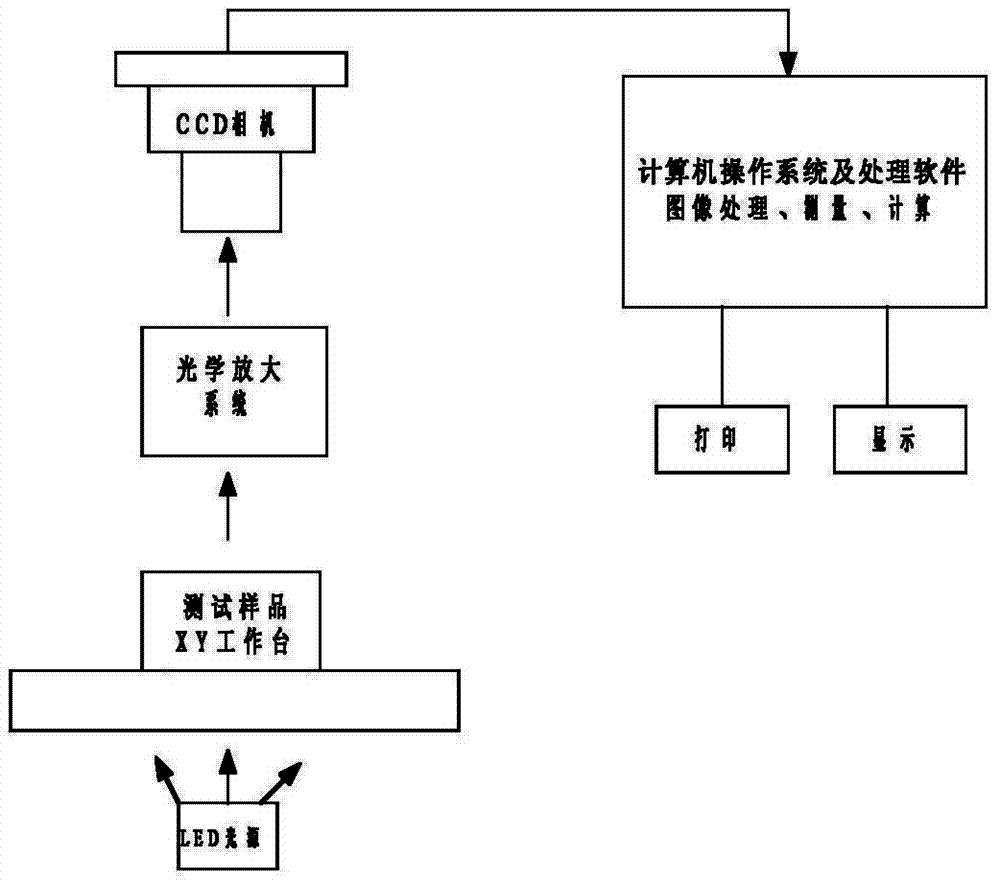

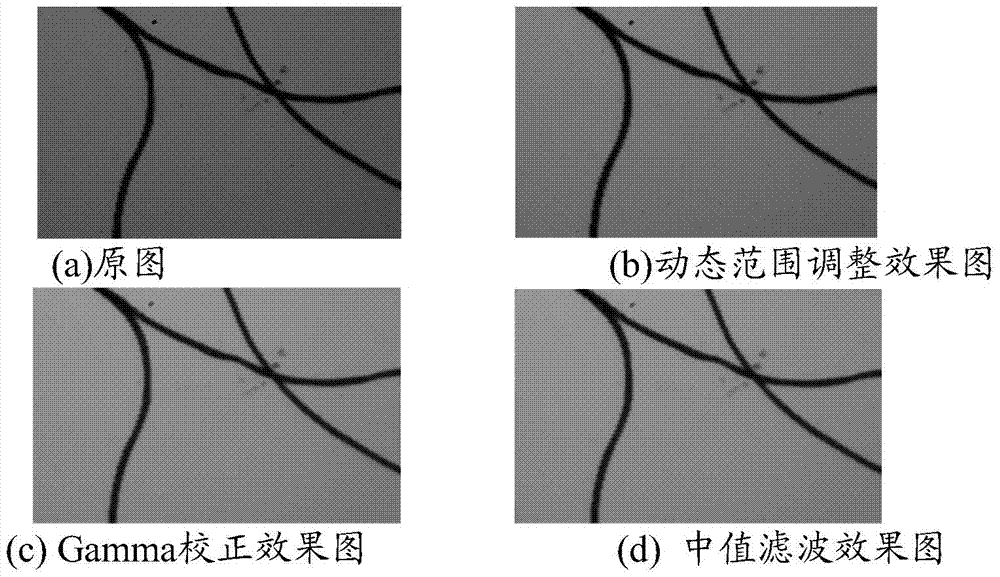

Wool fineness automatic measuring method

The invention discloses a wool fineness automatic measuring method, which comprises the following steps that instruments required for automatically measuring the wool fineness are prepared, and the instruments comprise an LED (light emitting diode) light source, a testing sample XY work table, an optical magnification system and a digital camera; light rays are irradiated to testing samples by the LED light source; through the optical magnification system, sample images are captured by a CCD (charge coupled device) camera; the sample images are sent to a computer processing system for measurement and calculation. The wool fineness automatic measuring method provided by the invention has the advantages that the manual intervention is not needed, manpower resources are reduced, and errors caused by subjective factors are avoided; simple and efficient processing links are adopted, the consumed time of the whole wool fineness automatic measuring process is shortened to be within 30ms, the original wool state is maintained to the maximum degree, and the damage to the geometric dimension of wool is avoided, so the basis is provided for guaranteeing measurement precision; during the diameter calculation, the condition that the wool edge is basically in a straight line state or an approximate straight line state is used as the basis for approximately solving the diameter by adopting an area method, so the measurement precision cannot be greatly influenced.

Owner:AIR FORCE UNIV PLA

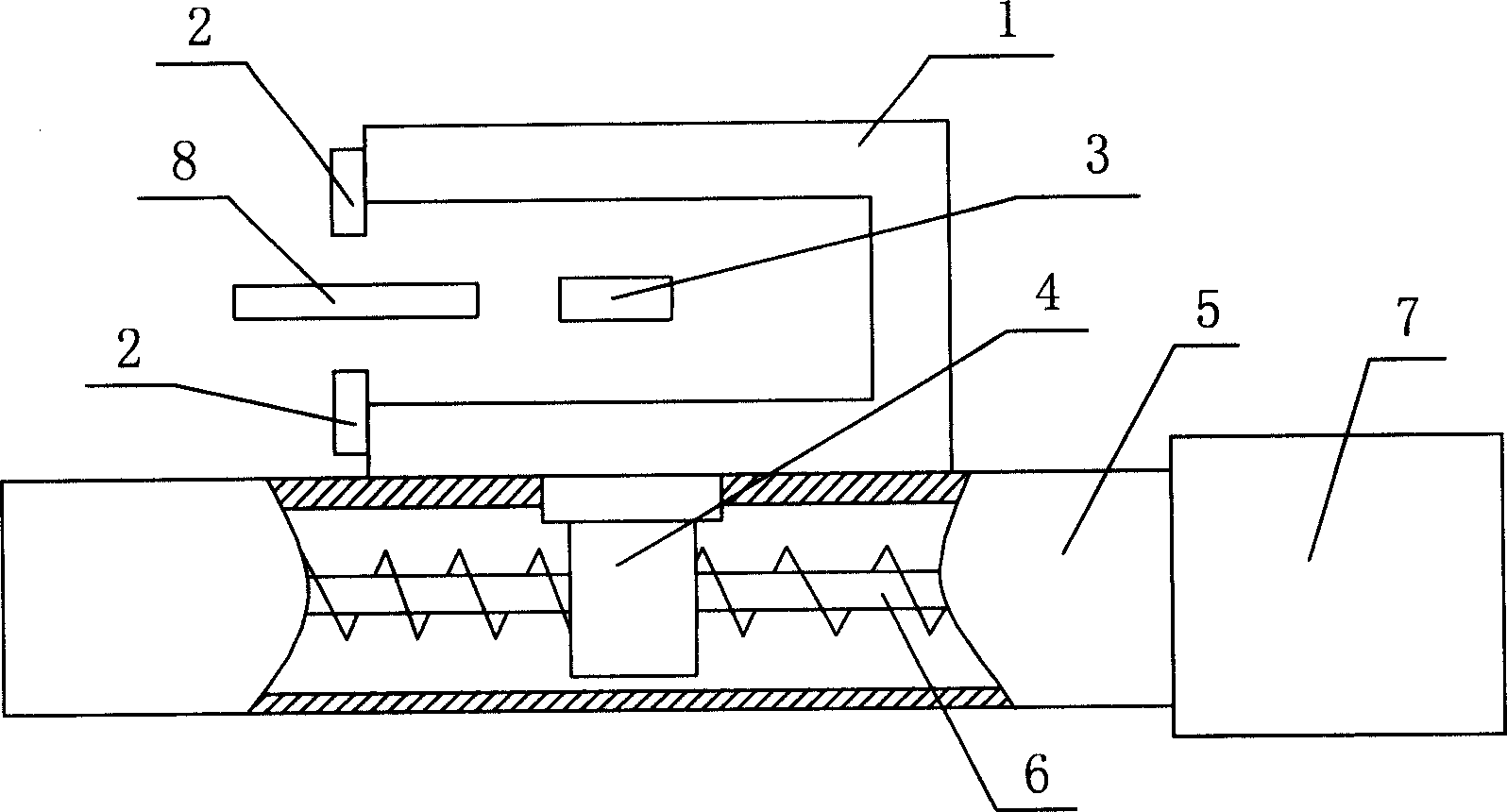

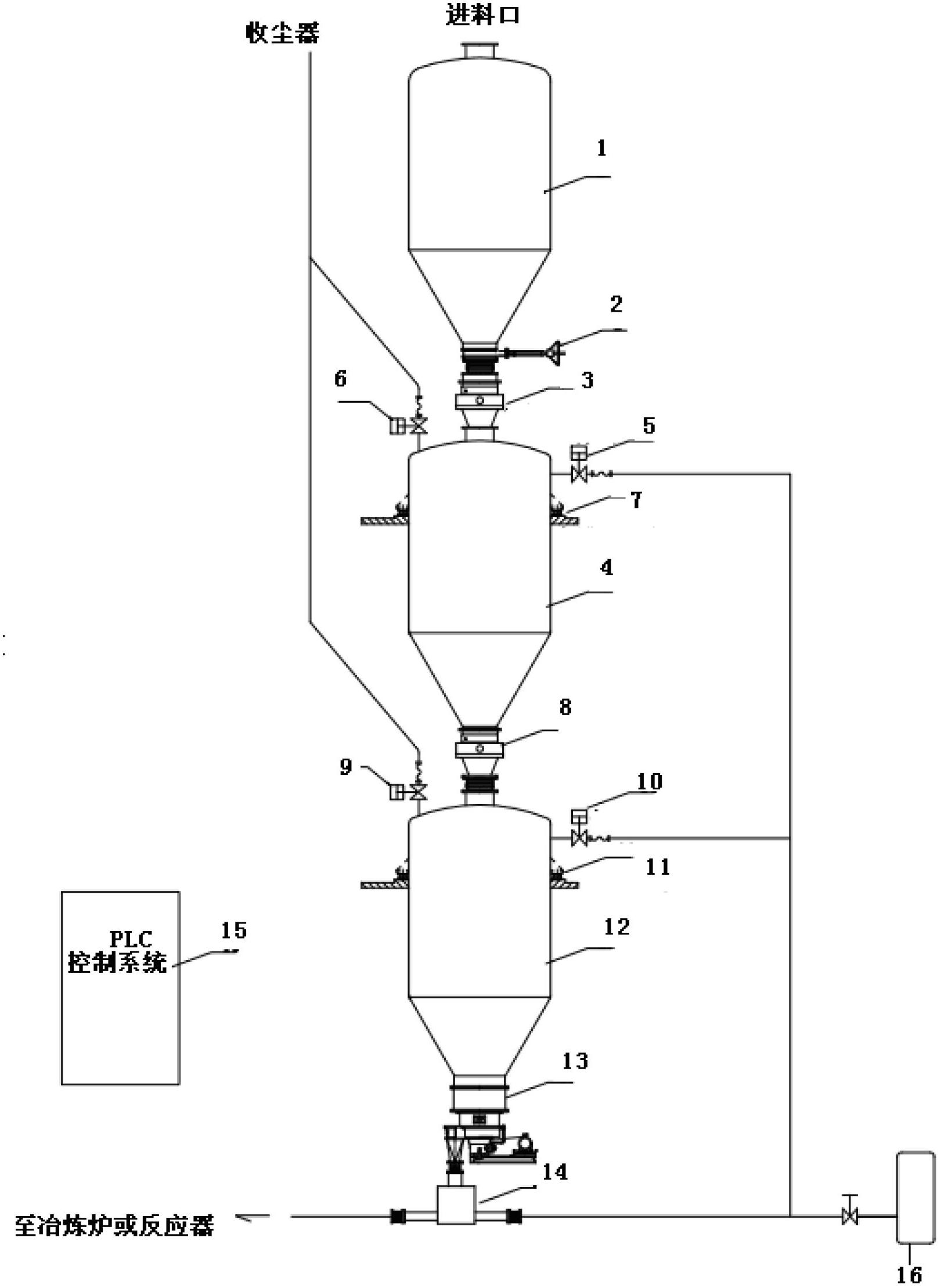

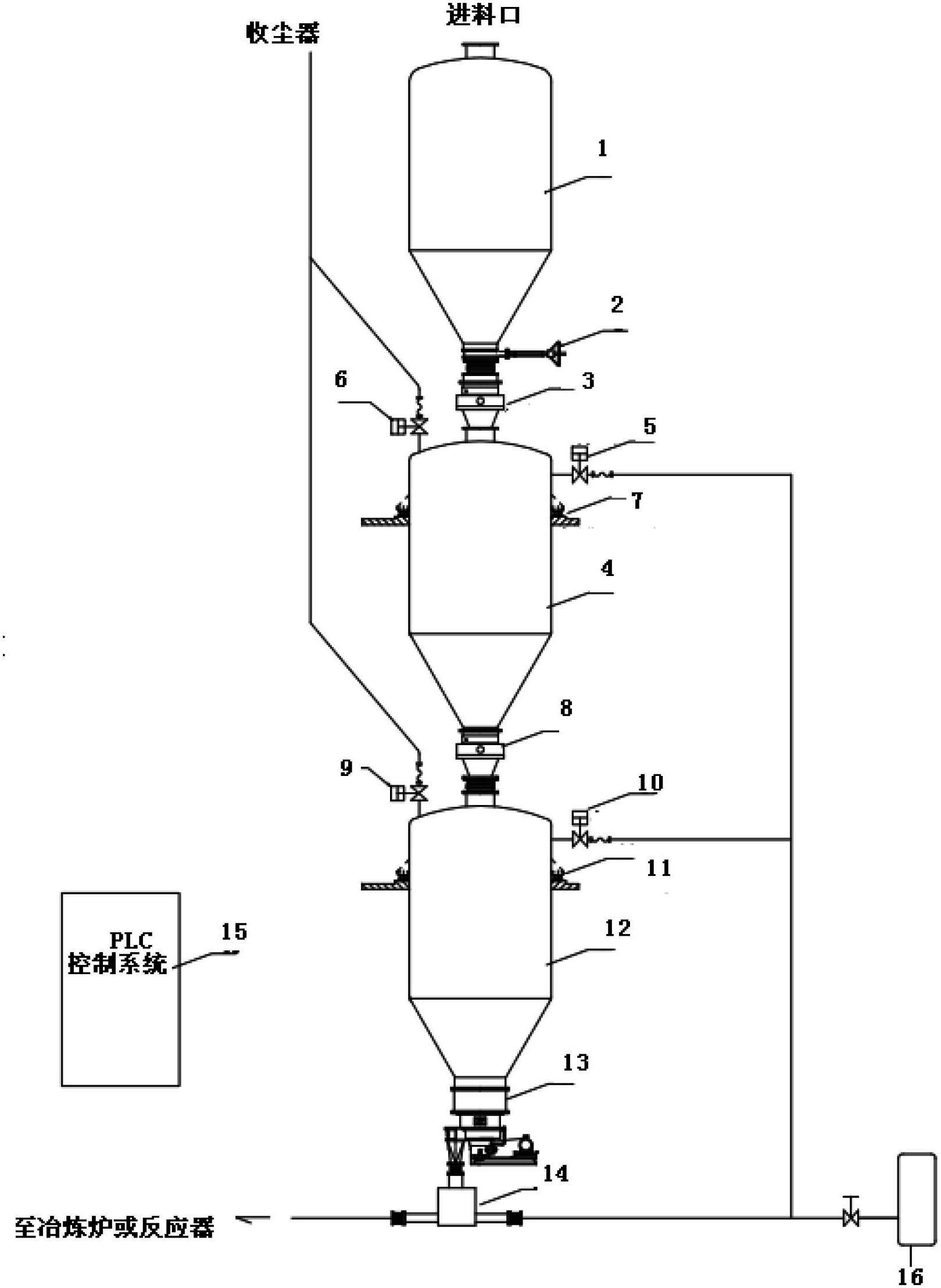

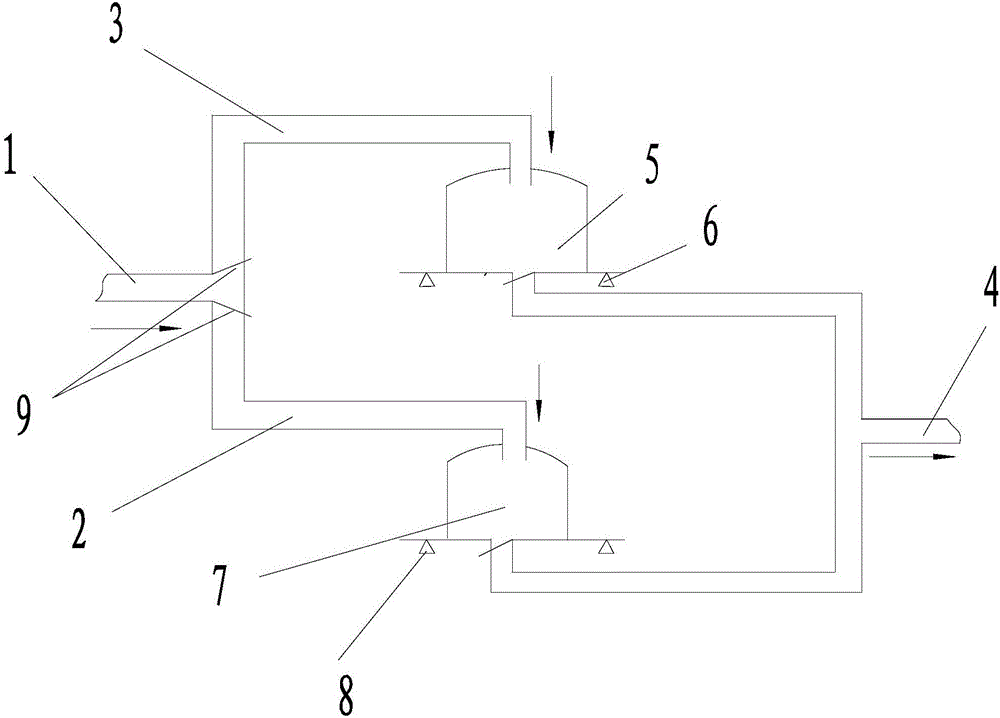

High-pressure conveyed continuous powder body quantitative feeding device

InactiveCN102658975AWill not affect supplyDoes not affect measurement accuracyBulk conveyorsPneumatic valveEngineering

The invention provides a high-pressure conveyed continuous powder body quantitative feeding device, which comprises a powder feeding bin, a gate valve, a pneumatic valve, a calibration bin, a weighing sensor, a weighing bin, a rotary material feeder, a Venturi pipe and a programmable logic control (PLC) system, wherein the weighing bin and the rotary material feeder form a weight loss type powder body quantitative feeder; the operation pressure of the powder feeding bin is normal pressure; the operation pressure of the calibration bin is normal pressure during material feeding and is pressure of an air storage tank during material discharging; and the operation pressure of the weighing bin is pressure of the air storage tank. The pressure in the weighing bin is always equal to the pressure in a conveying pipeline, so that the change of the pressure in the conveying pipeline does not influence the feeding and metering precision.

