Online monitoring system for measuring thickness of clean-surface panel

A monitoring system, a technology of smooth surface, applied in measurement devices, optical devices, instruments, etc., can solve problems such as accurate measurement, condition monitoring and data management, high working condition requirements, poor versatility, etc., to eliminate structural deformation. Influence, wide application, the effect of eliminating the influence of measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

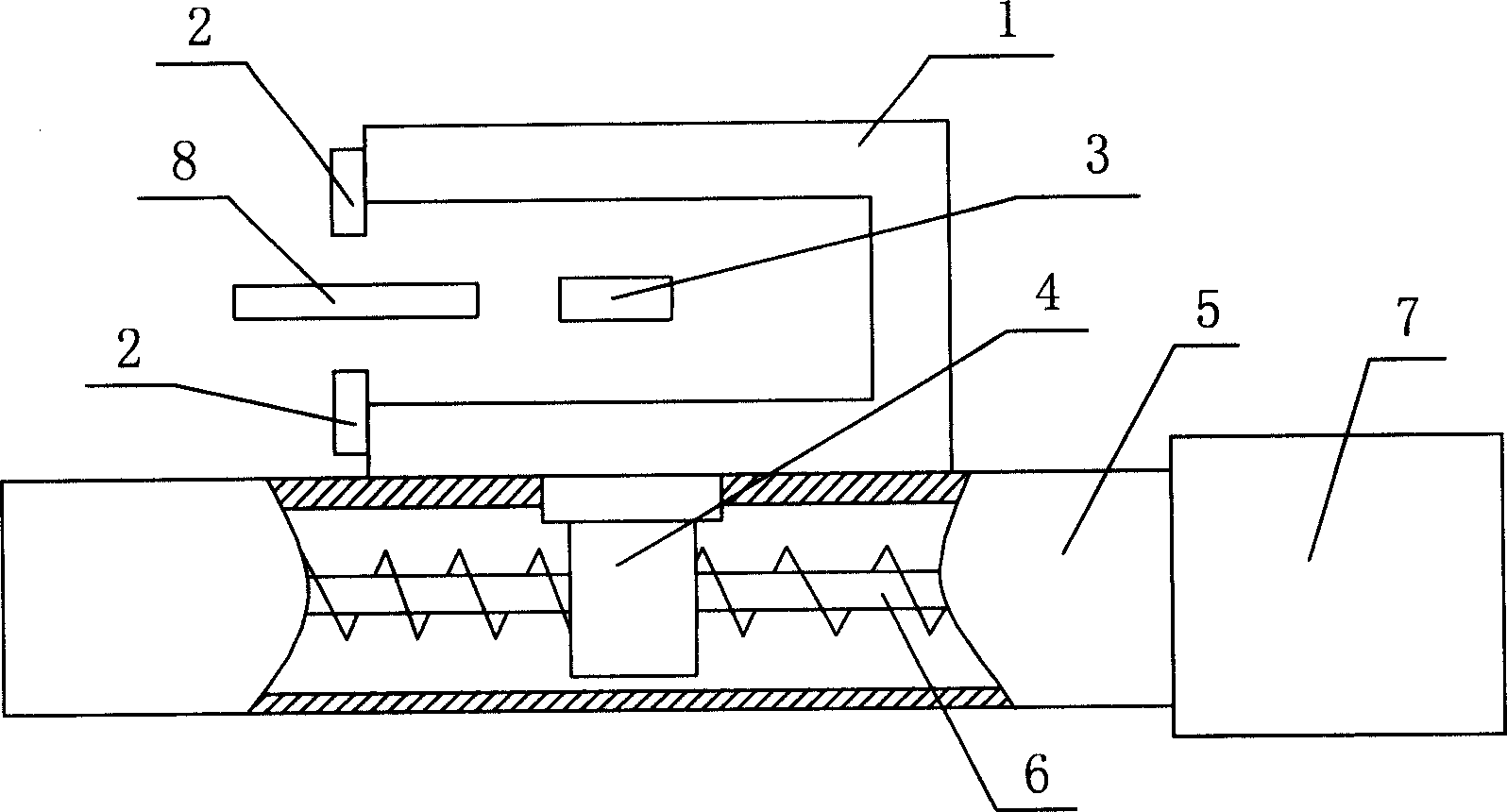

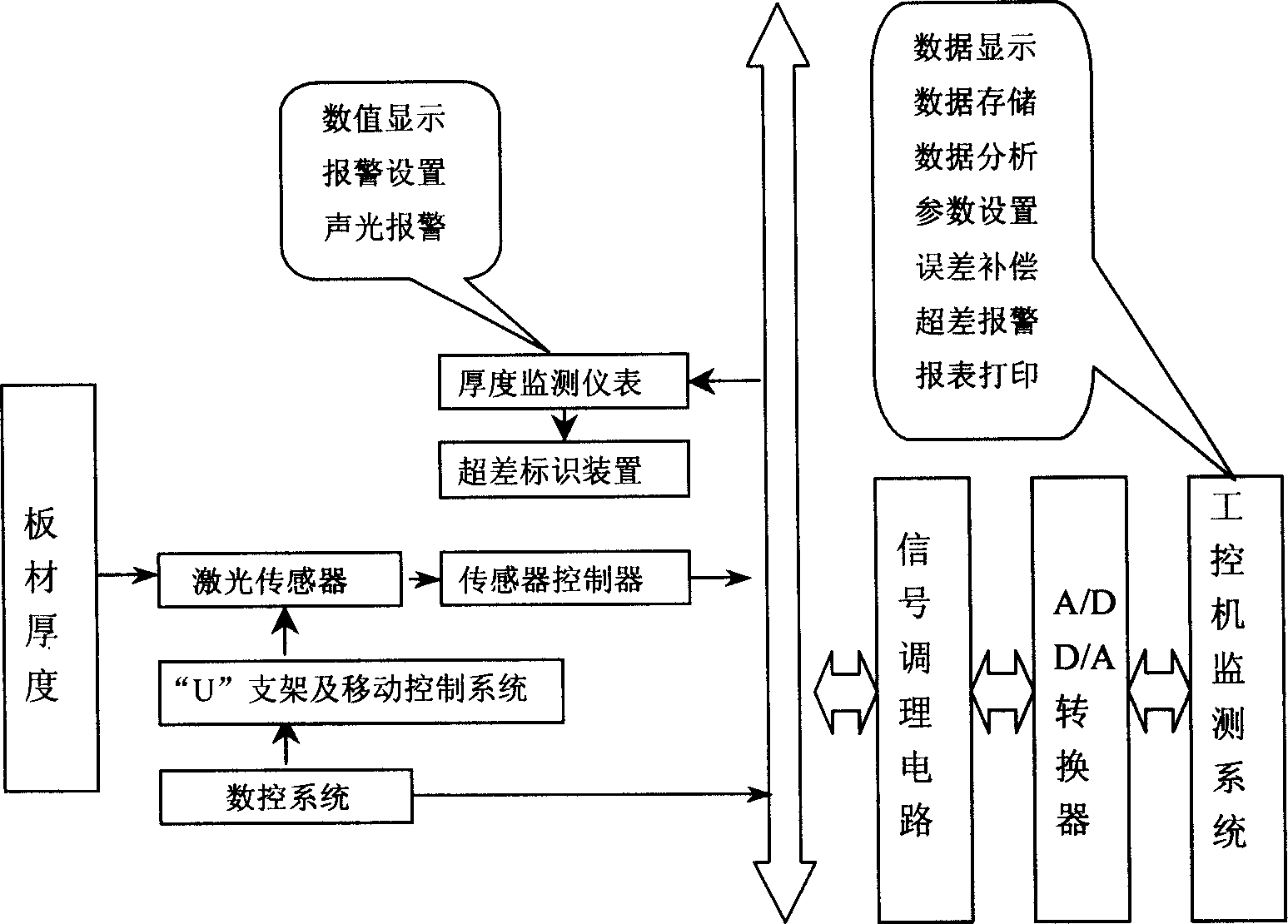

[0016] Specific embodiment: This online monitoring device for measuring the thickness of smooth panels includes a laser sensor 2 and a signal processing device. The sensors 2 exist in pairs, and the data are transmitted to the signal processing device through cables, and the signal processing device calculates The thickness of the plate 8 to be tested is obtained; the sensors 2 are installed in pairs at corresponding positions at both ends of a "U"-shaped bracket 1, and the "U"-shaped bracket 1 can move according to certain rules through control; the plate to be tested 8 is located on the "U"-shaped bracket 1 In the middle of the groove, crossing motion is performed perpendicular to the plane where the "U"-shaped support 1 is located; a temperature compensation block 3 is installed on the extension surface of the plate 8 to be tested to the "U"-shaped support 1.

[0017] The above-mentioned "U"-shaped bracket 1 is controlled by a moving mechanism, and the moving mechanism inclu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com