Potential ruler continuous material level measurement system and measurement method thereof

A technology of material level measurement and measurement method, which is applied in the direction of liquid level indicators for physical variable measurement, can solve the problems of easy material jamming of steel cables, affecting the flexibility of floating balls, and the influence of pipeline installation, and achieves high measurement accuracy and stability Reliable measurement accuracy, low-impact results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

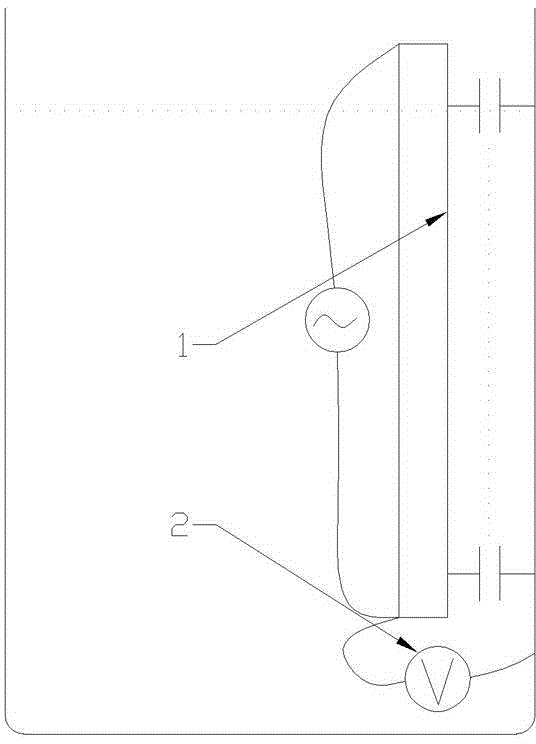

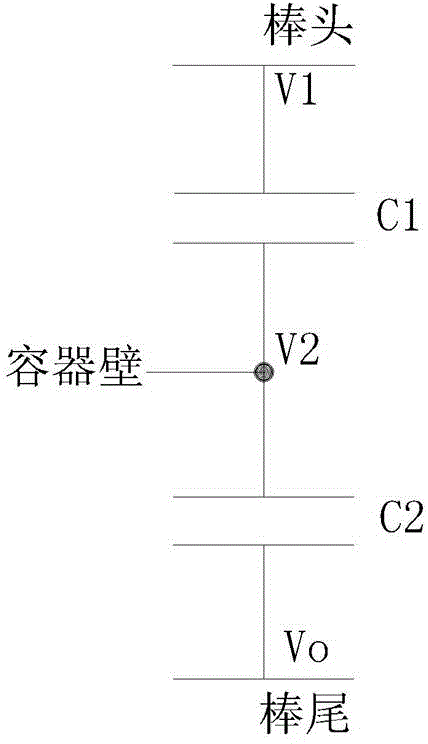

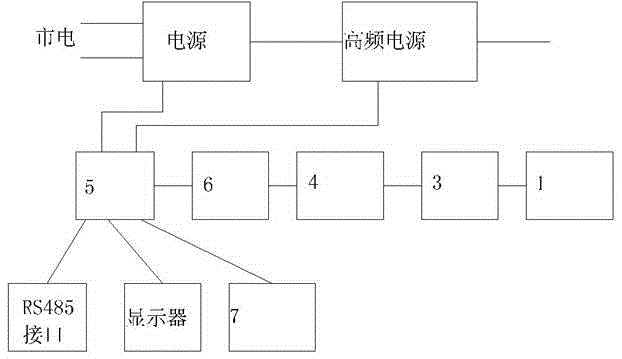

[0039] Such as Figure 1 to Figure 5 As shown, the system of the present invention includes a conductive measuring rod 1, which is arranged in a metal container. The measuring rod 1 is a hollow tube. On the wall of the measuring rod 1, there are several through holes spirally rising along the axis of the hollow tube. The several through holes are adjacent to each other to form a rising spiral. type channel. The measuring rod 1 is arranged along the height direction of the metal container and kept parallel to the wall surface of the metal container. A voltmeter 2 is connected between the bottom end of the measuring rod 1 and the wall of the metal container, and the voltmeter is a high-frequency voltmeter. The voltmeter 2 is electrically connected with a signal acquisition module 3 , a signal processing module 4 , a CPU 5 , an analog-to-digital converter 6 and an analog output module 7 . Apply a high-frequency voltage to the two ends of the measuring rod 1, when the material ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com