Owner:北京燕山粉研精机有限公司

Optical fiber sensing device for optical fiber chaos laser device and method thereof

InactiveCN102506917ALow costHigh precisionConverting sensor output opticallyTemperature and pressureGrating

The invention relates to an optical fiber sensing device for an optical fiber chaos laser device and a method thereof. The device comprises the optical fiber chaos laser device, a data processing system and an optical fiber sensing system. After chaos light emitted by a wavelength frequency-sweeping filter in the optical fiber chaos laser device enters into an optical fiber coupler, one path of the chaos light enters into the data processing system through a photoelectric detector, the other path of the chaos light enters into the optical fiber sensing system through a light circling device, is reflected back to the light circling device and enters into the photoelectric detector and the data processing system, and then the two paths of data signals are combined through a correlation method and a fiber grating sensor, thereby performing the temperature and pressure measurement and the network monitoring. In the invention, an optical fiber laser device is combined with the fiber grating sensor, a sensing information position of a detecting point is confirmed according to the wavelength frequency sweeping and the chaos related characteristics, and the chaos pulse wavelength frequency sweeping is utilized to realize the accurate measurement for the pressure or temperature of the position of the fiber grating.

Owner:TAIYUAN UNIV OF TECH

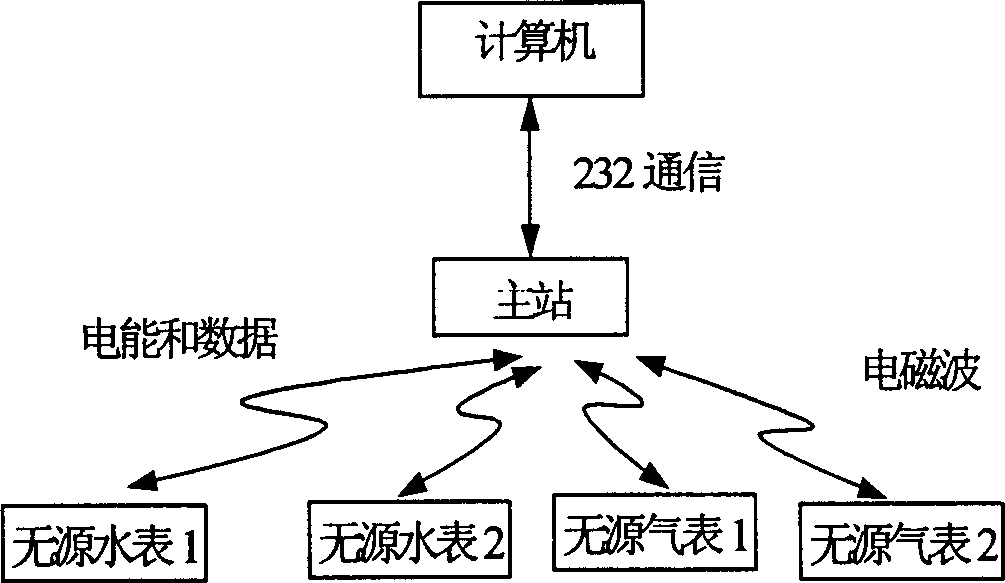

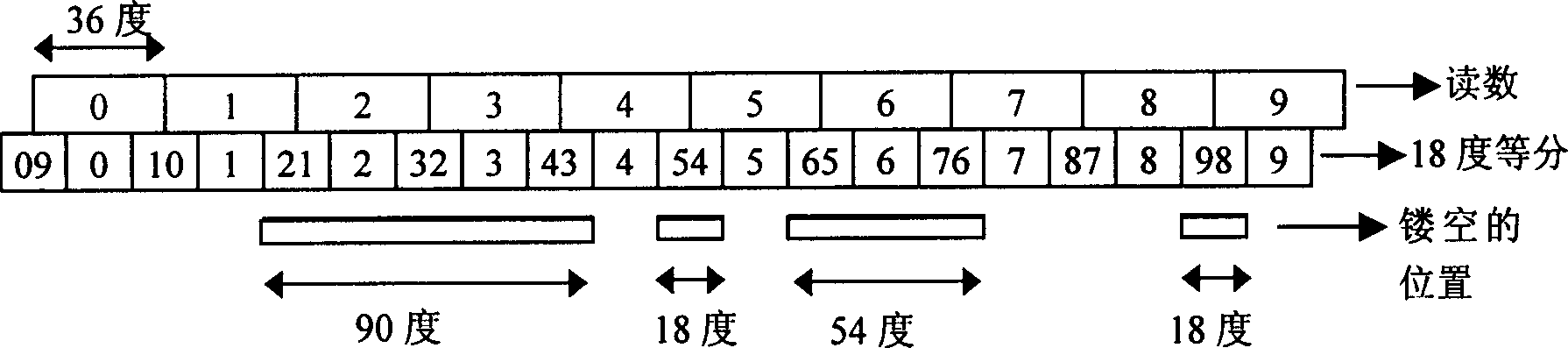

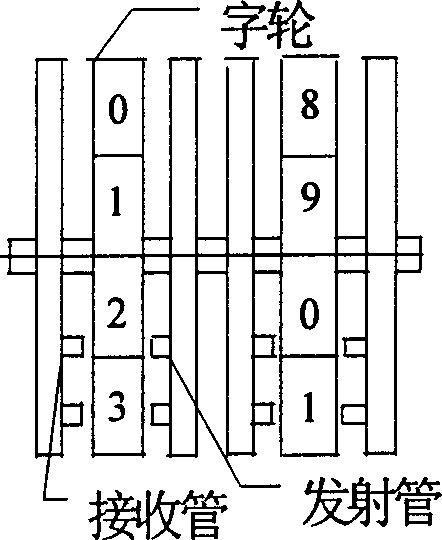

Wireless and passive water meter and gas meter

InactiveCN1687716ASmall footprintEasy to processTransmission systemsVolume indication and recording devicesDigital readingGas meter

The invention discloses a wireless and non-source water meter and gas meter. It has the intelligent water meter, the gas meter and the main station recording the meters. The intelligent water and gas meters carve the absolute codes on the mechanical character wheel of the meters; equip the infrared sending and receiving tubes at two sides of the wheel; equip the radio wave receiving and adjusting circuits in the meters; the water and the gas meters do not connect the electric source; the main station is the radio wave launching and receiving circuit. The effects of the invention are: (1) the absolute coding takes less space and is easily processes; (2) the meters simultaneously have mechanical and digital reading and keep accordance; (3) easily sealed; (4) the main station and the water and gas meter exchange the data through radio communication.

Owner:ZHEJIANG UNIV

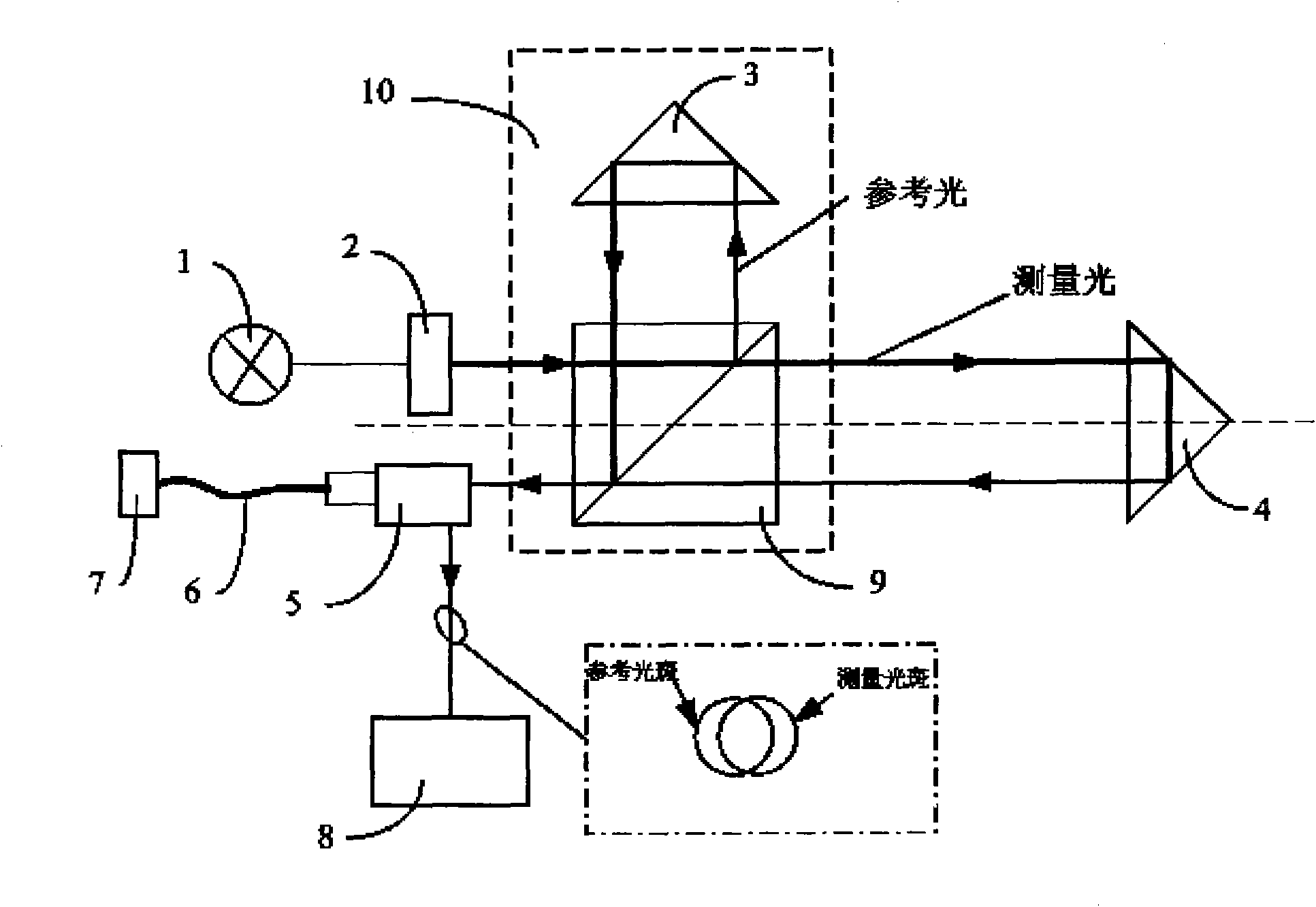

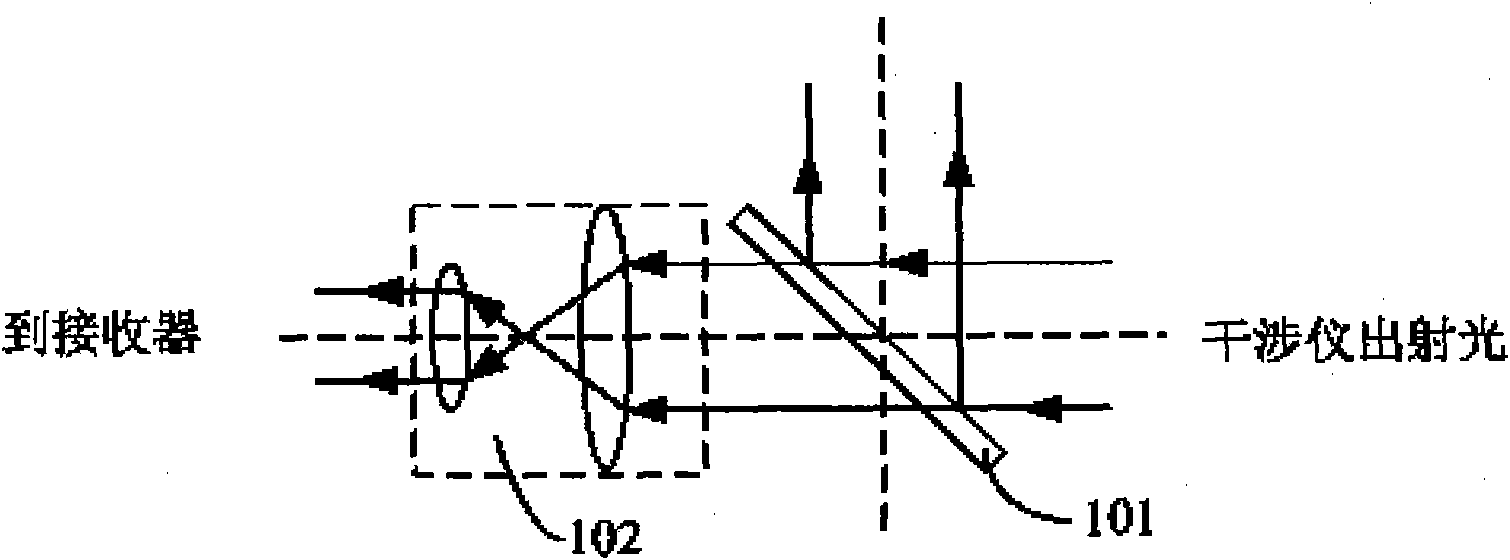

Light path alignment device of laser interferometer and method

ActiveCN102313508ADoes not affect measurement accuracyUsing optical meansPhotomechanical exposure apparatusLight spotBeam splitting

The invention relates to a light path alignment device of a laser interferometer and a method. Laser emitted by a laser device is adjusted by a reflective mirror adjusting mechanism and is then transmitted into the laser interferometer, a polarization beam-splitting mirror divides the laser into reference light and measurement light, the reference light is reflected by a reference reflective mirror, the measurement light is reflected by a measurement reflective mirror, is transmitted to the polarization beam-splitting mirror and is then reflected by the polarization beam-splitting mirror to the optical fiber receiving head, and the beam-splitting mirror divides incident light into two parts, wherein the majority of the light is compressed by a compression lens component in the optical fiber receiving head and is transmitted to a receiver, and the rest of the light is projected to a light spot observation device for observation of overlapping of a reference light spot and a measurementlight spot.

Owner:SHANGHAI MICRO ELECTRONICS EQUIP (GRP) CO LTD

MEMS thermal type wind speed sensor having on-chip self calibration function

ActiveCN104991087AReduce batch testing costsShort durationTesting/calibration of speed/acceleration/shock measurement devicesTemperature differenceEngineering

The invention discloses an MEMS thermal type wind speed sensor having an on-chip self calibration function. A thermal temperature difference signal provided by a heating element on a sensor encapsulation surface replaces a temperature difference signal generated by a wind tunnel, so the problem that sensor measurement and calibration must be performed in wind tunnel environment is prevented. The sensor has the advantages of simple structure encapsulation, very low testing cost and convenient maintenance, and can perform calibration detection on site.

Owner:SOUTHEAST UNIV

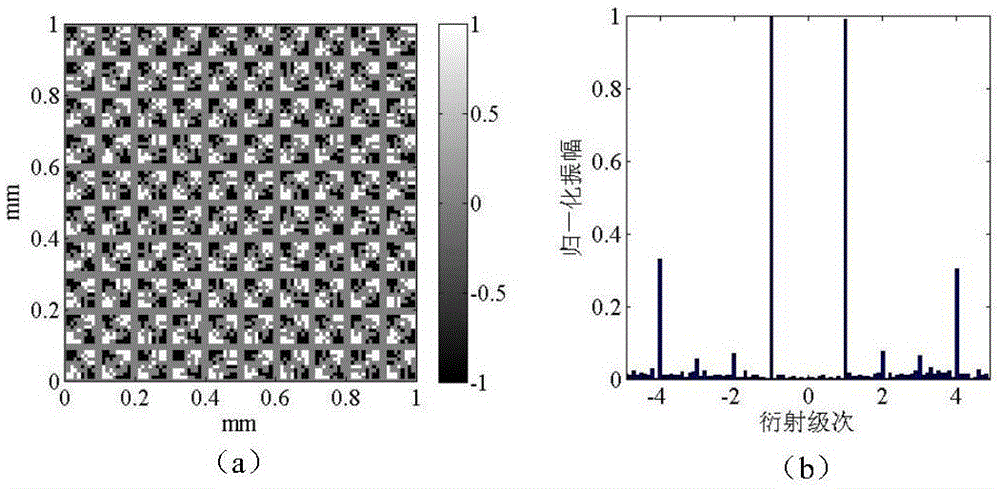

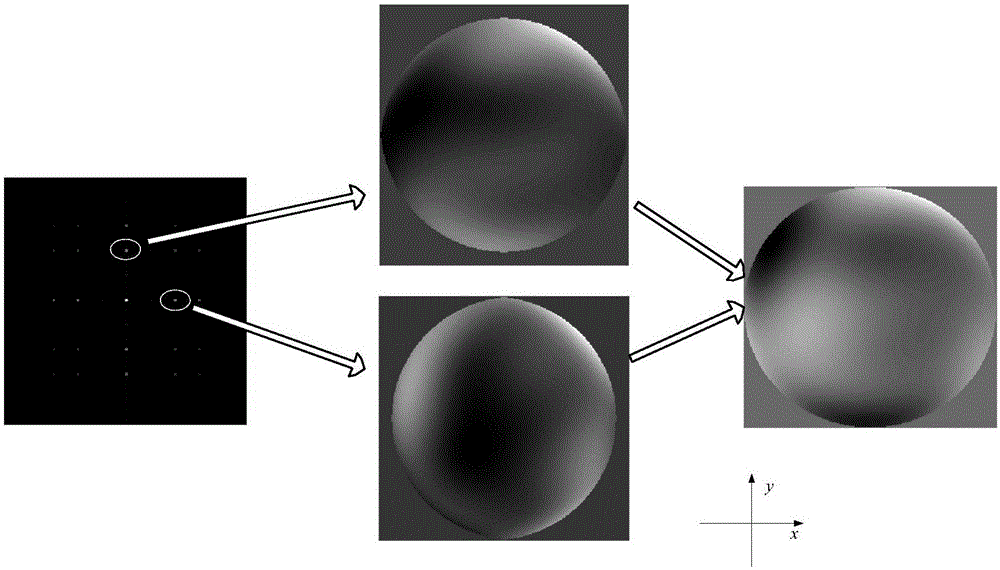

Wavefront sensor and wavefront measuring method

ActiveCN105115417AHigh interference contrastDoes not affect measurement accuracyUsing optical meansGratingWavefront sensor

A wavefront sensor and a wavefront measuring method are disclosed. The wavefront sensor comprises a two-dimensional random coding mixing raster and a detector, wherein the two-dimensional random coding mixing raster comprises a random coding amplitude raster and a chessboard type phase raster. The pixel dimension of the random coding amplitude raster, the processing difficulty is reduced, and the wavefront measuring precision is not affected.

Owner:SHANGHAI INST OF OPTICS & FINE MECHANICS CHINESE ACAD OF SCI

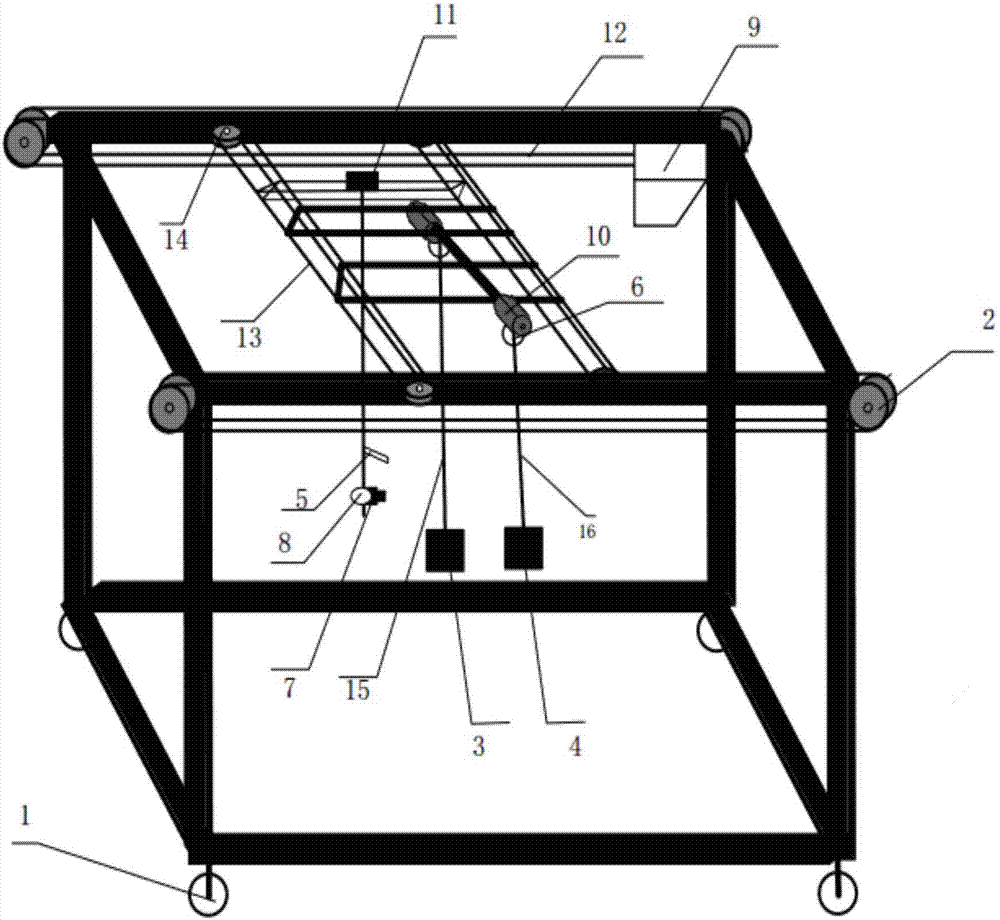

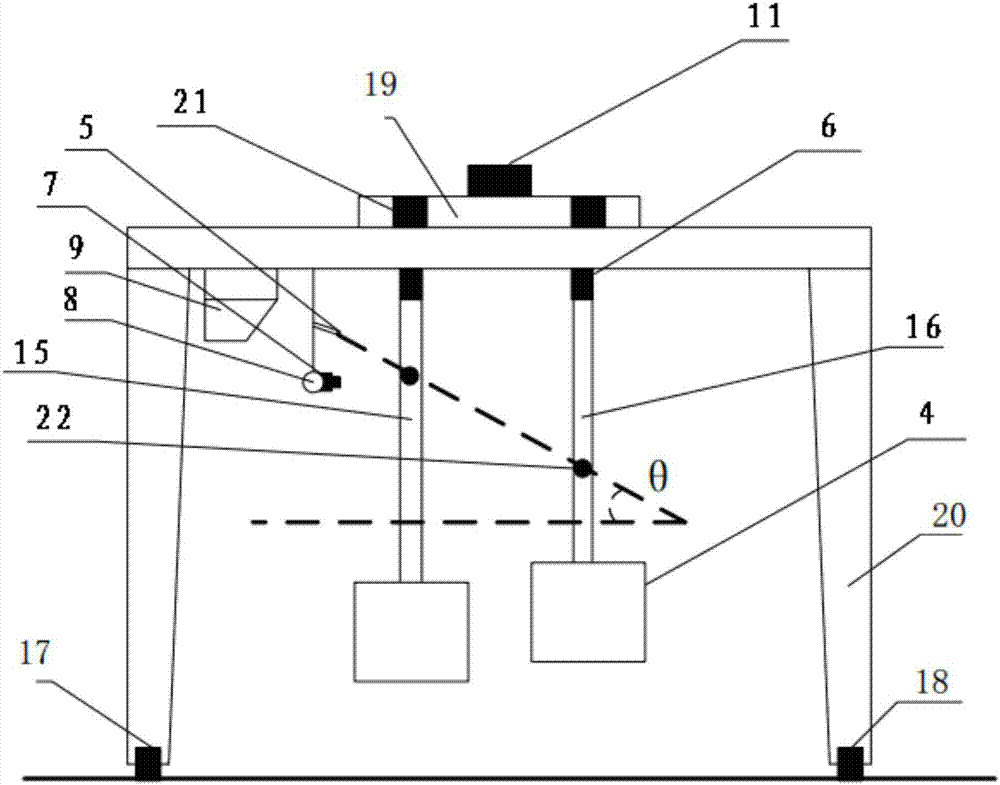

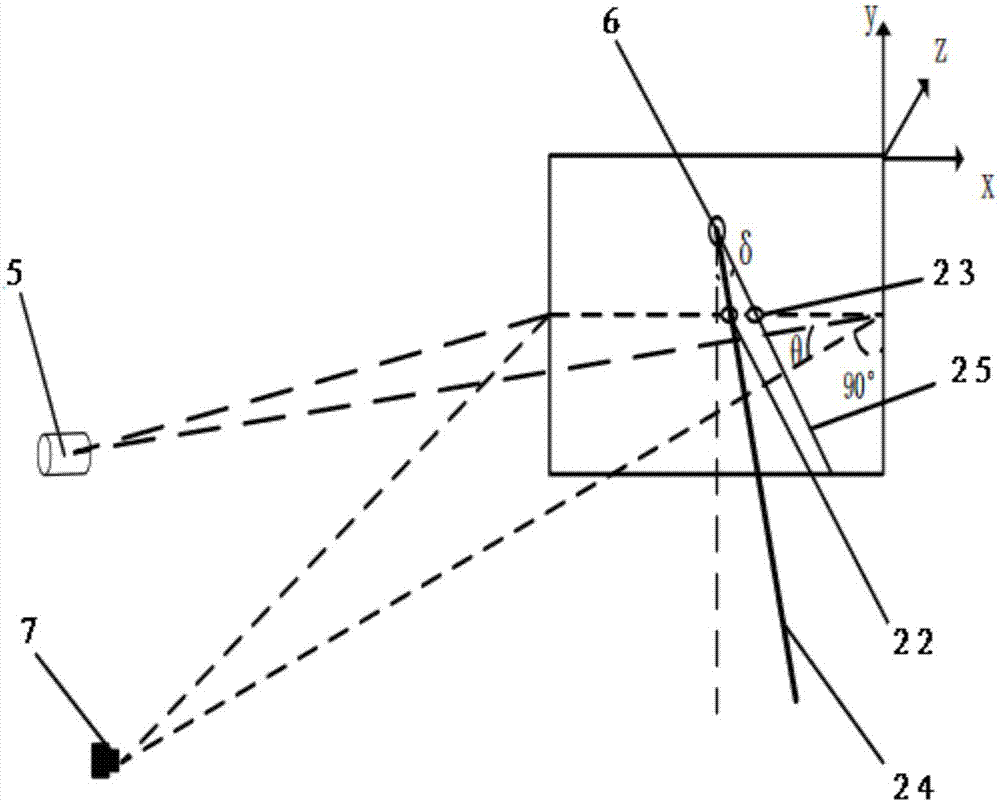

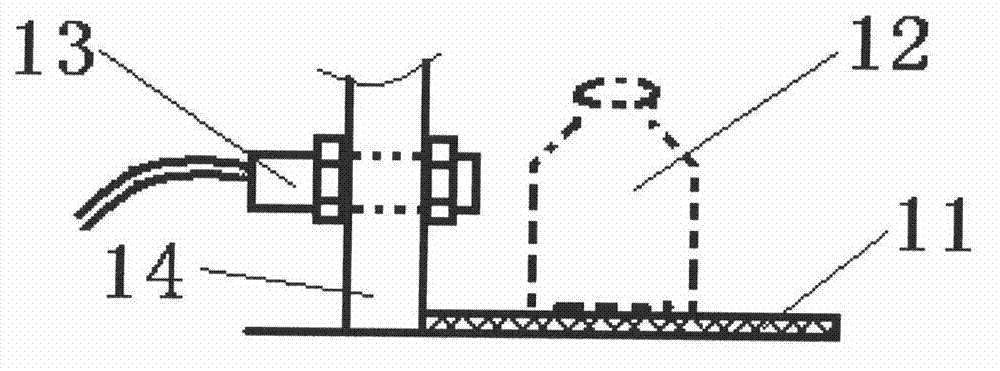

Measurement device for swing angle of multi-sling bridge crane and measurement method adopting device

InactiveCN107055326ADoes not affect measurement accuracySimple structureLoad-engaging elementsMeasurement deviceVideo image processor

The invention discloses a measurement device for the swing angle of a multi-sling bridge crane. The multi-sling bridge crane comprises a bridge crane trolley provided with first lifting ropes. The measurement device for the swing angle of the multi-sling bridge crane is characterized in that the measurement device comprises a swing angle calculation and control computer, a fan-shaped plane infrared light emitter, a swing angle detection camera, lifting rope vertex markers and a video image processor; the fan-shaped plane infrared light emitter is used for emitting fan-shaped infrared light, and the light encounters one or more of the first lifting ropes, so that light spots are left; the swing angle detection camera is used for shooting images of the first lifting ropes; the video image processor is used for receiving the images of the first lifting ropes and finding the positions of the light spots and the lifting rope vertex markers; the swing angle calculation and control computer, the fan-shaped plane infrared light emitter and the video image processor are arranged on a second lifting rope, and the second lifting rope moves along with moving of the bridge crane trolley; and the swing angle calculation and control computer works out the position coordinates of the light spots and the lifting rope vertex markers, and thus a swing angle value is obtained. By adoption of the measurement device for the swing angle of the multi-sling bridge crane, the swing angle of the bridge crane can be detected accurately, and the measurement device has the advantages of being low in cost and high in antijamming capability.

Owner:SHANGHAI MARITIME UNIVERSITY

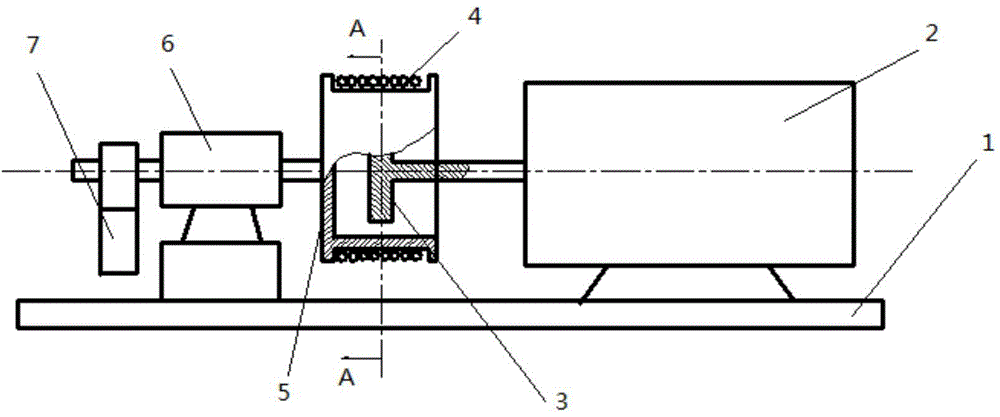

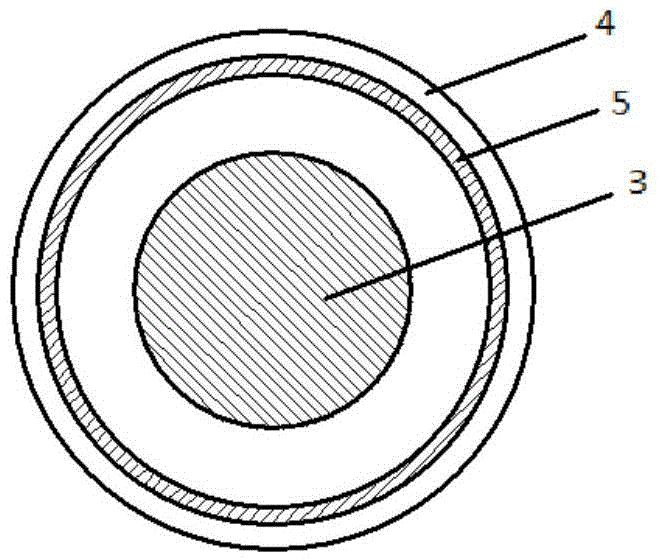

Small-sized ultra-high-speed motor test loading device

InactiveCN104697686ANo friction lossSimple structureWork measurementTorque measurementMagnetic field couplingDynamometer

The invention discloses a small-sized ultra-high-speed motor test loading device which comprises a base, a motor, an eddy-current disc, an exciting winding, an exciting sleeve, a support and a dynamometer load. The motor is arranged on the base and is connected with the eddy-current disc, the eddy-current disc is nested in the exciting sleeve, the eddy-current disc and the exciting sleeve are coaxially and parallelly arranged and transfer power through magnetic field coupling, the exciting sleeve is winded with the exciting winding, the exciting winding is connected with a voltage-adjustable direct-current power supply to produce exciting current, the exciting current produces an even unipolar magnetic field in the exciting sleeve, the magnetic field senses current in the rotary eddy-current disc to produce brake torque, a torque measurement system measures the brake torque, and the small-sized ultra-high-speed motor test loading device is provided with a rotation speed detection system for measuring the rotation speed of the motor or the eddy-current disc. The small-sized ultra-high-speed motor test loading device is simple in structure, small in rotational inertia, almost free of additional radial force, convenient to install and capable of reducing vibration and noise and is suitable for performance testing of small-sized high-speed motors, and a dynamometer rotor is free of friction loss.

Owner:王晛

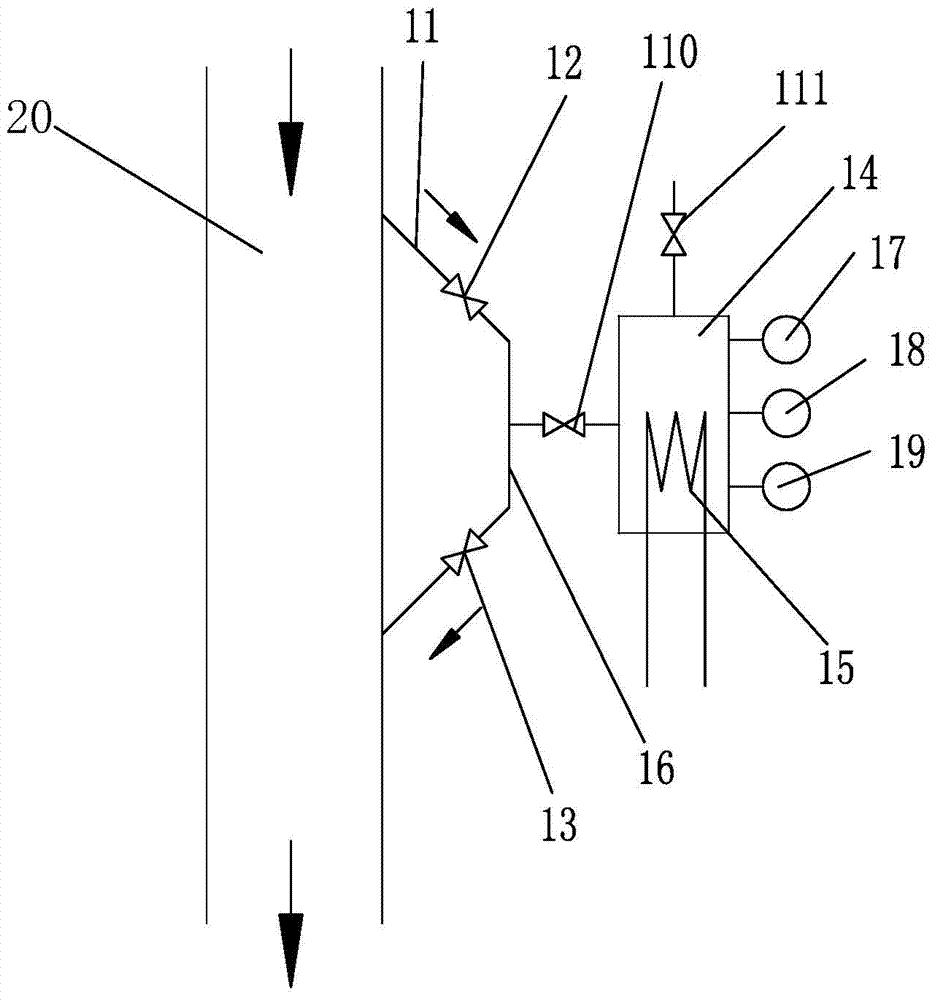

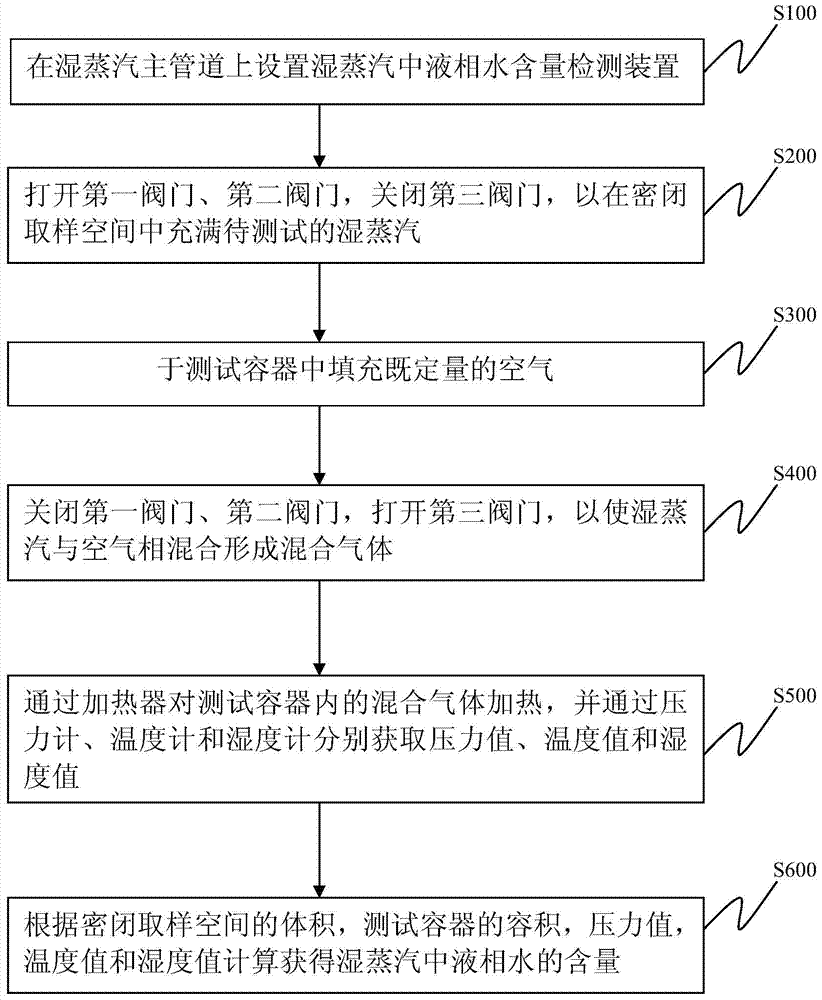

Liquid-phase water content detection device and liquid-phase water content detection method for wet steam

ActiveCN103592199AEasy to testDoes not affect measurement accuracyMaterial analysisWet steamEngineering

The invention relates to a liquid-phase water content detection device for wet steam. The liquid-phase water content detection device for the wet steam is arranged on a main wet steam pipeline and comprises a bypass pipeline, a first valve, a second valve, a test container and a heater, wherein the bypass pipeline is communicated with the main wet steam pipeline; the first valve and the second valve are arranged on the bypass pipeline; a set fixed quantity of air is filled in the test container; the heater is connected with the test container; the bypass pipeline between the first valve and the second valve forms a closed sampling space through a third valve; a pressure meter, a thermometer and a hygrometer are arranged on the test container; the test container is communicated with the closed sampling space through the third valve. The invention further provides a liquid-phase water content detection method for the wet steam. According to the liquid-phase water content detection device and the liquid-phase water content detection method, a state of tested gas can be measured on line, and only simple conventional accessory equipment is needed; the test process is simple and feasible; furthermore, calculation of heat is not needed; the heat dissipation loss cannot affect the measurement precision; the liquid-phase water content detection device and the liquid-phase water content detection method are suitable for the wet steam with various pressure levels.

Owner:CHINA IPPR INT ENG

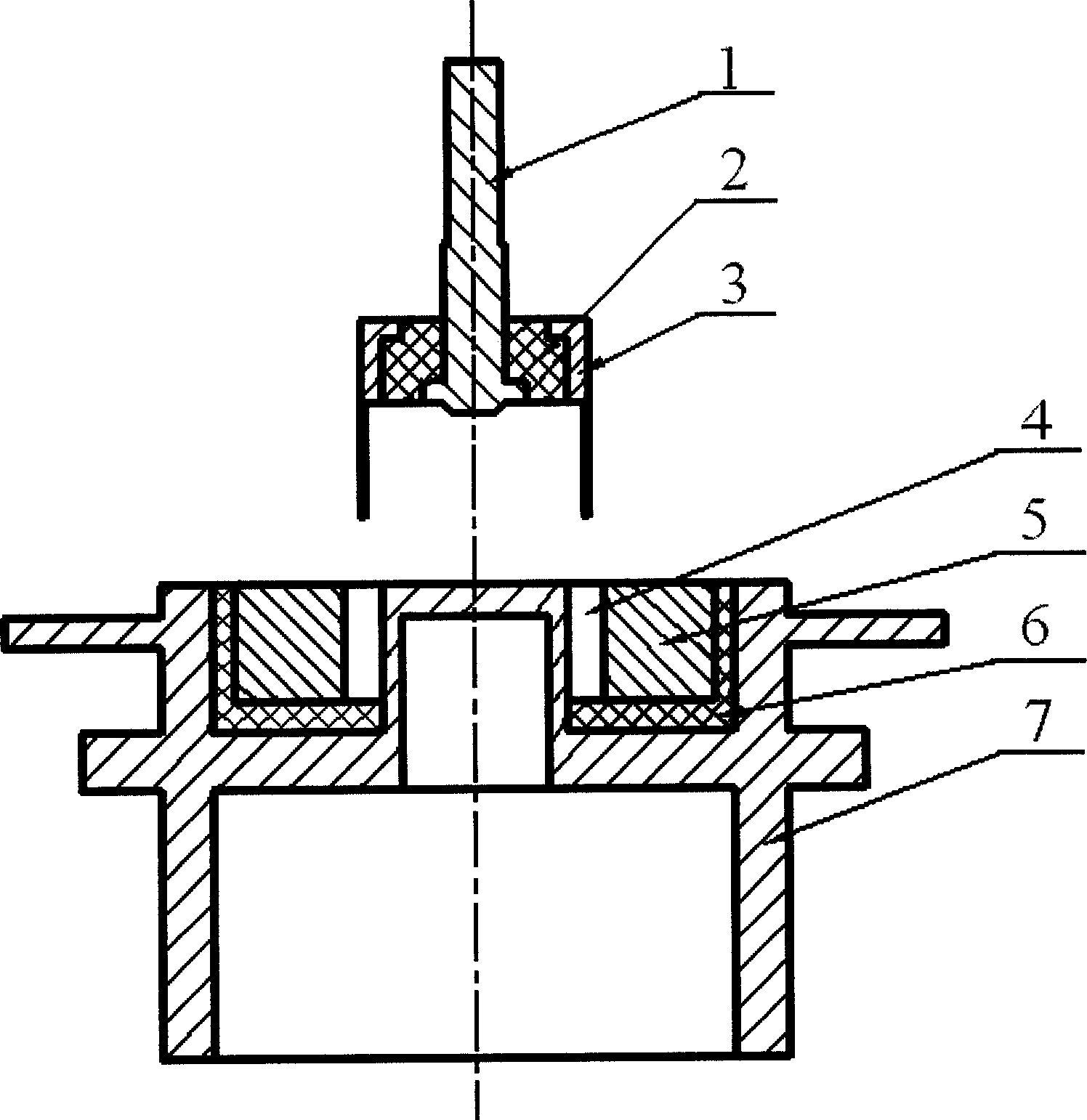

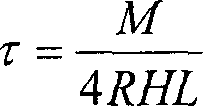

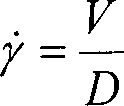

Measurement system for rheological property of electrorheological fluids (ERF)

InactiveCN1731140ASmall shear areaReduce dosageFlow propertiesElectrical field strengthHigh pressure

The invention relates to a measuring system in the field of measuring technology, which comprises: a rotating shaft, an upper part four fluorine insulating sleeve, a beam arm, a measuring space, a conductive ring, a lower part four fluorine insulating sleeve and a base seat. Wherein the rotating shaft, the upper part four fluorine insulating sleeve and the beam arm tightly matching forms the moving unit of the measuring system to displace the upper plate of the ammeter; the base seat adds the conductive ring and the lower part four fluorine insulating sleeve; the inner cylinder of the conductive ring, the lower part four fluorine insulating sleeve and the cylinder of the center of the base seat forms the measuring space; the electrorheological liquid is positioned inside the measuring space; the conductive ring is connected with the positive source; the base seat is connected with the negative source; the field density of the measuring space is radial radiation direction; the beam arm pokes into the measuring space to cut the electrorheological liquid along to the tangential direction.

Owner:SHANGHAI JIAO TONG UNIV

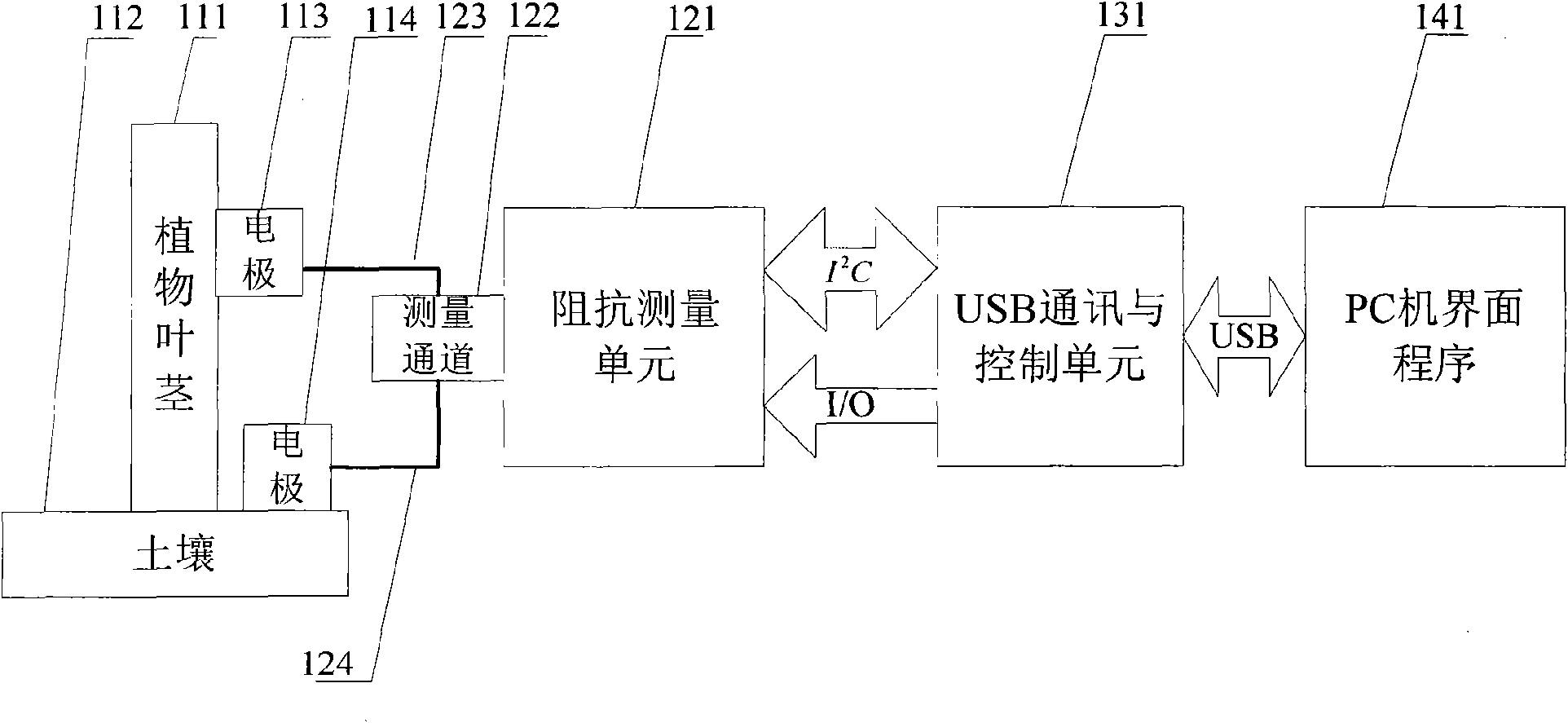

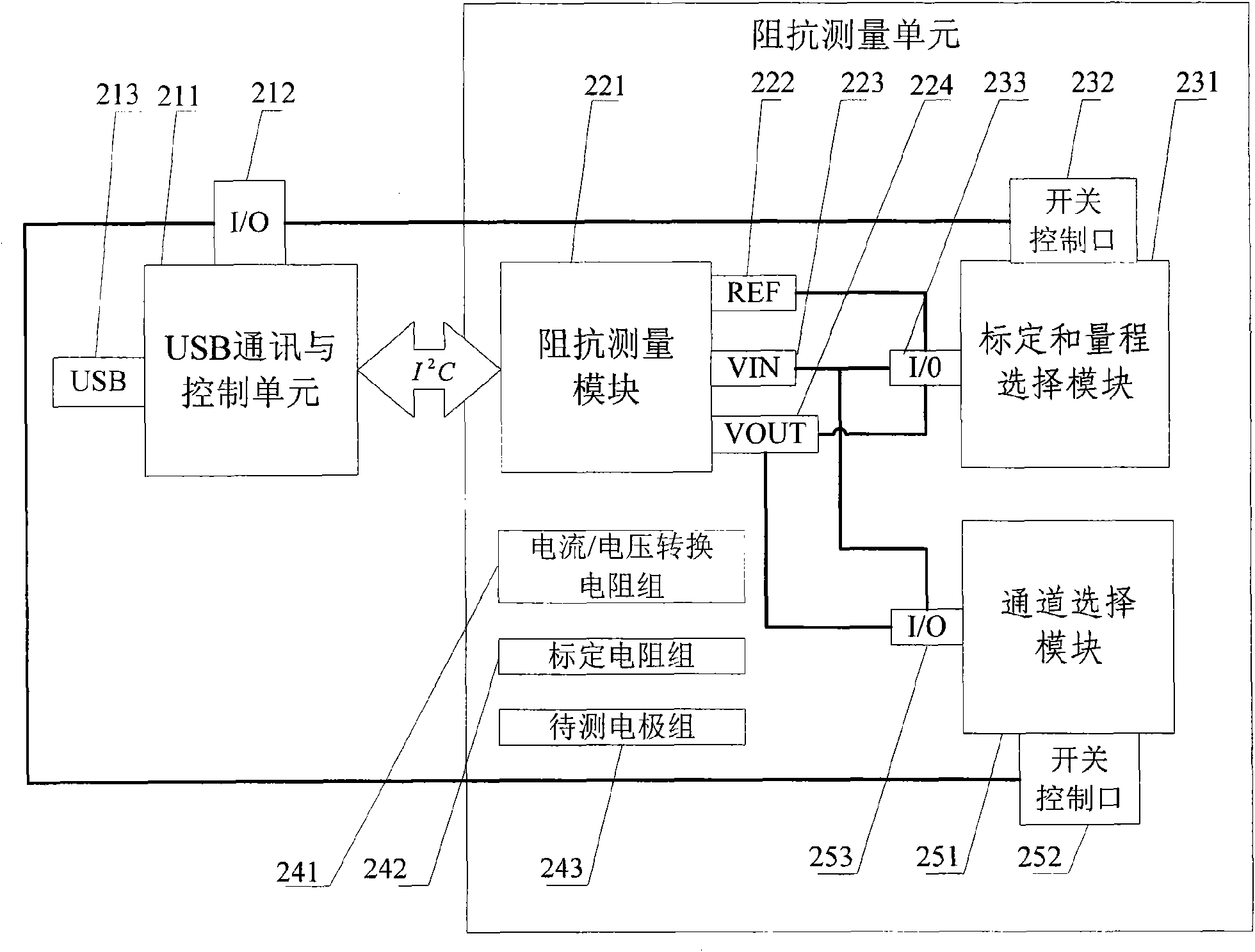

Multichannel plant hydropenia monitoring system based on impedance measurement

InactiveCN101666767AAvoid harmDoes not affect measurement accuracyComputer controlSimulator controlWater contentE communication

The invention relates to a multichannel plant hydropenia monitoring system based on impedance measurement. The system is a portable system comprising an electrode, a measuring lead, an impedance measuring unit, a USB communication and control unit and a personal computer, wherein the electrode adopts a metal sheet, is arranged at a plurality of parts of leaves and stems of a plant or inserted intosoil in a non-invasive way and connected to the impedance measuring unit by the single-core coaxial measuring lead; the impedance measuring unit comprises an impedance measuring module, a calibrationand measuring range selecting module and a channel selecting module and is supplied with power by a USB data line; and the USB communication and control unit realizes the communication between the impedance measuring unit and the personal computer. The system controls the switching-on and switching-off of a switch by an interface procedure on the personal computer, realizes the function of multichannel impedance measurement, acquires the change information of the impedance of a plurality of parts of the leaves and the stems of the plant and the soil along with water content and displays the hydropenia condition of the plant on the interface. The system can preset a time interval to carry out long-term monitoring so that the monitoring of the hydropenia condition of the plant is more portable.

Owner:BEIHANG UNIV

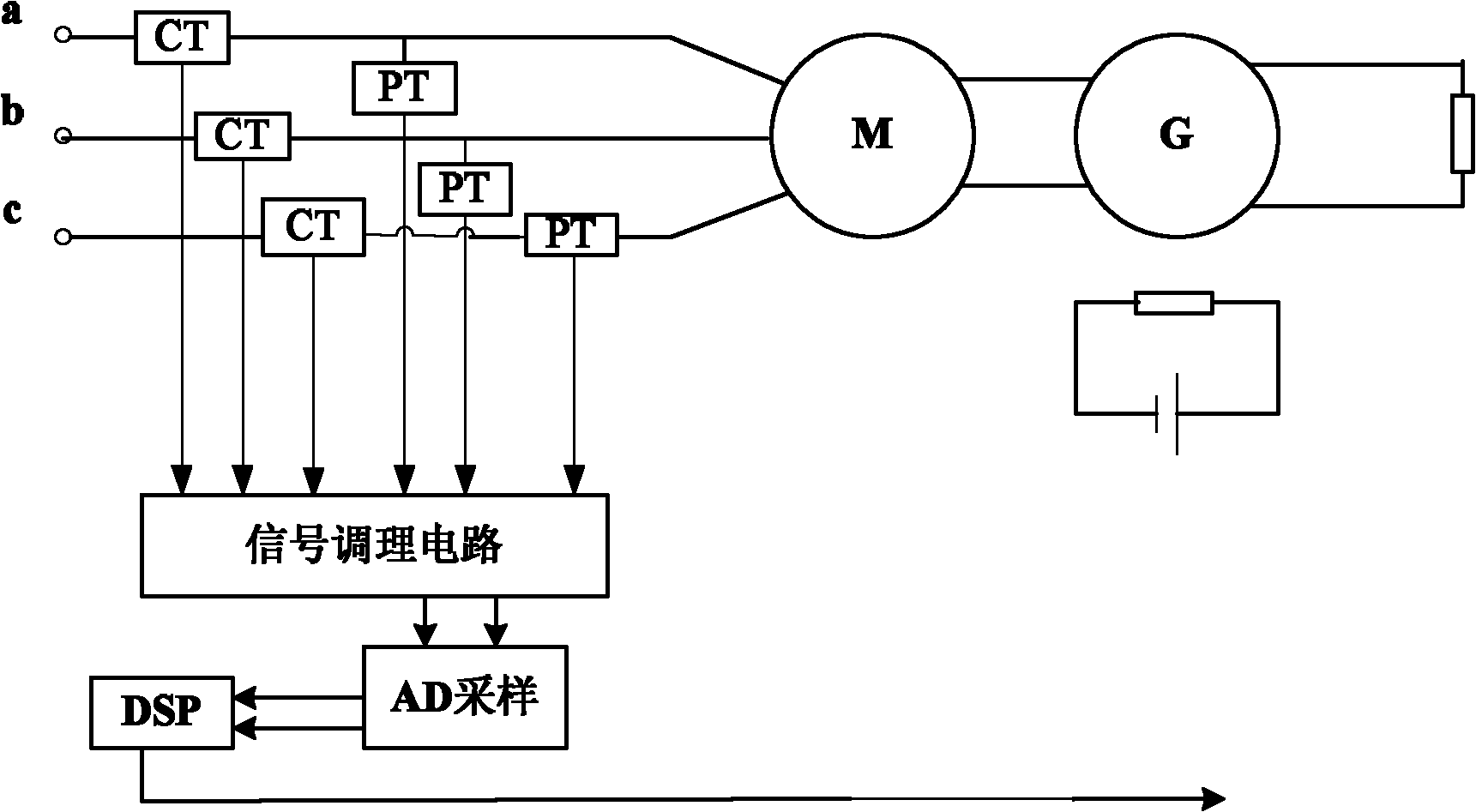

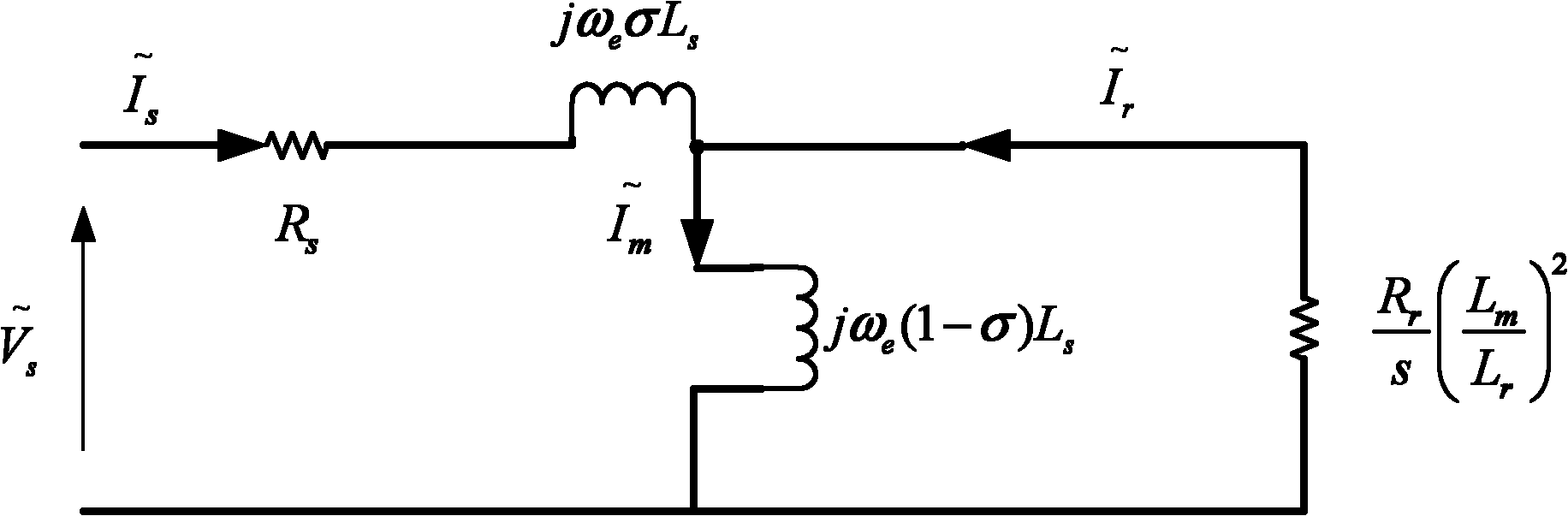

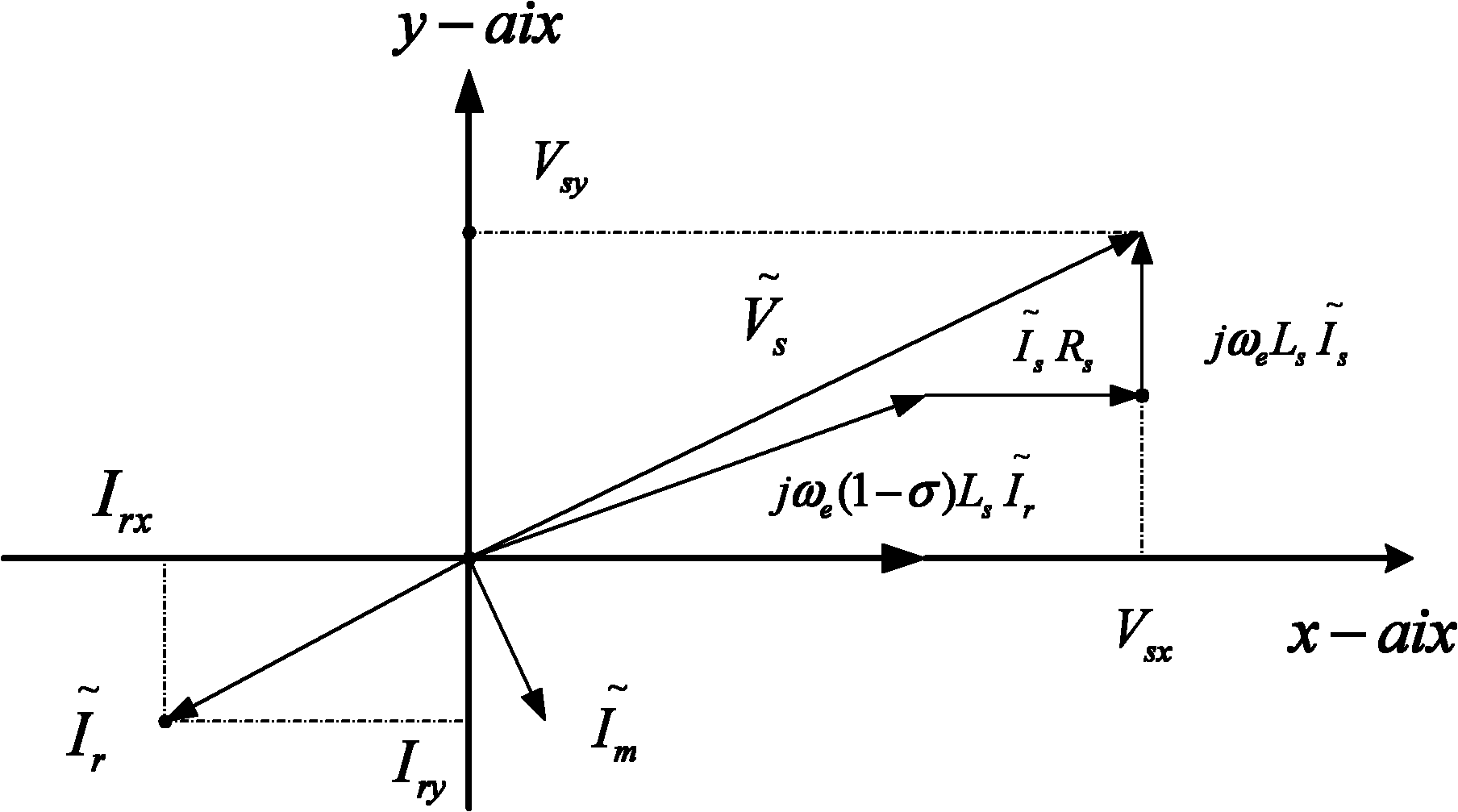

Rotor-groove harmonic analysis based method for identifying temperature of sensorless rotor for submersible motor

InactiveCN102072779AHigh working reliabilityWorking temperature real-time controlThermometers using electric/magnetic elementsUsing electrical meansStator voltageSignal conditioning circuits

The invention relates to a rotor-groove harmonic analysis based method for identifying the temperature of a sensorless rotor for a submersible motor, which belongs to the technical field of fundamental application combining power electronics modeling with motor control and solves the problem that the temperature identification of a rotor for a submersible motor greatly depends on motor parameters in the prior art. The method comprises the following steps of: firstly, acquiring the three-phase stator voltage and the three-phase stator current of the submersible motor; secondly, respectively processing the three-phase stator voltage and the three-phase stator current through a signal conditioning circuit, wherein processed signals are used as original stator current input signals and original stator voltage input signals; thirdly, converting frequency spectra of the original stator current input signals through a DSP (Digital Signal Processor), so as to obtain the harmonic frequency fseh of the rotor and further obtain the rotary speed s of the rotor; and fourthly, simultaneously calculating the inductance of the motor through an original one-phase stator voltage input signal vector and an original one-phase stator current input signal vector, so as to further obtain the temperature value of the rotor. The method provided by the invention is suitable for measuring the temperature of the rotor for the submersible motor.

Owner:HARBIN INST OF TECH

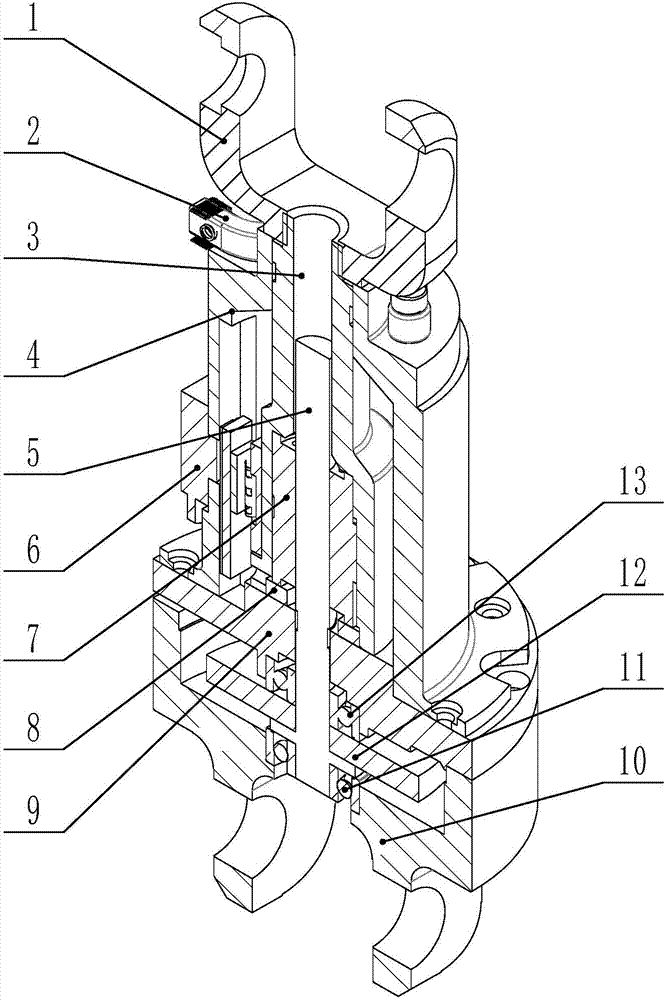

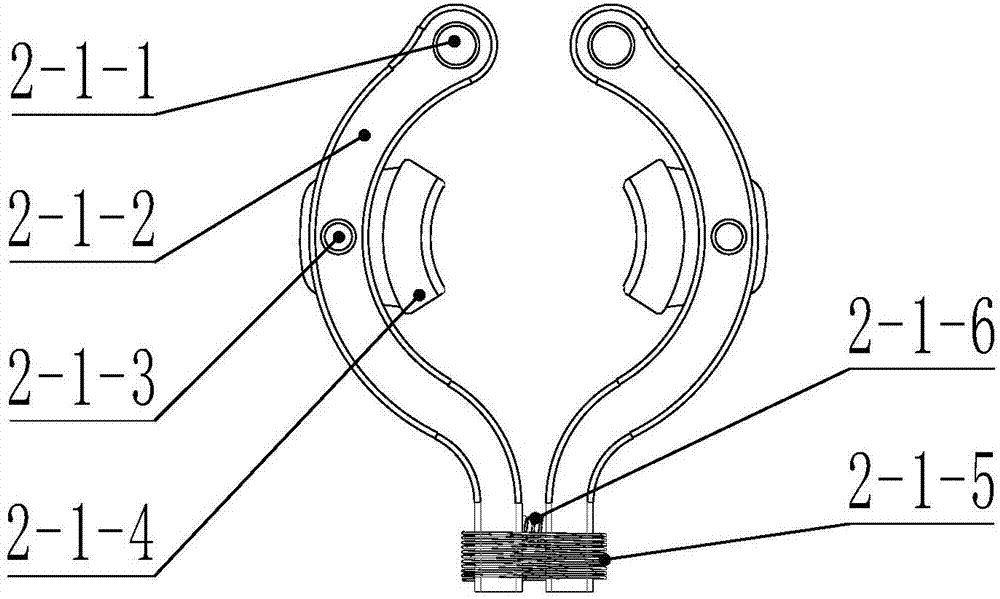

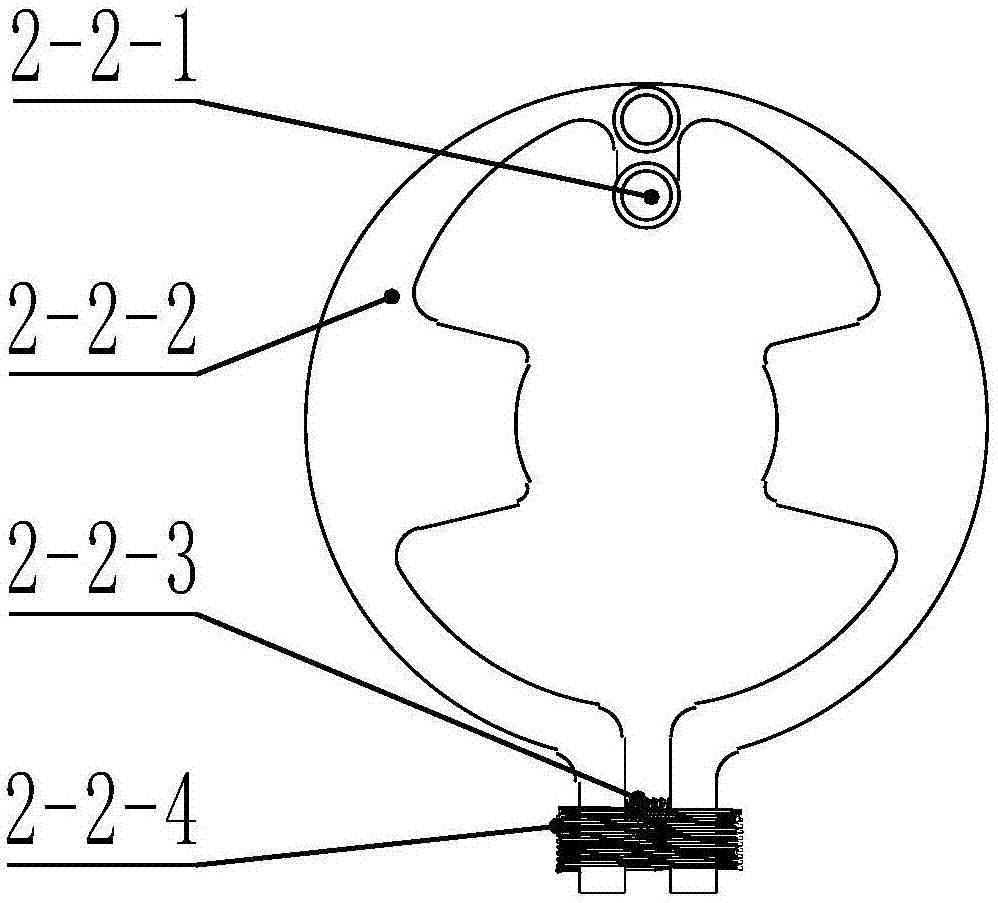

Precision actuator with impact-resistant locking device

ActiveCN107979222AAchieve shock-resistant lockingImplement mobile controlTelescopesStructural associationClosed loopMotor control

A precision actuator with an impact-resistant locking device comprises the impact-resistant locking device, a grating ruler swinging installation block, an extension rod installation head, an extension rod, a driving screw rod, a driving nut, a nut fastening piece, a first motor bearing, a main driving motor, a second motor bearing, a main shell, a motor upper shell and a base. The precision actuator has an impact-resistant locking function, a locking block and the extension rod are locked by a matched groove under a locking state, impact bearing employs a contact form, and the impact-resistant capability can be improved; by employing a fuse mechanism, extra motor control is reduced, and the control difficulty is reduced; and position feedback fully-closed loop is achieved, meanwhile, theextension rod can freely rotate at a small angle, the measurement accuracy cannot be affected, and the actuator is suitably applied to a multi-dimensional gesture adjustment platform.

Owner:YANSHAN UNIV

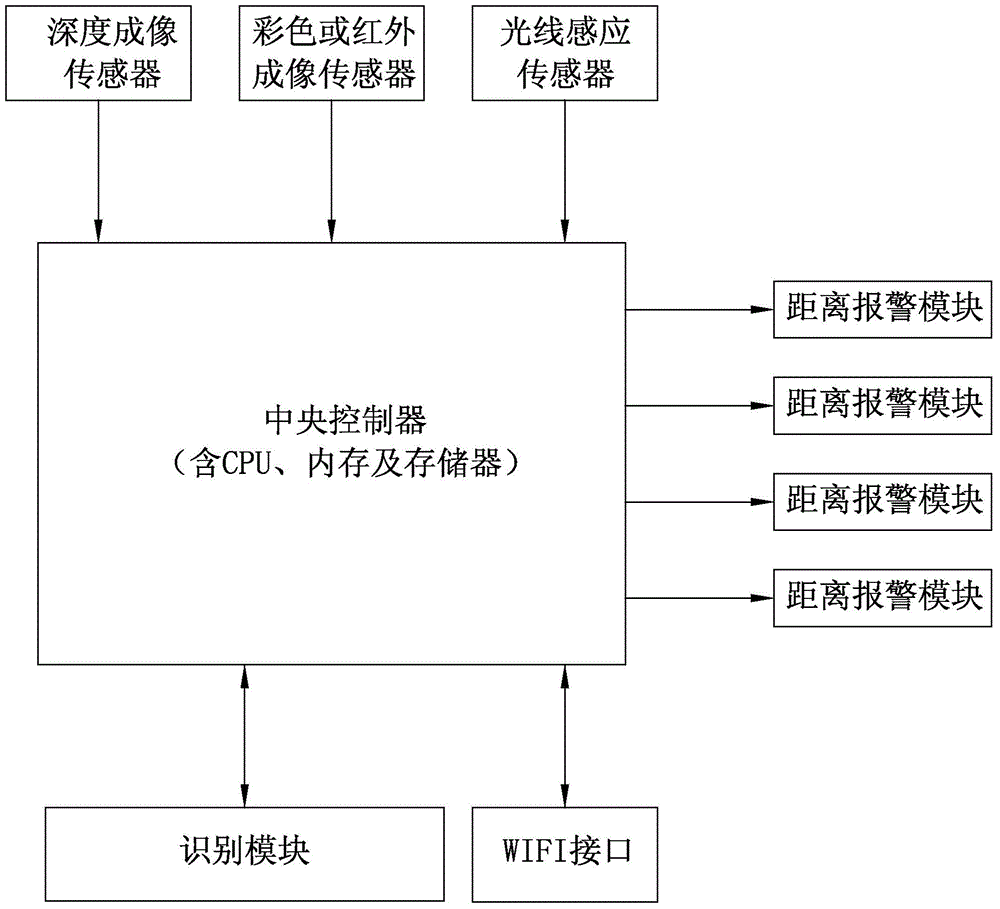

Intelligent table lamp with myopia prevention function

ActiveCN104952221ANo physical burdenAccurate measurementElectric circuit arrangementsLighting elementsPhysical medicine and rehabilitationEngineering

The invention provides an intelligent table lamp with a myopia prevention function. The intelligent table lamp with the myopia prevention function can acquire a read-write posture of a person who is tested in real time, meanwhile, can accurately analyze the read-write posture and sends out a warning when the read-write posture of the person is abnormal. The table lamp comprises a light source, a lamp pole and a lamp holder, wherein an intelligent myopia-preventing pre-warning device is mounted on the lamp pole or the lamp holder, the intelligent myopia-preventing pre-warning device comprises an input device, a storage module, a warning module and a central processor, the input device can input a real-time read-write posture of a user into a recognition module arranged in a computer in a color and depth dual-mode image information manner; the storage module can store measurement data corresponding to the real-time read-write posture of the user and standard parameters corresponding to a standard read-write posture respectively or concentratedly; the warning module is used for outputting an analysis result of the real-time posture, corresponding to the measurement data beyond a set range of the standard parameters, of the user through an audio signal. The table lamp can effectively acquire the posture of a teenager during reading and writing, gives a warning when the posture is incorrect, can measure the distance from the eyes of the user to a book accurately and has a positive meaning for myopia prevention.

Owner:SHENZHEN UNIV

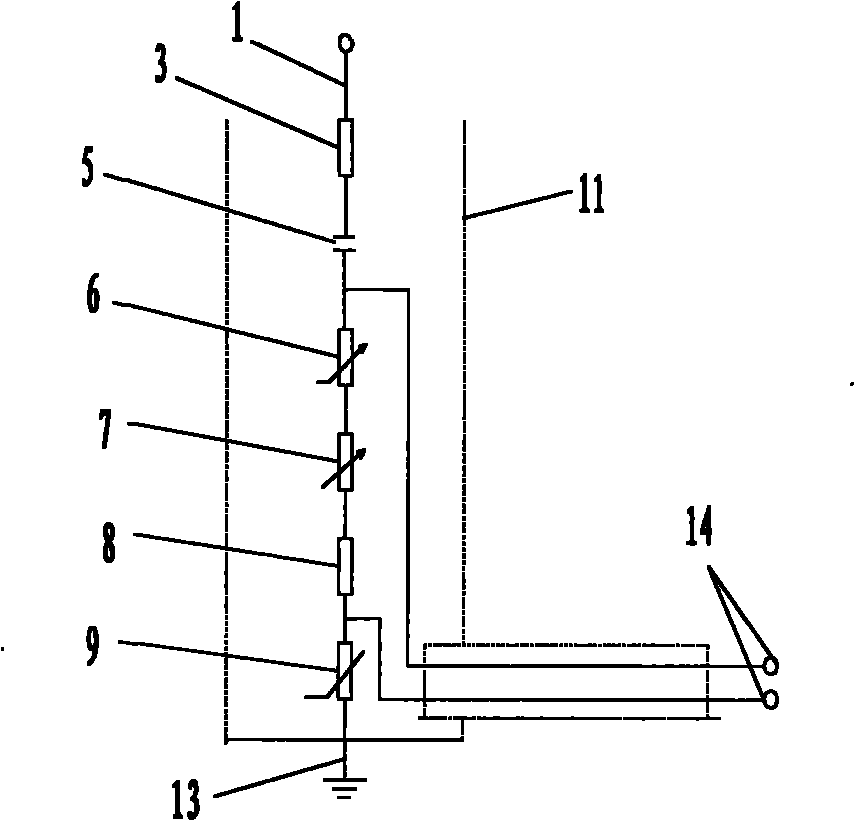

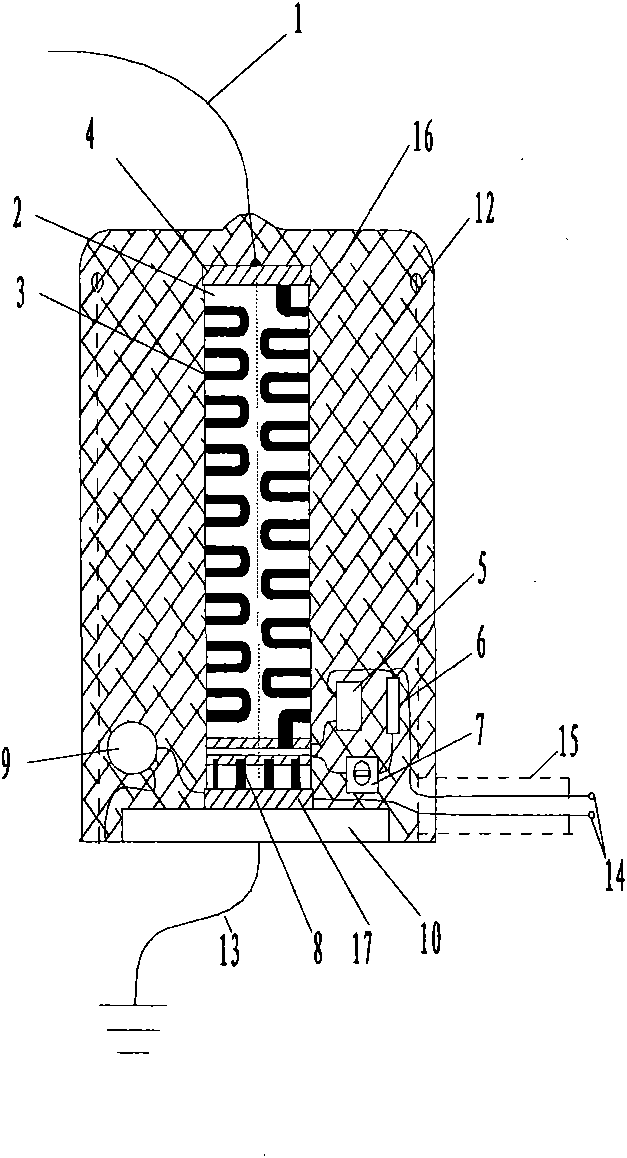

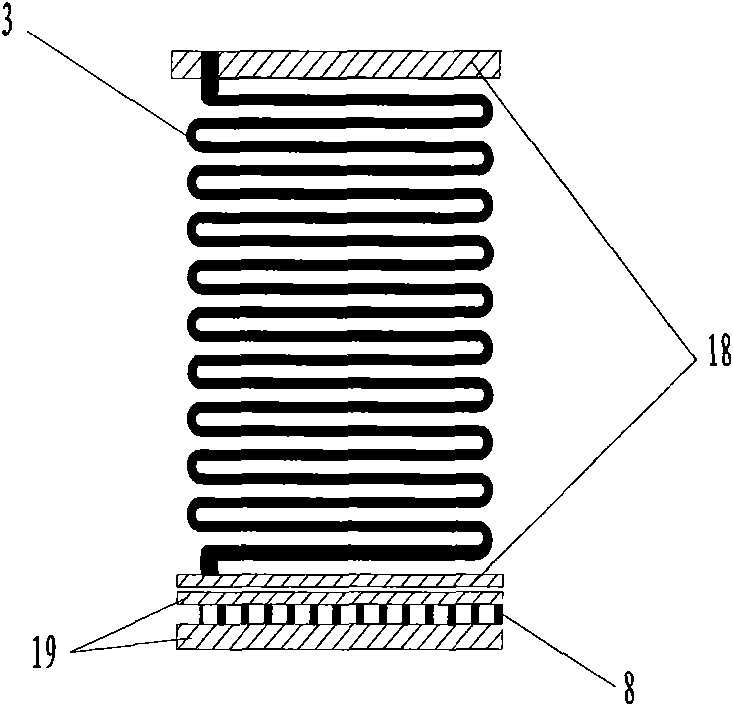

10 kV passive electronic voltage transformer

ActiveCN101901681AImprove shielding effectReduce offsetTransformersVoltage/current isolationTransformerLow voltage

The invention discloses a 10 kV passive electronic voltage transformer which does not need an external adjusting circuit board and has stable electrical parameters. In an insulator, a high-voltage insulated conductor, a high-voltage section resistor, a phase-shifting capacitor, a thermistor and a trimmer resistor are connected with a low-voltage section resistor in series; the joint of the phase-shifting capacitor and the thermistor and the lower end of the low-voltage section resistor respectively lead out a signal line; the two ends of a piezoresistor are respectively connected with the low-voltage section resistor and to ground; the low-voltage section resistor and the high-voltage section resistor are manufactured on the same ceramic tube; and the low-voltage section resistor, the high-voltage section resistor, the phase-shifting capacitor, the thermistor, the piezoresistor and the trimmer resistor are arranged in an integral metal shielding looped network. The electronic voltage transformer is used for electric energy metering in the 10 kV power system, is used for safe and reliable basic electrical appliances for protecting user power equipment and has obvious energy saving effect.

Owner:LANGFANG GAOSHAN ELECTRONICS TECH

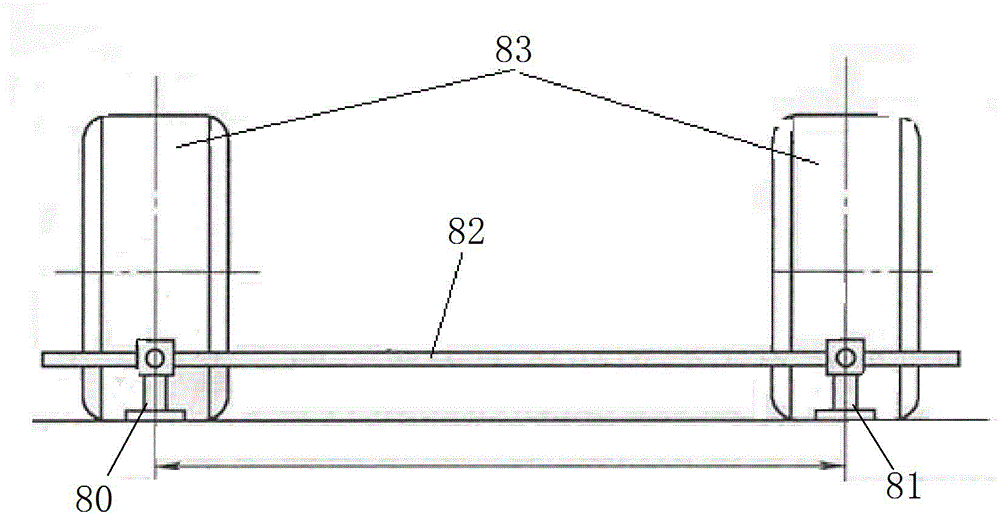

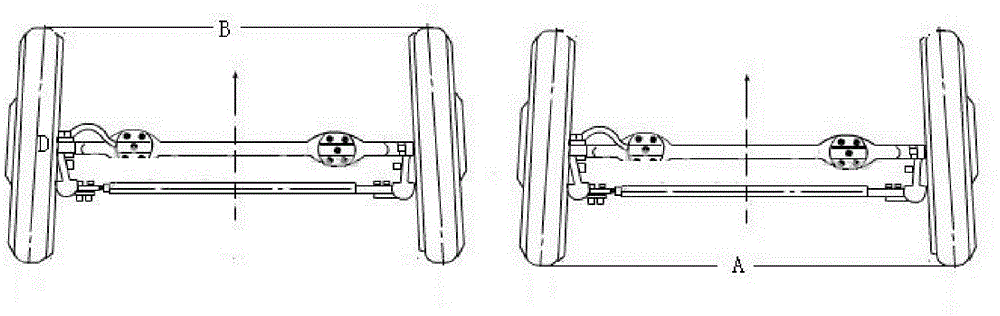

Automotive toe-in measuring device and automotive toe-in measuring method using same

ActiveCN104792555ADoes not affect measurement accuracySimple structureAngles/taper measurementsVehicle wheel testingMeasurement deviceEngineering

The invention relates to an automotive toe-in measuring device and an automotive toe-in measuring method using the same. The automotive toe-in measuring device comprises a base; a vertical arm capable of telescoping in the vertical direction is arranged on the base; a cross arm capable of telescoping in the front-rear direction is connected to the vertical arm; the cross arm is provided with an aligning device used for aligning the center of a wheel hub; the cross arm is provided with a graduation ruler capable of extending in the left-right direction and telescoping in the left-right direction; the graduation ruler is provided with a measuring head used for positioning and measuring a fixed point. The invention aims to solve the technical problem that the exiting wheel tire worn affects measuring precision.

Owner:ZHENGZHOU YUTONG BUS CO LTD

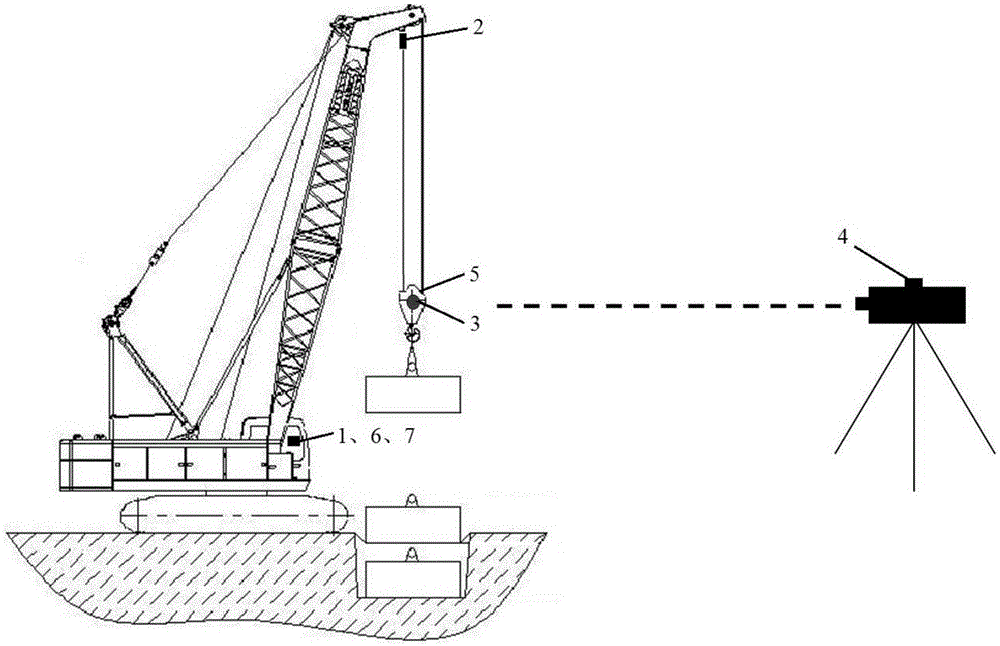

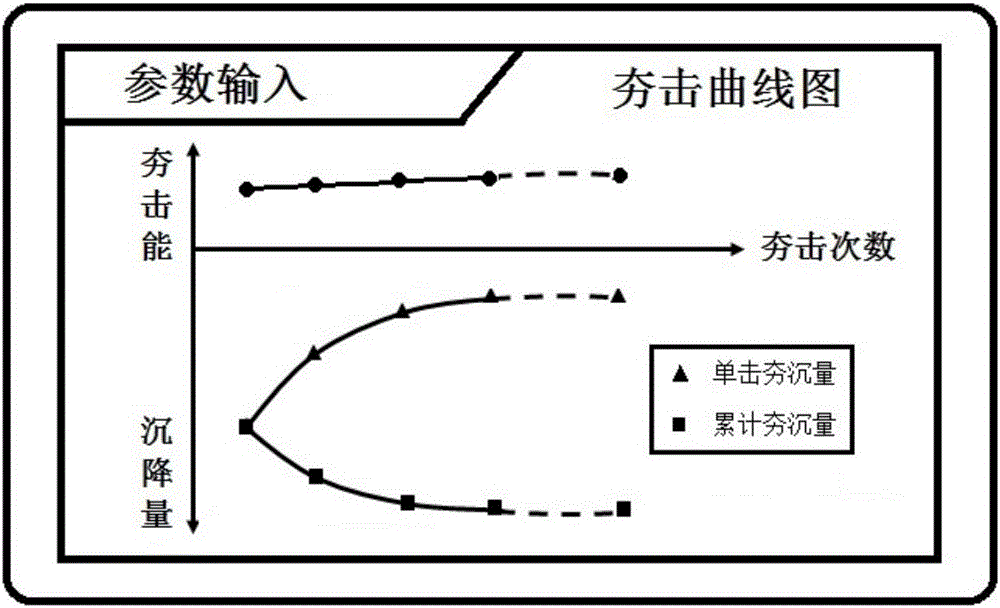

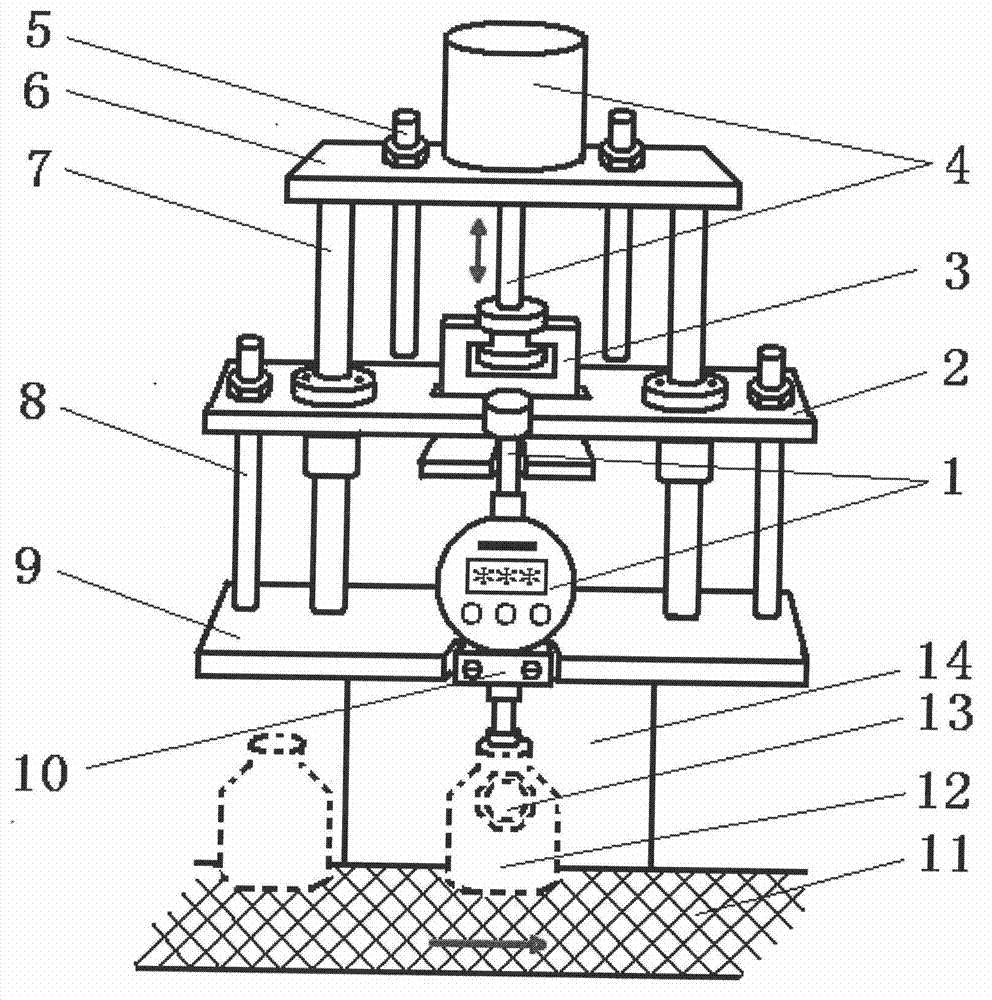

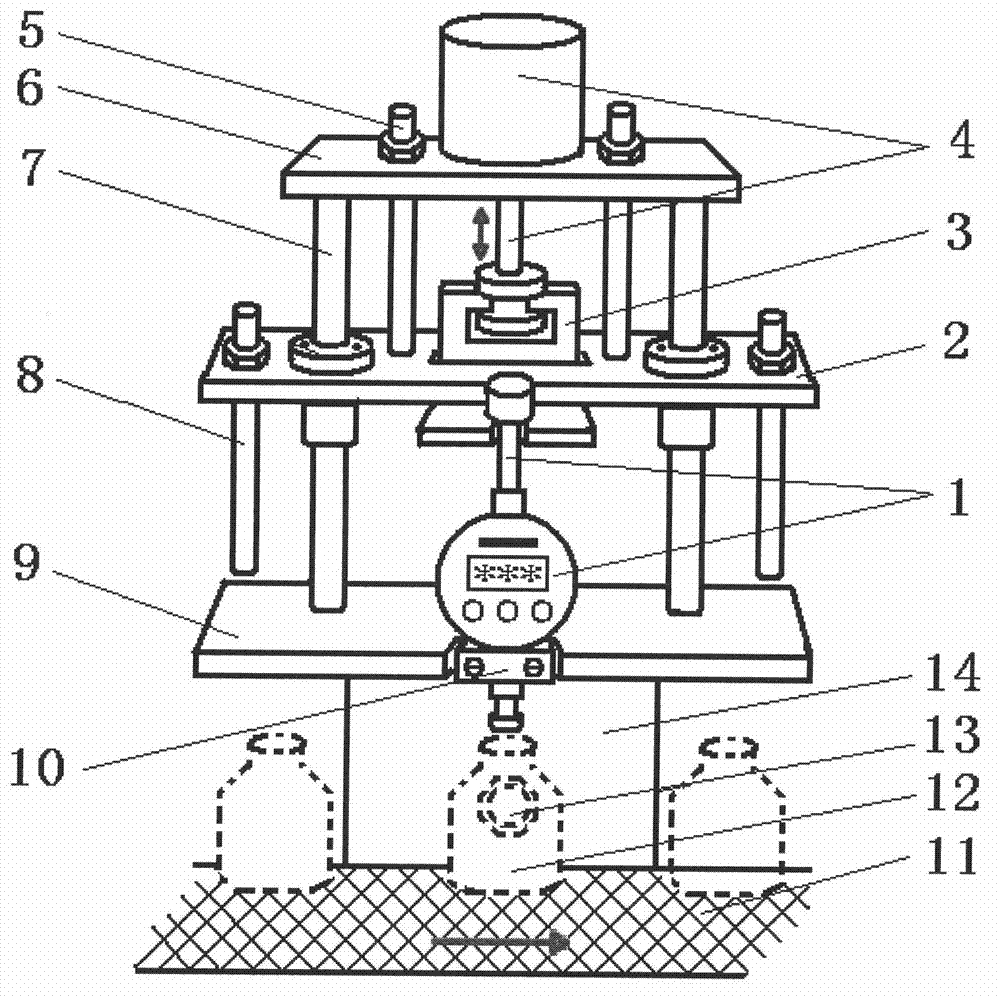

Dynamic compaction machine construction and operation parameter acquiring system and operating method thereof

ActiveCN106500770ASave human effortLow costMeasurement devicesSoil preservationProgrammable logic controllerReal time display

The invention comprises a dynamic compaction machine construction and operation parameter acquiring system and an operating method thereof. The dynamic compaction machine construction and operation parameter acquiring system is characterized in that: a programmable logic controller PLC is connected with a signal receiving device, an optical encoder, a tension sensor, a buzzer and a display, and the signal receiving device communicates with a signal transmitting device; the optical encoder is connected with a pulley above a pounder hammer hook, and the tension sensor is connected with a steel wire rope; and the signal transmitting device is arranged outside a dynamic compaction influence range and is leveled, and is aligned with a dynamic compaction machine. The dynamic compaction machine construction and operation parameter acquiring system and the operating method thereof have the beneficial effects that precise acquisition and dynamic real-time display of tamping settlement, accumulated tamping settlement, pounder hammer weight, falling distance and tamping energy data can be realized, the detection result cannot generate measurement errors due to the influence of factors such as sagging of the dynamic compaction machine.

Owner:SHANDONG UNIV

Method for manufacturing quartz crystal wafer for high-precision piezoelectric transducer

InactiveCN104526889AHigh precisionImprove stabilityAfter-treatment detailsLapping machinesStress relievingX-ray

The invention provides a method for manufacturing a quartz crystal wafer for a high-precision piezoelectric transducer. The method comprises the following steps: (1) material selection, wherein raw materials with the number of etch channels smaller than 50 are selected; (2), material orientation cutting, wherein the selected raw materials are oriented on an X-ray orientation device in the needed crystal orientation, and then a multiline cutting manner is used for cutting the quartz crystal into the wafer with the needed thickness; (3), material forming, wherein the wafer is machined into a needed shape; (4), surface treatment, wherein the formed wafer is ground by a green silicon carbide grinding material with the gradually-decreased granularity, and then polished; and (5), stress relieving. Through the five steps of material selection-material orientation cutting-material forming-surface treatment-stress relieving, the manufactured quartz crystal wafer is high in precision and stability and completely can meet needs of the piezoelectric transducer, and the processing steps can reach the higher processing precision.

Owner:SICHUAN SANTAI CRYSTAL ELECTRONICS

Perforating bullet height automatic measuring device

ActiveCN103162589APush and pullRealize automatic measurementMechanical measuring arrangementsLower limitMeasurement device

A perforating bullet height automatic measuring device comprises a conveying belt, a digital dial gauge, a connecting frame, an air cylinder and a support. The perforating bullet height automatic measuring device is characterized in that the support is formed by a support upper panel, a support lower panel, a supporting column and a support vertical board provided with an approach switch, wherein the support upper panel and the support lower panel respectively support and position the air cylinder and the digital dial gauge, the upper end of the connecting frame is closely connected with the air cylinder, and the lower end of the connecting frame is movably connected with the digital dial gauge. A movable panel is arranged on the connecting frame, and an upper limit rod and a lower limit rod are respectively arranged on the support upper panel and the movable panel, wherein the upper limit rod and the lower limit rod can limit the vertical motion range of the movable panel. The air cylinder, the digital dial gauge, the conveying belt, the approach switch, and a computer are respectively electrically connected with a programmable logic controller (PLC). The digital dial gauge is enabled to be kept still and a measuring rod is enabled to move in a limited range during the measuring process, the air cylinder simply plays the role of pulling and pushing the connecting frame, and automatic measuring of the perforating bullet height on an assembly line is achieved through the controlling of the PLC. The perforating bullet height automatic measuring device is high in efficiency, low in cost and good in measuring stability.

Owner:CHINA JILIANG UNIV

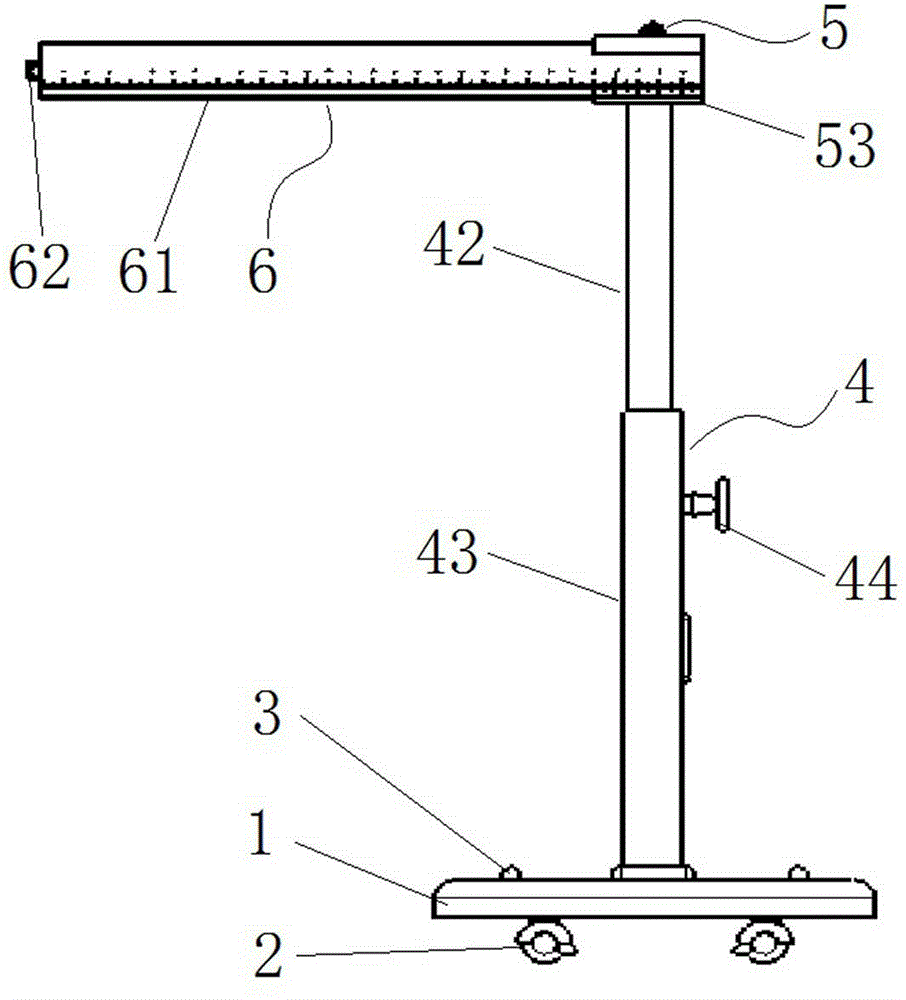

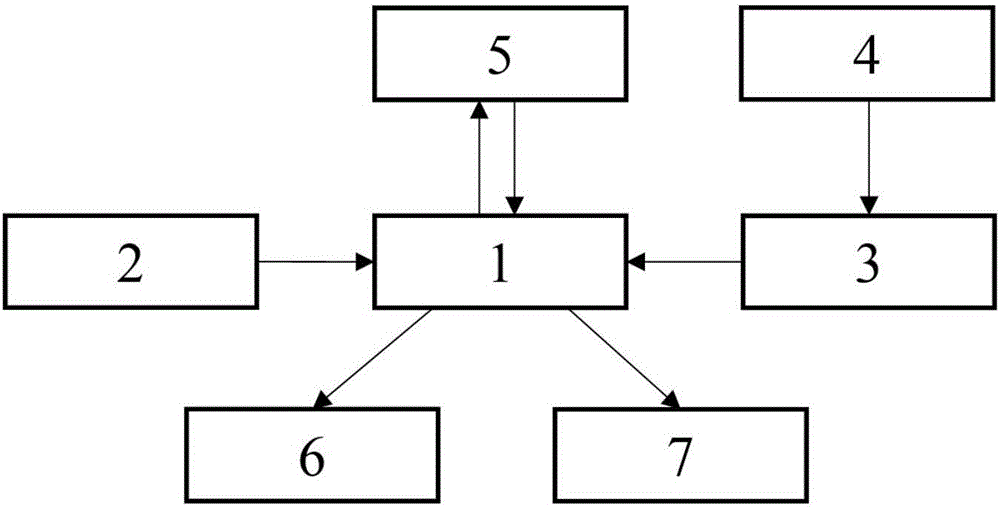

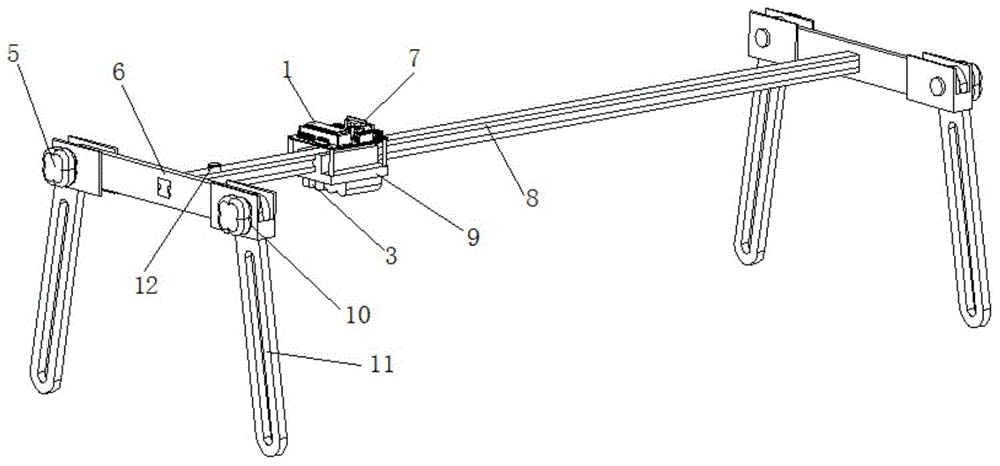

Agricultural land flatness measurement instrument and method

InactiveCN104536004AMeet data needsStrong battery lifeAcoustic wave reradiationTransceiverEngineering

The invention relates to the technical field of measurement, in particular to an agricultural land flatness measurement instrument and method. The agricultural land flatness measurement instrument comprises a supporting frame part, a single-chip microcomputer (1), an ultrasound transceiver (3), a temperature sensor and a digital display tube. According to the supporting frame part, a guide rail supporting leg (11) is connected with a guide rail supporting cross beam (6), and the connecting position is wrapped with a fastening piece (10) and fixed through a handle (5); the guide rail supporting cross beam (6) is matched with a guide rail (8) through a hole; a sliding block (9) is arranged on the guide rail (8) in a sliding mode; the single-chip microcomputer (1) is installed on a single-chip microcomputer main board (7) arranged above the sliding block (9), and the single-chip microcomputer main board (7) is provided with the temperature sensor and the digital display tube; the ultrasound transceiver (3) is arranged below the sliding block (9). The agricultural land flatness measurement instrument can work in a relatively bad environment while not affecting the accuracy of measurement, can carry out multi-point measurement at a time, and is high in efficiency, reliable in data, small in size, easy to assemble and portable.

Owner:CHINA AGRI UNIV

Method and device for measuring mass of solid in solid and liquid mixture

InactiveCN106404134AHigh measurement accuracyFew influence factors of errorVolume measurement apparatus/methodsWeighing apparatus for materials with special property/formChemistry

The invention relates to a method and device for measuring the mass of a solid in a solid and liquid mixture. The method comprises the following steps that a) the type of the solid in the solid and liquid mixture is determined, and the density Psolid of the solid is obtained by a table look-up or experiment method; b) the Volume Vmixutre and the mass Mmixture when the volume of the solid and liquid mixture equals Vm are measured; and c) according to that the volume of the solid and liquid mixture equals the sum of the volume of the solid and the volume of the liquid and that the mass of the of the solid and liquid mixture equals the sum of the mass of the solid and the mass of the liquid, an equation set is obtained, and values in the steps a) and b) are substituted into the equation set to obtain the Msolid. The method is simple and practical, realization approaches are diversified, both online measurement and static measurement can be realized, and the measuring precision is easy to control.

Owner:HUNAN CHENZHOU MINING CO LTD

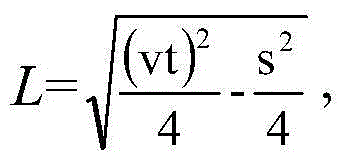

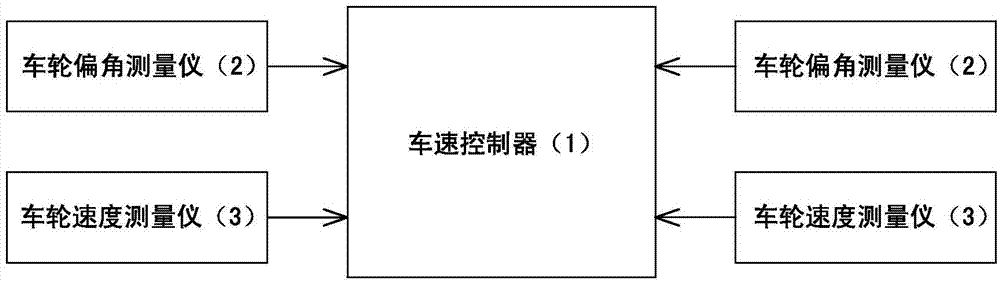

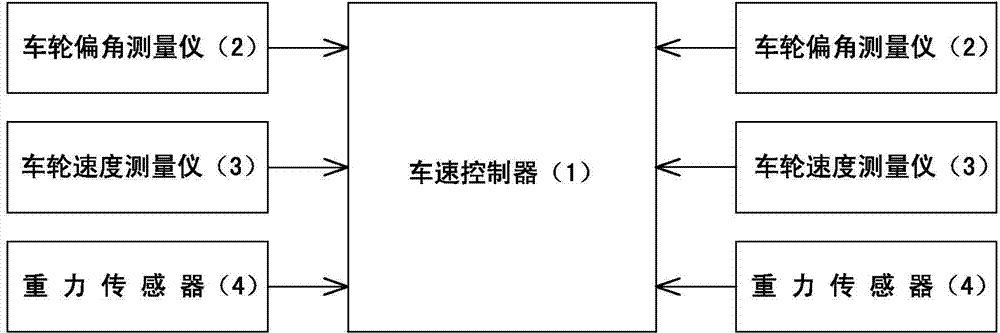

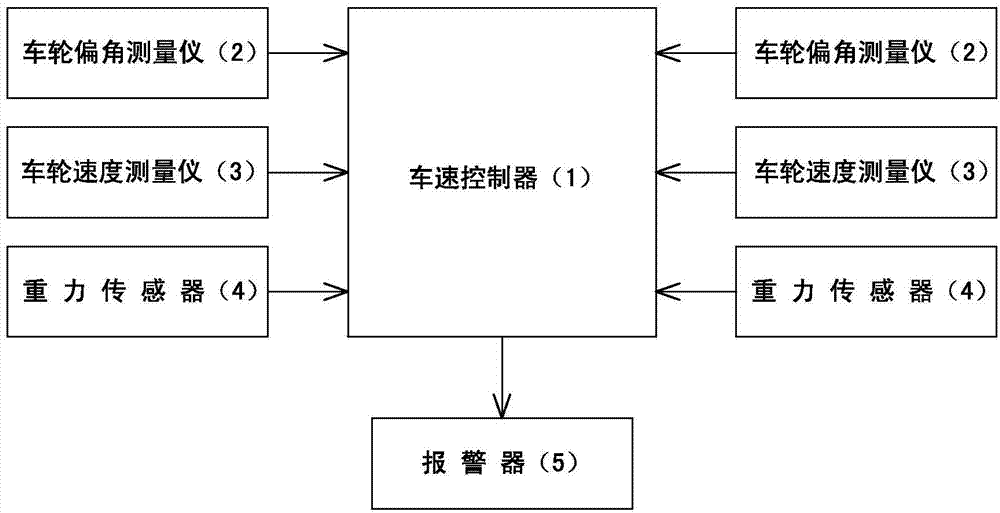

Automobile speed measuring device and automobile speed measuring and control method

ActiveCN104764897AAvoid computational difficultiesReduce system costLinear/angular speed measurementSpeed measurementAutomotive engineering

The invention discloses an automobile speed measuring device and an automobile speed measuring and control method. The automobile speed measuring device comprises an automobile speed controller, a wheel deflection measuring instrument, a wheel speed measuring instrument and a gravity sensor. The speed and the deflection angle of two front wheels are measured in real time, the speeds, of moving around an instantaneous center, of the left front wheel and the right front wheel of an automobile generated when the automobile turns are converted into the moving speeds of the automobile center, the average value of the two automobile speeds at the automobile center serves as the actual running speed generated when the automobile turns, and meanwhile, the automobile speed can be controlled according to the stress condition of two front wheel shafts. According to the automobile speed measuring device and the automobile speed measuring and control method, the problems that in the prior art, the transmission box output shaft rotating speed is adopted to be converted into the automobile speed, the automobile speed accuracy is low when the automobile turns, the control accuracy is lowered, and the automobile running accidents are caused easily are solved effectively, and the device and the method have very high practical value.

Owner:YANCHENG INST OF TECH

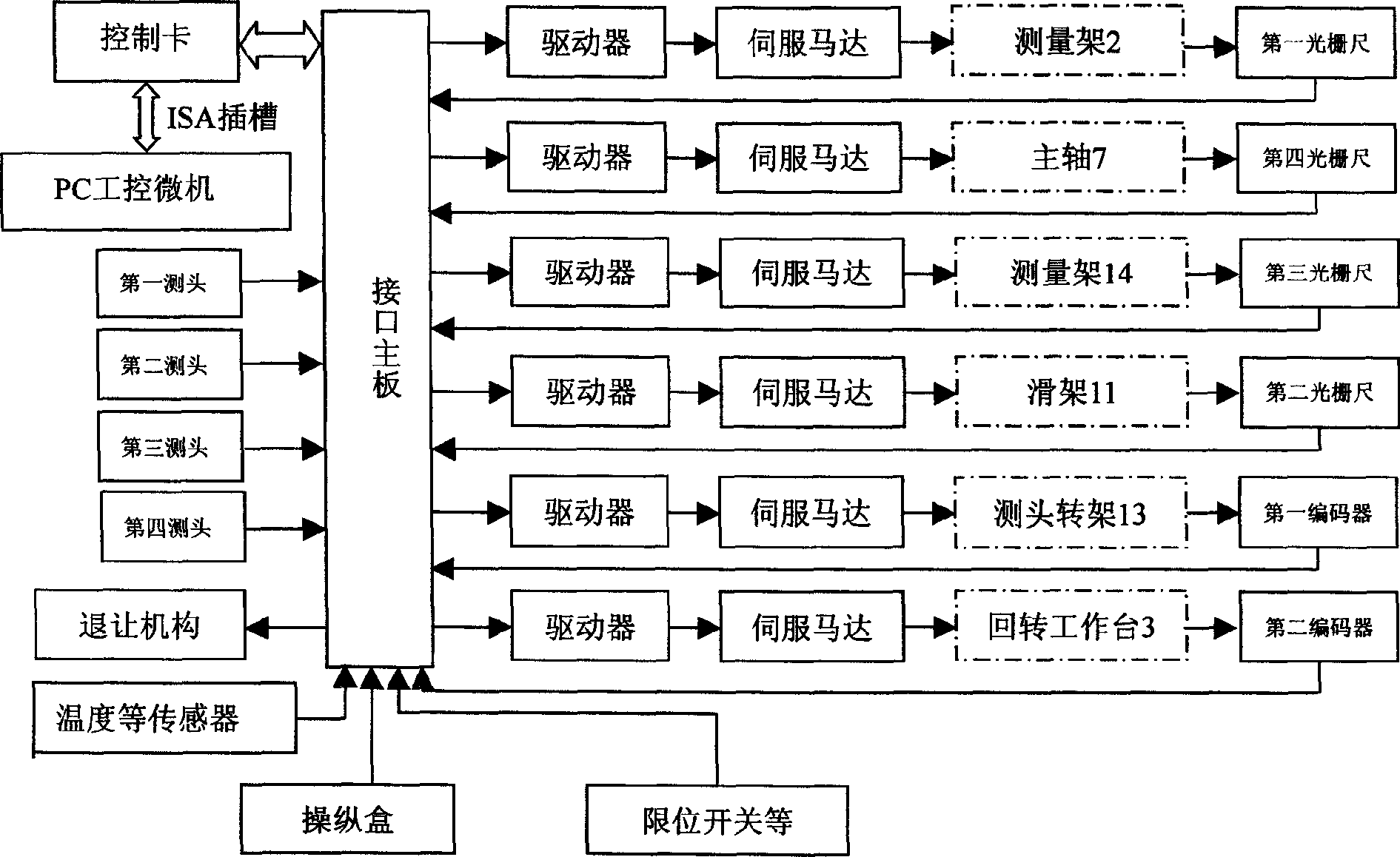

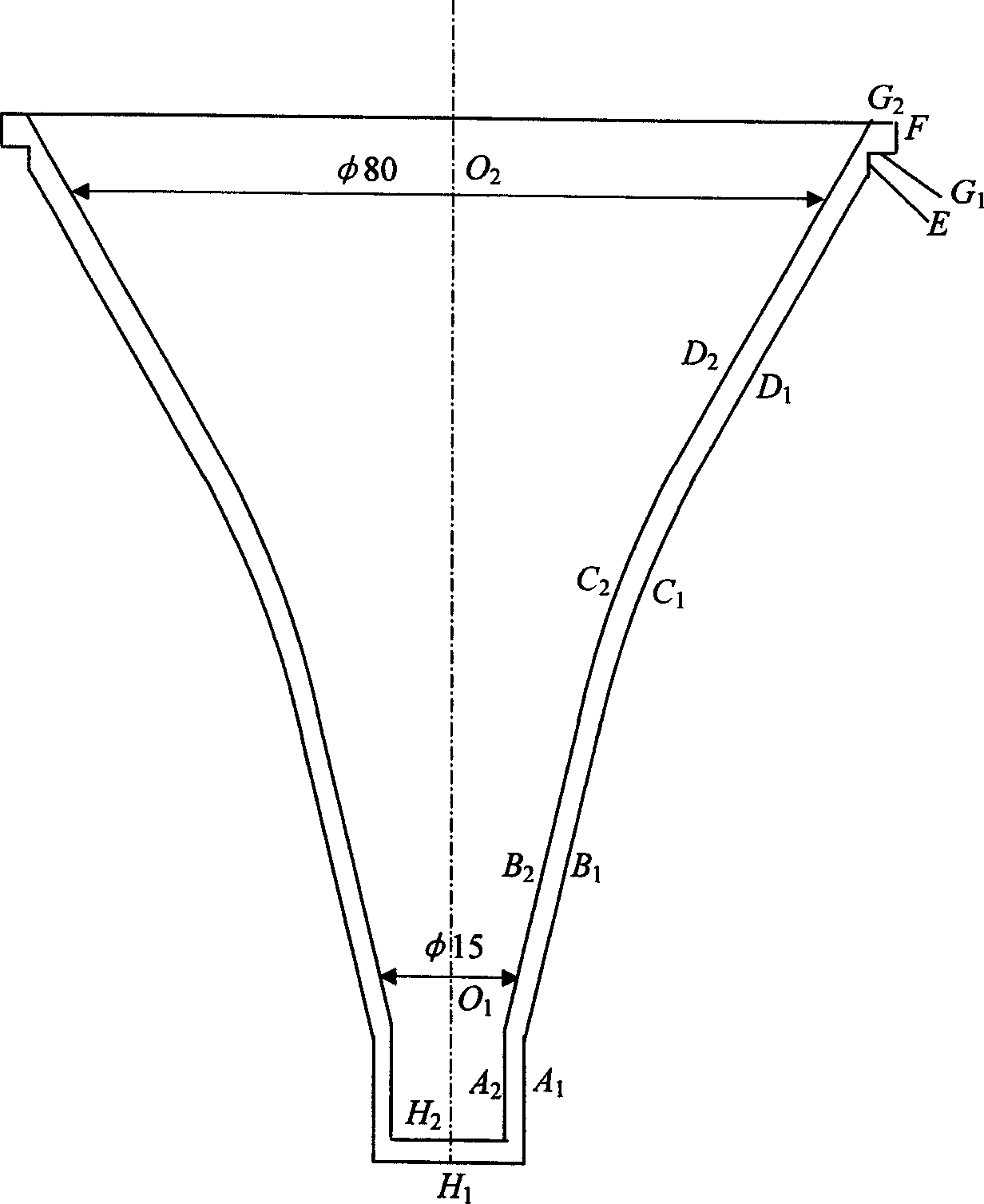

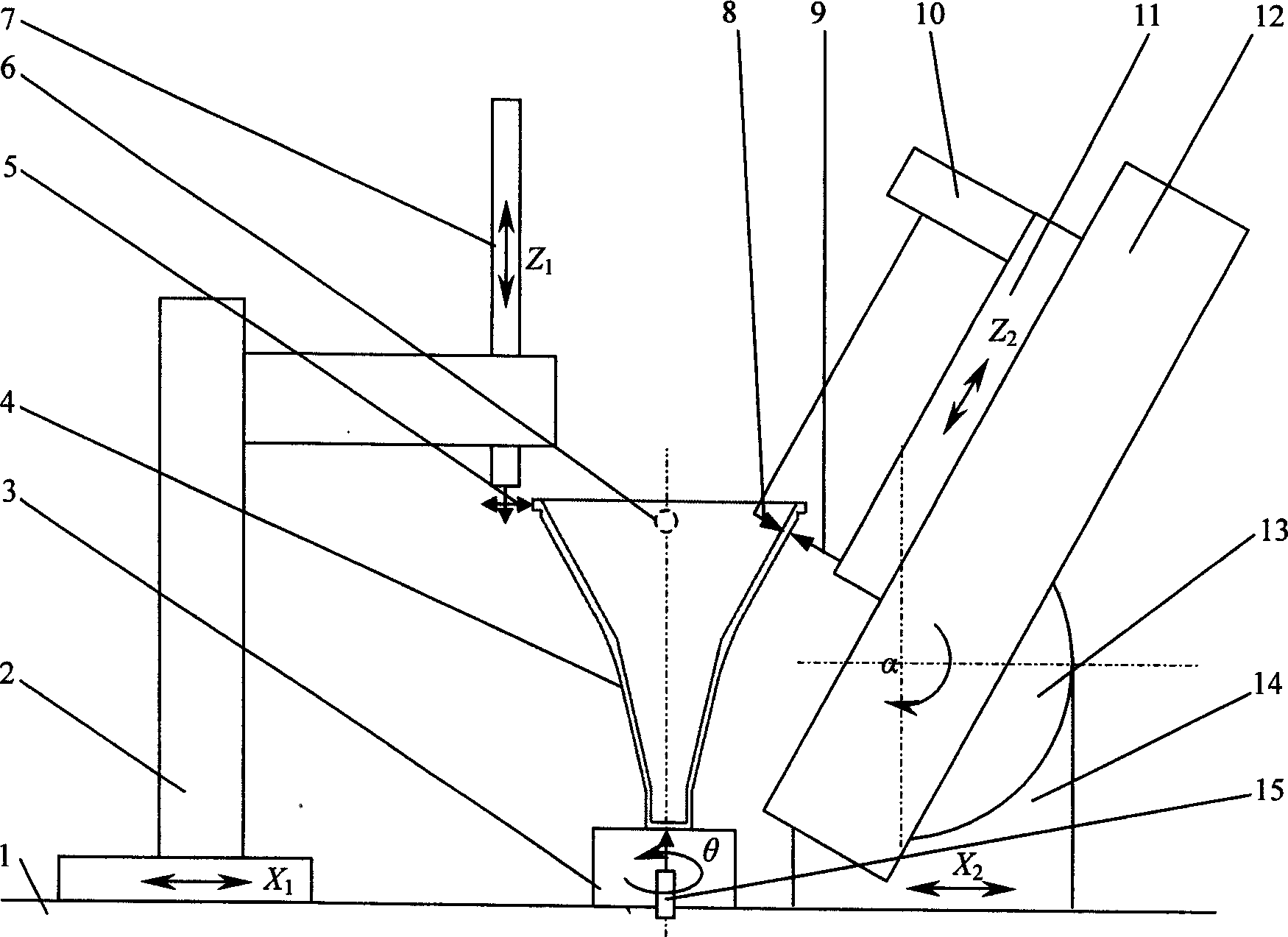

Rotary body wall thickness measuring electro-controlled systems

InactiveCN1645046AAdaptableSimple pathUsing optical meansElectric programme controlMeasurement deviceControl system

An electrical control system for measuring wall thickness of gyrorotor consists of process control microcomputer connected to four measuring heads, yielding mechanism, temperature sensor, control box, spacing switch, multiple control and driving circuits through interface master board connected with control card. The microcomputer controls moving parts with device indicating its displacement for measurement through driver and control servo motor.

Owner:TIANJIN UNIV

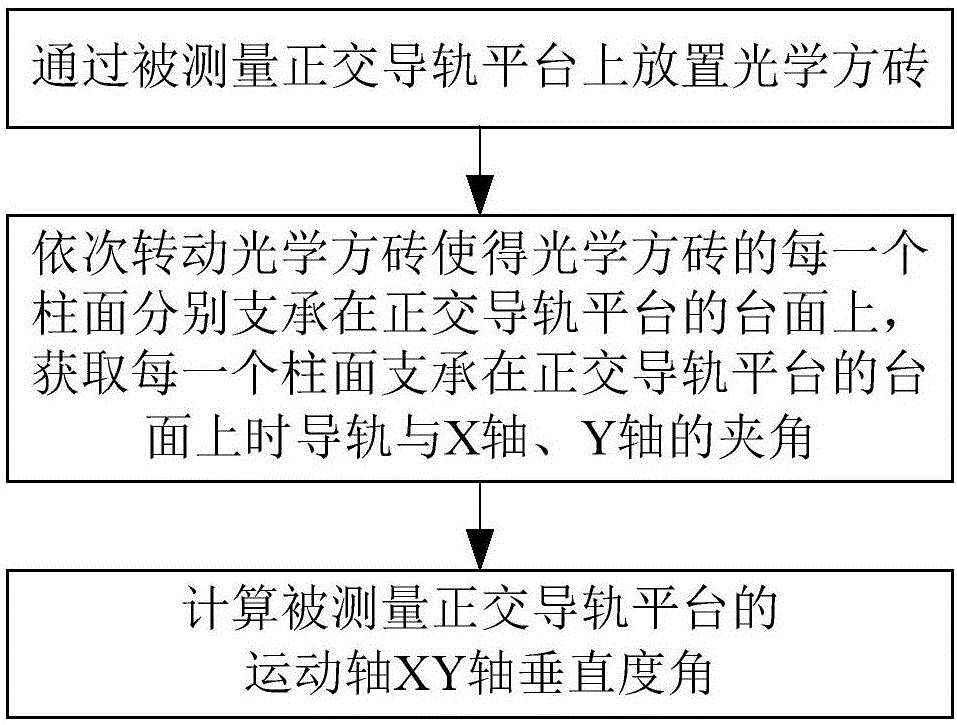

Verticality error measurement method used for orthogonal guide rail platform

ActiveCN106247997AHigh measurement accuracyGuaranteed high precisionUsing optical meansMeasuring equipmentEngineering

The invention discloses a verticality error measurement method used for an orthogonal guide rail platform. The method comprises the following steps of placing an optical square brick on an X axis slide block of an X axis slide rail of a measured orthogonal guide rail platform and successively overturning the optical square brick according to an assigned angle so that each cylindrical surface of the optical square brick is supported on the X axis slide block respectively; detecting included angles of the optical square brick and an X axis, and the optical square brick and a Y axis when each cylindrical surface of the optical square brick is supported on the X axis slide block and acquiring 8 included angles; and according to a formula (1), calculating verticality angles of movement axes X and Y of the measured orthogonal guide rail platform. By using the method of the invention, verticality measurement efficiency and precision can be greatly increased. And the method possesses advantages that a measurement error is not influenced by a standard component; measured equipment versatility is good; and operation of a measured process is simple and easy and measured objects are wide.

Owner:NAT UNIV OF DEFENSE TECH

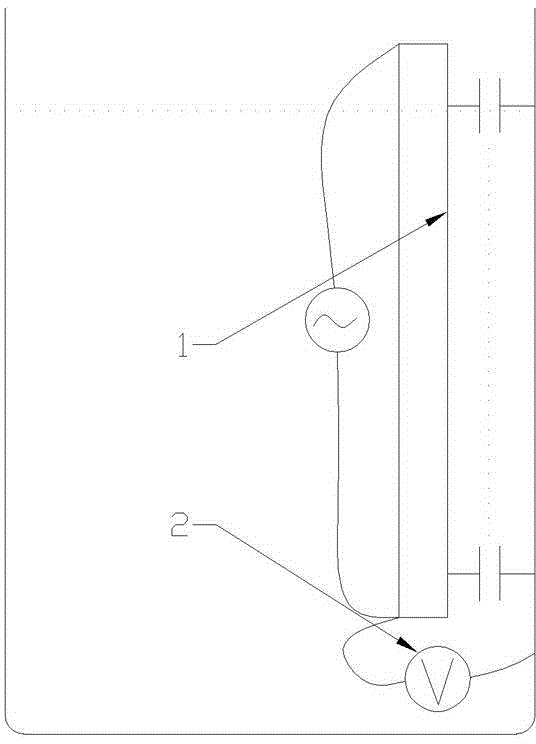

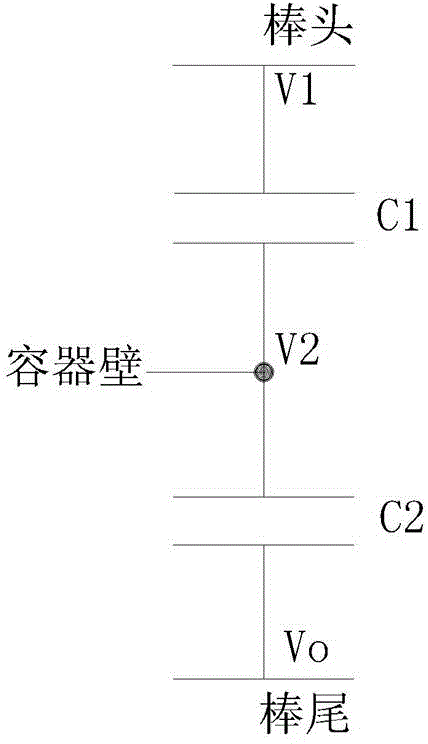

Potential ruler continuous material level measurement system and measurement method thereof

ActiveCN103557904AReal-time measurementHigh measurement accuracyLevel indicators by physical variable measurementVoltmeterLevel measurement

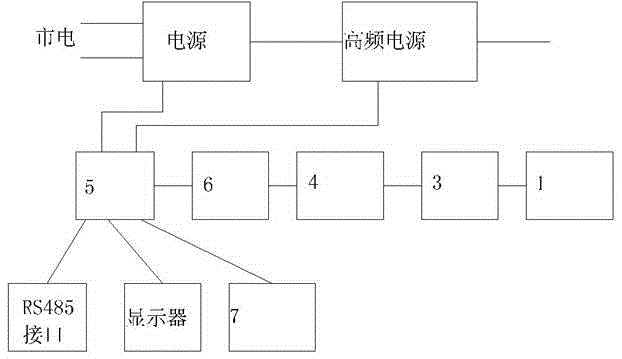

The invention discloses a potential ruler continuous material level measurement system free of adjustment, applicable to realtime measurement of material levels of various materials and high in measurement accuracy and a measurement method thereof. The potential ruler continuous material level measurement system comprises a conductive measurement rod (1) arranged in a metal container, wherein high-frequency voltages are applied to two ends of the measurement rod (1), a voltmeter (2) is connected between the bottom end of the measurement rod (1) and the metal container, and the periphery of the voltmeter (2) is electrically connected with a signal collecting module (3), a signal processing module (4), a central processing unit (CPU) (5), an analog-digital converter (6) and an analog quantity output module (7). When the materials make contact with the measurement rod (1), the signal collecting module (3) collects a voltage signal generated between the measurement rod (1) and the metal container, the voltage signal is subjected to calculation, voltage stabilizing and amplifying, and then the voltage signal is converted into a digital signal to be output by the analog quantity output module (7). The potential ruler continuous material level measurement system can be applied to the field of material level measurement.

Owner:珠海市长陆工业自动控制系统股份有限公司

Liquid level anti-blocking device for chilling chamber of gasification furnace

ActiveCN104232171APrevent subsidenceExtended service lifeCombustible gas productionInlet channelTransducer

The invention relates to a liquid level anti-blocking device for a chilling chamber of a gasification furnace. The liquid level anti-blocking device comprises a pressure taking pipe communicated with the chilling chamber and a flange type pressure transducer mounted at the outer end of the pressure taking pipe, wherein a flushing water ring is arranged between the pressure taking pipe and the pressure transducer; a through hole for communicating the surface of a film box of the pressure transducer with the pressure taking pipe is formed in the middle of the flushing water ring; a water inlet channel communicated with an external pipeline is formed in the side wall of the flushing water ring; a water outlet of the water inlet channel is formed in the end face of the flushing water ring on one side of the pressure taking pipe; a flushing water pipe, of which one end is connected with the water outlet formed in the end face of the flushing water ring, is arranged in the pressure taking pipe; the outlet end of the flushing water pipe is arranged in the pressure taking pipe leading to one side of the chilling chamber. High-pressure flushing water is led to one side close to the chilling chamber, so that settling of smudgy mediums can be prevented, the service life of a liquidometer can be prolonged, and the safety of gasification furnace running is improved.

Owner:ANHUI LIUGUO CHEM CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com